Coal Supply Chains: A Whole-Process-Based Measurement of Carbon Emissions in a Mining City of China

Abstract

:1. Introduction

2. Materials and Methods

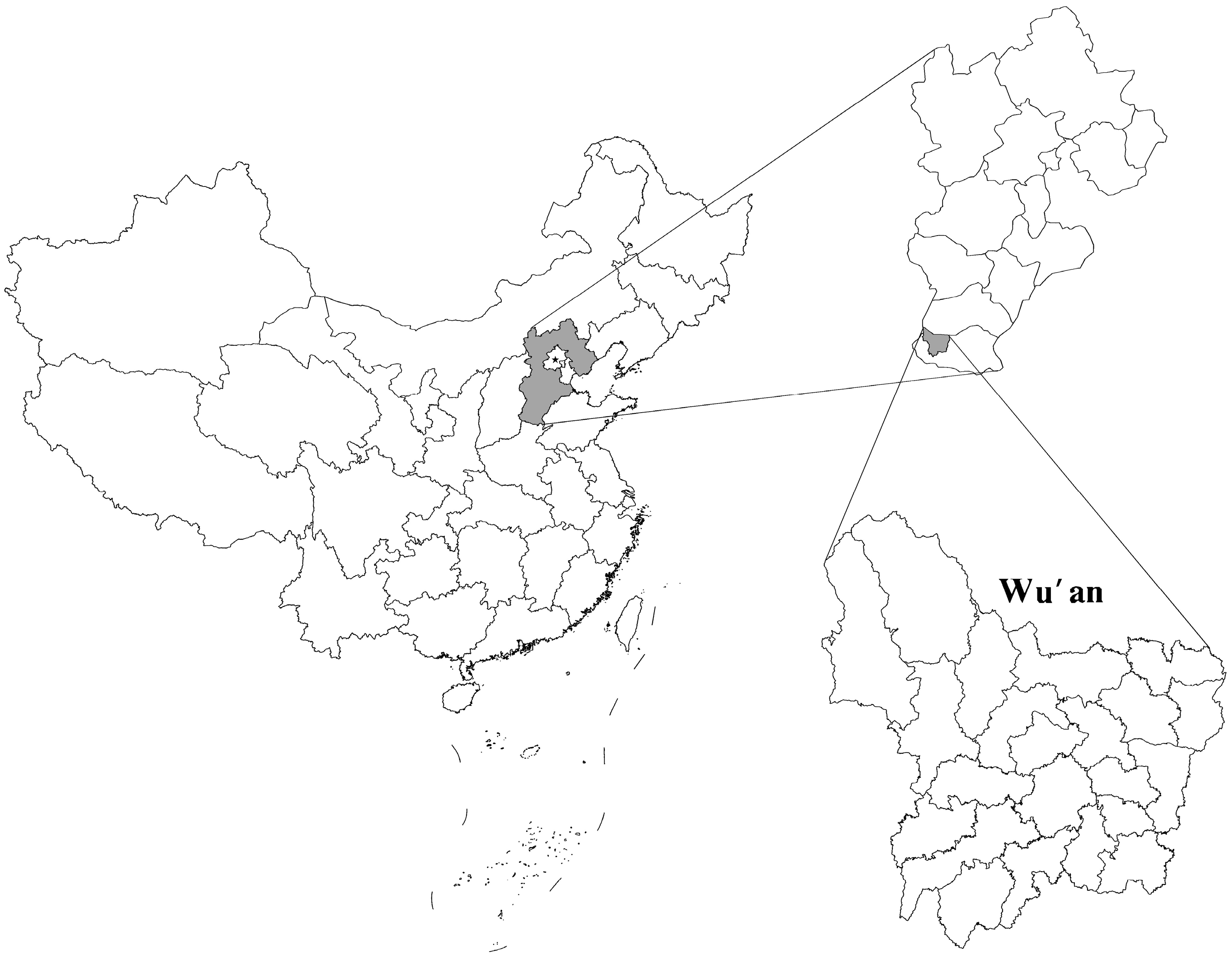

2.1. General Situation of the Study Area

2.2. Data Sources

2.3. Research Methods

2.3.1. Trace of Coal Supply Chains

2.3.2. Inventory of Carbon Emissions in Coal Supply Chains

Carbon Emissions in the Coal Mining Process

Carbon Emissions in the Coal Selection and Washing Process

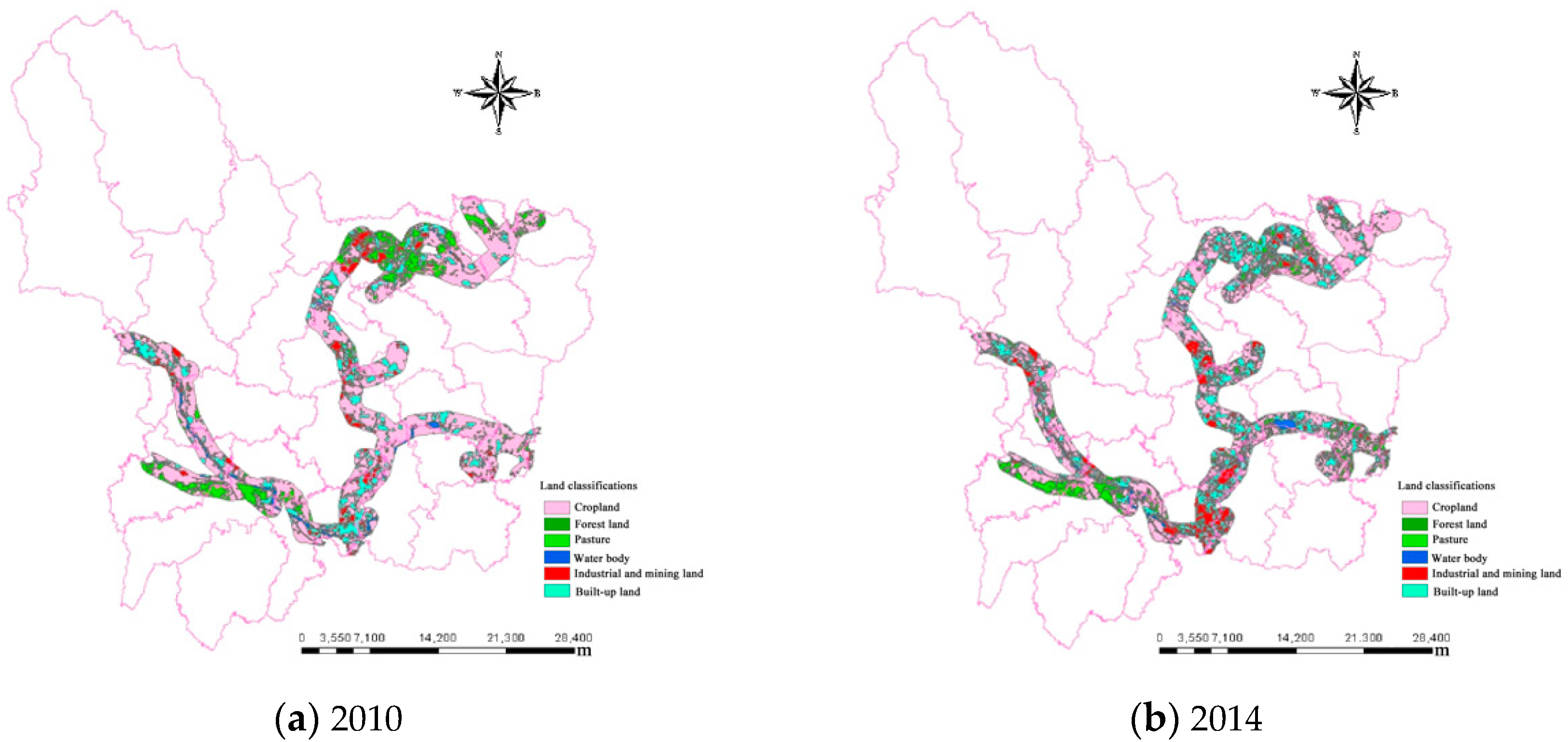

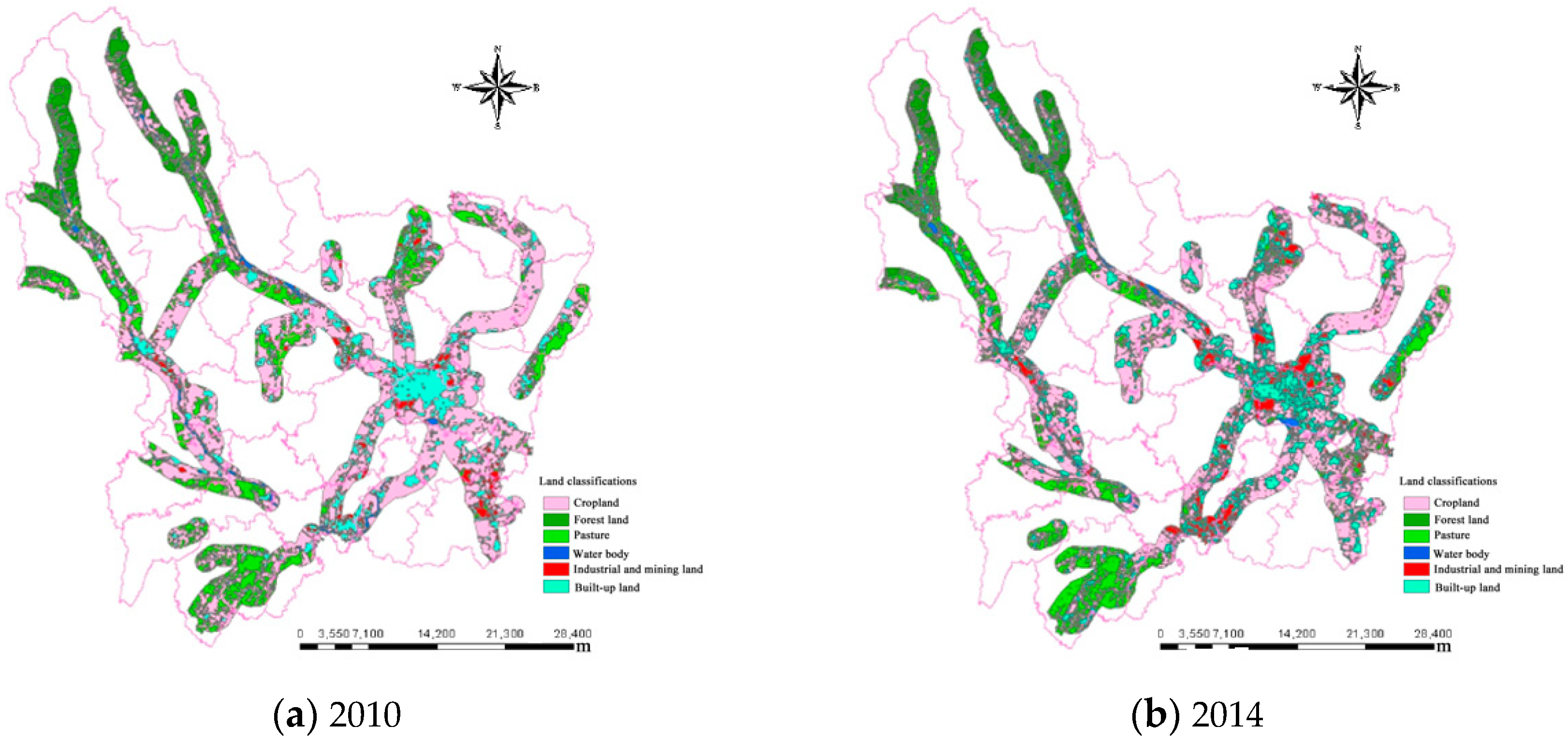

Carbon Emissions in the Coal Transportation Process

Carbon Emissions in the Coal Consumption Process

2.3.3. Analysis and Interpretation

3. Results and Analysis

3.1. Calculation of Carbon Emissions in Coal Supply Chains

3.1.1. Carbon Emissions in the Coal Mining Process

- CH4: 9.44 × 106 × 25 × 0.67 = 1.58 × 108 kg CH4 = 1.58 × 108 × 23 kg CO2 = 3.64 × 109 kg CO2

- CO2: 9.44 × 106 × 25 × 0.8 = 1.89 × 108 kg CO2

- Total: 3.64 × 109 + 1.89 × 108 = 3.83 × 109 kg CO2

- Coal consumption for heating boilers:CO2: 27.2 × 9.44 × 106 × 20,908 × 25.8 × 10−6 × 44/12 = 5.08 × 108 kg CO2

- Electricity consumption for mining equipment:CO2: 33.7 × 9.44 × 106 × 840.1914 × 10−3 = 2.67 × 108 kg CO2N2O: 33.7 × 9.44 × 106 × 0.053352 × 10−3 = 1.70 × 104 kg N2O = 1.70 × 104 × 296 kg CO2 = 5.03 × 106 kg CO2Total: 2.67 × 108 + 5.03 × 106 = 2.72 × 108 kg CO2

- Total:CO2: 5.08 × 108 + 2.72 × 108 = 7.80 × 108 kg CO2

3.1.2. Carbon Emissions in the Coal Selection and Washing Process

- By coal combustion:CO2: 9.44 × 109 × 1% × 20,908 × 25.8 × 10−6 × 44/12 = 1.87 × 108 kg CO2

- By electricity consumption:CO2: 9.44 × 106 × 3 × 840.1914 × 10−3 = 2.38 × 107 kg CO2N2O: 9.44 × 106 × 3 × 0.053352 × 10−3 = 1.51 × 103 kg CO2 = 1.51 × 103 × 296 kg CO2 = 4.50 × 105 kg CO2Total: 2.38 × 107 + 4.50 × 105 = 2.43 × 107 kg CO2

- Total carbon emission in coal selection and washing process:CO2: 1.87 × 108 + 2.43 × 107 = 2.11 × 108 kg CO2

3.1.3. Carbon Emissions in Coal Transportation Process

- By railway transport:CO2: 944 × 25% × 24.6 × 164.78 × 42,652 × 20.2 × 10−6 × 44/12 = 3.02 × 106 kg CO2

- By road transport:CO2: 944 × 75% × 650 × 386.22 × 42,652 × 20.2 × 10−6 × 44/12 = 5.61 × 108 kg CO2

- Total:CO2: 3.02 × 106 + 5.61 × 108 = 5.64 × 108 kg CO2

- By forest:CO2: 0.09 × 73.24 × 103 × 44/12 = 2.42 × 104 kg CO2

- By pasture:CO2: (2.26 + 1.09 + 3.32 + 0.91) × 6.20 × 103 × 44/12 = 1.72 × 105 kg CO2

- Total:CO2: 2.42 × 104 + 1.72 × 105 = 1.96 × 105 kg CO2

3.1.4. Carbon Emissions in the Coal Consumption Process

- By the combustion of fossil fuels:

- Raw coal:CO2: 41.70 × 107 × 20,908 × 25.8 × 10−6 × 44/12 = 8.25 × 108 kg CO2

- Cleaned coal:CO2: 233.26 × 107 × 26,344 × 26.209 × 10−6 × 44/12 = 5.90 × 109 kg CO2

- Coke:CO2: 610.19 × 107 × 28,435 × 29.2 × 10−6 × 75% × 44/12 = 1.39 × 1010 kg CO2

- Diesel fuel:CO2: 1.08 × 107 × 42,652 × 20.2 × 10−6 × 44/12 = 3.41 × 107 kg CO2

- Gasoline:CO2: 0.00476 × 107 × 43,070 × 18.9 × 10−6 × 44/12 = 1.42 × 105 kg CO2Total: 8.25 × 108 + 5.90 × 109 + 1.39 × 1010 + 3.41 × 107 + 1.42 × 105 = 2.07 × 1010 kg CO2

- By chemical reactionCO2: 610.19 × 107 × 25% × 3.1 = 4.73 × 109 kg CO2

- Total carbon emissions in the steel industry (electricity consumption not included)CO2: 2.07 × 1010 + 4.73 × 109 = 2.54 × 1010 kg CO2

- By the combustion of fossil fuels

- Raw coal:CO2: 17.04 × 107 × 20,908 × 25.8 × 10−6 × 44/12 = 3.37 × 108 kg CO2

- Diesel fuel:CO2: 0.0179 × 107 × 42,652 × 20.2 × 10−6 × 44/12 = 5.65 × 105 kg CO2Total: 3.37 × 108 + 5.65 × 105 = 3.38 × 108 kg CO2

- By the decomposition of limestoneCO2: 313.10 × 107 × 68% × 61% × 44/56 = 1.02 × 109 kg CO2

- Total carbon emissions in the cement industry (electricity consumption not included)CO2: 3.38 × 108 + 1.02 × 109 = 1.36 × 109 kg CO2

3.2. Inventory of Carbon Emissions in Coal Supply Chains

3.3. Analysis and Interpretation

3.3.1. Analysis by Different Processes

3.3.2. Analysis by Different Industrial Types

3.3.3. Analysis by Different Greenhouse Gas Types

4. Conclusions and Discussion

4.1. Main Achievements

4.2. Limitations and Uncertainties

4.3. Implications for Environmental Management

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sheinbaum, C.; Ruíz, B.J.; Ozawa, L.; Nebra, S.A.; De Oliveira, S., Jr.; Bazzo, E. Energy consumption and related CO2 emissions in five latin american countries: Changes from 1990 to 2006 and perspectives. Energy 2011, 36, 3629–3638. [Google Scholar] [CrossRef]

- Chen, Z.M.; Chen, G.Q.; Chen, B. Embodied carbon dioxide emission by the globalized economy: A systems ecological input-output simulation. J. Environ. Inform. 2013, 21, 35–44. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Y.P.; Huang, G.H. Planning sustainable electric-power system with carbon emission abatement through cdm under uncertainty. Appl. Energy 2015, 140, 350–364. [Google Scholar] [CrossRef]

- Eissa, A.E.; Zaki, M.M. The impact of global climatic changes on the aquatic environment. Procedia Environ. Sci. 2011, 4, 251–259. [Google Scholar] [CrossRef]

- Ghommem, M.; Hajj, M.R.; Puri, I.K. Influence of natural and anthropogenic carbon dioxide sequestration on global warming. Ecol. Model. 2012, 235–236, 1–7. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2001: The Scientific Basis. Third Assessment Report of the Intergovernmental Panel Onclimate Change; Cambridge University Press: Cambridge, UK, 2001. [Google Scholar]

- Cardoso, A. Behind the life cycle of coal: Socio-environmental liabilities of coal mining in Cesar, Colombia. Ecol. Econ. 2015, 120, 71–82. [Google Scholar] [CrossRef]

- Ou, Y.; Zhai, H.; Rubin, E.S. Life cycle water use of coal- and natural-gas-fired power plants with and without carbon capture and storage. Int. J. Greenh. Gas Control 2016, 44, 249–261. [Google Scholar] [CrossRef]

- Goto, K.; Yogo, K.; Higashii, T. A review of efficiency penalty in a coal-fired power plant with post-combustion CO2 capture. Appl. Energy 2013, 111, 710–720. [Google Scholar] [CrossRef]

- Dai, C.; Cai, X.H.; Cai, Y.P.; Huang, G.H. A simulation-based fuzzy possibilistic programming model for coal blending management with consideration of human health risk under uncertainty. Appl. Energy 2014, 133, 1–13. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Bumb, P.; Shah, N. Carbon capture from pulverized coal power plant (pcpp): Solvent performance comparison at an industrial scale. Appl. Energy 2016, 163, 423–435. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Climate change 2007: Impacts, Adaptation and Vulnerability; Contribution of Working Group II to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2007. [Google Scholar]

- Zhao, Y.; Yuan, S.; Yun, W.; Guan, W.; Liu, H. Monitoring-assessing-prewarning system for agricultural land resources security. Trans. Chin. Soc. Agric. Eng. 2007, 23, 77–81. [Google Scholar]

- Zhu, S. Good practices in australia for greenhouse gas inventory development. Adv. Clim. Chang. Res. 2011, 7, 204–209. [Google Scholar]

- US DOE. Carbon Dioxide Emissions From the Generation of Electric Power in the United States; Department of Energy and Environmental Protection Agency: Washington, DC, USA, 2000. [Google Scholar]

- Carney, S.; Shackley, S. The greenhouse gas regional inventory project (grip): Designing and employing a regional greenhouse gas measurement tool for stakeholder use. Energy Policy 2009, 37, 4293–4302. [Google Scholar] [CrossRef]

- Xing, F.F.; Ouyang, Z.Y.; Wang, X.K.; Duan, X.N.; Zheng, H.; Miao, H. Inventory of final energy-carbon consumption and its structure in beijing; Abstracts of Ecosummit 2007—Ecological Complexity and Sustainability—Challenges & Opportunities for Century’s Ecology. Huanjing Kexue 2007, 28, 1918–1923. [Google Scholar] [PubMed]

- Benetto, E.; Rousseaux, P.; Blondin, J. Life cycle assessment of coal by-products based electric power production scenarios. Fuel 2004, 83, 957–970. [Google Scholar] [CrossRef]

- Branco, D.A.C.; Moura, M.C.P.; Szklo, A.; Schaeffer, R. Emissions reduction potential from CO2 capture: A life-cycle assessment of a brazilian coal-fired power plant. Energy Policy 2013, 61, 1221–1235. [Google Scholar] [CrossRef]

- Odeh, N.A.; Cockerill, T.T. Life cycle analysis of uk coal fired power plants. Energy Convers. Manag. 2008, 49, 212–220. [Google Scholar] [CrossRef]

- Stanek, W.; Czarnowska, L.; Pikoń, K.; Bogacka, M. Thermo-ecological cost of hard coal with inclusion of the whole life cycle chain. Energy 2015, 92, 341–348. [Google Scholar] [CrossRef]

- Díaz, E.; Fernández, J.; Ordóñez, S.; Canto, N.; González, A. Carbon and ecological footprints as tools for evaluating the environmental impact of coal mine ventilation air. Ecol. Indic. 2012, 18, 126–130. [Google Scholar] [CrossRef]

- Nease, J.; Ii, T.A.A. Comparative life cycle analyses of bulk-scale coal-fueled solid oxide fuel cell power plants. Appl. Energy 2015, 150, 161–175. [Google Scholar] [CrossRef]

- Qin, Z.; Zhai, G.; Wu, X.; Yu, Y.; Zhang, Z. Carbon footprint evaluation of coal-to-methanol chain with the hierarchical attribution management and life cycle assessment. Energy Convers. Manag. 2016, 124, 168–179. [Google Scholar] [CrossRef]

- Restrepo, Á.; Bazzo, E.; Miyake, R. A life cycle assessment of the brazilian coal used for electric power generation. J. Clean. Prod. 2014, 92, 179–186. [Google Scholar] [CrossRef]

- Andrić, I.; Jamali-Zghal, N.; Santarelli, M.; Lacarrière, B.; Corre, O.L. Environmental performance assessment of retrofitting existing coal fired power plants to co-firing with biomass: Carbon footprint and emergy approach. J. Clean. Prod. 2015, 103, 13–27. [Google Scholar] [CrossRef]

- Peters, G.P. From production-based to consumption-based national emission inventories. Ecol. Econ. 2008, 65, 13–23. [Google Scholar] [CrossRef]

- Gavrilova, O.; Vilu, R. Production-based and consumption-based national greenhouse gas inventories: An implication for estonia. Ecol. Econ. 2012, 75, 161–173. [Google Scholar] [CrossRef]

- Mózner, Z.V. A consumption-based approach to carbon emission accounting—Sectoral differences and environmental benefits. J. Clean. Prod. 2013, 42, 83–95. [Google Scholar] [CrossRef] [Green Version]

- Xia, D.; Ren, Y.; Shi, L. Measurement of life-cycle carbon equivalent emissions of coal-energy chain. Stat. Res. 2010, 8, 13. [Google Scholar]

- Xiao, B.; Zhang, A.L.; Chen, G.F. Life cycle inventory of clean coal-fired power generation in China. Clean Coal Technol. 2005, 11, 1–4. [Google Scholar]

- Troy, S.; Schreiber, A.; Zapp, P. Life cycle assessment of membrane-based carbon capture and storage. Clean Technol. Environ. Policy 2016, 18, 1641–1654. [Google Scholar] [CrossRef]

- Zhang, D. A Study on Estimation Method of Carbon Emission in Industry Branch; Beijing Forestry University: Beijing, China, 2005. [Google Scholar]

- Lubetsky, J.; Steiner, B.A.; Lanza, R. 2006 Intergovernmental Panel on Climate Change (IPCC) Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2006. [Google Scholar]

- Jiang, G.Q. Research on the Process and Measurement of Electric-Coalsupply Chain Carbon Emissions; Beijing Jiaotong University: Beijing, China, 2013. [Google Scholar]

- Du, Q.; Chen, Q.; Yang, R. Forecast carbon emissions of provinces in China based on logistic model. Resour. Environ. Yangtze Basin 2013, 22, 143–151. [Google Scholar]

- Hamilton, L.D.; Goldstein, G.A.; Lee, J.; Marcuse, W.; Morris, S.C.; Manne, A.S.; Wene, C.O. Markal-Macro: An Overview; Brookhaven National Lab.: Upton, NY, USA, 1992. [Google Scholar]

- Qiu, S.M.; Gu, P.L.; Hao, H. Study on increase and control of carbon dioxide emission from energy consumption. J. China Coal Soc. 2002, 27, 412–416. [Google Scholar]

- Wang, X.N.; Gu, K.P. Present condition of estimate method of carbon emission in China. Environ. Sci. Manag. 2006, 31, 78–80. [Google Scholar]

- Bin, Y.E.; Qiang, L.U.; Ji, L.I.; Chang, K. Coal power ghg emission intensity model and its application. J. Harbin Univ. Sci. Technol. 2011, 5, 27. [Google Scholar]

- Weisser, D. A guide to life-cycle greenhouse gas (ghg) emissions from electric supply technologies. Energy 2007, 32, 1543–1559. [Google Scholar] [CrossRef]

- Pehnt, M.; Henkel, J. Life cycle assessment of carbon dioxide capture and storage from lignite power plants. Int. J. Greenh. Gas Control 2009, 3, 49–66. [Google Scholar] [CrossRef]

- Hou, Y.; Liang, C.; Tian, X.; Pan, D. Study on chinese steel industry carbon footprint analysis and emission reduction countermeasures. Ecol. Econ. 2012, 12, 22. [Google Scholar]

- Hondo, H. Life cycle ghg emission analysis of power generation systems: Japanese case. Energy 2014, 30, 2042–2056. [Google Scholar] [CrossRef]

- Yu, S.; Wei, Y.M.; Guo, H.; Ding, L. Carbon emission coefficient measurement of the coal-to-power energy chain in China. Appl. Energy 2014, 114, 290–300. [Google Scholar] [CrossRef]

- Review, B.P.S.; June, W.E. Bp Statistical Review of World Energy June 2011; Bp España: London, UK, 2011. [Google Scholar]

- You, C.F.; Xu, X.C. Coal combustion and its pollution control in China. Energy 2010, 35, 4467–4472. [Google Scholar] [CrossRef]

- Liu, Z.; Feng, K.; Hubacek, K.; Liang, S.; Anadon, L.D.; Zhang, C.; Guan, D. Four system boundaries for carbon accounts. Ecol. Model. 2015, 318, 118–125. [Google Scholar] [CrossRef]

- Geng, Y. Quantification and Characteristics of Provincial-Level Carbon Emission from Energy Consumption in China; China University of Geosciences: Wuhan, China, 2011. [Google Scholar]

- Zhao, R. A Study on Carbon Cycle and Land Control in Urban System; Nanjing University Press: Nanjing, Chian, 2012. [Google Scholar]

- Xia, D. The Research on Life Cycle Carbon Emissions Measurement of Electric Power Generation Side Based on the Scenario Analysis Method; Chongqing University: Chongqing, China, 2010. [Google Scholar]

- Ge, Q.S.; Dai, J.H.; He, F.N.; Yuan, P.; Wang, M.M. Land use changes and their relations with carbon cycles over the past 300 a in China. Sci. China Earth Sci. 2008, 51, 871–884. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, J.; Liu, L.; Bai, W.; Li, S.; Zheng, D. Impact of qinghai-xizang highway on land use and landscape pattern change: From golmud to tanggulashan pass. Acta Geogr. Sin. 2002, 57, 253–266. [Google Scholar]

- Watson, R.T. Land Use, Land-Use Change, and Forestry : A Special Report of the IPCC; Cambridge University: Cambridge, UK, 2000. [Google Scholar]

- Canadell, J.G.; Le Quéré, C.; Raupach, M.R.; Field, C.B.; Buitenhuis, E.T.; Ciais, P.; Conway, T.J.; Gillett, N.P.; Houghton, R.A.; Marland, G. Contributions to accelerating atmospheric CO2 growth from economic activity, carbon intensity, and efficiency of natural sinks. Proc. Natl. Acad. Sci. USA 2007, 104, 18866–18870. [Google Scholar] [CrossRef] [PubMed]

- Gullison, R.E.; Frumhoff, P.C.; Canadell, J.G.; Field, C.B.; Nepstad, D.C.; Hayhoe, K.; Avissar, R.; Curran, L.M.; Friedlingstein, P.; Jones, C.D. Tropical forests and climate policy: New science underscores the value of a climate policy initiative to reduce emissions from tropical deforestation. Environment 2007, 316, 985. [Google Scholar]

- Lv, M. Impact Studies of Tourism Development on Land Use Pattern in Jilin Changbai Mountain National Nature Reserve; Northeast Normal University: Changchun, China, 2010. [Google Scholar]

- Kerang, L.I.; Wang, S.; Cao, M. Vegetation and soil carbon storage in China. Sci. China Ser. 2004, 47, 49–57. [Google Scholar]

- Fang, J.; Liu, G.; Xu, S. Soil carbon pool in China and its global significance. J. Environ. Sci. 1996, 23, 249–254. [Google Scholar]

- Fang, J.; Chen, A.; Peng, C.; Zhao, S.; Ci, L. Changes in forest biomass carbon storage in China between 1949 and 1998. Science 2001, 292, 2320–2322. [Google Scholar] [CrossRef] [PubMed]

- Tong, H.F.; Cui, Y.S.; Wei-Shuang, Q.U.; Liu, Y. System dynamic scenarios analysis of CO2 emissions of China’s cement industry. China Soft Sci. 2010, 3, 40–50. [Google Scholar]

- West, T.O.; Marland, G. A synthesis of carbon sequestration, carbon emissions, and net carbon flux in agriculture: Comparing tillage practices in the United States. Agric. Ecosyst. Environ. 2002, 91, 217–232. [Google Scholar] [CrossRef]

- Bacon, P.J.; Cain, J.D.; Howard, D.C. Belief network models of land manager decisions and land use change. J. Environ. Manag. 2002, 65, 1–23. [Google Scholar] [CrossRef]

- Mohamed, A.A.; Sharifi, M.A.; Keulen, H.V. An integrated agro-economic and agro-ecological methodology for land use planning and policy analysis. Int. J. Appl. Earth Obs. Geoinform. 2000, 2, 87–103. [Google Scholar] [CrossRef]

- Lebel, L.; Garden, P.; Banaticla, M.R.N.; Lasco, R.D.; Contreras, A.; Mitra, A.P.; Sharma, C.; Nguyen, H.T.; Ooi, G.L.; Sari, A. Management into the development strategies of urbanizing regions in asia: Implications of urban function, form, and role. J. Ind. Ecol. 2007, 11, 61–81. [Google Scholar] [CrossRef]

- Zhang, J.; Fu, M.; Tao, J.; Huang, Y.; Hassani, F.P.; Bai, Z. Response of ecological storage and conservation to land use transformation: A case study of a mining town in China. Ecol. Model. 2010, 221, 1427–1439. [Google Scholar] [CrossRef]

| Mining Type | Mining Depth (m) | Emission Factors (m3/t) |

|---|---|---|

| Underground coal mine | <200 | 10 |

| <400 | 18 | |

| >400 | 25 | |

| Open strip mines | <25 | 0.3 |

| <50 | 1.2 | |

| >50 | 2 |

| GHG | GWP Default Values (g CO2 Equivalent/g GHG) |

|---|---|

| CO2 | 1 |

| CH4 | 23 |

| N2O | 296 |

| Type | Lower Calorific Value (kJ/kg kJ/m3) | Carbon Content (kg/GJ) |

|---|---|---|

| Raw coal | 20,908 | 25.8 |

| Coke | 28,435 | 29.2 |

| Washed coal | 26,344 | 26.2 |

| Crude oil | 41,816 | 20 |

| Gasoline | 43,070 | 18.9 |

| Kerosene | 43,070 | 19.6 |

| Diesel fuel | 42,652 | 20.2 |

| Natural gas | 38,931 | 15.3 |

| Land Use Type | Built-Up Land (ha) | Industrial and Mining Land (ha) |

|---|---|---|

| Cropland | 6.12/8.00 | 0.63/0.61 |

| Forest | 0/0.09 | 0/0 |

| Pasture | 2.26/3.32 | 1.09/0.91 |

| Water body | 0.54/0.99 | 0.06/0.12 |

| Built-up land | 20.16/37.77 | 3.19/3.03 |

| Process | GHG Type | GHG Emission (kg) | CO2 Equivalent (kg) | Subtotal (kg) | Subtotal’ (kg) | Total (kg) | ||

|---|---|---|---|---|---|---|---|---|

| Mining | Coalbed carbon leak | CO2 | 1.89 × 108 | 1.89 × 108 | 3.83 × 109 | 4.61 × 109 | 3.51 × 1010 | |

| CH4 | 1.58 × 108 | 3.64 × 109 | ||||||

| Energy consumption | CO2 | 7.75 × 108 | 7.75 × 108 | 7.80 × 108 | ||||

| N2O | 1.70 × 104 | 5.03 × 106 | ||||||

| Selecting and washing | Coal combustion | CO2 | 1.87 × 108 | 1.87 × 108 | 1.87 × 108 | 2.11 × 108 | ||

| Electricity consumption | CO2 | 2.38 × 107 | 2.38 × 107 | 2.43 × 107 | ||||

| N2O | 1.51 × 103 | 4.50 × 105 | ||||||

| Transportation | Direct emission | CO2 | 5.64 × 108 | 5.64 × 108 | 5.64 × 108 | 5.64 × 108 | ||

| Indirect emission | CO2 | 1.96 × 105 | 1.96 × 105 | 1.96 × 105 | ||||

| Consumption | Electricity industry | CO2 | 2.91 × 109 | 2.91 × 109 | 2.96 × 109 | 2.97 × 1010 | ||

| N2O | 1.85 × 105 | 5.48 × 107 | ||||||

| Steel industry | Combustion of fossil fuels | CO2 | 2.07 × 1010 | 2.07 × 1010 | 2.54 × 1010 | |||

| Chemical reaction | CO2 | 4.73 × 109 | 4.73 × 109 | |||||

| Cement industry | Combustion of fossil fuels | CO2 | 3.38 × 108 | 3.38 × 108 | 1.36 × 109 | |||

| Decomposition of limestone | CO2 | 1.02 × 109 | 1.02 × 109 | |||||

| Chemical industry | CO2 | 1.54 × 107 | 1.54 × 107 | 1.54 × 107 | ||||

| Processes | Carbon Emission (1010 kg) | Proportion (%) |

|---|---|---|

| Mining | 0.46 | 13.10 |

| Selecting and washing | 0.02 | 0.57 |

| Transportation | 0.06 | 1.71 |

| Consumption | 2.97 | 84.62 |

| Total | 3.51 | 100 |

| Industrial Types | Carbon Emission (1010 kg) | Proportion (%) |

|---|---|---|

| Electricity industry | 0.296 | 9.95 |

| Steel industry | 2.540 | 85.41 |

| Cement industry | 0.136 | 4.57 |

| Chemical industry | 0.002 | 0.07 |

| Total | 2.974 | 100 |

| Greenhouse Gases | Equivalent Carbon Emission (1010 kg) | Proportion (%) |

|---|---|---|

| CO2 | 3.14 | 89.46 |

| N2O | 0.01 | 0.28 |

| CH4 | 0.36 | 10.26 |

| Total | 3.51 | 100 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, G.; Zhang, J.; Rao, Y.; Zhu, X.; Guo, Y. Coal Supply Chains: A Whole-Process-Based Measurement of Carbon Emissions in a Mining City of China. Energies 2017, 10, 1855. https://doi.org/10.3390/en10111855

Luo G, Zhang J, Rao Y, Zhu X, Guo Y. Coal Supply Chains: A Whole-Process-Based Measurement of Carbon Emissions in a Mining City of China. Energies. 2017; 10(11):1855. https://doi.org/10.3390/en10111855

Chicago/Turabian StyleLuo, Guangfang, Jianjun Zhang, Yongheng Rao, Xiaolei Zhu, and Yiqiang Guo. 2017. "Coal Supply Chains: A Whole-Process-Based Measurement of Carbon Emissions in a Mining City of China" Energies 10, no. 11: 1855. https://doi.org/10.3390/en10111855