Anti-Freezing Mechanism Analysis of a Finned Flat Tube in an Air-Cooled Condenser

Abstract

:1. Introduction

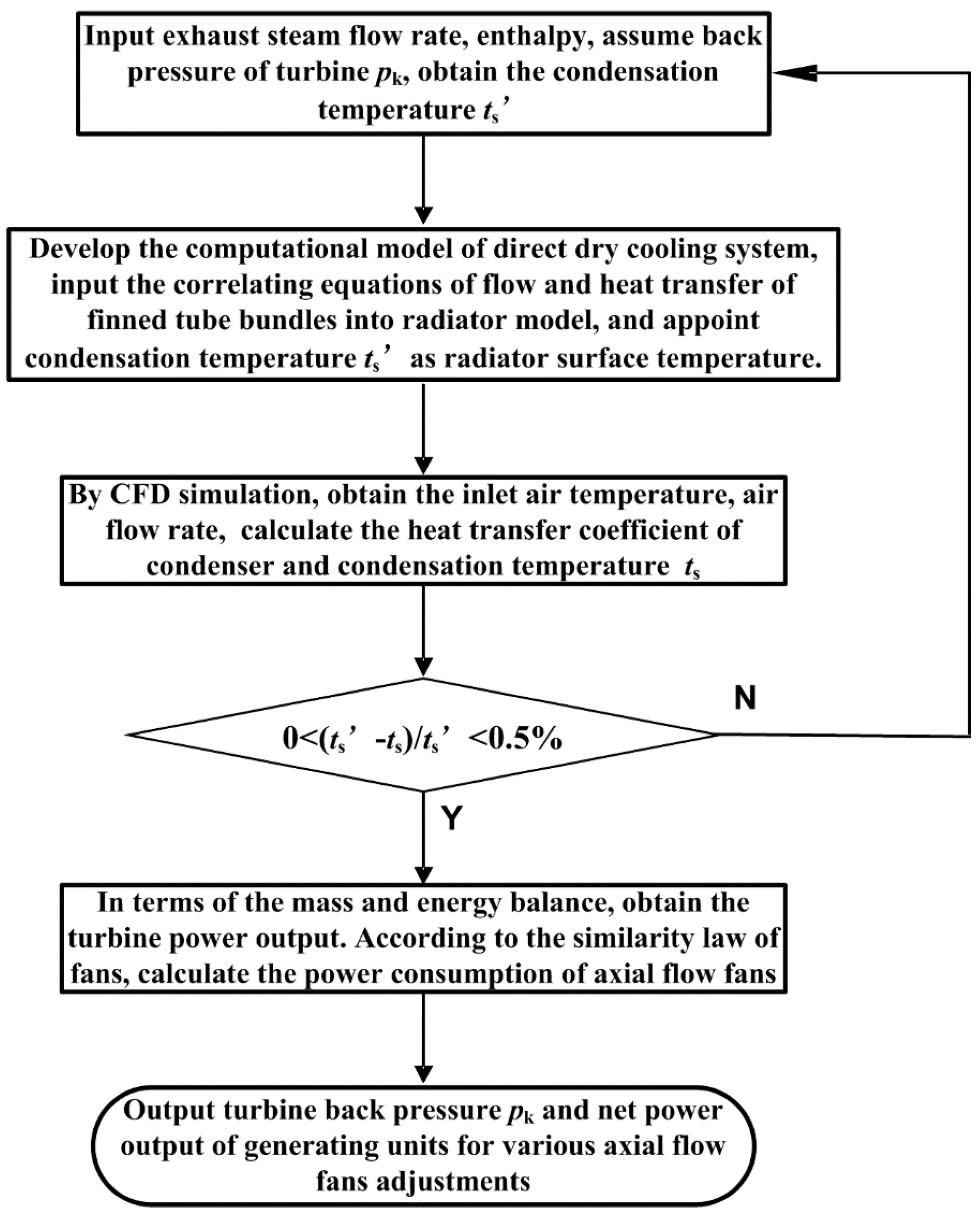

2. Modeling and Methods

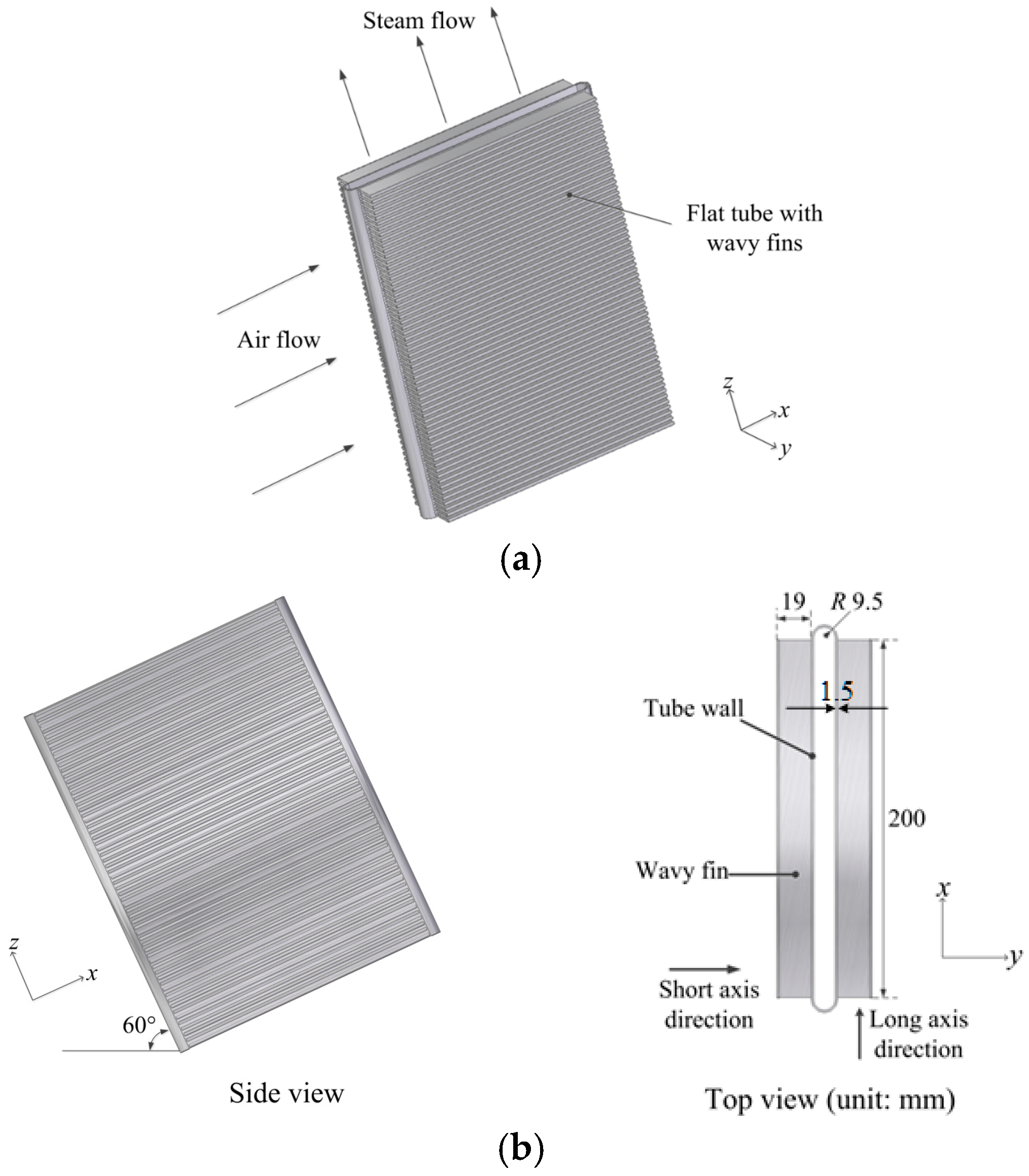

2.1. Physical Model

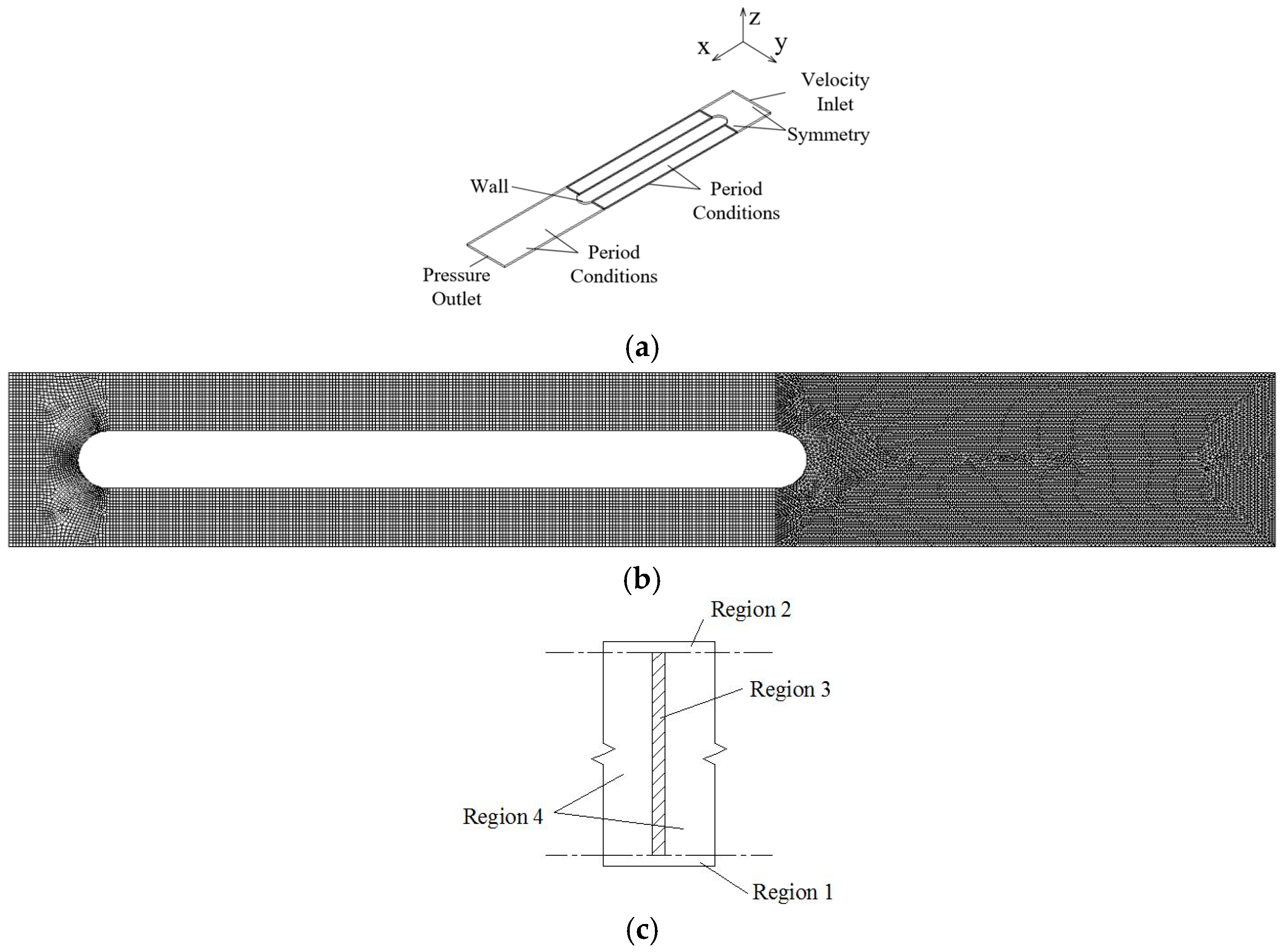

2.2. Numerical Model

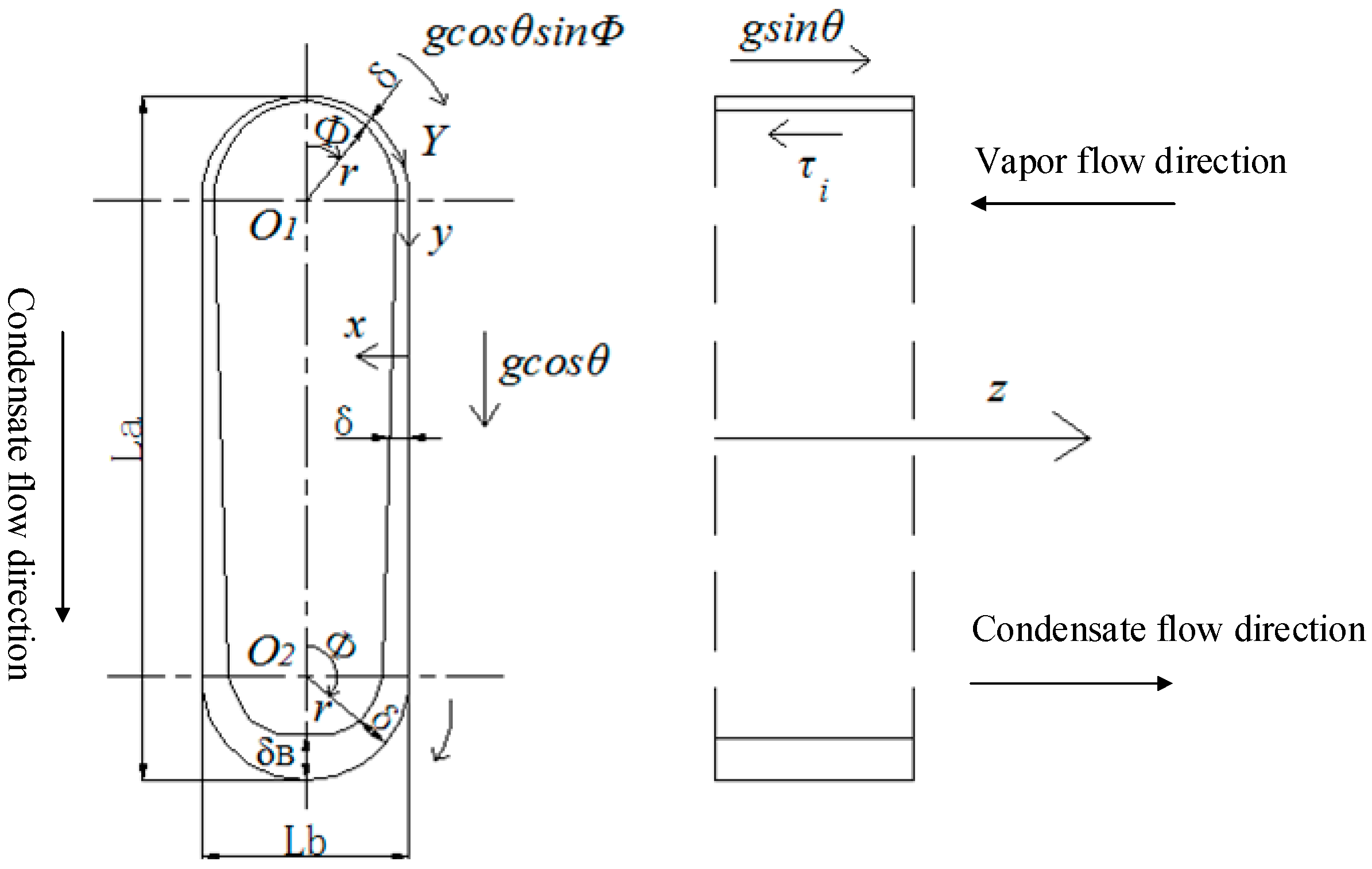

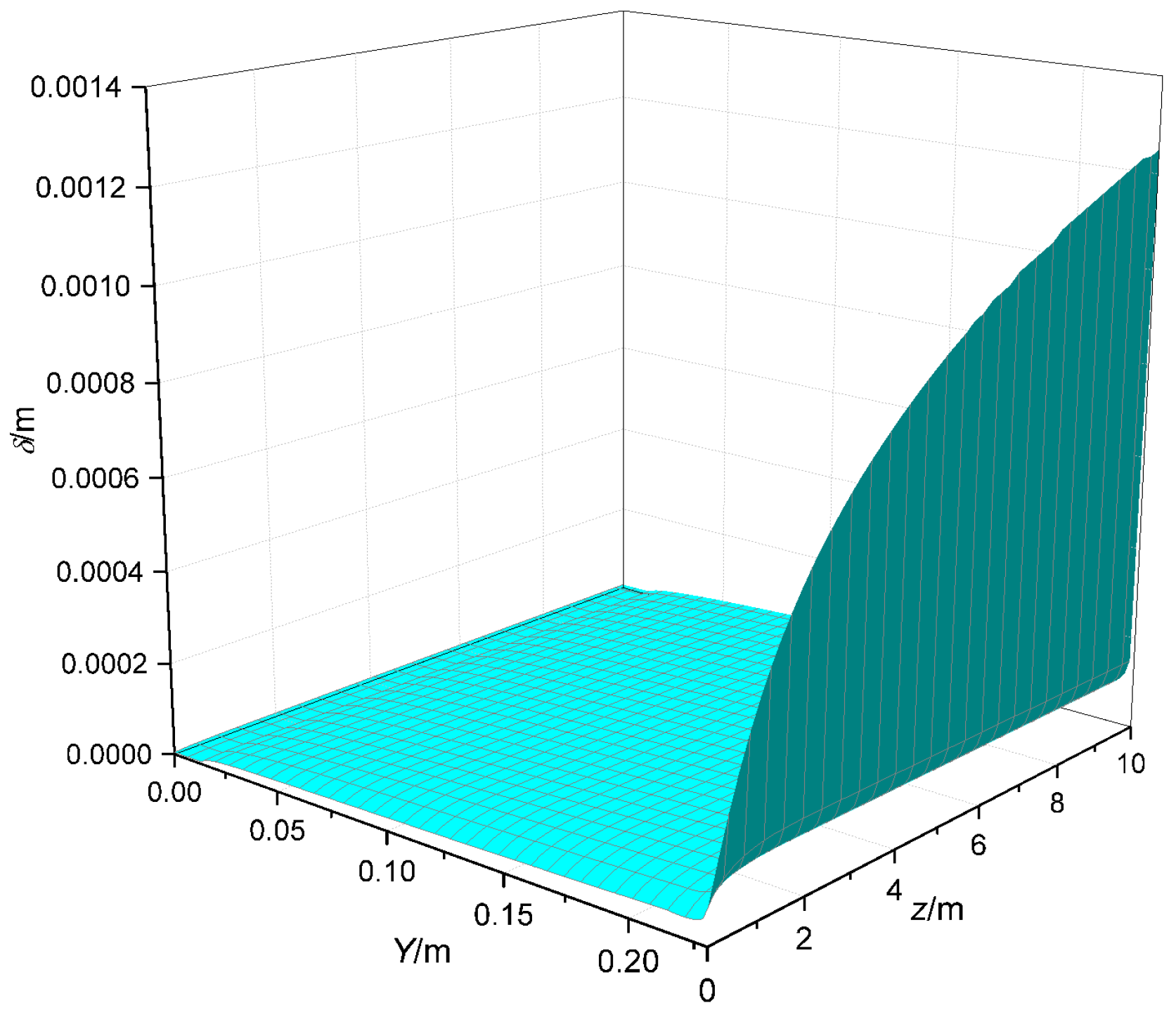

2.3. Condensate Film Development Inside Finned Flat Tube

2.4. Mathematical Model of Condensation

2.4.1. Top Arc Region

2.4.2. Straight Wall Region

2.4.3. Development of Condensation

2.4.4. Condensate Pool Model

2.5. Heat and Mass Transfer Models

3. Result and Discussion

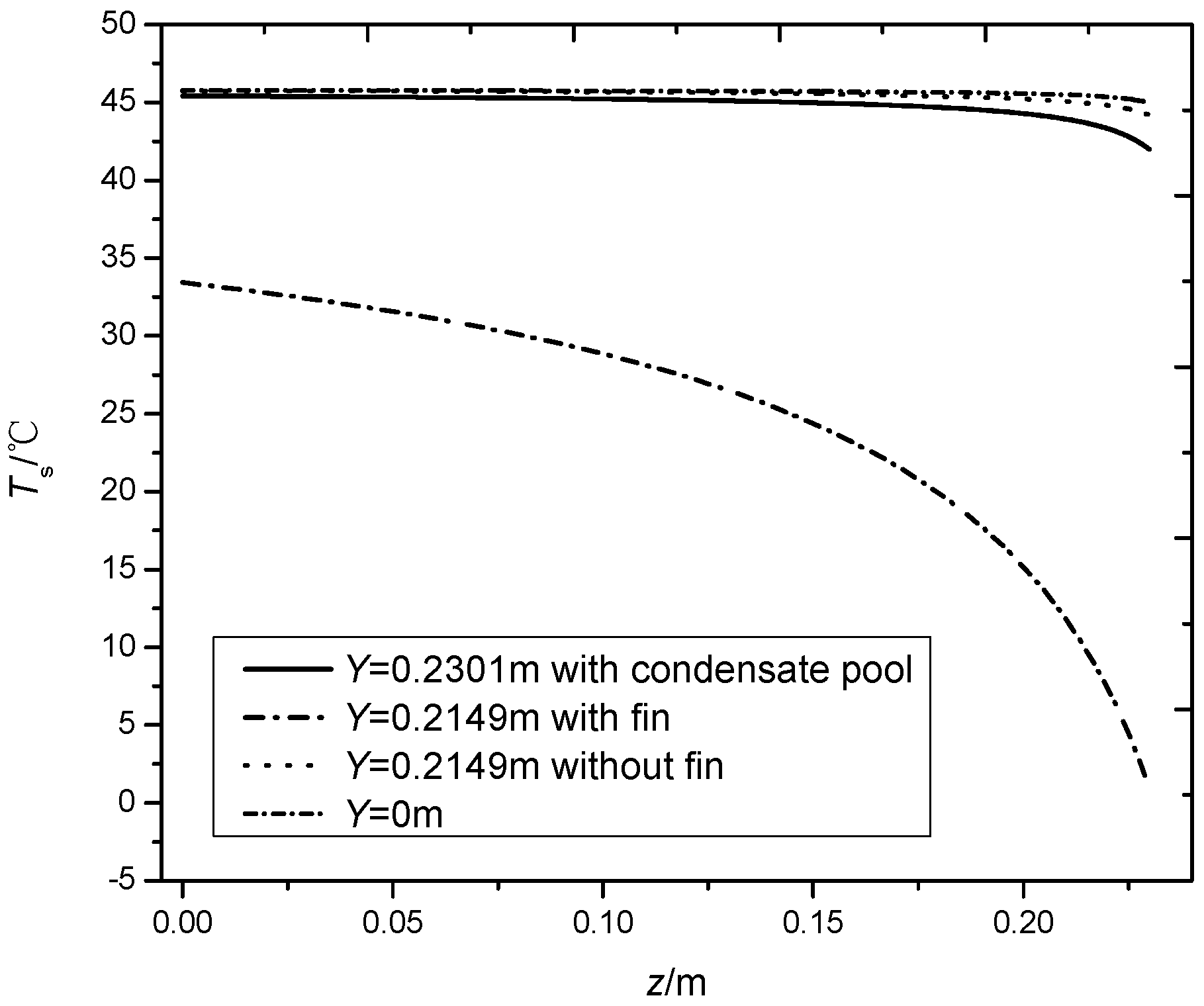

3.1. Typical Case

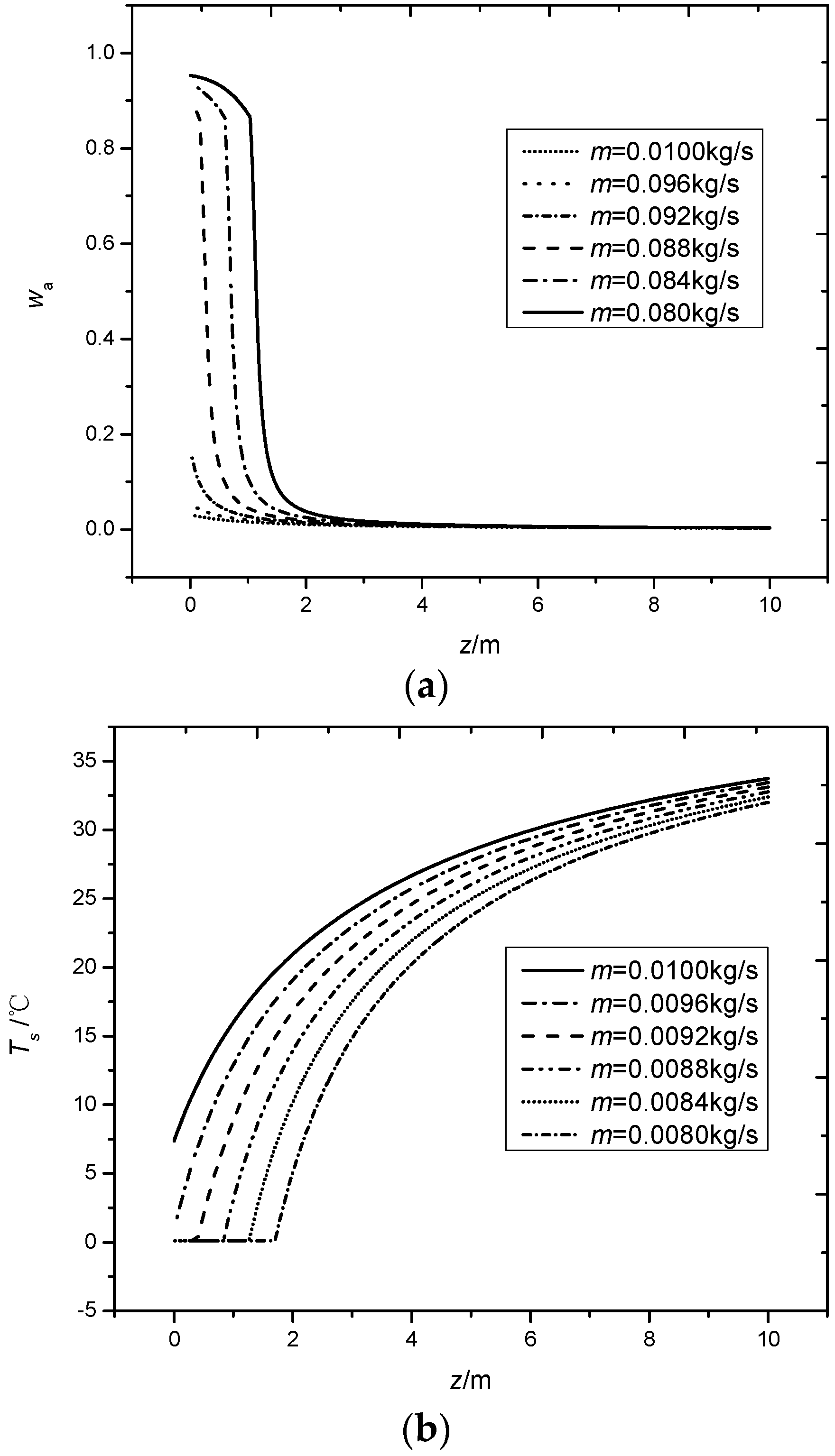

3.2. Effects of Inlet Steam Flow on Freezing Risk

3.3. Effects of Inlet Non-Condensable Gas Flow on Freezing Risk

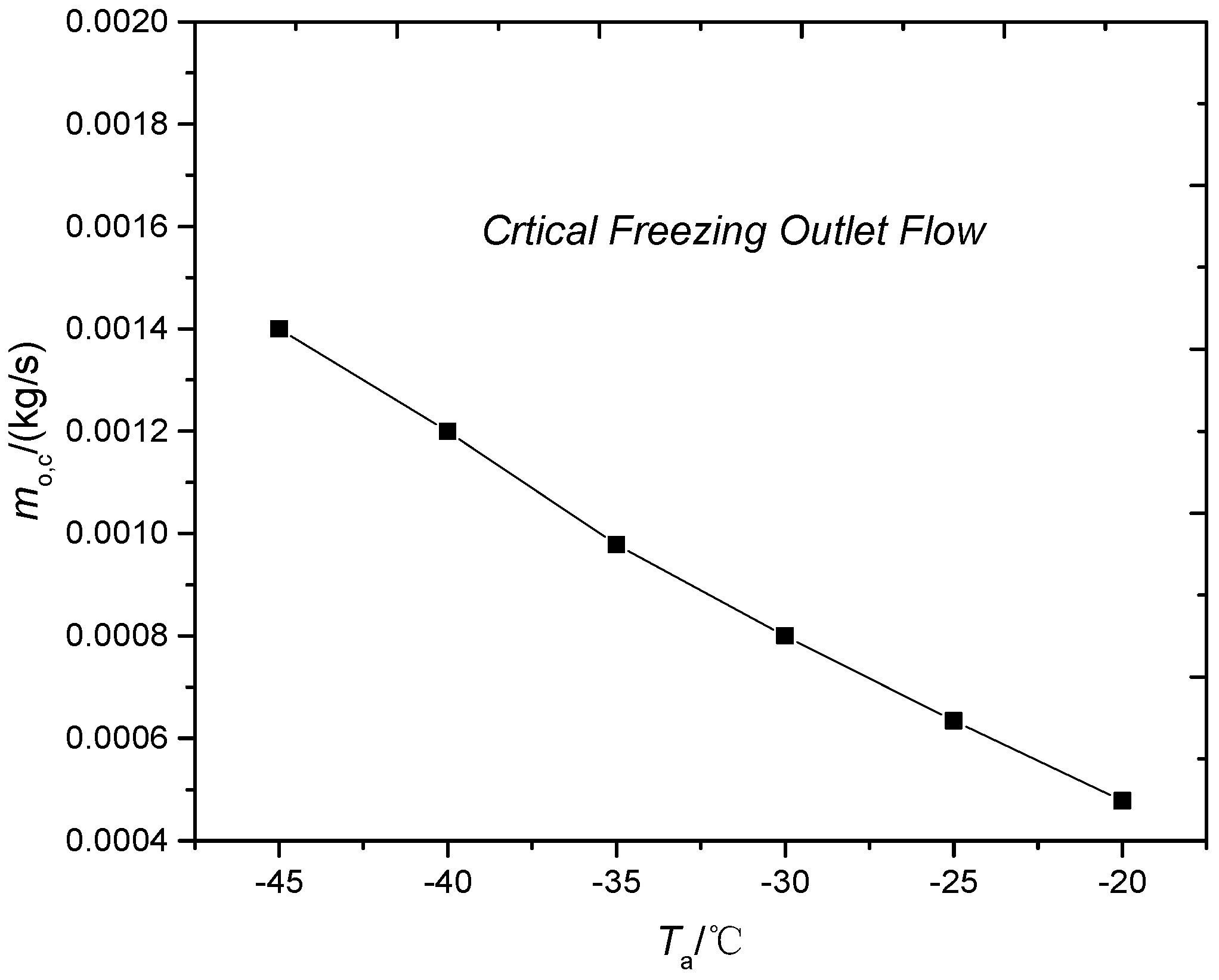

3.4. Effects of Ambient Temperature on Freezing Risk

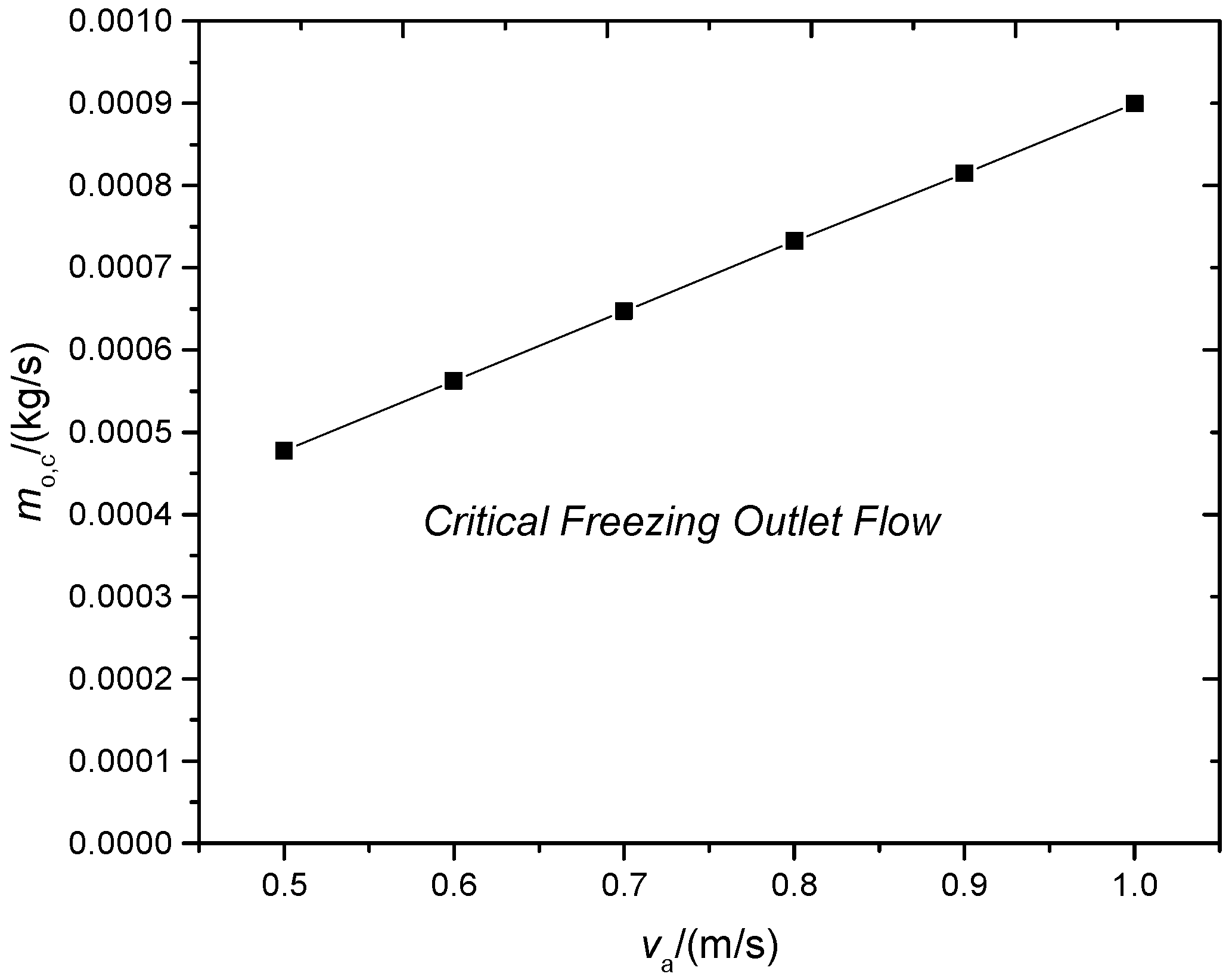

3.5. Effects of Windward Velocity on Freezing Risk

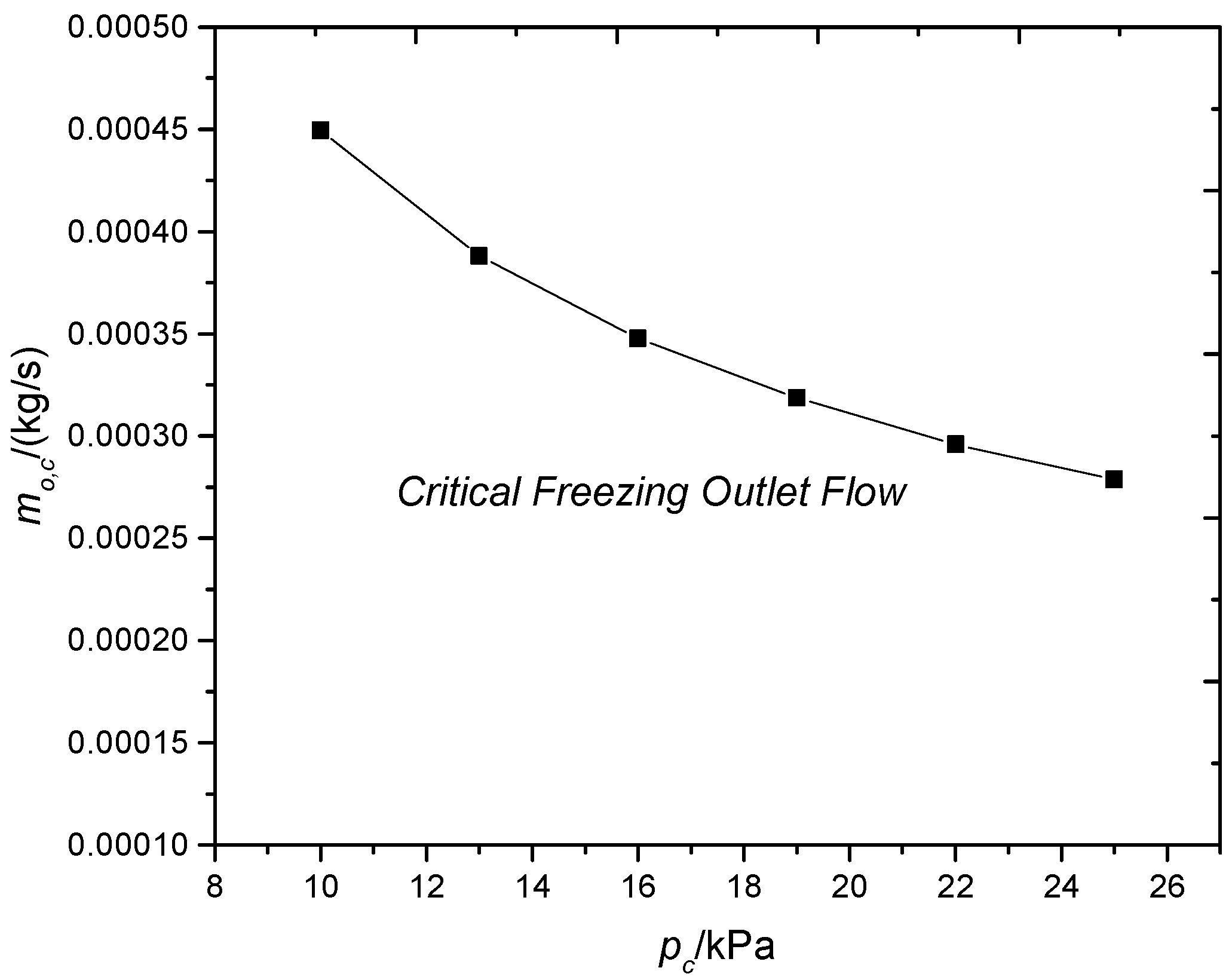

3.6. Effects of Back Pressure on Freezing Risk

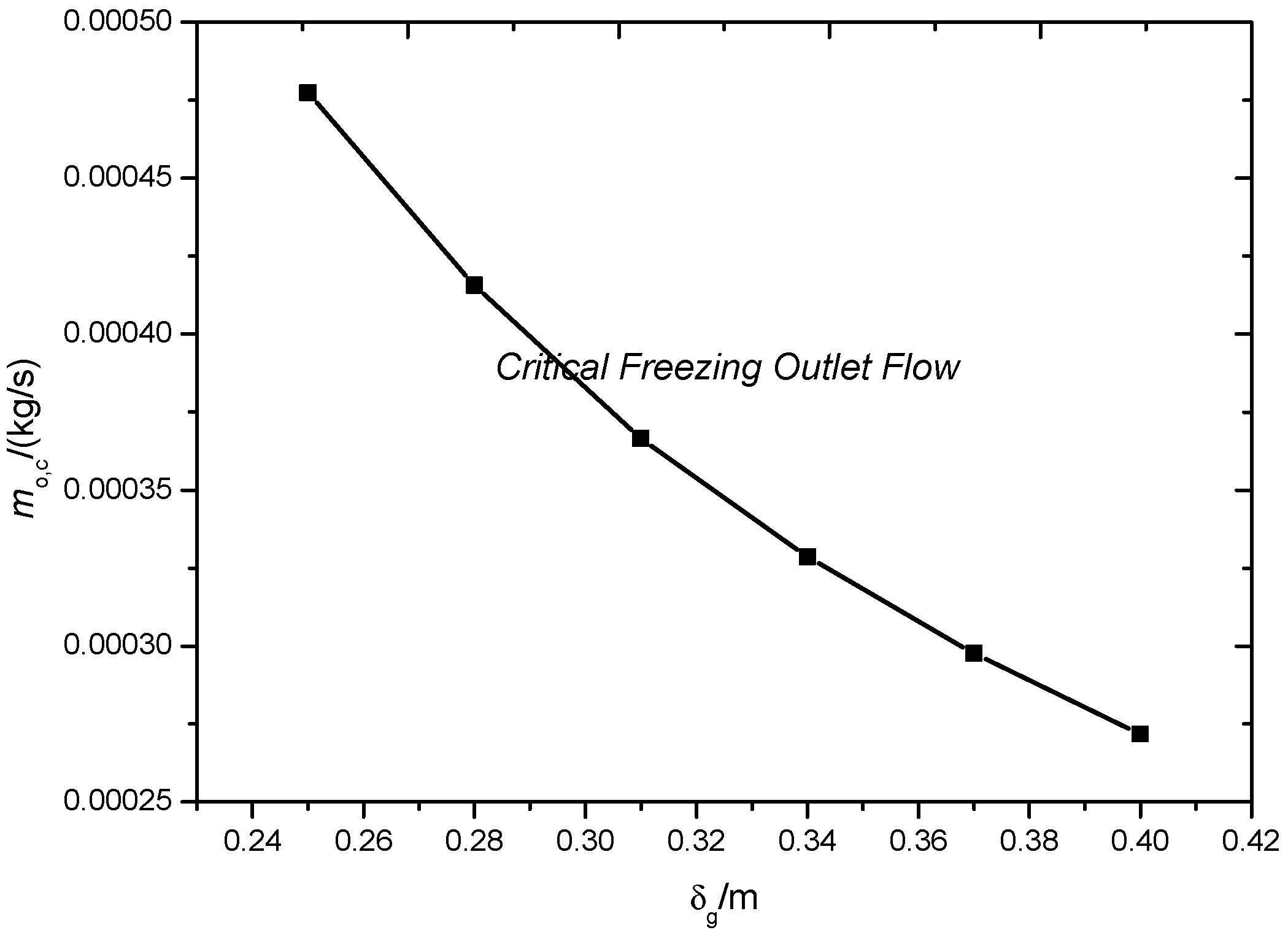

3.7. Effects of Fin Thickness on Freezing Risk

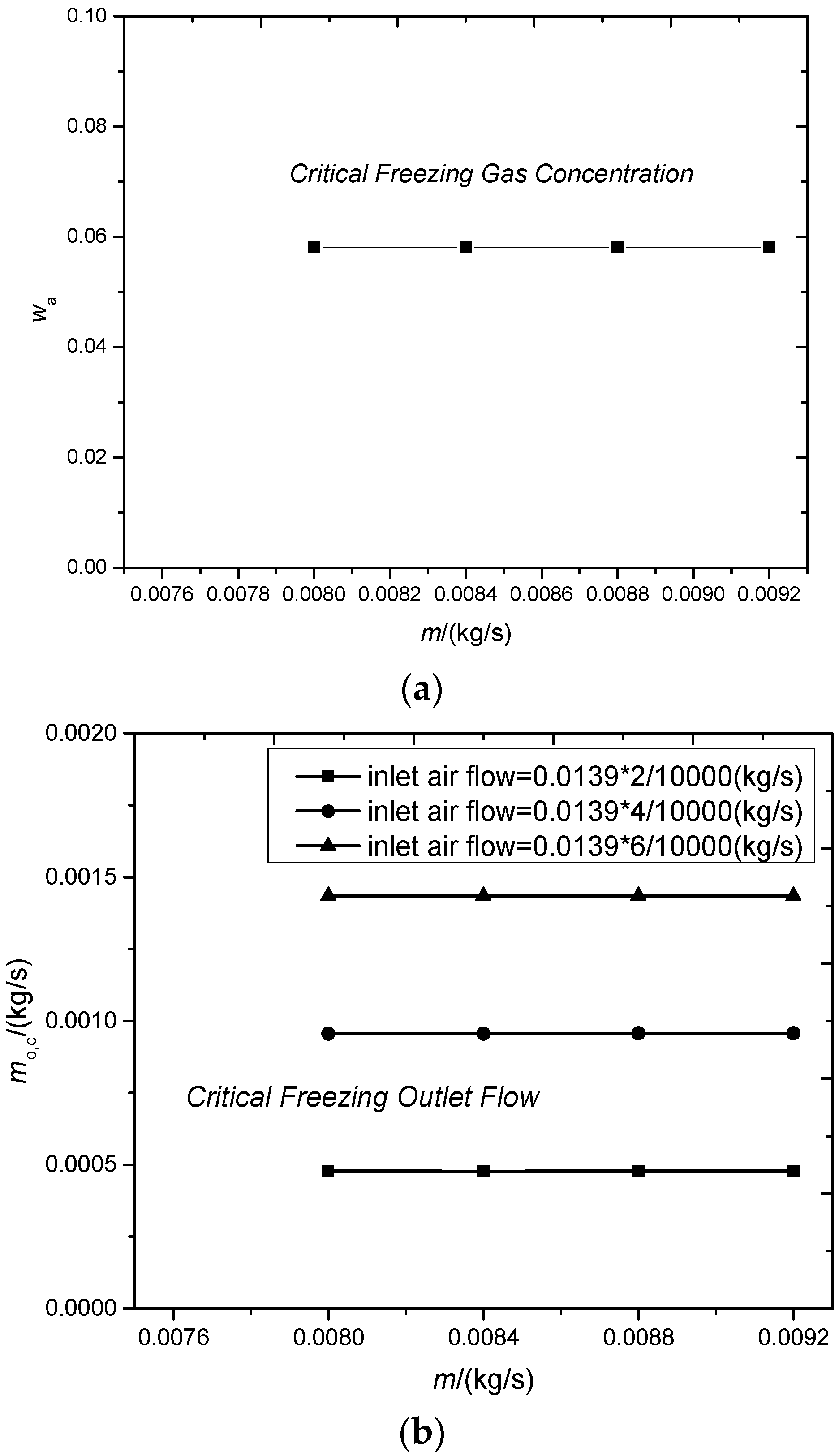

3.8. Adjustment of Critical Freezing Outlet Flow

4. Conclusions

- (1)

- The condensate film on inner flat tube wall has a non-uniform distribution and most of the condensate is formed in the arc region. However, the maximum film thickness at the condensate pool is small, which has little impact on the freezing risk. The lowest temperature occurs at the initial position of the flat fin, resulting from the non-condensable gas collection and big air-side heat capacity.

- (2)

- An adjustment principle of critical freezing outlet flow is proposed. If the outflow of low pressure system is higher than the critical freezing outlet flow, the freezing risk of finned tube bundle can be prevented for ACCs. What’s more, the anti-freezing capacity can be calculated referring to the critical freezing value.

- (3)

- Anti-freezing measures of ACCs are given. In practical engineering, increasing the fin thickness and decreasing the fan rotating speed are proposed as a priority. Besides, increasing the back pressure based on the control logic could also be adopted. However, the adjustment of outlet steam-air flow may not be recommended due to the fixed sealing performance of cold end system.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| A | area of section (m2) |

| cf | friction coefficient for single phase |

| D | equivalent diameter of flat tube (m) |

| F | condensate flow of grid in circumferential direction, (kg·s−1) |

| g | acceleration of gravity, (m·s−2) |

| G | condensate flow of grid in axial direction, (kg·s−1) |

| h | heat transfer coefficient ( W·m−2·°C−1) |

| hfg | latent heat, (kJ·kg−1) |

| m | steam flow (kg·s−1) |

| m″ | mass transfer rate in condensation process (kg·s−1·m−2) |

| p | pressure (Pa) |

| Q | heat transfer rate at grid wall (W) |

| q | thermal flux (W·m−2) |

| R | arc radius of flat tube (m) |

| Re | Reynolds number |

| r | polar radius (m) |

| T | temperature (°C) |

| u | average circumferential velocity of condensate film on straight wall (m·s−1) |

| v | windward velocity (m·s−1) |

| w | average axial velocity of condensate film (m·s−1) |

| x | coordinate from tube inside wall to phase interface (m) |

| y | rectangular coordinate in straight wall (m) |

| Y | curvilinear coordinate following circumferential direction of flat tube (m) |

| z | axial direction of tube (m) |

| Greek symbols | |

| δ | condense film thickness (m) |

| η | dynamic viscosity (Pa·s) |

| λ | conduction coefficient (W·m−1·K−1) |

| ρ | density (kg·m−3) |

| σ | coefficient of surface tension (N·m) |

| θ | declining angle (°) |

| τ | shear stress (N·m−2) |

| φ | polar angle (°) |

| Subscripts | |

| a | air |

| av | average |

| c | curvature |

| f | friction, fin |

| fg | phase change |

| g | steam-gas mixture |

| i | interfacial surface of liquid and vapor |

| l | liquid |

| L | local |

| m | mass transfer |

| s | steam, saturation |

| t | tension |

| w | wall |

References

- Ge, Z.; Du, X.; Yang, L.; Yang, Y.; Li, Y.; Jin, Y. Performance monitoring of direct air-cooled power generating unit with infrared thermography. Appl. Therm. Eng. 2011, 31, 418–424. [Google Scholar] [CrossRef]

- Gu, Z.; Chen, X.; Lubitz, W.; Li, Y.; Luo, W. Wind tunnel simulation of exhaust recirculation in an air-cooling system at a large power plant. Int. J. Therm. Sci. 2007, 46, 308–317. [Google Scholar] [CrossRef]

- Du, X.; Feng, L.; Yang, Y.; Yang, L. Experimental study on heat transfer enhancement of wavy finned flat tube with longitudinal vortex generators. Appl. Therm. Eng. 2013, 50, 55–62. [Google Scholar] [CrossRef]

- Yang, L.; Tan, H.; Du, X.; Yang, Y. Thermal-flow characteristics of the new wave-finned flat tube bundles in air-cooled condensers. Int. J. Therm. Sci. 2012, 53, 166–174. [Google Scholar] [CrossRef]

- Hu, H.; Du, X.; Yang, L.; Yang, Y.; Cheng, T. Cross scale simulation on transport phenomena of direct air-cooling system of power generating units based on reduced order modeling. Int. J. Heat Mass Transf. 2014, 75, 156–164. [Google Scholar] [CrossRef]

- Nebuloni, S.; Thome, J.R. Film condensation under normal and microgravity: Effect of channel shape. Microgravity Sci. Technol. 2007, 19, 125–127. [Google Scholar] [CrossRef]

- Nebuloni, S.; Thome, J.R. Numerical modeling of laminar annular film condensation for different channel shapes. Int. J. Heat Mass Transf. 2010, 53, 2615–2627. [Google Scholar] [CrossRef]

- Nebuloni, S.; Thome, J.R. Numerical modeling of the effects of oil on annular laminar film condensation in minichannels. Int. J. Refrig. 2013, 36, 1545–1556. [Google Scholar] [CrossRef]

- Szczukiewicz, S.; Magnini, M.; Thome, J.R. Proposed models, ongoing experiments, and latest numerical simulations of microchannel two-phase flow boiling. Int. J. Multiph. Flow 2014, 59, 84–101. [Google Scholar] [CrossRef]

- Almmer, A.; Bakran, B.; Hoxtermann, L. VGB Guideline Acceptance Test Measurements and Operation Monitoring of Air-Cooled Condensers under Vacuum; Vgb Technische Vereinigung Der Grosskraftwerksbetreiber EV: Essen, Germany, 1997. [Google Scholar]

- Zanobini, A. Formation and development of non-condensable gases in air cooled steam condensers. Quad. Pignone 1982, 34, 39–45. [Google Scholar]

- Joo, J.A.; Hwang, I.H.; Lee, D.H.; Cho, Y.I. Preventing freezing of condensate inside tubes of air cooled condenser. Trans. Korean Soc. Mech. Eng. B 2012, 36, 811–819. [Google Scholar] [CrossRef]

- Larinoff, M. Air-cooled steam condensers non-freeze warranties. In Proceedings of the American Power Conference, Chicago, IL, USA, 18–20 April 1995. [Google Scholar]

- Larinoff, M. Inquiry specs can improve air-cooled condenser design. Power Eng. 1990, 94, 41–43. [Google Scholar]

- Wang, W.; Yang, L.; Du, X.; Yang, Y. Anti-freezing water flow rates of various sectors for natural draft dry cooling system under wind conditions. Int. J. Heat Mass Transf. 2016, 102, 186–200. [Google Scholar] [CrossRef]

- Wang, W.; Kong, Y.; Huang, X.; Yang, L.; Du, X.; Yang, Y. Anti-freezing of air-cooled heat exchanger by switching off sectors. Appl. Therm. Eng. 2017, 120, 327–339. [Google Scholar] [CrossRef]

- Chen, L.; Yang, L.; Du, X.; Yang, Y. Anti-freezing of air-cooled heat exchanger by air flow control of louvers in power plants. Appl. Therm. Eng. 2016, 106, 537–550. [Google Scholar] [CrossRef]

- Zeng, S. Numerical Investigation of the Heat Transfer and Fluid Flow of Finned-Tube and the Flow Characteristics of a Condenser Unit in Direct Air-Cooled Power Plant; Beijing Jiaotong University: Beijing, China, 2007. [Google Scholar]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Bortolin, S.; Da Riva, E.; Del Col, D. Condensation in a square minichannel: Application of the VOF method. Heat Transf. Eng. 2014, 35, 193–203. [Google Scholar] [CrossRef]

- Das, S.; Gada, V.H.; Sharma, A. Analytical and Level Set Method-Based Numerical Study for Two-Phase Stratified Flow in a Pipe. Numer. Heat Transf. Part A Appl. 2015, 67, 1253–1281. [Google Scholar] [CrossRef]

- Wang, H.; Rose, J. Effect of interphase matter transfer on condensation on low-finned tubes—A theoretical investigation. Int. J. Heat Mass Transf. 2004, 47, 179–184. [Google Scholar] [CrossRef]

- Wang, H.; Rose, J.W. Film condensation in horizontal microchannels: Effect of channel shape. In Proceedings of the ASME 3rd International Conference on Microchannels and Minichannels, Toronto, ON, Canada, 13–15 June 2005; pp. 729–735. Available online: http://proceedings.asmedigitalcollection.asme.org/proceeding.aspx?articleid=1573844 (accessed on 20 September 2017).

- Wang, H.; Rose, J.W. Theory of heat transfer during condensation in microchannels. Int. J. Heat Mass Transf. 2011, 54, 2525–2534. [Google Scholar] [CrossRef]

- Fiedler, S.; Auracher, H. Experimental and theoretical investigation of reflux condensation in an inclined small diameter tube. Int. J. Heat Mass Transf. 2004, 47, 4031–4043. [Google Scholar] [CrossRef]

- Fiedler, S.; Thonon, B.; Auracher, H. Flooding in small-scale passages. Exp. Therm. Fluid Sci. 2002, 26, 525–533. [Google Scholar] [CrossRef]

- Fiedler, S.; Auracher, H.; Winkelmann, D. Effect of inclination on flooding and heat transfer during reflux condensation in a small diameter tube. Int. Commun. Heat Mass Transf. 2002, 29, 289–302. [Google Scholar] [CrossRef]

- Fiedler, S.; Auracher, H. Pressure drop during reflux condensation of R134A in a small diameter tube. Exp. Therm. Fluid Sci. 2004, 28, 139–144. [Google Scholar] [CrossRef]

- Cheng, T.; Du, X.; Yang, L. Experimental and Theoretical Analysis on Reflux Flow Condensation of Vapor Inside Flat Tube. 2015. Available online: https://www.researchgate.net/publication/317255194_Experimental_and_theoretical_analysis_on_reflux_flow_condensation_of_vapor_inside_flat_tube (accessed on 18 September 2017).

- Wang, B.-X.; Du, X.-Z. Study on laminar film-wise condensation for vapor flow in an inclined small/mini-diameter tube. Int. J. Heat Mass Transf. 2000, 43, 1859–1868. [Google Scholar] [CrossRef]

- Uchida, H.; Oyama, A.; Togo, Y. Evaluation of Post-Incident Cooling Systems of Light Water Power Reactors; Tokyo University: Bunkyo, Tokyo, 1964. [Google Scholar]

- Rose, J. Approximate equations for forced-convection condensation in the presence of a non-condensing gas on a flat plate and horizontal tube. Int. J. Heat Mass Transf. 1980, 23, 539–546. [Google Scholar] [CrossRef]

- Nagae, T.; Murase, M.; Chikusa, T.; Vierow, K.; Wu, T. Reflux condensation heat transfer of steam-air mixture under turbulent flow conditions in a vertical tube. J. Nucl. Sci. Technol. 2007, 44, 171–182. [Google Scholar] [CrossRef]

- Nagae, T.; Chikusa, T.; Murase, M.; Minami, N. Analysis of noncondensable gas recirculation flow in steam generator U-tubes during reflux condensation using RELAP5. J. Nucl. Sci. Technol. 2007, 44, 1395–1406. [Google Scholar] [CrossRef]

- Nithianandan, C.; Morgan, C.; Shah, N.; Miller, F. RELAP5/MOD2 model for surface condensation in the presence of noncondensable gases. In Proceedings of the 8th International Heat Transfer Conference, San Francisco, CA, USA, 17–22 August 1986; pp. 1627–1633. [Google Scholar]

- Colburn, A.P.; Hougen, O.A. Design of cooler condensers for mixtures of vapors with noncondensing gases. Ind. Eng. Chem. 1934, 26, 1178–1182. [Google Scholar] [CrossRef]

- Peterson, P. Theoretical basis for the Uchida correlation for condensation in reactor containments. Nucl. Eng. Des. 1996, 162, 301–306. [Google Scholar] [CrossRef]

- Peterson, P.F. Diffusion layer modeling for condensation with multicomponent noncondensable gases. J. Heat Transf. 2000, 122, 716–720. [Google Scholar] [CrossRef]

- Liao, Y.; Vierow, K. A generalized diffusion layer model for condensation of vapor with noncondensable gases. J. Heat Transf. 2007, 129, 988–994. [Google Scholar] [CrossRef]

| Variables | wa | Ta/°C | va/(m/s) | pc/kPa | δg/mm |

|---|---|---|---|---|---|

| Variable increment | 2.2/100,000 | 1 | 0.1 | 1 | 0.01 |

| Critical freezing outlet flow increment (kg/s) | 2.390 × 10−5 | 3.690 × 10−5 | 8.445 × 10−5 | 1.428 × 10−5 | 1.370 × 10−5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Cheng, T.; Du, X.; Yang, L. Anti-Freezing Mechanism Analysis of a Finned Flat Tube in an Air-Cooled Condenser. Energies 2017, 10, 1872. https://doi.org/10.3390/en10111872

Guo Y, Cheng T, Du X, Yang L. Anti-Freezing Mechanism Analysis of a Finned Flat Tube in an Air-Cooled Condenser. Energies. 2017; 10(11):1872. https://doi.org/10.3390/en10111872

Chicago/Turabian StyleGuo, Yonghong, Tongrui Cheng, Xiaoze Du, and Lijun Yang. 2017. "Anti-Freezing Mechanism Analysis of a Finned Flat Tube in an Air-Cooled Condenser" Energies 10, no. 11: 1872. https://doi.org/10.3390/en10111872