Regenerative Intelligent Brake Control for Electric Motorcycles

Abstract

:1. Introduction

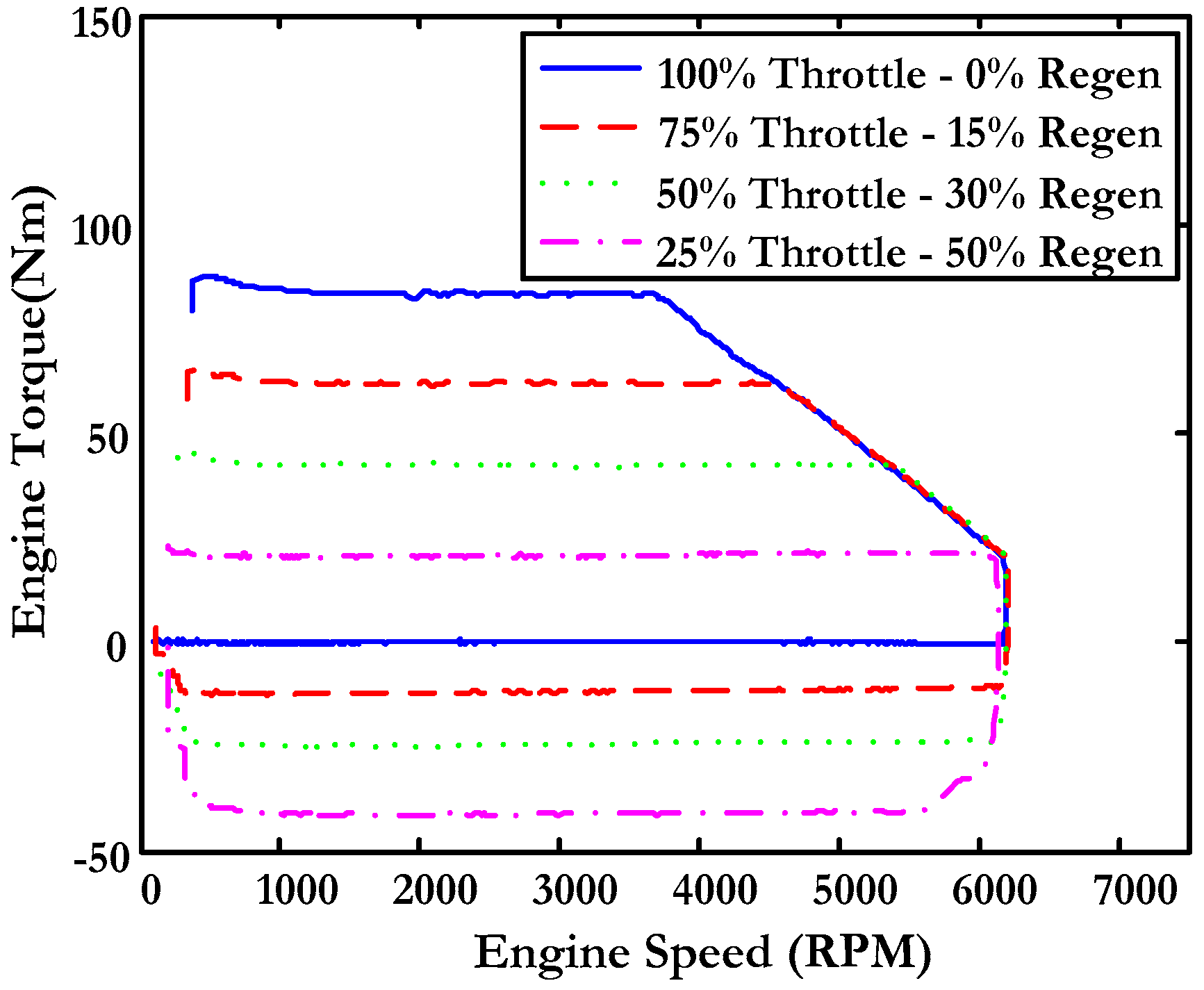

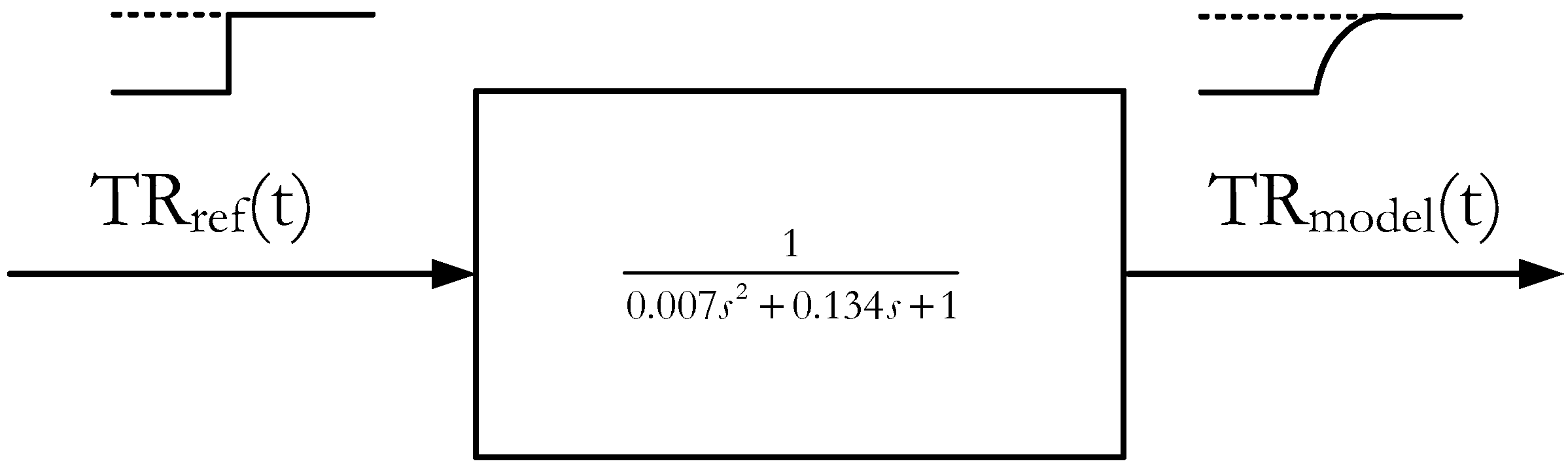

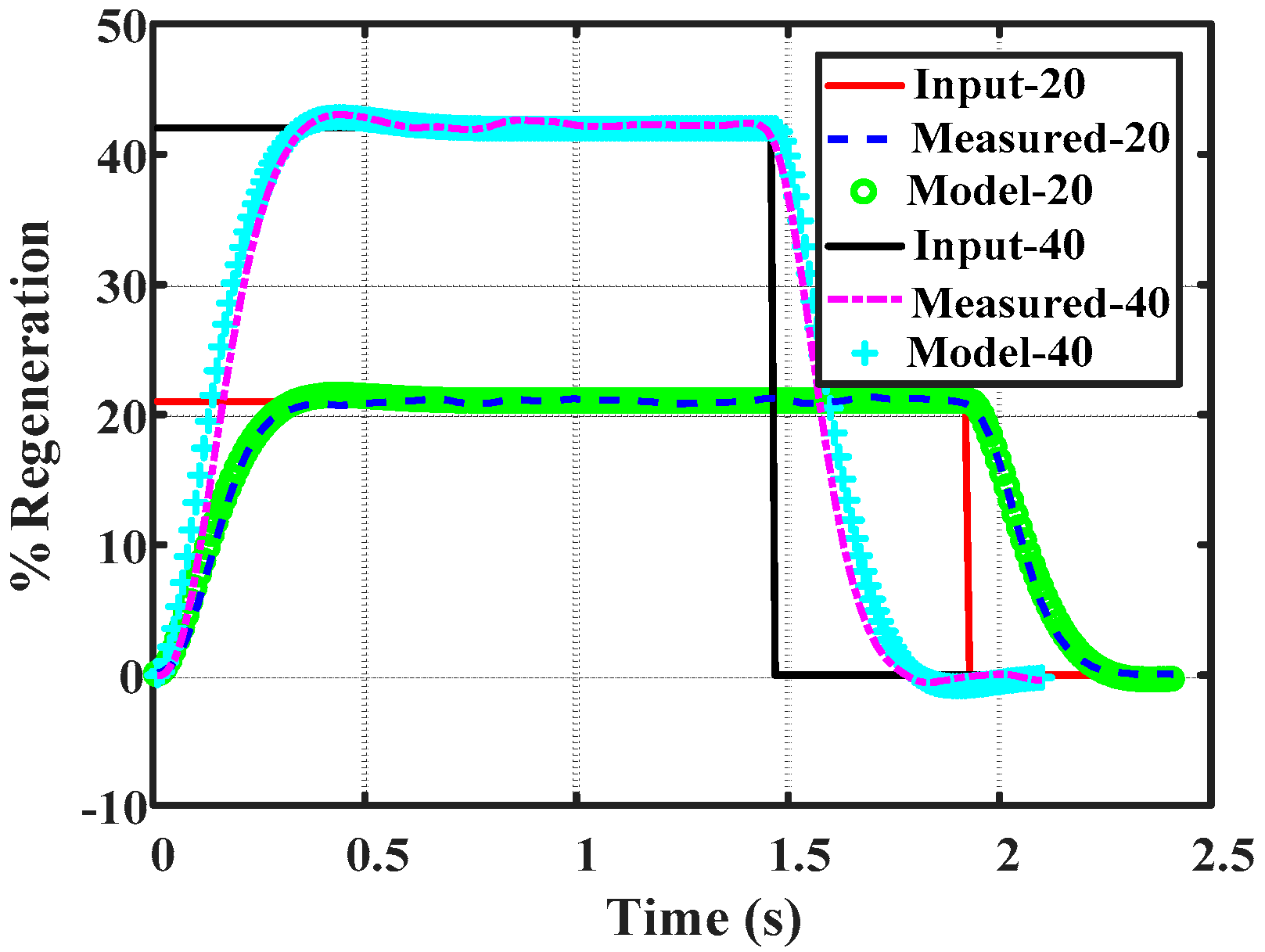

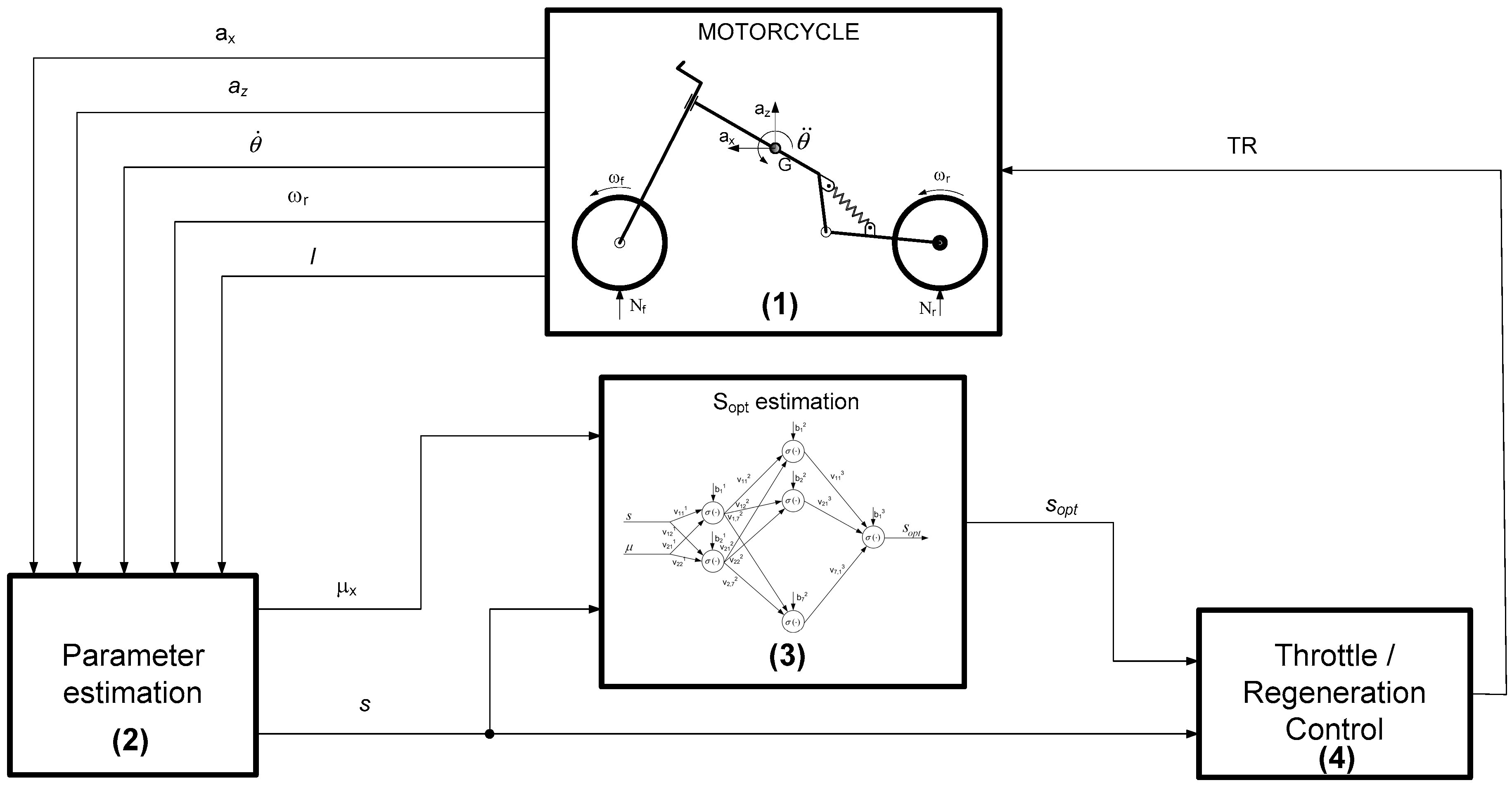

2. Electric Motor Model

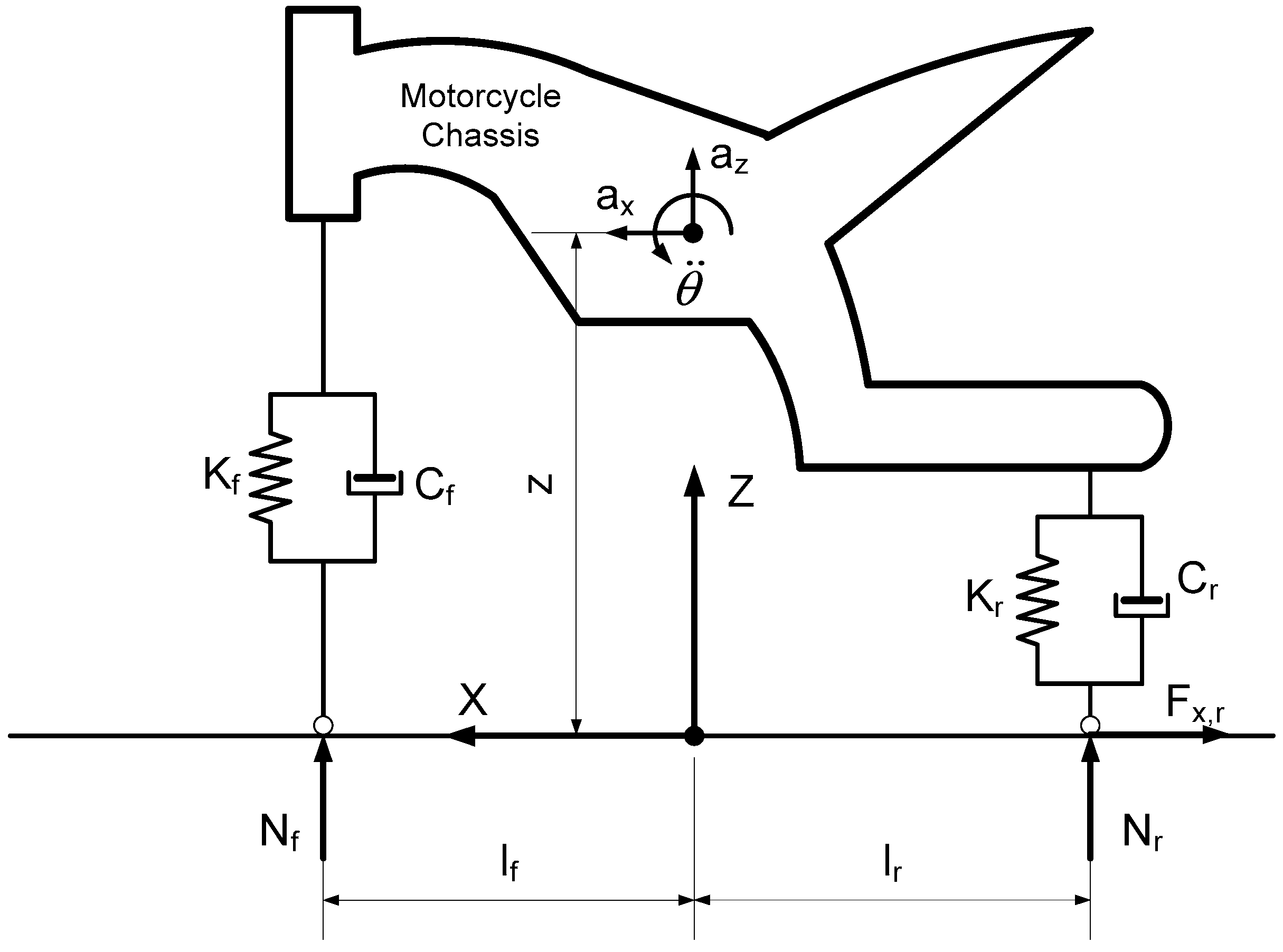

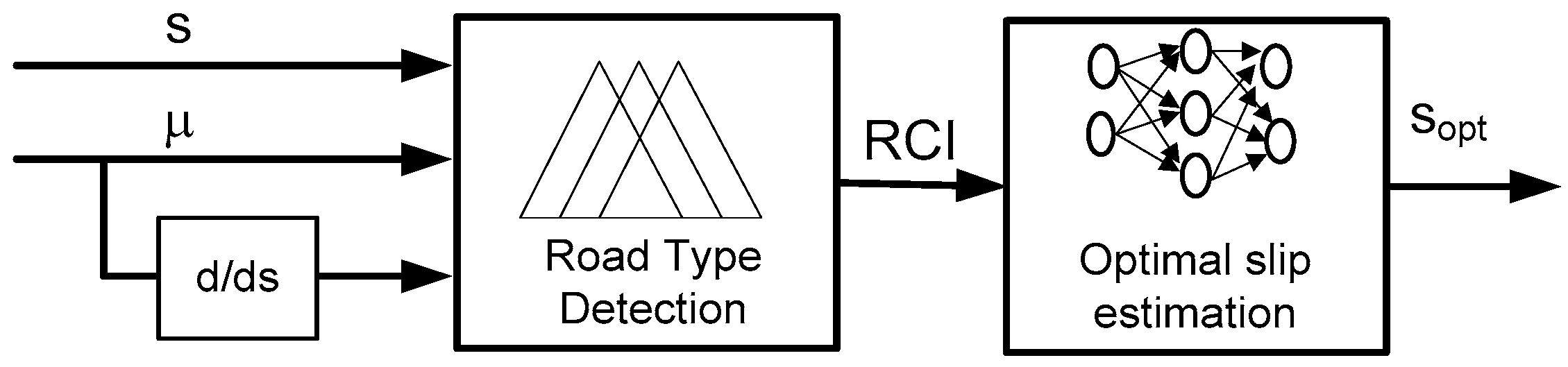

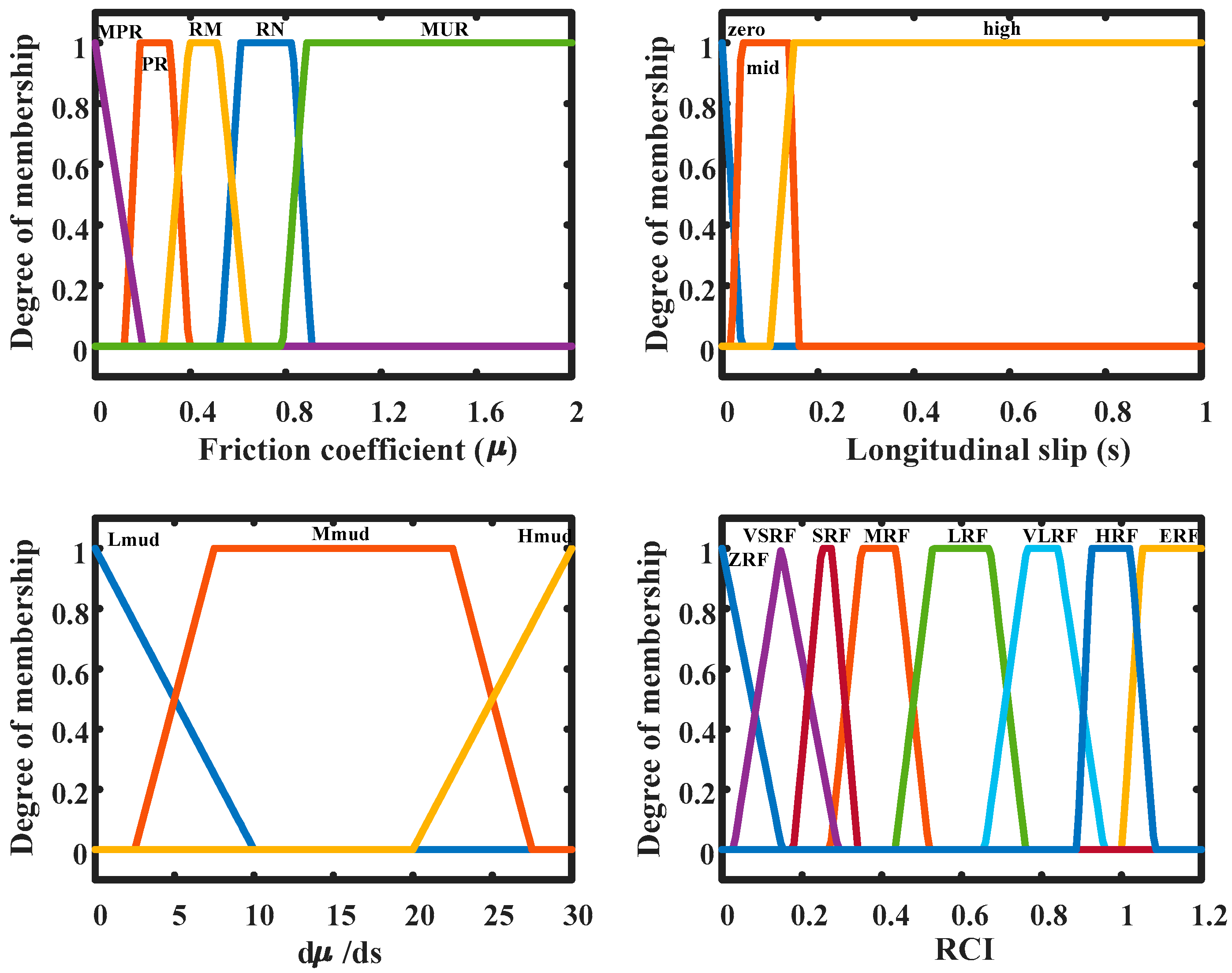

3. Estimation of Road Type and Vehicle Parameters

4. Regenerative Control

5. Simulations

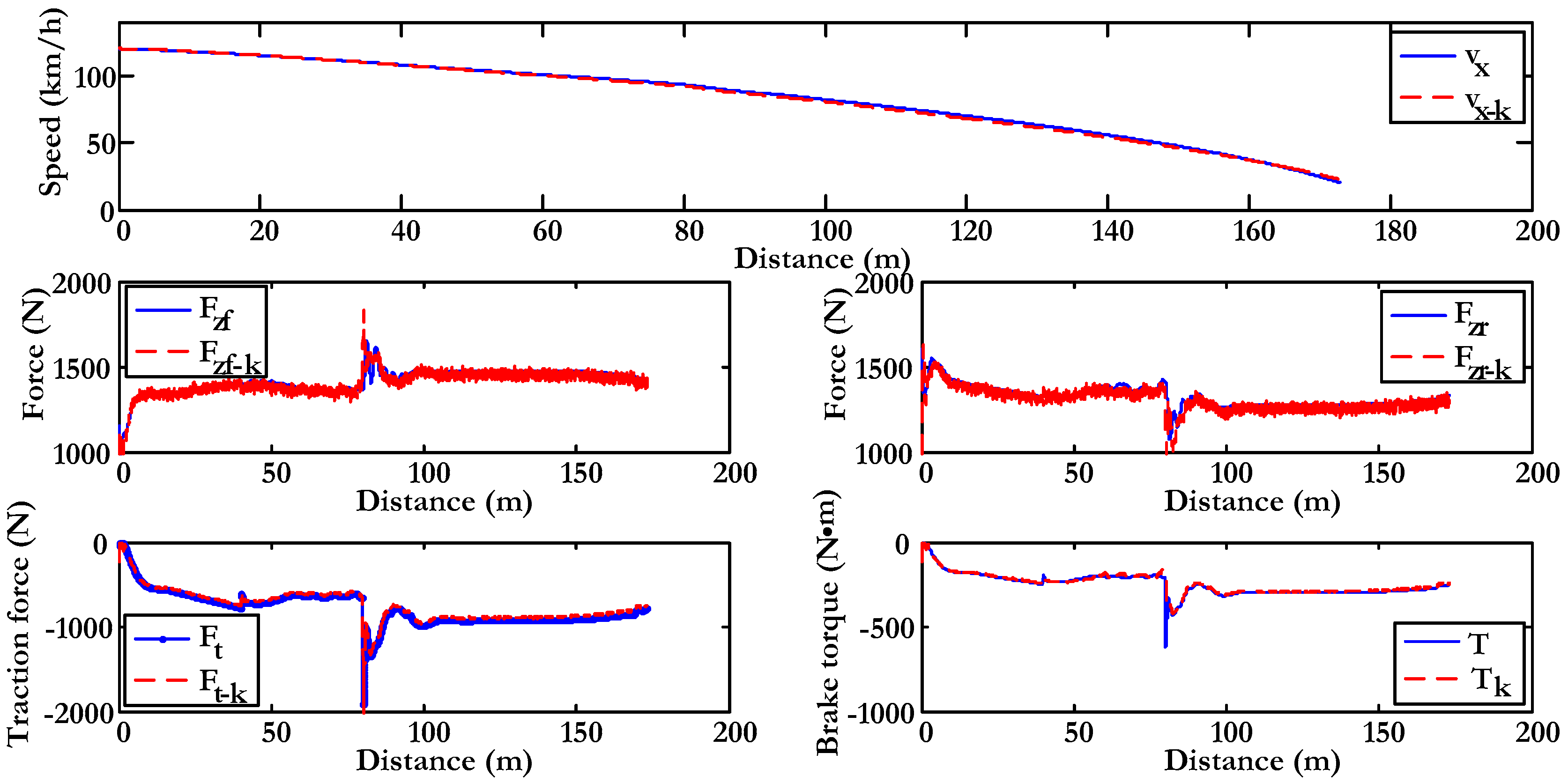

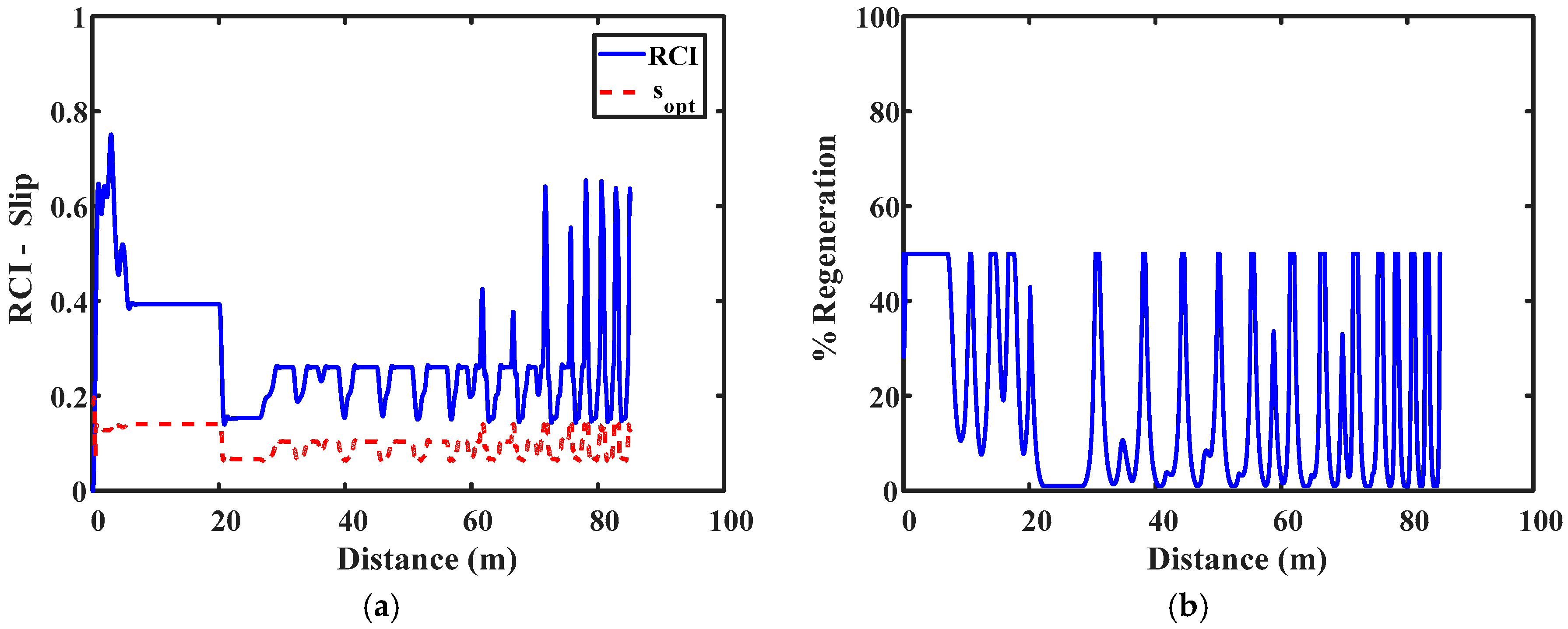

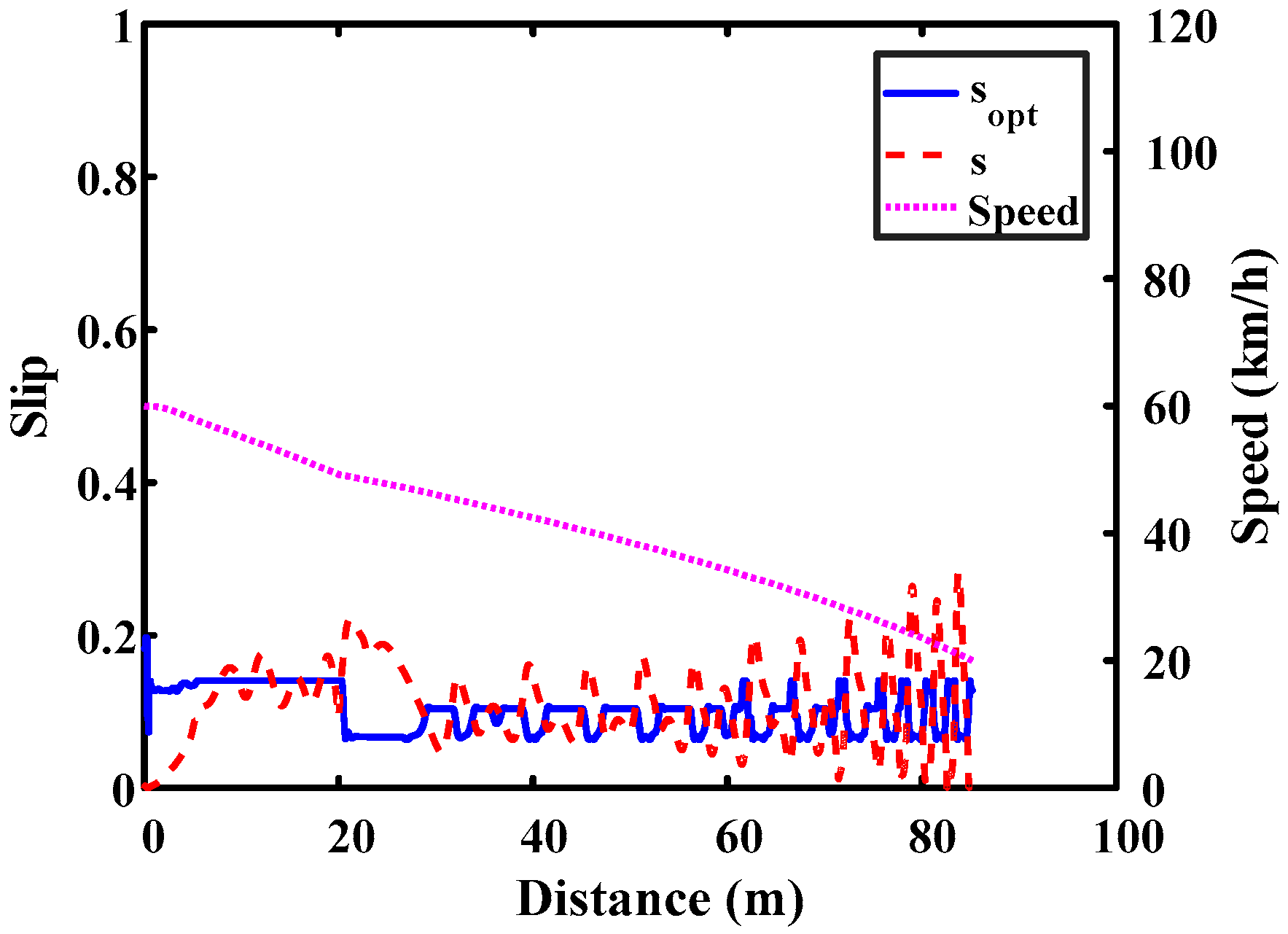

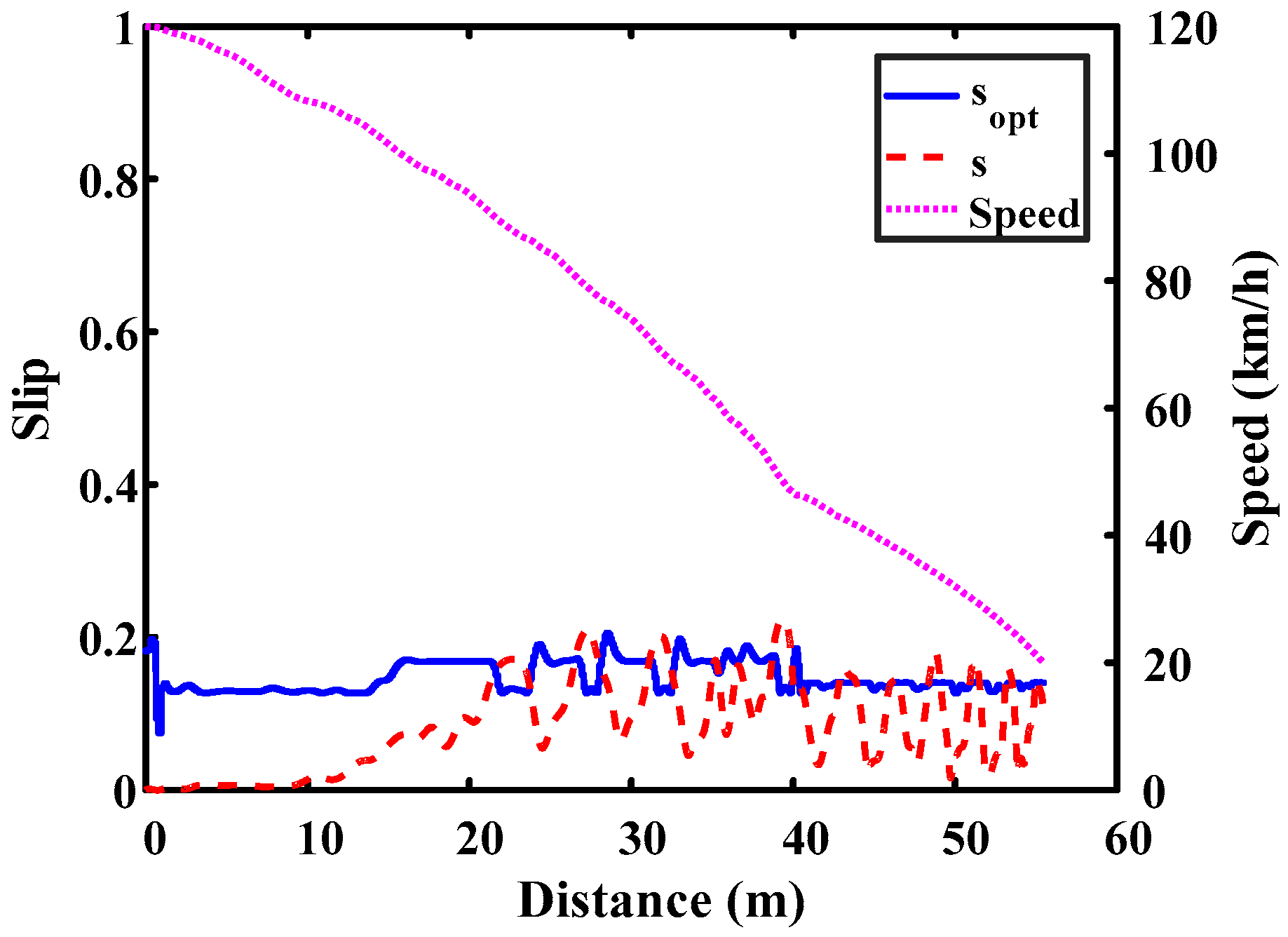

5.1. Low Adhesion Condition Simulation

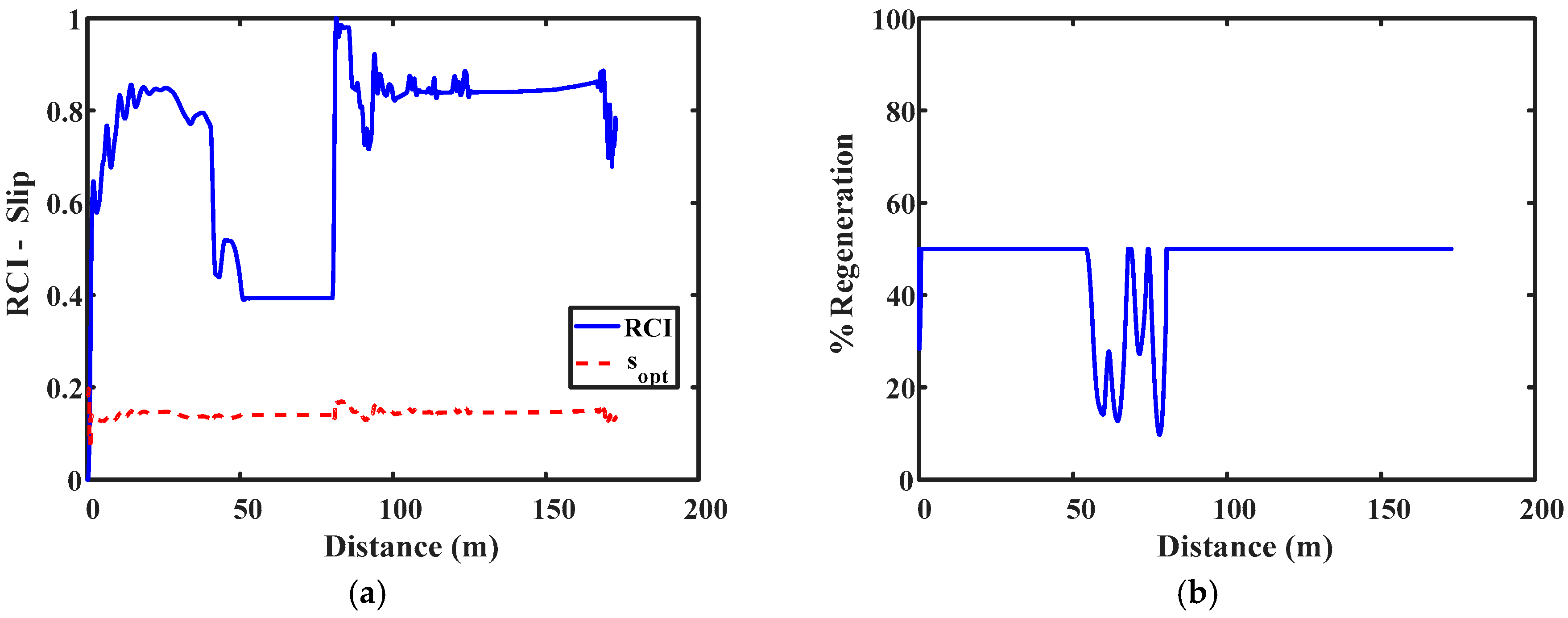

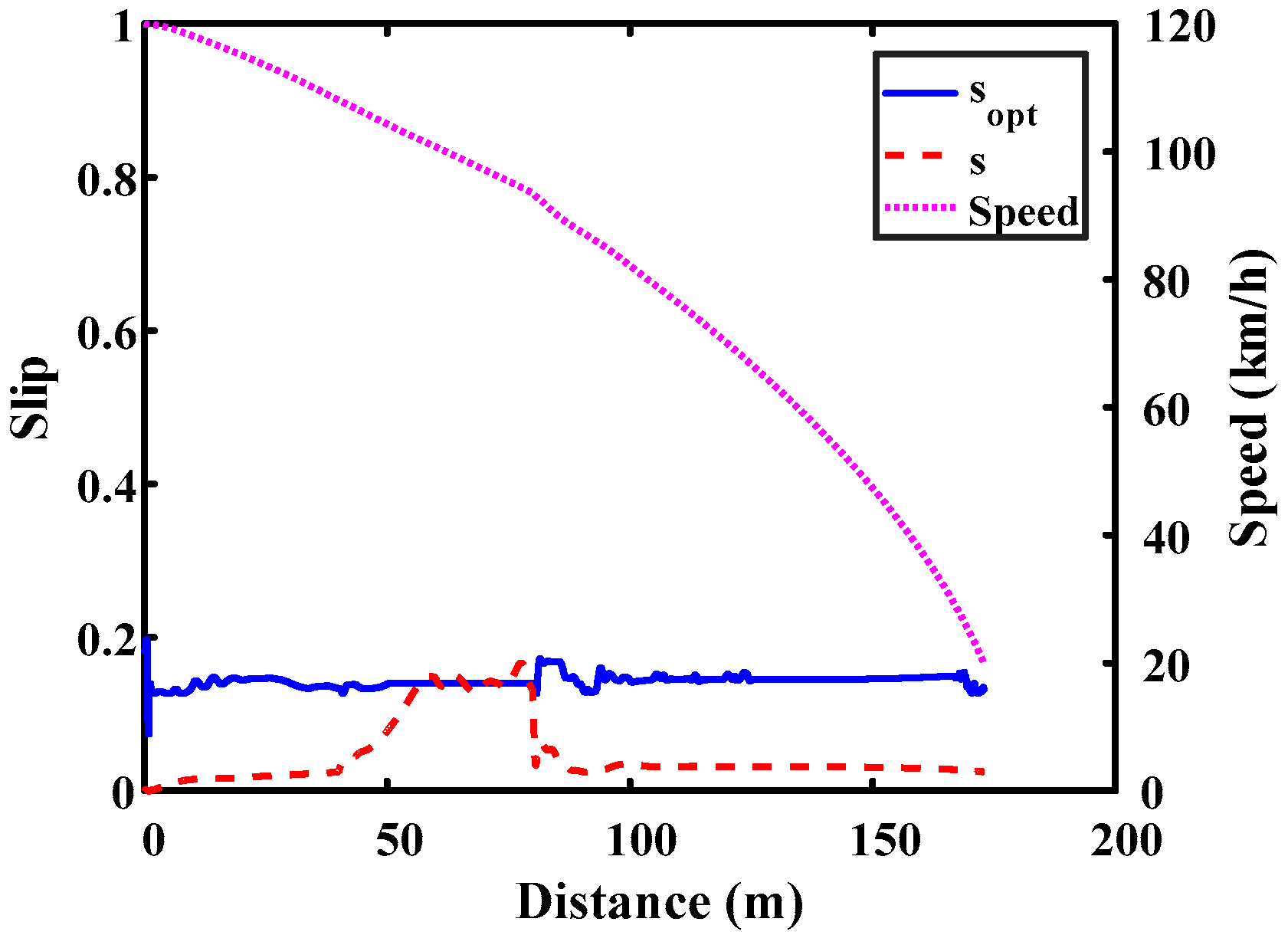

5.2. High to Low Adhesion Transition Simulation

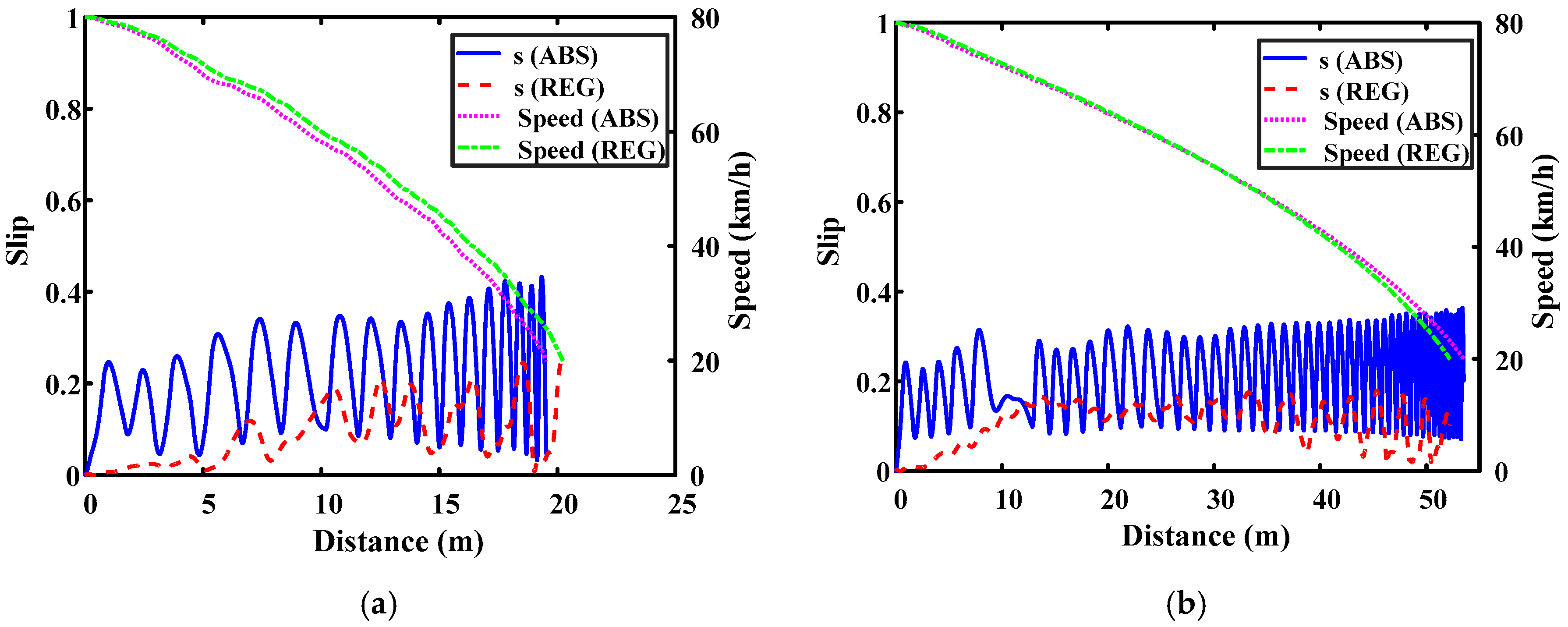

5.3. Controls Comparison

5.4. Regenerative vs. Conventional Brake Comparison

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A. Experimental Vehicle

| Component | Parameter | Description |

|---|---|---|

| Vehicle | Motorcycle weight | 135 Kg |

| Chassis Type | Steel Tubular | |

| Height of gravity centre | 621 mm | |

| Distance between axis | 1370 mm | |

| Wheel radius | 300 mm | |

| Distance from the COG to the front axle | 670 mm | |

| Front tire | 95/70 R 17 | |

| Rear tire | 115/70 R 17 | |

| Electric motor | Brand | Heinzmann PMS 150 |

| Type | Axial Flux Permanent Magnet | |

| Maximum speed | 6000 rpm | |

| Maximum torque | 80 Nm | |

| Torque constant (Km) | 0.145 Nm/A | |

| Maximum power | 34.1 KW (46.36 CV) | |

| Battery | Battery Type | LiPo |

| Cell layout | 26S5P | |

| Total capacity | 4.8 KWh | |

| Rated Voltage | 96 V | |

| Maximum discharge current | 1250 A | |

| Maximum load current | 300 A |

References

- Ferrero, E.; Alessandrini, S.; Balanzino, A. Impact of the electric vehicles on the air pollution from a highway. Appl. Energy 2016, 169, 450–459. [Google Scholar] [CrossRef]

- Ye, M.; Bai, Z.F.; Cao, B.G. Energy recovery for battery electric vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2008, 222, 1827–1839. [Google Scholar] [CrossRef]

- Tehrani, M.; Hairi-Yazdi, R.; Haghpanah-Jahromi, B.; Esfahanian, V.; Amiri, M.; Jafari, R. Design of an anti-lock regenerative braking system for a series hybrid electric vehicle. Int. J. Automot. Eng. 2011, 1, 16–20. [Google Scholar]

- Gao, Y.; Chen, L.; Ehsani, M. Investigation of the effectiveness of regenerative braking for EV and HEV. SAE Tech. Pap. 1999. [Google Scholar] [CrossRef]

- Cabrera, J.A.; Castillo, J.J.; Carabias, E.; Ortiz, A. Evolutionary Optimization of a Motorcycle Traction Control System Based on Fuzzy Logic. IEEE Trans. Fuzzy Syst. 2015, 23, 1594–1607. [Google Scholar] [CrossRef]

- Lin, H.; Song, C. Design of a fuzzy logic controller for ABS of Electric Vehicle based on AMESim and Simulink. In Proceedings of the 2011 International Conference on Transportation, Mechanical, and Electrical Engineering (TMEE), Changchun, China, 16–18 December 2011; pp. 779–782. [Google Scholar]

- Choi, S.; Cho, D.W. Design of Nonlinear Sliding Mode Controller with Pulse Width Modulation for Vehicular Slip Ratio Control. Veh. Syst. Dyn. 2011, 36, 57–72. [Google Scholar] [CrossRef]

- Harifi, A.; Aghagolzadeh, A.; Alizadeh, G.; Sadeghi, M. Designing a sliding mode controller for slip control of antilock brake systems. Transp. Res. Part C 2008, 16, 731–741. [Google Scholar] [CrossRef]

- Habibi, M.; Yazdizadeh, A. A novel Fuzzy-Sliding Mode Controller for Antilock Braking System. In Proceedings of the 2010 2nd International Conference on Advanced Computer Control (ICACC), Shenyang, China, 27–29 March 2010; Volume 4, pp. 110–114. [Google Scholar]

- Topalov, A.; Oniz, Y.; Kayacan, E.; Kaynak, O. Neuro-fuzzy control of antilock braking system using sliding mode incremental learning algorithm. Neurocomputing 2011, 74, 1883–1893. [Google Scholar] [CrossRef]

- Cirovic, V.; Aleksendric, D.; Mladenovic, D. Braking torque control using recurrent neural networks. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2012, 226, 754–766. [Google Scholar] [CrossRef]

- Gerard, M.; Pasillas-Lépine, W.; de Vries, E.; Verhaegen, M.; Cho, D.W. Improvements to a five-phase ABS algorithm for experimental validation. Veh. Syst. Dyn. 2012, 50, 1585–1611. [Google Scholar] [CrossRef]

- Tanelli, M.; Astolfi, A.; Savaresi, S. Robust nonlinear output feedback control for brake by wire control systems. Automatica 2008, 44, 1078–1087. [Google Scholar] [CrossRef]

- Sun, L. Systematic experimental evaluation of a novel regenerative braking system on DC motor drive using super-capacitors. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–6. [Google Scholar]

- Guarisco, M.; Bouriot, B.; Ravey, A.; Bouquain, D. Powertrain energy management for Hybrid Electric Scooter. In Proceedings of the 2014 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, NI, USA, 15–18 June 2014; pp. 1–4. [Google Scholar]

- Andorinha, N.; Sousa, S.; Antunes, V. A new control method of an electric scooter with a hybrid ultracapacitor/battery energy storage topology. In Proceedings of the 2nd Experiment@ International Conference (exp.at’13), Coimbra, Portugal, 18–20 September 2013; pp. 11–16. [Google Scholar]

- Lai, Y.S.; Lin, Y.K. Design and implementation of digital-controlled bi-directional converter for scooter applications. In Proceedings of the 2013 IEEE 10th International Conference on Power Electronics and Drive Systems (PEDS), Kitakyushu, Japan, 22–25 April 2013; pp. 271–276. [Google Scholar]

- Robinson, J.; Singh, T. eABS: Regenerative Anti-Lock Braking for Electric Motorcycles. SAE Int. J. Passeng. Cars Mech. Syst. 2013, 6, 1484–1492. [Google Scholar] [CrossRef]

- Lin, W.C.; Lin, C.L.; Hsu, P.M.; Wu, M.T. Realization of anti-lock braking strategy for electric scooters. IEEE Trans. Ind. Electron. 2014, 61, 2826–2833. [Google Scholar] [CrossRef]

- Castillo, J.J.; Cabrera, J.A.; Guerra, A.J.; Simón, A. A Novel Electrohydraulic Brake System with Tire–Road Friction Estimation and Continuous Brake Pressure Control. IEEE Trans. Ind. Electron. 2016, 63, 1863–1875. [Google Scholar] [CrossRef]

| Description | Description | ||

|---|---|---|---|

| M | Mass | J | Moment of inertia of the wheel |

| ax | Longitudinal acceleration | Iy | Inertia on the Y axis |

| az | Vertical Acceleration | Nf | Normal front force |

| x | Longitudinal displacement | Nr | Normal rear force |

| z | Vertical displacement | lf | Front half length |

| θ | Pitch angle | lr | Rear half-length |

| Rr | Rear tire radius | kf | Stiffness of front suspension |

| T | Torque applied on rear wheel | kr | Stiffness of rear suspension |

| C | Aerodynamic coefficient | cf | Front Damping |

| Fxr | Longitudinal rear wheel force | cr | Rear damping |

| ωr | Rear wheel angular speed | L0 | Suspension length |

| Km | Torque-Intensity Ratio | I | Intensity |

| Rule Number | Friction Coefficient | Slip | dμ/ds | RCI |

|---|---|---|---|---|

| 1 | MPR | mid | --- | VSRF |

| 2 | MPR | high | --- | ZRF |

| 3 | MPR | zero | Lmud | MRF |

| 4 | MPR | zero | Mmud | LRF |

| 5 | MPR | zero | Hmud | LRF |

| 6 | PR | mid | --- | SRF |

| 7 | PR | high | --- | VSRF |

| 8 | PR | zero | Lmud | LRF |

| 9 | PR | zero | Mmud | LRF |

| 10 | PR | zero | Hmud | VLRF |

| 11 | RM | mid | --- | MRF |

| 12 | RM | high | --- | MRF |

| 13 | RM | zero | Lmud | LRF |

| 14 | RM | zero | Mmud | VLRF |

| 15 | RM | zero | Hmud | HRF |

| 16 | RN | mid | --- | VLRF |

| 17 | RN | high | --- | LRF |

| 18 | RN | zero | Lmud | VLRF |

| 19 | RN | zero | Mmud | HRF |

| 20 | RN | zero | Hmud | ERF |

| 21 | MUR | mid | --- | HRF |

| 22 | MUR | high | --- | ERF |

| 23 | MUR | zero | Lmud | HRF |

| 24 | MUR | zero | Mmud | ERF |

| 25 | MUR | zero | Hmud | ERF |

| Description Value | |

|---|---|

| Total mass | 275 kg |

| Wheel radius | 0.32 m |

| Moment of inertia of the wheel | 0.484 kg·m2 |

| Distance from the COG * to the front axle | 0.86 m |

| Distance from the COG * to the rear axle | 0.67 m |

| Height of gravity centre | 0.4 m |

| Front area | 0.6 m2 |

| Aerodynamic coefficient | 0.55 |

| Motor-wheel transmission ratio | 1:6.4 |

| Surface/Control | Vo (km/h) | Vf (km/h) | Energy (Wh) |

|---|---|---|---|

| High adhesion/Regen. cte. (10%) | 80 | 55.52 | 4.53 |

| High adhesion/Controlled regeneration | 80 | 22.4 | 15.93 |

| Medium adhesion/Regen. cte. (10%) | 80 | 55.54 | 4.53 |

| Medium adhesion/Controlled regeneration | 80 | 36.5 | 11.37 |

| Low adhesion/Regen. cte. (10%) | 80 | 55.54 | 4.53 |

| Low adhesion/Controlled regeneration | 80 | 56.1 | 4.54 |

| Surface | Control | ABS | Regenerative Reg. Max. = 50% | Regenerative Reg. Max. = 80% |

|---|---|---|---|---|

| High adhesion | Time (s) | 1.39 | 1.42 | 1.40 |

| Distance (m) | 19.54 | 20.24 | 20.85 | |

| Mean deceleration (m/s2) | 11.95 | 11.71 | 11.86 | |

| Low adhesion | Time (s) | 3.90 | 3.76 | 3.80 |

| Distance (m) | 53.51 | 52.19 | 52.62 | |

| Mean deceleration (m/s2) | 4.27 | 4.44 | 4.38 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castillo Aguilar, J.J.; Pérez Fernández, J.; Velasco García, J.M.; Cabrera Carrillo, J.A. Regenerative Intelligent Brake Control for Electric Motorcycles. Energies 2017, 10, 1648. https://doi.org/10.3390/en10101648

Castillo Aguilar JJ, Pérez Fernández J, Velasco García JM, Cabrera Carrillo JA. Regenerative Intelligent Brake Control for Electric Motorcycles. Energies. 2017; 10(10):1648. https://doi.org/10.3390/en10101648

Chicago/Turabian StyleCastillo Aguilar, Juan Jesús, Javier Pérez Fernández, Juan María Velasco García, and Juan Antonio Cabrera Carrillo. 2017. "Regenerative Intelligent Brake Control for Electric Motorcycles" Energies 10, no. 10: 1648. https://doi.org/10.3390/en10101648