Flow Behavior and Displacement Mechanisms of Nanoparticle Stabilized Foam Flooding for Enhanced Heavy Oil Recovery

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Nanoparticle-Surfactant Dispersion

2.3. Preparation and Characterization of Foam

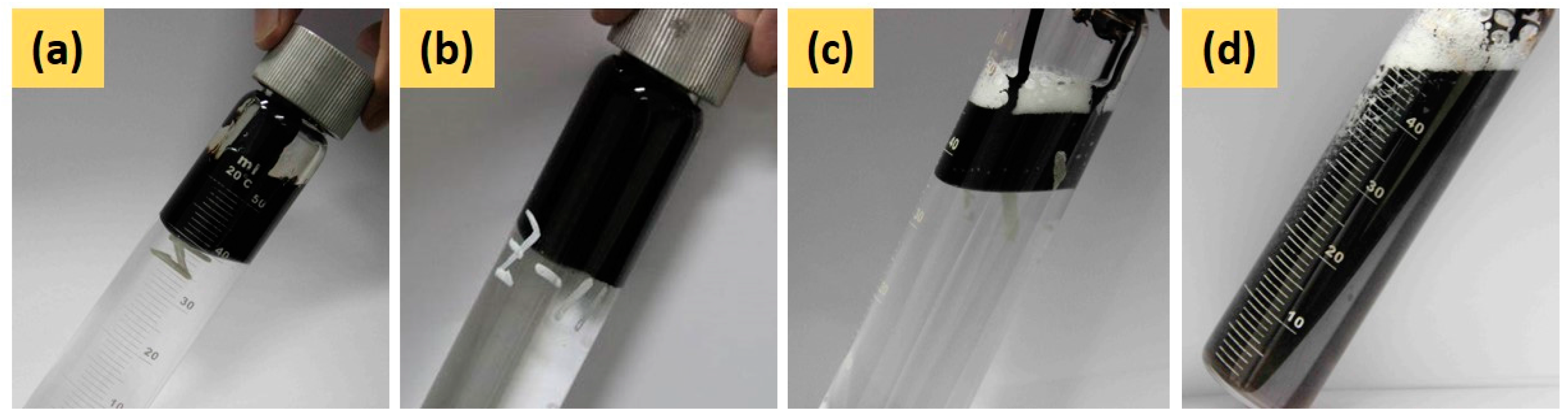

2.4. Emulsification Tests

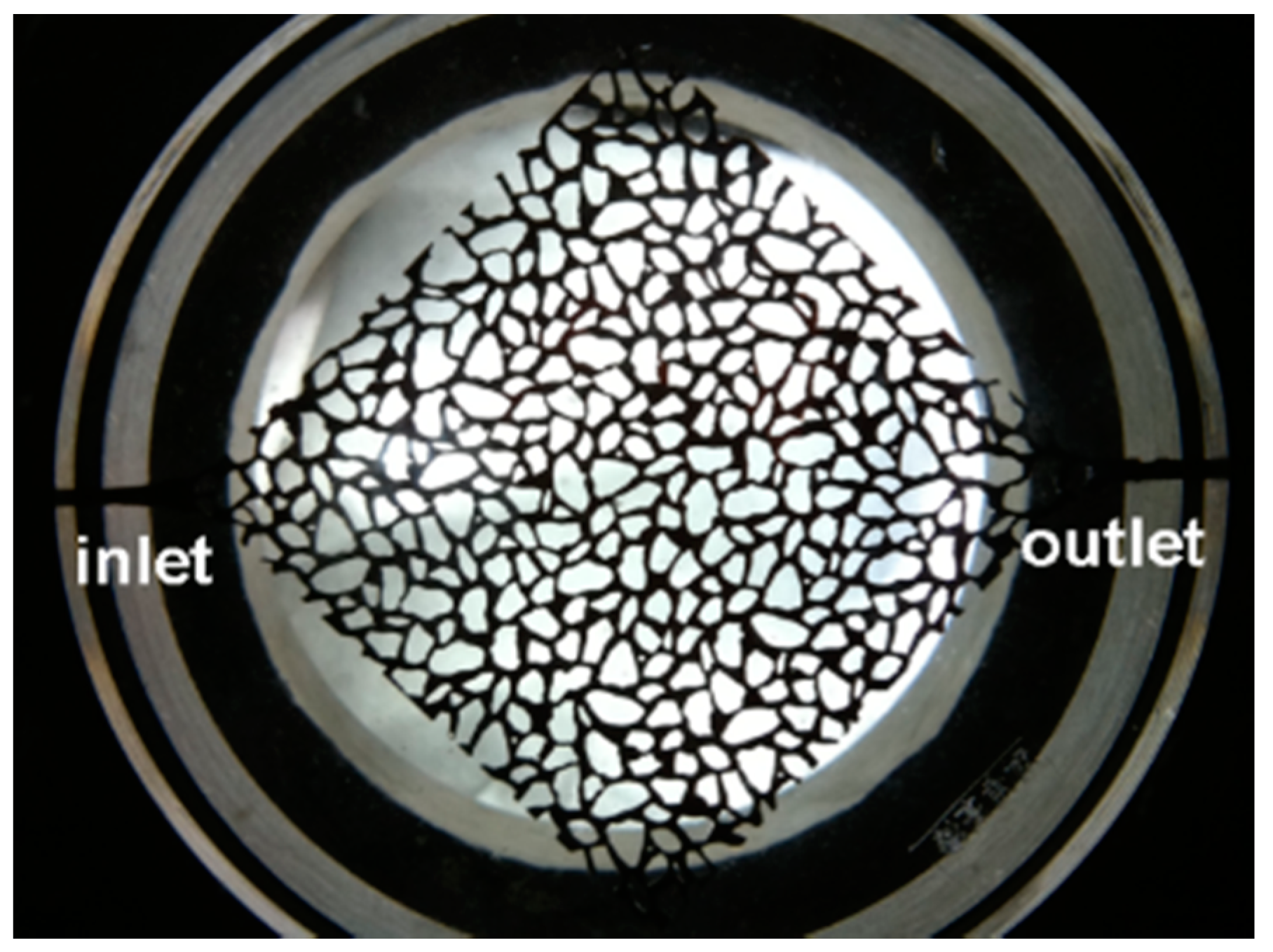

2.5. Micromodel Setup

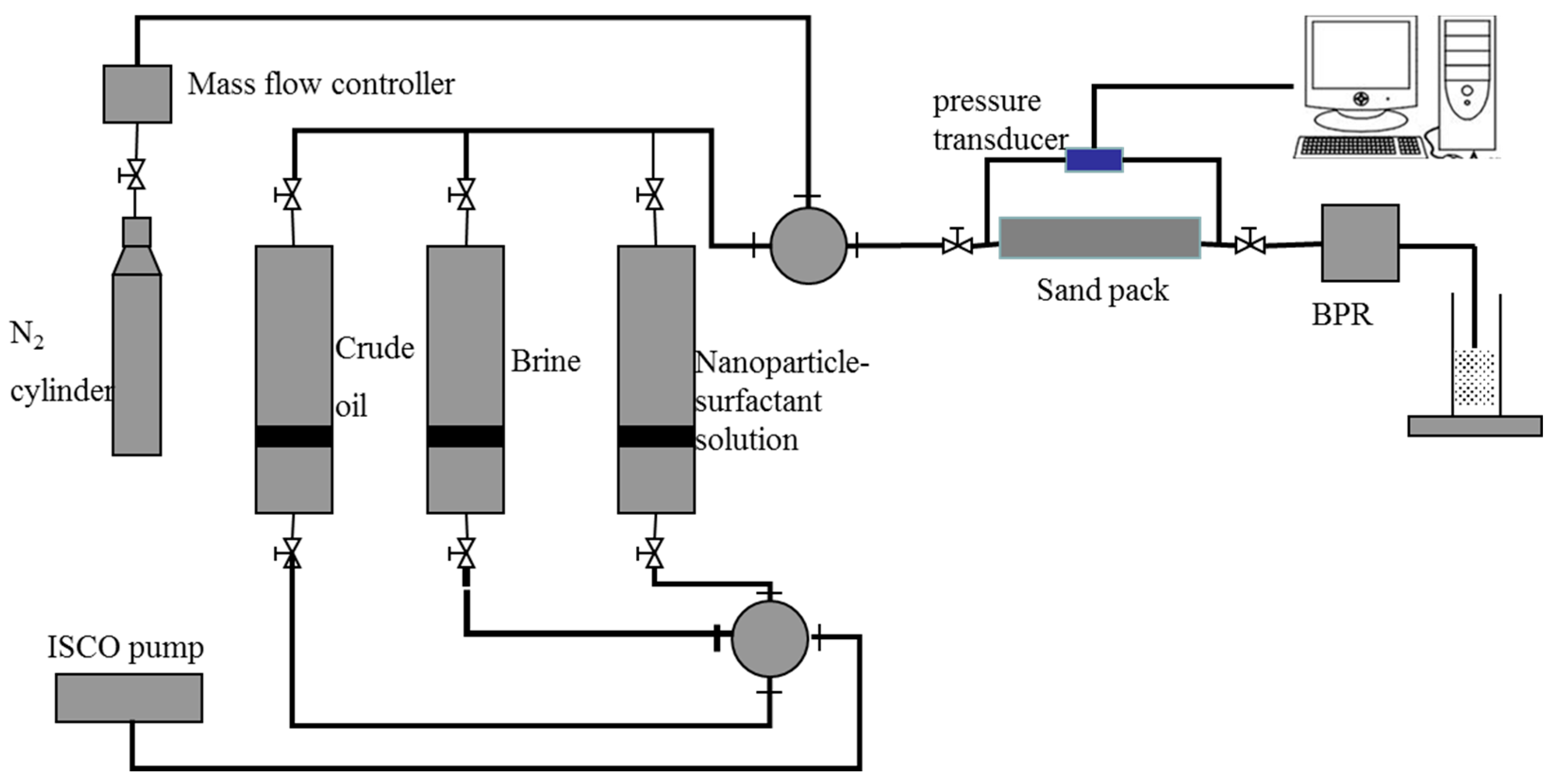

2.6. Sandpack Flood Studies

3. Results and Discussion

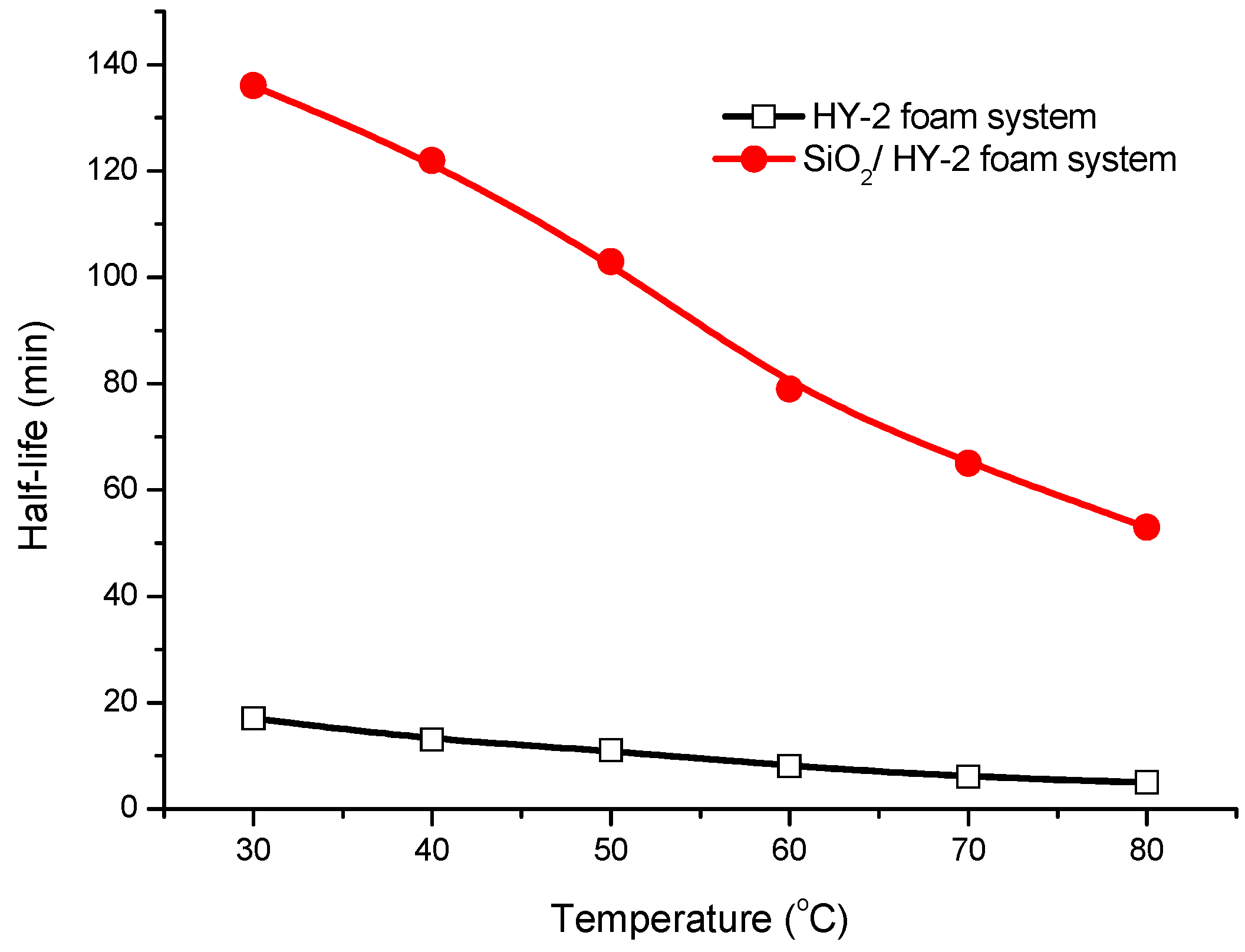

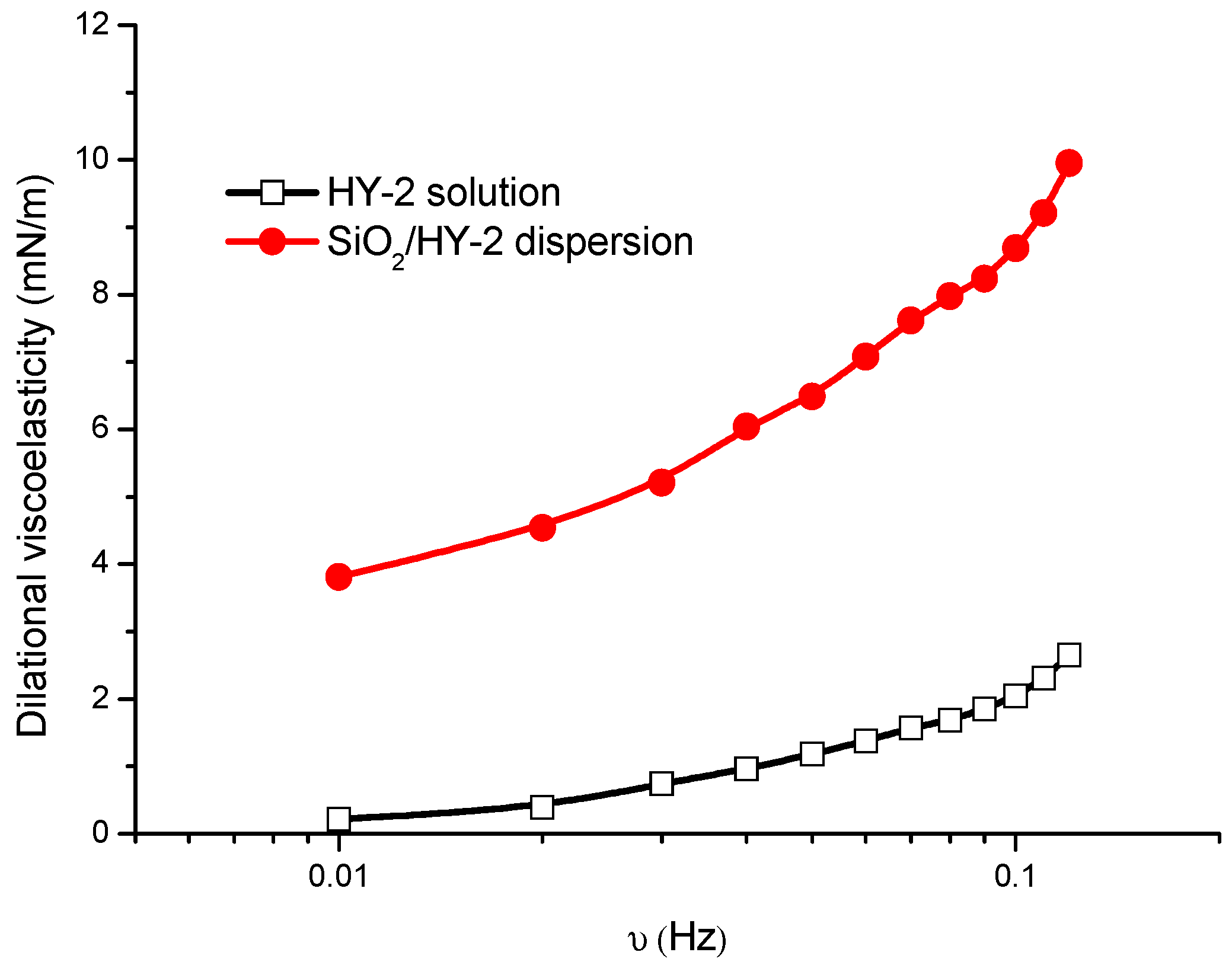

3.1. Characterization of the Foam in Bulk Tests

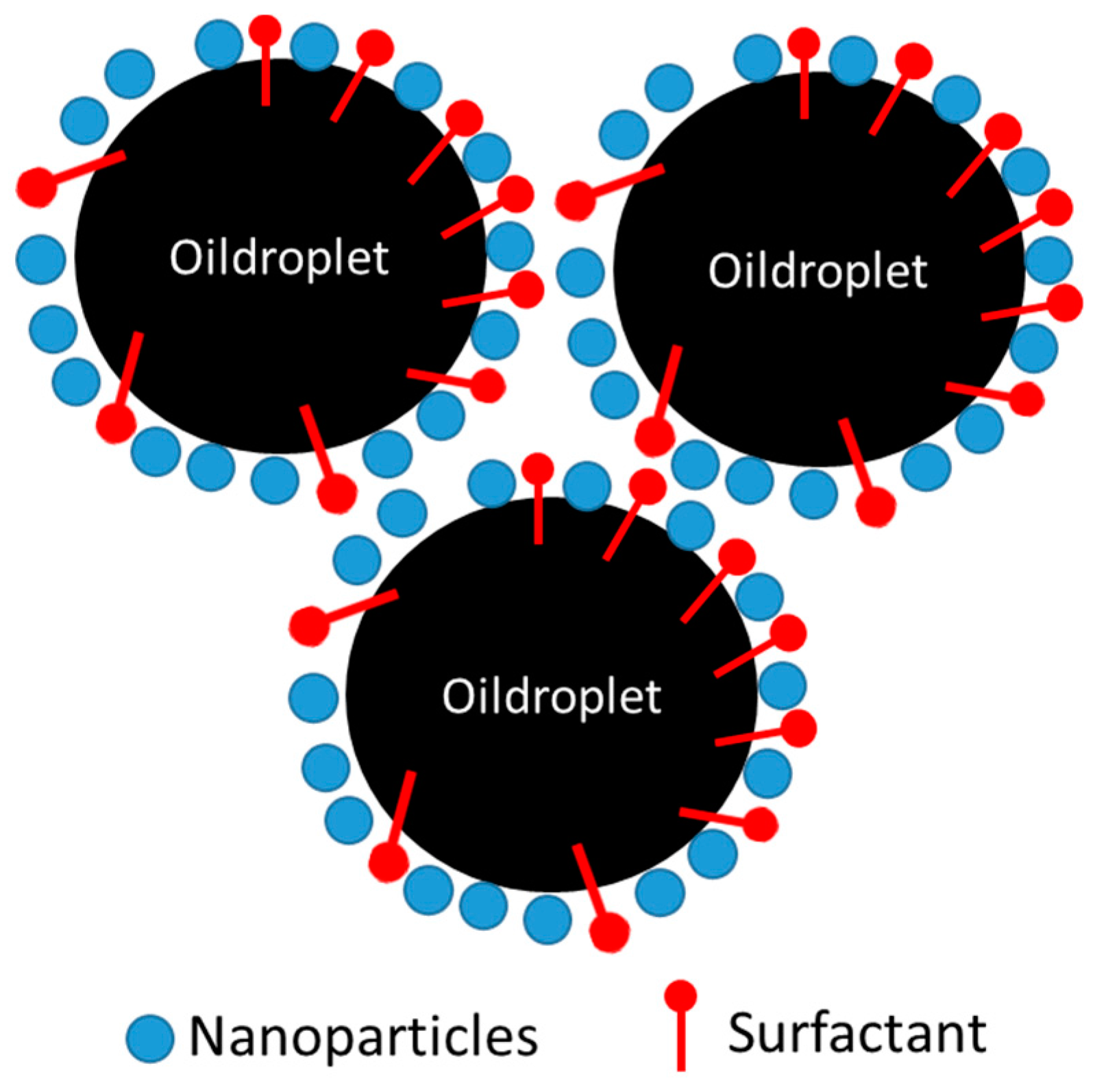

3.2. Emulsification Tests

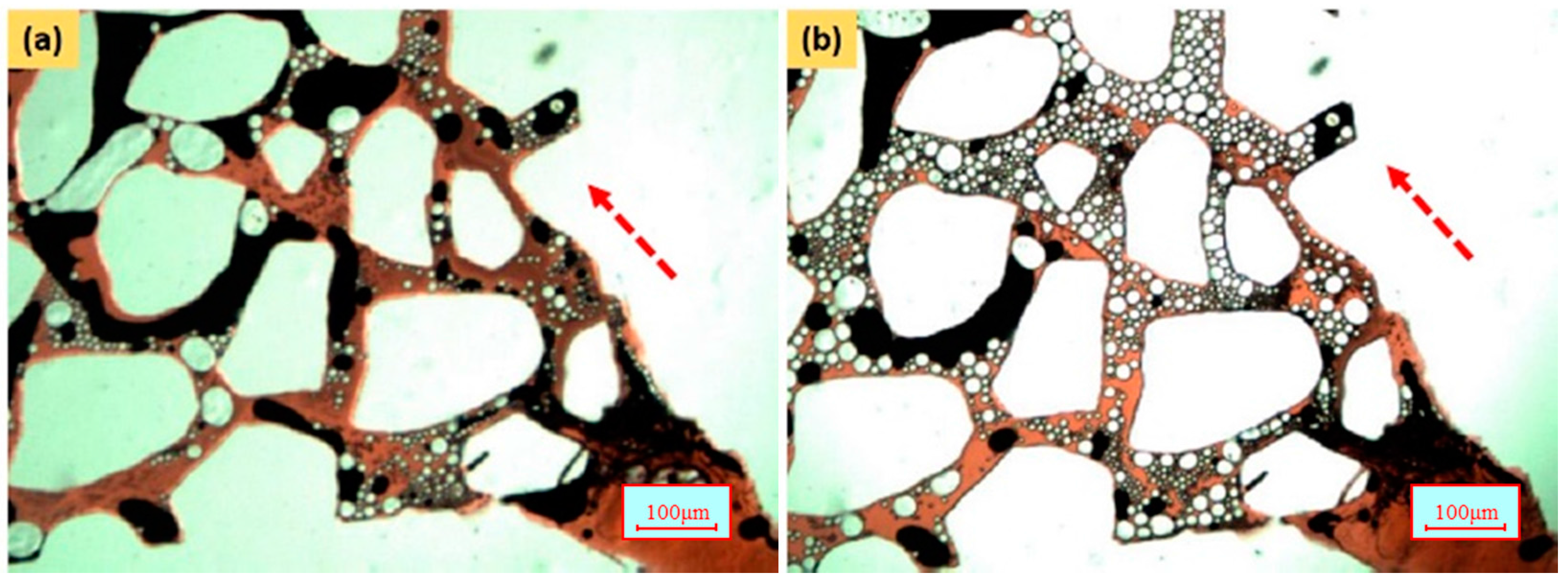

3.3. Micromodel Flood Study

3.3.1. Transport of Gas Bubbles in Porous Media

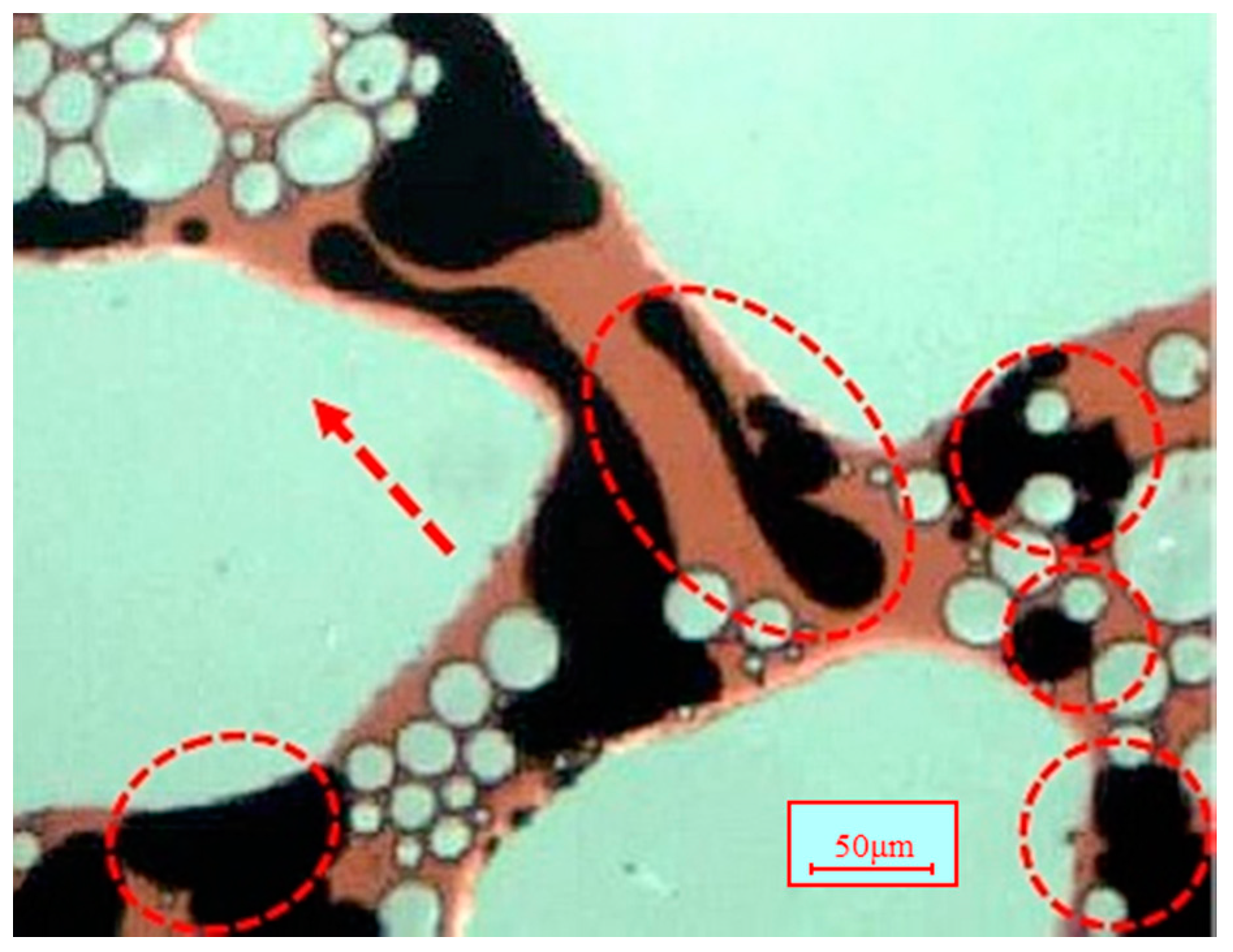

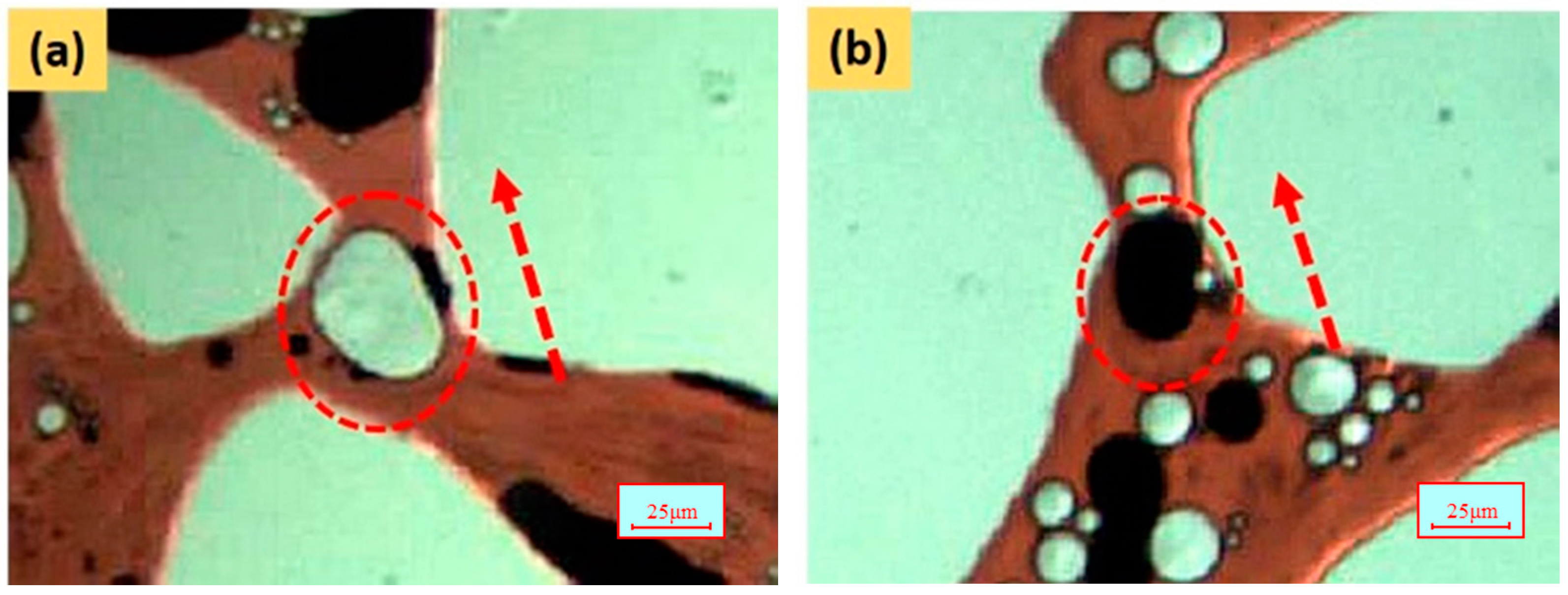

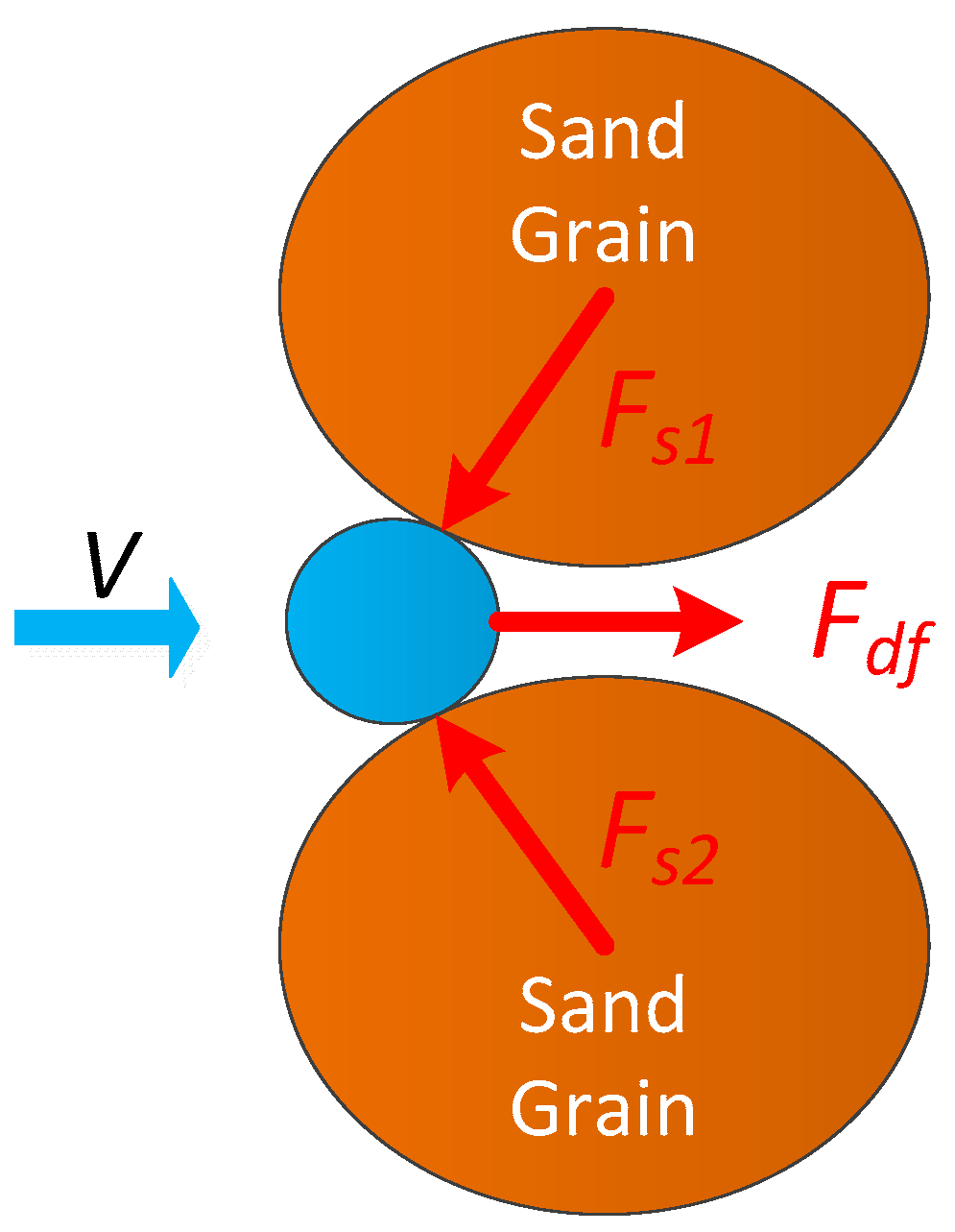

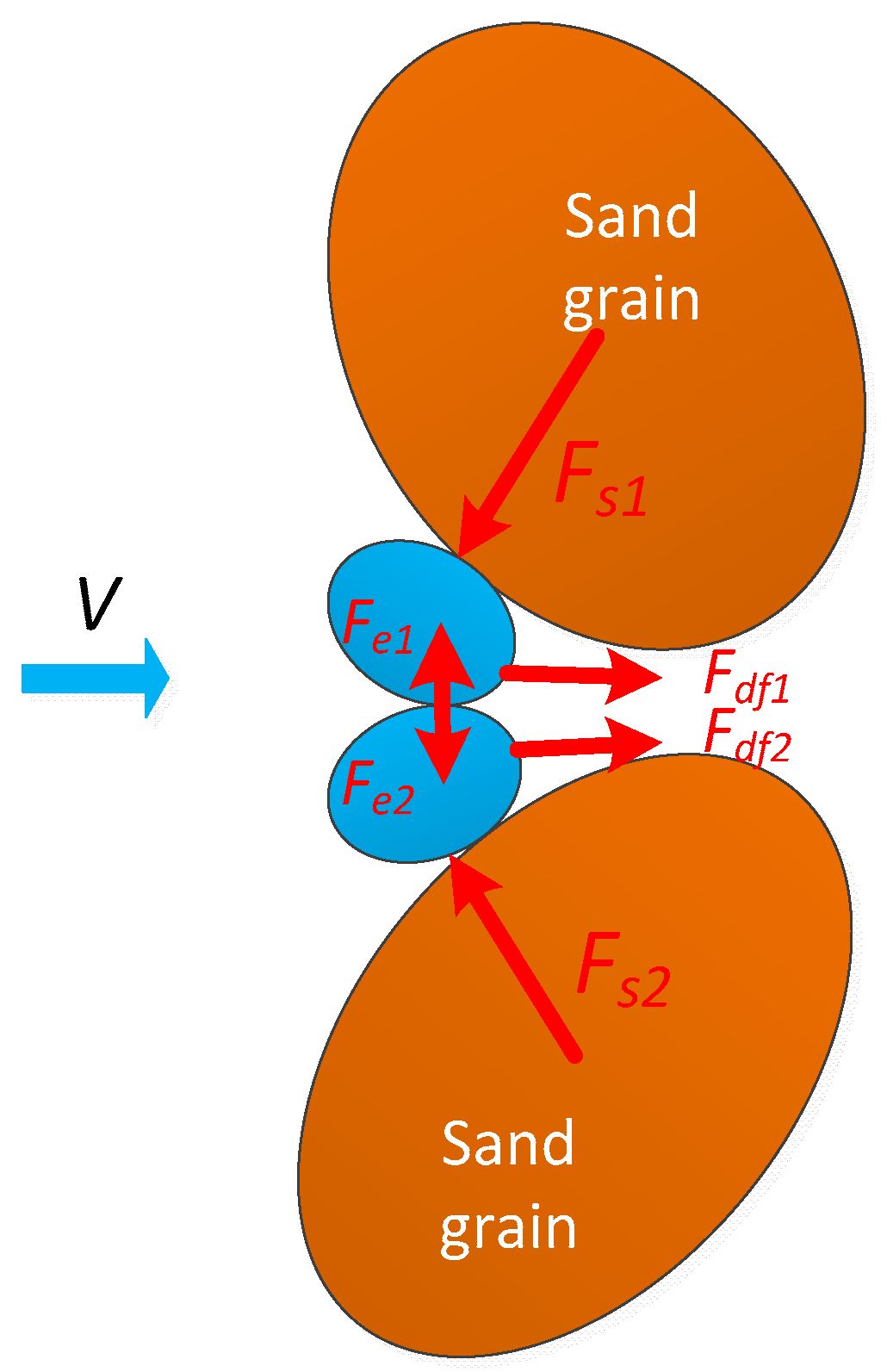

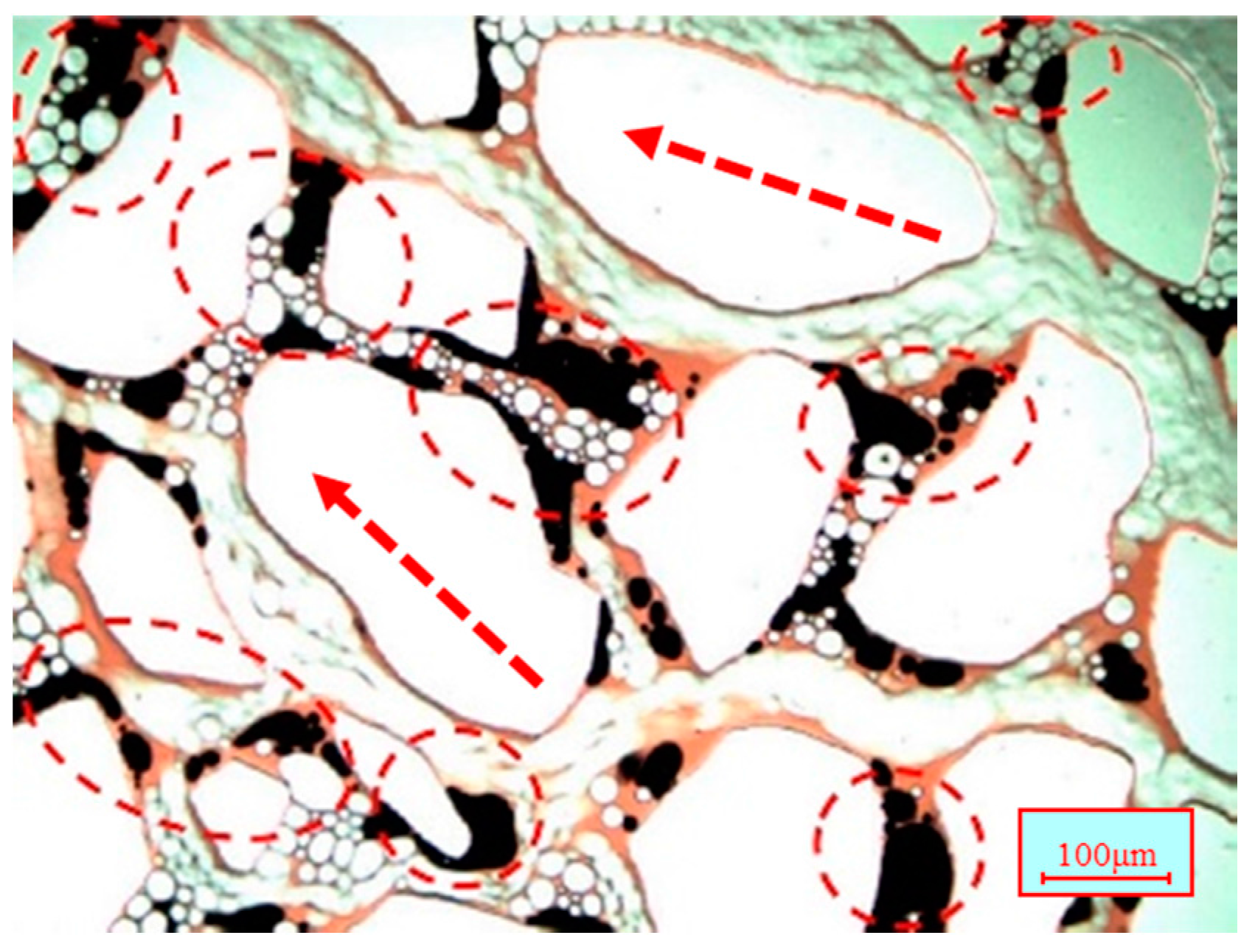

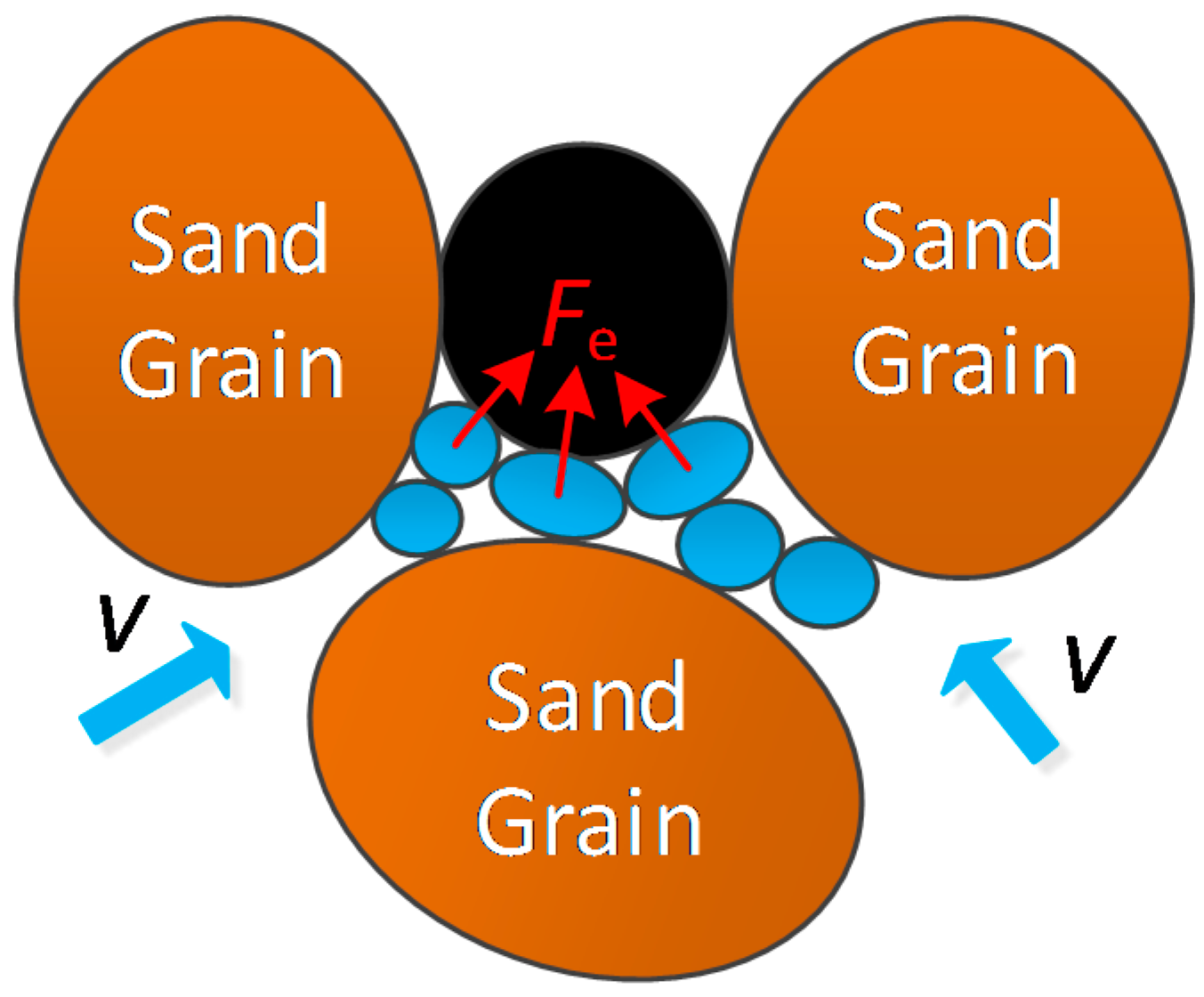

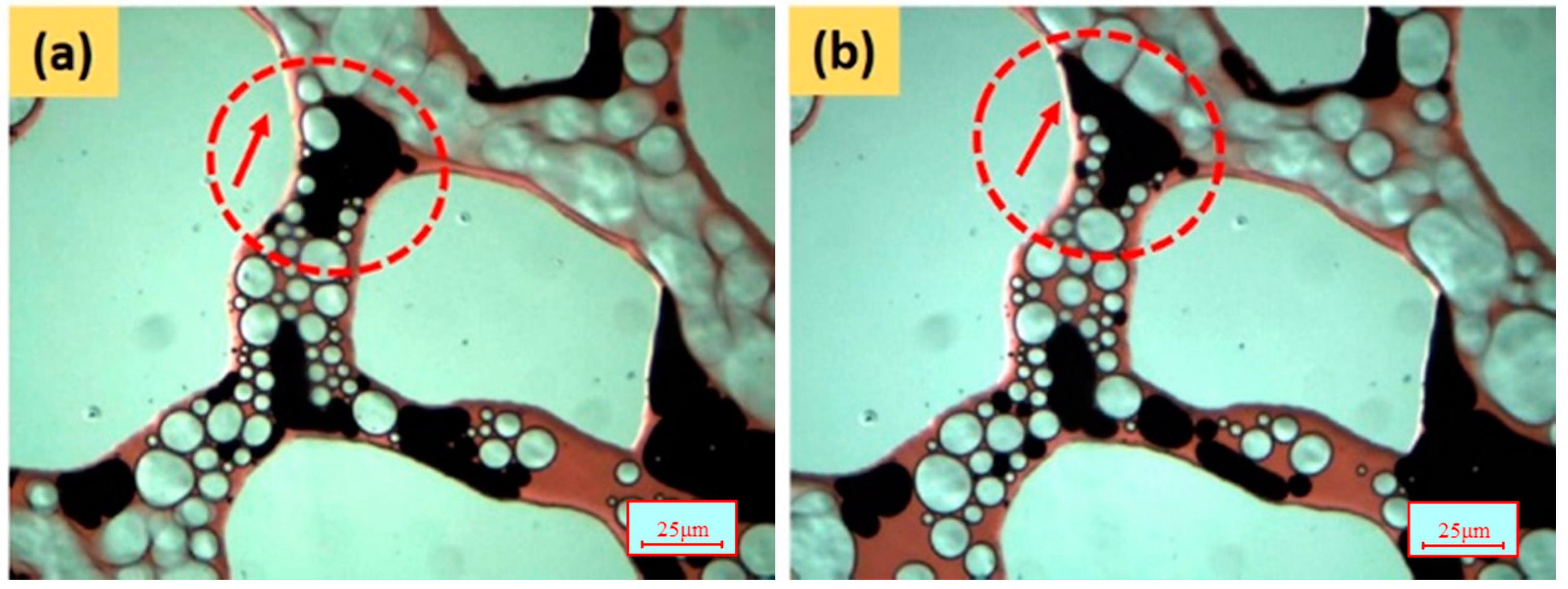

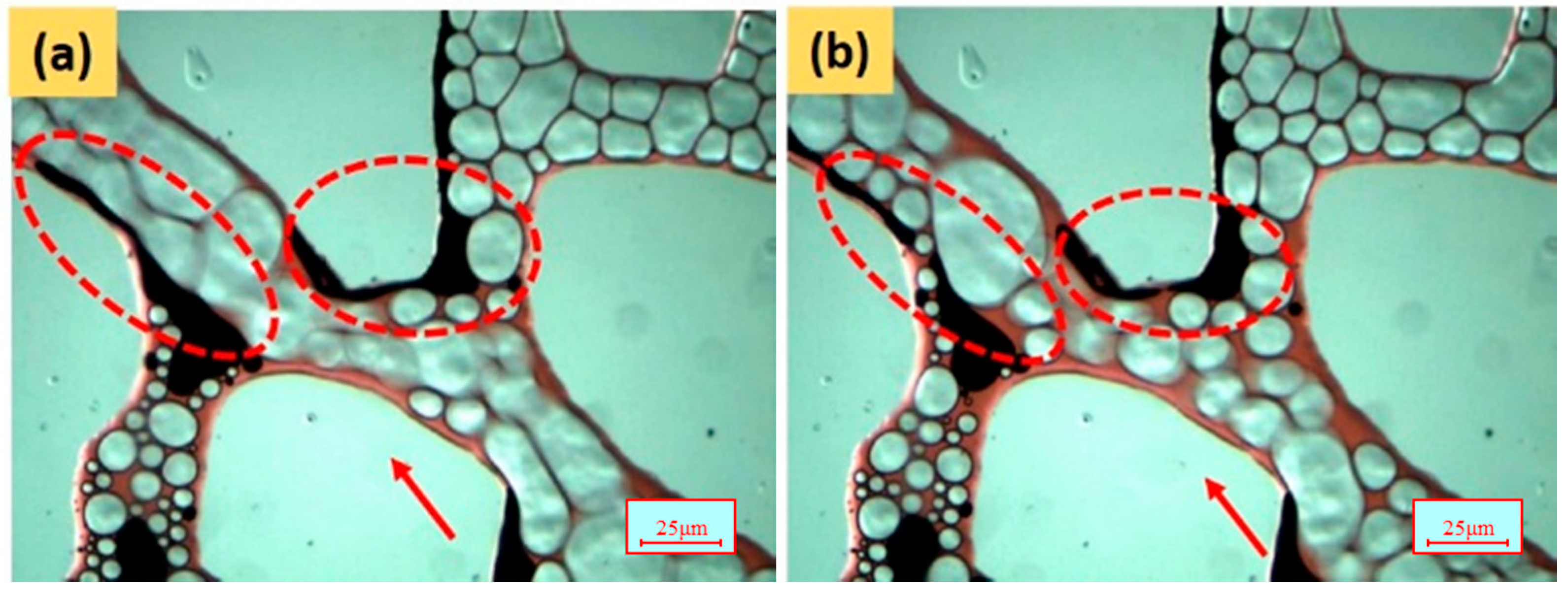

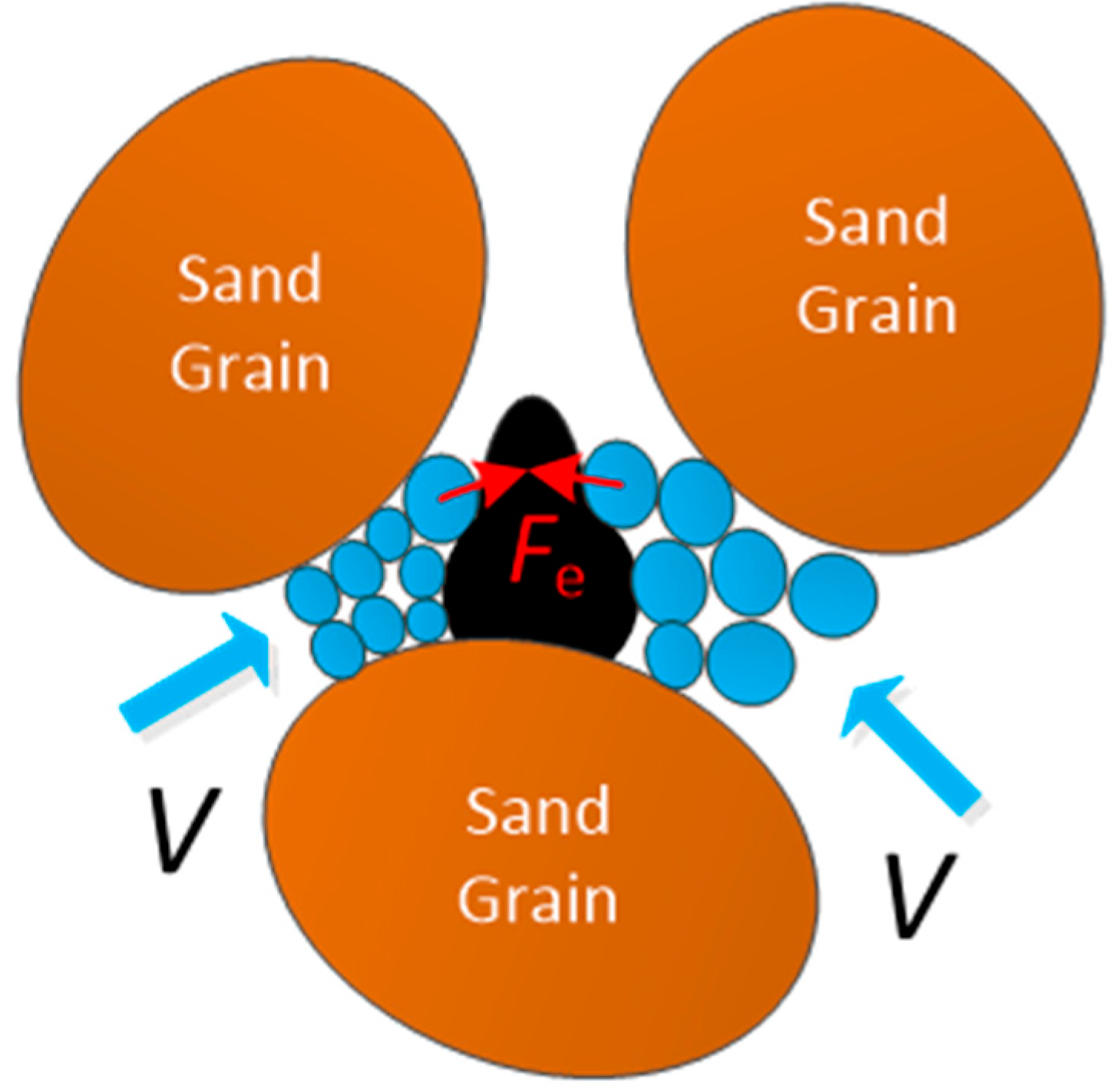

3.3.2. Mechanisms for Plugging Pores with Gas Bubbles and Oil Droplets

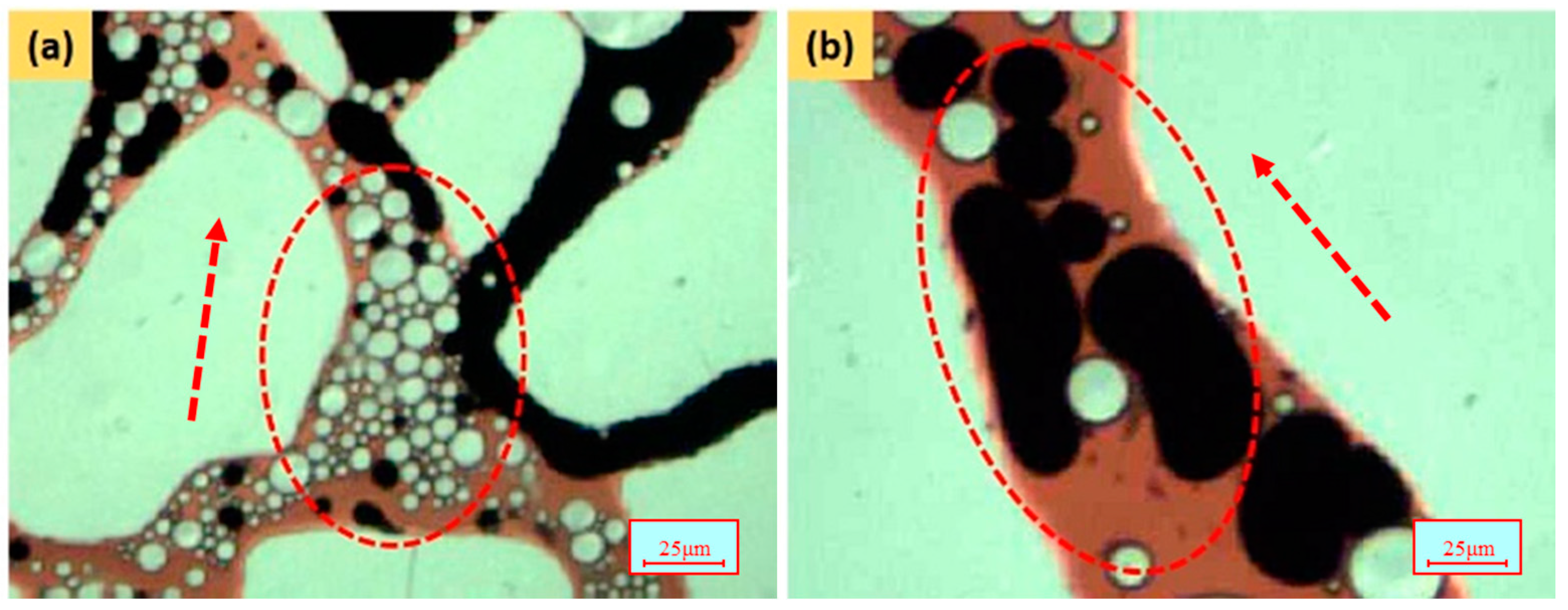

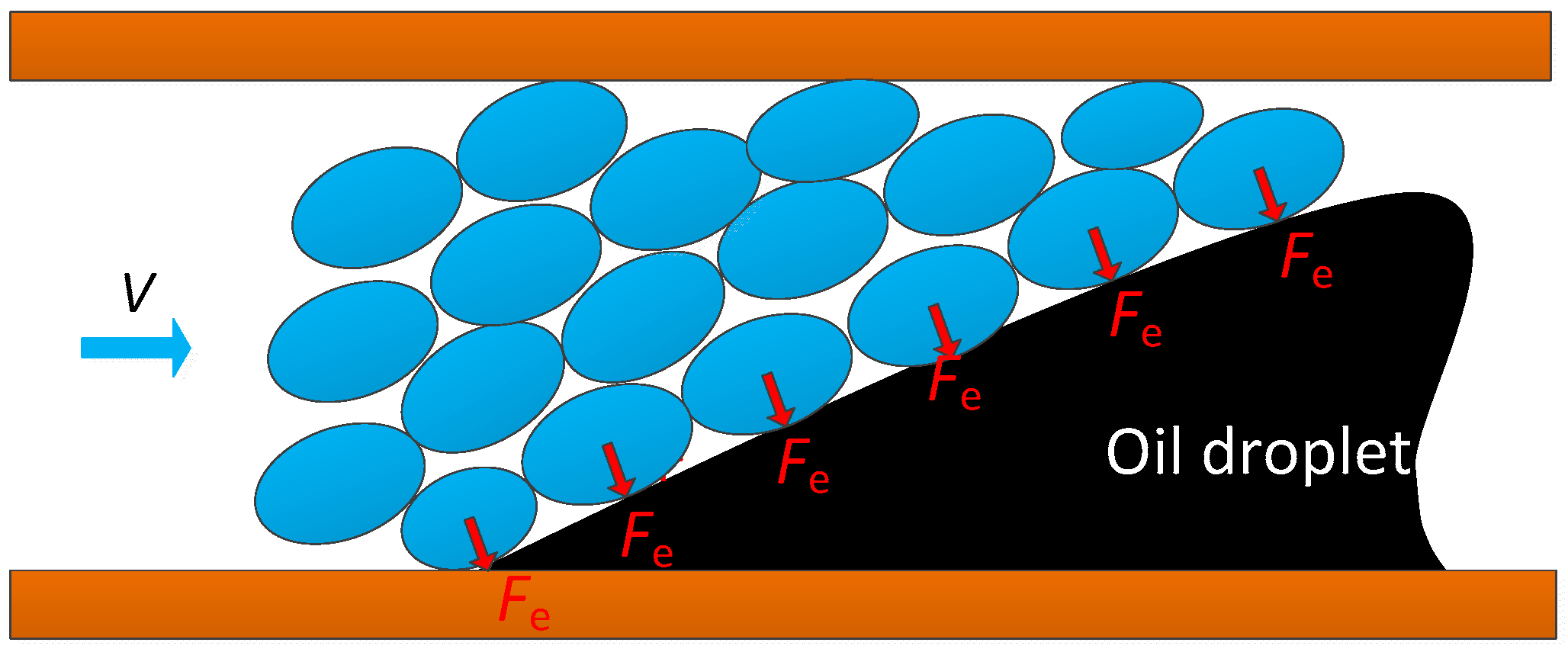

3.3.3. Mechanisms for Displacing Residual Oil with Gas Bubbles

3.4. Sandpack Flood Study

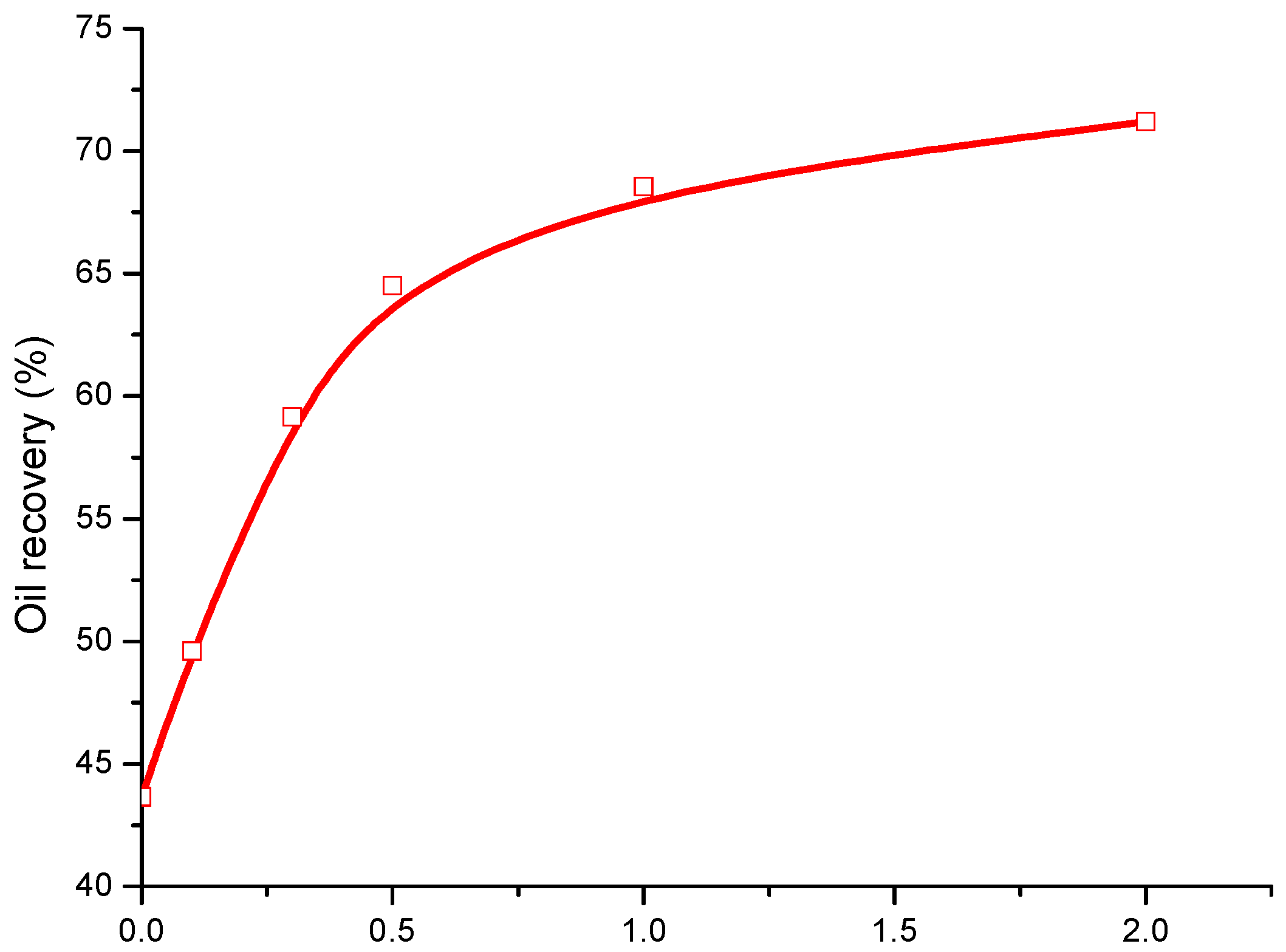

3.4.1. Effect of the Nanoparticle Concentration

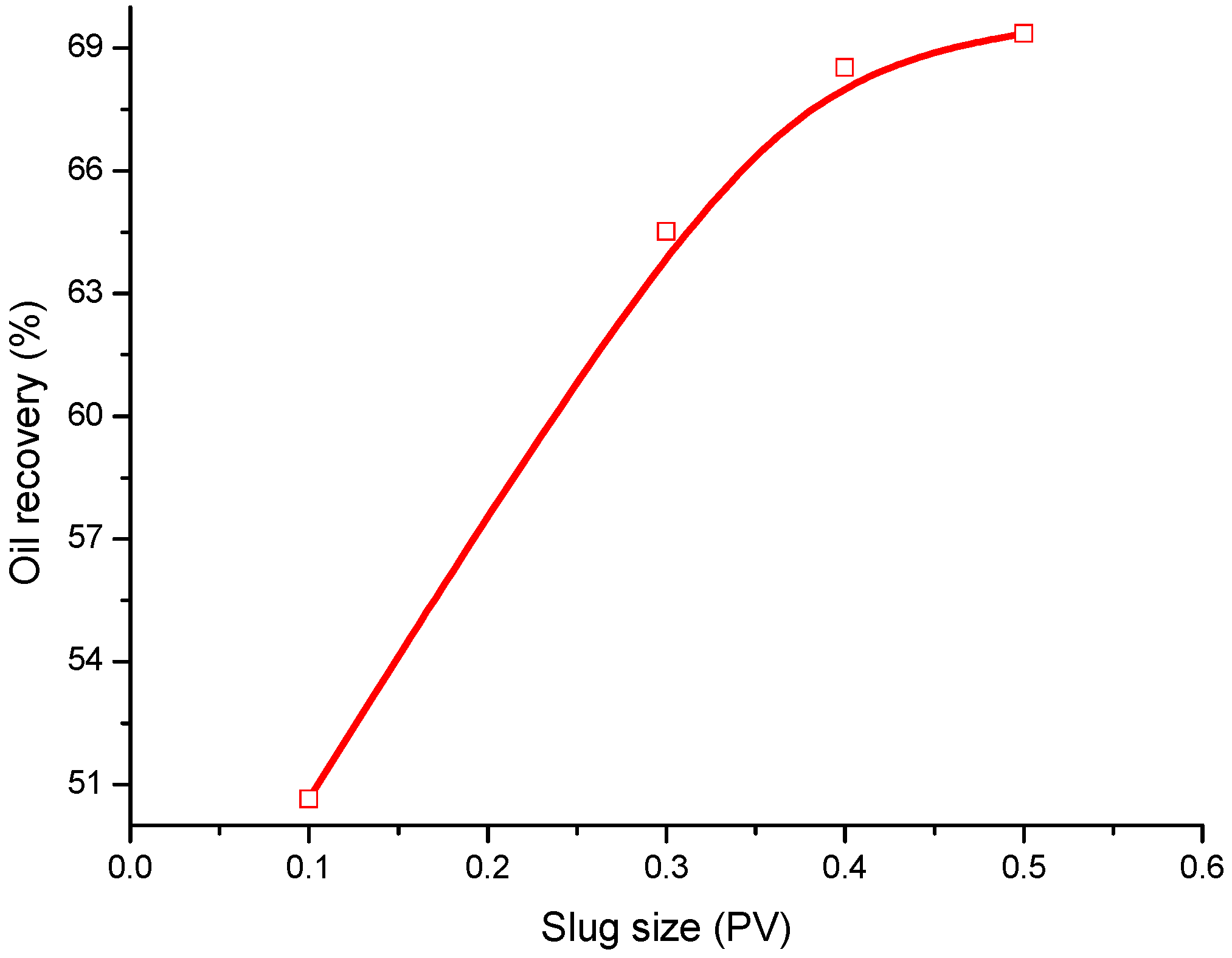

3.4.2. Effect of the Foam Slug Size

3.4.3. Effect of Gas Liquid Ratio

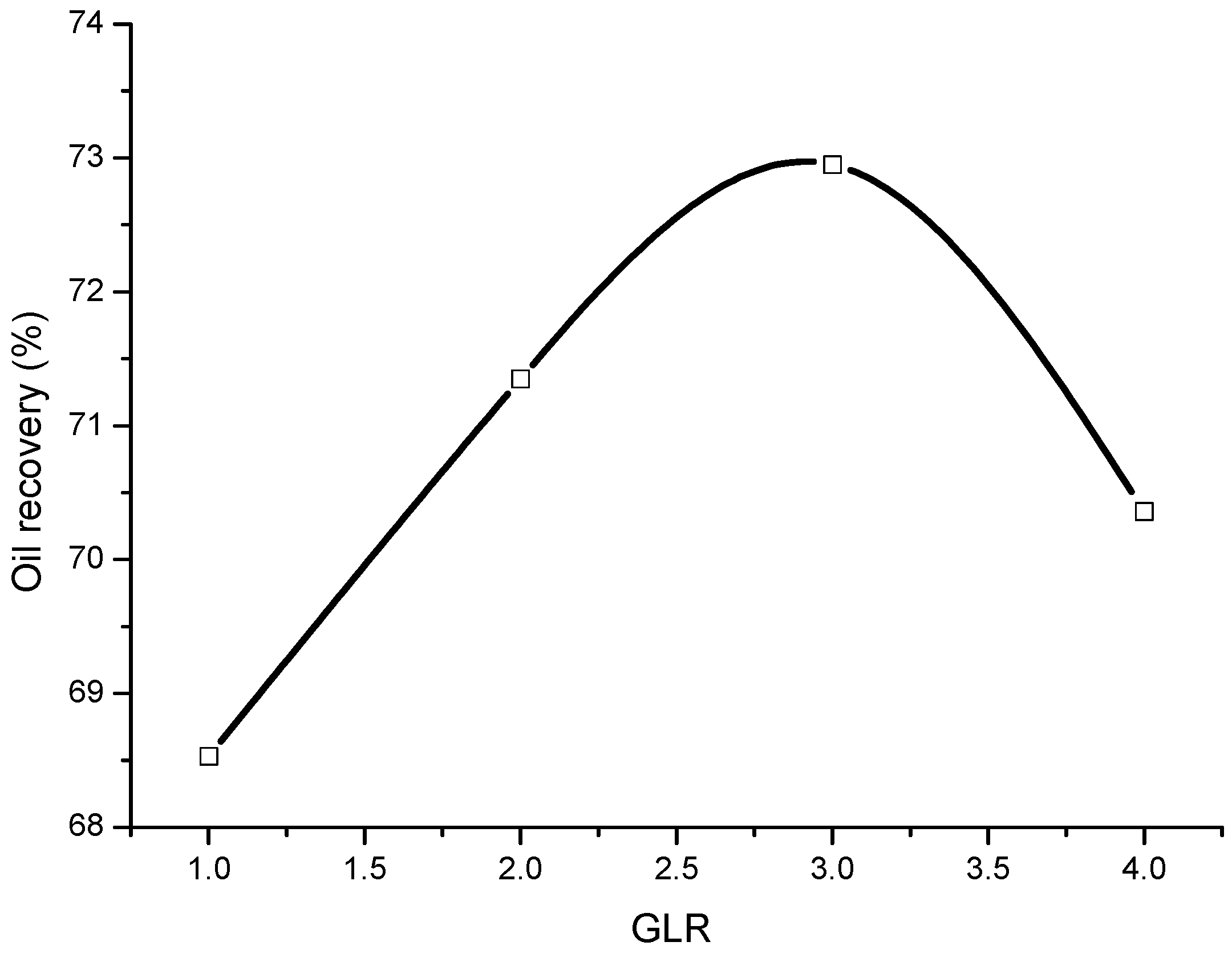

3.4.4. Effect of the Injection Pattern

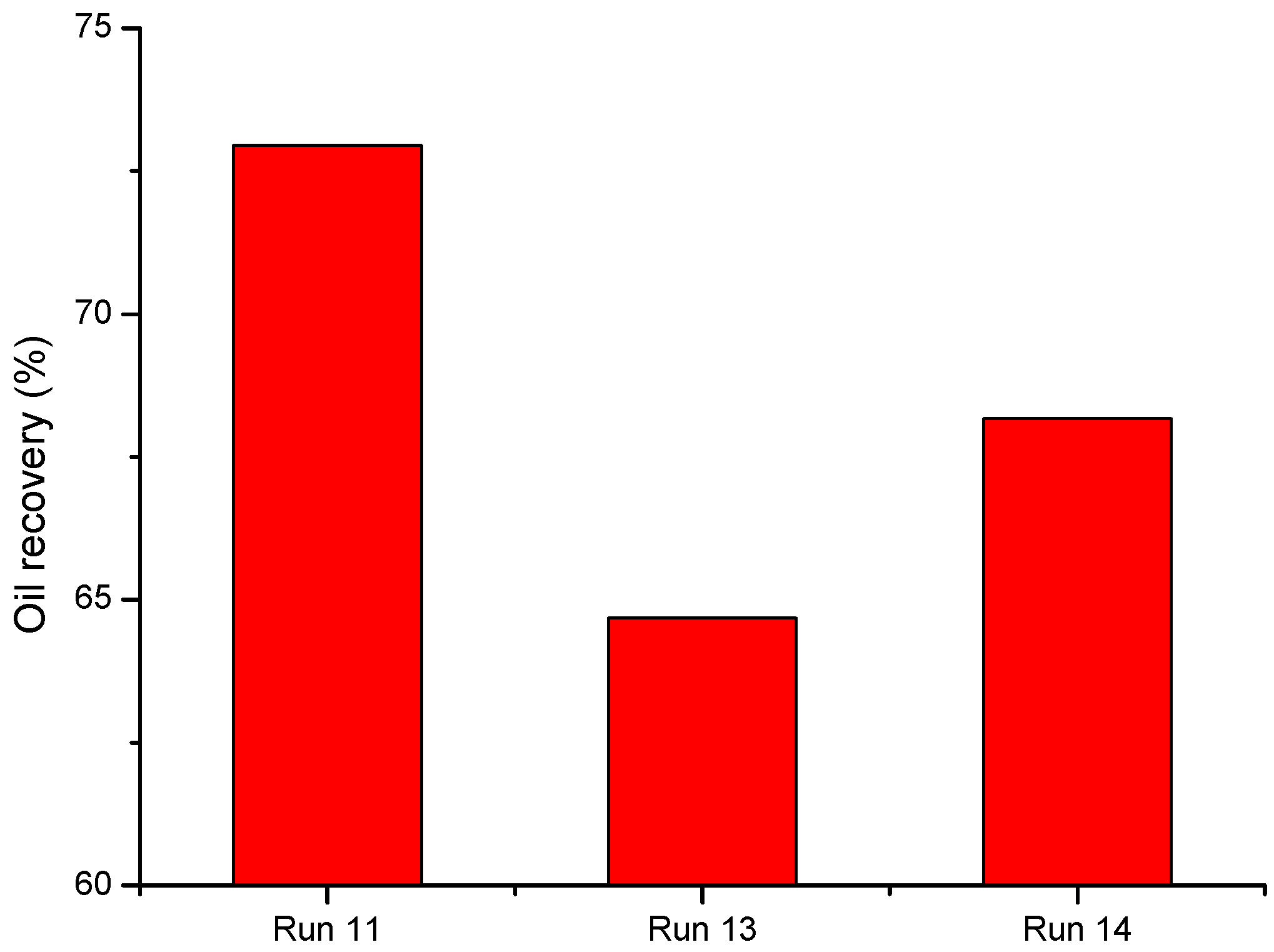

4. Conclusions

- (1)

- The stabilities of the foam and O/W emulsion increase when silica nanoparticles were added. As a result, a large number of gas bubbles and oil droplets were stably dispersed in the porous media during the nanoparticle stabilized foam flooding.

- (2)

- The SiO2 nanoparticles can increase the dilational viscoelasticity of the gas-water interface, which is an important phenomenon for improving the enhanced heavy oil recovery. The gas bubbles and oil droplets can plug pores through the mechanisms of capture-plugging and bridge-plugging, thereby increasing the sweep efficiency. The trapped residual oil could be pushed to the pores gradually by the elastic forces of gas bubbles, and subsequently, it could be pulled into oil threads by the flowing gas bubbles. As a result, a greater improvement in displacement efficiency is obtained.

- (3)

- The sandpack test results show that the tertiary oil recovery of nanoparticle stabilized foam flooding can reach about 27% using 0.5 wt % SiO2 nanoparticles. The foam slug size of 0.3 PV and the gas liquid ratio (GLR) of 3 were found to be the optimum conditions in terms of the heavy oil recovery by nanoparticle stabilized foam flooding in this study. Continuous nanoparticle dispersion and N2 could be more effective when compared with the cyclic injection pattern.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Al-Bahlani, A.; Babadagli, T. SAGD laboratory experimental and numerical simulation studies: A review of current status and future issues. J. Pet. Sci. Eng. 2009, 68, 135–150. [Google Scholar] [CrossRef]

- Pei, H.; Zhang, G.; Ge, J.; Jin, L.; Ma, C. Potential of alkaline flooding to enhance heavy oil recovery through water-in-oil emulsification. Fuel 2013, 104, 284–293. [Google Scholar] [CrossRef]

- Mai, A.; Bryan, J.; Goodarzi, N.; Kantzas, A.; Mai, A.; Bryan, J.; Goodarzi, N.; Kantzas, A. Insights Into Non-Thermal Recovery of Heavy Oil. J. Can. Pet. Technol. 2009, 48, 27–35. [Google Scholar] [CrossRef]

- Kumar, M.; Hoang, V.T.; Satik, C.; Rojas, D.H. High-Mobility-Ratio Waterflood Performance Prediction: Challenges and New Insights. SPE Reserv. Eval. Eng. 2008, 11, 186–196. [Google Scholar] [CrossRef]

- Mai, A.; Kantzas, A. Heavy Oil Waterflooding: Effects of Flow Rate and Oil Viscosity. J. Can. Pet. Technol. 2007, 48, 42–51. [Google Scholar] [CrossRef]

- Liu, Q.; Dong, M.; Ma, S.; Tu, Y. Surfactant enhanced alkaline flooding for Western Canadian heavy oil recovery. Colloids Surf. A Physicochem. Eng. Asp. 2007, 293, 63–71. [Google Scholar] [CrossRef]

- Dong, M.; Ma, S.; Liu, Q. Enhanced heavy oil recovery through interfacial instability: A study of chemical flooding for Brintnell heavy oil. Fuel 2009, 88, 1049–1056. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, M.; Zhao, S. Which One Is More Important in Chemical Flooding for Enhanced Court Heavy Oil Recovery, Lowering Interfacial Tension or Reducing Water Mobility? Energy Fuels 2010, 24, 1829–1836. [Google Scholar] [CrossRef]

- Benucci, M.; Corvaro, F.; Dall’Acqua, D.; del Monaco, A.; Giacchetta, G.; Marchetti, B. A study to increase the success rate in pipeline deliquification by foamier injection. In Proceedings of the XX Summer School Francesco Turco, Naples, Italy, 6–8 July 2015; pp. 217–223. [Google Scholar]

- Pei, H.; Zhang, G.; Ge, J.; Wang, J.; Ding, B.; Liu, X. Investigation of Polymer-Enhanced Foam Flooding with Low Gas/Liquid Ratio for Improving Heavy Oil Recovery. In Proceedings of the Canadian Unconventional Resources and International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010. [Google Scholar]

- Kang, W.; Liu, S.; Meng, L.W.; Cao, D.; Fan, H. A Novel Ultra-Low Interfacial Tension Foam Flooding Agent to Enhance Heavy Oil Recovery. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010. [Google Scholar]

- Farzaneh, S.A.; Sohrabi, M. A Review of the Status of Foam Application in Enhanced Oil Recovery. In Proceedings of the EAGE Annual Conference & Exhibition incorporating SPE Europec, London, UK, 10–13 June 2013. [Google Scholar]

- Hassen, J.E.; Dalland, M. Increased Oil Tolerance of Polymer-Enhanced Foams: Deep Chemistry or Just “Simple” Displacement Effects? In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 3–5 April 2000. [Google Scholar]

- Espinosa, D.; Johnston, K.; Bryant, S.L.; Huh, C. Nanoparticle-Stability Supercritical CO2 Foams for Potential Mobility Control Applications. In Proceedings of the 2010 SPE Improved Oil Recovery Symposium, Society of Petroleum Engineers, Tulsa, OK, USA, 24–28 April 2010. [Google Scholar]

- Sun, Q.; Li, Z.; Li, S.; Jiang, L.; Wang, J.; Wang, P. Utilization of surfactant-stabilized foam for enhanced oil recovery by adding nanoparticles. Energy Fuels 2014, 28, 2384–2394. [Google Scholar] [CrossRef]

- Nguyen, P.; Fadaei, H.; Sinton, D. Pore-scale assessment of nanoparticle-stabilized CO2 foam for enhanced oil recovery. Energy Fuels 2014, 28, 6221–6227. [Google Scholar] [CrossRef]

- Singh, R.; Mohanty, K.K. In Foams Stabilized by In-Situ Surface Activated Nanoparticles in Bulk and Porous Media. In Proceedings of the SPE Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. [Google Scholar]

- Aminzadeh, B.; DiCarlo, D.A.; Chung, D.H.; Kianinejad, A.; Bryant, S.L.; Huh, C. Effect of Nanoparticles on Flow Alteration during CO2 Injection; SPE Paper 1600052; Society of Petroleum Engineers (SPE): Richardson, TX, USA, 2012. [Google Scholar]

- Lv, Q.; Li, Z.; Li, B.; Li, S.; Sun, Q. Study of nanoparticle–surfactant-stabilized foam as a fracturing fluid. Ind. Eng. Chem. Res. 2015, 54, 9456–9477. [Google Scholar] [CrossRef]

- Santini, E.; Ravera, F.; Ferrari, M.; Alfè, M.; Ciajolo, A.; Liggieri, L. Interfacial properties of carbon particulate-laden liquid interfaces and stability of related foams and emulsions. Colloids Surf. A Physicochem. Eng. Asp. 2010, 365, 189–198. [Google Scholar] [CrossRef]

- Hunter, T.N.; Wanless, E.J.; Jameson, G.J.; Pugh, R.J. Non-ionic surfactant interactions with hydrophobic nanoparticles: Impact on foam stability. Colloids Surf. A Physicochem. Eng. Asp. 2009, 347, 81–89. [Google Scholar] [CrossRef]

- Walker, E.M.; Frost, D.S.; Dai, L.L. Particle self-assembly in oil-in-ionic liquid Pickering emulsions. J. Colloid Interface Sci. 2011, 363, 307–313. [Google Scholar] [CrossRef] [PubMed]

| Density at 60 °C (kg/m3) | Viscosity at 60 °C (mPa·s) | Saturate (wt %) | Aromatic (wt %) | Resin (wt %) | Asphaltenes (wt %) | Acid Number (mg KOH/g oil) |

|---|---|---|---|---|---|---|

| 986.8 | 2240 | 39.19 | 38.49 | 19.58 | 2.35 | 2.71 |

| Test | Properties of Sandpacks | Waterflood Recovery (%) | Chemical Formula | Vl (mL/min) | Vg (mL/min) | GLR | Foam Slug Size (PV) | Injection Pattern | Tertiary Recovery (%) | Final Recovery (%) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Φ (%) | K (mD) | Soi (%) | ||||||||||

| 1 | 35.21 | 1024 | 0.78 | 38.14 | 0.5 wt % HY-2 | 0.5 | 0.5 | 1:1 | 0.3 | co-injection | 5.51 | 43.65 |

| 2 | 32.14 | 1089 | 0.75 | 36.24 | 0.5 wt % HY-2 + 0.1 wt % SiO2 | 0.5 | 0.5 | 1:1 | 0.3 | co-injection | 13.37 | 49.61 |

| 3 | 35.36 | 1152 | 0.71 | 36.95 | 0.5 wt % HY-2 + 0.3 wt % SiO2 | 0.5 | 0.5 | 1:1 | 0.3 | co-injection | 22.2 | 59.15 |

| 4 | 36.95 | 1247 | 0.76 | 37.15 | 0.5 wt % HY-2 + 0.5 wt % SiO2 | 0.5 | 0.5 | 1:1 | 0.3 | co-injection | 27.37 | 64.52 |

| 5 | 34.21 | 1026 | 0.81 | 38.06 | 0.5 wt % HY-2 + 1.0 wt % SiO2 | 0.5 | 0.5 | 1:1 | 0.3 | co-injection | 30.51 | 68.57 |

| 6 | 36.98 | 1125 | 0.79 | 38.36 | 0.5 wt % HY-2 + 2.0 wt % SiO2 | 0.5 | 0.5 | 1:1 | 0.3 | co-injection | 32.85 | 71.21 |

| 7 | 35.68 | 1201 | 0.81 | 36.95 | 0.5 wt % HY-2 + 0.5 wt % SiO2 | 0.5 | 0.5 | 1:1 | 0.1 | co-injection | 13.7 | 50.65 |

| 8 | 39.32 | 1036 | 0.71 | 36.32 | 0.5 wt % HY-2 + 0.5 wt % SiO2 | 0.5 | 0.5 | 1:1 | 0.4 | co-injection | 32.21 | 68.53 |

| 9 | 35.14 | 1158 | 0.74 | 38.14 | 0.5 wt % HY-2 + 0.5 wt % SiO2 | 0.5 | 0.5 | 1:1 | 0.5 | co-injection | 31.22 | 69.36 |

| 10 | 36.32 | 1135 | 0.72 | 37.15 | 0.5 wt % HY-2 + 0.5 wt % SiO2 | 0.34 | 0.66 | 2:1 | 0.4 | co-injection | 34.2 | 71.35 |

| 11 | 34.58 | 1058 | 0.73 | 38.06 | 0.5 wt % HY-2 + 0.5 wt % SiO2 | 0.25 | 0.75 | 3:1 | 0.4 | co-injection | 34.89 | 72.95 |

| 12 | 38.65 | 1063 | 0.76 | 36.96 | 0.5 wt % HY-2 + 0.5 wt % SiO2 | 0.2 | 0.8 | 4:1 | 0.4 | co-injection | 33.4 | 70.36 |

| 13 | 36.25 | 1114 | 0.75 | 38.35 | 0.5 wt % HY-2 + 0.5 wt % SiO2 | 0.25 | 0.75 | 3:1 | 0.1 + 0.3 | nanoparticle dispersion alternating N2 | 26.33 | 64.68 |

| 14 | 39.63 | 1031 | 0.69 | 39.65 | 0.5 wt % HY-2 + 0.5 wt % SiO2 | 0.25 | 0.75 | 3:1 | 0.05 + 0.15 + 0.05 + 0.15 | nanoparticle dispersion alternating N2 | 28.52 | 68.17 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, T.; Li, Z.; Zhou, Y. Flow Behavior and Displacement Mechanisms of Nanoparticle Stabilized Foam Flooding for Enhanced Heavy Oil Recovery. Energies 2017, 10, 560. https://doi.org/10.3390/en10040560

Lu T, Li Z, Zhou Y. Flow Behavior and Displacement Mechanisms of Nanoparticle Stabilized Foam Flooding for Enhanced Heavy Oil Recovery. Energies. 2017; 10(4):560. https://doi.org/10.3390/en10040560

Chicago/Turabian StyleLu, Teng, Zhaomin Li, and Yan Zhou. 2017. "Flow Behavior and Displacement Mechanisms of Nanoparticle Stabilized Foam Flooding for Enhanced Heavy Oil Recovery" Energies 10, no. 4: 560. https://doi.org/10.3390/en10040560