Environmental and Economic Benefit Analysis of an Integrated Heating System with Geothermal Energy—A Case Study in Xi’an China

Abstract

:1. Introduction

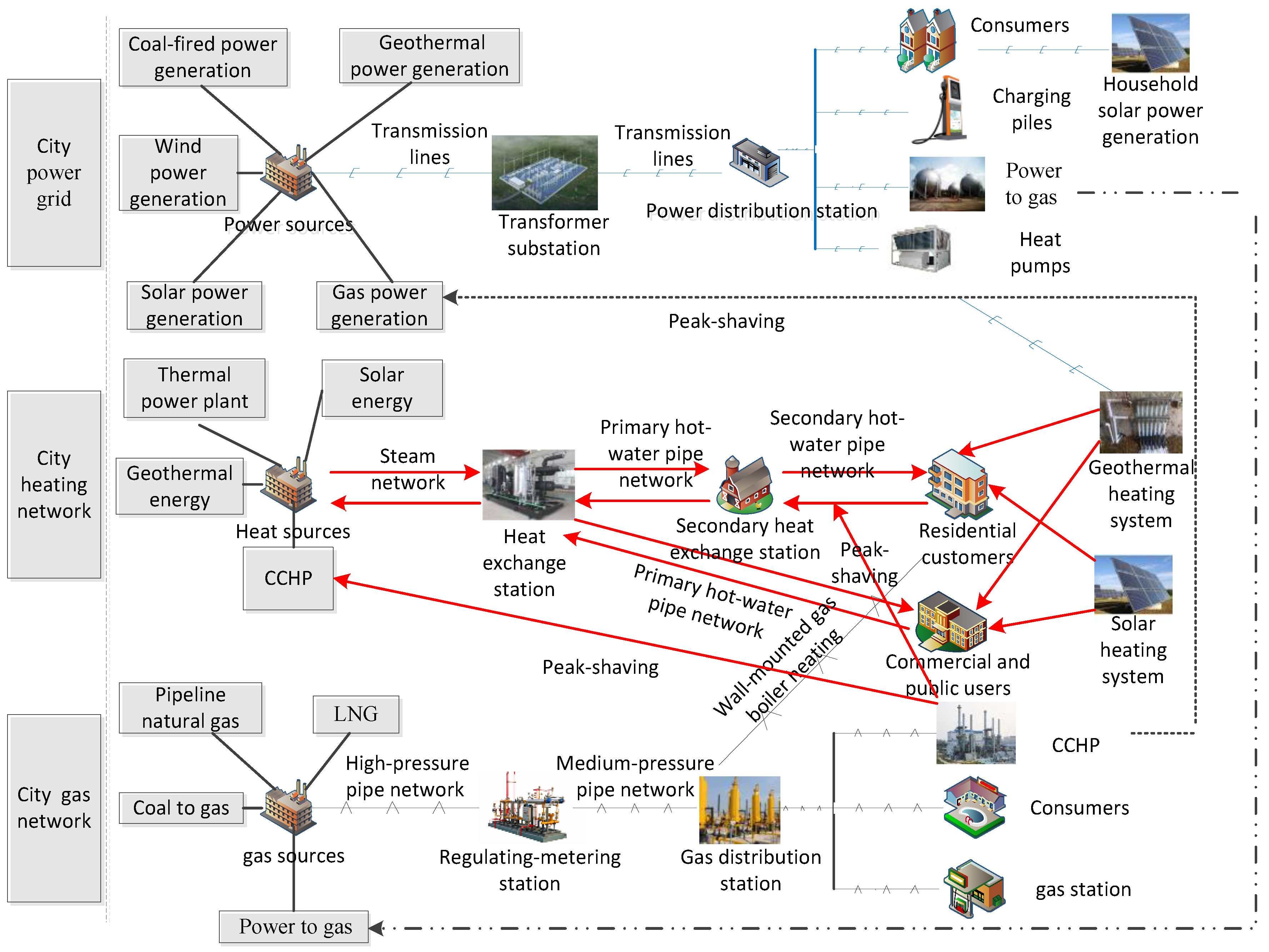

2. Integrated Energy System Design

2.1. Integrated Energy System Containing Electricity, Heating, and Gas

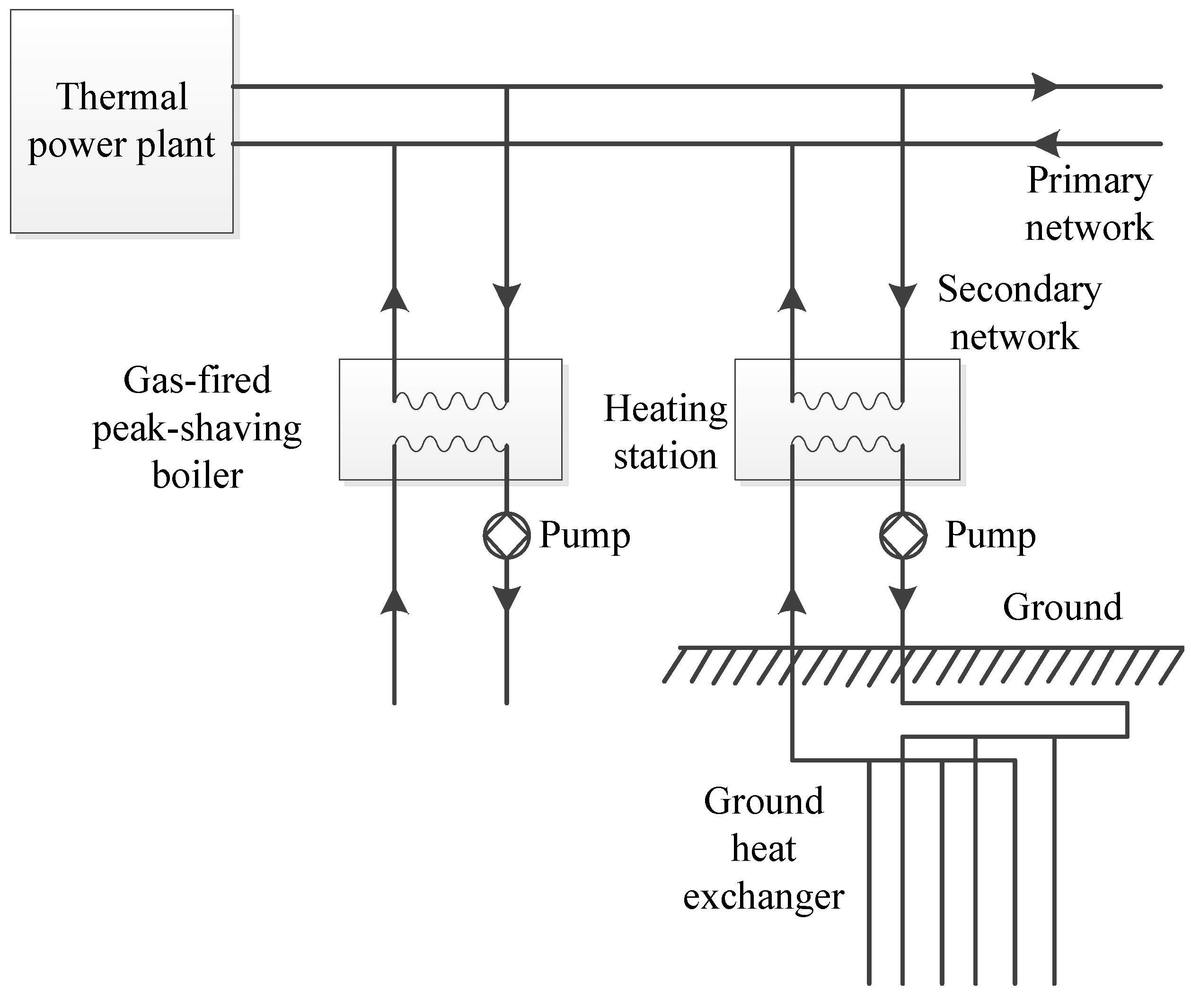

2.2. Integrated Heating System with Geothermal Energy

3. Environmental and Economic Benefit Analysis

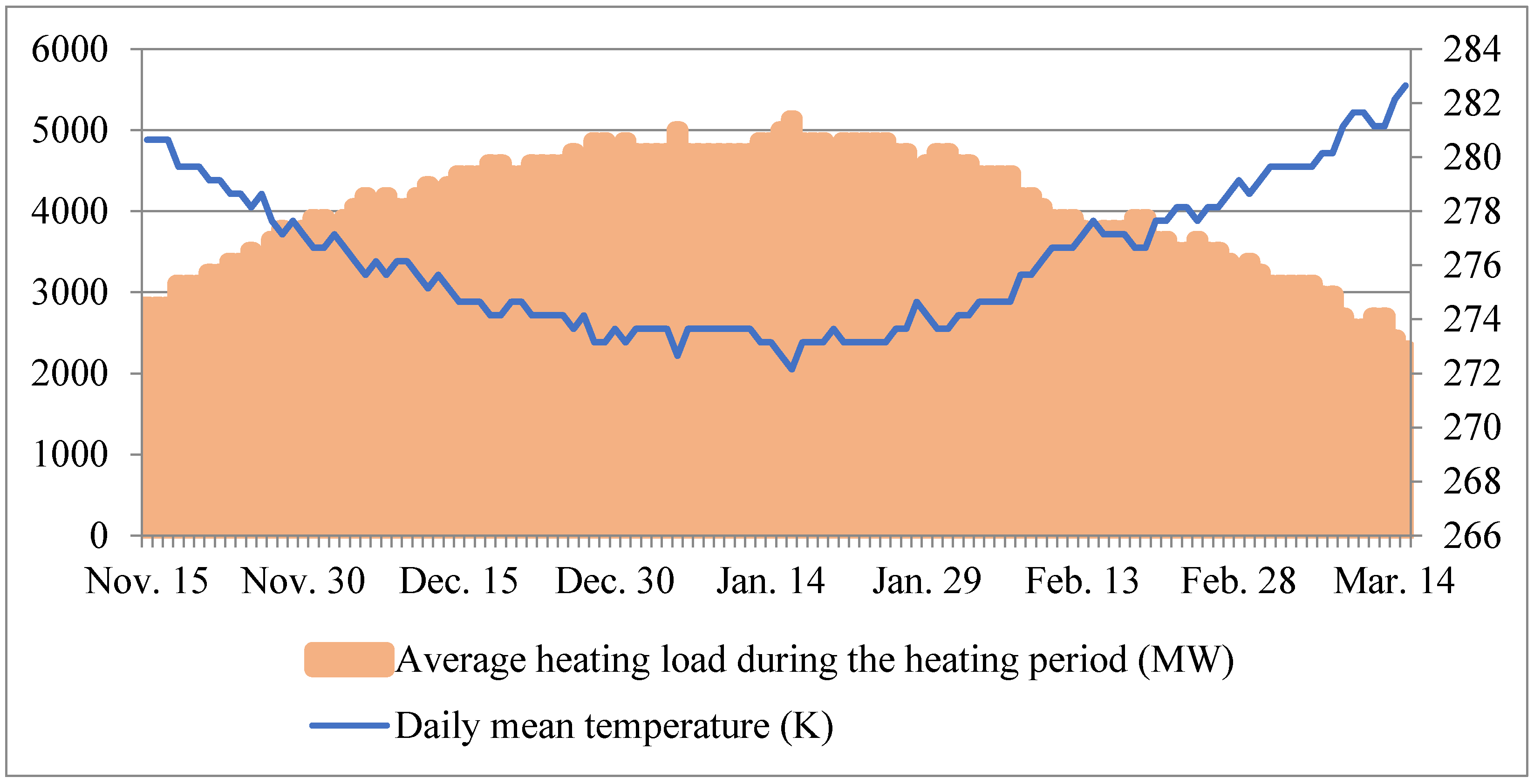

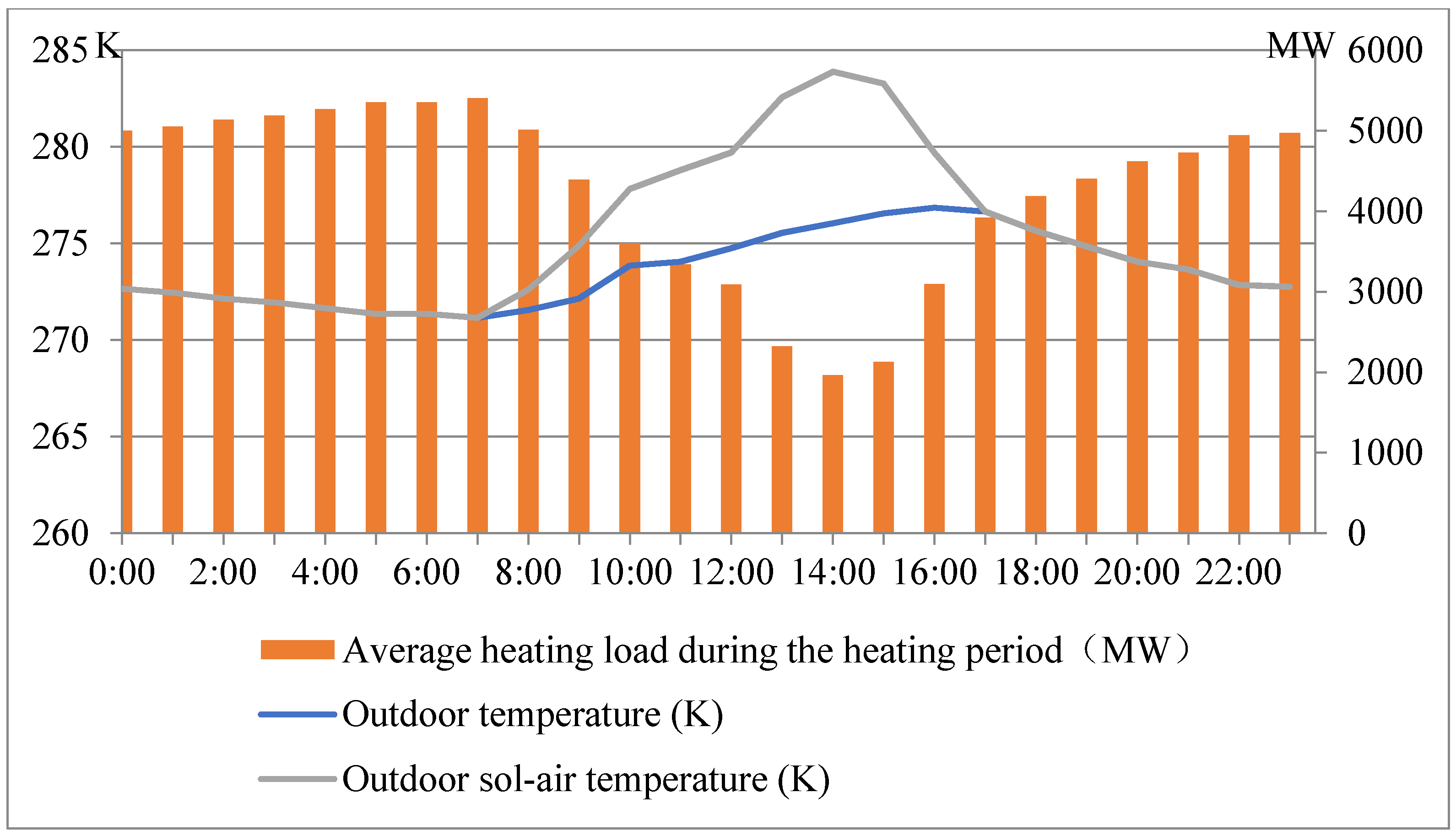

3.1. Heating Load during the Heating Period

3.2. Environmental Benefit Evaluation Model

3.3. Economic Benefit Evaluation Model

4. Example Analysis

4.1. Calculation of Heat Demand and Heating Load

4.2. Environmental Benefit Evaluation Model

4.3. Economic Benefit Analysis

5. Sensitivity Analysis

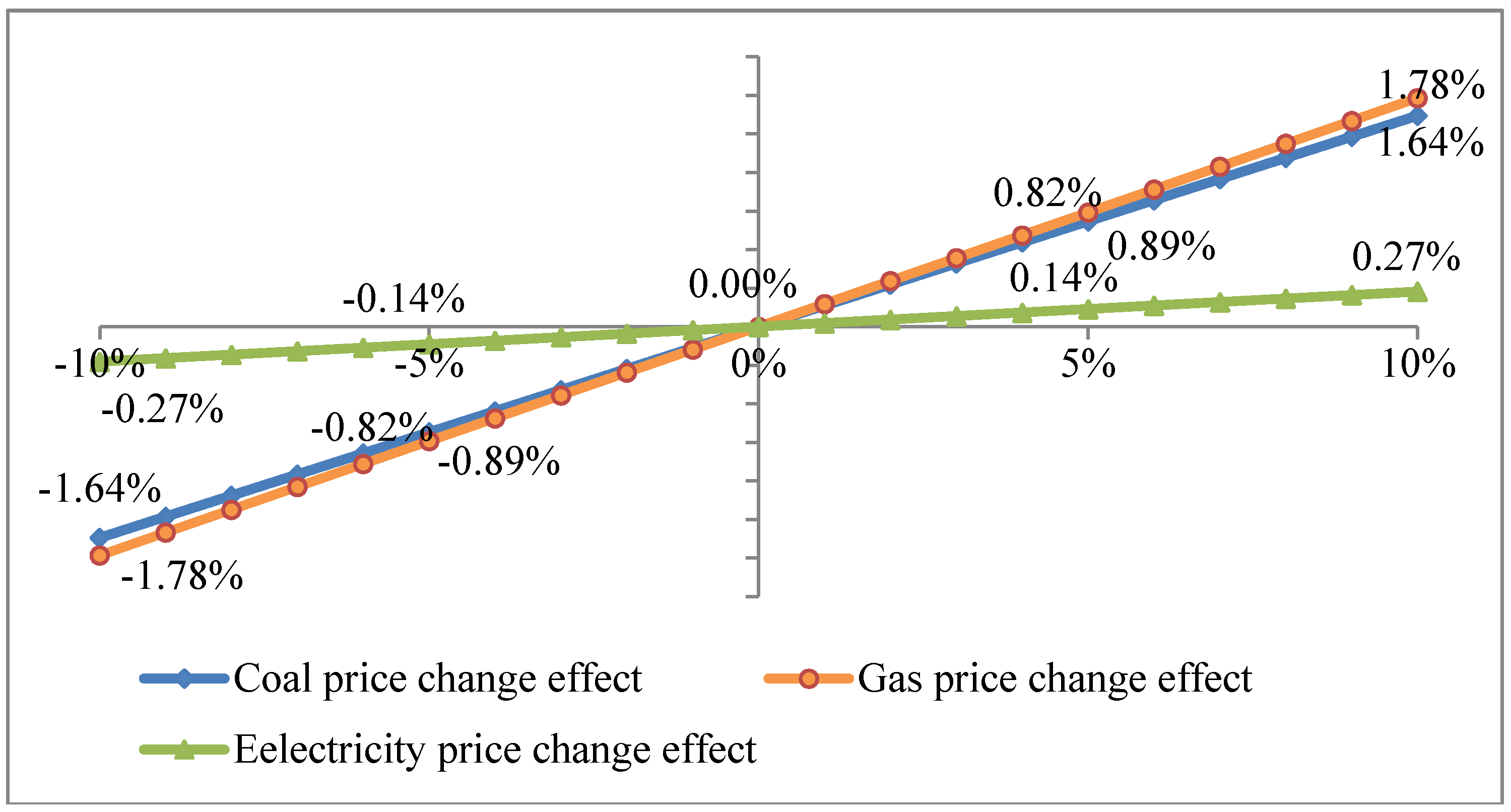

5.1. Sensitivity Analysis of Heat Sources to the Price Factors

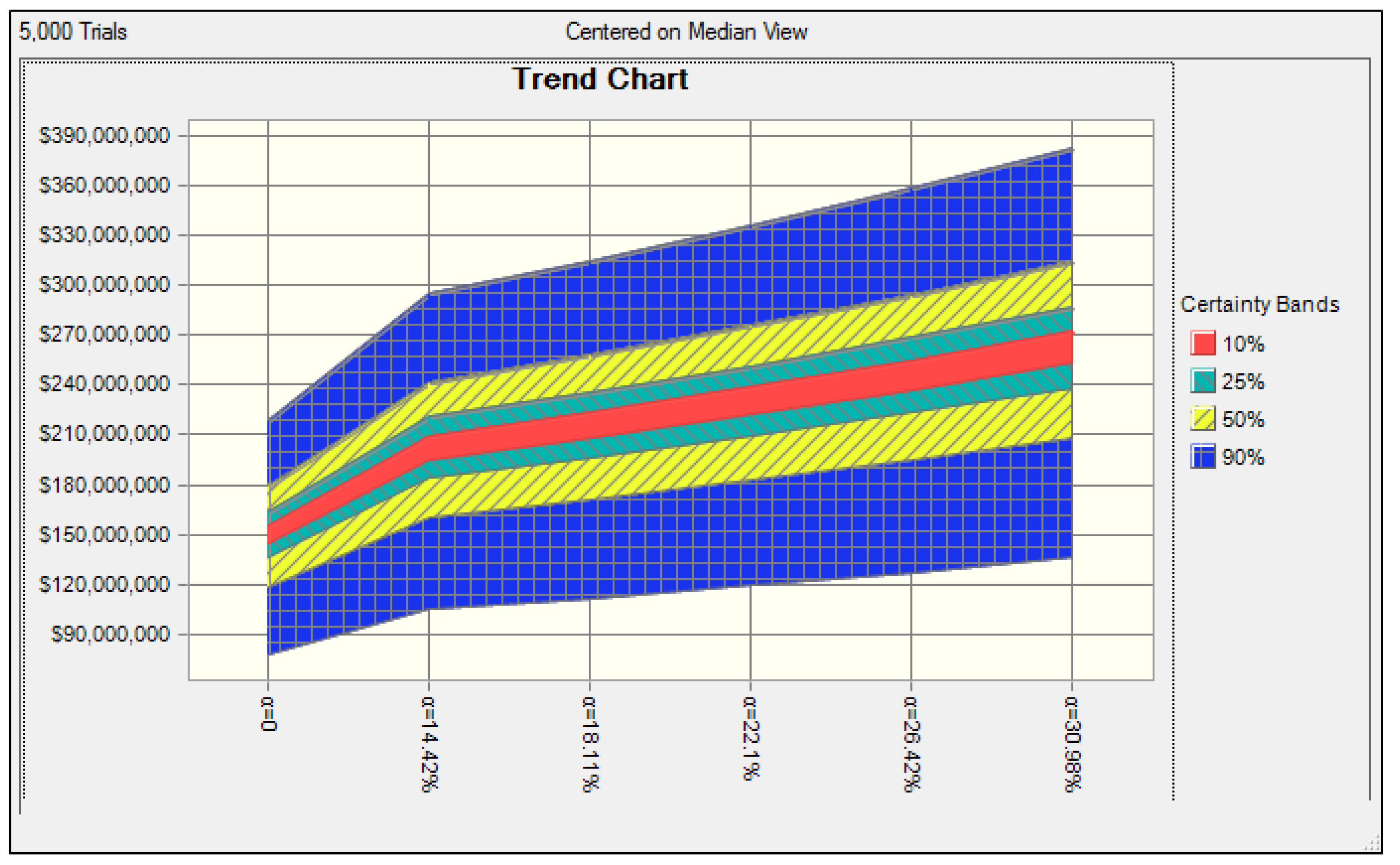

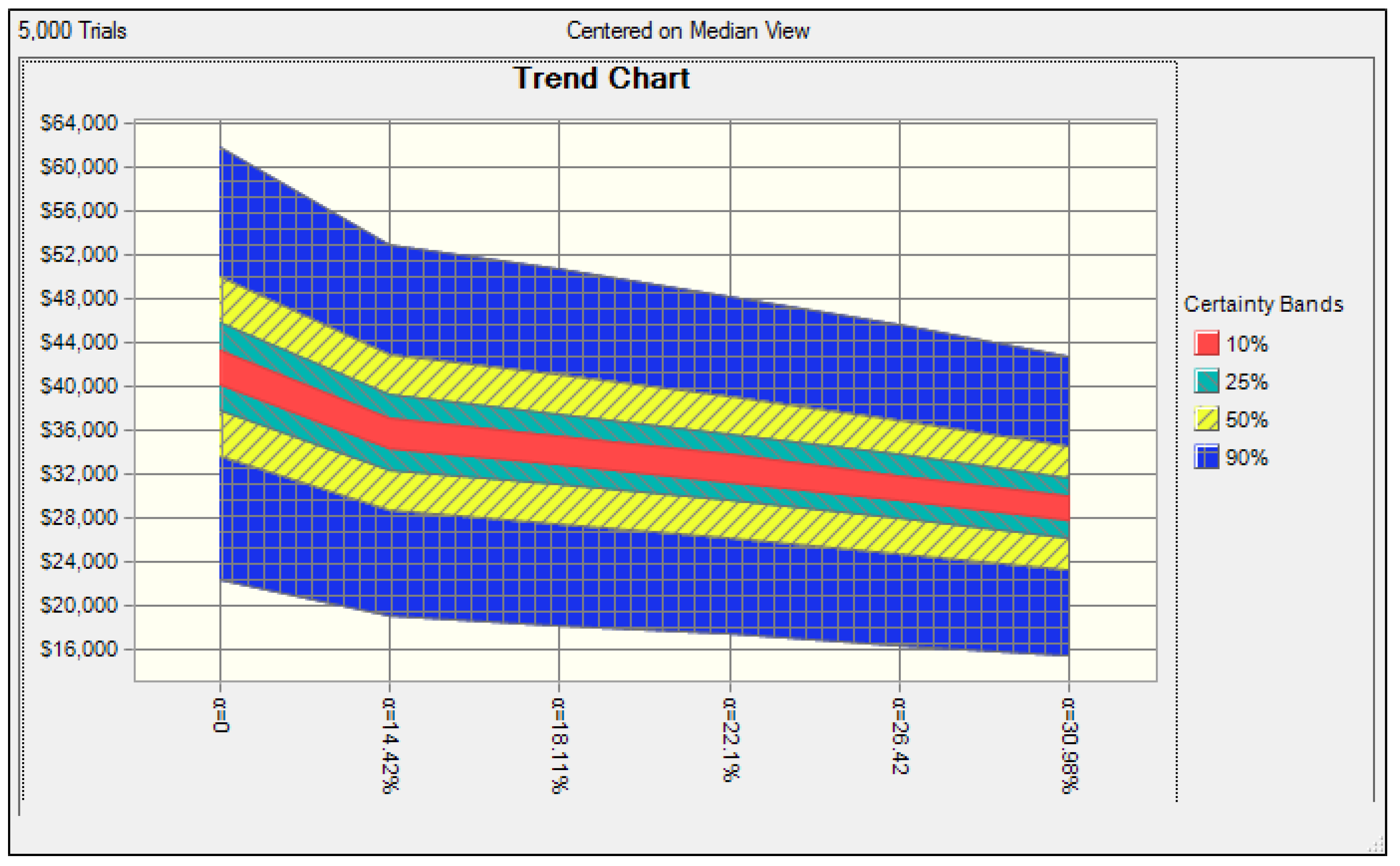

5.2. Sensitivity Analysis of Heat Sources to the Load Ratios

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Guiding Opinions of the State Council on Promoting “Internet +” Action; The State Council: Beijing, China, 2015. (In Chinese)

- Jia, H.; Wang, D.; Xu, X.; Yu, X. Research on some key problems related to integrated energy system. Autom. Electr. Power Syst. 2015, 39, 198–207. (In Chinese) [Google Scholar]

- Dong, Z.; Zhao, J.; Wen, F.; Xue, Y. From smart grid to Energy Internet: Basic concept and research framework. Autom. Electr. Power Syst. 2014, 38, 1–11. (In Chinese) [Google Scholar]

- Mehleri, E.D.; Sarimveis, H.; Markatos, N.C.; Papageorgiou, L.G. A mathematical programming approach for optimal design of distributed energy systems at the neighbourhood level. Energy 2012, 44, 96–104. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, P.; Li, Z.; Ni, W. An engineering approach to the optimal design of distributed energy systems in China. Appl. Therm. Eng. 2013, 53, 387–396. [Google Scholar] [CrossRef]

- Gu, W.; Wu, C.; Wang, J.; Lu, S.; Luo, Z. Optimal operation for integrated energy system considering thermal inertia of district heating network and buildings. Appl. Energy 2017, 199, 234–246. [Google Scholar] [CrossRef]

- Guo, P.; He, M.; Zheng, L.; Zhang, N. A geothermal recycling system for cooling and heating in deep mines. Appl. Therm. Eng. 2017, 116, 833–839. [Google Scholar] [CrossRef]

- Sobhy, I.; Brakez, A.; Benhamou, B. Energy performance and economic study of a solar floor heating system for a Hammam. Energy Build. 2017, 141, 247–261. [Google Scholar] [CrossRef]

- Wang, H. Study on Peak-Shaving Heating Modes of Combined District Heating Systems and the Comprehensive Optimization. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2013. (In Chinese). [Google Scholar]

- Jia, H.; Mu, Y.; Yu, X. Thought About the Integrated Energy System in China. Electr. Power Constr. 2015, 36, 16–25. (In Chinese) [Google Scholar]

- Liu, L.; Qu, N.; Cao, Y. Economic Analysis of Combined Heat and Power. Technol. Enterp. 2014, 173. [Google Scholar] [CrossRef]

- Shabbir, I.; Mirzaeian, M. Carbon Emissions Reduction Potentials in Pulp and Paper Mills by Applying Cogeneration Technologies. Energy Procedia 2017, 112, 142–149. [Google Scholar] [CrossRef]

- Tomofuji, D.; Morimoto, Y.; Sugiura, E.; Ishii, T.; Akisawa, A. The prospects of the expanded diffusion of cogeneration to 2030—Study on new value in cogeneration. Appl. Therm. Eng. 2016, 114, 1403–1413. [Google Scholar] [CrossRef]

- Zhang, J. Geothermal Energy, Heat and Heat Pump Technology; Chemical Industry Press: Beijing, China, 2014. (In Chinese) [Google Scholar]

- Kaldehi, B.J.; Keshavarz, A.; Pirooz, A.A.S.; Batooei, A.; Ebrahimi, M. Designing a micro Stirling engine for cleaner production of combined cooling heating and power in residential sector of different climates. J. Clean. Prod. 2017, 154, 502–516. [Google Scholar] [CrossRef]

- Meybodi, M.A.; Behnia, M. Impact of carbon tax on internal combustion engine size selection in a medium scale CHP system. Appl. Energy 2011, 88, 5153–5163. [Google Scholar] [CrossRef]

- Wang, J.; Zhai, Z.; Jing, Y.; Zhang, C. Optimization design of BCHP system to maximize to save energy and reduce environmental impact. Energy 2010, 35, 3388–3398. [Google Scholar] [CrossRef]

- Abdurafikov, R.; Grahn, E.; Kannari, L.; Ypyä, J.; Kaukonen, S.; Heimonen, I.; Paiho, S. An analysis of heating energy scenarios of a Finnish case district. Sustain. Cities Soc. 2017, 32, 56–66. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sharma, C.; Mullick, S.C.; Kandpal, T.C. Solar industrial process heating: A review. Renew. Sustain. Energy Rev. 2017, 78, 124–137. [Google Scholar] [CrossRef]

- Zhao, D.; Ji, J.; Yu, H.; Wei, W.; Zheng, H. Numerical and experimental study of a combined solar Chinese kang and solar air heating system based on Qinghai demonstration building. Energy Build. 2017, 143, 61–70. [Google Scholar] [CrossRef]

- Alam, M.M.R.; Behfar, A.; Shahmoradi, R. Potential Application of Solar Power Systems for Residential Buildings in High-Density Urban Pattern: The Case of the Eixample District, City of the Barcelona, in Spain. In Recent Researches in Environmental and Geological Sciences; WSEAS Press: Kos Island, Greece, 2012; pp. 342–347. ISBN 978-1-61804-110-4. [Google Scholar]

- Muniak, D.; Wabik, K.; Korzeń, A. Analysis of the cost of preparation of domestic hot water in a single-family home, taking account of the subvention under the Limitations of Low Emission Programme in Krakow. Dist. Heat. Heat. Ventilation 2017, 2, 63–71. [Google Scholar]

- Muniak, D. The Impact of the Requirements Of Limitation of Low Emission Programme in Krakow on the EP Factor Value. Dist. Heat. Heat. Ventilation 2017, 5, 192–195. [Google Scholar]

- Badami, M.; Gerboni, R.; Portoraro, A. Determination and assessment of indices for the energy performance of district heating with cogeneration plants. Energy 2017, 127, 697–703. [Google Scholar] [CrossRef]

- Dai, Y.; Chen, J. Solar Cogeneration/Trigeneration. In Encyclopedia of Sustainable Technologies, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 357–366. ISBN 9780128047927. [Google Scholar]

- Febrianto, R.; Thain, I.; Zarrouk, S.J. The geothermal heating system at Taupo Hospital, New Zealand. Geothermics 2016, 59, 347–356. [Google Scholar] [CrossRef]

- Islam, S.; Dincer, I. Development, analysis and performance assessment of a combined solar and geothermal energy-based integrated system for multigeneration. Sol. Energy 2017, 147, 328–343. [Google Scholar] [CrossRef]

- Kaushal, M. Geothermal cooling/heating using ground heat exchanger for various experimental and analytical studies: Comprehensive review. Energy Build. 2017, 139, 634–652. [Google Scholar] [CrossRef]

- Tester, J.W.; Reber, T.J.; Beckers, K.F.; Lukawski, M.Z. 4: Deep Geothermal Energy for District Heating: Lessons Learned from the U.S. and beyond. In Advanced District Heating and Cooling (DHC) Systems; Wiltshire, R., Ed.; Woodhead Publishing: Oxford, UK, 2016; pp. 75–98. [Google Scholar]

- Lucia, U.; Simonetti, M.; Chiesa, G.; Grisolia, G. Ground-source pump system for heating and cooling: Review and thermodynamic approach. Renew. Sustain. Energy Rev. 2016, 70, 867–874. [Google Scholar] [CrossRef]

- Lund, J.W.; Boyd, T.L. Direct utilization of geothermal energy 2015 worldwide review. Geothermics 2016, 60, 66–93. [Google Scholar] [CrossRef]

- Keçebaş, A.; Coskun, C.; Oktay, Z.; Hepbasli, A. Comparing advanced exergetic assessments of two geothermal district heating systems for residential buildings. Energy Build. 2014, 81, 141–151. [Google Scholar] [CrossRef]

- Keçebaş, A.; Hepbasli, A. Conventional and advanced exergoeconomic analyses of geothermal district heating systems. Energy Build. 2014, 69, 434–441. [Google Scholar] [CrossRef]

- Keçebaş, P.; Gökgedik, H.; Alkan, M.A.; Keçebaş, A. An economic comparison and evaluation of two geothermal district heating systems for advanced exergoeconomic analysis. Energy Convers. Manag. 2014, 84, 471–480. [Google Scholar] [CrossRef]

- Kyriakis, S.A.; Younger, P.L. Towards the increased utilization of geothermal energy in a district heating network through the use of a heat storage. Appl. Therm. Eng. 2016, 94, 99–110. [Google Scholar] [CrossRef]

- Yamankaradeniz, N. Thermodynamic performance assessments of a district heating system with geothermal by using advanced exergy analysis. Renew. Energy 2016, 85, 965–972. [Google Scholar] [CrossRef]

- Arat, H.; Arslan, O. Optimization of district heating system aided by geothermal heat pump: A novel multistage with multilevel ANN modelling. Appl. Therm. Eng. 2017, 111, 608–623. [Google Scholar] [CrossRef]

- Arat, H.; Arslan, O.; Lund, H.; Kaiser, M.J. Exergoeconomic analysis of district heating system boosted by the geothermal heat pump. Energy 2017, 119, 1159–1170. [Google Scholar] [CrossRef]

- Keçebaş, A. Exergoenvironmental analysis for a geothermal district heating system: An application. Energy 2016, 94, 391–400. [Google Scholar] [CrossRef]

- Yürüsoy, M.; Keçebaş, A. Advanced exergo-environmental analyses and assessments of a real district heating system with geothermal energy. Appl. Therm. Eng. 2016, 113, 449–459. [Google Scholar] [CrossRef]

- Martín-Gamboa, M.; Iribarren, D.; Dufour, J. On the environmental suitability of high- and low-enthalpy geothermal systems. Geothermics 2015, 53, 27–37. [Google Scholar] [CrossRef]

- Aslan, A.; Yüksel, B.; Akyol, T. Effects of different operating conditions of Gonen geothermal district heating system on its annual performance. Energy Convers. Manag. 2014, 79, 554–567. [Google Scholar] [CrossRef]

- Noorollahi, Y.; Arjenaki, H.G.; Ghasempour, R. Thermo-economic modeling and GIS-based spatial data analysis of ground source heat pump systems for regional shallow geothermal mapping. Renew. Sustain. Energy Rev. 2017, 72, 648–660. [Google Scholar] [CrossRef]

- Song, J.; Wallin, F.; Li, H. District heating cost fluctuation caused by price model shift. Appl. Energy 2017, 194, 715–724. [Google Scholar] [CrossRef]

- Yan, S.; Li, S.; Li, H. Analysis of geo-temperature recovery under intermittent operation of ground-source heat pump. Energy Build. 2011, 43, 935–943. [Google Scholar]

- Zhao, W. Application of crystal ball software in management simulation. In Proceedings of the International Conference on Computer Science and Service System, Nanjing, China, 27–29 June 2011; pp. 2099–2101. [Google Scholar]

- Abhishek, B.; Ashok, K. Application of the Crystal Ball® software for uncertainty and sensitivity analyses for predicted concentration and risk levels. Environ. Prog. Sustain. Energy 2010, 27, 289–294. [Google Scholar]

- Tian, T. Technical and Economic Analysis of Gas Power Plant on Power Peaking; North China Electric Power University: Beijing, China, 2015. (In Chinese) [Google Scholar]

| Scenarios | Basic Heating Load (MW) | Basic Heating Load Ratio during Heating Period (%) | Gas Peak-Shaving Heating Load Ratio during Heating Period (%) | Basic Heating Load Ratio on a Typical Day (%) | Gas Peak-Shaving Heating Load Ratio on a Typical Day (%) |

|---|---|---|---|---|---|

| Scenario 2 | 2,800 | 69.02 | 30.98 | 63.63 | 36.37 |

| Scenario 3 | 3,000 | 73.58 | 26.42 | 67.73 | 32.27 |

| Scenario 4 | 3,200 | 77.9 | 22.1 | 71.62 | 28.38 |

| Scenario 5 | 3,400 | 81.89 | 18.11 | 75.27 | 24.73 |

| Scenario 6 | 3,500 | 85.58 | 14.42 | 78.78 | 21.22 |

| Scenarios | Peak-Shaving Ratio (%) | GSHP to the Basic Heating Load Ratio (%) | Coal Consumption (million tons) | Coal Saving (million tons) | Emission Reductions (million tons) | ||

|---|---|---|---|---|---|---|---|

| Sulfur Dioxide | Nitrogen Oxides | TSP | |||||

| Scenario 1 | 0 | 0 | 1.7236 | 0.1393 | 33.4489 | 9.7533 | 947.7186 |

| Scenario 2 | 30.98 | 10 | 1.1349 | 0.7280 | 174.3540 | 49.4478 | 4,950.6359 |

| Scenario 3 | 26.42 | 10 | 1.2099 | 0.6530 | 156.4154 | 44.4222 | 4,440.8133 |

| Scenario 4 | 22.1 | 10 | 1.2809 | 0.5820 | 139.4308 | 39.6638 | 3,958.1057 |

| Scenario 5 | 18.11 | 10 | 1.3465 | 0.5164 | 123.7241 | 35.2635 | 3,511.7164 |

| Scenario 6 | 14.42 | 10 | 1.4072 | 0.4557 | 109.2134 | 31.1982 | 3,099.3173 |

| Scenario 7 | 0 | 10 | 1.6443 | 0.2186 | 52.4724 | 15.3018 | 1,486.7180 |

| Scenarios | Peak-Shaving Ratio (%) | GSHP tor the Basic Heating Load Ratio (%) | Initial Investment | Peak-Shaving Ratio (%) | GSHP tor the Basic Heating Load Ratio (%) | Initial Investment |

|---|---|---|---|---|---|---|

| Scenario 1 | 0 | 0 | 4,698.33 | 150.19 | 559.82 | 63.94 |

| Scenario 2 | 30.98 | 10 | 4,429.2 | 268.66 | 654.82 | 42.14 |

| Scenario 3 | 26.42 | 10 | 4,536.32 | 252.32 | 647.82 | 44.91 |

| Scenario 4 | 22.1 | 10 | 4,637.81 | 236.85 | 641.20 | 47.54 |

| Scenario 5 | 18.11 | 10 | 4,731.54 | 222.54 | 635.06 | 49.97 |

| Scenario 6 | 14.42 | 10 | 4,818.22 | 209.33 | 629.4 | 52.22 |

| Scenario 7 | 0 | 10 | 5,156.97 | 157.64 | 607.25 | 61 |

| Scenarios | Peak-Shaving Ratio (%) | Fuel Cost of Thermal Power Plant (USD million) | Fuel Cost of Gas-Fired Boiler (USD million) | Pollutant Charge of Thermal Power Plant (USD million) | Pollutant Charge of Gas-Fired Boiler (USD million) | Residential Heating Expenditure (USD million) |

|---|---|---|---|---|---|---|

| Scenario 1 | 0 | 150.19 | 0 | 63.94 | 0 | 285.67 |

| Scenario 8 | 14.42 | 128.54 | 74.41 | 54.72 | 0.02 | 285.67 |

| Scenario 9 | 18.11 | 122.99 | 93.45 | 52.36 | 0.02 | 285.67 |

| Scenario 10 | 22.1 | 117.00 | 114.04 | 49.81 | 0.03 | 285.67 |

| Scenario 11 | 26.42 | 110.51 | 136.33 | 47.05 | 0.03 | 285.67 |

| Scenario 12 | 30.98 | 103.66 | 159.86 | 44.13 | 0.04 | 285.67 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Q.; Qin, C. Environmental and Economic Benefit Analysis of an Integrated Heating System with Geothermal Energy—A Case Study in Xi’an China. Energies 2017, 10, 2090. https://doi.org/10.3390/en10122090

Yan Q, Qin C. Environmental and Economic Benefit Analysis of an Integrated Heating System with Geothermal Energy—A Case Study in Xi’an China. Energies. 2017; 10(12):2090. https://doi.org/10.3390/en10122090

Chicago/Turabian StyleYan, Qingyou, and Chao Qin. 2017. "Environmental and Economic Benefit Analysis of an Integrated Heating System with Geothermal Energy—A Case Study in Xi’an China" Energies 10, no. 12: 2090. https://doi.org/10.3390/en10122090