A 3-D Coupled Magneto-Fluid-Thermal Analysis of a 220 kV Three-Phase Three-Limb Transformer under DC Bias

Abstract

:1. Introduction

2. Theory and Equations

2.1. Circuit Model

2.2. Electromagnetic Field Equations

2.3. Fluid-Thermal Field Equations

- (1)

- oil flow inside the transformer is laminar flow;

- (2)

- oil is ideally incompressible Newtonian fluid.

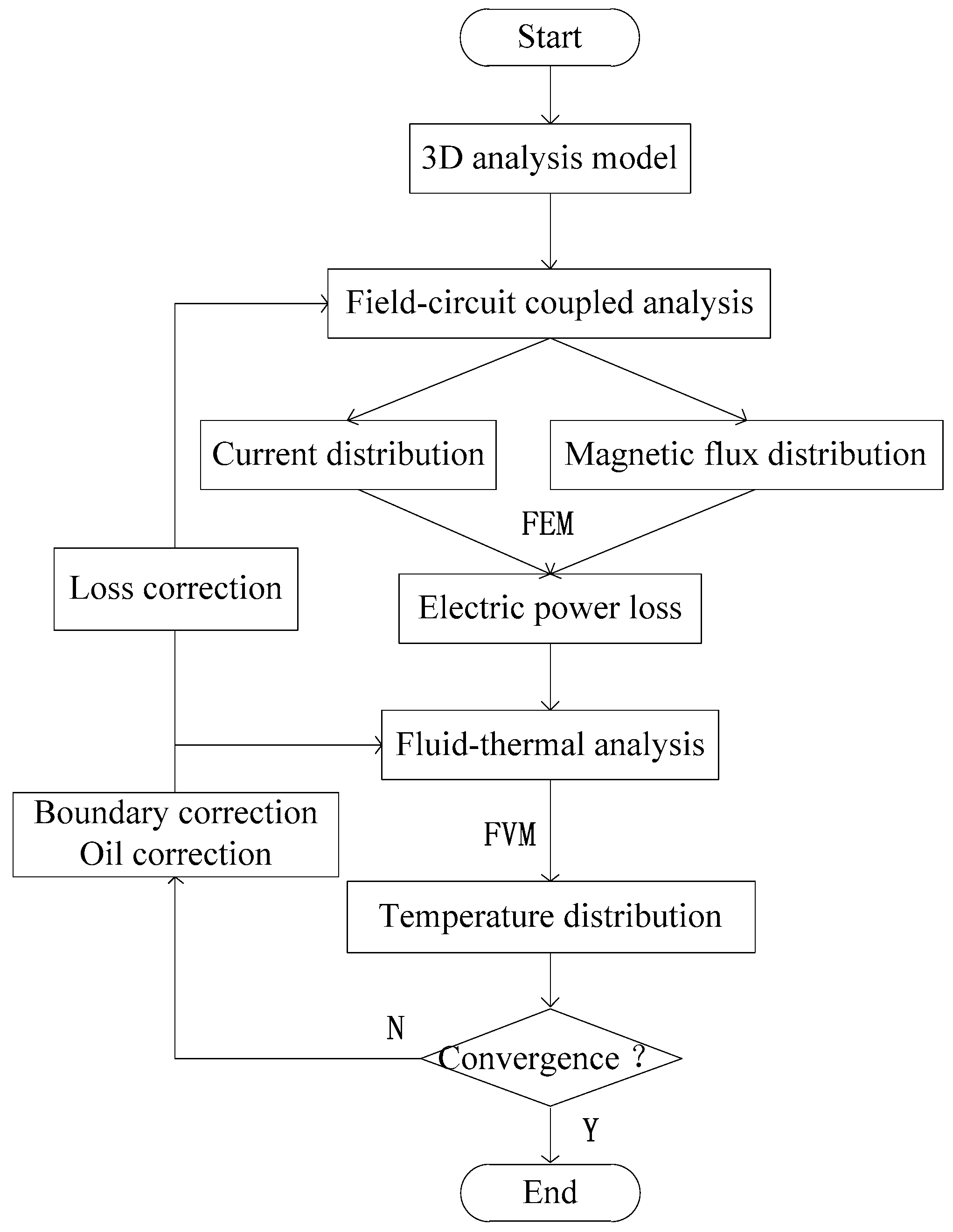

2.4. Magneto-Fluid-Thermal Coupling Method

3. Calculation of Three-Phase Three-Limb Transformer

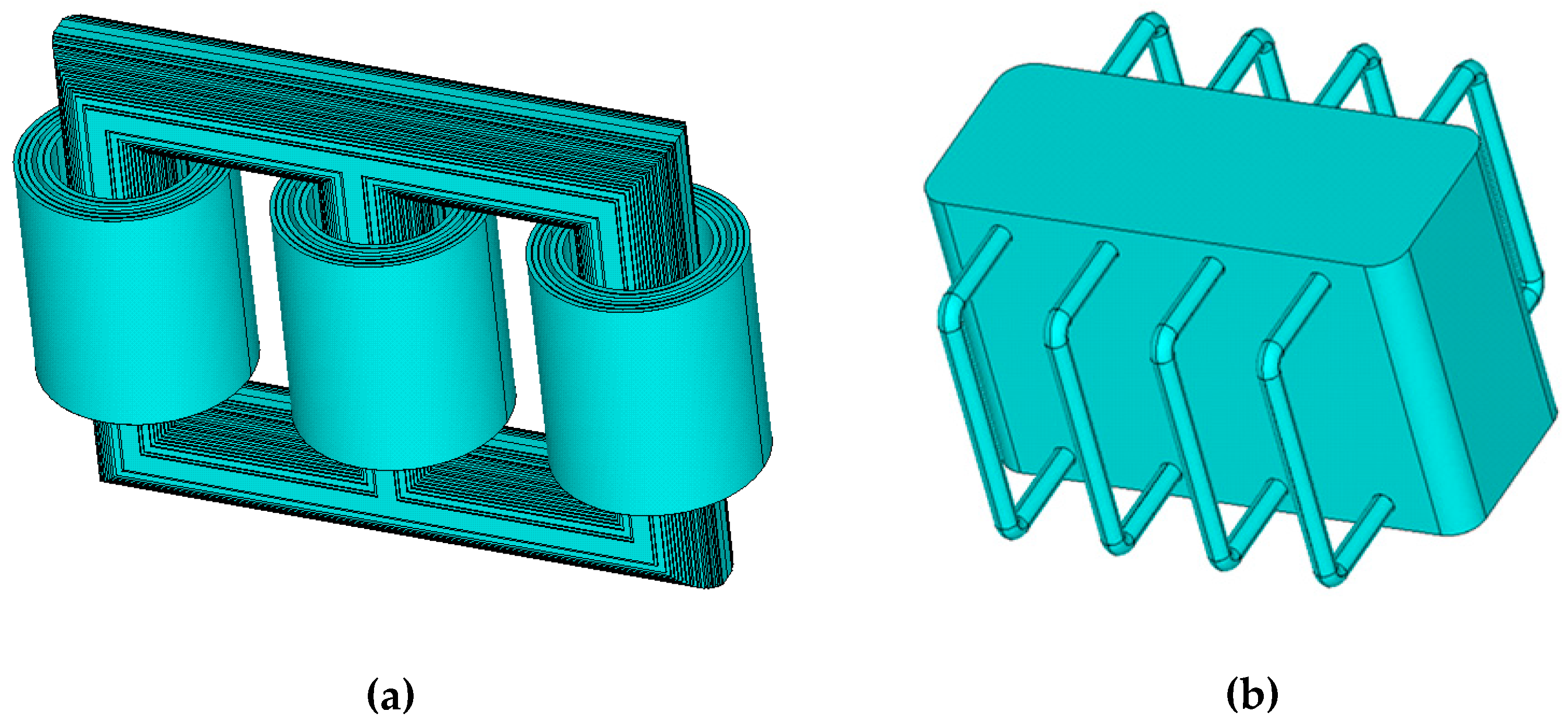

3.1. The 220 kV Three-Phase Three Limb Transformer

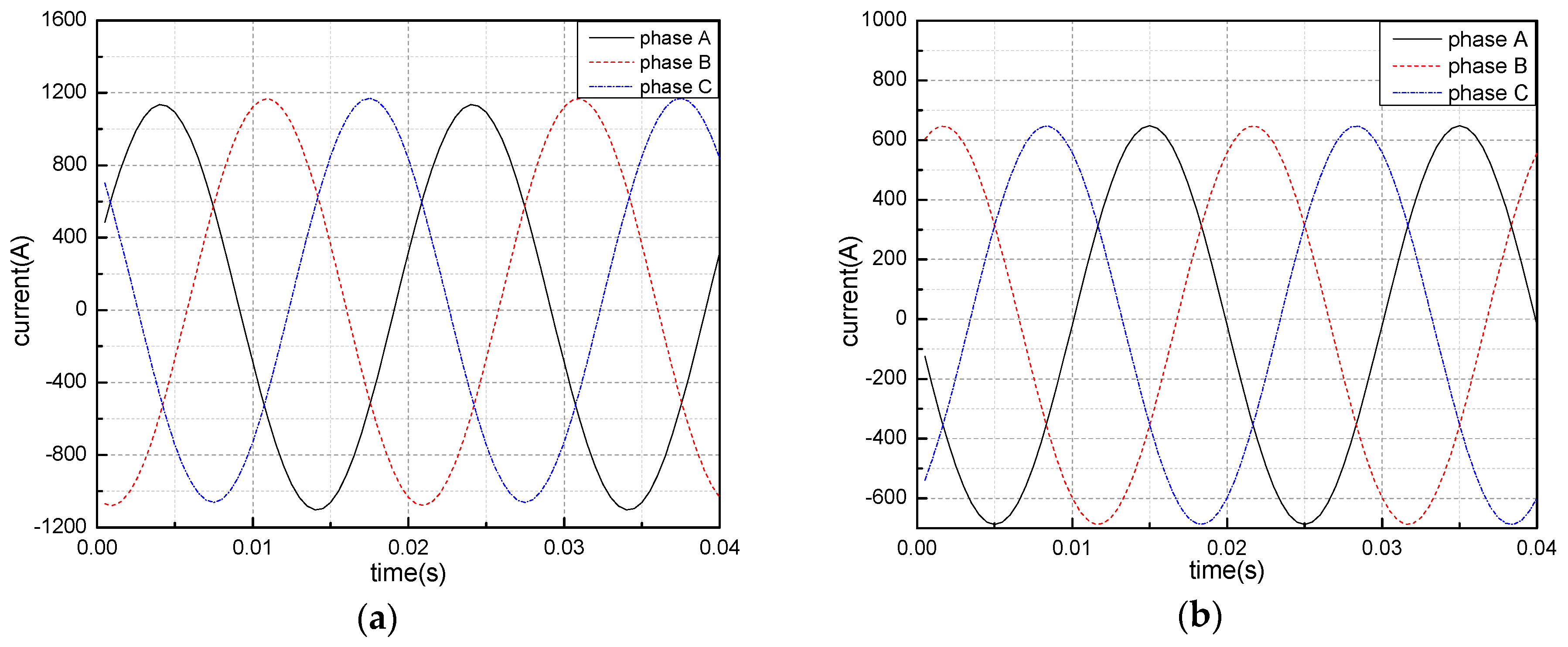

3.2. Circuit-Field Coupled Analysis

- (1)

- HV windings and MV windings are at a rated current;

- (2)

- LV windings are no-load;

- (3)

- 20 A DC current flows into HV windings through the neutral point.

3.3. Electromagnetic Field Analysis

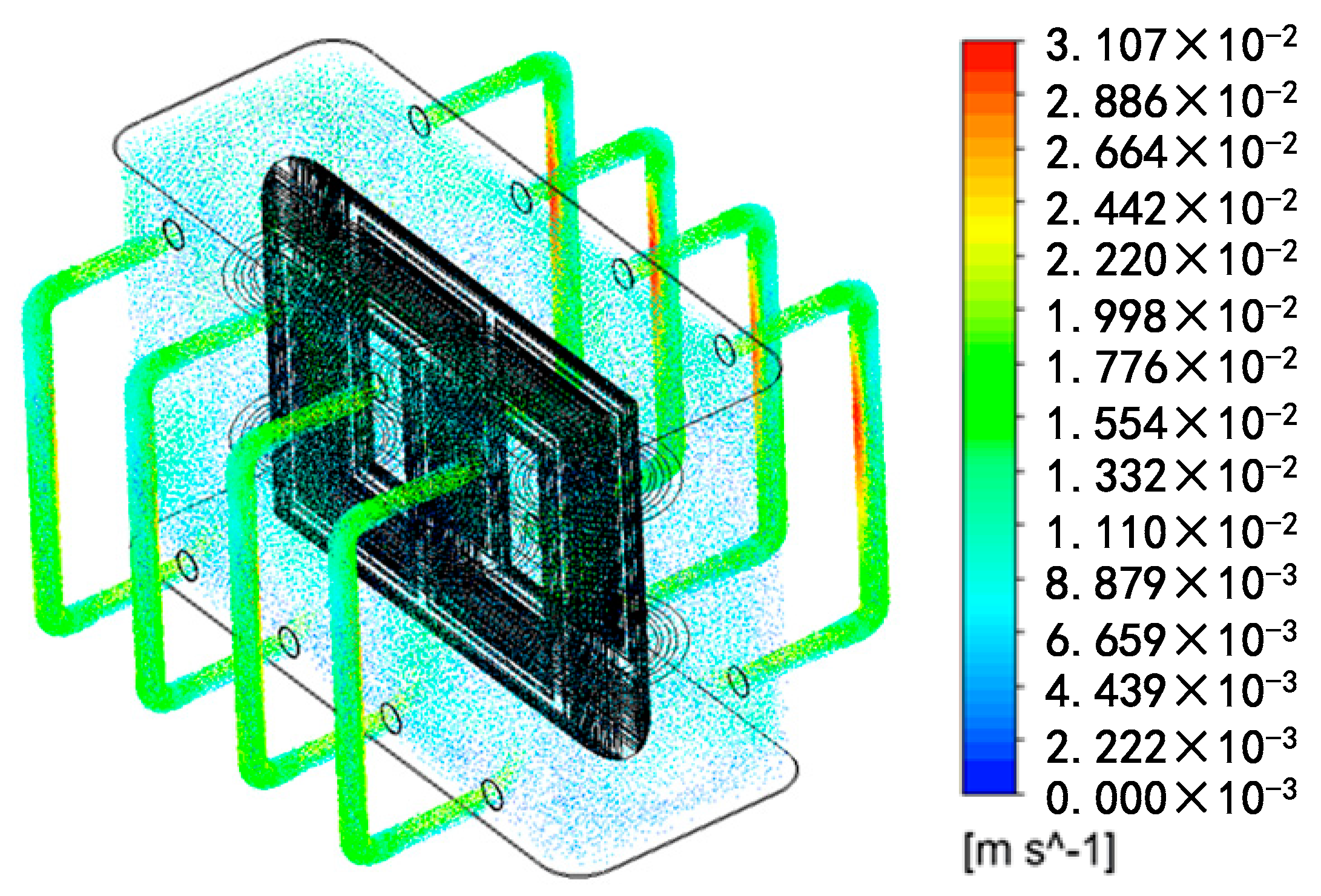

3.4. Fluid-Thermal Field Analysis

- (1)

- For the ONAN transformer, the surface area of the outside radiator should be as large as possible;

- (2)

- The design of the windings should make sure the vertical oil duct is large enough for the oil flow.

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, Y.J.; Ruan, J.J.; Huang, T.; Yang, X.P.; Zhu, H.Q.; Yang, G. Calculation of temperature rise in air-cooled induction motors through 3-D coupled electromagnetic fluid-dynamic and thermal finite-element analysis. IEEE Trans. Magn. 2012, 48, 1047–1050. [Google Scholar] [CrossRef]

- Jahromi, A.; Piercy, R.; Cress, S.; Service, J.; Fan, W. An approach to power transformer asset management using health index. IEEE Electr. Insul. Mag. 2009, 25, 20–34. [Google Scholar] [CrossRef]

- Bicen, Y.; Cilliyuz, Y.; Aras, F.; Aydugan, G. An assessment on aging model of IEEE/IEC standards for natural and mineral oil-immersed transformer. In Proceedings of the IEEE International Conference on Dielectric Liquids, Trondheim, Norway, 26–30 June 2011; pp. 1–4. [Google Scholar]

- Li, C.Y. Effect of DC monopole operation on AC transformers. East China Electr. Power 2005, 33, 52–54. [Google Scholar]

- Price, P.R. Geomagnetically induced current effects on transformers. IEEE Trans. Power Deliv. 2002, 17, 1002–1008. [Google Scholar] [CrossRef]

- Li, Z.; Yun, Y.X. Harmonic distortion feature of AC transformers caused by DC bias. Power Syst. Prot. Control 2010, 34, 52–54. [Google Scholar]

- Li, X.P.; Wen, X.S.; Fan, Y.D.; Zhang, Y.; Lan, L.; Chen, C.X. Computation of Exciting Current and Harmonic for Three-phase and Three Limbs Transformer Under DC Inrushing. High Volt. Eng. 2006, 32, 69–72. [Google Scholar]

- Lefevre, A.; Miegeville, L.; Fouladgar, J.; Olivier, G. 3-D computation of transformers overheating under nonlinear loads. IEEE Trans. Magn. 2007, 41, 1564–1567. [Google Scholar] [CrossRef]

- Matthew, N.; Sadiku, O. Elements of Electromagnetics; Oxford University Press: Oxford, UK, 2007. [Google Scholar]

- Li, W.L.; Ding, S.Y.; Jin, H.Y.; Luo, Y.L. Numerical calculation of multi-coupled fields in large salient synchronous generator. IEEE Trans. Magn. 2007, 43, 1449–1452. [Google Scholar] [CrossRef]

- Anderson, J.D. Computational Fluid Dynamics: The Basics with Applications; McGraw–Hill: New York, NY, USA, 1995. [Google Scholar]

- Amoda, O.A.; Tylavsky, D.J.; McCulla, G.A.; Knuth, W.A. Acceptability of three transformer hottest-spot temperature models. IEEE Trans. Power Deliv. 2012, 27, 13–22. [Google Scholar] [CrossRef]

- Cengel, Y.A. Heat Transfer; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Power Transformers—Part 7: Loading Guide for Oil-Immersed Power Transformers; IEC 60076-7; IEC Central Office: Geneva, Switzerland, 2005; pp. 53–59.

| Parameters of Oil | Function Fitting |

|---|---|

| Density | 1098.72 − 0.712 T |

| Specific heat capacity | 807.163 + 3.58T |

| Heat conductivity | 0.1509 − 7.101 × 10−5 T |

| Viscosity | 0.08467 − 4 × 10−4 T + 5 × 10−7 T2 |

| Classification | Value |

|---|---|

| Rated Power/MVA | 180 |

| Rated Voltage/kV | 220/110/35 |

| Frequency/Hz | 50 |

| Connection Group | YNyn0d11 |

| Core type | Planar laminated core |

| Core Weight/kg | 68140 |

| Cooling Type | ONAN |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, R.; Ruan, J.; Chen, J.; Quan, Y.; Wang, J.; Jin, S. A 3-D Coupled Magneto-Fluid-Thermal Analysis of a 220 kV Three-Phase Three-Limb Transformer under DC Bias. Energies 2017, 10, 422. https://doi.org/10.3390/en10040422

Gong R, Ruan J, Chen J, Quan Y, Wang J, Jin S. A 3-D Coupled Magneto-Fluid-Thermal Analysis of a 220 kV Three-Phase Three-Limb Transformer under DC Bias. Energies. 2017; 10(4):422. https://doi.org/10.3390/en10040422

Chicago/Turabian StyleGong, Ruohan, Jiangjun Ruan, Jingzhou Chen, Yu Quan, Jian Wang, and Shuo Jin. 2017. "A 3-D Coupled Magneto-Fluid-Thermal Analysis of a 220 kV Three-Phase Three-Limb Transformer under DC Bias" Energies 10, no. 4: 422. https://doi.org/10.3390/en10040422