Development Patterns of Fractured Water-Conducting Zones in Longwall Mining of Thick Coal Seams—A Case Study on Safe Mining Under the Zhuozhang River

Abstract

:1. Introduction

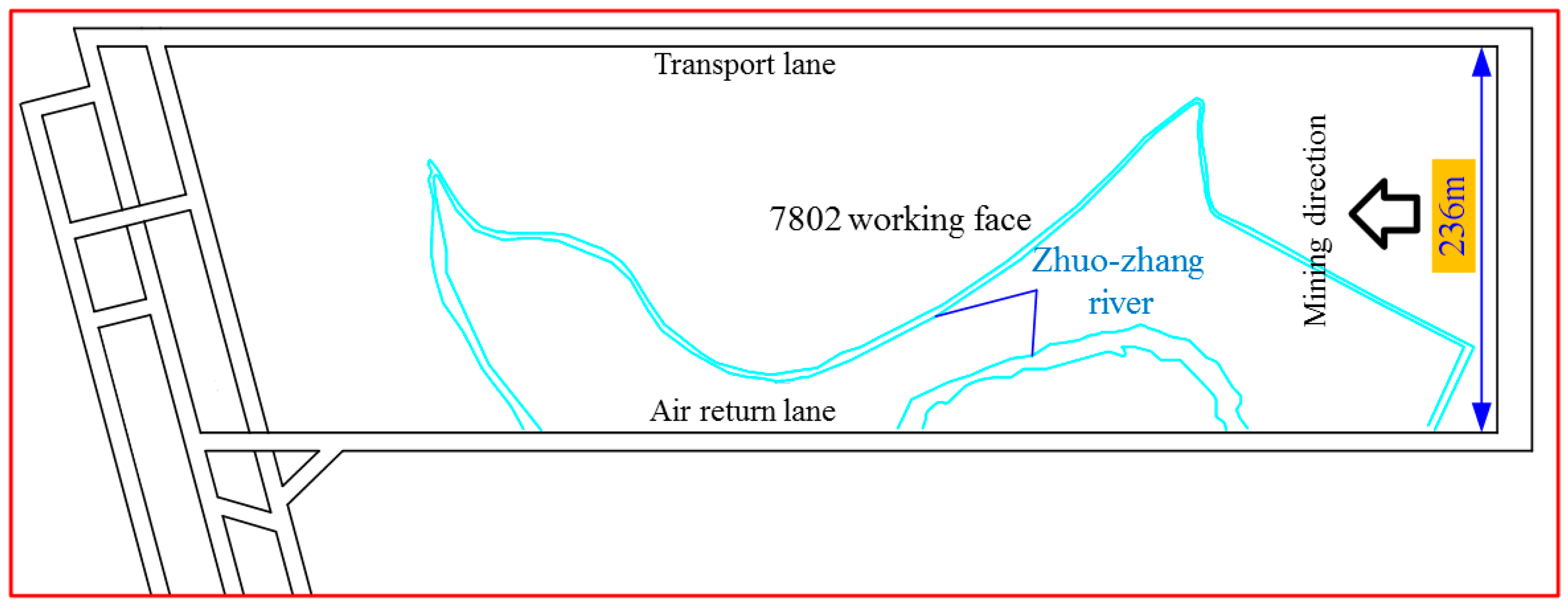

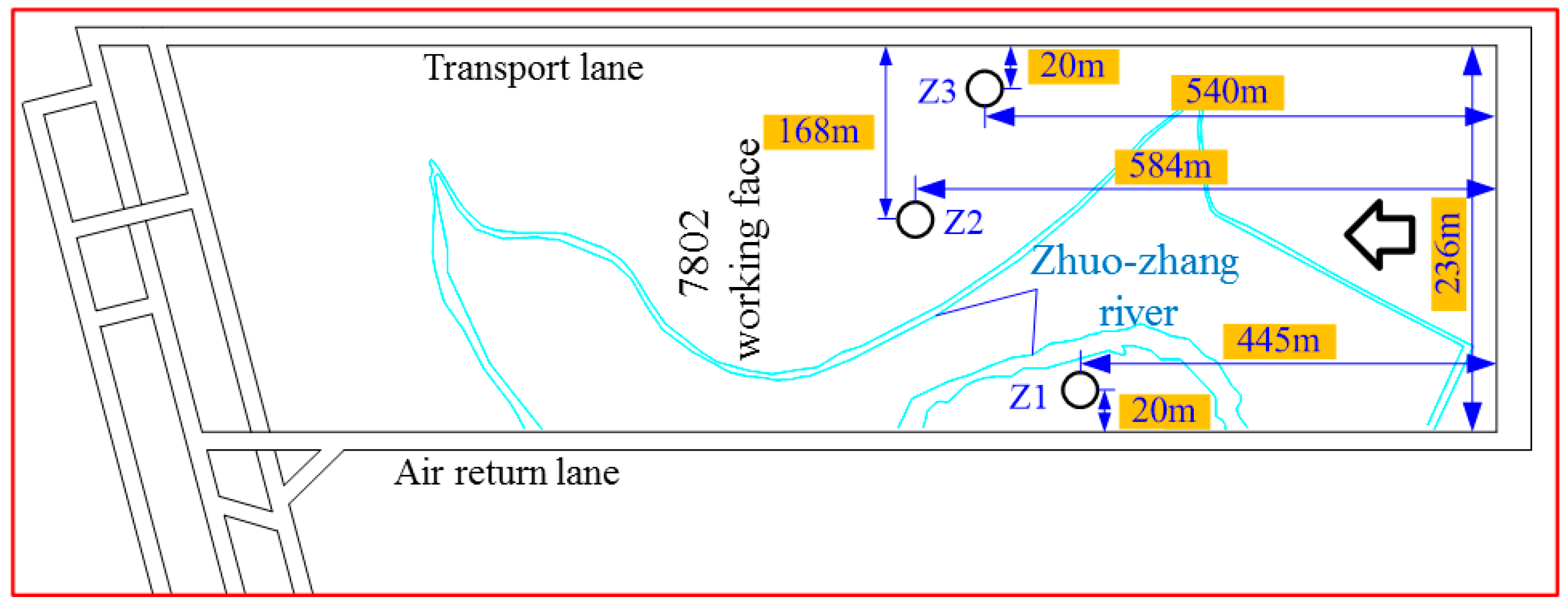

2. Background

3. Numerical Modeling

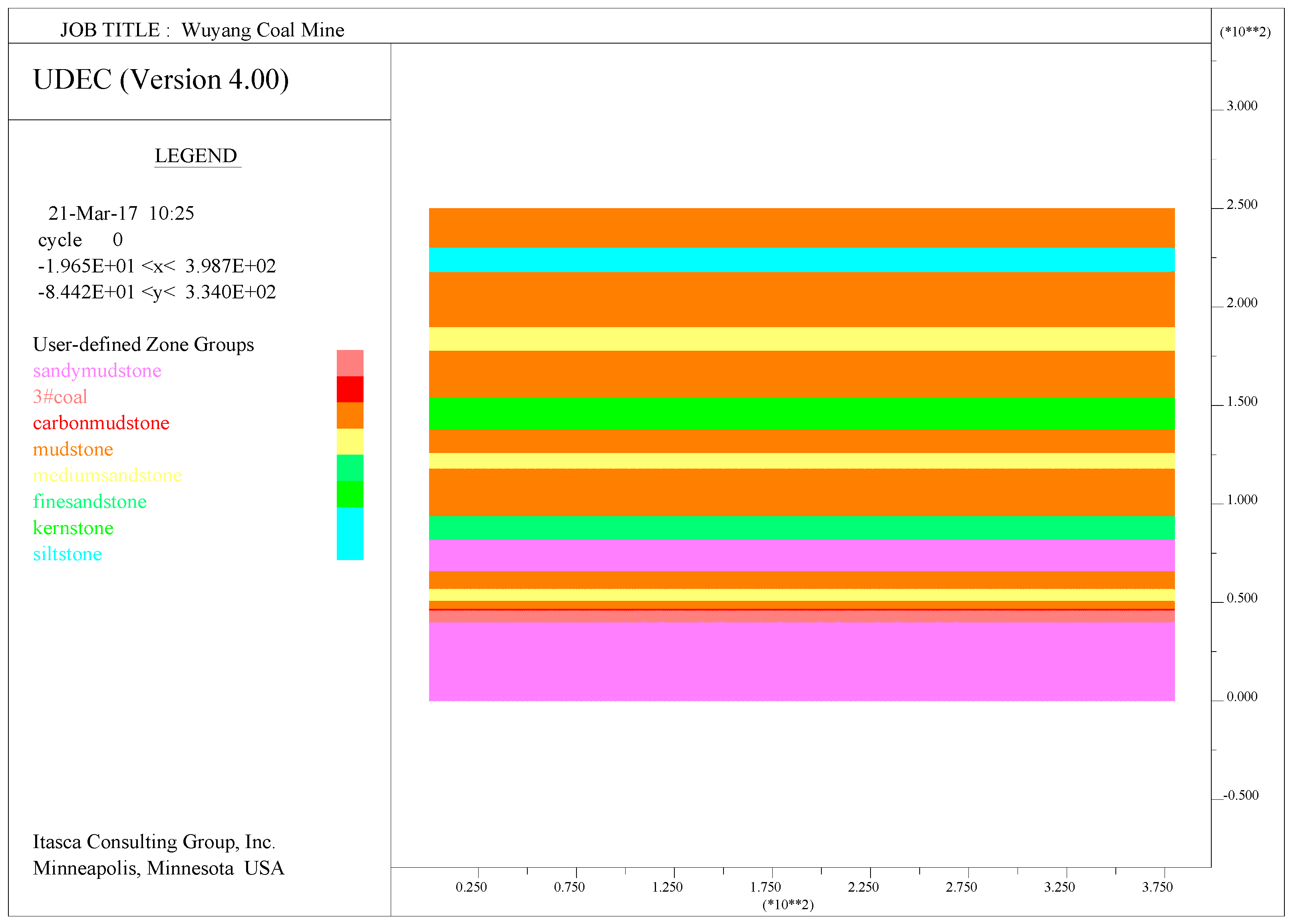

3.1. Numerical Calculation Models

3.1.1. Geometric Model

3.1.2. Boundary Conditions

3.1.3. Excavation Processes

3.1.4. Numerical Calculation Scheme

3.1.5. Classification Criteria for the Water Flowing Fractured Zone

3.2. Simulation Results and Analysis

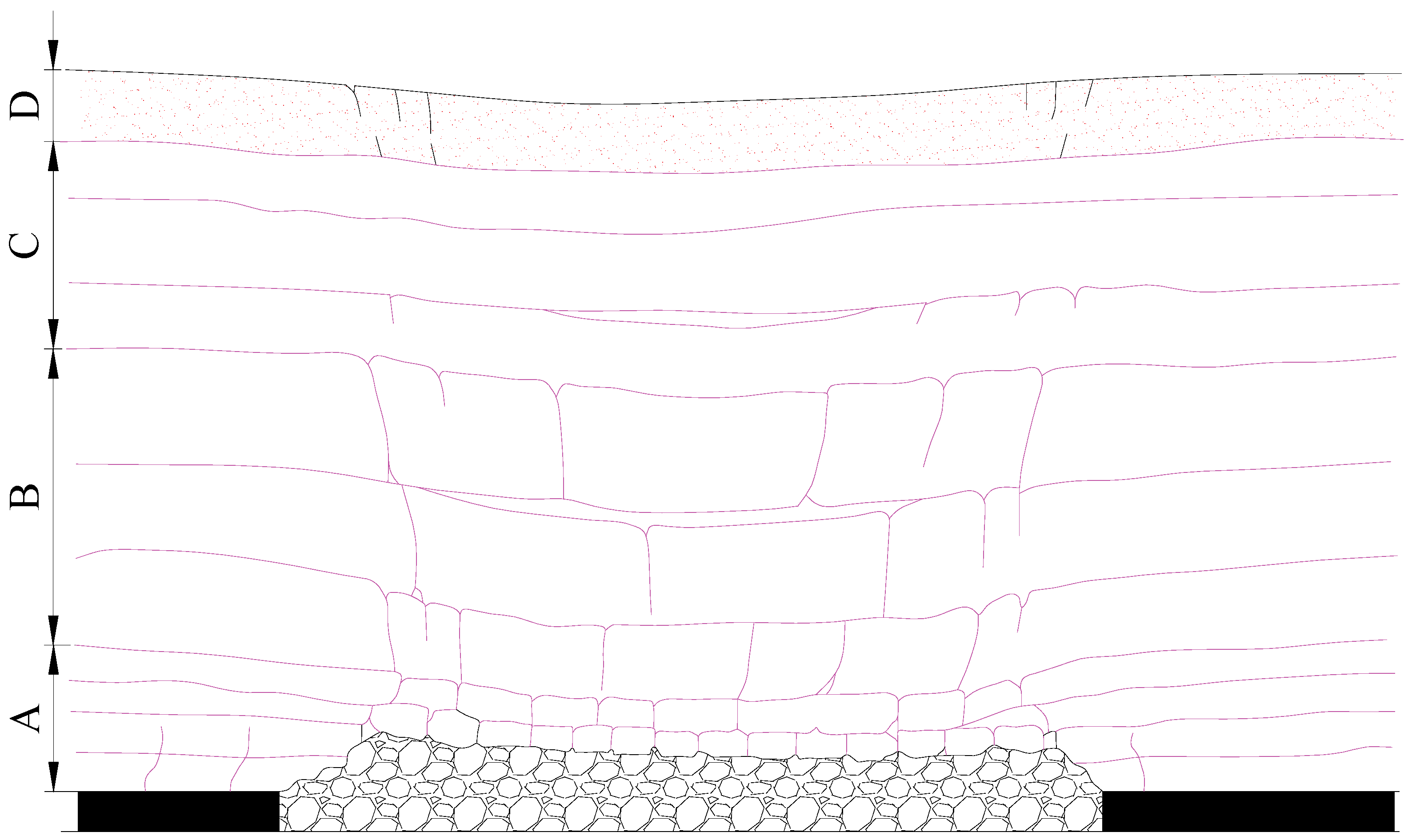

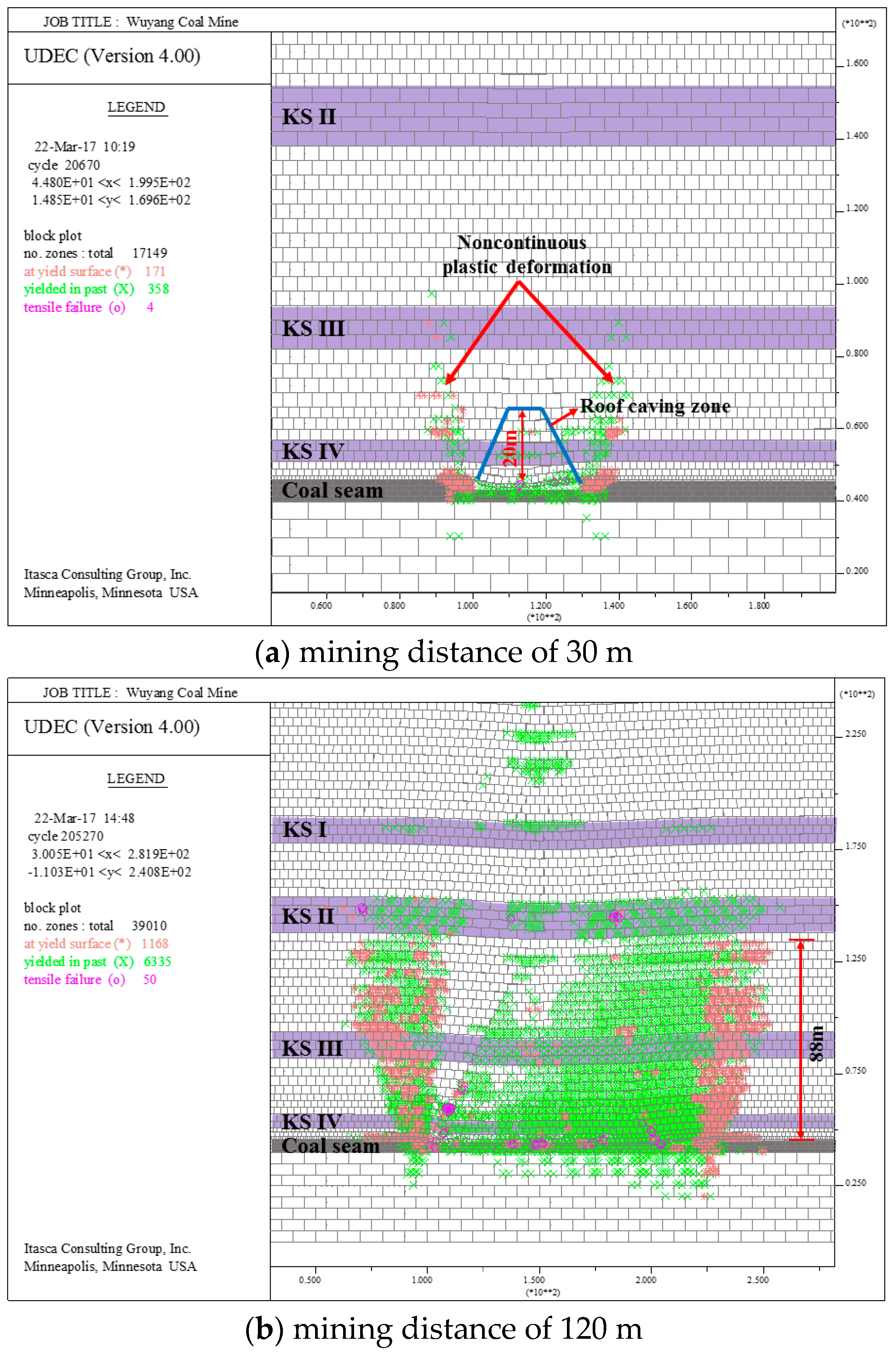

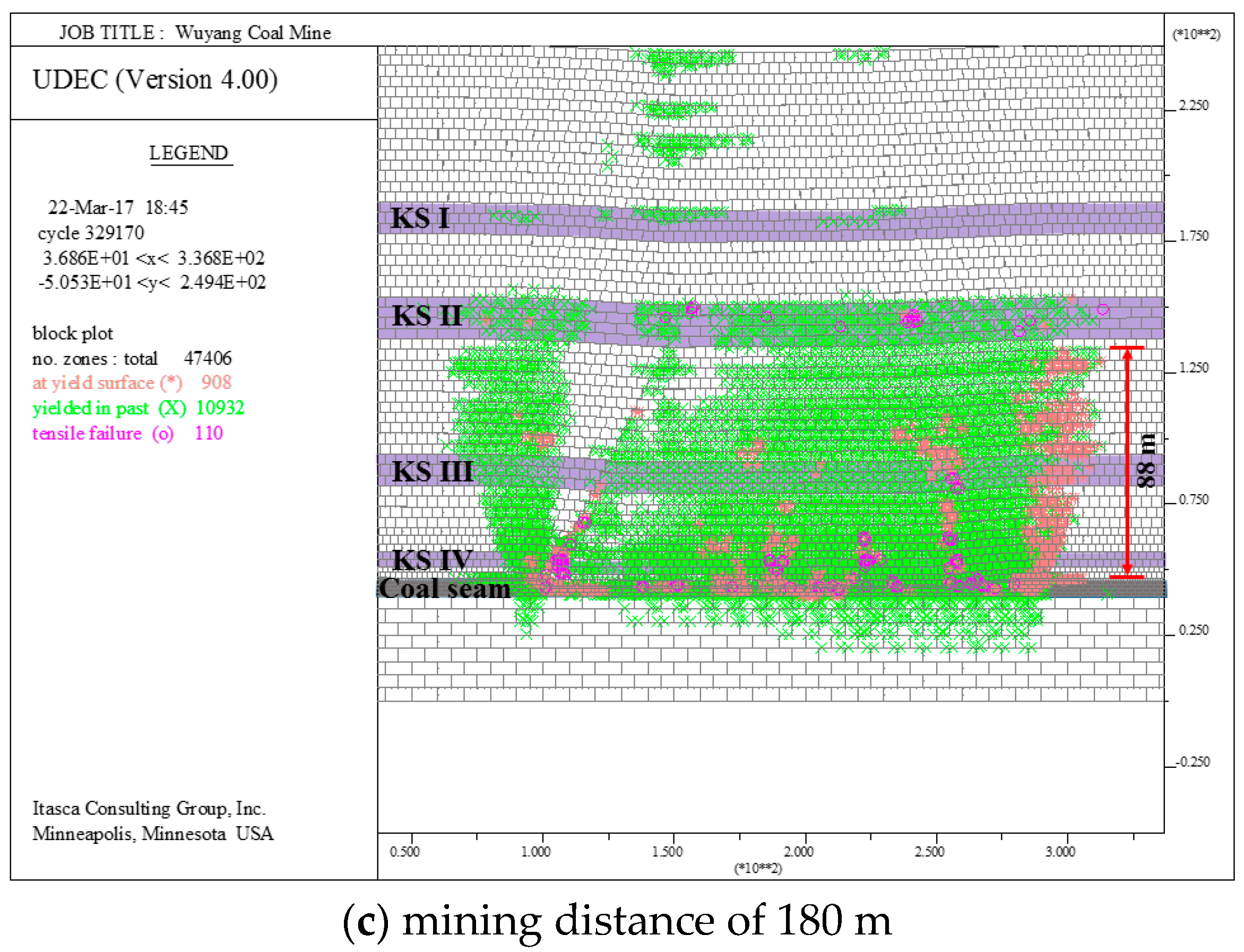

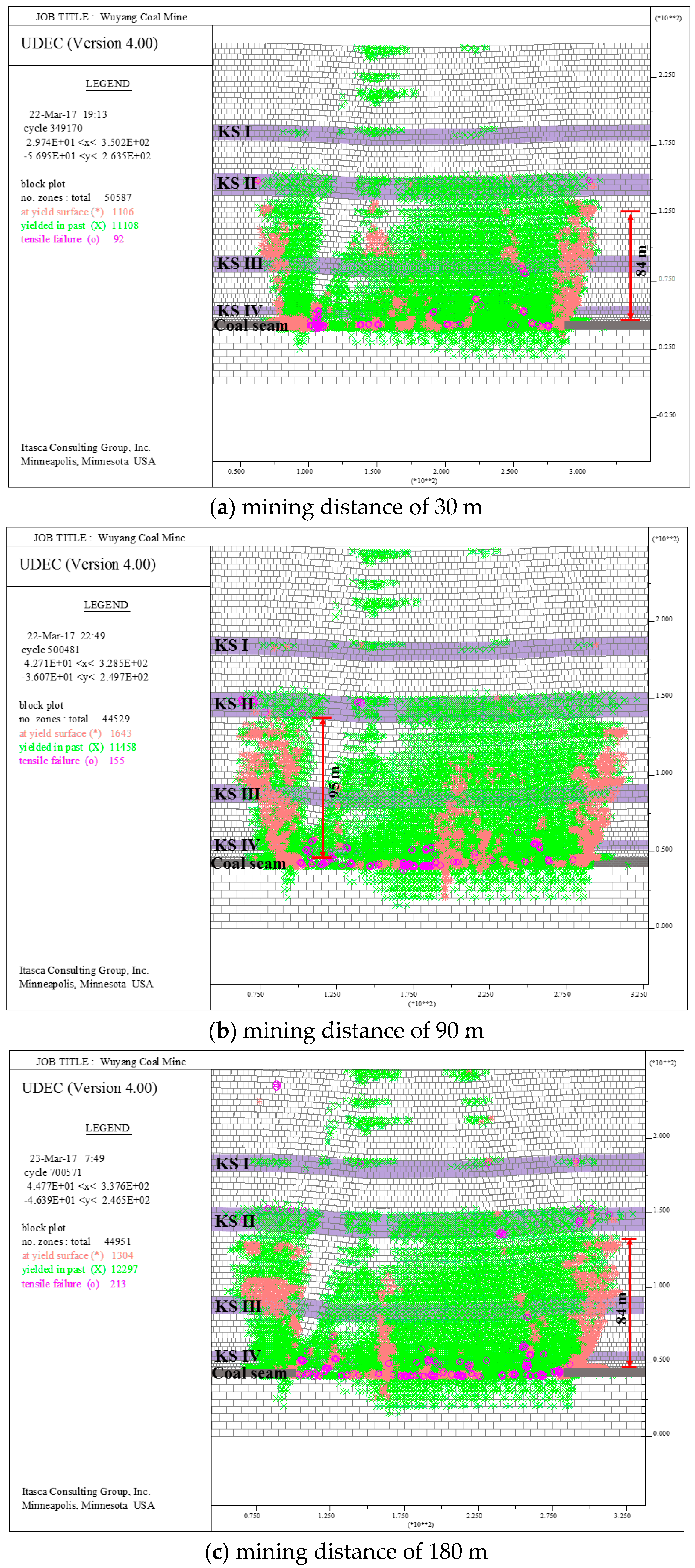

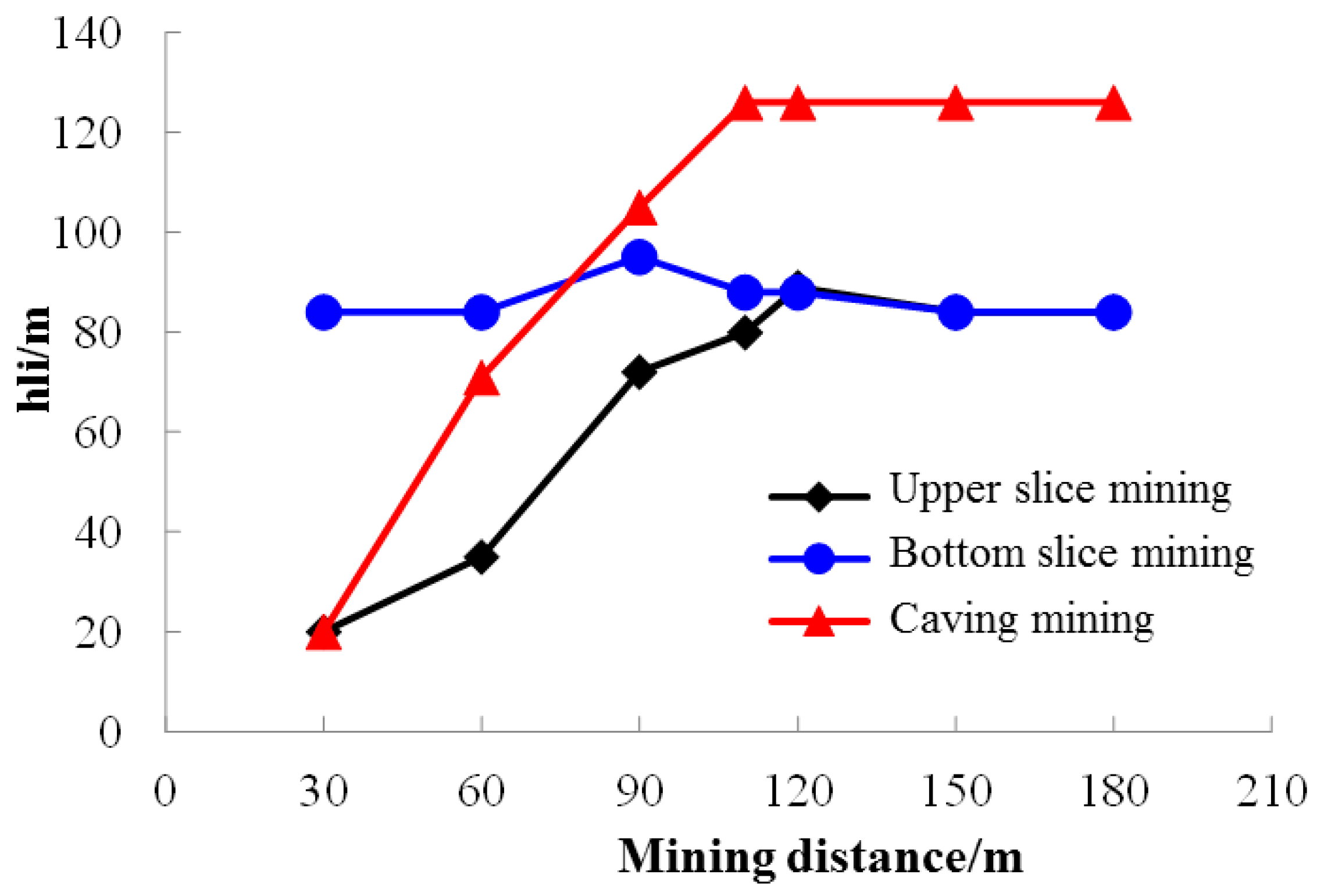

3.2.1. Development Patterns of FWCZ during Slice Mining

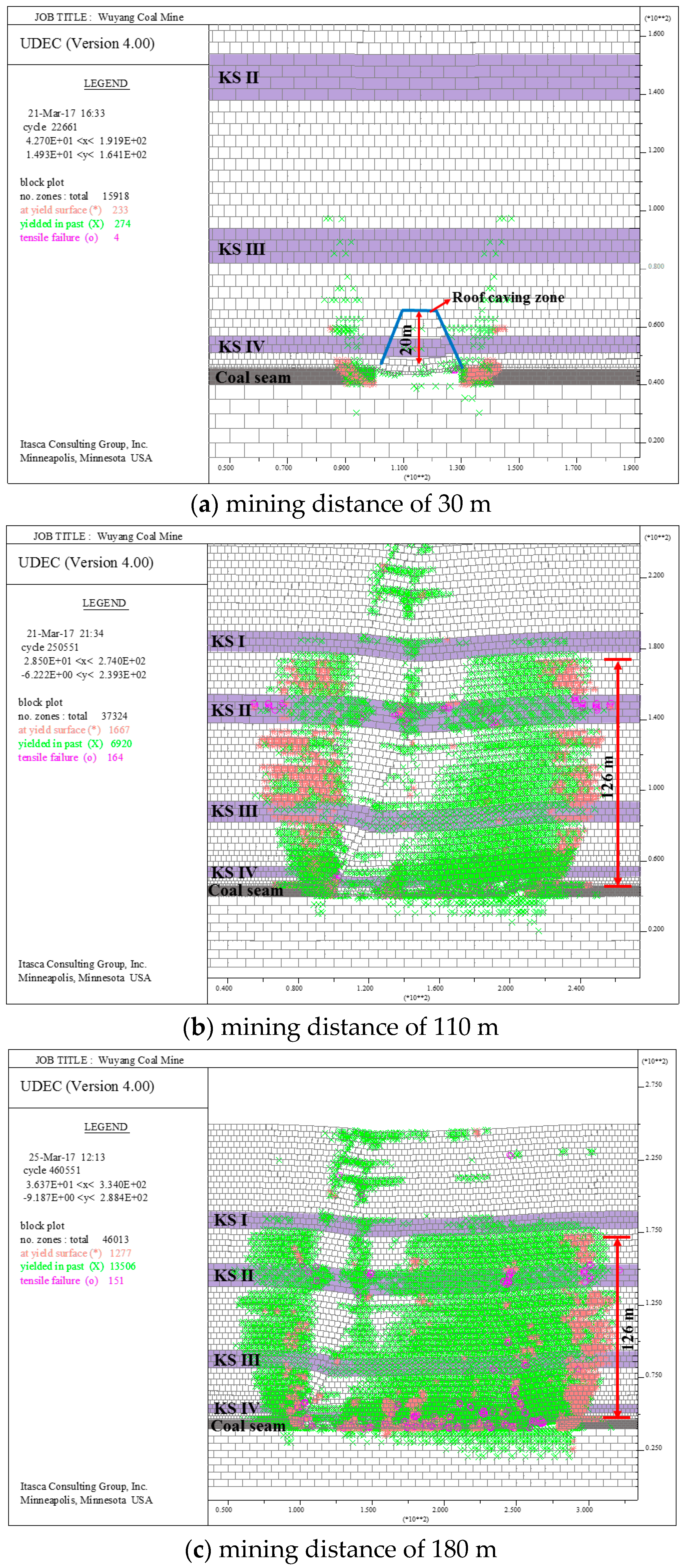

3.2.2. Development Patterns of FWCZ during Longwall Caving

4. Field Measurements on Heights of FWCZ

4.1. Locations of Monitoring Holes

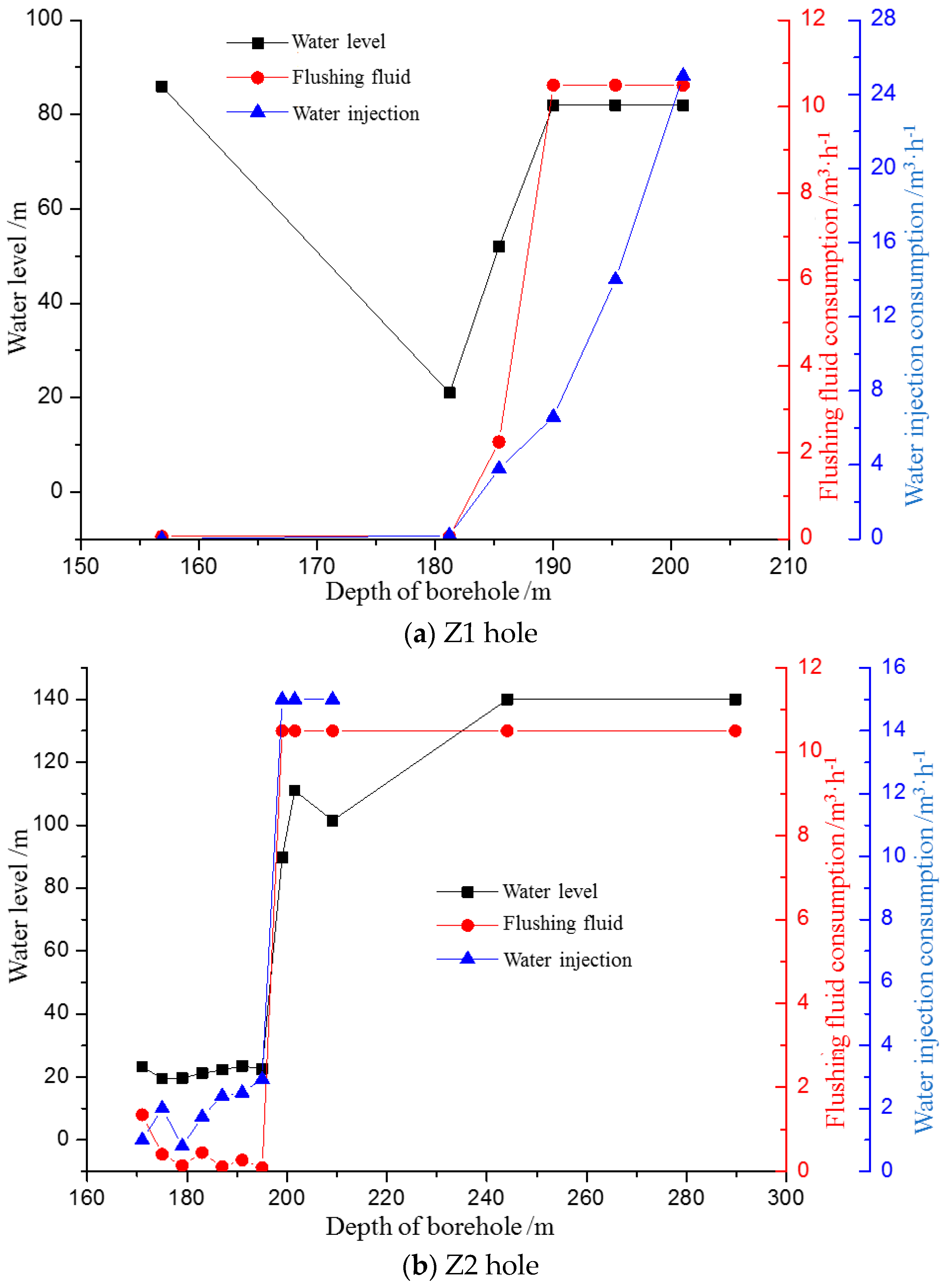

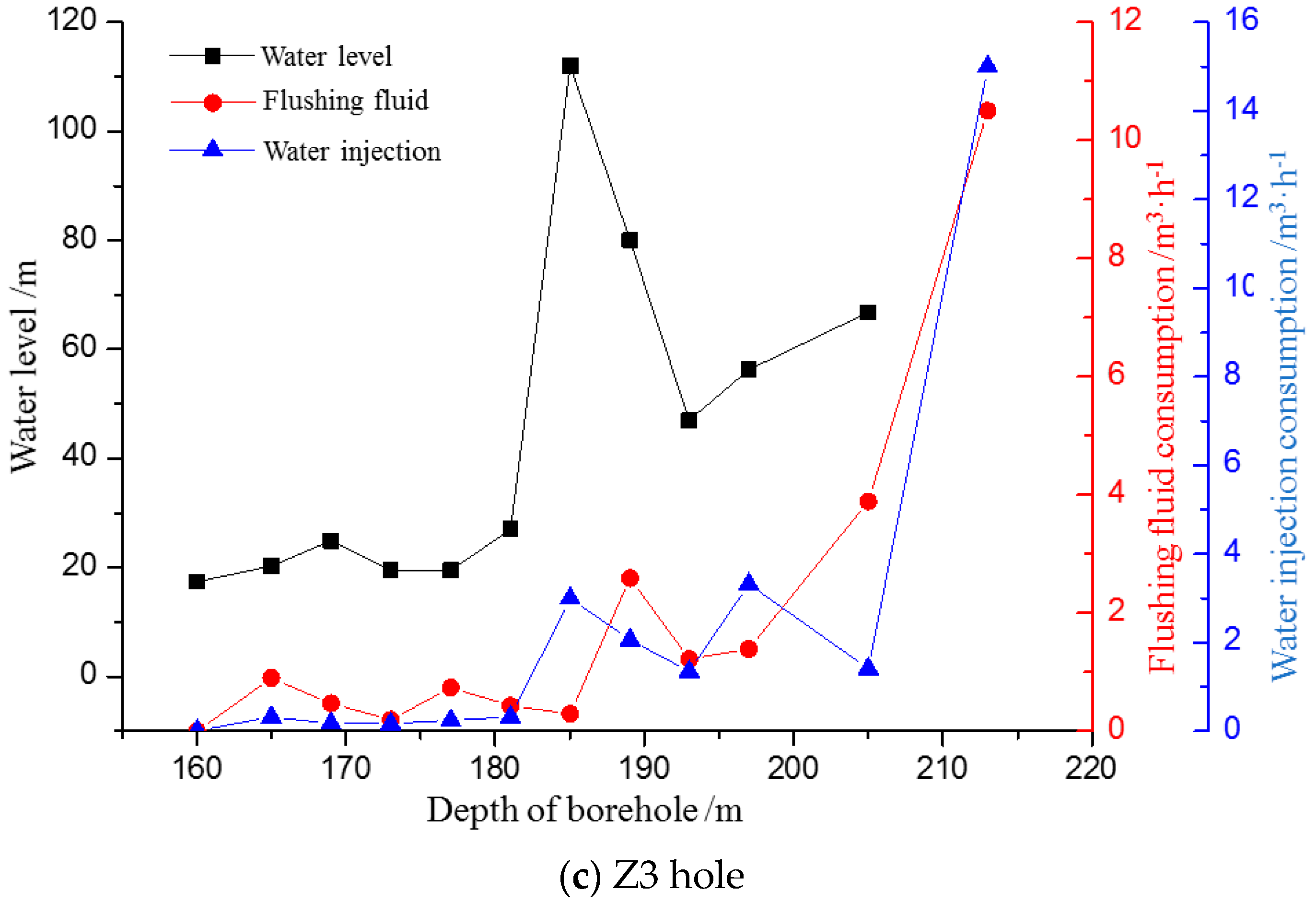

4.2. Analysis of Field Measurements

5. Analyses and Discussion

5.1. Bulking Factor Variations

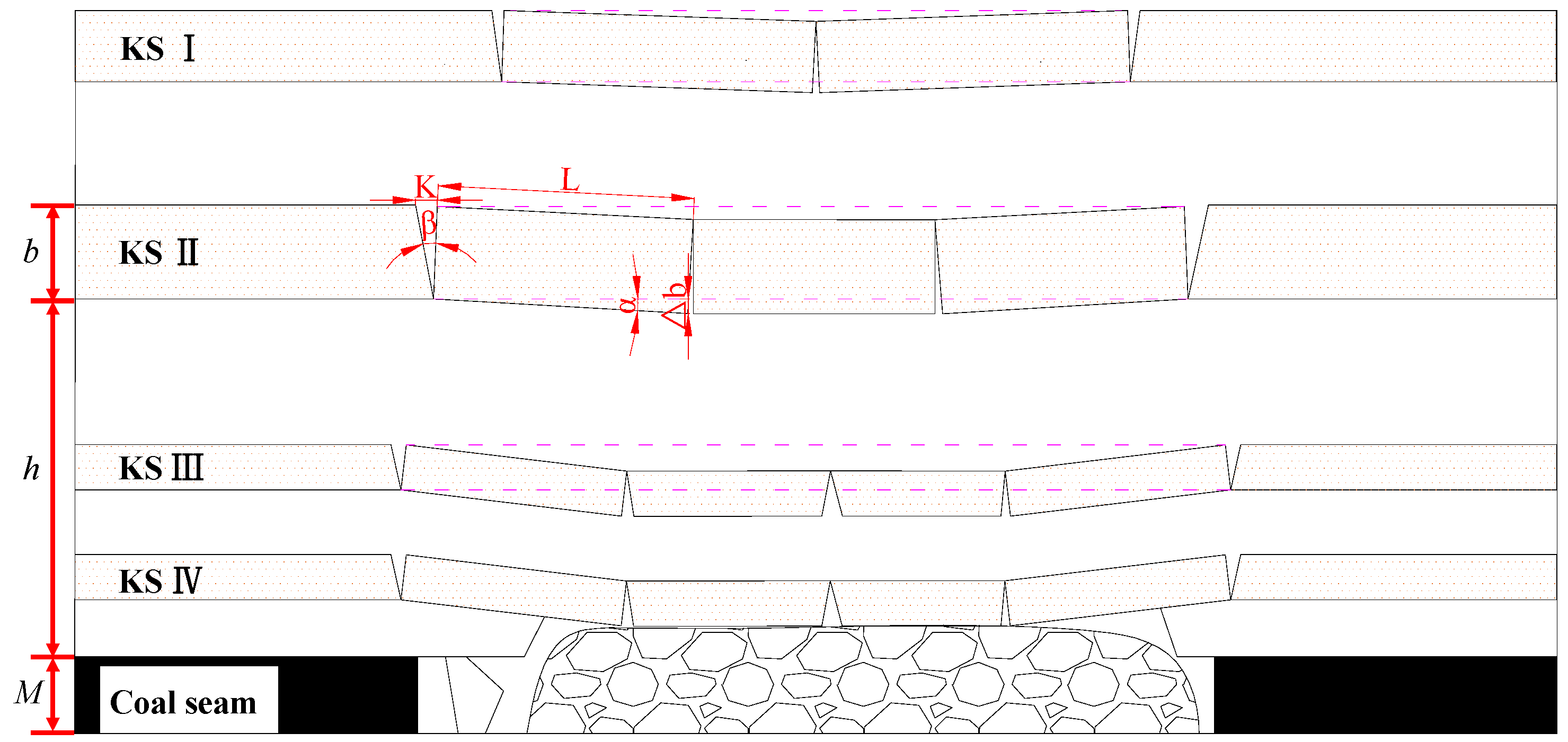

5.2. Structural Stability of Key Strata

6. Conclusions

- Under the same stratigraphic conditions, mining methods significantly affect the heights of water flowing fractured zones. The numerical results by UDEC indicate that, when slice mining is adopted, the maximum height of the FWCZ in the upper slice is 88 m, while that in the lower slice is 7 m higher, reaching 95 m. The fracture height-to-caving thickness ratio is 15.8. For longwall caving, the maximum height is 126 m, and the ratio is 21. The FWCZ in longwall caving is 31 m higher than those in slice mining.

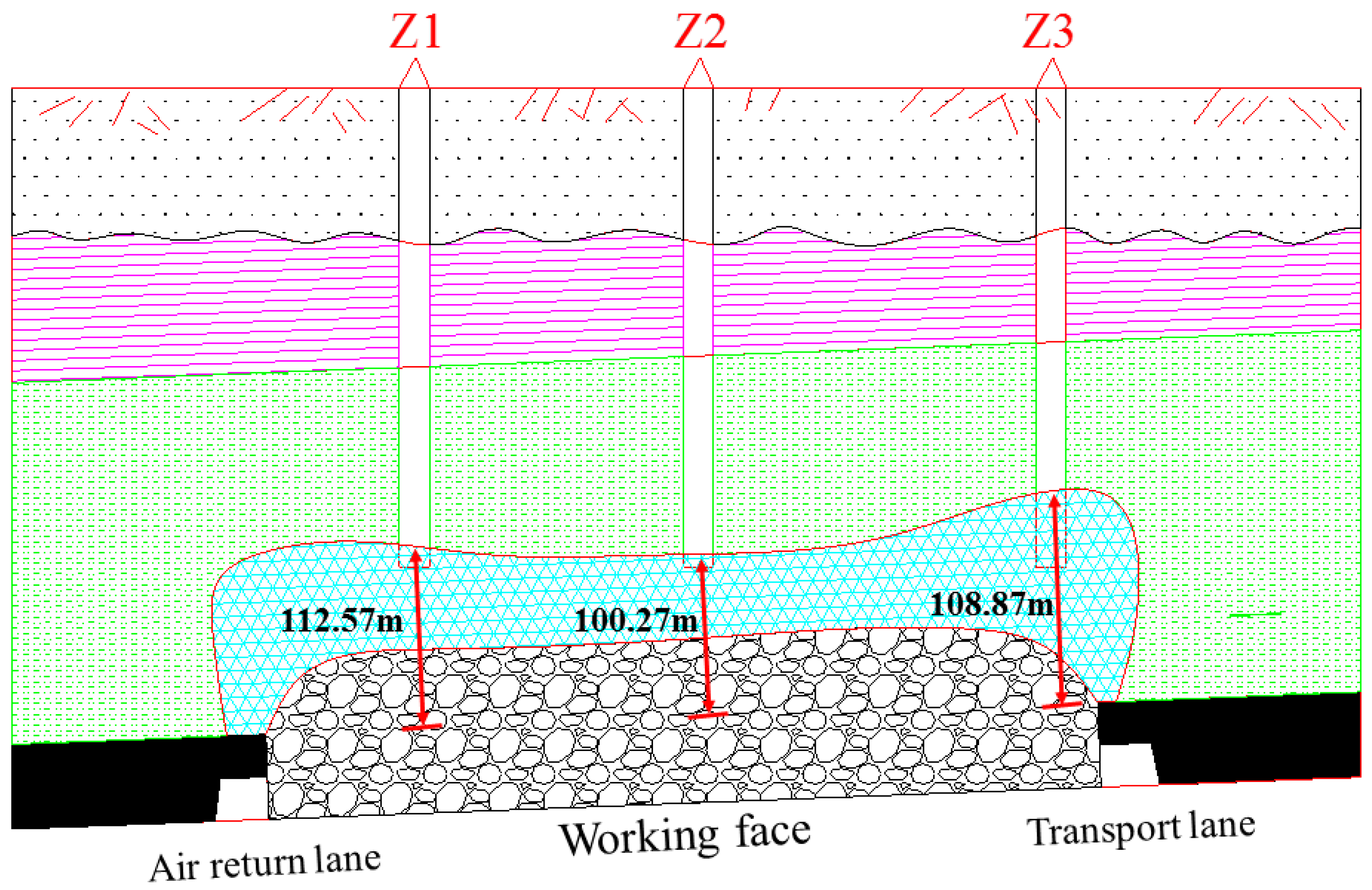

- The heights of the FWCZ can be accurately obtained by monitoring wells. Monitoring wells Z1, Z2, and Z3 were installed at the 7802 face to analyze variation patterns in water levels, flushing fluid consumption rates, and water injection rates. The heights of the FWCZ were 112.57 m, 110.27 m, and 108.87 m at Z1, Z2, and Z3, respectively (coal thickness M: 5.9 m, 5.2 m, and 5.7 m, respectively). The fracture height-to-caving thickness ratios at Z1, Z2, and Z3 were 19.08, 19.28 and 19.1, respectively.

- Both numerical results and field measurements demonstrate that, with the face advancement, the FWCZ finally shows a saddle-shaped pattern, in which the fractures are higher at the open-off cut sides and lower in the middle.

- Mining methods influence the heights of FWCZ primarily through variations in the bulking factor and the structural stability of KS. When slice mining is employed, as the strata experience excavation twice, they are more fragmented, and the bulking factor is, therefore, relatively larger. Compressible rotational spaces in the lower parts of KS are limited, and the strata are more stable, prohibiting the development of FWCZ. During longwall caving, the fragmented blocks are relatively large and complete, so the bulking factor is relatively small. There are more compressible rotational spaces in the lower parts of KS, and the strata are more prone to fracturing deformation. This causes the controlling weak strata above to fracture at the same time, facilitating the development of fractures.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, J.; Shen, B. Coal mining aquifers in China: A case study. Int. J. Rock Mech. Min. Sci. 2004, 41, 629–639. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, M.; Wu, X. Investigations of groundwater bursting into coal mine seam floors from fault zones. Int. J. Rock Mech. Min. Sci. 2004, 41, 557–571. [Google Scholar] [CrossRef]

- Wang, J.-A.; Park, H.D. Coal mining above a confined aquifer. Int. J. Rock Mech. Min. Sci. 2003, 40, 537–551. [Google Scholar] [CrossRef]

- Wang, G.; Wu, M.; Wang, R.; Xu, H.; Song, X. Height of the mining-induced fractured fractured zone above a coal face. Eng. Geol. 2017, 216, 140–152. [Google Scholar] [CrossRef]

- Feng, S.; Sun, S.; Lv, Y.; Lv, J. Research on the height of water flowing fractured zone of fully mechanized caving mining in extra-thick coal seam. Procedia Eng. 2011, 26, 466–471. [Google Scholar]

- Zhang, D.; Fan, G.; Ma, L.; Wang, X. Aquifer protection during longwall caving mining of shallow coal seams: A case study in the Shendong Coalfield of China. Int. J. Coal Geol. 2011, 86, 190–196. [Google Scholar] [CrossRef]

- Peng, S.S. Surface Subsidence Engineering; SME: New York, NY, USA, 1992. [Google Scholar]

- Peng, S.S. Coal Mine Ground Control, 2nd ed.; Wiley: New York, NY, USA, 1986. [Google Scholar]

- Dahl, H.D.; Von schonfeldt, H.A. Rock Mechanics Elements of Coal Mine Design. In Proceedings of the 17th U.S. Symposium on Rock Mechanics (USRMS), Snow Bird, UT, USA, 25–27 August 1976; pp. 31–39. [Google Scholar]

- Palchik, V. Analytical and empirical prognosis of rock foliation in rock masses. J. Coal Ukr. 1989, 7, 45–46. [Google Scholar]

- Palchik, V. Influence of physical characteristics of weak rock mass on height of caved zone over abandoned subsurface coal mines. Environ. Geol. 2002, 42, 92–101. [Google Scholar] [CrossRef]

- Palchik, V. Formation of fractured zones in overburden due to longwall mining. Environ. Geol. 2003, 44, 28–38. [Google Scholar]

- Palchik, V. Location of mining-induced horizontal fractures along rock layer interfaces in overburden: Field measurements and prediction. Environ. Geol. 2005, 48, 68–80. [Google Scholar] [CrossRef]

- Palchik, V. Experimental investigation of apertures of mining-induced horizontal fractures. Int. J. Rock Mech. Min. Sci. 2010, 47, 502–508. [Google Scholar] [CrossRef]

- Liu, T.Q. Surface Movements, Overburden Failure and Its Application; Coal Industry Press: Beijing, China, 1981. (In Chinese) [Google Scholar]

- Hu, W.; Xu, Z.; Wang, W.; Xing, C. Research on development of water flowing fractures in soft overlying strata for coal mining under sea. J. China Coal Soc. 2013, 38, 1338–1344. [Google Scholar]

- Sun, Y.; Xu, Z.; Dong, Q. Monitoring and simulation research on development of water flowing fractures for coal mining under Xiao Langdi reservoir. Chin. J. Rock Mech. Eng. 2009, 28, 238–245. [Google Scholar]

- Gao, F.; Stead, D.; Coggan, J. Evaluation of coal longwall caving charateristics using an innovative UDEC Trigon approach. Comput. Geotech. 2014, 55, 448–460. [Google Scholar] [CrossRef] [Green Version]

- Lai, X.; Cai, M.; Ren, F.; Xie, M.; Esaki, T. Assessment of rock mass characteristics and the excavation disturbed zone in the Lingxin Coal Mine beneath the Xitian river, China. Int. J. Rock Mech. Min. Sci. 2006, 44, 572–581. [Google Scholar] [CrossRef]

- Liu, X.S.; Tan, Y.L.; Ning, J.G. The height of water-conducting fractured zones in longwall mining of shallow coal seams. Geotech. Geol. Eng. 2015, 33, 693–700. [Google Scholar] [CrossRef]

- Dong, D.L.; Lin, G.; Lin, Y.F.; Zhao, M.D.; Li, K. Evaluating induced fractures between a large artificial lack and an aquifer-coal seam system: A case study in Tangshan coal mine, China. Mine Water Environ. 2016, 35, 253–260. [Google Scholar] [CrossRef]

- Wu, Q.; Fan, Z.L.; Zhang, Z.W.; Zhou, W.F. Evaluation and zoning of groundwater hazards in Pingshuo No.1 underground coal mine, Shanxi Province, China. Hydrogeol. J. 2014, 22, 1693–1705. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Li, Z. A new research system for caving mechanism analysis and its application to sublevel top-coal caving mining. Int. J. Rock Mech. Min. Sci. 2016, 88, 273–285. [Google Scholar] [CrossRef]

- Yu, B.; Zhao, J.; Kuang, T.; Meng, X. In situ investigations into overburden failures of a super-thick coal seam for longwall top coal caving. Int. J. Rock Mech. Min. Sci. 2015, 78, 155–162. [Google Scholar] [CrossRef]

- Minggao, Q.; Xiexing, M.; Jialin, X. Theoretical Study of Key Stratum in Ground Control. J. China Coal Soc. 1996, 21, 225–230. [Google Scholar]

- Miao, X.; Cui, X.; Wang, J.; Xu, J. The Height of fractured Water-conducting zone in undermined rock strata. Eng. Geol. 2011, 120, 32–39. [Google Scholar] [CrossRef]

- Xu, J.; Wang, X.; Liu, W.; Wang, Z. Effects of primary key stratum location on height of water flowing fracture zone. Chin. J. Rock Mech. Eng. 2009, 28, 380–385. [Google Scholar]

- Ju, J.; Xu, J. Surface stepped subsidence related to top-coal caving longwall caving mining of extremely thick coal seam under shallow cover. Int. J. Rock Mech. Min. Sci. 2015, 78, 27–35. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Zhu, W. Influence of primary key stratum structure stability on evolution of water flowing fracture. J. China Coal Soc. 2012, 37, 606–612. [Google Scholar]

- Gui, H.; Zhou, Q.; Liao, D.; Kang, Q.; Fan, Z.; Zou, H. Prediction of maximum height of the fractured zone by stressing method for sub-level caving mining. J. China Coal Soc. 1997, 22, 375–379. [Google Scholar]

| Lithology | Thickness/m | Density/kg/m3 | Elastic Modulus/GPa | Poisson’s Ratio | Tensile Strength/MPa | Cohesive Force/MPa | Angle of Internal Friction/° | Key Stratum Location |

|---|---|---|---|---|---|---|---|---|

| Mudstone | 24 | 2500 | 12 | 0.30 | 1.2 | 4.8 | 28 | |

| Siltstone | 12 | 2570 | 14 | 0.28 | 1.4 | 5.0 | 33 | |

| Mudstone | 28 | 2500 | 12 | 0.30 | 1.2 | 4.8 | 28 | |

| Medium Sandstone | 12 | 2700 | 22 | 0.25 | 2.8 | 8.7 | 38 | KS I |

| Mudstone | 24 | 2500 | 12 | 0.30 | 1.2 | 4.8 | 28 | |

| Coarse Sandstone | 16 | 2750 | 24 | 0.26 | 2.6 | 8.4 | 36 | KS II |

| Mudstone | 12 | 2500 | 12 | 0.30 | 1.2 | 4.8 | 28 | |

| Medium Sandstone | 8 | 2700 | 22 | 0.25 | 2.8 | 8.7 | 38 | |

| Mudstone | 24 | 2500 | 14 | 0.30 | 1.2 | 4.8 | 28 | |

| Fine Sandstone | 12 | 2650 | 20 | 0.24 | 3.0 | 9.2 | 34 | KS III |

| Sandy Mudstone | 16 | 2560 | 14 | 0.28 | 1.4 | 5.0 | 30 | |

| Mudstone | 9 | 2500 | 12 | 0.30 | 1.2 | 4.8 | 28 | |

| Medium Standstone | 6 | 2700 | 22 | 0.25 | 2.8 | 8.7 | 28 | KS IV |

| Mudstone | 4 | 2500 | 12 | 0.30 | 1.1 | 4.8 | 23 | |

| Carbonaceous Mudstone | 1 | 2500 | 12 | 0.32 | 1.0 | 2.3 | 23 | |

| 3 Coal | 6 | 1300 | 3 | 0.35 | 0.15 | 1.0 | 28 | |

| Sandy Mudstone | 40 | 2560 | 14 | 0.28 | 1.4 | 5.0 | 35 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, F.; Gao, R. Development Patterns of Fractured Water-Conducting Zones in Longwall Mining of Thick Coal Seams—A Case Study on Safe Mining Under the Zhuozhang River. Energies 2017, 10, 1856. https://doi.org/10.3390/en10111856

Du F, Gao R. Development Patterns of Fractured Water-Conducting Zones in Longwall Mining of Thick Coal Seams—A Case Study on Safe Mining Under the Zhuozhang River. Energies. 2017; 10(11):1856. https://doi.org/10.3390/en10111856

Chicago/Turabian StyleDu, Feng, and Rui Gao. 2017. "Development Patterns of Fractured Water-Conducting Zones in Longwall Mining of Thick Coal Seams—A Case Study on Safe Mining Under the Zhuozhang River" Energies 10, no. 11: 1856. https://doi.org/10.3390/en10111856