Critical Speed Control for a Fixed Blade Variable Speed Wind Turbine

Abstract

:1. Introduction

- Region 1: Below cut in wind speed.

- Region 2: Between cut-in and below nominal wind speed.

- Region 3: Above nominal wind speed.

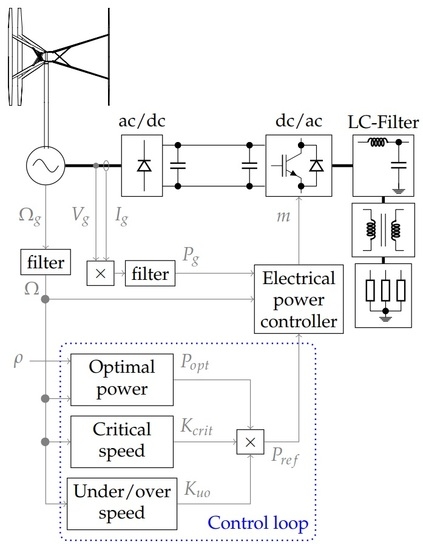

2. Control and Electrical Design

2.1. Optimal Power Control in Region 2

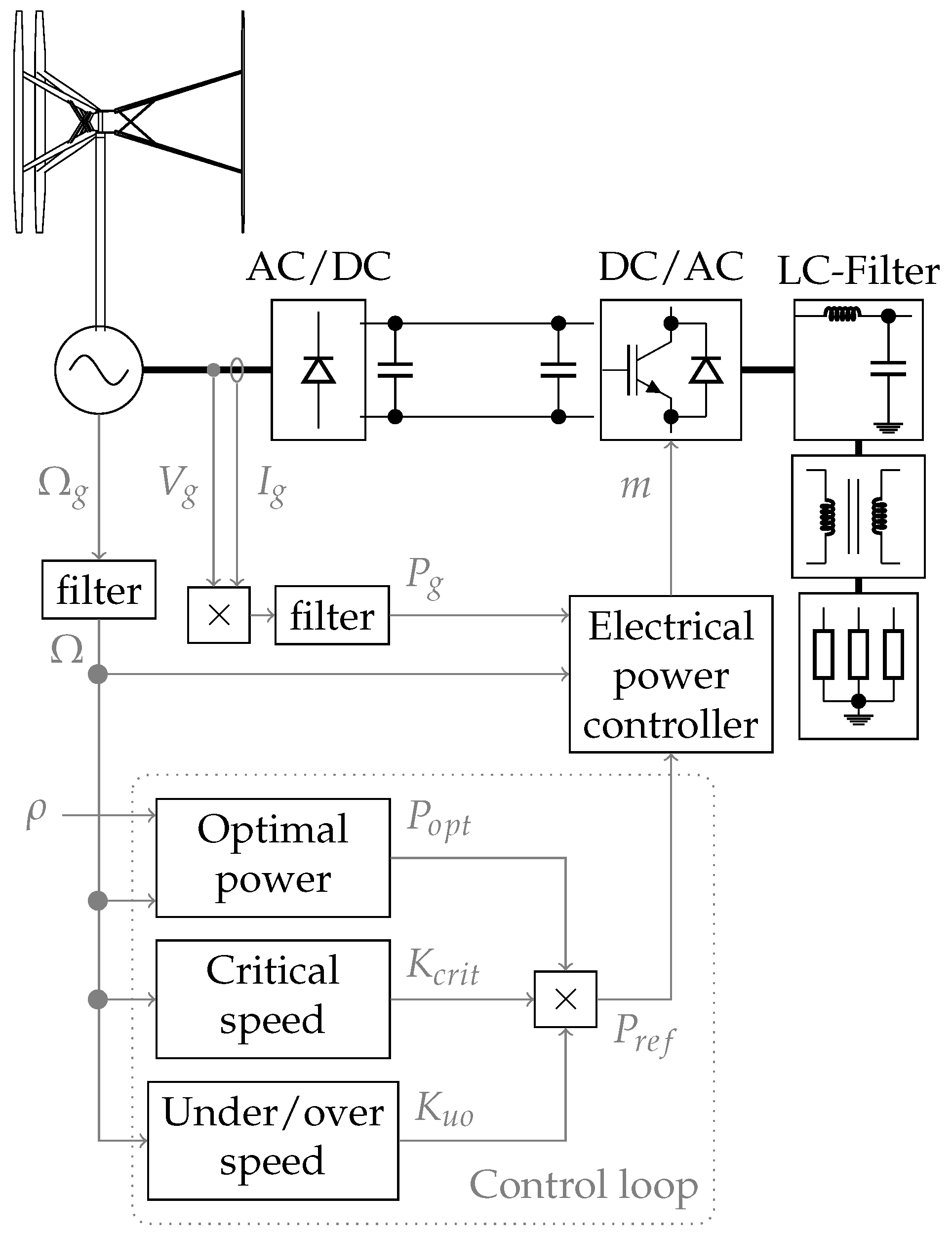

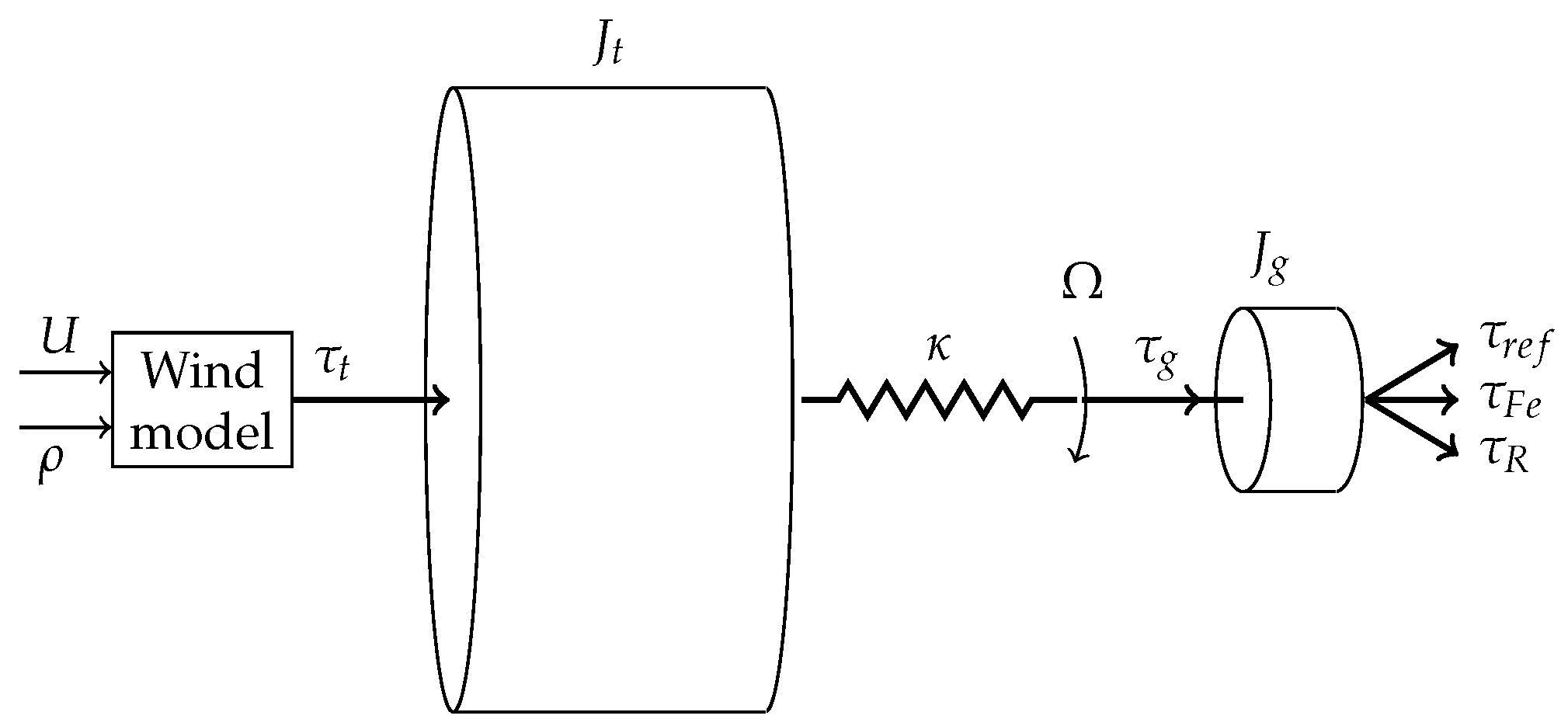

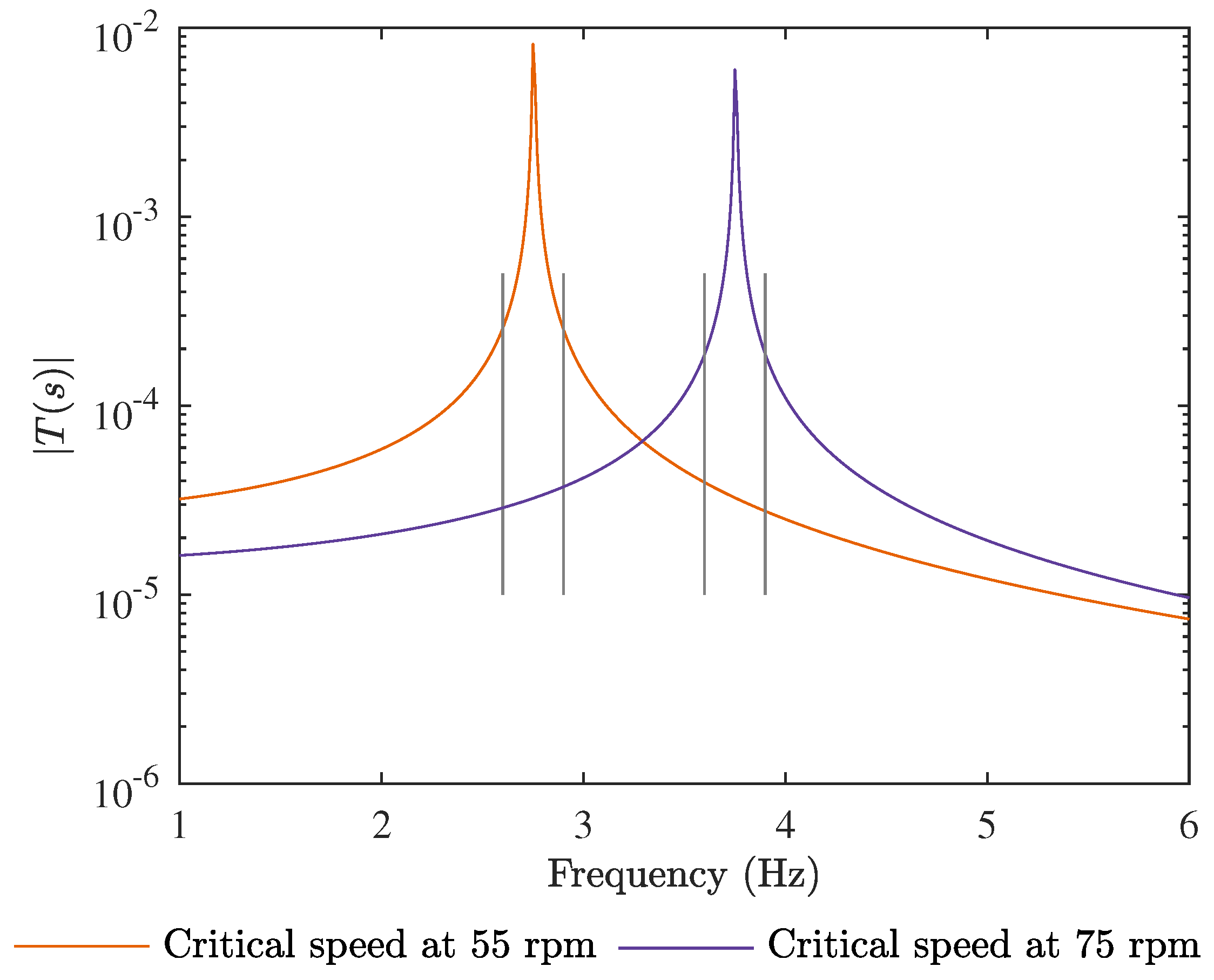

2.2. Critical Speed Controller

- “Init”: At system start, “Low” or “High” is selected based on if it is above or below “Switch-point HIGH”.

- The “Low”-strategy is used up until the rotational speed of “Switch-point HIGH”.

- The “High”-strategy is used down to the rotational speed of “Switch-point LOW”.

2.2.1. Hold Low, Hold High

2.2.2. Switch-Point Low, Switch-Point High

2.2.3. Critical

2.2.4. Controller Limitation

2.3. Under-/Over-Speed Control

2.4. Electrical Power Controller

2.5. Rotational Speed Filter

2.6. Generator Power Filter

3. Experiments

3.1. The Prototype

3.2. Measurement Campaign and Data Treatment

4. Simulations

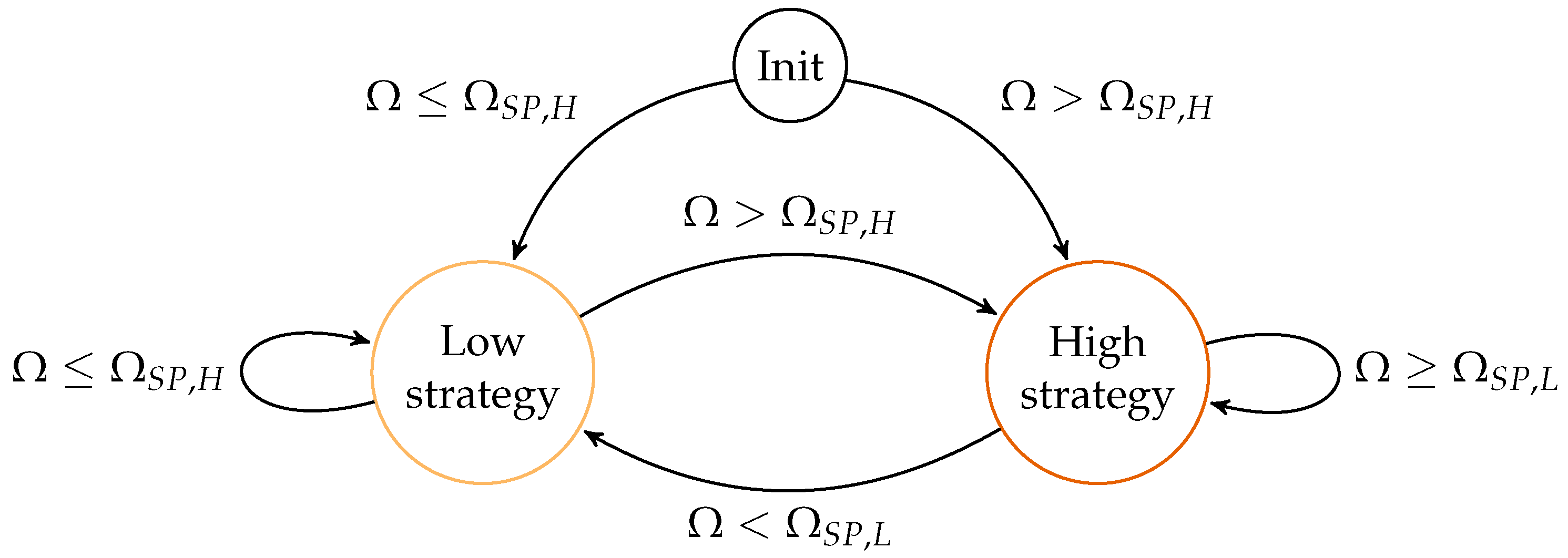

4.1. Wind Model

4.2. Load Model

4.3. Model of the Power Controller with Critical Speed

- Optimal power: This block was using the filtered rotational speed together with the power from (3) to obtain the torque reference.

- Critical speed control: This block contains the state machine and the two LUTs of relative power for the low and high strategy. The LUTs, with a resolution of rad/s, were implemented in a function block. The state was fed back to the next iteration using a delay-block.

- Under-/over-speed control: This block was using the filtered input rotational speed together with (4) to obtain the relative torque output.

4.4. Tower Model

4.5. Validation of the Simulation Model

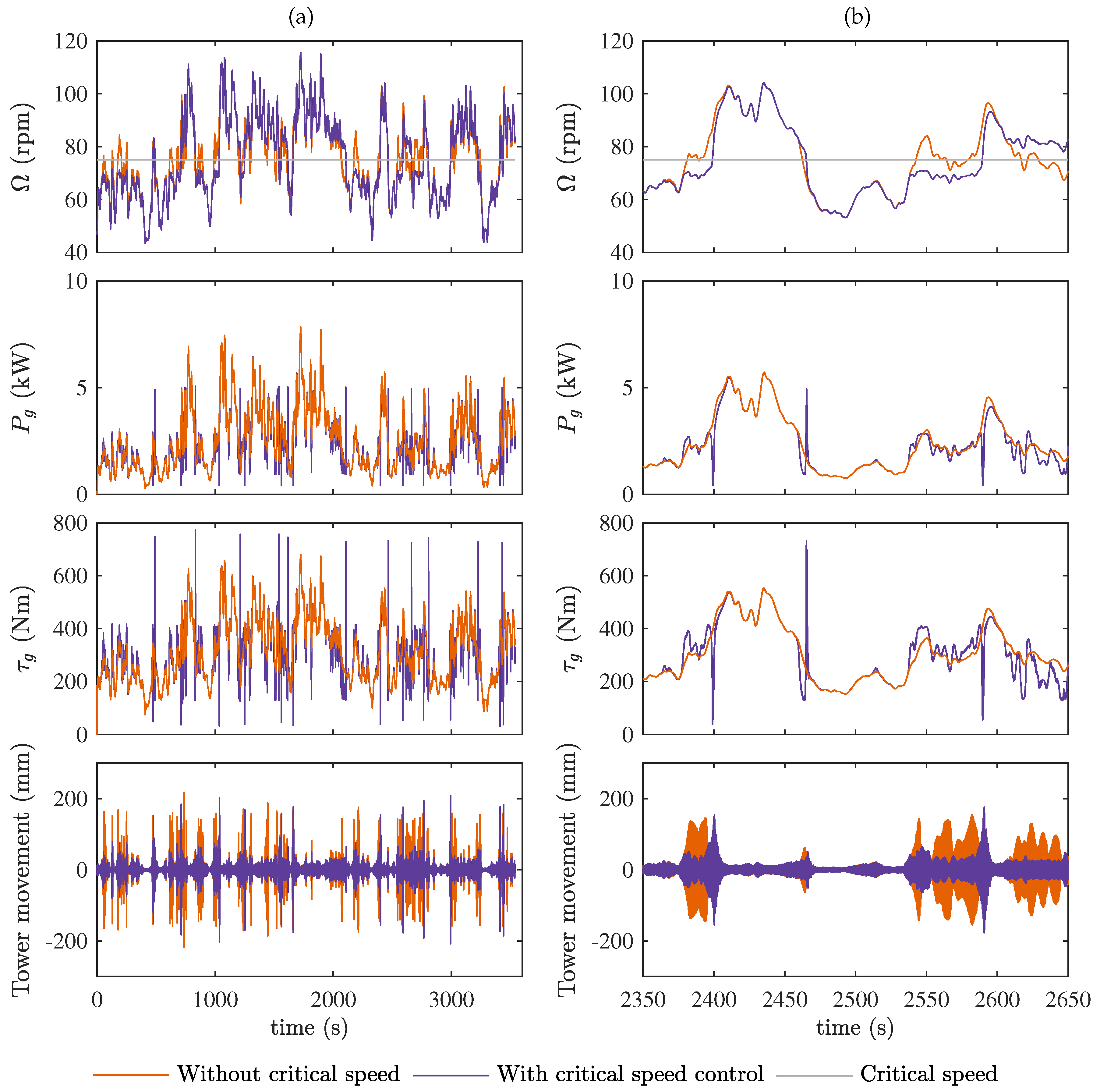

4.6. Evaluation of the Critical Speed Controller

- Number of skips (transactions) across the critical speed (up or down).

- Energy capture.

- Time spent within rpm of the critical speed; see Figure 5.

- The MAD (mean absolute deviation) of the power fluctuation.

- The expected tower dimension based on fatigue due to the movement at critical speed.

- Maximum shaft torque.

4.6.1. Tower Fatigue Estimations

4.6.2. Driveline Endurance Limit

4.6.3. Parameter Study of the Critical Coefficient

5. Results and Discussion

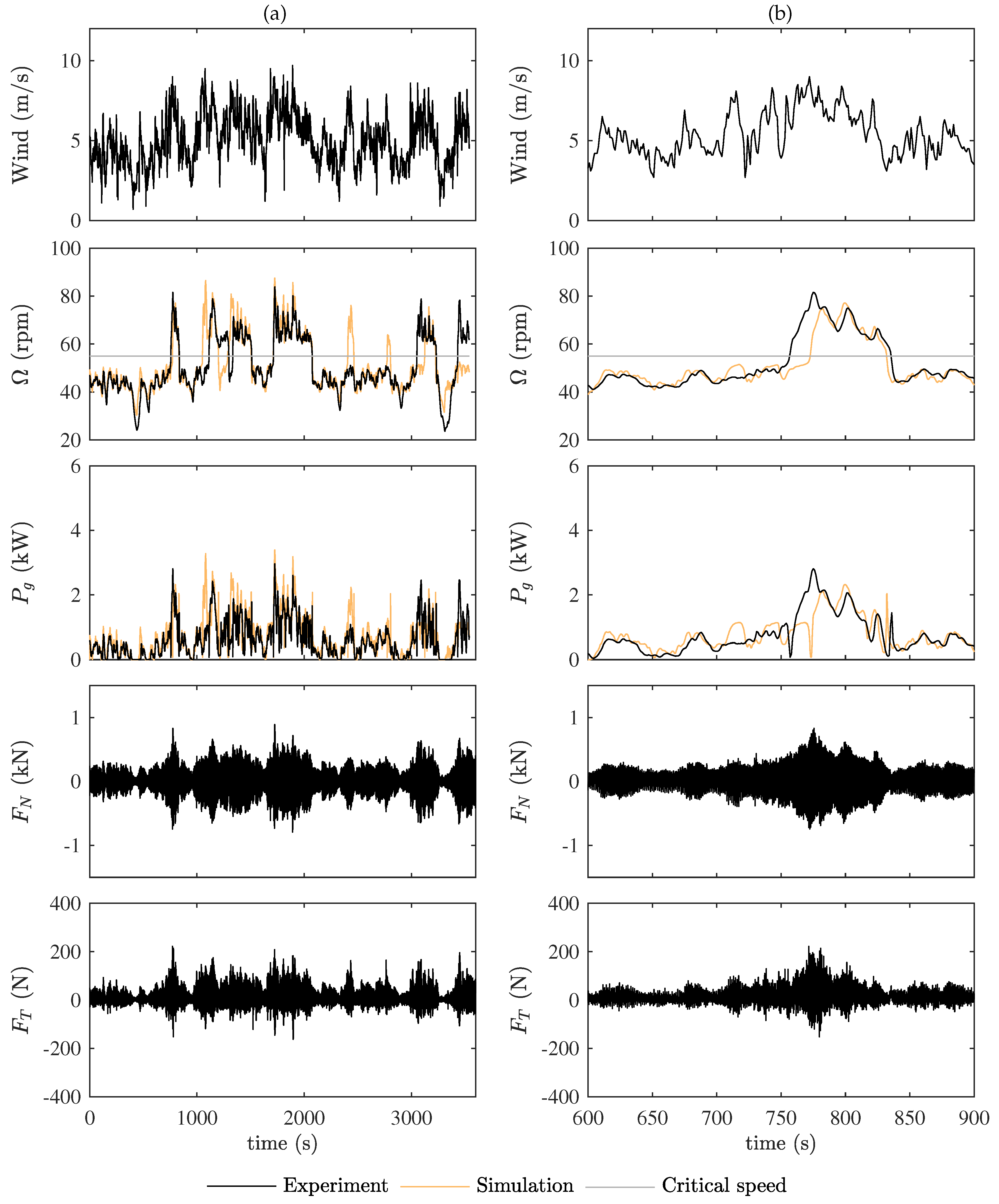

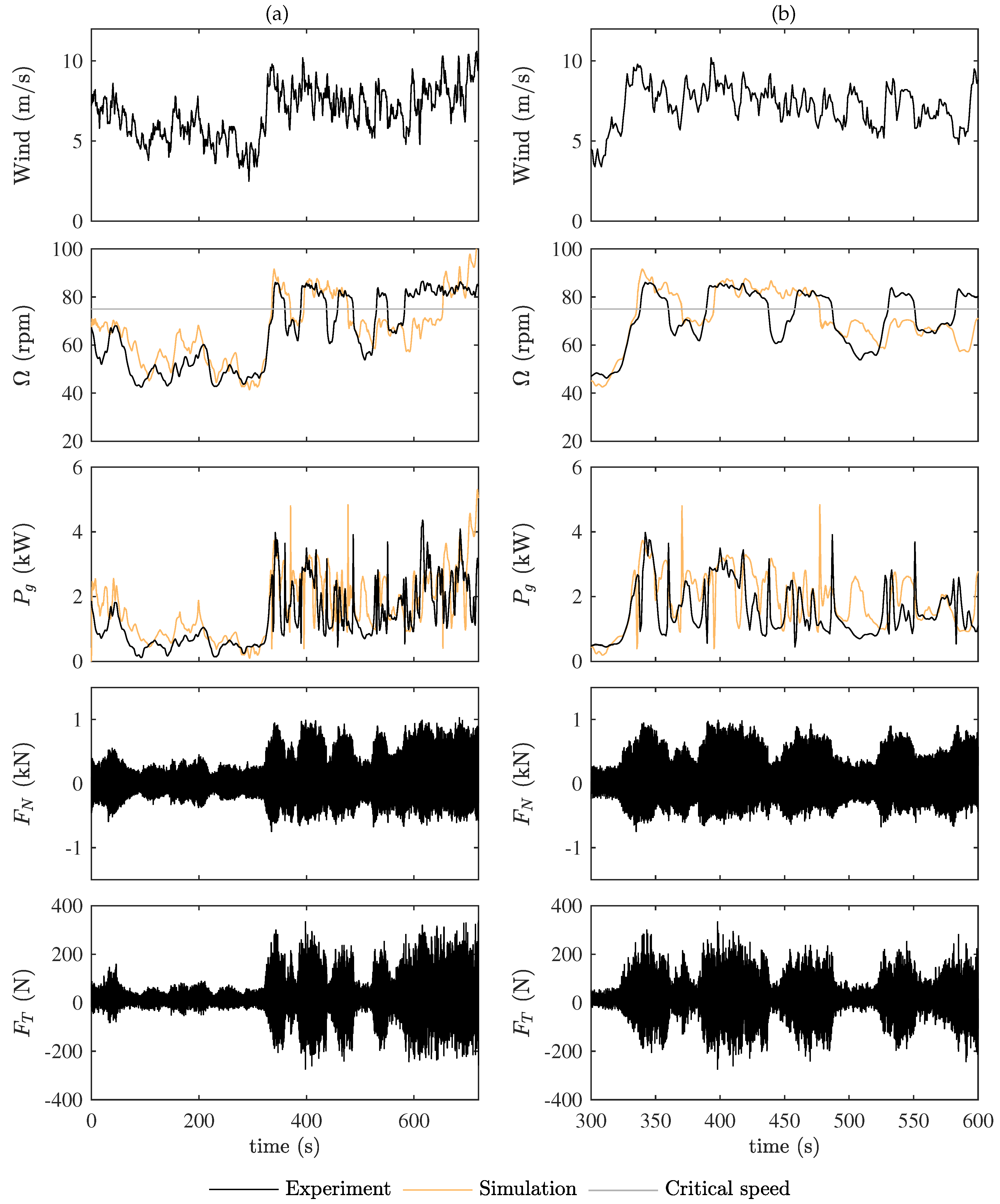

5.1. Experiments

5.2. Validation of the Simulation Model

5.3. Evaluation of the Critical Speed Controller

5.4. General Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A. Power at Hold Positions

References

- Darrieus, G.J.M. Turbine Having Its Rotating Shaft Transverse to the Flow of the Current. U.S. Patent 1,835,018, 8 December 1931. [Google Scholar]

- Tjiu, W.; Marnoto, T.; Mat, S.; Ruslan, M.H.; Sopian, K. Darrieus vertical axis wind turbine for power generation I: Assessment of Darrieus VAWT configurations. Renew. Energy 2015, 75, 50–67. [Google Scholar] [CrossRef]

- Tjiu, W.; Marnoto, T.; Mat, S.; Ruslan, M.H.; Sopian, K. Darrieus vertical axis wind turbine for power generation II: Challenges in HAWT and the opportunity of multi-megawatt Darrieus VAWT development. Renew. Energy 2015, 75, 560–571. [Google Scholar] [CrossRef]

- Apelfröjd, S.; Eriksson, S.; Bernhoff, H. A Review of Research on Large Scale Modern Vertical Axis Wind Turbines at Uppsala University. Energies 2016, 9, 570. [Google Scholar] [CrossRef]

- Sutherland, H.J.; Berg, D.E.; Ashwill, T.D. A Retrospective of VAWT Technology; Technical Report SAND2012-0304; Sandia National Laboratories: Albuquerque, NM, USA, 2012. [Google Scholar]

- Bossanyi, E.A. Individual Blade Pitch Control for Load Reduction. Wind Energy 2003, 6, 119–128. [Google Scholar] [CrossRef]

- Abdullah, M.A.; Yatim, A.H.M.; Tan, C.W.; Saidur, R. A review of maximum power point tracking algorithms for wind energy systems. Renew. Sustain. Energy Rev. 2012, 16, 3220–3227. [Google Scholar] [CrossRef]

- Musunuri, S.; Ginn, H.L. Comprehensive review of wind energy maximum power extraction algorithms. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–29 July 2011; pp. 1–8. [Google Scholar]

- Novak, P.; Ekelund, T.; Jovik, I.; Schmidtbauer, B. Modeling and control of variable-speed wind-turbine drive-system dynamics. IEEE Control Syst. 1995, 15, 28–38. [Google Scholar] [CrossRef]

- Johnson, K.E.; Fingersh, L.J.; Balas, M.J.; Pao, L.Y. Methods for increasing Region 2 power capture on a variable-speed wind turbine. J. Sol. Energy Eng. 2004, 126, 1092. [Google Scholar] [CrossRef]

- Muljadi, E.; Pierce, K.; Migliore, P. Soft-stall control for variable-speed stall-regulated wind turbines. J. Wind Eng. Ind. Aerodyn. 2000, 85, 277–291. [Google Scholar] [CrossRef]

- Dalala, Z.M.; Zahid, Z.U.; Lai, J.S. New Overall Control Strategy for Small-Scale WECS in MPPT and Stall Regions With Mode Transfer Control. IEEE Trans. Energy Convers. 2013, 28, 1082–1092. [Google Scholar] [CrossRef]

- Andriollo, M.; Bortoli, M.D.; Martinelli, G.; Morini, A.; Tortella, A. Control strategies for a VAWT driven PM synchronous generator. In Proceedings of the 2008 International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Ischia, Italy, 11–13 June 2008; pp. 804–809. [Google Scholar]

- Bossanyi, E.A. The Design of closed loop controllers for wind turbines. Wind Energy 2000, 3, 149–163. [Google Scholar] [CrossRef]

- Licari, J.; Ekanayake, J.B.; Jenkins, N. Investigation of a Speed Exclusion Zone to Prevent Tower Resonance in Variable-Speed Wind Turbines. IEEE Trans. Sustain. Energy 2013, 4, 977–984. [Google Scholar] [CrossRef]

- Schaak, P.; Corten, G.; van der Hooft, E. Crossing Resonance Rotor Speeds of Wind Turbines; Technical Report; Energy Research Centre of the Netherlands: Petten, The Netherlands, 2003. [Google Scholar]

- Yang, J.; Song, D.; Dong, M.; Chen, S.; Zou, L.; Guerrero, J.M. Comparative studies on control systems for a two-blade variable-speed wind turbine with a speed exclusion zone. Energy 2016, 109, 294–309. [Google Scholar] [CrossRef]

- Goude, A.; Bülow, F. Robust VAWT control system evaluation by coupled aerodynamic and electrical simulations. Renew. Energy 2013, 59, 193–201. [Google Scholar] [CrossRef]

- Kjellin, J.; Bülow, F.; Eriksson, S.; Deglaire, P. Power coefficient measurement on a 12 kW straight bladed vertical axis wind turbine. Renew. Energy 2011, 36, 3050–3053. [Google Scholar] [CrossRef]

- Dyachuk, E.; Rossander, M.; Goude, A.; Bernhoff, H. Measurements of the Aerodynamic Normal Forces on a 12-kW Straight-Bladed Vertical Axis Wind Turbine. Energies 2015, 8, 8482–8496. [Google Scholar] [CrossRef]

- Rossander, M.; Goude, A.; Bernhoff, H.; Eriksson, S. Frequency analysis of tangential force measurements on a vertical axis wind turbine. J. Phys. Conf. Ser. 2016, 753, 042016. [Google Scholar] [CrossRef]

- Rossander, M.; Goude, A.; Eriksson, S. Mechanical Torque Ripple From a Passive Diode Rectifier in a 12 kW Vertical Axis Wind Turbine. IEEE Trans. Energy Convers. 2017, 32, 164–171. [Google Scholar] [CrossRef]

- Eriksson, S.; Kjellin, J.; Bernhoff, H. Tip speed ratio control of a 200 kW VAWT with synchronous generator and variable DC voltage. Energy Sci. Eng. 2013, 1, 135–143. [Google Scholar] [CrossRef]

- Kjellin, J.; Eriksson, S.; Bernhoff, H. Electric Control Substituting Pitch Control for Large Wind Turbines. J. Wind Energy 2013, 2013, 1–4. [Google Scholar] [CrossRef]

- Rossander, M.; Dyachuk, E.; Apelfröjd, S.; Trolin, K.; Goude, A.; Bernhoff, H.; Eriksson, S. Evaluation of a Blade Force Measurement System for a Vertical Axis Wind Turbine Using Load Cells. Energies 2015, 8, 5973–5996. [Google Scholar] [CrossRef]

- Bossanyi, E.A. Wind Turbine Control for Load Reduction. Wind Energy 2003, 6, 229–244. [Google Scholar] [CrossRef]

- Knight, A.M.; Peters, G.E. Simple Wind Energy Controller for an Expanded Operating Range. IEEE Trans. Energy Convers. 2005, 20, 459–466. [Google Scholar] [CrossRef]

- Bohn, C.; Atherton, D.A. Analysis package comparing PID anti-windup strategies. IEEE Control Syst. Mag. 1995, 15, 34–40. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, K.; Gao, Z.; Moan, T. A comparative study on dynamic responses of spar-type floating horizontal and vertical axis wind turbines. Wind Energy 2016, 17, 657–669. [Google Scholar] [CrossRef]

- Bülow, F.; Eriksson, S.; Bernhoff, H. No-load core loss prediction of PM generator at low electrical frequency. Renew. Energy 2012, 43, 389–392. [Google Scholar] [CrossRef]

- Möllerström, E.; Ottermo, F.; Goude, A.; Eriksson, S.; Hylander, J.; Bernhoff, H. Turbulence influence on wind energy extraction for a medium size vertical axis wind turbine. Wind Energy 2016, 19, 1963–1973. [Google Scholar] [CrossRef]

- Boardman, B. Fatigue Resistance of Steels. In ASM Handbook, Volume 01—Properties and Selection: Irons, Steels, and High-Performance Alloys; ASM International: Geauga County, OH, USA, 1990; Volume 1, pp. 673–688. [Google Scholar]

| Description | Rotational Speed, Ω | for the Low Strategy | for the High Strategy |

|---|---|---|---|

| Start * | 1 | 1 | |

| Switch-point LOW | |||

| Hold Low ** | - | ||

| Critical ** | |||

| Hold High ** | - | ||

| Switch-point HIGH | |||

| End * | 1 | 1 |

| Parameter | Experiment | Simulation | Guide for Selection * |

|---|---|---|---|

| Hold margin, | 0.4 rad/s | Specifies the speed exclusion zone as . | |

| Switch point margin, | 0.5 rad/s | Keep close to ⇒ low risk of failed skips. | |

| Increase ⇒ smooth transaction to the hold point. | |||

| Start/end margin, | 1.0 rad/s | Low value ⇒ narrow affected range. | |

| Large value ⇒ smooth transaction to the hold point. | |||

| Critical coefficient, | 0.5 | 0.5 ** | Within 0.1–0.9. Low value ⇒ less drivetrain stress. |

| Large value ⇒ fast, ensured skips. | |||

| Hold Low coefficient, | 1.00 | 1.10 *** | Around 1. Increase ⇒ decrease skip up tendency |

| Hold High coefficient, | 1.00 | 0.85 *** | Around 1. Increase ⇒ increase skip down tendency |

| Rated power | 12 kW |

| Nominal rotational speed | 127 rpm |

| Nominal torque | 900 Nm |

| Number of generator pole-pairs | 16 |

| No load voltage, line to neutral | 161 V |

| DC-link capacitance | mF |

| Number of blades | 3 |

| Turbine radius, | m |

| Shaft torsion spring constant , | kNm/rad |

| Inertia of generator rotor, | kg m2 |

| Inertia of turbine, | 525 kg m2 |

| Optimal power coefficient , | 0.29 |

| Optimal tip speed ratio , | 3.4 |

| Measurement sample rate | 2 kHz |

| Rotational speed filter order | 25 |

| Rotational speed filter cutoff | p |

| Power filter order | 2 |

| Power filter cutoff | 10 Hz |

| Control loop speed | 10 Hz |

| Electric power controller loop speed | 1 kHz |

| SPWM switching frequency | kHz |

| Wind Optimization Method | (rpm) | No. of Skips | Critical Speed Control Compared to Optimal Power Control | ||||

|---|---|---|---|---|---|---|---|

| Energy Capture (%) | Time in Critical (%) | Power Fluctuation (%) | Tower Strength * (%) | Shaft Torque (%) | |||

| AVG | 55 | 17 | 90.8 | 8.2 | 90.6 | 70.3 | 100.0 |

| CMC | 55 | 15 | 91.9 | 7.4 | 91.8 | 75.9 | 103.1 |

| AVG | 75 | 23 | 98.2 | 7.7 | 103.7 | 76.5 | 113.9 |

| CMC | 75 | 29 | 98.3 | 8.3 | 103.4 | 75.6 | 123.4 |

| (rpm) | No. of Skips | Critical Speed Control Compared to Optimal Power Control | Max Shaft Torque (Nm) | ||||

|---|---|---|---|---|---|---|---|

| Energy Capture (%) | Time in Critical (%) | Power Fluctuation (%) | Tower Strength * (%) | ||||

| 0.2 | 55 | 17 | 90.8 | 8.8 | 90.5 | 69.3 | 456 |

| 0.3 | 55 | 17 | 90.8 | 8.6 | 90.6 | 69.8 | 456 |

| 0.4 | 55 | 17 | 90.8 | 8.4 | 90.7 | 70.3 | 456 |

| 0.5 | 55 | 17 | 90.8 | 8.2 | 90.6 | 70.3 | 456 |

| 0.6 | 55 | 17 | 90.8 | 8.1 | 91.0 | 70.1 | 456 |

| 0.7 | 55 | 17 | 90.9 | 8.0 | 91.1 | 70.1 | 470 |

| 0.8 | 55 | 17 | 90.9 | 7.9 | 91.3 | 70.1 | 519 |

| 0.2 | 75 | 23 | 98.2 | 8.7 | 103.0 | 77.2 | 679 |

| 0.3 | 75 | 23 | 98.2 | 8.3 | 103.2 | 77.3 | 679 |

| 0.4 | 75 | 23 | 98.2 | 8.0 | 103.6 | 77.2 | 724 |

| 0.5 | 75 | 23 | 98.2 | 7.7 | 103.7 | 76.5 | 774 |

| 0.6 | 75 | 23 | 98.2 | 7.4 | 104.1 | 75.8 | 821 |

| 0.7 | 75 | 23 | 98.3 | 7.2 | 104.1 | 75.2 | 903 |

| 0.8 | 75 | 23 | 98.3 | 7.1 | 104.4 | 75.0 | 980 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rossander, M.; Goude, A.; Eriksson, S. Critical Speed Control for a Fixed Blade Variable Speed Wind Turbine. Energies 2017, 10, 1699. https://doi.org/10.3390/en10111699

Rossander M, Goude A, Eriksson S. Critical Speed Control for a Fixed Blade Variable Speed Wind Turbine. Energies. 2017; 10(11):1699. https://doi.org/10.3390/en10111699

Chicago/Turabian StyleRossander, Morgan, Anders Goude, and Sandra Eriksson. 2017. "Critical Speed Control for a Fixed Blade Variable Speed Wind Turbine" Energies 10, no. 11: 1699. https://doi.org/10.3390/en10111699