An Experimental Study on the Radiation Noise Characteristics of a Centrifugal Pump with Various Working Conditions

Abstract

:1. Introduction

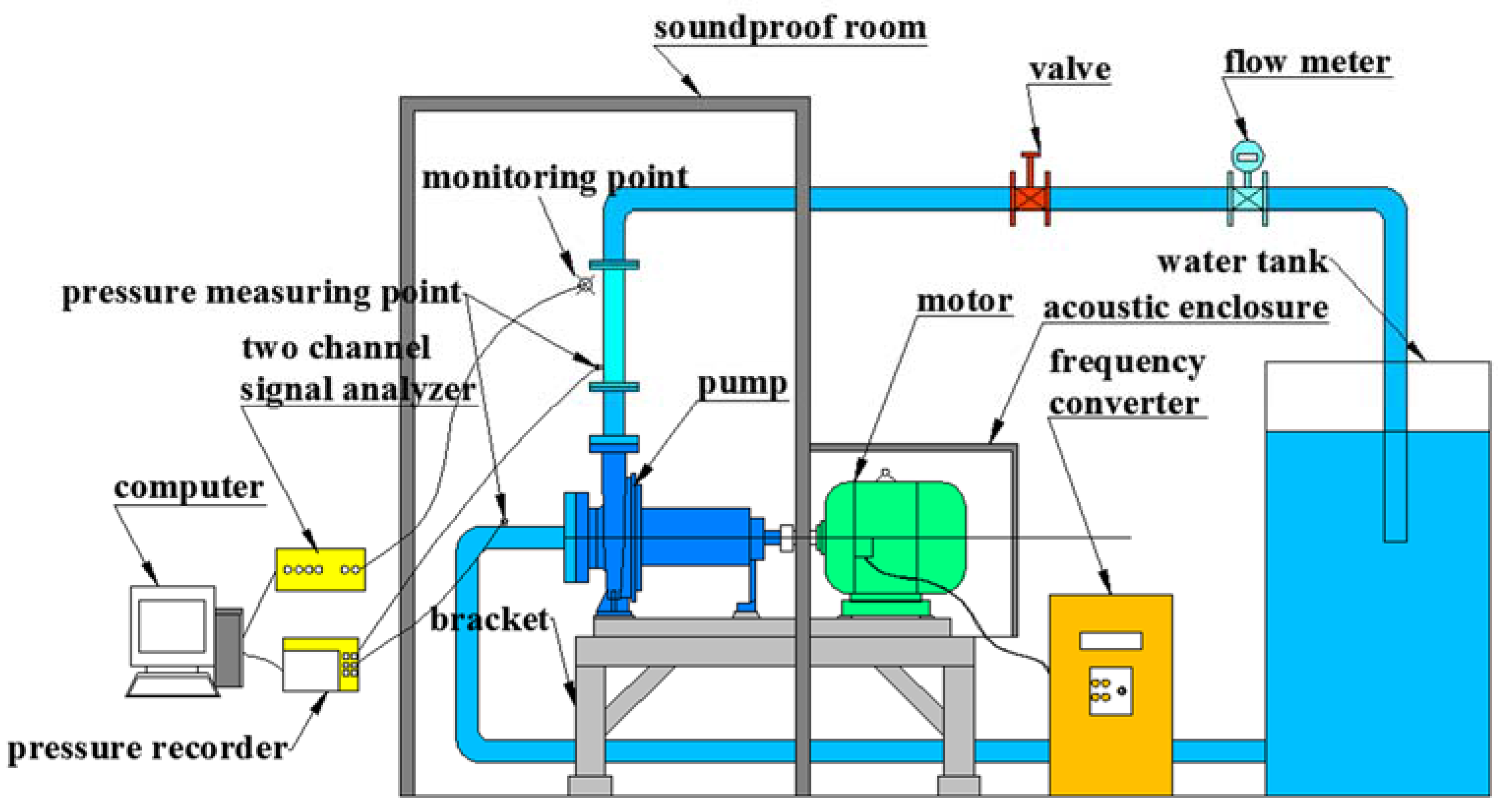

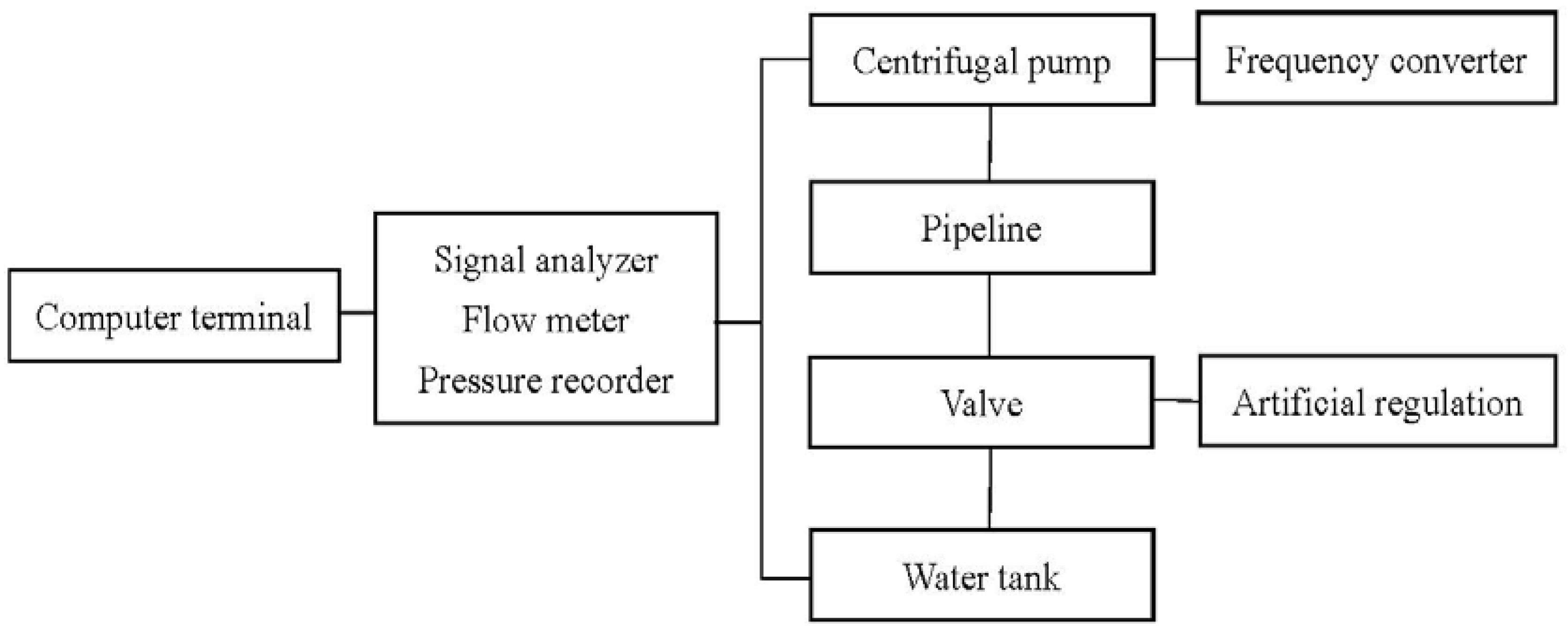

2. Experimental Facility and Procedure

2.1. Parameters of the Test Pump

2.2. Radiation Noise Measurement System

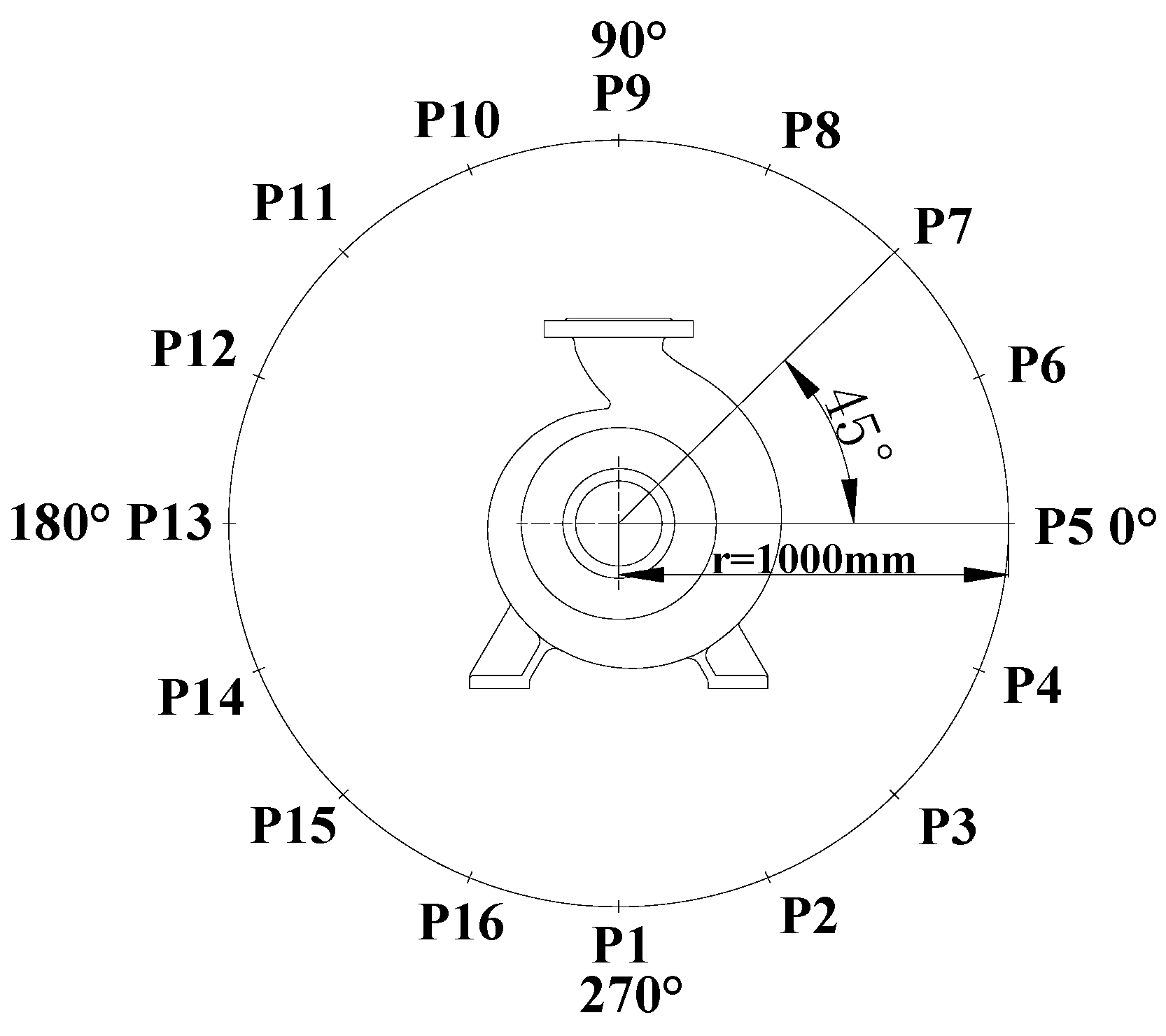

2.3. Arrangement of the Monitoring Points

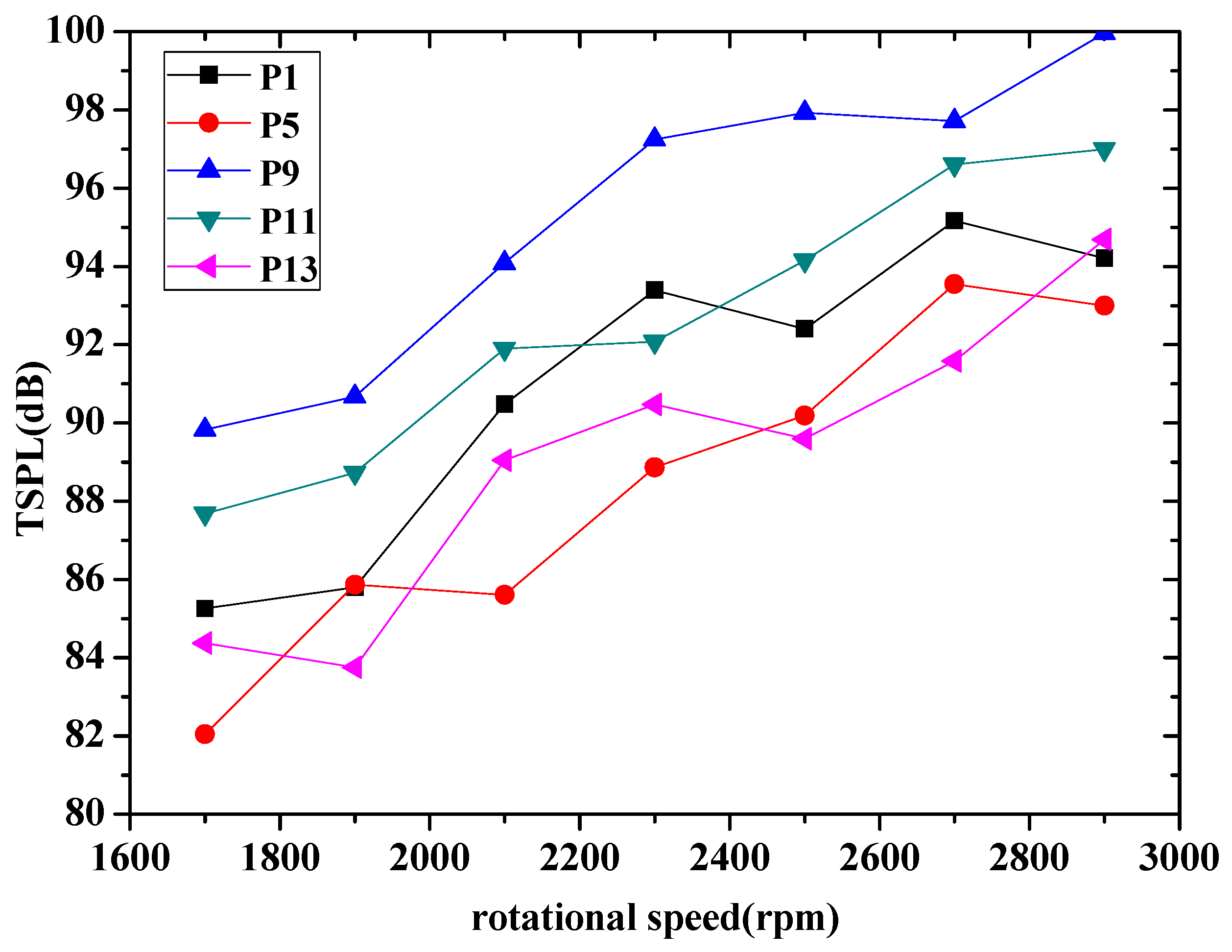

3. Radiation Noise Characteristic under Various Rotational Speed Conditions

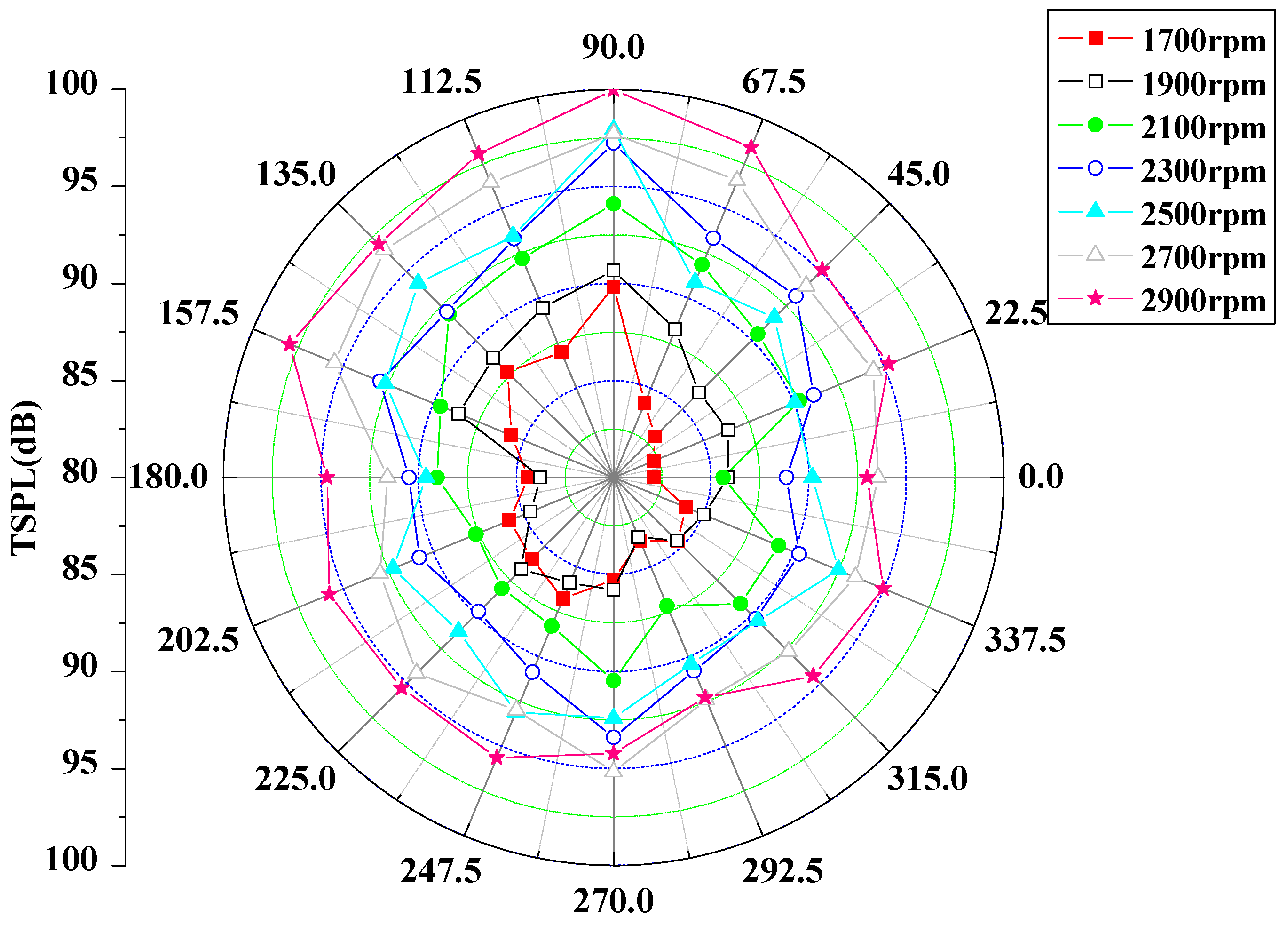

3.1. Directivity Characteristic of Radiation Noise under Various Rotational Speed Conditions

3.2. Changing Rules of Radiation Noise under Various Rotational Speed Conditions

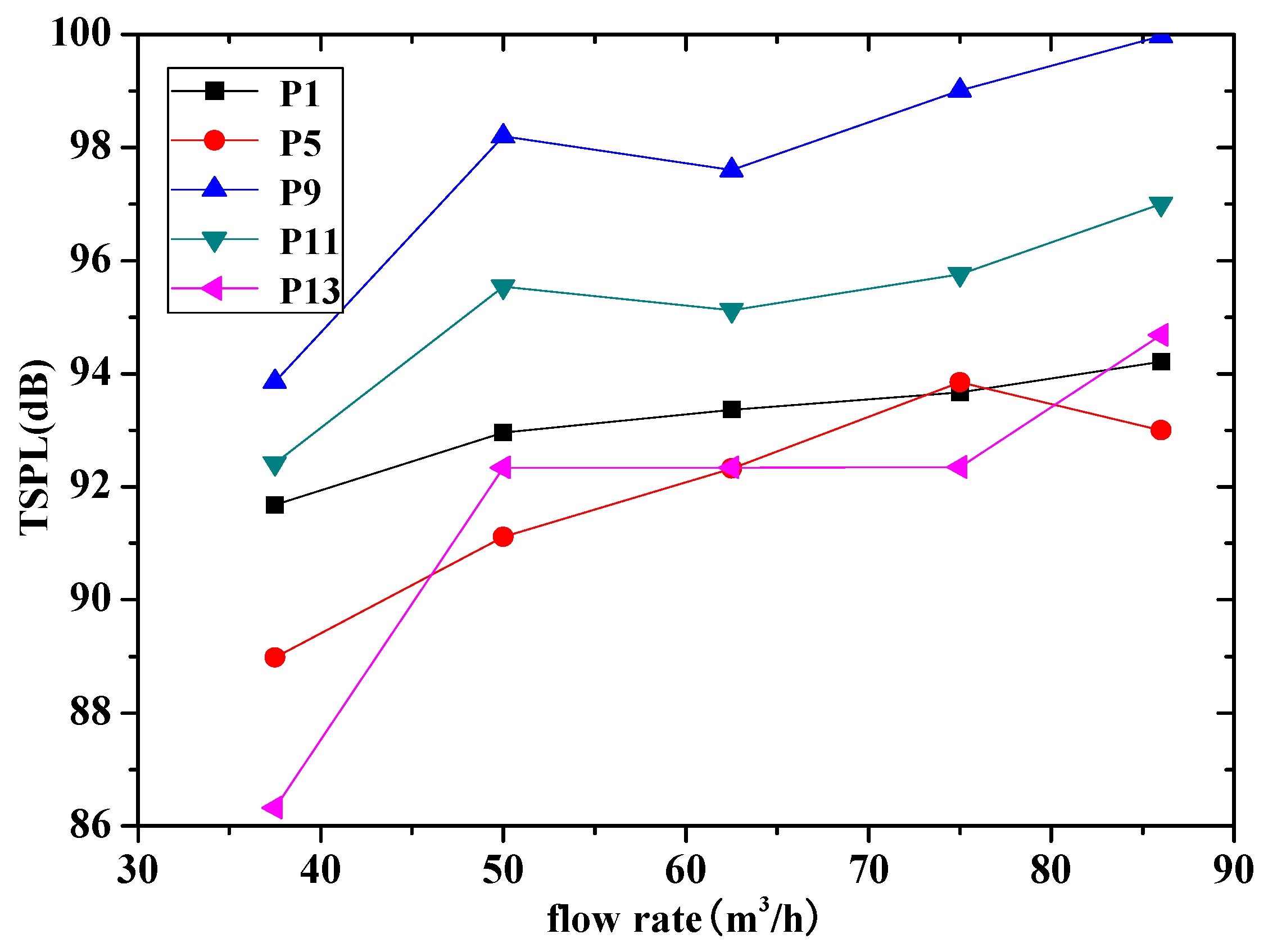

4. Radiation Noise Characteristics under Various Flow Rate Conditions

4.1. Directivity Characteristic of Radiation Noise under Various Flow Rate Conditions

4.2. Changing Rules of Radiation Noise under Various Flow Rate Conditions

5. Conclusions

- (a)

- Under various working conditions, the total sound pressure level distribution for different monitoring points is dipolar; specifically, the two valley values appear at 0° (in the direction against the tongue) and 180°, and the minimum valley values are presented at the minimum rotational speed and minimum flow rate condition. Additionally, asymmetry is also validated, i.e., the noise level in the direction facing the volute tongue is higher than that in the direction against the tongue, and the monitoring point in outlet direction is the highest noise level point.

- (b)

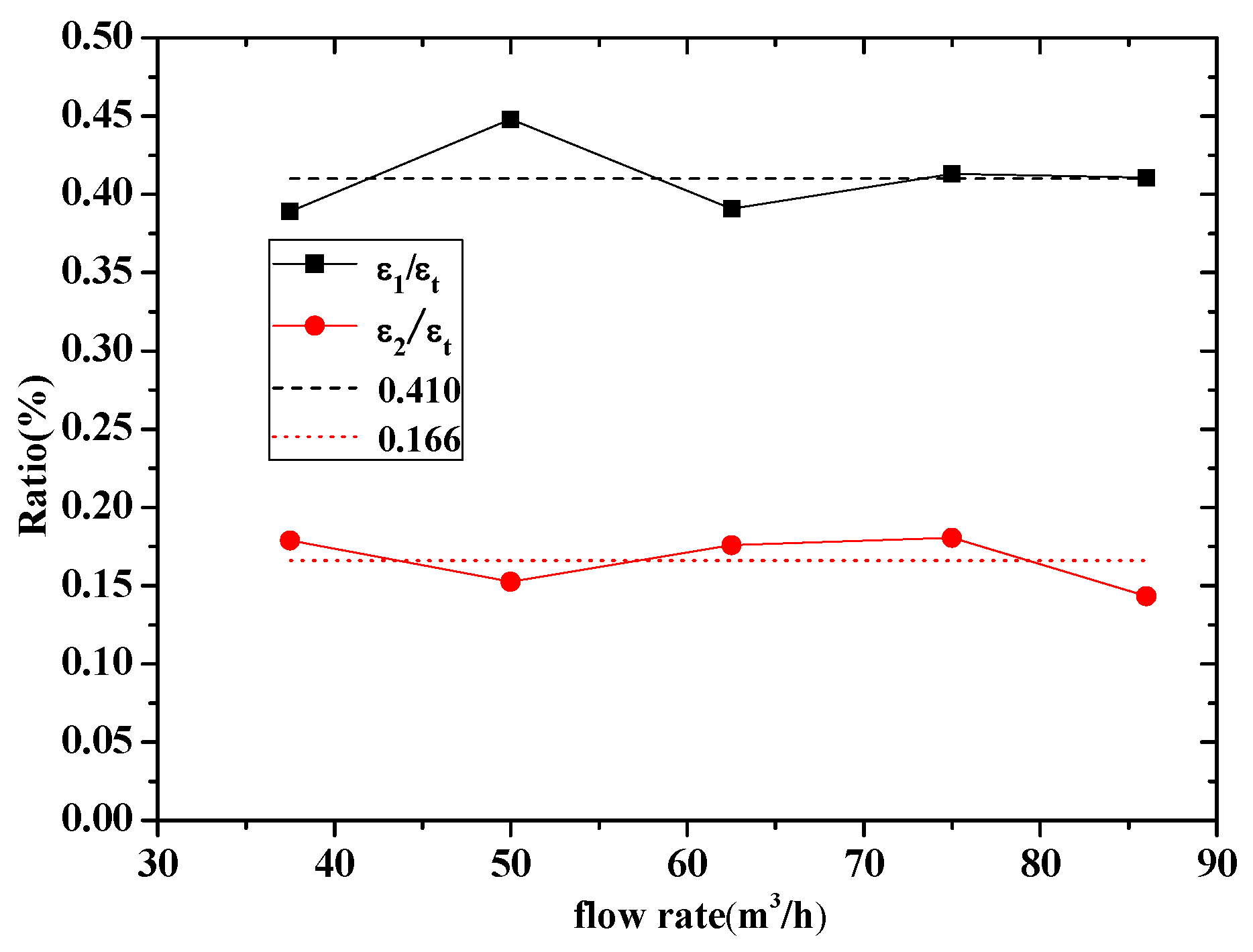

- The change in working conditions has little impact on the acoustic energy distribution of different intervals, and the ratios of the acoustic energy in the direction facing the tongue (ε1), as well as that in the direction against the tongue (ε2), to the total acoustic energy (εt) fluctuate around 0.410 and 0.160, respectively.

- (c)

- In the operation of variable speed regulation, the average A-weighted sound pressure level (LpA) increases gradually with the increasing of rotational speed, and it increases by 12.40% when rotational speed increases from 1700 to 2900 rpm, but the growth slope decreases gradually with the rise of pump rotational speed. While in the operation of throttling regulation, LpA first increases, then remains stable, and continues to increase with the increase in flow rate, and it increases by 5.10% when flow rate grows from 37.5 to 86 m3/h.

Supplementary Files

Supplementary File 1Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mao, D.X.; Hong, Z.H. Environmental Noise Control Engineering; Higher Education Press: Beijing, China, 2002. [Google Scholar]

- Shah, S.R.; Jain, S.V.; Patel, R.N.; Lakhera, V.J. CFD for centrifugal pumps: A review of the state-of-the-art. Procedia Eng. 2013, 51, 715–720. [Google Scholar] [CrossRef]

- Wu, D.F.; Liu, Y.S.; Li, D.L.; Zhao, X.F.; Li, C. Effect of materials on the noise of a water hydraulic pump used in submersible. Ocean Eng. 2017, 131, 107–113. [Google Scholar] [CrossRef]

- Choi, J.S.; Mclaughlin, D.K.; Thompson, D.E. Experiments on the unsteady flow field and noise generation in a centrifugal pump impeller. J. Sound Vib. 2003, 263, 493–514. [Google Scholar] [CrossRef]

- Chu, S.; Dong, R.; Katz, J. Relationship between unsteady flow, pressure fluctuation, and noise in a centrifugal pump—Part A: Use of PDV data to compute the pressure field. J. Fluid Eng. 1995, 117, 24–29. [Google Scholar] [CrossRef]

- Chu, S.; Dong, R.; Katz, J. Relationship between unsteady flow, pressure fluctuation, and noise in a centrifugal pump—Part B: Effects of blade-tongue interactions. J. Fluid Eng. 1995, 117, 30–35. [Google Scholar] [CrossRef]

- Dong, R.; Chu, S.; Katz, J. Effect of Modification to Tongue and Impeller Geometry on Unsteady Flow, Pressure Fluctuations, and Noise in a Centrifugal Pump. J. Turbomach. 1997, 119, 506–515. [Google Scholar] [CrossRef]

- Parrondo, J.; Pérez, J.; Barrio, R.; González, J. A simple acoustic model to characterize the internal low frequency sound field in centrifugal pumps. Appl. Acoust. 2011, 72, 59–64. [Google Scholar] [CrossRef]

- Cai, J.C.; Pan, J.; Andrew, G. Experimental study of the pressure fluctuation around the volute tongue of a centrifugal pump at variable rotating speed. Fluid Mach. 2015, 43, 13–16. [Google Scholar]

- Rzentkowski, G.; Zbroja, S. Experimental characterization of centrifugal pumps as an acoustic source at the blade-passing frequency. J. Fluid Struct. 2000, 14, 529–558. [Google Scholar] [CrossRef]

- Wang, Q.Y. Numerical and Experimental Research on the Flow-Induced Noise of Centrifugal Pump in the Seawater Pipe. Master’s Thesis, Harbin Engineering University, Harbin, China, 2010. [Google Scholar]

- Si, Q.R.; Yuan, S.Q.; Yuan, J.P. Experimental study on the influence of impeller-tongue gap on the performance and flow-induced noise characteristics of centrifugal pumps. J. Vib. Shock 2016, 35, 164–168. [Google Scholar]

- Yuan, S.Q.; Yang, Y.; Yuan, J.P.; Luo, Y. Measurement system design of flow-induced noise in centrifugal pumps. Drain. Irrig. Mach. 2009, 27, 10–14. [Google Scholar]

- Liu, H.L.; Wang, Y.; Yuan, S.Q.; Tan, M.G. Effects of impeller outlet width on the vibration and noise from centrifugal pumps induced by flow. J. Huazhong Univ. Sci. Technol. 2012, 40, 123–127. [Google Scholar]

- Tan, M.G.; Wang, Y.; Liu, H.L.; Wu, X.F.; Wang, W. Effects of number of blades on flow induced noise vibration and noise of centrifugal pumps. J. Drain. Irrig. Mach. Eng. 2012, 30, 131–135. [Google Scholar]

- Wang, Y.; Liu, H.L.; Liu, D.X.; Wang, J.; Wu, X.F. Effects of vane wrap angle on flow induced vibration and noise of centrifugal pumps. Trans. Chin. Soc. Agric. Eng. 2013, 29, 72–77. [Google Scholar]

- Ye, X.M.; Pei, J.J.; Li, C.X.; Liu, Z. Experimental Study on Nosie Characteristics of Centrifugal Pump Based on Near-Field Acoustic Pressure Method. Chin. J. Power Eng. 2013, 33, 375–380. [Google Scholar]

- Wang, M.; Freund, J.B.; Lele, S.K. Computational prediction of flow-generated sound. Annu. Rev. Fluid Mech. 2015, 38, 483–512. [Google Scholar] [CrossRef]

- Liu, H.L.; Dai, H.W.; Ding, J.; Tan, M.G.; Wang, Y.; Huang, H.Q. Numerical and experimental studies of hydraulic noise induced by surface dipole sources in a centrifugal pump. J. Hydrodyn. 2016, 28, 43–51. [Google Scholar] [CrossRef]

- Langthjem, M.A.; Olhoff, N. A numerical study of flow-induced noise in a two-dimensional centrifugal pump. Part I. Hydrodynamics. J. Fluid Struct. 2004, 19, 349–368. [Google Scholar] [CrossRef]

- Langthjem, M.A.; Olhoff, N. A numerical study of flow-induced noise in a two-dimensional centrifugal pump. Part II. Hydroacoustics. J. Fluid Struct. 2004, 19, 36–386. [Google Scholar] [CrossRef]

- Huang, J.X.; Geng, S.J.; Wu, R.; Liu, K.; Nie, C.Q.; Zhang, H.W. Comparison of noise characteristics in centrifugal pumps with different types of impellers. Acta Acoust. 2010, 35, 113–118. [Google Scholar]

- Ma, Z.L.; Chen, E.Y.; Guo, Y.L.; Yang, A.L. Numerical Simulation of the Influence of the Diameter at the Outlet of an Impeller on the Noise Level Induced by the Flow Inside a Centrifugal Pump. J. Eng. Therm. Energy Power 2016, 31, 93–98. [Google Scholar]

- Liu, H.L.; Ding, J.; Tan, M.G.; Cui, J.B.; Wang, Y. Analysis and experimental of centrifugal pump noise based on outlet width of impeller. Trans. Chin. Soc. Agric. Eng. 2013, 29, 66–73. [Google Scholar]

- Gao, M.; Dong, P.X.; Lei, S.H.; Turan, A. Computational Study of the Noise Radiation in a Centrifugal Pump When Flow Rate Changes. Energies 2017, 10, 221. [Google Scholar] [CrossRef]

- Dong, P.X.; Gao, M.; Guan, H.J.; Lu, D.Y.; Song, K.Q.; Sun, F.Z. Numerical simulation for variation law of volute radiated noise in centrifugal pumps under variable rotating speed. J. Vib. Shock 2017, 36, 128–133. [Google Scholar]

- Tao, J.Y.; Lu, X.N.; Wang, L.L. Methods of Measuring and Evaluating Noise of Pumps; Chinese Quality Supervision Bureau: Beijing, China, 2013.

- Du, G.H.; Zhu, Z.M.; Gong, X.F. Fundamentals of Acoustics; Nanjing University Press: Nanjing, China, 2001. [Google Scholar]

- Dong, P.X. Computational Study on the Noise Radiation of a Centrifugal Pump Based on 3-D Flow field with Varying Working Condition. Master’s Thesis, Shandong University, Jinan, China, 2016. [Google Scholar]

| Parameter | Value |

|---|---|

| Inlet diameter, mm | 80 |

| Impeller diameter, mm | 250 |

| Outlet diameter, mm | 50 |

| Nominal flow rate, m3/h | 50 |

| Best efficiency | 63% (50 m3/h) |

| Design head, m | 80 |

| Nominal rotational speed, rpm | 2900 |

| Blade number | 6 |

| Instruments | Type | Application | Measuring Range | Accuracy or Sensitivity |

|---|---|---|---|---|

| Flow meter | SLDG-800 (SLDG-800, Nanjing Shunlaida Measurement and Control Equipment Co., Ltd., Nanjing, Jiangsu, China) | Measuring flow rate | 0–100 m3/h | 0.2% (accuracy) |

| Pressure transducer | MIK-300 (MIK-300, Hangzhou Meikong Automation Technology Co., Ltd., Hangzhou, China) | Measuring inlet pressure | −100–0 kPa (inlet pipe) | 0.5% (accuracy) |

| Measuring outlet pressure | 0–1600 kPa (outlet pipe) | 0.5% (accuracy) | ||

| Pressure recorder | RX-200D (RX-200D, Hangzhou Meikong Automation Technology Co., Ltd., Hangzhou, China) | Recording pressure | / | / |

| Microphone | AWA14423L (AWA14423L, Hangzhou Aihua Instruments Co., Ltd., Hangzhou, China) | Measuring radiation noise | 10–20 kHz | 50 mV/Pa (sensitivity) |

| Two channel signal analyzer | AWA6290M+ (AWA6290M+, Hangzhou Aihua Instruments Co., Ltd., Hangzhou China) | Recording radiation noise | / | / |

| Rotational Speed, rpm | Flow Rate, m3/h |

|---|---|

| 1700 | 56.9 |

| 1900 | 64.8 |

| 2100 | 69.6 |

| 2300 | 74 |

| 2500 | 78.2 |

| 2700 | 82.1 |

| 2900 | 86 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, C.; Gao, M.; Lu, D.; Wang, K. An Experimental Study on the Radiation Noise Characteristics of a Centrifugal Pump with Various Working Conditions. Energies 2017, 10, 2139. https://doi.org/10.3390/en10122139

Guo C, Gao M, Lu D, Wang K. An Experimental Study on the Radiation Noise Characteristics of a Centrifugal Pump with Various Working Conditions. Energies. 2017; 10(12):2139. https://doi.org/10.3390/en10122139

Chicago/Turabian StyleGuo, Chang, Ming Gao, Dongyue Lu, and Kun Wang. 2017. "An Experimental Study on the Radiation Noise Characteristics of a Centrifugal Pump with Various Working Conditions" Energies 10, no. 12: 2139. https://doi.org/10.3390/en10122139