Potential of Utilizing Different Natural Cooling Sources to Reduce the Building Cooling Load and Cooling Energy Consumption: A Case Study in Urumqi

Abstract

:1. Introduction

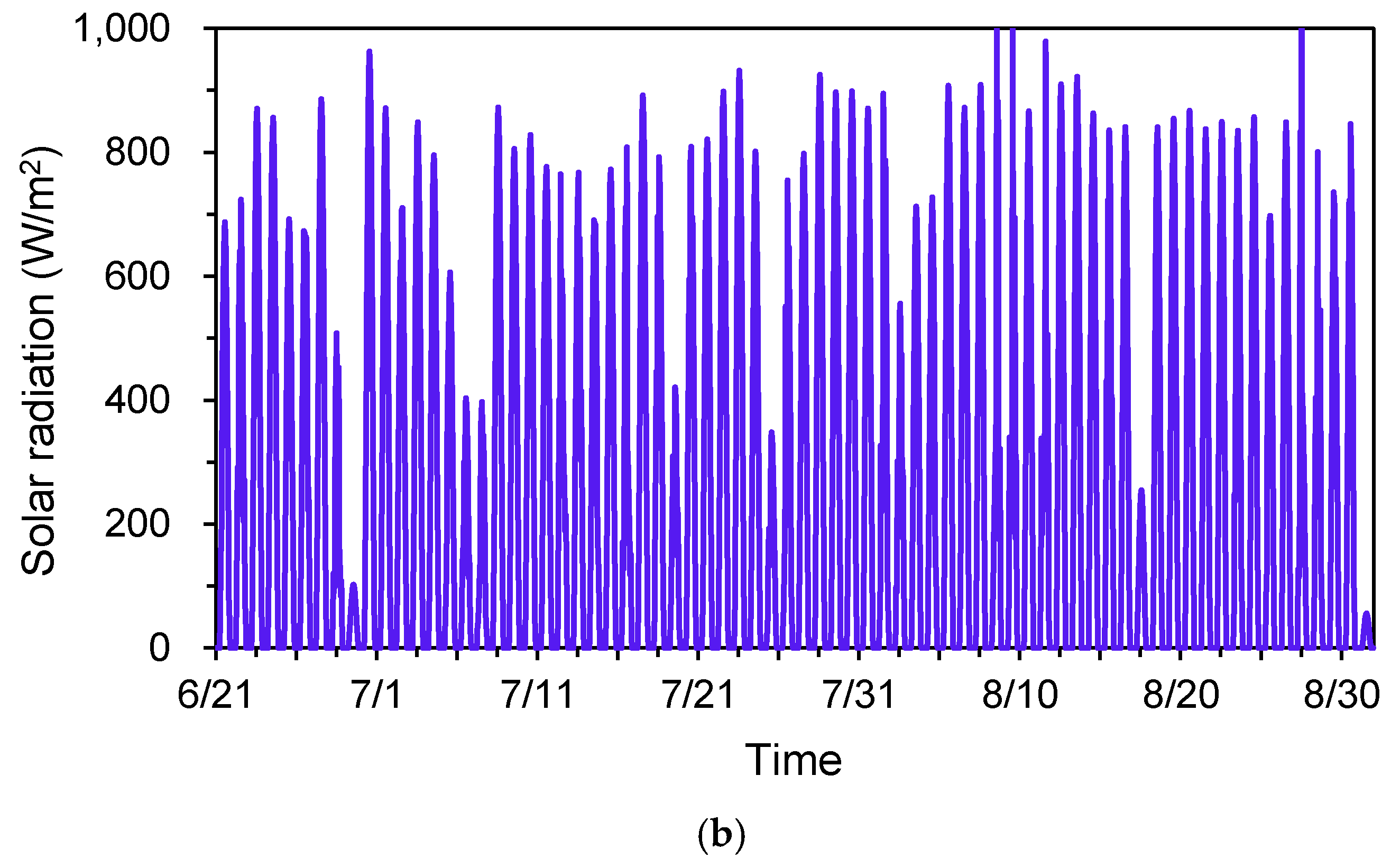

2. Methodology

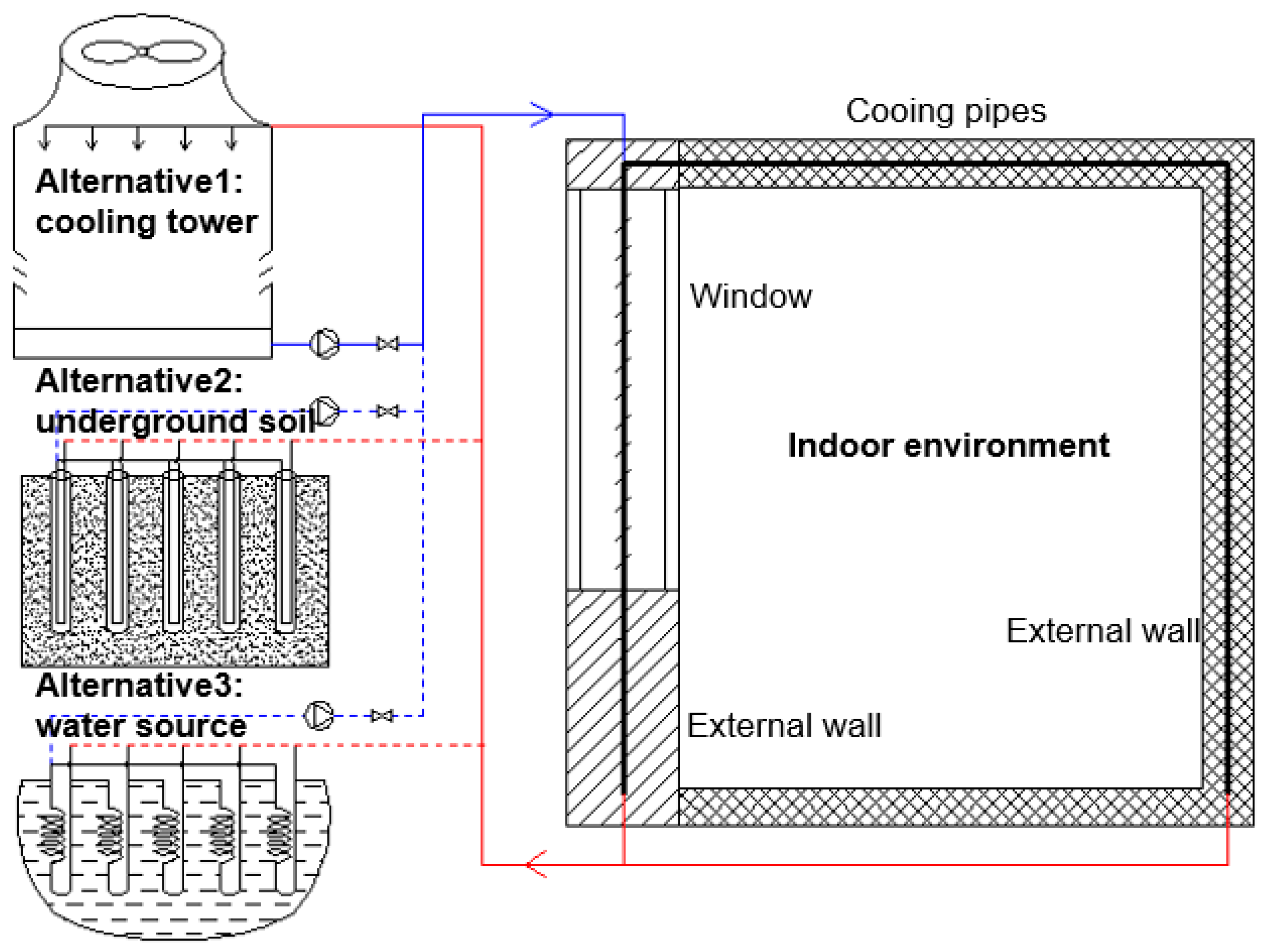

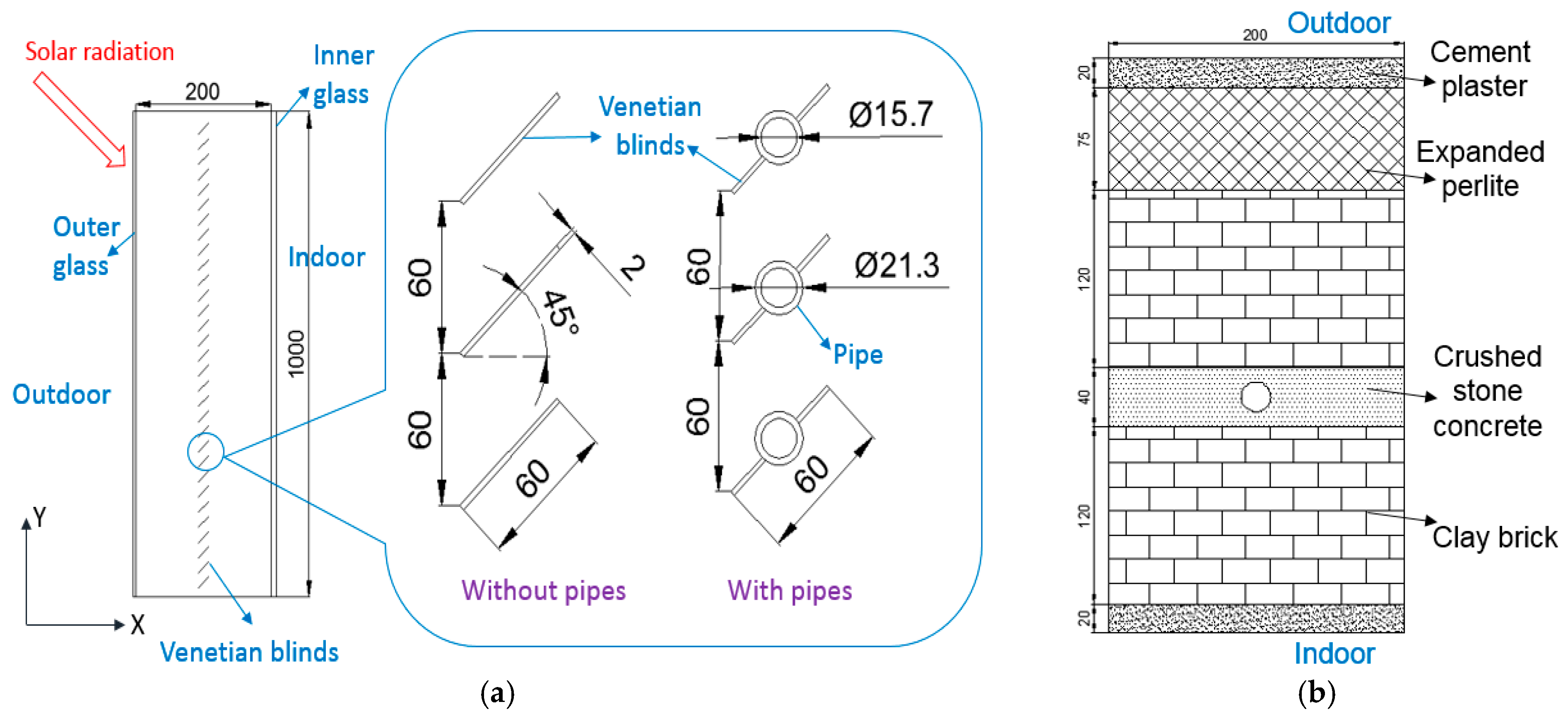

2.1. Description of the Synthetic Pipe-Embedded Envelope

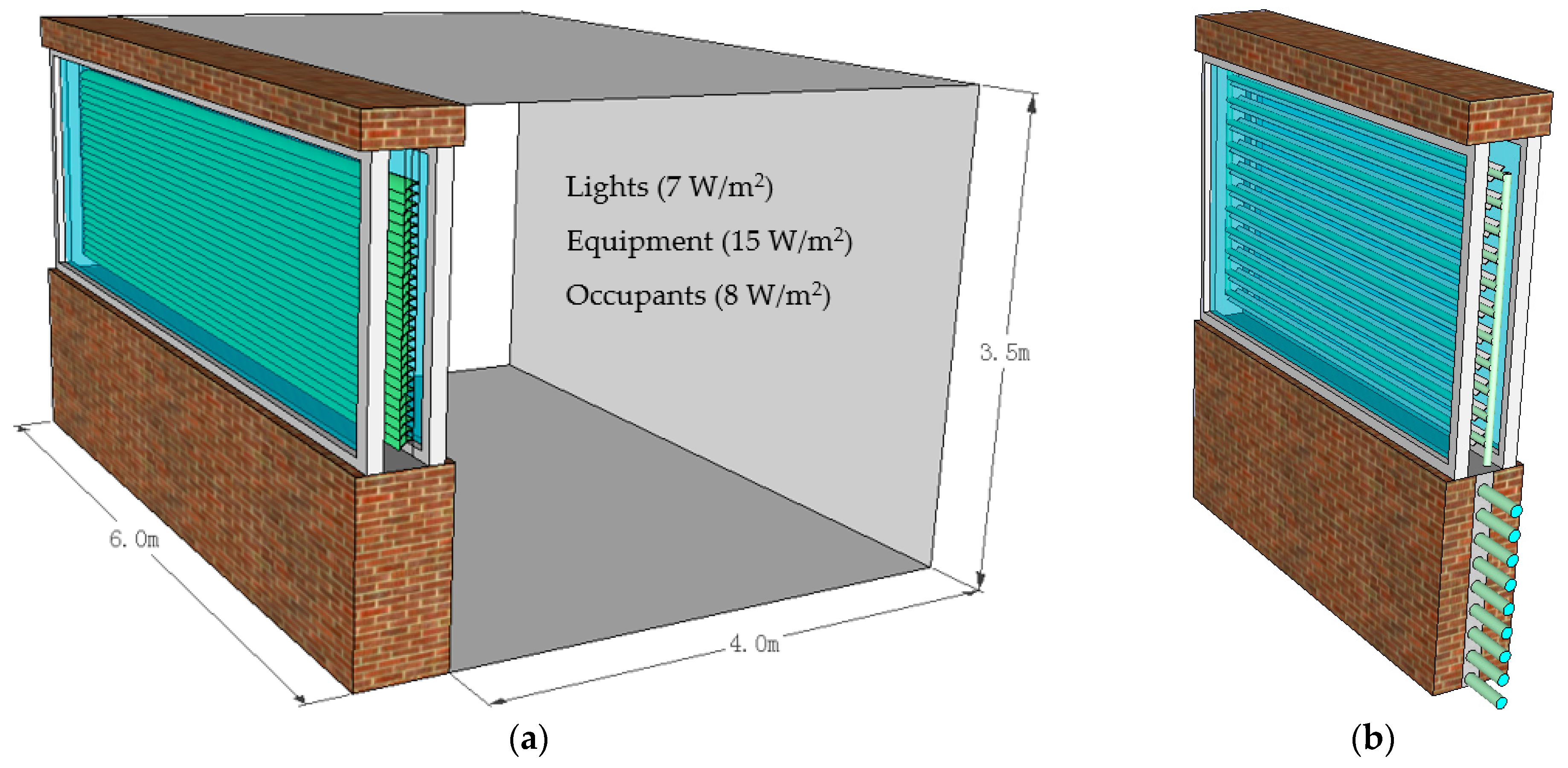

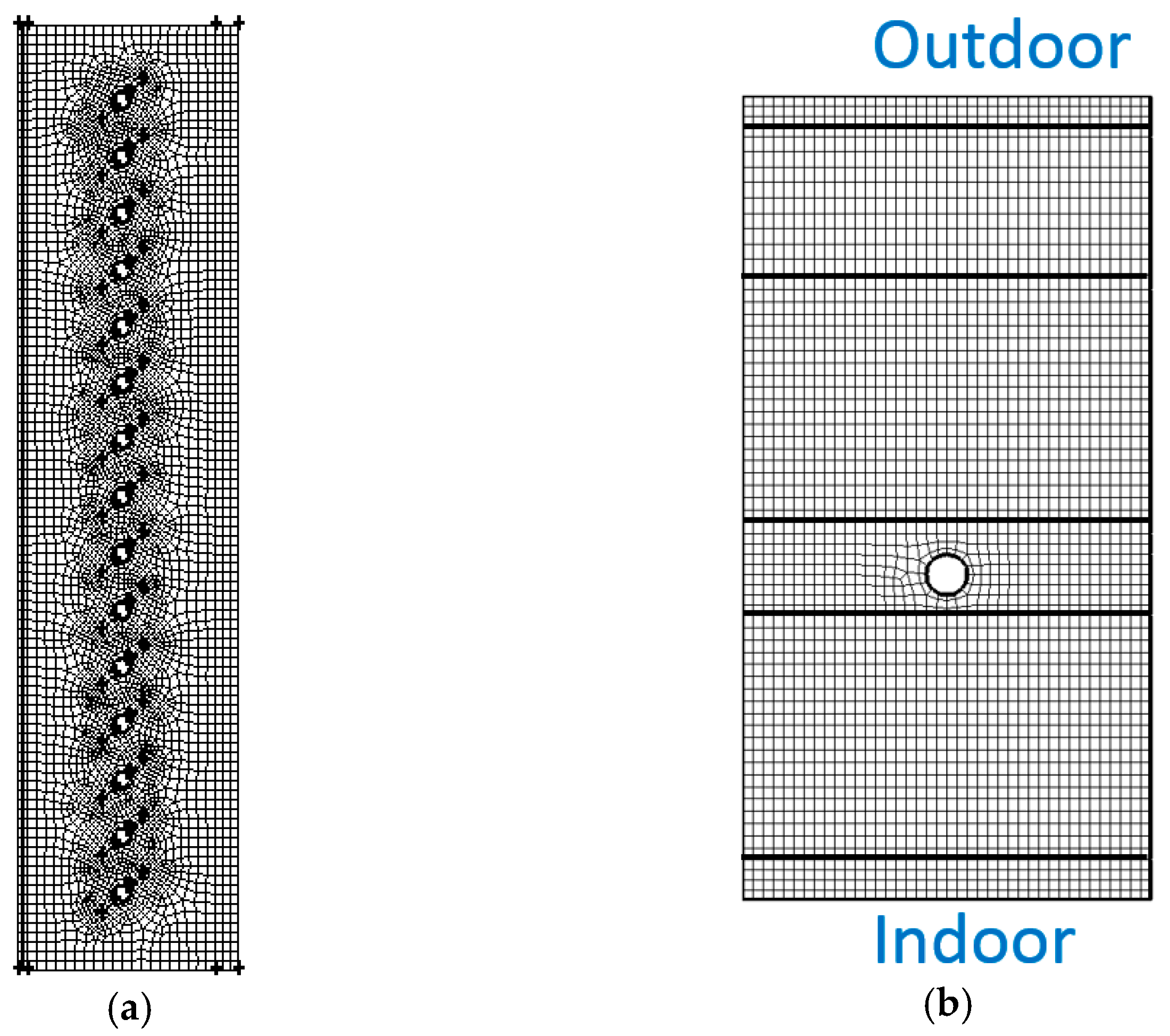

2.2. Physical Model

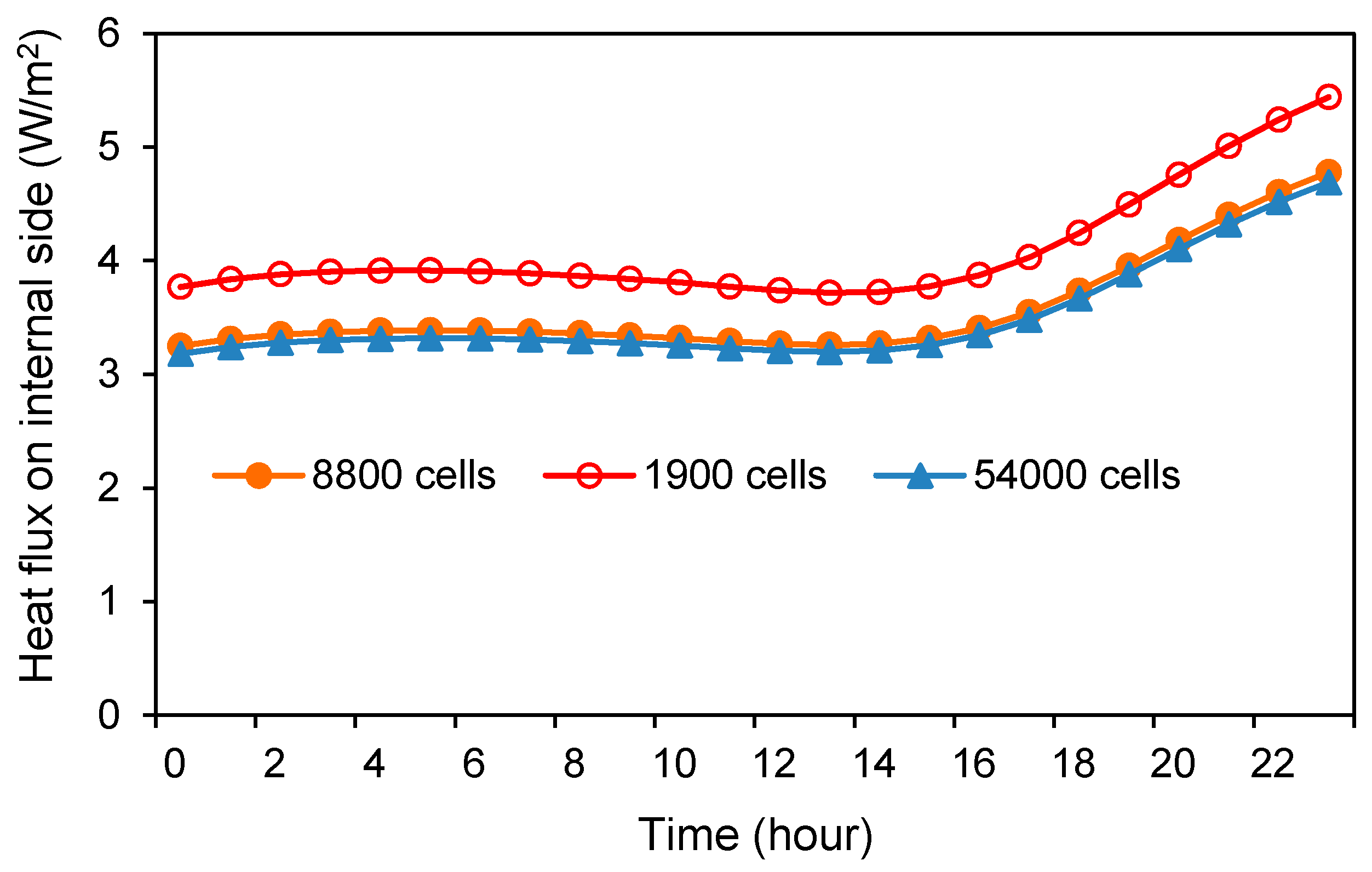

2.3. Numerical Method and Validation

2.4. Evaluation Index

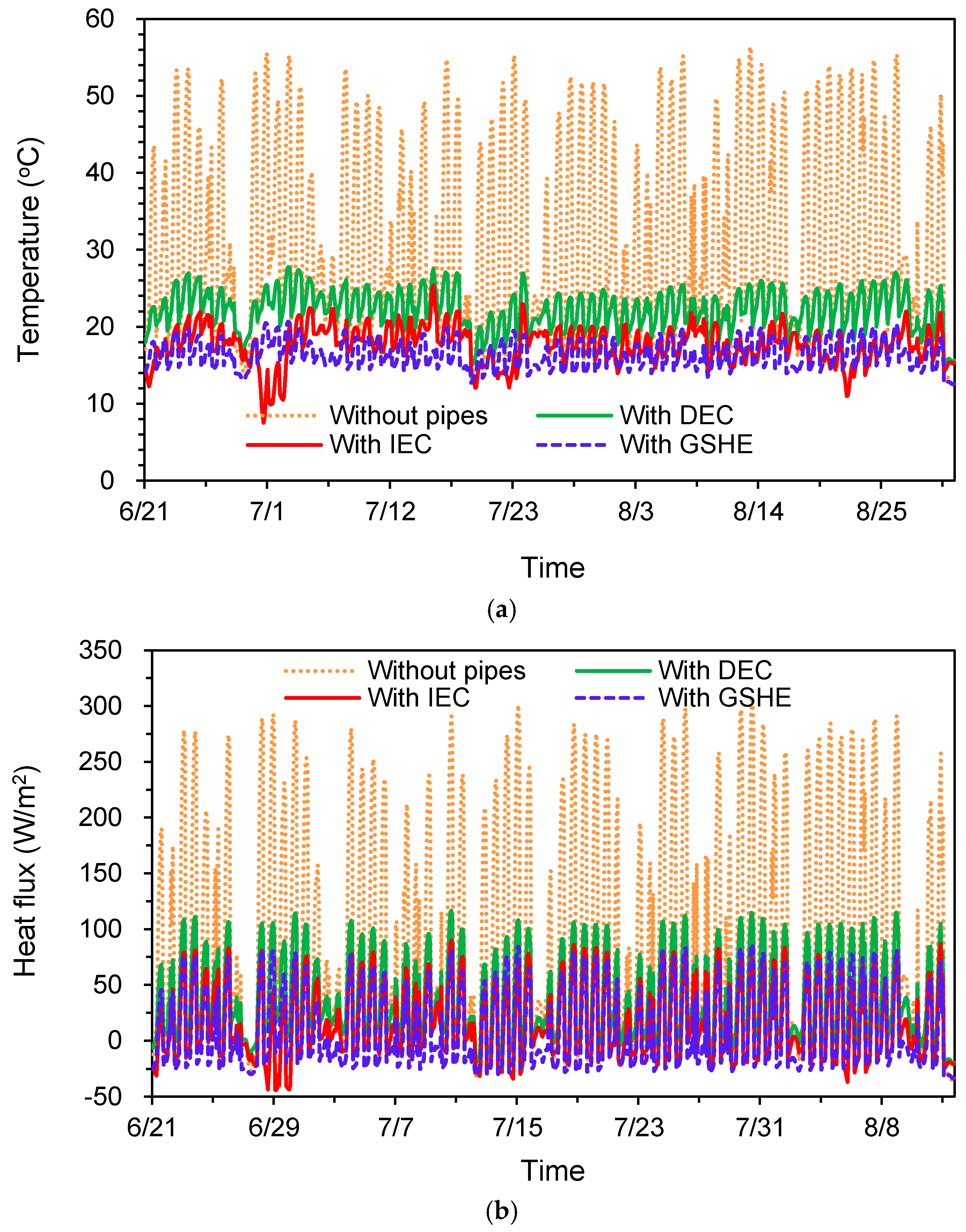

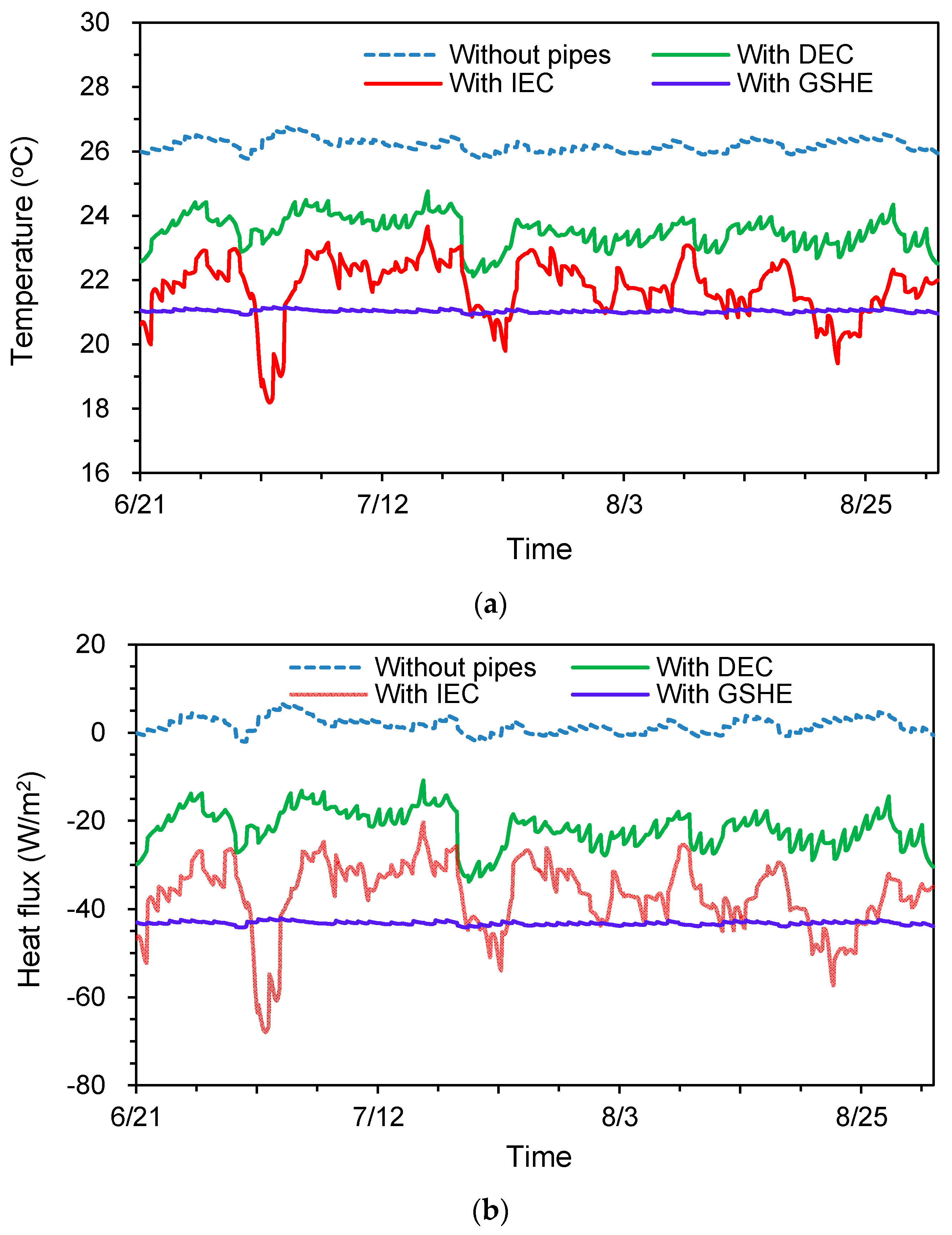

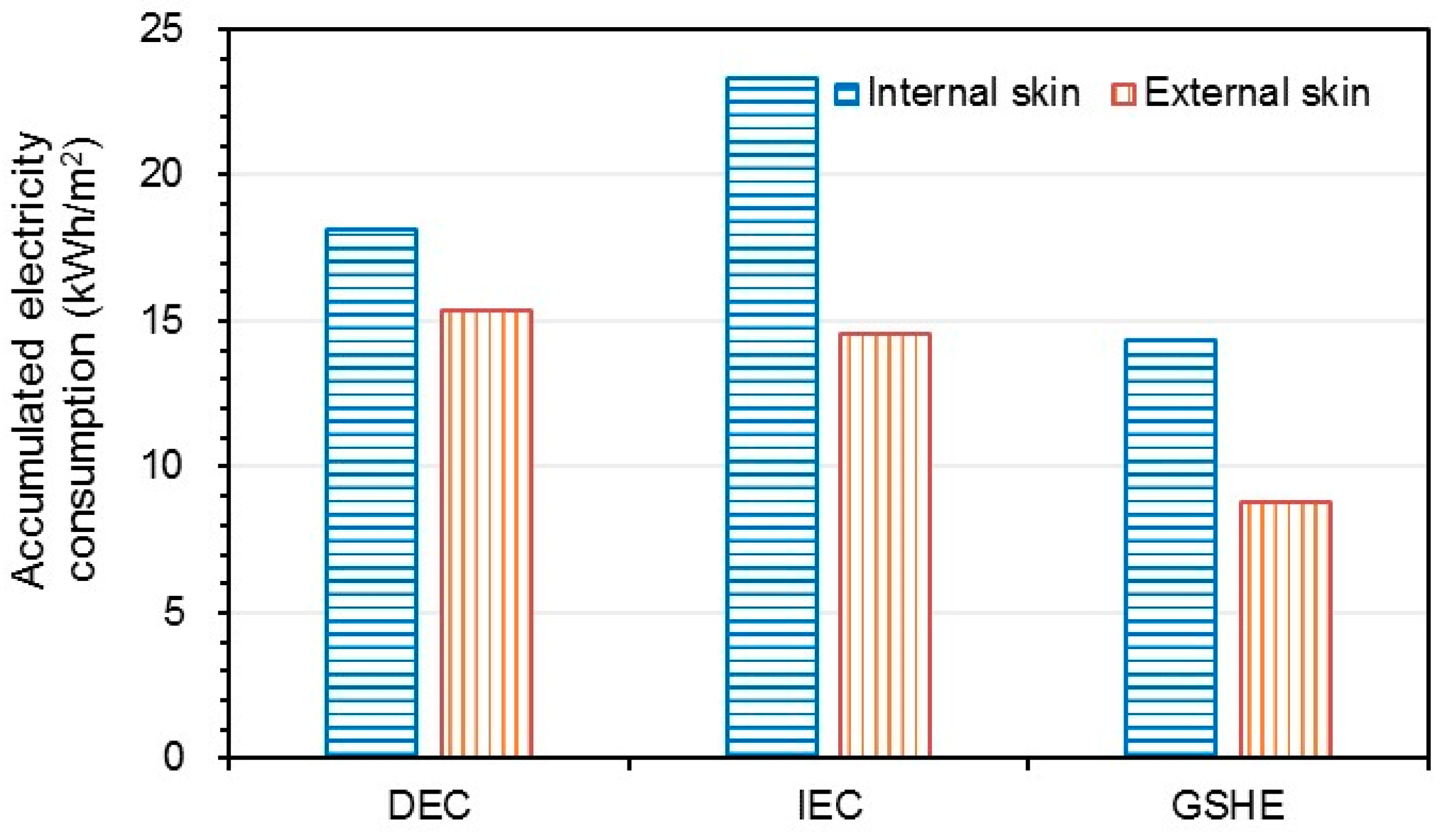

3. Results and Discussion

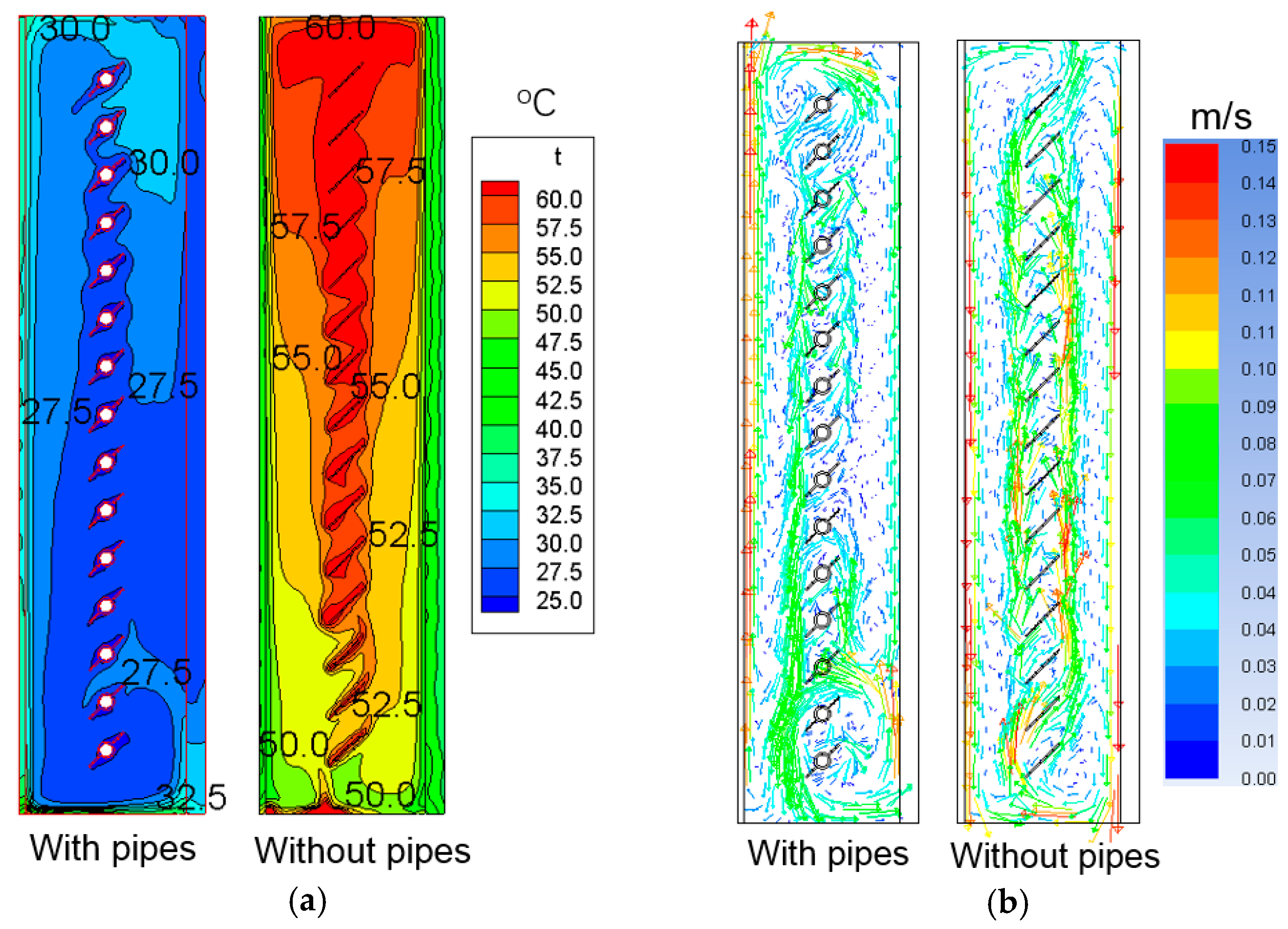

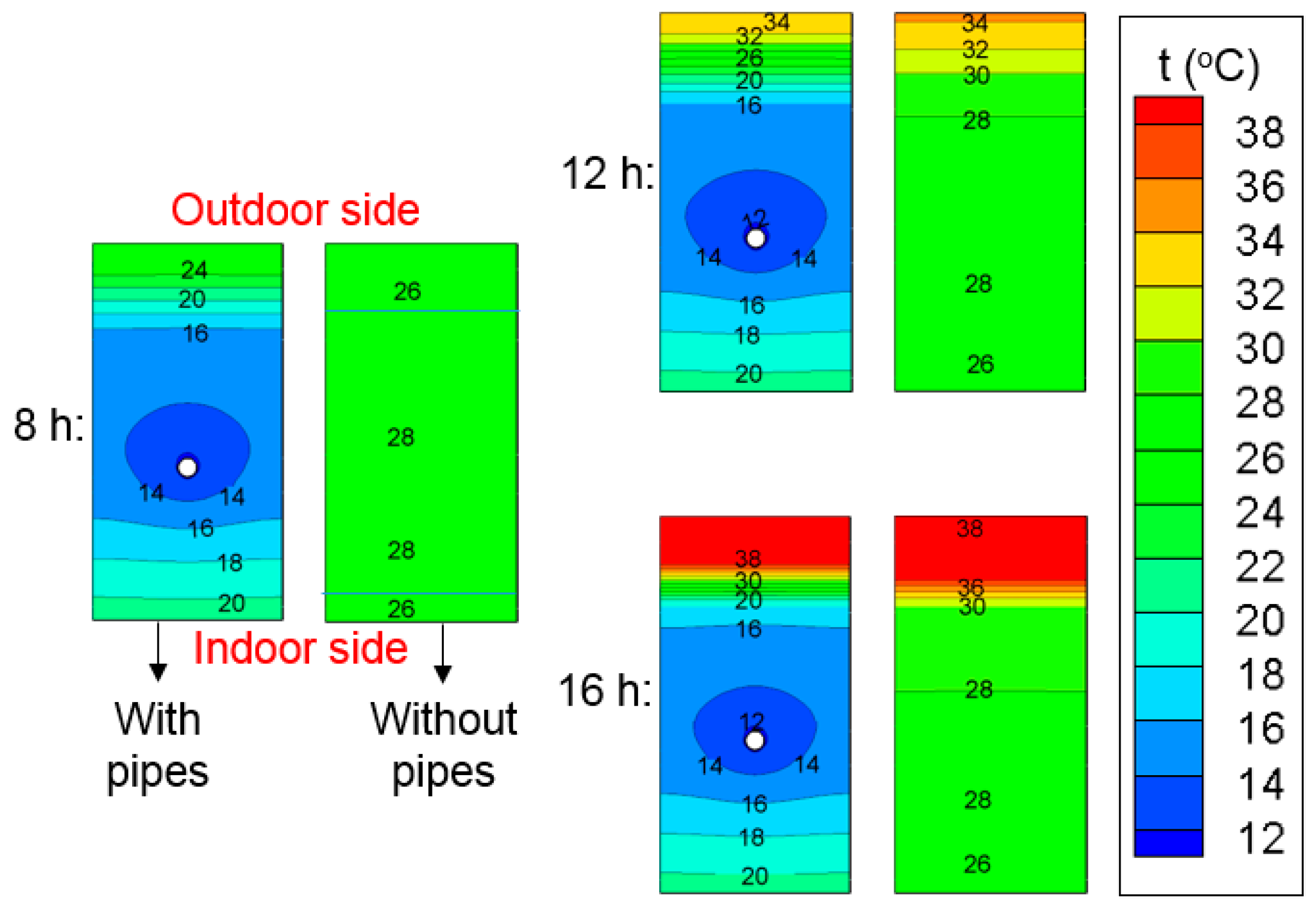

3.1. Temperature Distribution in the Envelope

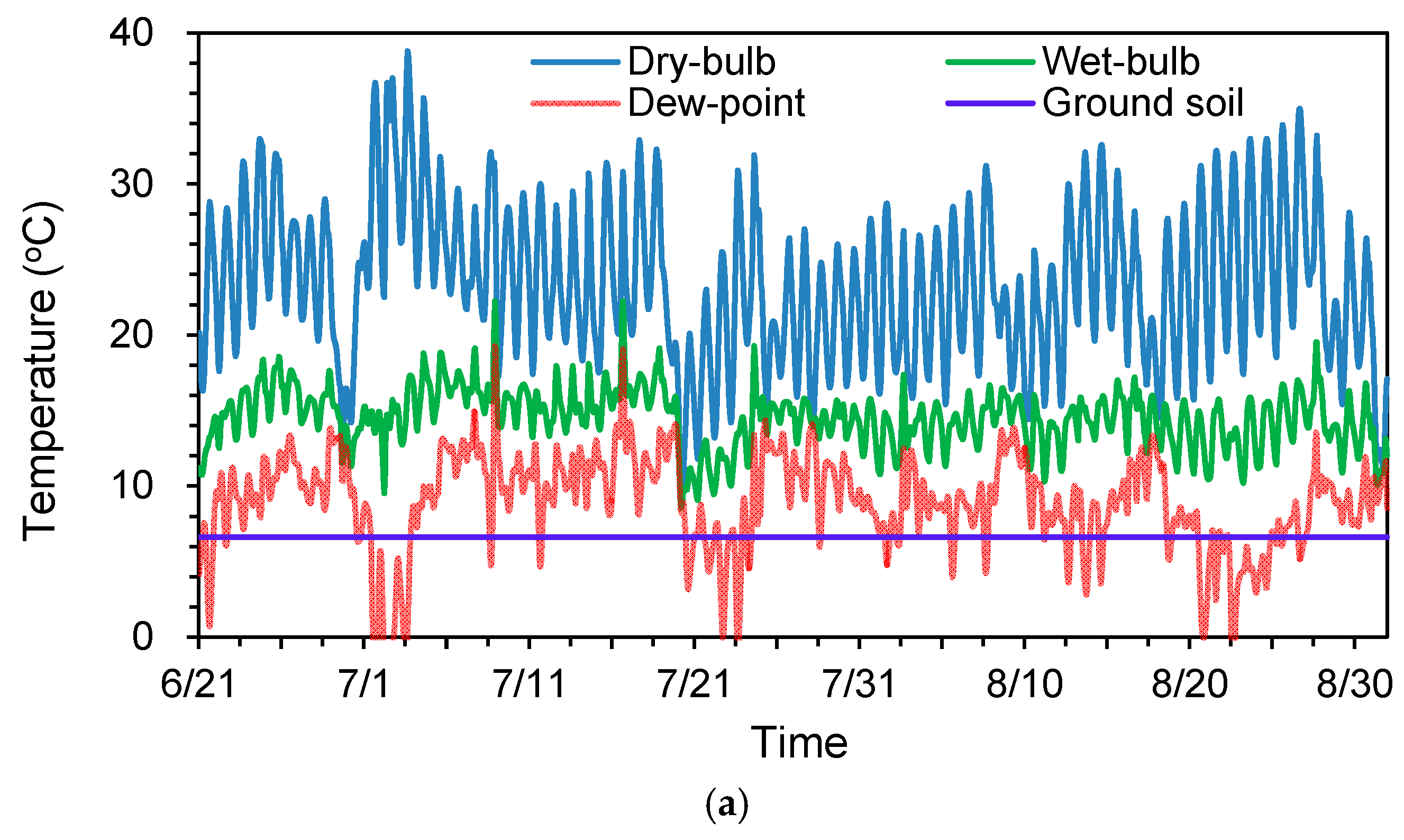

3.2. Dynamic Heat Transfer with Different Cooling Sources

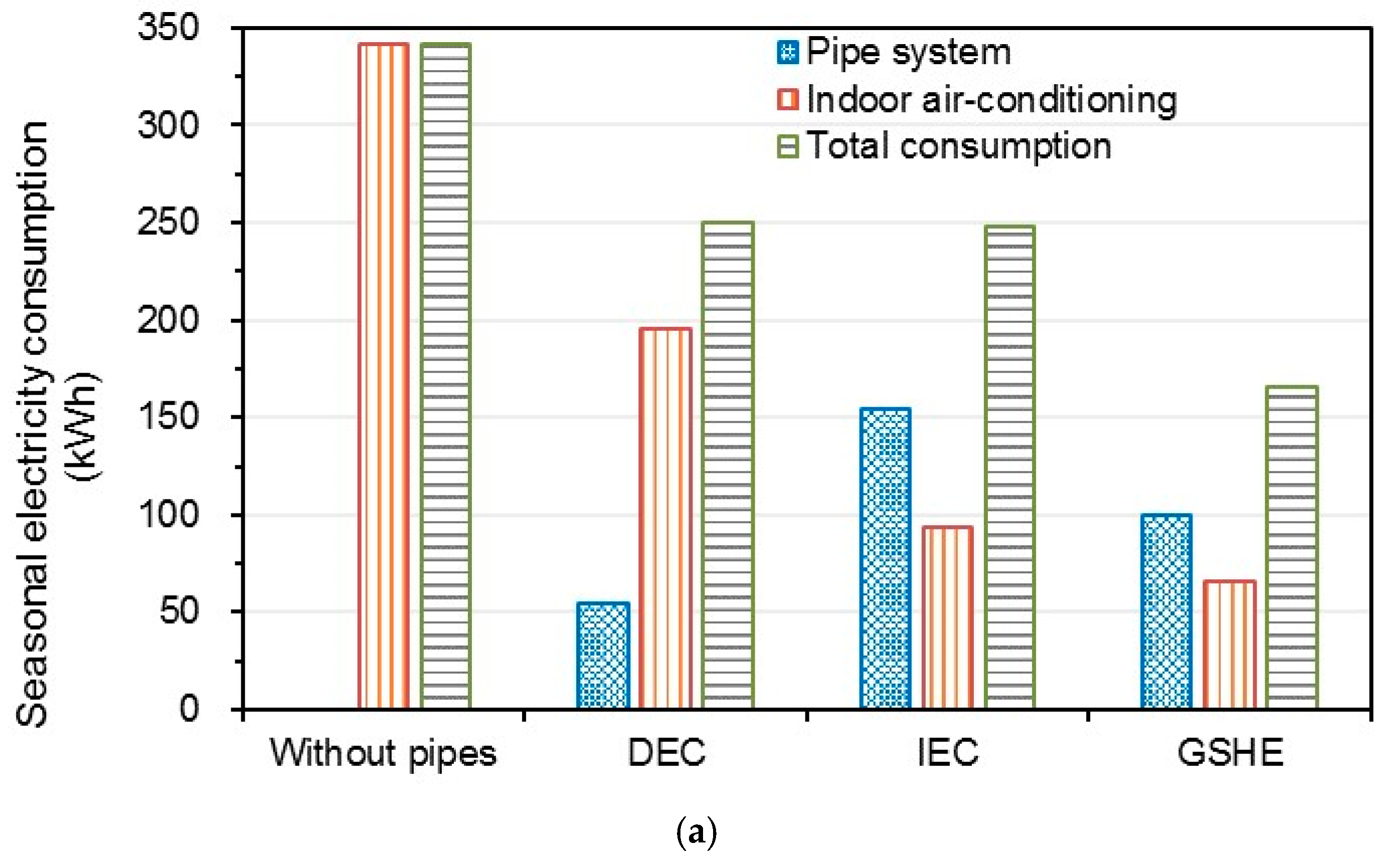

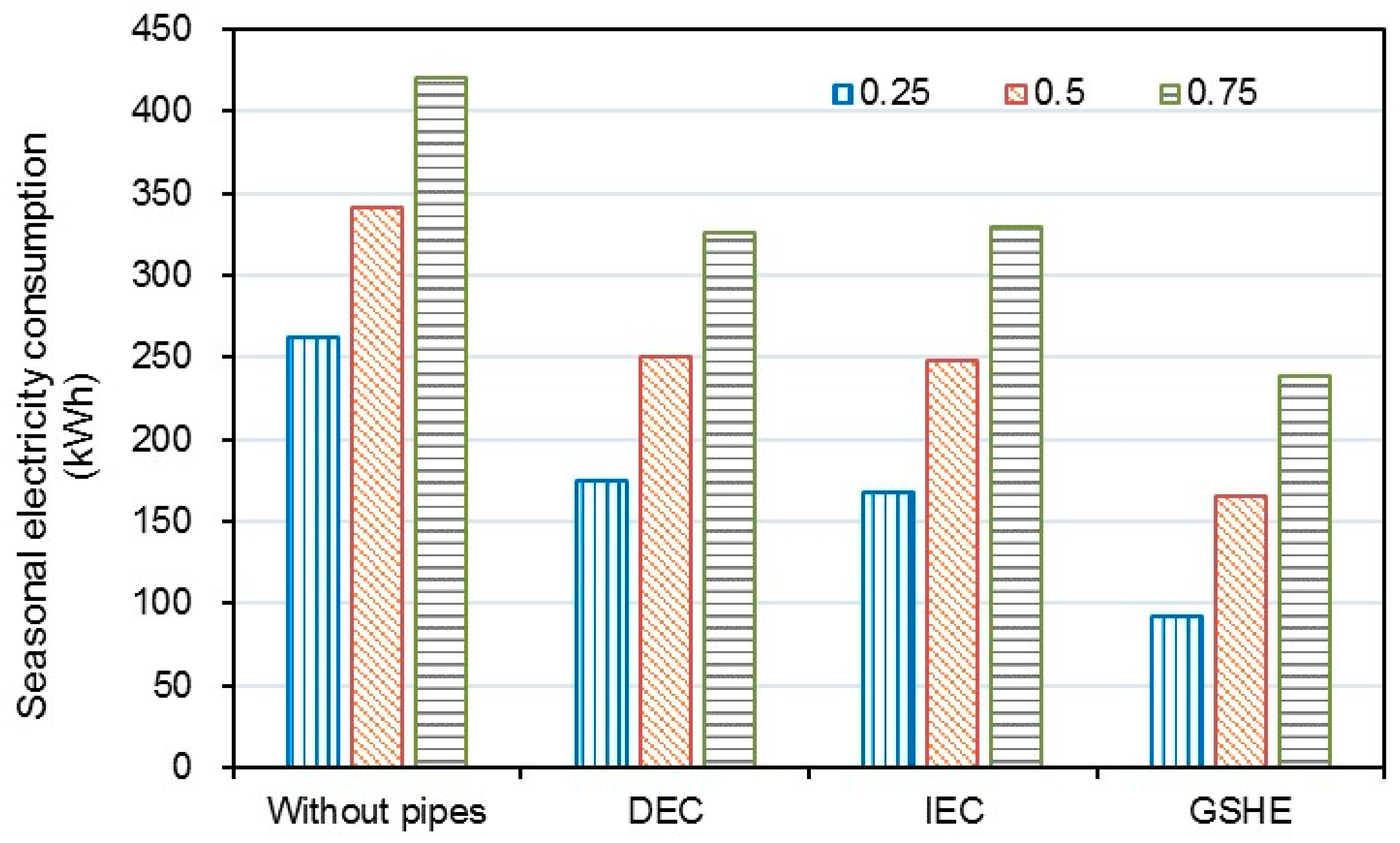

3.3. Seasonal Electricity Consumption under Different WWRs and Orientations

4. Conclusions

- In windows, cooling pipes can remove 60% of the solar radiation directly and only less than 15% of the radiation can transfer into the room. The insulated glass should be installed to the external skin of a pipe-embedded double window to reduce the heat dissipation. The pipe effectiveness η is around 60%.

- In walls, cooling pipes can reduce the internal surface temperature by more than 4 °C. The pipe-embedded wall becomes an efficient radiant cooling panel absorbing the heat from the room. The pipe effectiveness η is around 83%.

- The seasonal cooling energy consumption of the office with pipes is reduced by 25%–50%. A large WWR is acceptable with the cooling effect of pipes.

- The performance of GSHE is the best among the three sources in Urumqi. The effectiveness of DEC and IEC is also satisfactory, with an average energy saving rate of 27%. IEC can reduce more heat flux through the envelope, but it consumes more energy to provide the cooling water.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| A | area, m2 |

| E | electricity consumption, W/m2 |

| q | heat gain, W/m2 |

| Q | cooling load, W/m2 |

| ε | electricity reduction rate of pipe-embedded envelope |

| η | effectiveness of pipes |

| Abbreviations | |

| DEC | direct evaporative cooling |

| DSF | double skin façade |

| EER | energy efficiency ratio |

| GSHE | ground-source heat exchanger |

| IEC | indirect evaporative cooling |

| WWR | window-to-wall ratio |

References

- Bisegna, F.; Mattoni, B.; Gori, P.; Asdrubali, F.; Guattari, C.; Evangelisti, L.; Sambuco, S.; Bianchi, F. Influence of insulating materials on green building rating system results. Energies 2016, 9, 712. [Google Scholar] [CrossRef]

- Ojanen, T.; Seppä, I.P.; Nykänen, E. Thermal insulation products and applications—Future road maps. Energy Procedia 2015, 78, 309–314. [Google Scholar] [CrossRef]

- Ji, Y.; Fitton, R.; Swan, W.; Webster, P. Assessing overheating of the UK existing dwellings—A case study of replica Victorian end terrace house. Build. Environ. 2014, 77, 1–11. [Google Scholar] [CrossRef]

- Sadineni, S.B.; Madala, S.; Boehm, R.F. Passive building energy savings: A review of building envelope components. Renew. Sustain. Energy Rev. 2011, 15, 3617–3631. [Google Scholar] [CrossRef]

- Pargana, N.; Pinheiro, M.D.; Silvestre, J.D.; de Brito, J. Comparative environmental life cycle assessment of thermal insulation materials of buildings. Energy Build. 2014, 82, 466–481. [Google Scholar] [CrossRef]

- Hidalgo, J.P.; Welch, S.; Torero, J.L. Performance criteria for the fire safe use of thermal insulation in buildings. Constr. Build. Mater. 2015, 100, 285–297. [Google Scholar] [CrossRef]

- Bahaj, A.S.; James, P.A.B.; Jentsch, M.F. Potential of emerging glazing technologies for highly glazed buildings in hot arid climates. Energy Build. 2008, 40, 720–731. [Google Scholar] [CrossRef]

- Garrison, J.D.; Collins, R.E. Manufacture and cost of vacuum glazing. Sol. Energy 1995, 55, 151–161. [Google Scholar] [CrossRef]

- Manz, H.; Brunner, S.; Wullschleger, L. Triple vacuum glazing: Heat transfer and basic mechanical design constraints. Sol. Energy 2006, 80, 1632–1642. [Google Scholar] [CrossRef]

- Mohelnikova, J. Materials for reflective coatings of window glass applications. Constr. Build. Mater. 2009, 23, 1993–1998. [Google Scholar] [CrossRef]

- Hong, T.; Kim, J.; Lee, J.; Koo, C.; Park, H. Assessment of seasonal energy efficiency strategies of a double skin façade in a monsoon climate region. Energies 2013, 6, 4352–4376. [Google Scholar] [CrossRef]

- Cetiner, I.; Özkan, E. An approach for the evaluation of energy and cost efficiency of glass façades. Energy Build. 2005, 37, 673–684. [Google Scholar] [CrossRef]

- Chan, A.L.S.; Chow, T.T.; Fong, K.F.; Lin, Z. Investigation on energy performance of double skin façade in Hong Kong. Energy Build. 2009, 41, 1135–1142. [Google Scholar] [CrossRef]

- Shen, C.; Li, X. Thermal performance of double skin façade with built-in pipes utilizing evaporative cooling water in cooling season. Sol. Energy 2016, 137, 55–65. [Google Scholar] [CrossRef]

- Parra, J.; Guardo, A.; Egusquiza, E.; Alavedra, P. Thermal performance of ventilated double skin façades with venetian blinds. Energies 2015, 8, 4882–4898. [Google Scholar] [CrossRef] [Green Version]

- Manz, H. Total solar energy transmittance of glass double façades with free convection. Energy Build. 2004, 36, 127–136. [Google Scholar] [CrossRef]

- Gratia, E.; De Herde, A. Greenhouse effect in double-skin facade. Energy Build. 2007, 39, 199–211. [Google Scholar] [CrossRef]

- Xu, X.; Wang, S.; Wang, J.; Xiao, F. Active pipe-embedded structures in buildings for utilizing low-grade energy sources: A review. Energy Build. 2010, 42, 1567–1581. [Google Scholar] [CrossRef]

- Shen, C.; Li, X. Dynamic thermal performance of pipe-embedded building envelope utilizing evaporative cooling water in the cooling season. Appl. Therm. Eng. 2016, 106, 1103–1113. [Google Scholar] [CrossRef]

- Li, A.; Xu, X.; Sun, Y. A study on pipe-embedded wall integrated with ground source-coupled heat exchanger for enhanced building energy efficiency in diverse climate regions. Energy Build. 2016, 121, 139–151. [Google Scholar] [CrossRef]

- Shen, C.; Li, X. Solar heat gain reduction of double glazing window with cooling pipes embedded in venetian blinds by utilizing natural cooling. Energy Build. 2016, 112, 173–183. [Google Scholar] [CrossRef]

- Ministry of Housing Urban-Rural Development. National Standard GB 50736-2012-Code for Design of Heating Ventilation and Air Conditioning; Ministry of Housing Urban-Rural Development: Beijing, China, 2012.

- Zeng, Z.; Li, X.; Li, C.; Zhu, Y. Modeling ventilation in naturally ventilated double-skin façade with a venetian blind. Build. Environ. 2012, 57, 1–6. [Google Scholar] [CrossRef]

- Iyi, D.; Hasan, R.; Penlington, R.; Underwood, C. Double skin façade: Modelling technique and influence of venetian blinds on the airflow and heat transfer. Appl. Therm. Eng. 2014, 71, 219–229. [Google Scholar] [CrossRef]

- Xie, J.; Zhu, Q.; Xu, X. An active pipe-embedded building envelope for utilizing low-grade energy sources. J. Cent. South Univ. 2012, 19, 1663–1667. [Google Scholar] [CrossRef]

- Lu, Y. Practical Design Handbook for HVAC, 2nd ed.; China Building Industry Press: Beijing, China, 2008. [Google Scholar]

- Saelens, D.; Roels, S.; Hens, H. Strategies to improve the energy performance of multiple-skin facades. Build. Environ. 2008, 43, 638–650. [Google Scholar] [CrossRef]

- Shen, C.; Li, X. Energy saving potential of pipe-embedded building envelope utilizing low-temperature hot water in the heating season. Energy Build. 2017, 138, 318–331. [Google Scholar] [CrossRef]

- China Meteorological Administration. Weather Database for Analyzing the Building Thermal Environment in China, 1st ed.China Architectural & Building Press: Beijing, China, 2005.

- Klimanek, A.; Cedzich, M.; Białecki, R. 3D CFD modeling of natural draft wet-cooling tower with flue gas injection. Appl. Therm. Eng. 2015, 91, 824–833. [Google Scholar] [CrossRef]

- Duan, Z.; Zhan, C.; Zhang, X.; Mustafa, M.; Zhao, X.; Alimohammadisagvand, B.; Hasan, A. Indirect evaporative cooling: Past, present and future potentials. Renew. Sustain. Energy Rev. 2012, 16, 6823–6850. [Google Scholar] [CrossRef]

- Zhu, Y. Built Environment, 3rd ed.; China Architectural & Building Press: Beijing, China, 2010. [Google Scholar]

- Wu, W.; Wang, B.; You, T.; Shi, W.; Li, X. A potential solution for thermal imbalance of ground source heat pump systems in cold regions: Ground source absorption heat pump. Renew. Energy 2013, 59, 39–48. [Google Scholar] [CrossRef]

- National Development and Reform Commission. National Standard GB/T 17981-2007-Economic Operation of Air Conditioning Systems; National Development and Reform Commission: Beijing, China, 2008.

- Duan, Z. Investigation of a Novel Dew Point Indirect Evaporative Air Conditioning System for Buildings. Ph.D. Thesis, The University of Nottingham, Nottingham, UK, September 2011. [Google Scholar]

| Components | Internal Skin | External Skin | Venetian Blinds |

|---|---|---|---|

| Material | Double glazing | Stalinite | Aluminum alloy |

| Thickness (mm) | 6 + 12 (air) + 6 | 9 | 2 |

| Specific heat (J/kg·K) | 100 | 840 | 880 |

| Density (kg/m3) | 1000 | 2200 | 2700 |

| Heat conductivity coefficient (W/(m·K)) | 0.09 | 0.28 | 180 |

| Transmissivity-SW 1 (%) | 65 | 86 | 0 |

| Absorptivity-SW (%) | 17 | 7 | 80 |

| Reflectivity-SW (%) | 18 | 7 | 20 |

| Transmissivity-LW 2 (%) | 34 | 50 | 0 |

| Absorptivity-LW (%) | 48 | 40 | 90 |

| Reflectivity-LW (%) | 18 | 10 | 10 |

| Materials | Cement Plaster | Crushed Stone Concrete | Expanded Perlite | Clay Brick |

|---|---|---|---|---|

| Thermal conductivity (W/(m·K)) | 0.93 | 1.51 | 0.065 | 0.81 |

| Density (kg/m3) | 1800 | 2400 | 670 | 1800 |

| Specific heat (J/(kg·K)) | 837 | 920 | 250 | 1050 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, C.; Li, X. Potential of Utilizing Different Natural Cooling Sources to Reduce the Building Cooling Load and Cooling Energy Consumption: A Case Study in Urumqi. Energies 2017, 10, 366. https://doi.org/10.3390/en10030366

Shen C, Li X. Potential of Utilizing Different Natural Cooling Sources to Reduce the Building Cooling Load and Cooling Energy Consumption: A Case Study in Urumqi. Energies. 2017; 10(3):366. https://doi.org/10.3390/en10030366

Chicago/Turabian StyleShen, Chong, and Xianting Li. 2017. "Potential of Utilizing Different Natural Cooling Sources to Reduce the Building Cooling Load and Cooling Energy Consumption: A Case Study in Urumqi" Energies 10, no. 3: 366. https://doi.org/10.3390/en10030366