1. Introduction

In contrast with lives illuminated by electricity in well-developed urban areas, over 1085 million people around the globe are still managing to make a living in the dark with no access to electricity [

1]. For remote areas such as rural villages and isolated islands, conventional grid electrification is extremely expensive, or even impractical due to geographical inaccessibility. In this context, small autonomy power system (SAPS), composed of diesel generator, is generally considered as a feasible solution for power supply [

2]. Nevertheless, continuous burning of fossil fuel releases a huge amount of greenhouse gas into the atmosphere as an inevitable consequence, which will lead to serious deterioration of ecological environment.

Fortunately, the majority of these remote areas usually reserve abundant of renewable sources such as solar and wind energy, which are widely distributed, freely available and environmental friendly comparing to the conventional fossil based energy [

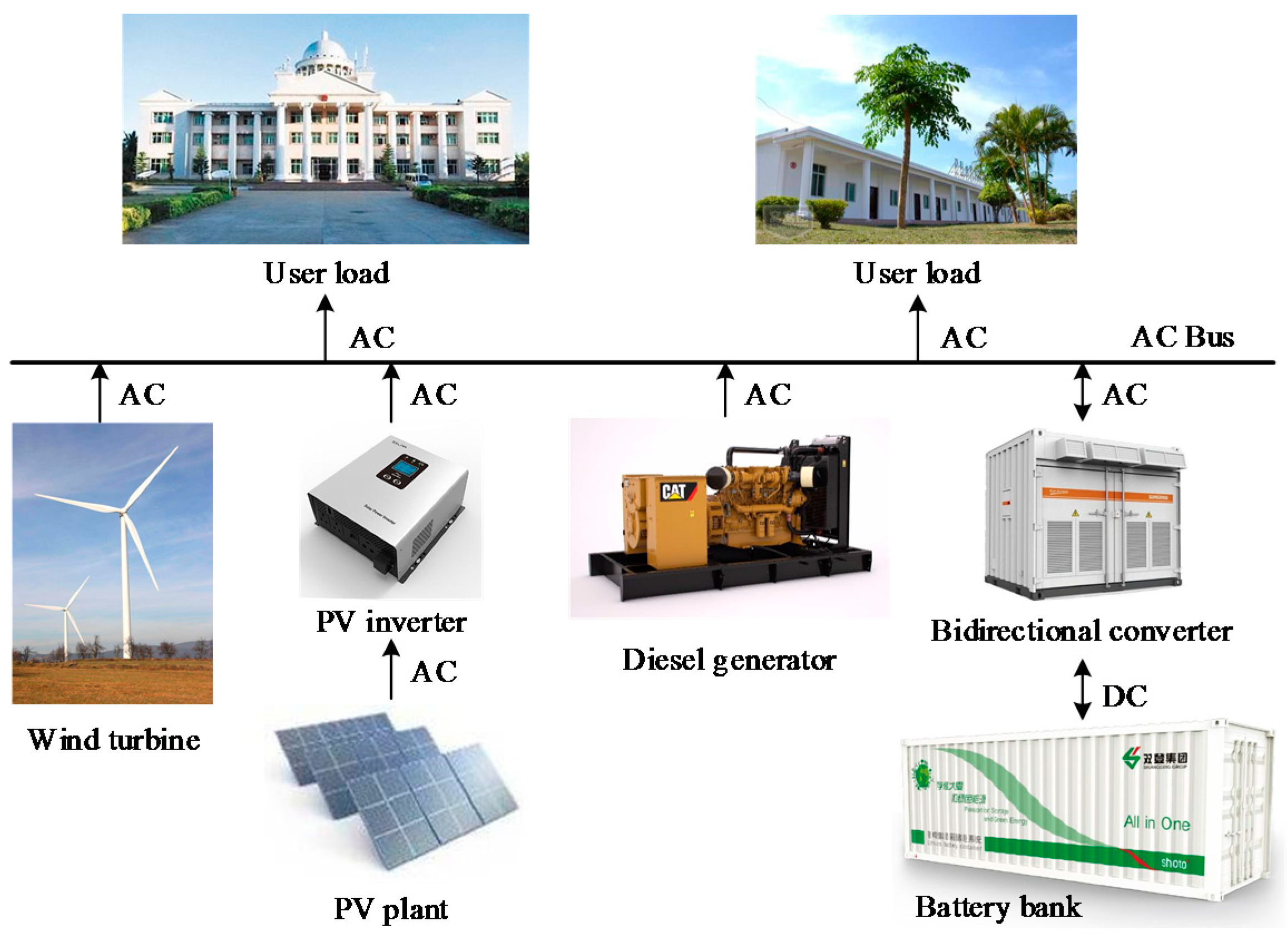

3]. In this regard, integrating these renewable based generating units with battery storage and backup diesel generator into a HES cannot only tackle the aforementioned environmental problems, but also satisfy the electrification requirements for these remote areas.

However, with the growing penetration of renewable power in HES, the unpredictable output of renewable based generating units has a significant impact on the reliability of distribution system, since the intermittent and stochastic nature of renewable sources impose considerable uncertainty to the power generation [

4]. In this case, it is quite necessary for an optimal design of HES to ensure the consistency of power supply, as well as to utilize the renewable sources in an efficient and economic manner.

The optimal design of HES is a multi-objective optimization problem with contradicting objectives [

5]. Several literatures on HES optimization have been published with different methodologies and objectives [

6,

7,

8,

9]. The classic optimization approaches such as iterative technique [

10], linear programming method [

11], design space concept [

12] and analytical model [

13] were adopted in earlier researches. Nevertheless, classic optimization approaches are easily trapped in the local optimum [

14]. In order to overcome this drawback, the meta-heuristic approaches were adopted owing to their ability to find the global optimum. Wu et al. [

15] introduced a novel reconfiguration methodology for distribution system that guaranteed increment of load balance factor with minimum power loss, and the ant colony algorithm was used to find the global optimal solution due to its outstanding characteristics of positive feedback, constructive greedy heuristics and distributed computation. Shayeghi and Hashemi [

16] addressed the attuned design of a hybrid generation system by using the non-dominated sorting genetic algorithm-II. Three principal aims including economic, reliability and environmental criteria were simultaneously considered, and the fuzzy decision making method was introduced for selecting the best compromised configuration from a set of Pareto optimum solutions. Raji et al. [

17] proceeded a dimensioning of distributed renewable generation and a distributed energy storage system by utilizing the genetic algorithm (GA). Minimization of the power supply cost and the battery value loss were achieved, and a distribution microgrid in Okinawa was used for testing the algorithm. Baghaee et al. [

18] proposed a multi-objective particle swarm optimization based methodology for sizing a stand-alone solar/wind/fuel cell generation microgrid system, in order to minimize three objective functions viz. loss of load expected, annualized cost of system and loss of energy expected during 20 years operation period. Katsigiannis et al. [

19] presented a simulated annealing-tabu search hybrid optimization algorithm, which fully took the advantages of both meta-heuristic methods to design a small autonomous power system with the least cost of energy. Dufo-López et al. [

20] developed the Hybrid Optimization by Genetic Algorithms (HOGA) as a design tool for HES optimization. HOGA utilized the multi-objective evolutionary algorithm as main algorithm to find the optimal size of major components to minimize CO

2 emissions and cost of energy, then, GA was applied as secondary algorithm to search the optimum control strategy for each feasible combination of components with least cost. Apparently, the meta-heuristic approaches have excellent performance on identifying the global optimum solution. However, it should be noted that, complicated codification and long computational time due to massive iterative calculations are the two main shortcomings of metaheuristic approaches. In addition, a set of trade-off solutions known as the Pareto optimal set is mostly obtained by using the Pareto based meta-heuristic method. Although the Pareto optimal set is able to provide an effective support on decision-making, the final decision still relies heavily on the subjective judgments of designer.

In the last decade, several softwares have been developed for designing and optimizing HES [

21]. The Hybrid Optimization of Multiple Energy Resources (HOMER) is one of the most popular optimization softwares with the advantage of easy implementation and high efficiency [

22,

23,

24,

25]. It is able to conduct a time series simulation of HES and generate a set of feasible configurations sorted by the total net present cost. During the optimization process, both reliability and environmental indices will be converted into penalty functions as the additional cost of the system. Then, the multi-objective optimization problem is transformed into a single-objective one with the only target of system cost. Finally, the configuration with minimum total net present cost will be recommended as the optimal system. However, for practical design of HES, it is more reasonable to take all of these indices into consideration rather than just converting them into penalty functions.

For this reason, a decision-making methodology is proposed for searching the best trade-off configuration of HES from a set of feasible combinations obtained from HOMER. A multi-objective function, which comprises four crucial and representative indices, is formulated considering the reliable, economic, practical and environmental performance of HES. Moreover, in order to enhance the objectivity of decision making, the entropy weight method is employed as a quantitative methodology for weighting factors calculation. In the end, the optimal design of a stand-alone PV/wind/battery/diesel HES in Yongxing Island, China, is conducted as a case study in order to validate the effectiveness of the proposed optimization method.

This paper is organized as follows,

Section 1 gives the introduction.

Section 2 describes the proposed HES. The optimization problem is formulated in

Section 3.

Section 4 elaborates the proposed method. Results and discussions are presented in

Section 5. In the end,

Section 6 summarizes the conclusion.

5. Results and Discussions

5.1. Case Study

The proposed method was adopted for optimal design of a stand-alone HES in Yongxing Island, China, which is one of the remote islands located in The South China Sea (11.84° N latitude and 112.34° E longitude).

The meteorological data including monthly average solar irradiation, wind speed and ambient temperature of Yongxing Island are obtained from NASA atmospheric database [

42]. The annual average solar irradiation and wind speed are 5.57 kWh/m

2/day and 7.29 m/s, respectively.

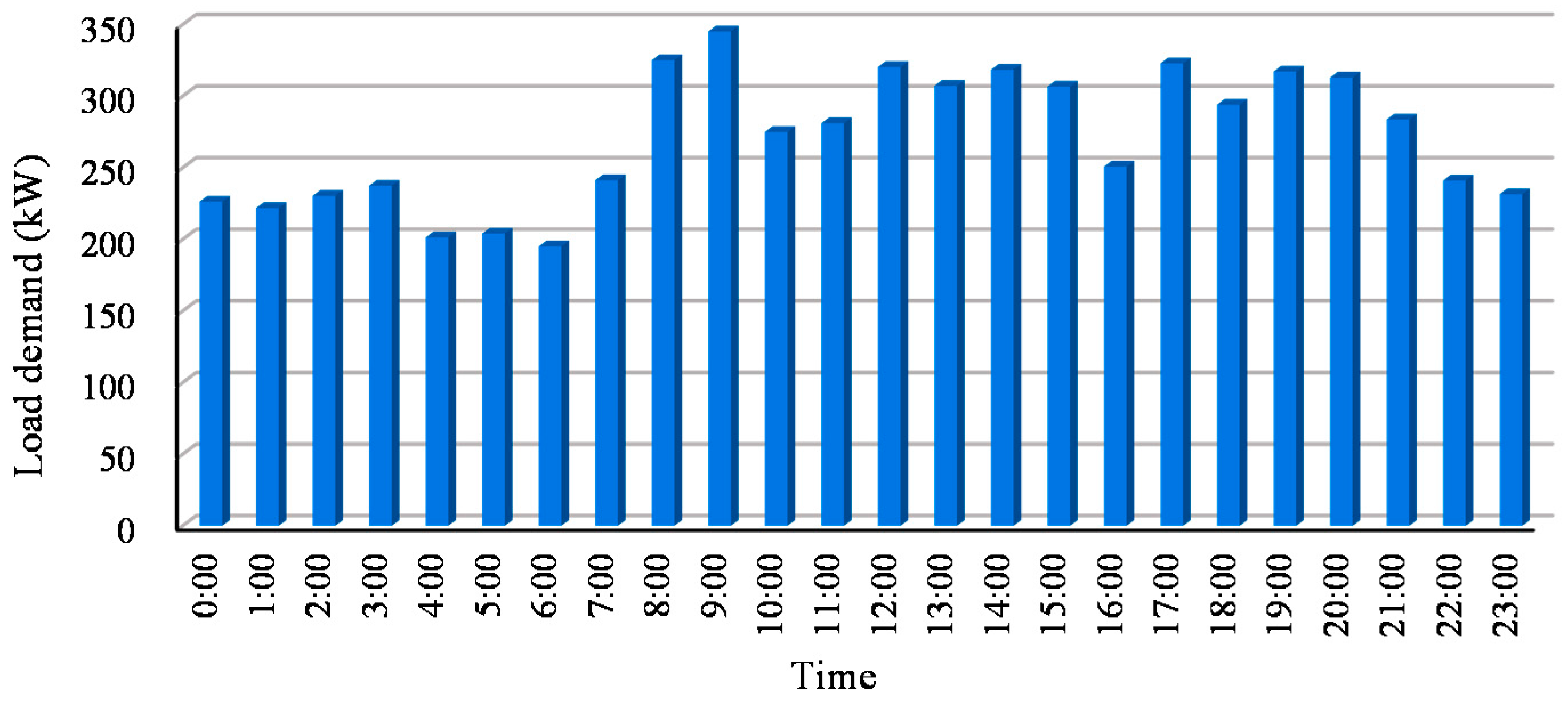

The typical daily load profile is taken from the existing energy management system on Yongxing Island. As shown in

Figure 4, the average and peak load are 269.5 kW and 345.2 kW, respectively. The load profile maintains in the vicinity of 200 kW from 11 p.m. to 6 a.m., accounting for about 60% of the total capacity of the system due to many refrigeration equipment operates around the clock under the high annual average temperature (26.1 °C). Moreover, the price of fossil fuel is 1.38

$/L since high transport costs.

According to the specifications of selected battery in

Table 3 and Equation (4), each autonomy-hour corresponds to approximately 234 batteries (about 449 kWh of the capacity of battery bank). The minimum

is assumed to be 1 h to offer the emergency power supply for HES.

Given the land planning of Yongxing Island, the maximum OA for PV panel and wind turbine installation are 4800 m2 and 4250 m2, respectively. Therefore, the rated power of PV panel is set between 0 kWp to 948.09 kWp (correspond to 4794 m2) with a step size of 55.77 kWp, the rated number of wind turbine is predefined from 0 to 22 (correspond to 4202 m2) with a step size of 1, and the is set between 1 h to 5 h with a step size of 1 h, which means there are 2070 configurations in the search space and to be simulated by HOMER.

5.2. Economic Analysis

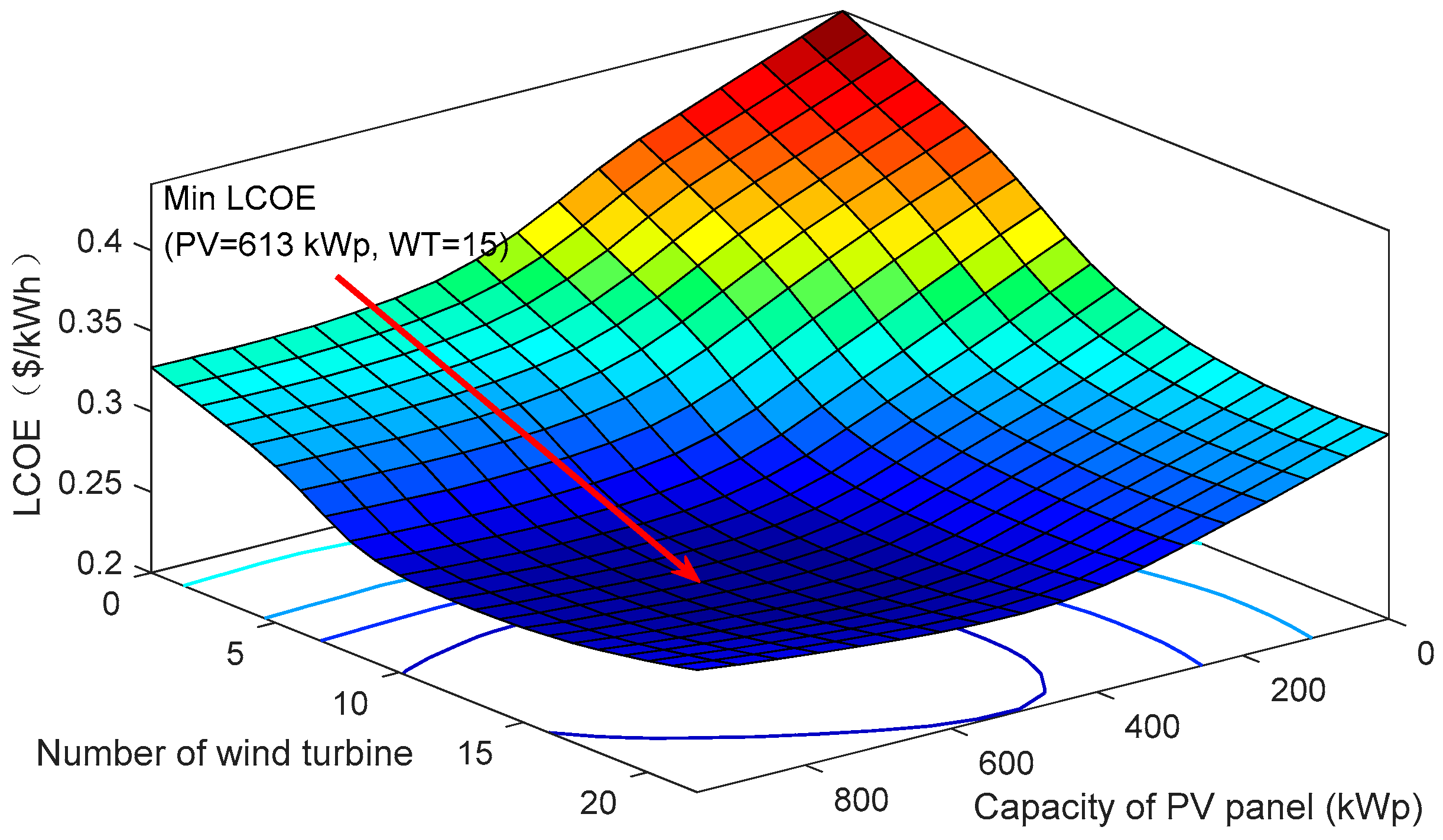

In order to investigate the economic performance of proposed HES,

Figure 5 gives the

LCOE for different sizes of PV panels and wind turbines (with

), which are calculated according to the simulation results obtained from HOMER.

As shown in

Figure 5, the

LCOE decreases gradually with the increasing size of PV panels and wind turbines, and reaches the lowest value at the sizing point of PV = 613.47 kWp and WT = 15. For this reason, HES is economically feasible comparing with the conventional diesel generator system with the assumption of using the same generator (correspond to the sizing point of PV = 0 kWp, WT = 0). Moreover,

LCOE of the economic best scenario (PV = 613.47 kWp, WT = 15,

AH = 2) is 0.25

$/kWh, the reduction is as high 43.6% as compared to the conventional diesel generator system.

5.3. Environmental Analysis

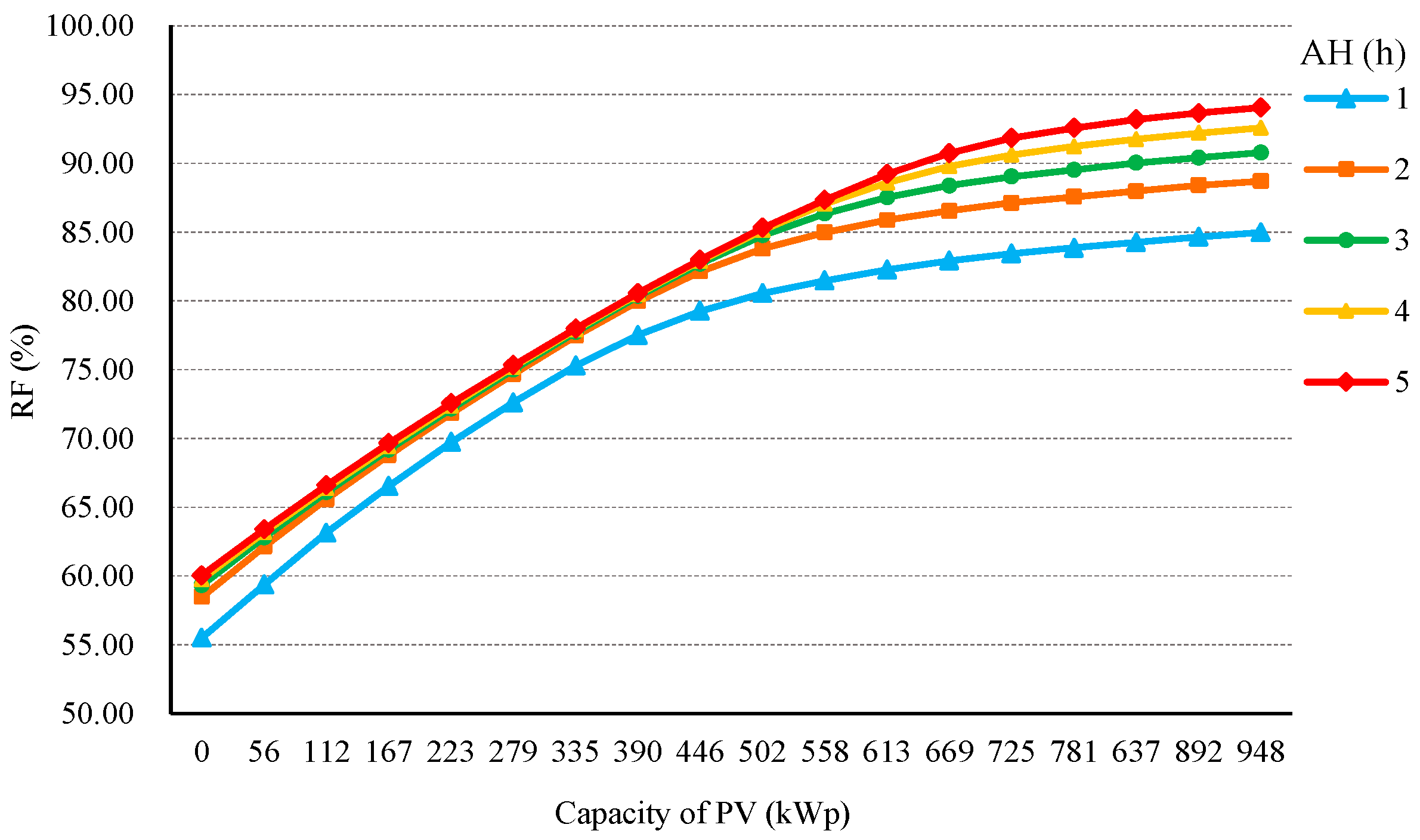

Figure 6 shows the

RF for different sizes of PV panels and

AH (with WT = 15). It is obvious that, the application of the proposed HES is beneficial for environment since the majority of scenarios reach

RF more than 50%. Meanwhile, with the same number of wind turbines, the more capacity of PV panels, the more penetration of renewable power is achieved. Besides, from the environmental perspective, it is more reasonable to meet the power deficit by expanding the capacity of battery bank, rather than utilizing the backup diesel generator and burning fossil fuel. Thus, the

RF would reach the maximum value of 97.08% at the sizing point of PV = 948.09 kWp, WT = 22 and

AH = 5, which are the upper limit for each component.

5.4. Optimal Design of HES

In the beginning of the optimization process, both the information entropy and the weighting factors of each index are calculated based on the simulation data obtained from HOMER and the entropy weight method. Calculation results are presented in

Table 5.

As mentioned in

Section 4.1, the information entropy is a quantitative measurement of uncertainty. Hence, when the

ith index has more disorder rating values, its information entropy is lower, and the weighting factor is higher, which means this index provides more valuable information from the viewpoint of information theory, and should be especially considered. In this regard, the practical index

OA which possesses the lowest value of information entropy among all the indices, can be regarded as the most important factor for the objective function. Eventually, according to the rating values of each alternative, the configuration with a PV panel capacity of 613.47 kW, wind turbine number of 9 and battery bank capacity of 1796 kWh is recommended as the best configuration.

In order to demonstrate the effectiveness of the proposed method, three scenarios have been created with different indices:

Scenario 1: The most economical scenario. Only LCOE is taken into consideration, and the rest of the indices in Equation (18) are neglected. Configuration with least LCOE would be recognized as the most economical scenario.

Scenario 2: The most practical scenario. According to simulation results from HOMER, there are only 1941 feasible configurations compliant with the regulations presented by the State Grid Corporation of China (LOLE ≤ 8). Among them, the configuration with least OA would be recognized as the most practical scenario.

Scenario 3: The environmental best scenario. This scenario is similar to the most economical one, except the index is composed of RF only, and the configuration with maximum RF would be recognized as the environmental best scenario.

Here, simulation results of abovementioned scenarios and the best configuration are presented in

Table 6.

Apparently, there are prominent differences in the indices of different scenarios. In terms of system reliability, LOLE of the best configuration is 0 h, indicating that the best configuration is able to provide a reliable and sustainable power supply. Besides, comparing to the most economical scenario, LCOE of the best configuration increase 4.18% only, whereas OA decrease over 25%, meaning that the best configuration achieves an excellent trade-off between economic and practical performance of HES. Moreover, in the best configuration, renewable energy provides the majority of total electric load demand (81%), by contrast, duo to the environmental best scenario suggests more capacity of distributed generating units, the capacity of PV panels and wind turbines are 54.5% and 144% more than that of the best configuration. Furthermore, although OA of the best configuration is six times of the most practical solution, the best configuration which only covers an area of 3361 m2 (about 2% of the island area), still has a high practicability. Therefore, we can draw a conclusion that the best configuration can be recognized as the best trade-off solution among system reliability, economy, practicability and environmental sustainability.

5.5. Analysis of the Best Configuration

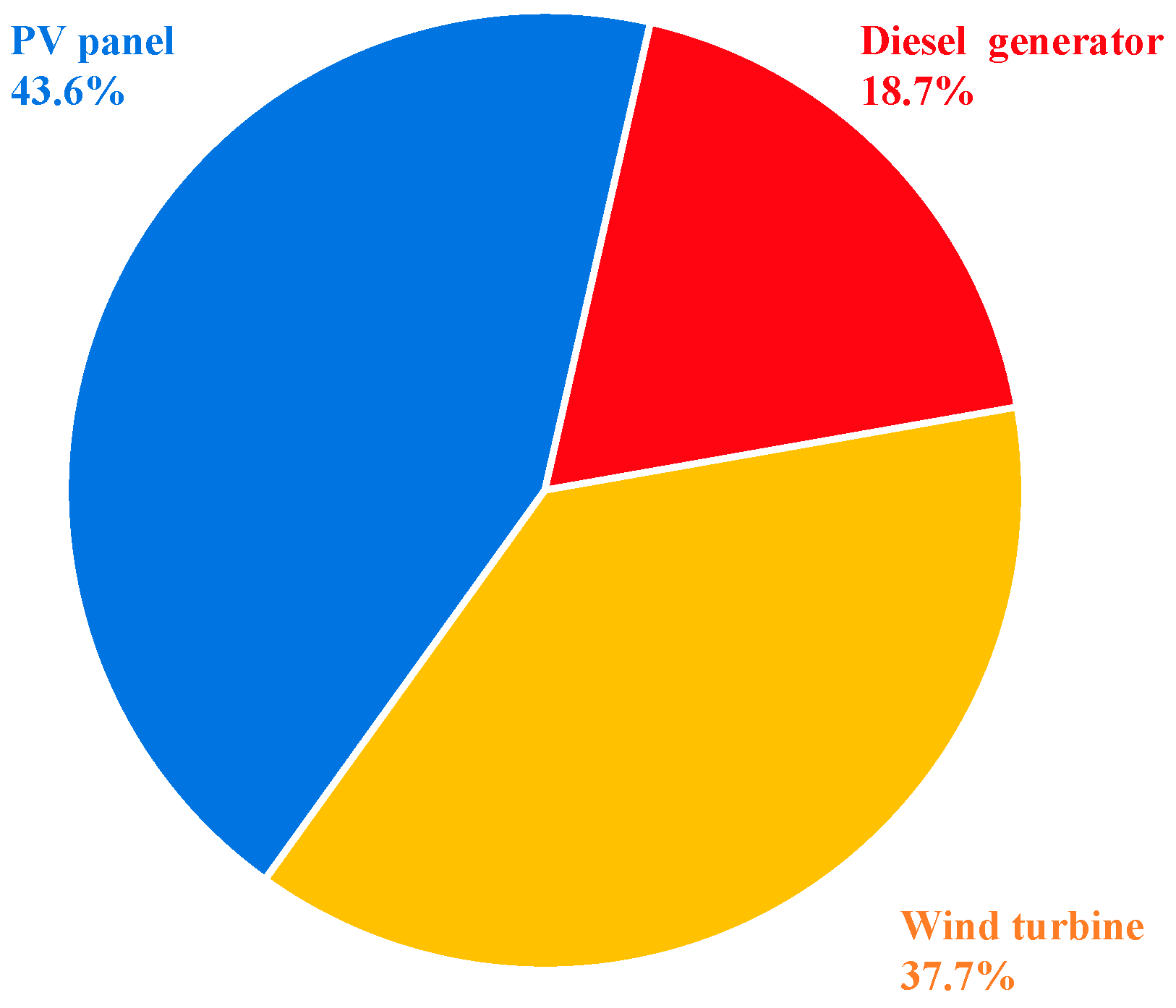

For the best configuration, the percentage of power generation from PV panels, wind turbines and diesel generator over a year are exhibited in

Figure 7. The system mainly works on PV panels and wind turbines, with a high penetration of energy generated from renewables. Therefore, considering the intense solar irradiation and high wind speed, the proposed HES can be considered as a promising alternative for electrification in Yongxing Island.

The cost distribution for the best configuration is illustrated in

Figure 8. Apparently, with enormous cost of fossil fuel which is caused by high transportation expenses, the cost of diesel generator accounting for 38.89% of total costs is the highest among all of these distributed generating units. In contrast, despite generating about 43.6% of the system’s total power generation, the cost of PV panel is still lower than that of diesel generator, which signifies the fact that the PV panel is the most cost-effective choice for power generation in the study area. It is noteworthy that battery bank covers 15.64% of total costs, due to the expensive replacement cost and the short life of batteries caused by frequent charging and discharging operation for power balancing.

5.6. Sensitivity Analysis

Sensitivity analysis is utilized to confirm how the results are affected according to the sensitivity variables. Multiple economic parameters such as the cost of PV panel, wind turbine, as well as fossil fuel are selected as the main sensitivity variables, which range from 30% below to 30% above the current price. The spider graph in

Figure 9 gives the result of economic sensitivity analysis. Comparing the three lines, it can be seen that,

LCOE is most sensitive to the cost of wind turbine, since its line is steeper than rest of the variables. In this regard, the selection of the most cost-effective wind turbine according to existing wind resource is of great importance on the economical operation of HES.

Figure 10 displays the effects of wind speed and solar irradiation on the most economical system type. As shown in the figure, a particular system type is economical at a certain wind speed or solar irradiation. Apparently, the PV-WT-Diesel generator-Battery bank system is cost-effective only when the annual average wind speed is higher than 5.1 m/s, since wind turbines start up and generate amount of electric power at such high wind speeds. By contrast, PV panel is a favorable way to tackle varying wind speed, indicating that PV panel should be integrated into the HES as long as the system is deployed in remote island like Yongxing.

6. Conclusions

The implementation of HES is generally considered as a promising alternative for electrification in remote areas. In this paper, a decision making methodology based on the weighted sum method was proposed with the aim of identifying the best trade-off configuration of HES from a set of feasible combinations obtained from HOMER.

Both the simulation and optimization results indicate that, the proposed method is able to identify the best trade-off configuration among system reliability, economy, practicability and environmental sustainability. Furthermore, the objectivity of decision-making is enhanced by employing the entropy weight method as a quantitative methodology for the calculation of weighting factors.

According to the analysis of the best configuration, PV panel can be considered as the most cost-effective component for power generation in Yongxing Island, since it accounts for approximately 43.6% of the system’s total power generation, while taking only 16.71% of total costs. The selection of the most cost-effective wind turbine according to existing wind resource is of great importance on the economical operation of HES. In terms of renewable energy resources, the PV-WT-Diesel-Battery bank system is cost-effective only when the annual average wind speed is higher than 5.1 m/s, indicating that PV panel should be integrated into the HES as long as the system is deployed in remote island like Yongxing. Finally, all the proposed models and methods are available for HES designing and optimization in any installation site.