Grain Size Distribution Effect on the Hydraulic Properties of Disintegrated Coal Mixtures

Abstract

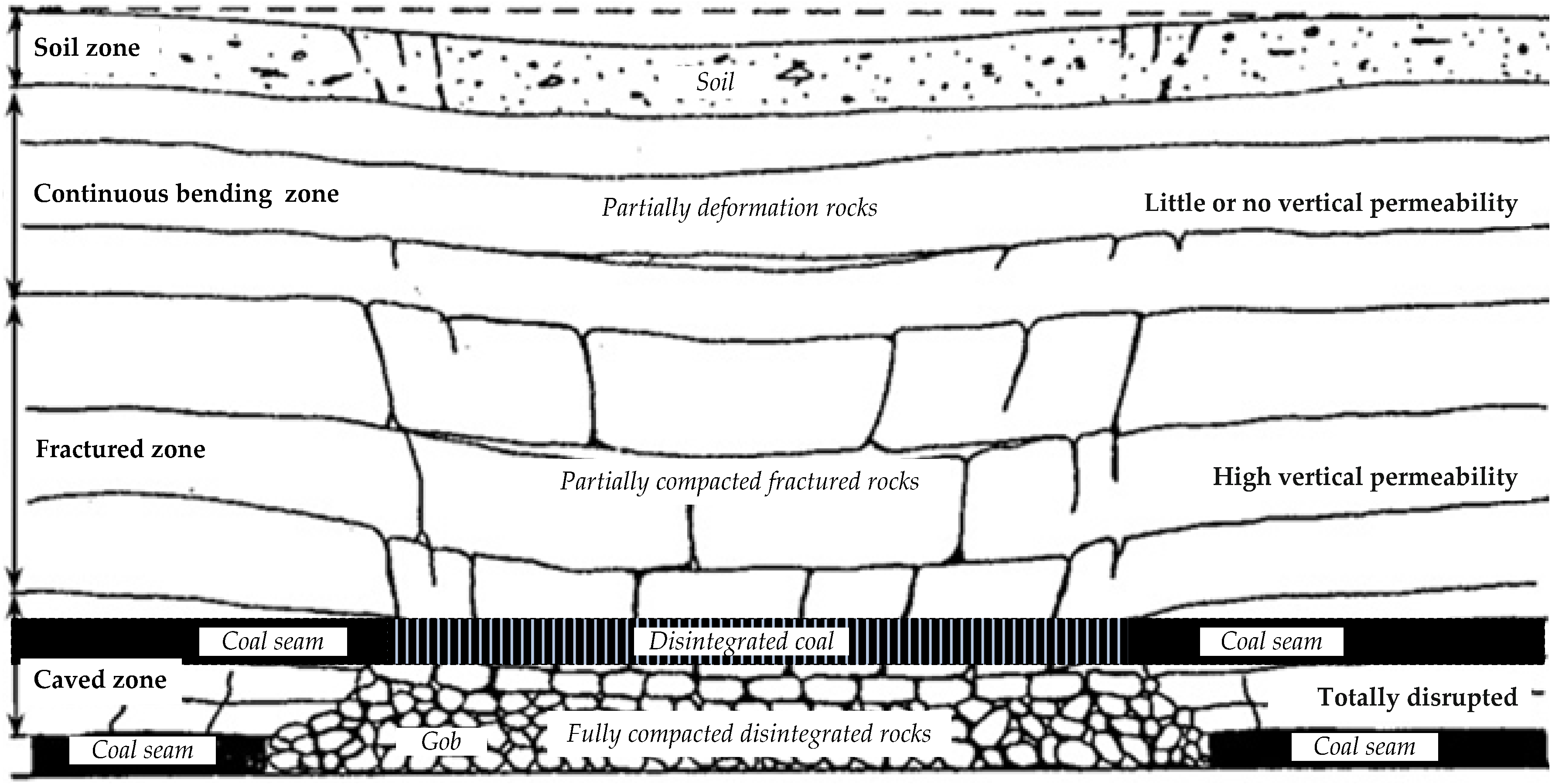

:1. Introduction

2. Experimental Equipment and Conditions

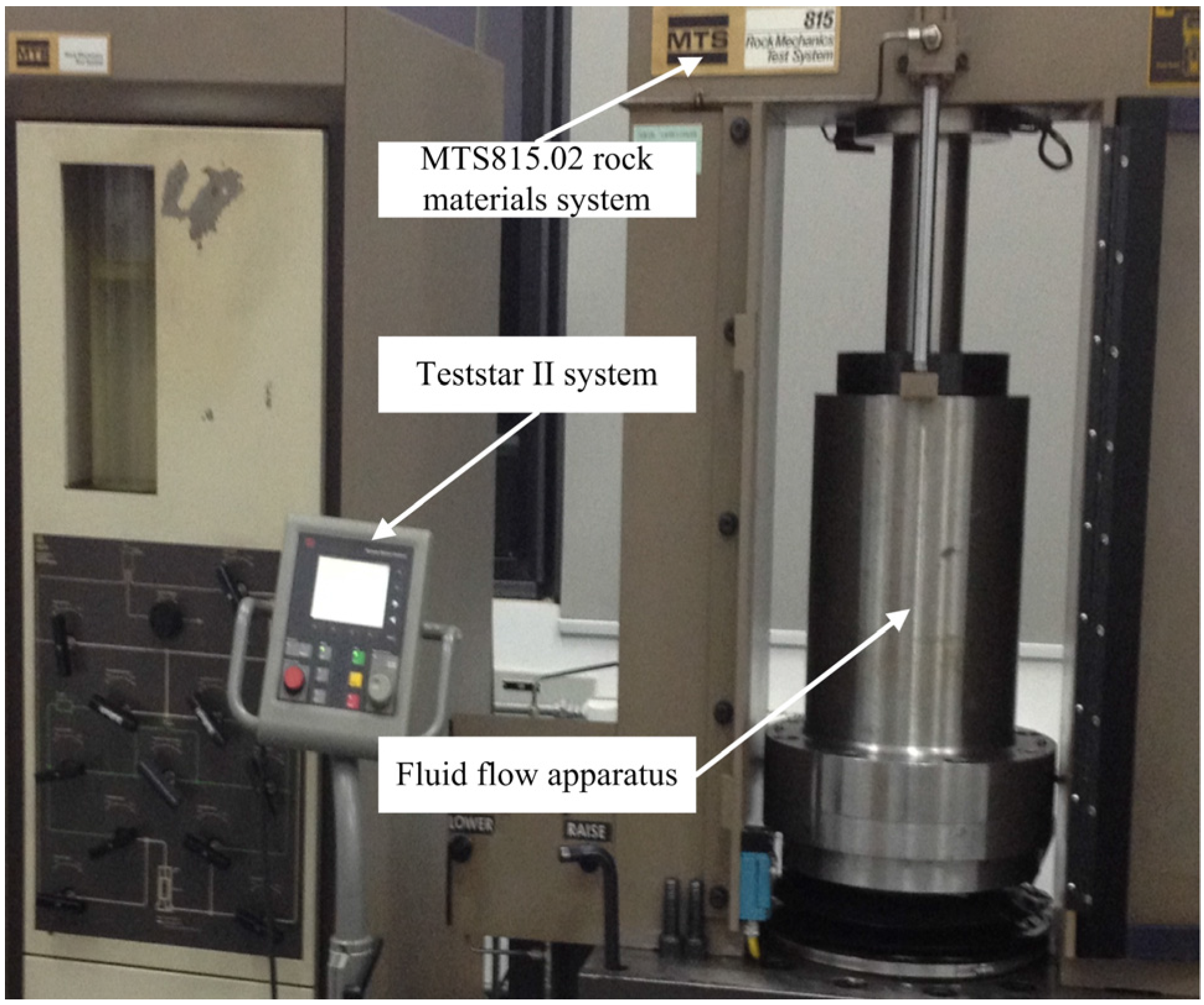

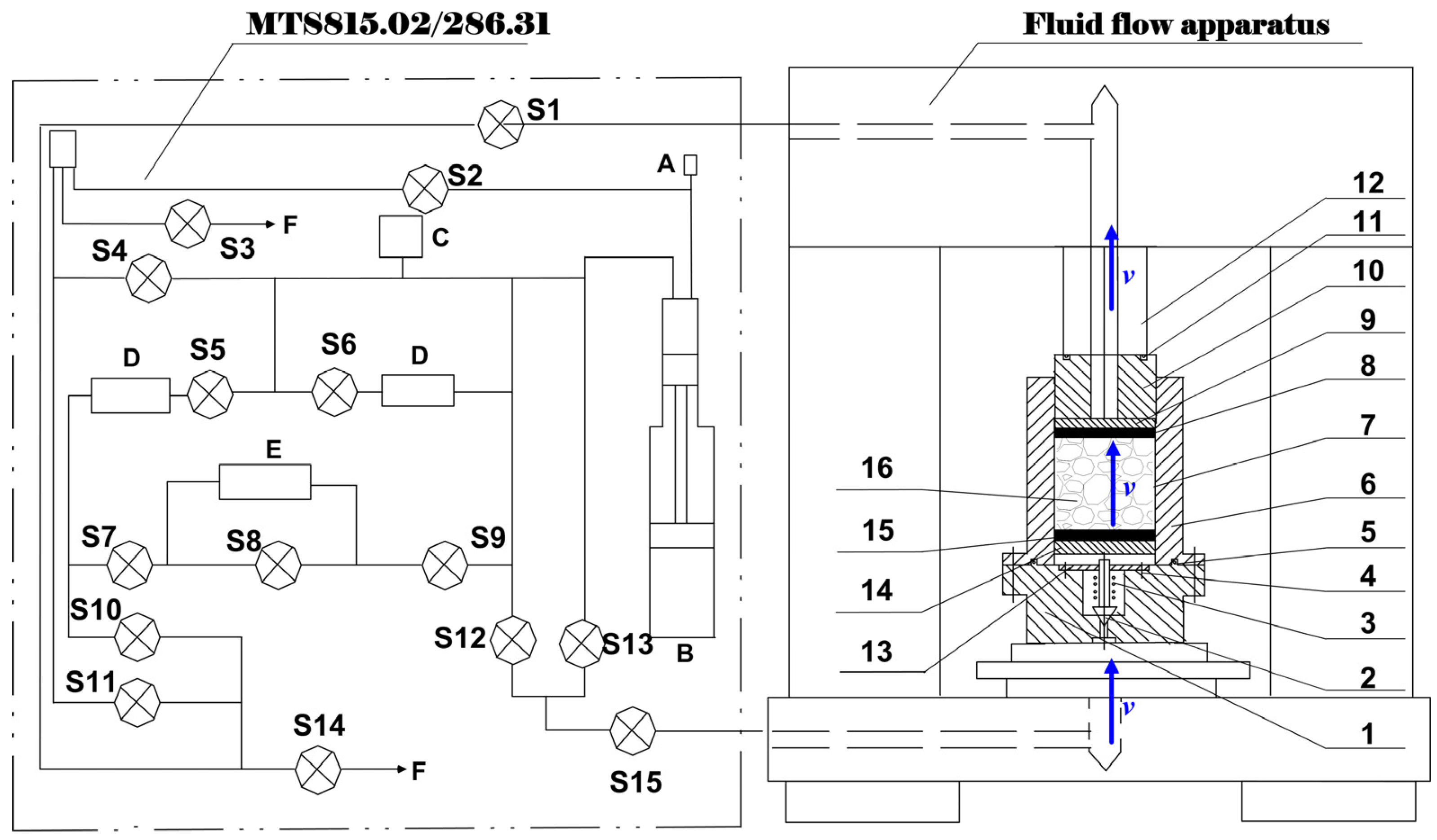

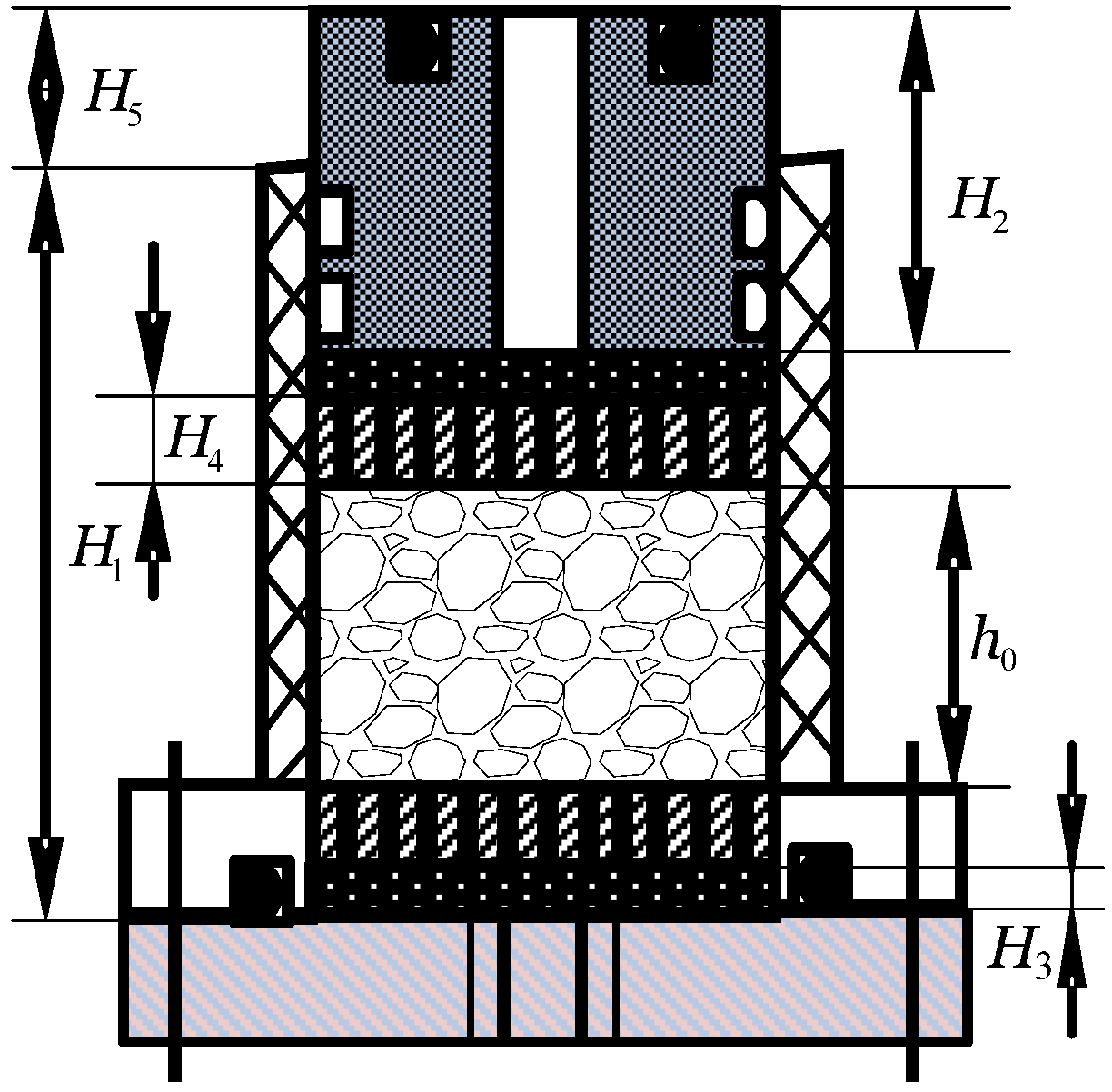

2.1. Experimental Equipment

2.2. Experimental Conditions

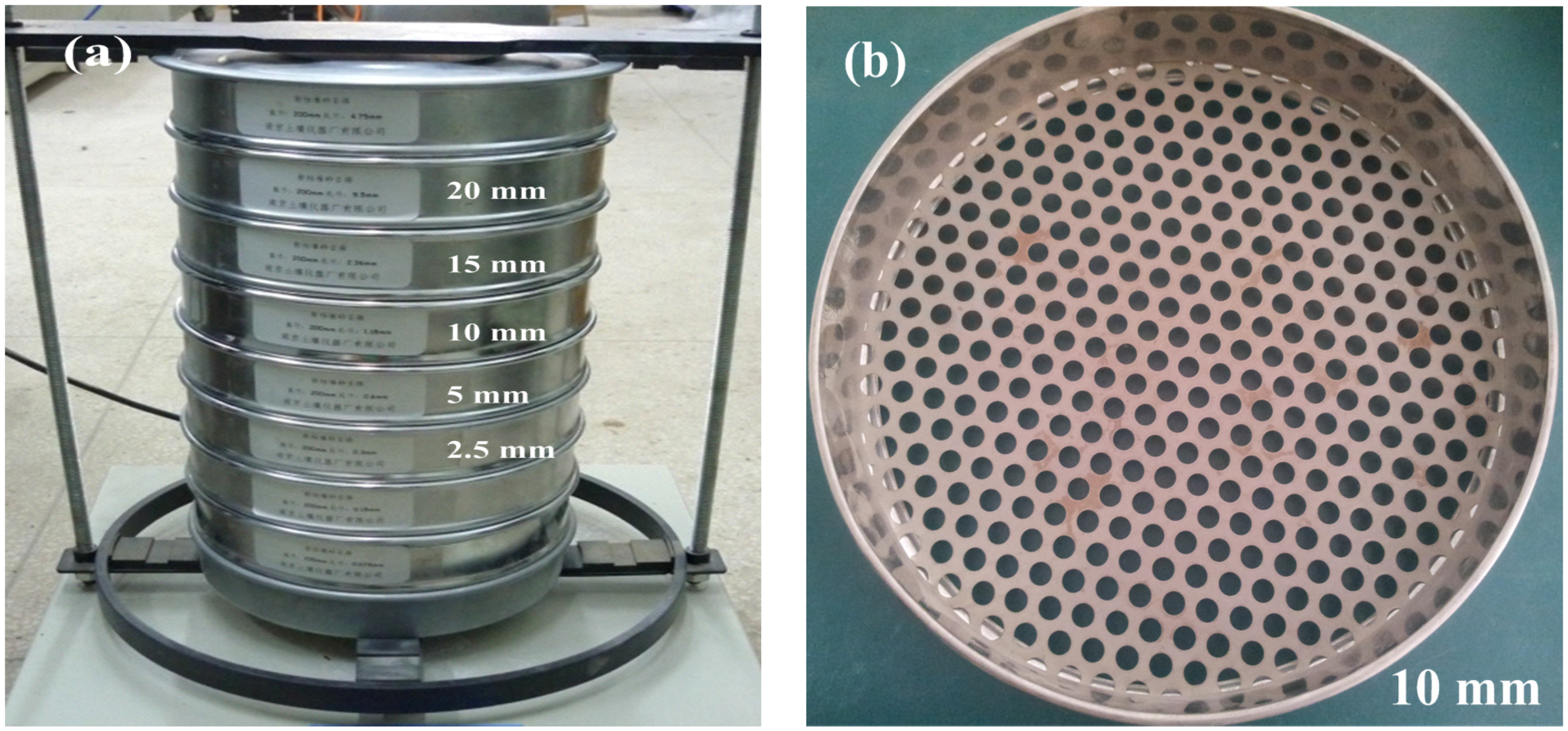

2.2.1. Sample Preparation

2.2.2. Water Pressure

2.2.3. Compaction Behavior

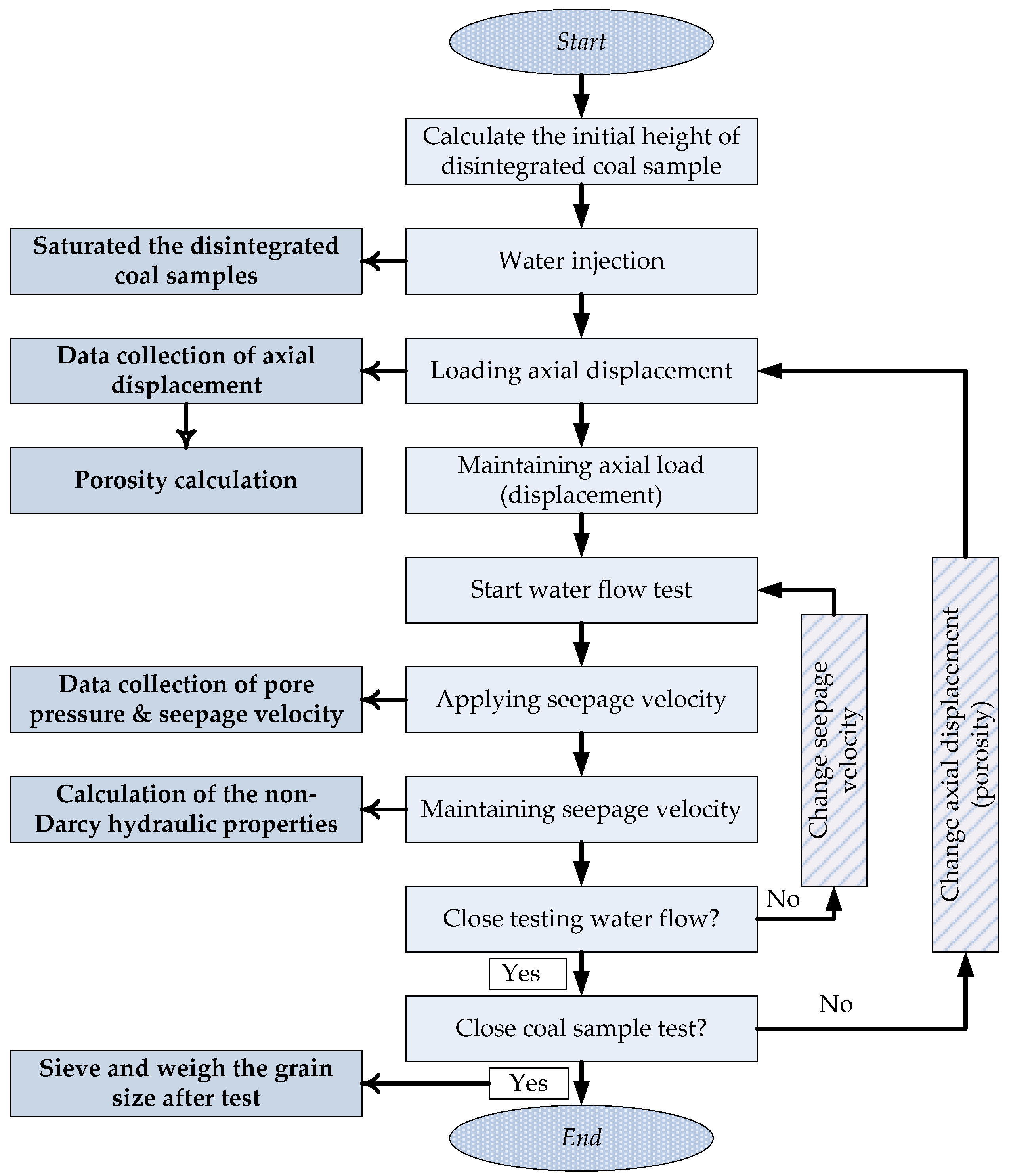

3. Experimental Procedure

- (1)

- Calculation of the original length (porosity) of sample before load application.

- (2)

- Saturation of the coal samples.

- (3)

- Application of the load.

- (4)

- Application of the water flow.

4. Experimental Results and Discussion

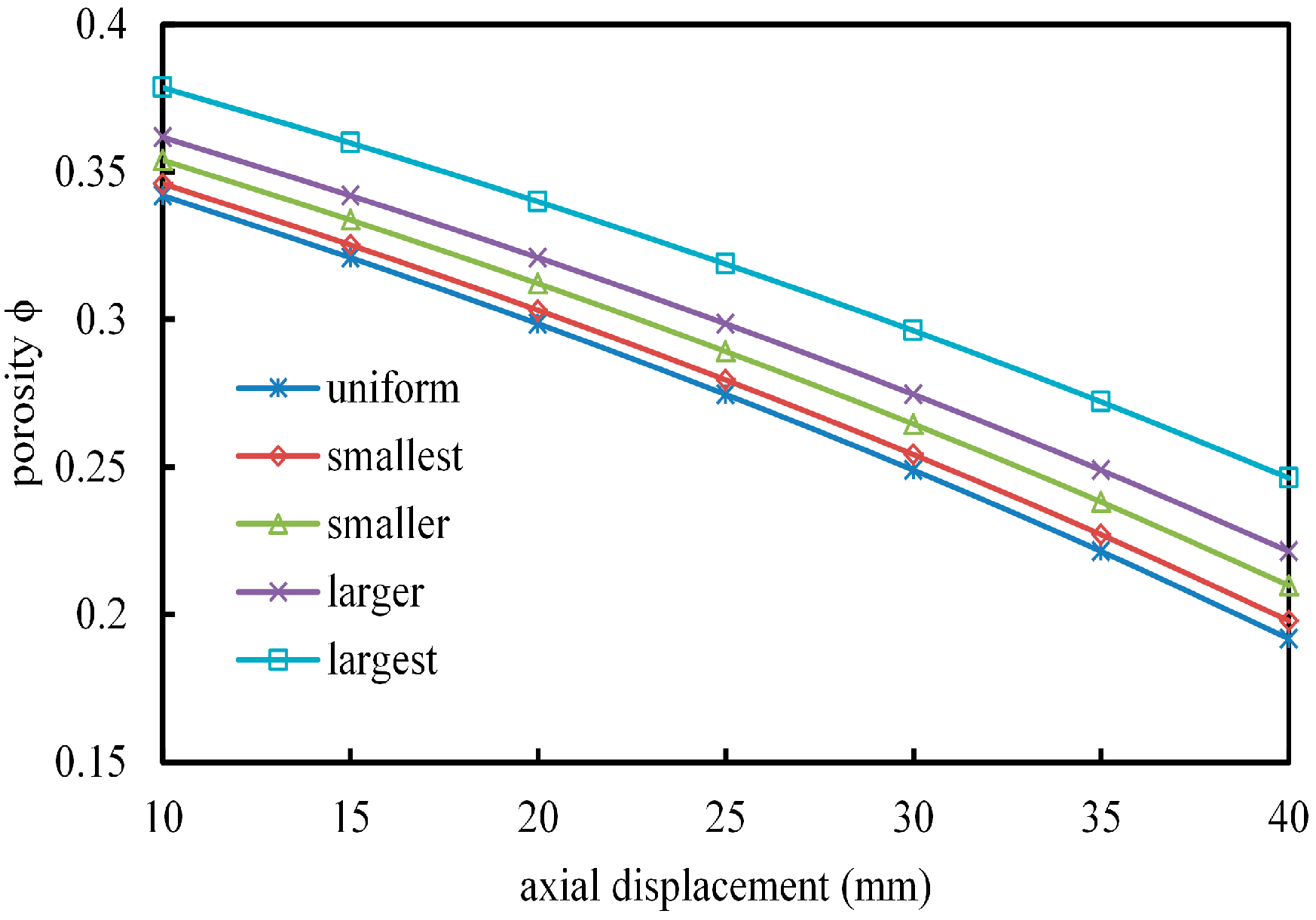

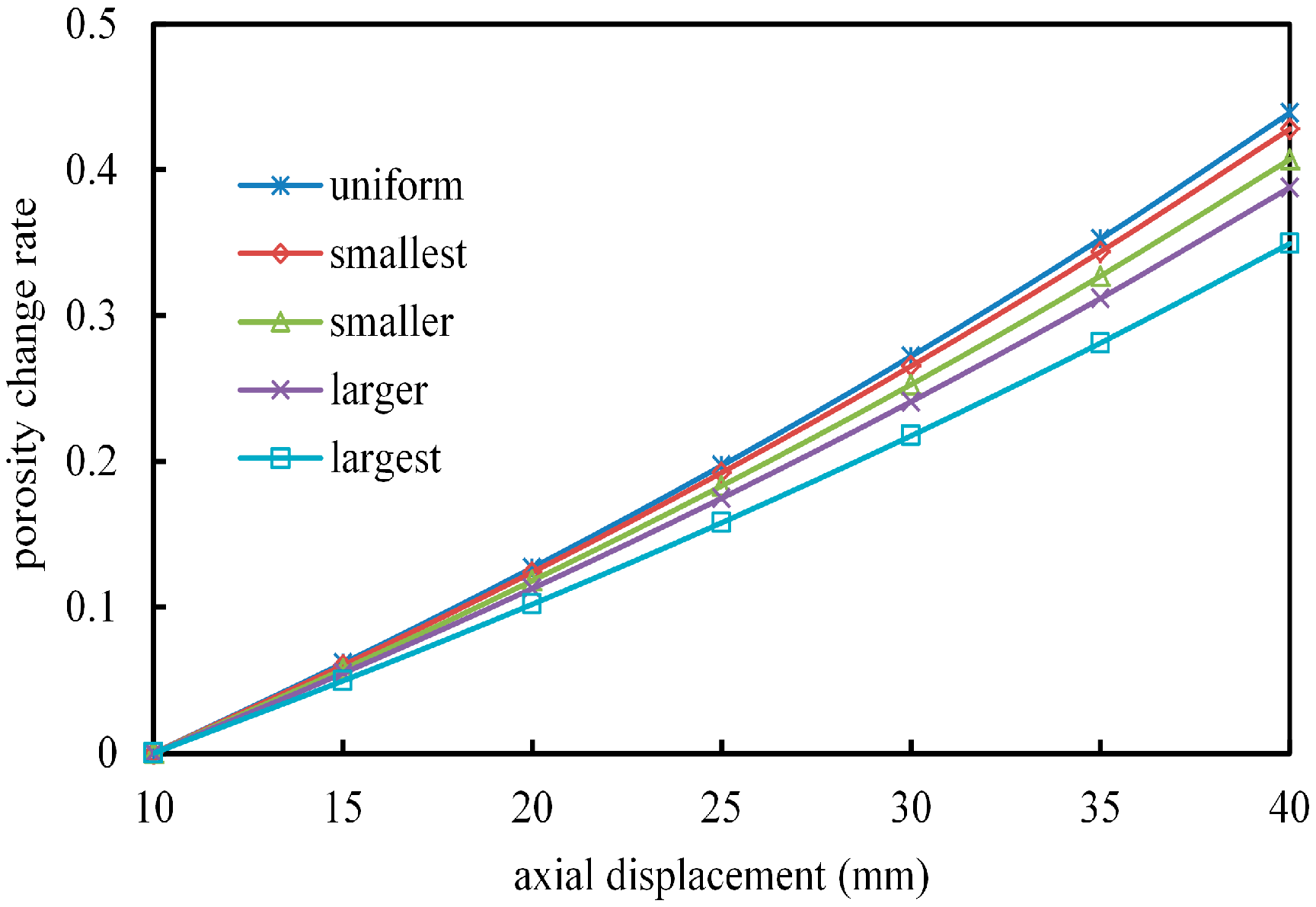

4.1. Porosity Evolution during Compaction

4.2. Non-Darcy Flow Type

4.2.1. Reynolds Number Calculation

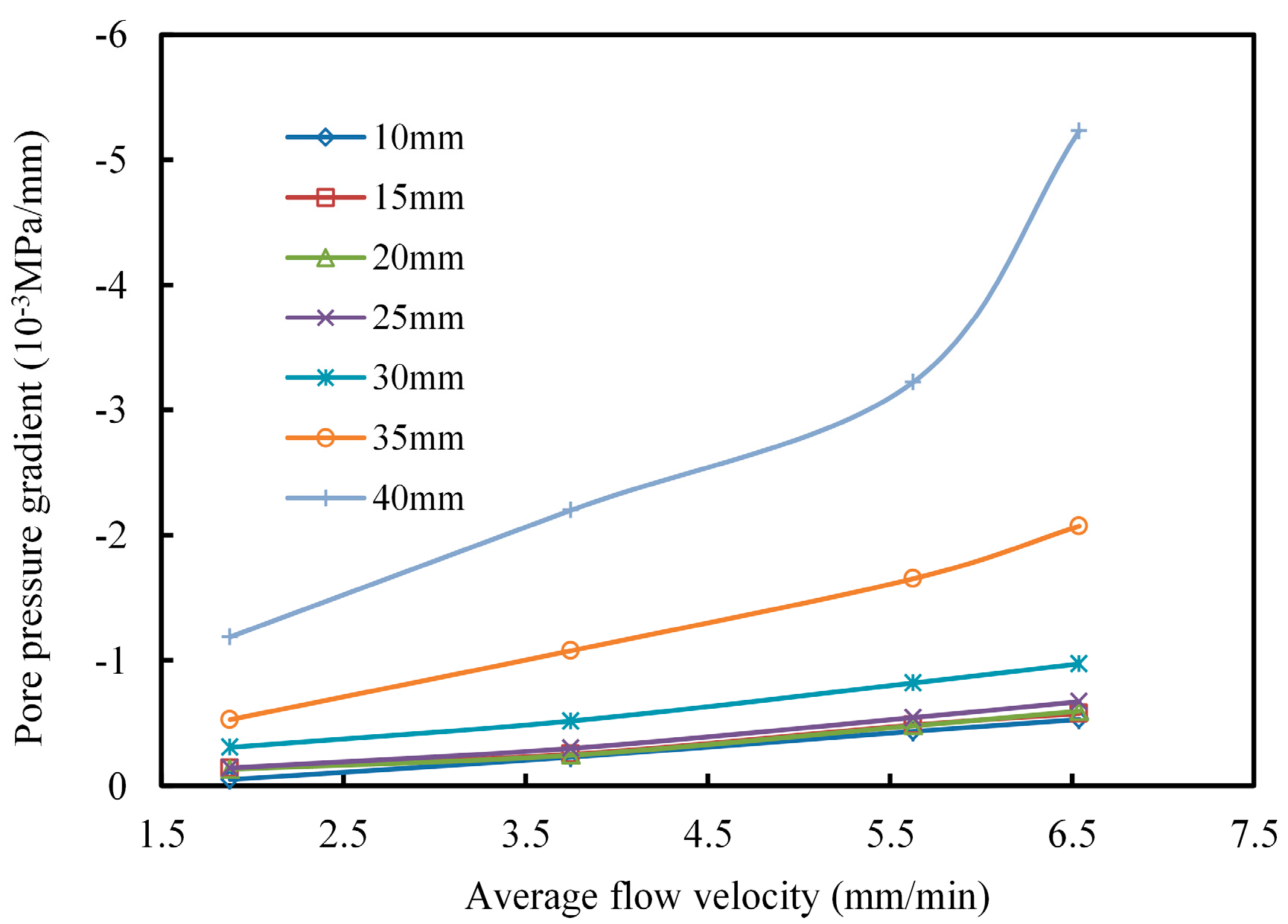

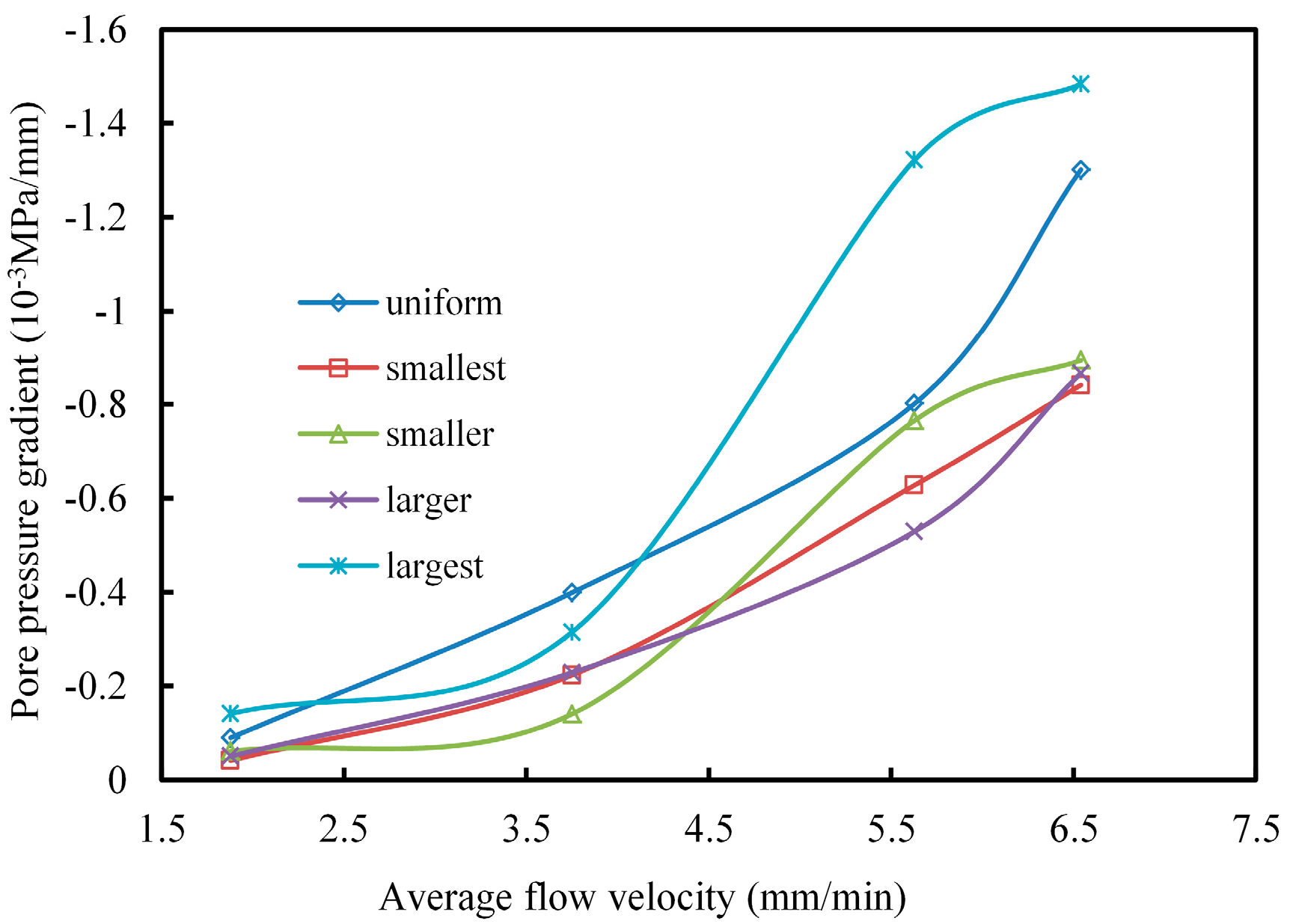

4.2.2. Relationship of Flow Rate and Water Pressure Gradient

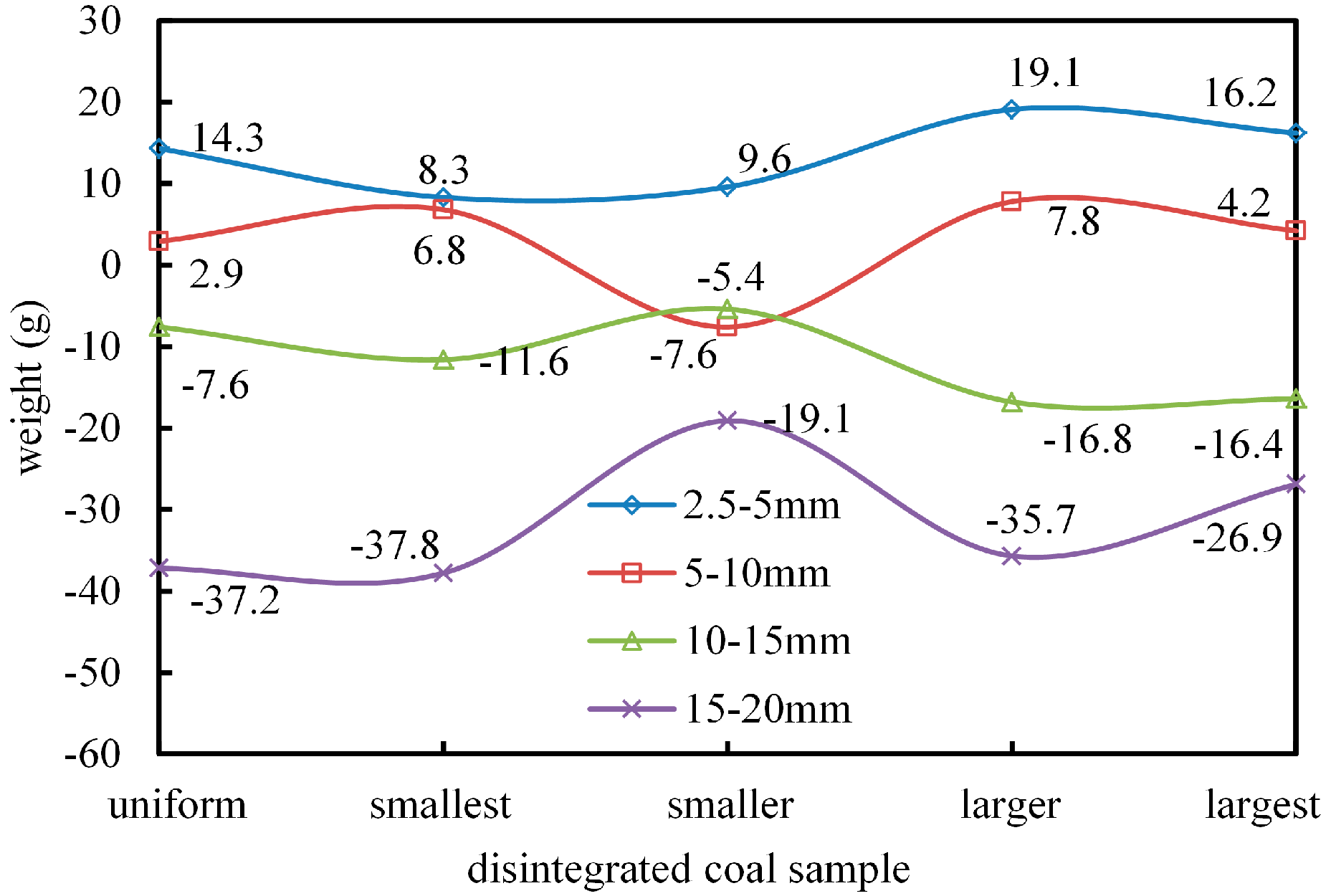

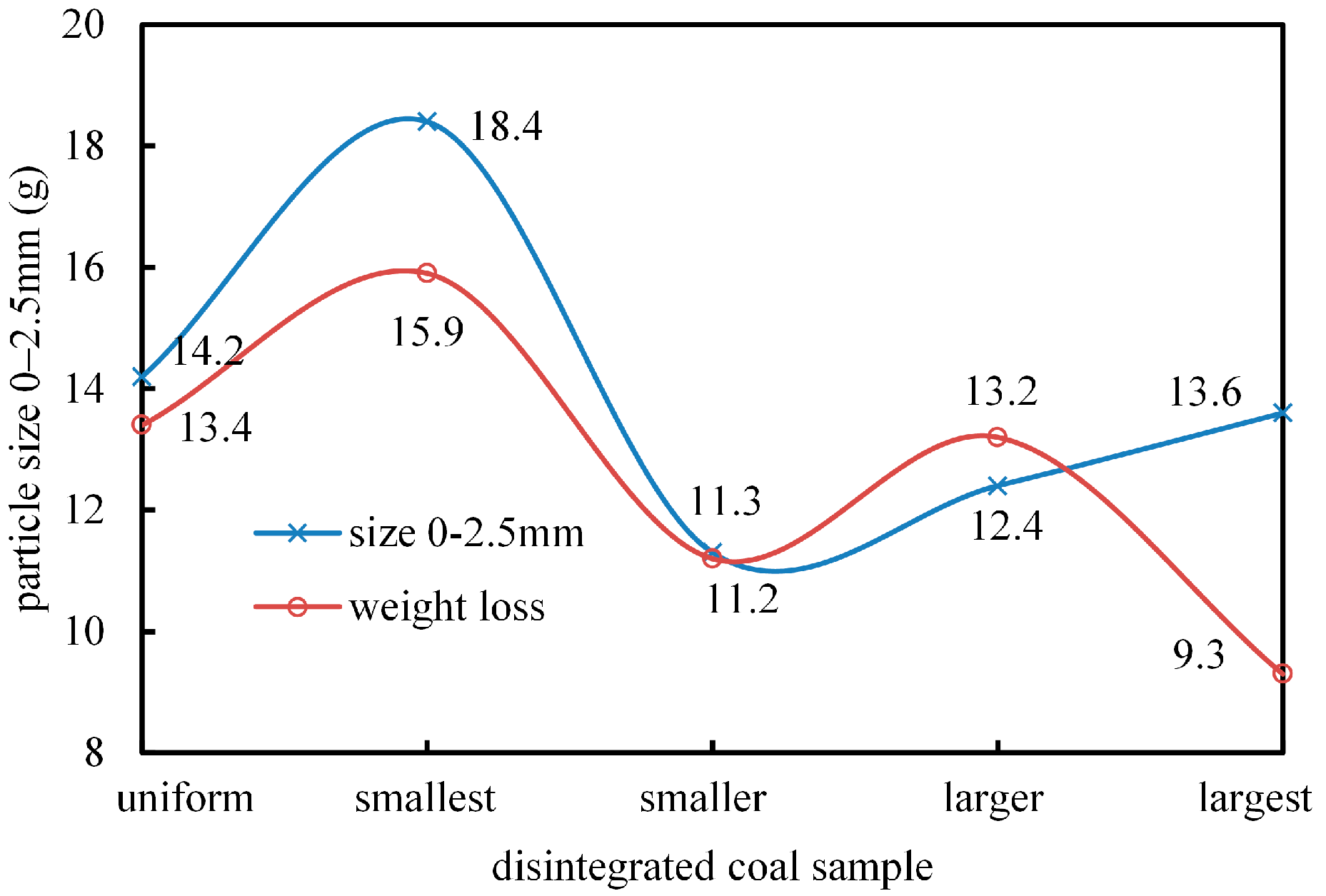

4.3. Grain Mixture Alterations during the Tests

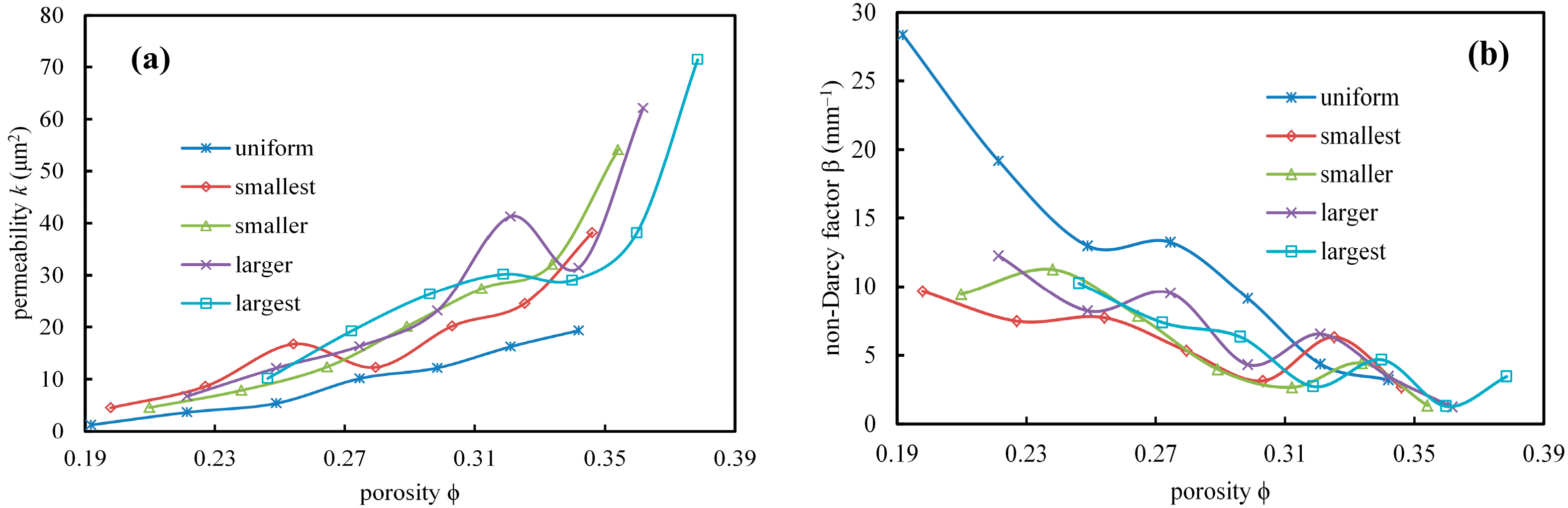

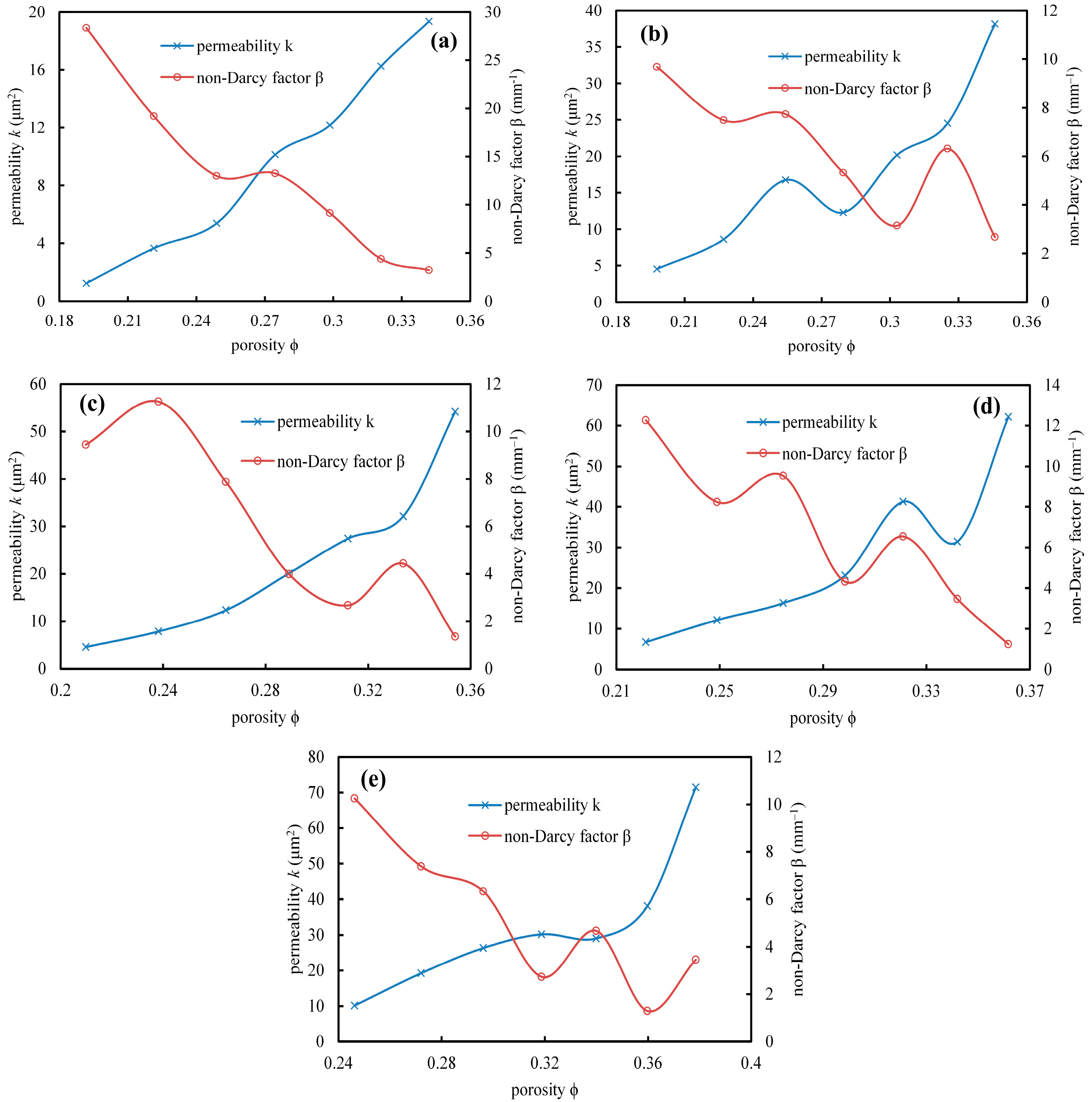

4.4. Non-Darcy Flow Characteristics

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Average diameter of the grains (L) | Cross section area of cylindrical tube (L2) | ||

| Original height of the coal sample (L) | Reynolds number (-) | ||

| H1 | Height of cylindrical tube (L) | Axial displacement (L) | |

| H2 | Height of plunger (L) | Time (T) | |

| H3 | Thickness of the filter pad (L) | Water flow velocity (L·T−1) | |

| H4 | Thickness of the porous disk (L) | Vertical axis going through the center of the sample (L) | |

| Spatial indices (-) | Partial differential operator (-) | ||

| Permeability (L2) | Nabla operator (L−1) | ||

| Sample length (L) | β | Non-Darcy factor (L−1) | |

| Mass of the coal sample (M) | Viscosity (L2·T−1) | ||

| Pore pressure (mL−1·T−2) | Porosity (-) | ||

| Pore pressure at the intake boundary (mL−1·T−2) | Coal mass density (mL−3) | ||

| Pore pressure connected with the atmosphere (mL−1·T−2) | Water density (mL−3) |

References

- Yin, S.X.; Zhang, J.C.; Liu, D.M. A study of mine water inrushes by measurements of in situ stress and rock failures. Nat. Hazards 2015, 79, 1961–1979. [Google Scholar] [CrossRef]

- Zhang, J.C.; Peng, S.P. Water inrush and environmental impact of shallow seam mining. Environ. Geol. 2005, 48, 1068–1076. [Google Scholar] [CrossRef]

- Ma, D.; Miao, X.X.; Bai, H.B.; Huang, J.H.; Pu, H.; Wu, Y.; Zhang, G.M.; Li, J.W. Effect of mining on shear sidewall groundwater inrush hazard caused by seepage instability of the penetrated karst collapse pillar. Nat. Hazards 2016, 82, 73–93. [Google Scholar] [CrossRef]

- Ma, D.; Miao, X.X.; Bai, H.B.; Pu, H.; Chen, Z.Q.; Liu, J.F.; Huang, Y.H.; Zhang, G.M.; Zhang, Q. Impact of particle transfer on flow properties of crushed mudstones. Environ. Earth Sci. 2016, 75, 593. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Bai, H.B.; Zhang, K. Seepage characteristics of collapse column fillings. Int. J. Min. Sci. Technol. 2016, 26, 333–338. [Google Scholar] [CrossRef]

- Zhang, J.; Li, M.; Liu, Z.; Zhou, N. Fractal characteristics of crushed particles of coal gangue under compaction. Powder Technol. 2017, 305, 12–18. [Google Scholar] [CrossRef]

- Hamdani, I.H. Optimum moisture content for compacting soils one-point method. J. Irrig. Drain. Eng. 1983, 109, 232–237. [Google Scholar] [CrossRef]

- Cho, G.C.; Dodds, J.; Santamarina, J.C. Particle shape effects on packing density, stiffness, and strength: natural and crushed sands. J. Geotech. Geoenviron. Eng. 2006, 132, 591–602. [Google Scholar] [CrossRef]

- Fredlund, D.G.; Morgenstern, N.R.; Widger, R.A. The shear strength of unsaturated soils. Can. Geotech. J. 1978, 15, 313–321. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhao, D.; Liang, Y.; Wen, H.-B. Angle of repose of landslide debris deposits induced by 2008 Sichuan Earthquake. Eng. Geol. 2013, 156, 103–110. [Google Scholar] [CrossRef]

- Yan, Z.L.; Wang, J.J.; Chai, H.J. Influence of water level fluctuation on phreatic line in silty soil model slope. Eng. Geol. 2010, 113, 90–98. [Google Scholar] [CrossRef]

- Coop, M.R.; Sorensen, K.K.; Freitas, T.B.; Georgoutsos, G. Particle breakage during shearing of a carbonate sand. Geotechnique 2004, 54, 157–163. [Google Scholar] [CrossRef]

- Casini, F.; Viggiani, G.M.B. Experimental investigation of the evolution of grading of an artificial material with crushable grains under different loading conditions. In Proceedings of the 5th International Symposium on Deformation Characteristics of Geomaterials, Seoul, Korea, 1–3 September 2011. [Google Scholar]

- Zhou, Z.; Cai, X.; Cao, W.; Li, X.; Xiong, C. Influence of water content on mechanical properties of rock in both saturation and drying processes. Rock Mech. Rock Eng. 2016, 49, 3009–3025. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Chen, L.; Cao, W.; Zhao, Y.; Xiong, C. Influence of cyclic wetting and drying on physical and dynamic compressive properties of sandstone. Eng. Geol. 2017, 220, 1–12. [Google Scholar] [CrossRef]

- Yan, K.Z.; Xu, H.B.; Shen, G.H. Novel approach to resilient modulus using routine subgrade soil properties. Int. J. Geomech. 2014, 14, 04014025. [Google Scholar] [CrossRef]

- Casini, F.; Viggiani, G.M.B.; Springman, S.M. Breakage of an artificial crushable material under loading. Granul. Matter 2013, 15, 661–673. [Google Scholar] [CrossRef]

- Silveira, A.; de Lorena Peixoto, T.; Nogueira, J. On void size distribution of granular materials. In Proceedings of the 5th Pan-American Conference on Soil Mechanics and Foundation Engineering, Buenos Aires, Argentina, 17–22 November 1975; pp. 161–176. [Google Scholar]

- Sherard, J.L.; Dunnigan, L.P. Filters and leakage control in embankment dams. In Proceedings of the Symposium on Seepage and Leakage from Dams and Impoundments, Denver, CO, USA, 5 May 1985; pp. 1–30. [Google Scholar]

- Indraratna, B.; Locke, M.R. Design methods for granular filters—Critical review. Geotech. Eng. 1999, 137, 137–147. [Google Scholar] [CrossRef]

- Zareifard, M.; Fahimifar, A. Elastic-brittle-plastic analysis of circular deep underwater cavities in a Mohr-Coulomb rock mass considering seepage forces. Int. J. Geomech. 2014, 15, 04014077. [Google Scholar] [CrossRef]

- Wang, D.Y.; Gao, Z.R.; Lee, J.L.; Gao, W.S. Assessment and optimization of soil mixing and umbrella vault applied to a cross-passage excavation in soft soils. Int. J. Geomech. 2014, 14, 0000374. [Google Scholar] [CrossRef]

- Shahriar, M.A.; Sivakugan, N.; Das, B.M.; Urquhart, A.; Tapiolas, M. Water table correction factors for settlements of shallow foundations in granular soils. Int. J. Geomech. 2015, 15, 06014015. [Google Scholar] [CrossRef]

- Turner, D.; Nakshatrala, K.; Martinez, M. Framework for coupling flow and deformation of a porous solid. Int. J. Geomech. 2014, 14, 04014076. [Google Scholar] [CrossRef]

- Ghabchi, R.; Zaman, M.; Kazmee, H.; Singh, D. Effect of shape parameters and gradation on laboratory-measured permeability of aggregate bases. Int. J. Geomech. 2014, 14, 04014070. [Google Scholar] [CrossRef]

- Engelhardt, I.; Finsterle, S. Thermal-hydraulic experiments with bentonite/crushed rock mixtures and estimation of effective parameters by inverse modeling. Appl. Clay Sci. 2003, 23, 111–120. [Google Scholar] [CrossRef]

- Legrand, J. Revisited analysis of pressure drop in flow through crushed rocks. J. Hydraul. Eng. 2002, 128, 1027–1031. [Google Scholar] [CrossRef]

- Ma, D.; Miao, X.X.; Jiang, G.H.; Bai, H.B.; Chen, Z.Q. An experimental investigation of permeability measurement of water flow in crushed rocks. Transp. Porous Media 2014, 105, 571–595. [Google Scholar] [CrossRef]

- Guida, G.; Bartoli, M.; Casini, F.; Viggiani, G.M. Weibull distribution to describe grading evolution of materials with crushable grains. Proced. Eng. 2016, 158, 75–80. [Google Scholar] [CrossRef]

- Whitaker, S. The Forchheimer equation: A theoretical development. Transp. Porous Media 1996, 25, 27–61. [Google Scholar] [CrossRef]

- Liu, X.H.; Xu, G.W.; Gao, S.Q. Fluidization of extremely large and widely sized coal particles as well as its application in an advanced chain grate boiler. Powder Technol. 2008, 188, 23–29. [Google Scholar] [CrossRef]

- Slezak, A.; Kuhlman, J.M.; Shadle, L.J.; Spenik, J.; Shi, S.P. CFD simulation of entrained-flow coal gasification: Coal particle density/size fraction effects. Powder Technol. 2010, 203, 98–108. [Google Scholar] [CrossRef]

- Li, Y.F.; Zhao, W.D.; Xu, S.H.; Xia, W.C. Changes of size, ash and density of coal particles on the column axis of a liquid–solid fluidized bed. Powder Technol. 2013, 245, 251–254. [Google Scholar] [CrossRef]

- Gao, J.H.; Liu, J.X.; Gao, J.M.; Du, Q.; Wang, X.F.; Wu, S.H. Modelling and experimental study on agglomeration of particles from coal combustion in multistage spouted fluidized tower. Adv. Powder Technol. 2009, 20, 375–382. [Google Scholar] [CrossRef]

- He, J.F.; Zhao, Y.M.; He, Y.Q.; Luo, Z.F.; Duan, C.L. Force characteristic of the large coal particle moving in a dense medium gas-solid fluidized bed. Powder Technol. 2014, 254, 548–555. [Google Scholar] [CrossRef]

- Liu, J.X.; Jiang, X.M.; Shen, J.; Zhang, H. Influences of particle size, ultraviolet irradiation and pyrolysis temperature on stable free radicals in coal. Powder Technol. 2015, 272, 64–74. [Google Scholar] [CrossRef]

- Ma, D.; Li, Q.; Hall, M.R.; Wu, Y. Experimental investigation of stress rate and grain size on gas seepage characteristics of granular coal. Energies 2017, 10, 527. [Google Scholar] [CrossRef]

- Liu, J.; Wang, J.; Chen, Z.; Wang, S.; Elsworth, D.; Jiang, Y. Impact of transition from local swelling to macro swelling on the evolution of coal permeability. Int. J. Coal Geol. 2011, 88, 31–40. [Google Scholar] [CrossRef]

- Wang, S.; Elsworth, D.; Liu, J. Permeability evolution in fractured coal: The roles of fracture geometry and water-content. Int. J. Coal Geol. 2011, 87, 13–25. [Google Scholar] [CrossRef]

- Han, F.; Busch, A.; van Wageningen, N.; Yang, J.; Liu, Z.; Krooss, B.M. Experimental study of gas and water transport processes in the inter-cleat (matrix) system of coal: Anthracite from Qinshui Basin, China. Int. J. Coal Geol. 2010, 81, 128–138. [Google Scholar] [CrossRef]

- Ma, D.; Bai, H.B.; Chen, Z.Q.; Pu, H. Effect of particle mixture on seepage properties of crushed mudstones. Transp. Porous Media 2015, 108, 257–277. [Google Scholar] [CrossRef]

- Peng, S.S. Coal Mine Ground Control, 3rd ed.; Society for Mining Metallurgy: Morgantown, VA, USA, 2008. [Google Scholar]

- Pappas, D.M.; Mark, C. Behavior of Simulated Longwall Gob Material, Report of Investigations; US Bureau of Mines: Pittsburgh, PA, USA, 1993. [Google Scholar]

- Bai, H.B.; Ma, D.; Chen, Z.Q. Mechanical behavior of groundwater seepage in karst collapse pillars. Eng. Geol. 2013, 164, 101–106. [Google Scholar] [CrossRef]

- Blodgett, S.; Kuipers, J.R. Underground Hard-Rock Mining: Subsidence and Hydrologic Environmental Impacts; Centre of Science in Public Participation: Bozeman, MT, USA, 2002. [Google Scholar]

- Ma, D.; Rezania, M.; Yu, H.S.; Bai, H.B. Variations of hydraulic properties of granular sandstones during water inrush: Effect of small particle migration. Eng. Geol. 2017, 217, 61–70. [Google Scholar] [CrossRef]

- Singh, M.M. Mine subsidence. In SME Mining Engineers Handbook; Society for Mining, Metallurgy, and Exploration, Inc.: LitUeton, CO, USA, 1992; pp. 938–971. [Google Scholar]

- Li, G.C.; Jiang, Z.H.; Lv, C.X.; Huang, C.; Chen, G.; Li, M.Y. Instability mechanism and control technology of soft rock roadway affected by mining and high confined water. Int. J. Min. Sci. Technol. 2015, 25, 573–580. [Google Scholar] [CrossRef]

- Booth, C.J. The effects of longwall coal mining on overlying aquifers. In Mine Water Hydrogeology and Geochemistry; Younger, P.L., Robins, N.S., Eds.; Geological Society Special Publications: London, UK, 2002; Volume 198, pp. 17–45. [Google Scholar]

- Booth, C.J. Groundwater as an environmental constraint of longwall coal mining. Environ. Geol. 2006, 49, 796–803. [Google Scholar] [CrossRef]

- Chu, T.X.; Yu, M.G.; Jiang, D.Y. Experimental investigation on the permeability evolution of compacted broken coal. Transp. Porous Media 2017, 116, 847–868. [Google Scholar] [CrossRef]

- Ma, D.; Miao, X.X.; Wu, Y.; Bai, H.B.; Wang, J.G.; Rezania, M.; Huang, Y.H.; Qian, H.W. Seepage properties of crushed coal particles. J. Pet. Sci. Eng. 2016, 146, 297–307. [Google Scholar]

- Kong, X.Y. Advanced Mechanics of Fluid in Porous Media, 2nd ed.; Press of University of Science and Technology of China: Hefei, China, 2010. [Google Scholar]

- Lu, H.F.; Yao, D.X.; Shen, D.; Cao, J.Y. Fracture mechanics solution of confined water progressive intrusion height of mining fracture floor. Int. J. Min. Sci. Technol. 2015, 25, 99–106. [Google Scholar] [CrossRef]

- Liu, W.Q.; Fei, X.D.; Fang, J.N. Rules for confidence intervals of permeability coefficients for water flow in over–broken rock mass. Int. J. Min. Sci. Technol. 2012, 22, 29–33. [Google Scholar] [CrossRef]

| Sample | Weight Ratio to Each Grain Size | Weight to Each Grain Size (g) | |||

|---|---|---|---|---|---|

| 2.5–5 mm | 5–10 mm | 10–15 mm | 15–20 mm | ||

| Uniform | 1:1:1:1 | 375 | 375 | 375 | 375 |

| Smallest | 2:1:1:1 | 600 | 300 | 300 | 300 |

| Smaller | 1:2:1:1 | 300 | 600 | 300 | 300 |

| Larger | 1:1:2:1 | 300 | 300 | 600 | 300 |

| Largest | 1:1:1:2 | 300 | 300 | 300 | 600 |

| Sample | Axial Displacement (mm) | ||||||

|---|---|---|---|---|---|---|---|

| 10 | 15 | 20 | 25 | 30 | 35 | 40 | |

| Uniform | 0.342 | 0.321 | 0.299 | 0.275 | 0.249 | 0.221 | 0.192 |

| Smallest | 0.346 | 0.326 | 0.303 | 0.279 | 0.254 | 0.227 | 0.198 |

| Smaller | 0.354 | 0.333 | 0.312 | 0.289 | 0.265 | 0.238 | 0.21 |

| Larger | 0.362 | 0.342 | 0.321 | 0.299 | 0.275 | 0.249 | 0.221 |

| Largest | 0.379 | 0.36 | 0.34 | 0.319 | 0.296 | 0.272 | 0.246 |

| Sample | Weight to Each Grain Size (g) | Weight Change (g) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2.5–5 mm | 5–10 mm | 10–15 mm | 15–20 mm | 0–2.5 mm (Increase) | Wight Loss | |||||

| Before | After | Before | After | Before | After | Before | After | |||

| Uniform | 375 | 389.3 | 375 | 377.9 | 375 | 367.4 | 375 | 337.8 | 14.2 | 13.4 |

| Smallest | 600 | 608.3 | 300 | 306.8 | 300 | 288.4 | 300 | 262.2 | 18.4 | 15.9 |

| Smaller | 300 | 309.6 | 600 | 592.4 | 300 | 294.6 | 300 | 280.9 | 11.3 | 11.2 |

| Larger | 300 | 319.1 | 300 | 307.8 | 600 | 583.2 | 300 | 264.3 | 12.4 | 13.2 |

| Largest | 300 | 316.2 | 300 | 304.2 | 300 | 283.6 | 600 | 573.1 | 13.6 | 9.3 |

| Sample | Characteristics | Axial Displacement (mm) | ||||||

|---|---|---|---|---|---|---|---|---|

| 10 | 15 | 20 | 25 | 30 | 35 | 40 | ||

| Uniform | k (μm2) | 19.344 | 16.241 | 12.167 | 10.13 | 5.38 | 3.655 | 1.234 |

| β (mm−1) | 3.215 | 4.367 | 9.135 | 13.244 | 12.983 | 19.167 | 28.344 | |

| Smallest | k (μm2) | 38.167 | 24.531 | 20.188 | 12.28 | 16.732 | 8.63 | 4.529 |

| β (mm−1) | 2.673 | 6.314 | 3.145 | 5.328 | 7.73 | 7.481 | 9.673 | |

| Smaller | k (μm2) | 54.135 | 32.148 | 27.44 | 20.128 | 12.35 | 7.862 | 4.583 |

| β (mm−1) | 1.355 | 4.432 | 2.673 | 3.985 | 7.872 | 11.256 | 9.442 | |

| Larger | k (μm2) | 62.137 | 31.455 | 41.263 | 23.145 | 16.33 | 12.15 | 6.732 |

| β (mm−1) | 1.235 | 3.467 | 6.548 | 4.32 | 9.531 | 8.237 | 12.258 | |

| Largest | k (μm2) | 71.427 | 38.135 | 29.037 | 30.182 | 26.355 | 19.247 | 10.156 |

| β (mm−1) | 3.455 | 1.293 | 4.673 | 2.732 | 6.329 | 7.383 | 10.252 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, D.; Zhou, Z.; Wu, J.; Li, Q.; Bai, H. Grain Size Distribution Effect on the Hydraulic Properties of Disintegrated Coal Mixtures. Energies 2017, 10, 612. https://doi.org/10.3390/en10050612

Ma D, Zhou Z, Wu J, Li Q, Bai H. Grain Size Distribution Effect on the Hydraulic Properties of Disintegrated Coal Mixtures. Energies. 2017; 10(5):612. https://doi.org/10.3390/en10050612

Chicago/Turabian StyleMa, Dan, Zilong Zhou, Jiangyu Wu, Qiang Li, and Haibo Bai. 2017. "Grain Size Distribution Effect on the Hydraulic Properties of Disintegrated Coal Mixtures" Energies 10, no. 5: 612. https://doi.org/10.3390/en10050612