Ride Comfort Optimization of In-Wheel-Motor Electric Vehicles with In-Wheel Vibration Absorbers

Abstract

:1. Introduction

2. Structure Design and Dynamics Modeling of the Electric Wheel

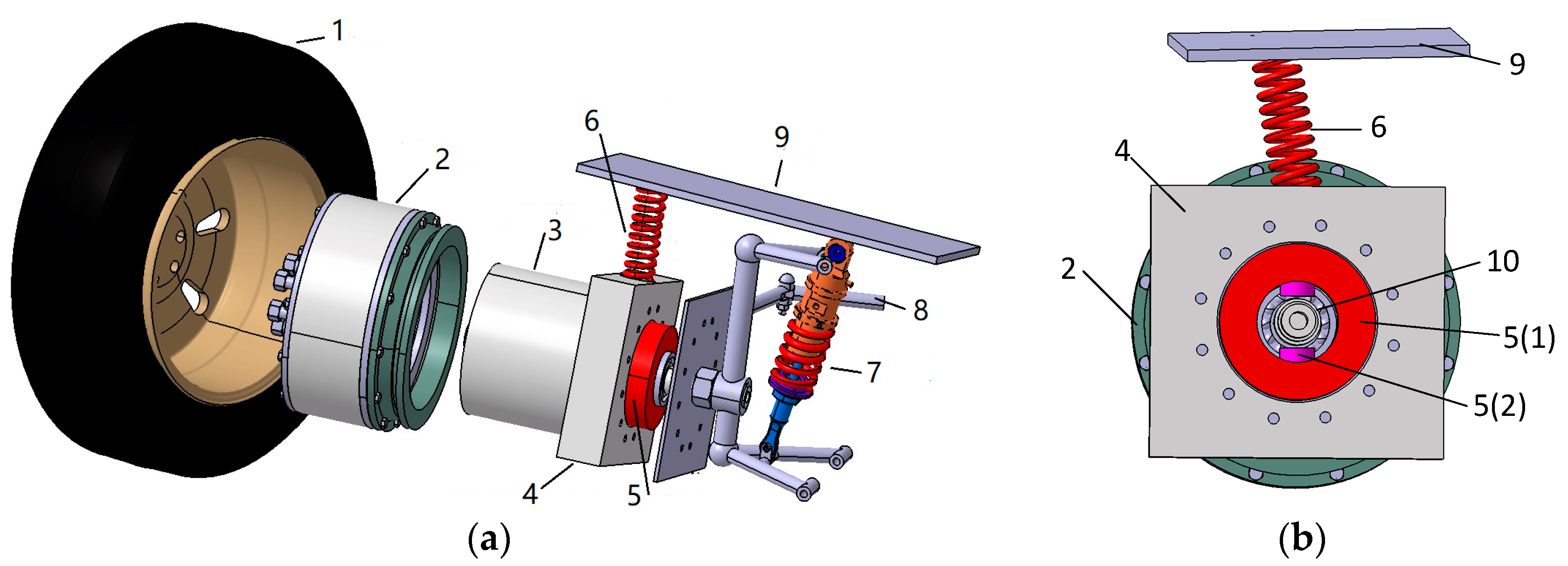

2.1. Structure Design of an Electric Wheel with an In-Wheel Vibration Absorber

- (1)

- In-wheel motor (IWM). As shown in Figure 1a, the IWM is a permanent magnet synchronous motor with an outer rotor. The two ends of the rotor are bolted to the wheel hub and brake disc, respectively, to move and stop the wheel. One end of the hollow motor stator is extended with a square block to which the in-wheel spring and damper are installed.

- (2)

- In-wheel vibration absorber. Figure 1b is a front view of the proposed in-wheel vibration absorber. The absorber is composed of a spring and a damper. The spring is mounted to an outer edge of the motor extension and another end of the spring is connected to vehicle body. The spring can passively absorb motor and body vibrations. Besides, the damper consists an annular rubber bushing and a controllable damper. The controllable damper is installed into the annular rubber bushing which is sheathed outside wheel shaft. The annular rubber bushing is utilized to absorb vibration passively, and the controllable damper force can be controlled according to the driving conditions to actively suppress the vertical vibrations of the motor.

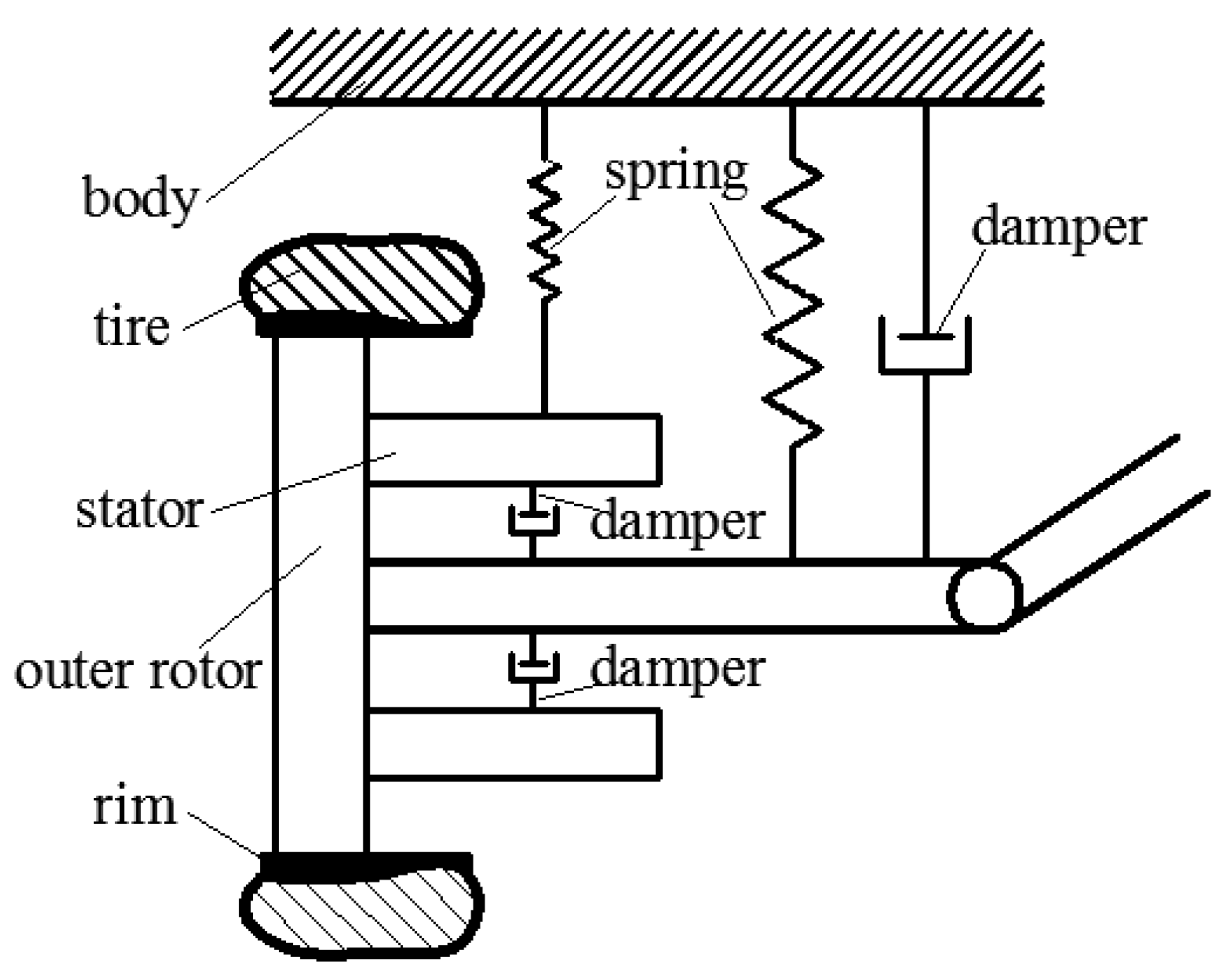

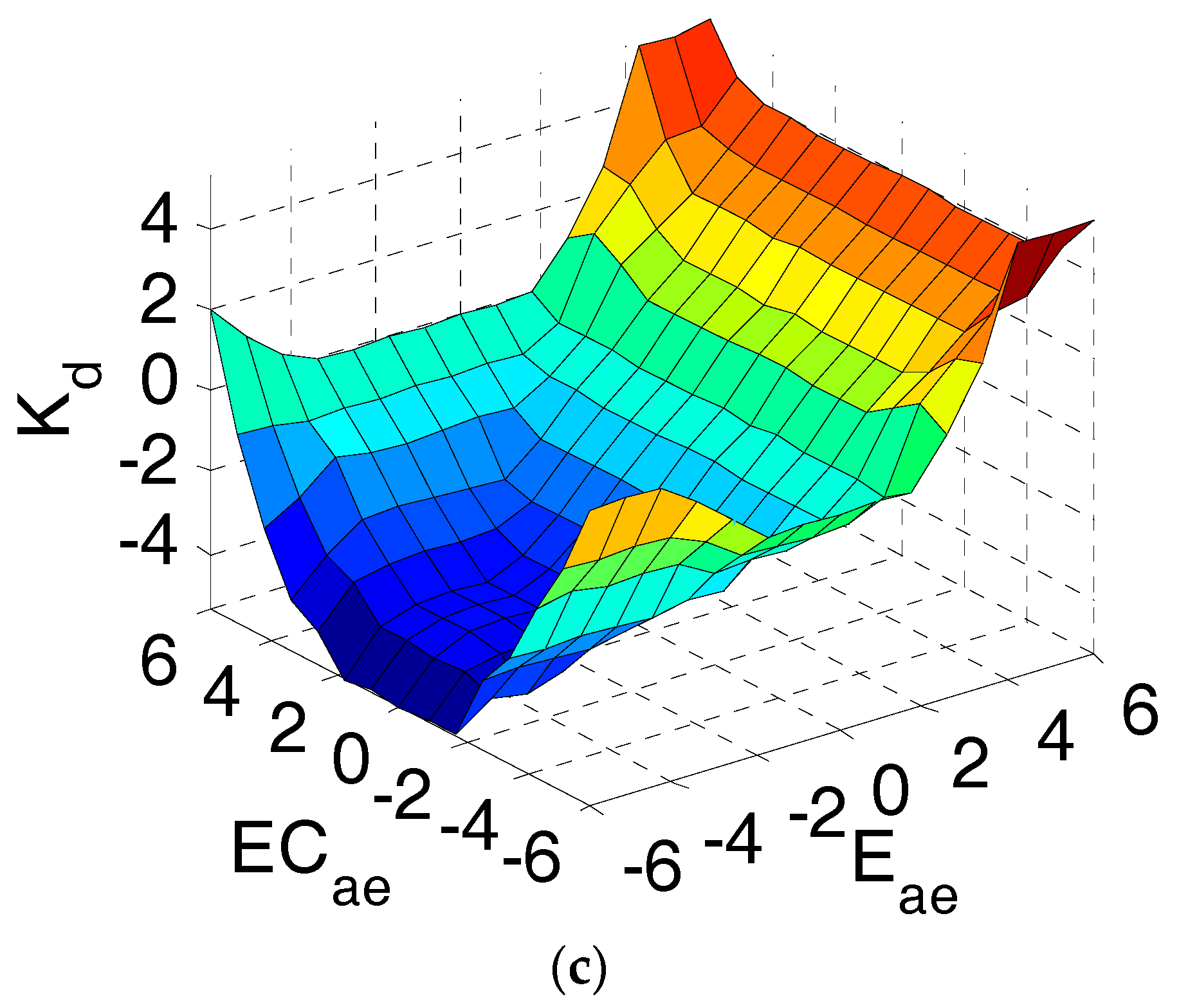

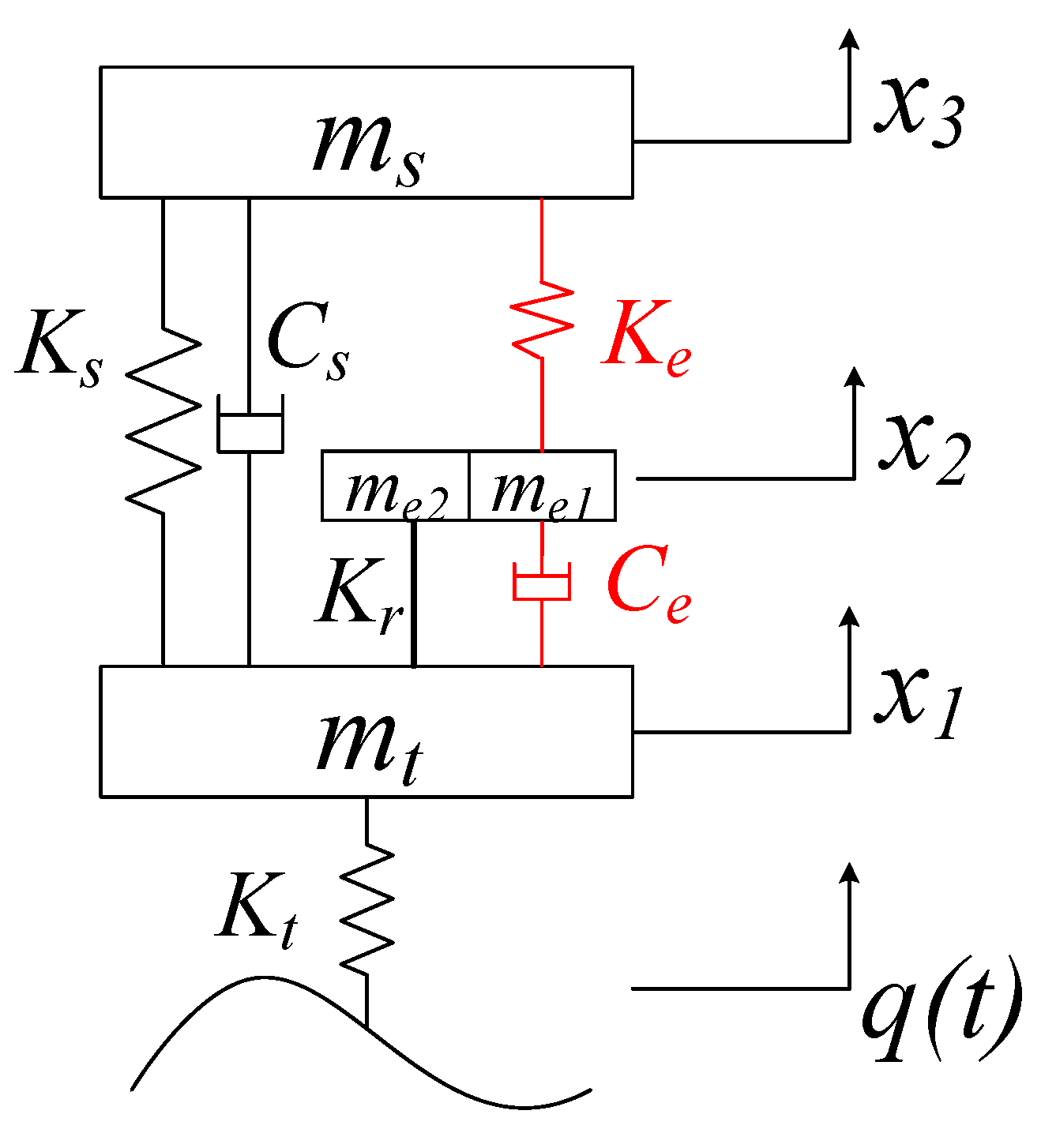

2.2. Dynamics Modeling of 1/4 Vehicle

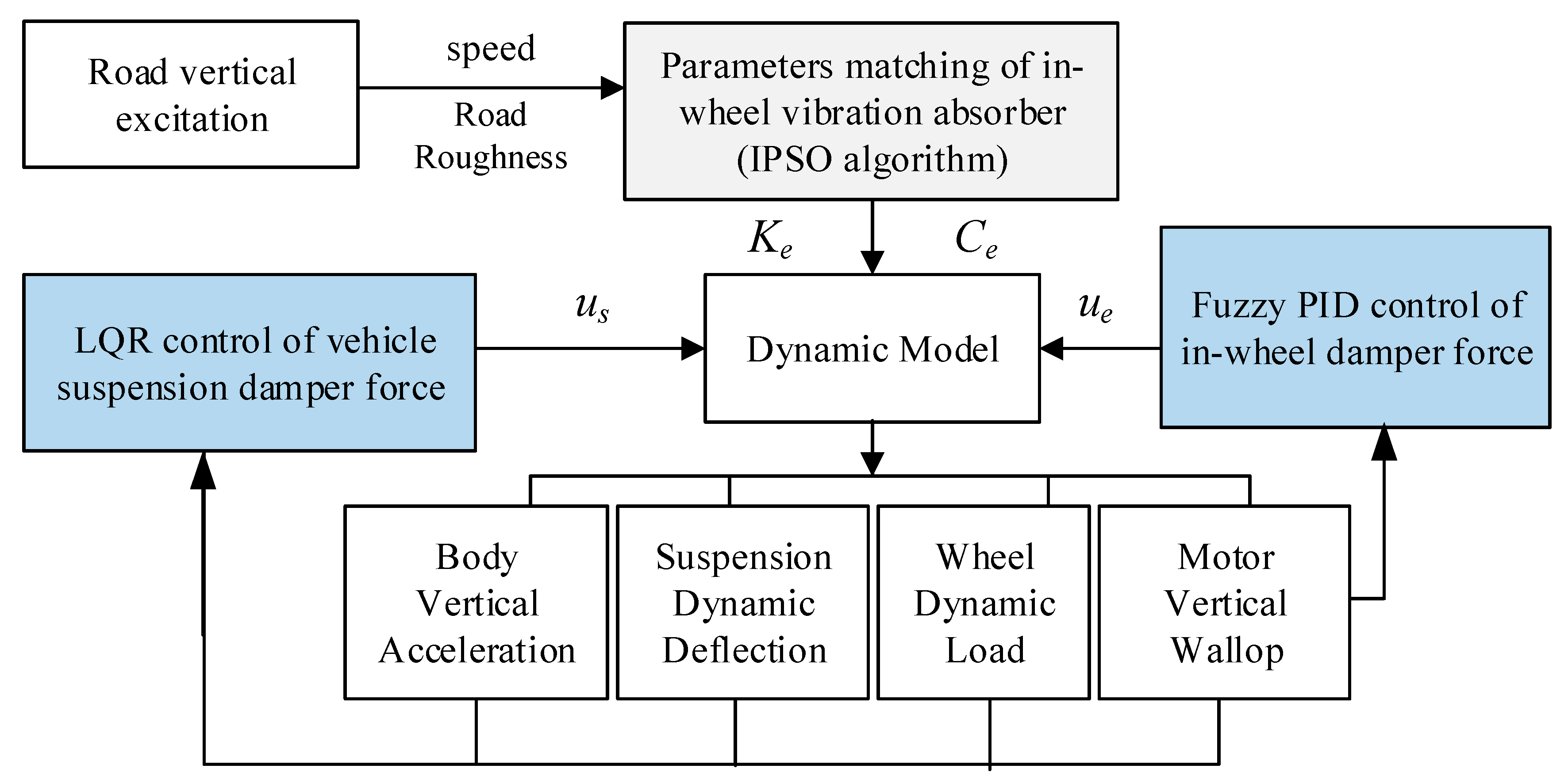

3. Optimization Control of In-Wheel Vibration Absorber and Vehicle Suspension

- (1)

- Parameter matching of the in-wheel vibration absorber. The in-wheel spring and annular rubber bushing are both utilized to absorb vibration passively. Under typical conditions, the improved particle swarm optimization (IPSO) algorithm can be utilized to solve the in-wheel spring stiffness Ke and the damper coefficient of the annular rubber bushing Ce.

- (2)

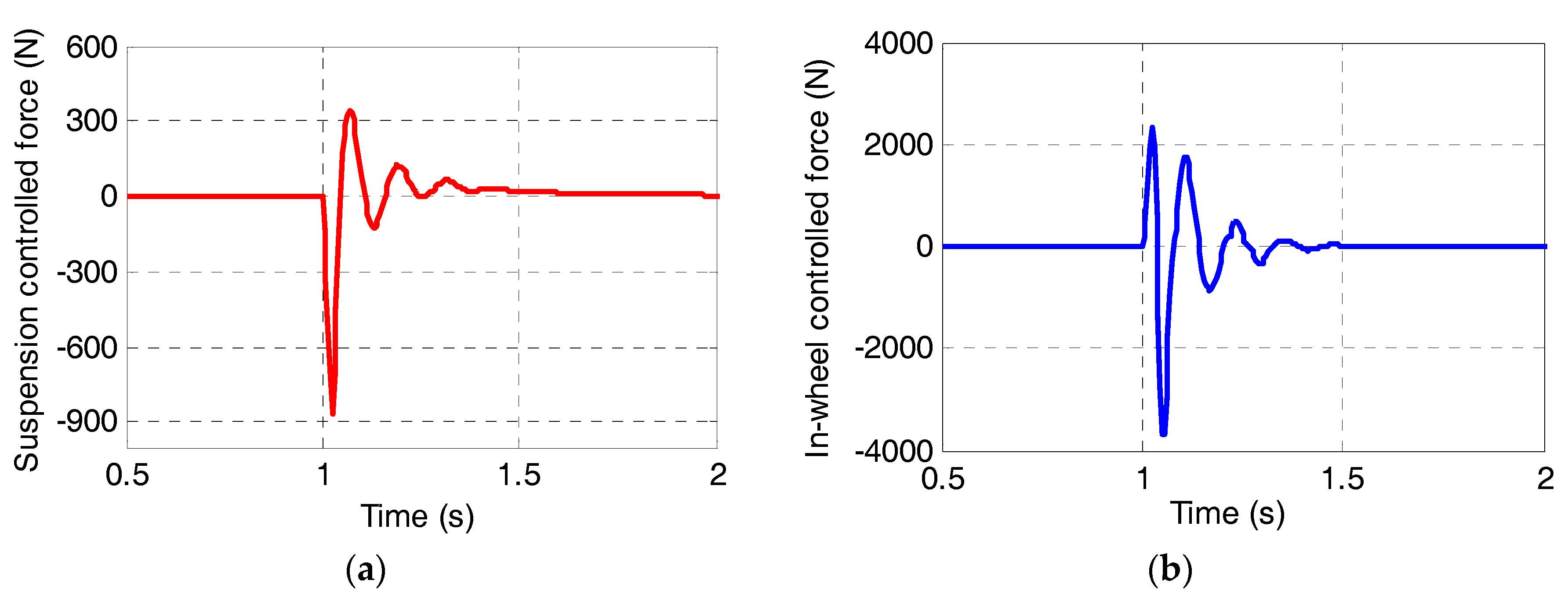

- Comprehensive control of the vehicle suspension force and the in-wheel damper force. In order to restrain the vertical vibration of vehicle body and the IWM, the body acceleration as and the motor wallop Fe can be chosen as the primary optimization variables, and the suspension dynamic deflection fd and the wheel dynamic load Fd as auxiliary optimization variables. In this study, the linear quadratic regulator algorithm (LQR) algorithm is suggested to control vehicle suspension force us to suppress vehicle body vibration, and meanwhile the fuzzy PID controller is suggested to adjust the in-wheel damper force ue to reduce motor wallop.

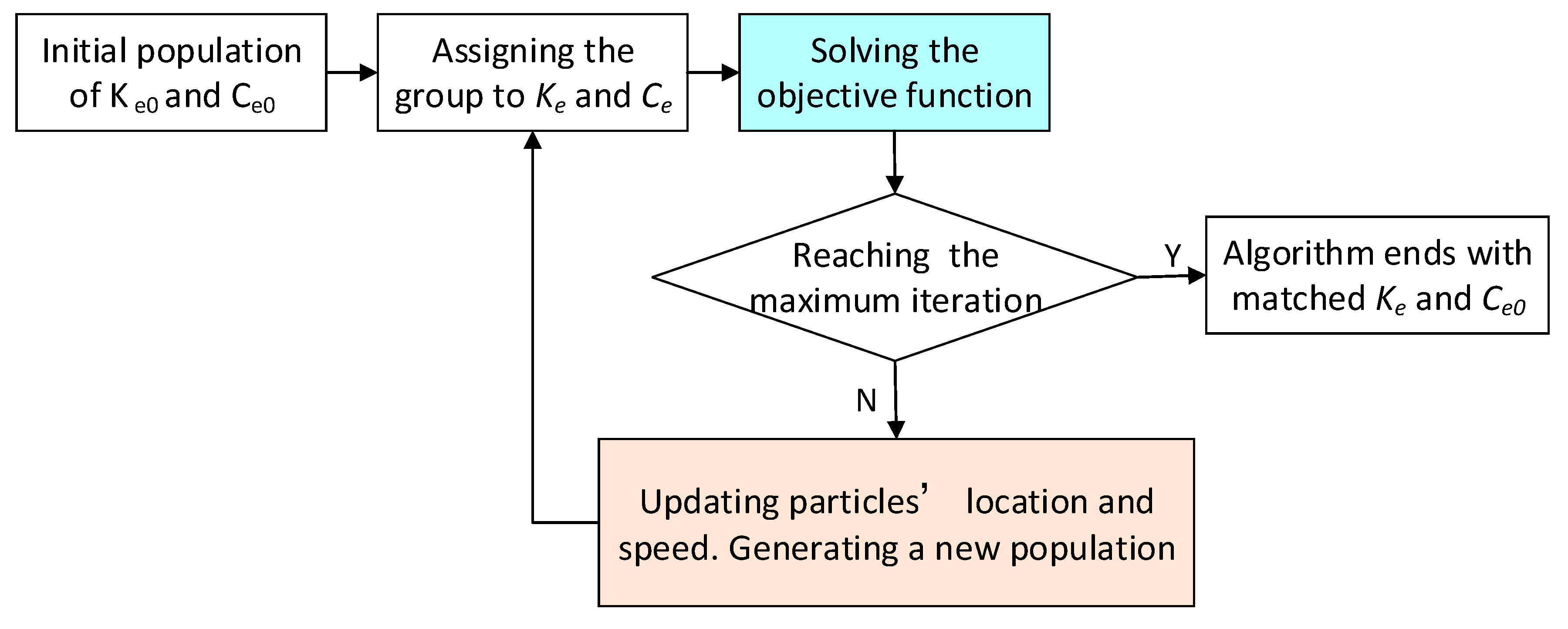

3.1. Parameters Matching of the In-Wheel Spring and Rubber Bushing

3.1.1. Updating Particles’ Lacation and Speed

3.1.2. Solving Objective Funtio

3.2. LQR Control of the Vehicle Suspension Damper Force

3.3. Fuzzy PID Control of In-Wheel Damper Force

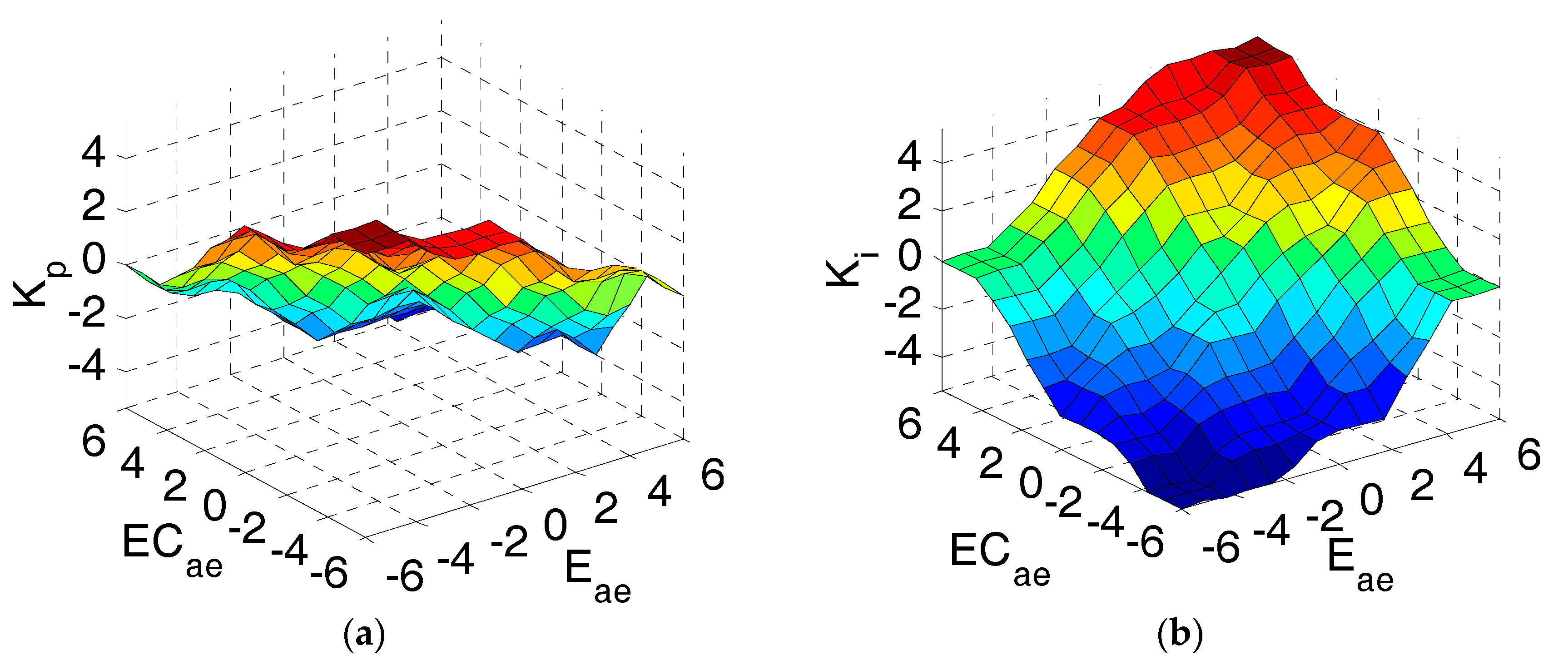

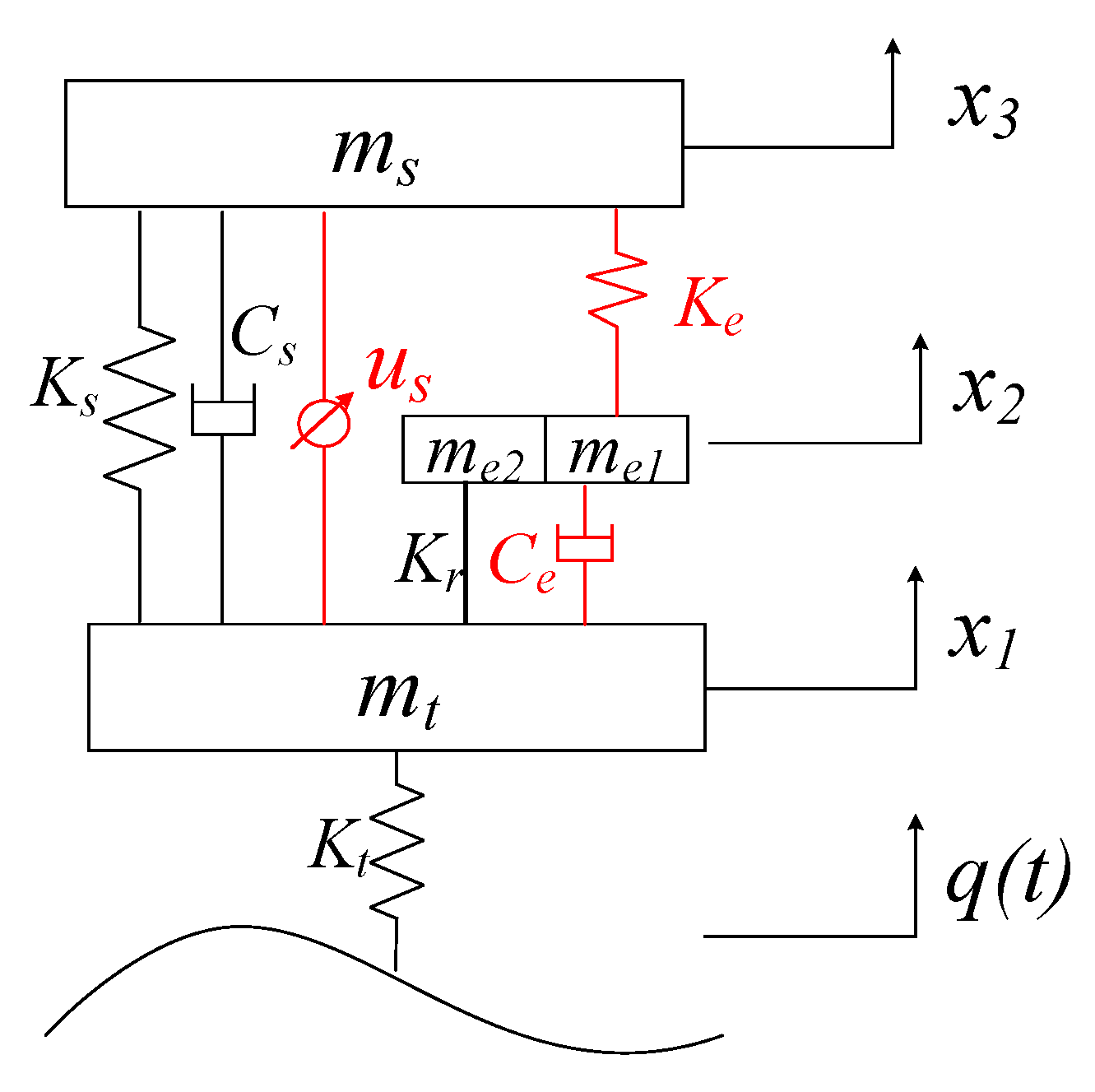

- The basic domains of Eae and ECae are set to [−6,6] and [−60,60], respectively, and the relevant fuzzy domains are both set to [−6,6]. The quantization factors are set as ke = 1 and kec = 0.1.

- The basic domains of output Kp, Ki and Kd are set to [−60,60], [−0.6,0.6], and [−0.00006,0.00006], respectively. The relevant fuzzy domains are all set to [−6,6]. The scale factors are set as kp = 10, ki = 0.1, kd = 0.00001. The initial values of Kp, Ki and Kd are set as:

- Seven fuzzy languages are selected to describe the values of inputs and outputs. They are Positive-Big (PB), Positive-Medium (PM), Positive-Small (PS), Zero (Z), Negative-Small (NS), Negative-Medium (NM), and Negative-Big (NB).

- All fuzzy subsets’ membership functions are selected as triangular functions.

4. Simulations and Discussions

- (1)

- The conventional electric wheel scheme without an in-wheel absorber, used in the passive suspension of vehicle (marked as NWR-PS), as shown in Figure 7.

- (2)

- (3)

- The electric wheel scheme with an in-wheel passive absorber, featured with in the controllable suspension force based on LQR method (marked as WPR-SS), as shown in Figure 9.

- (4)

- The electric wheel scheme with an in-wheel controllable absorber and the controllable suspension force proposed in this paper (marked as WSR-SS (1)), as shown in Figure 3.

- (5)

- The electric wheel scheme of WSR-SS as shown in Figure 3, whereas, the suspension force is controlled based on fuzzy rules as in-wheel damper force, rather than based on the LQR method. It is marked as WSR-SS (2).

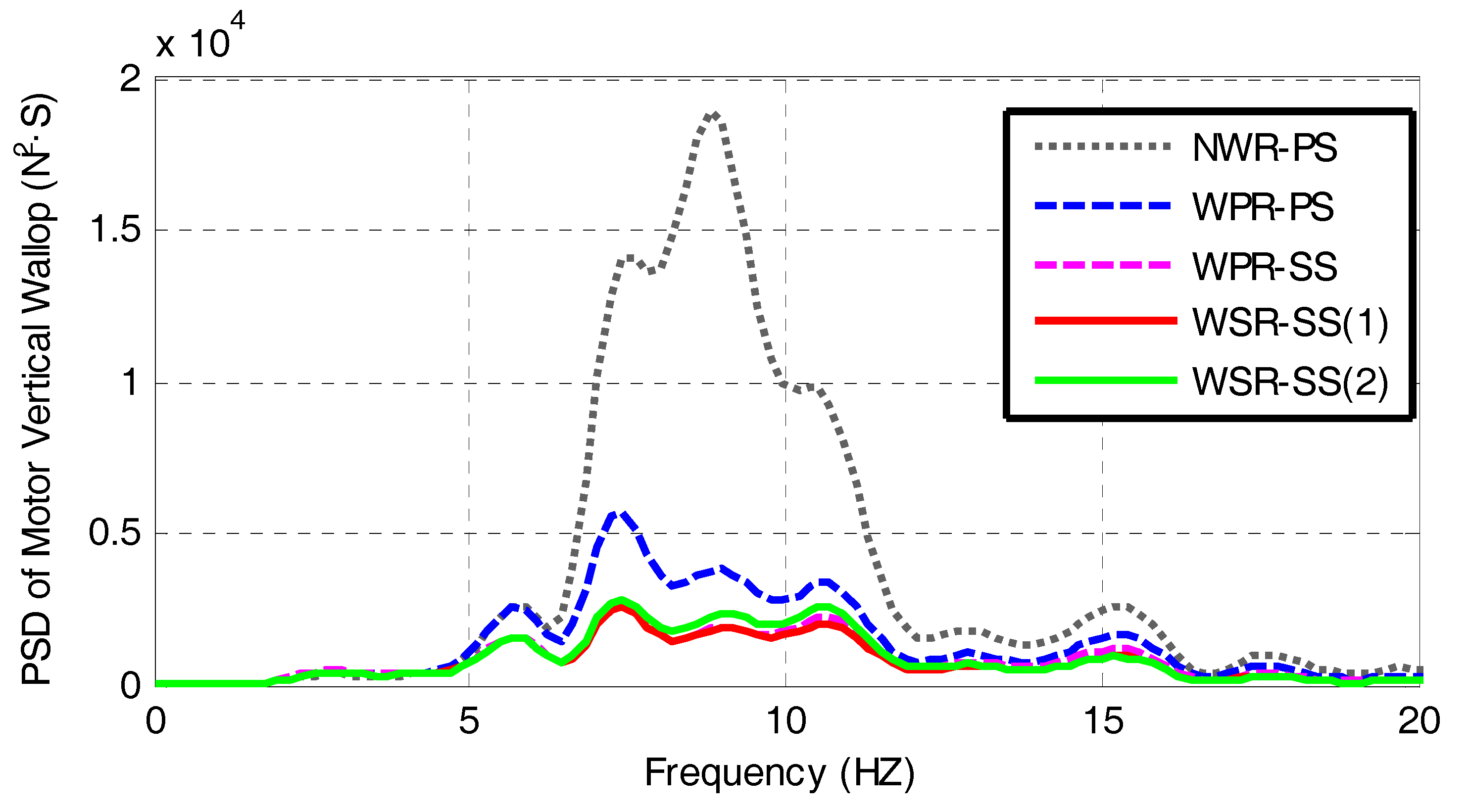

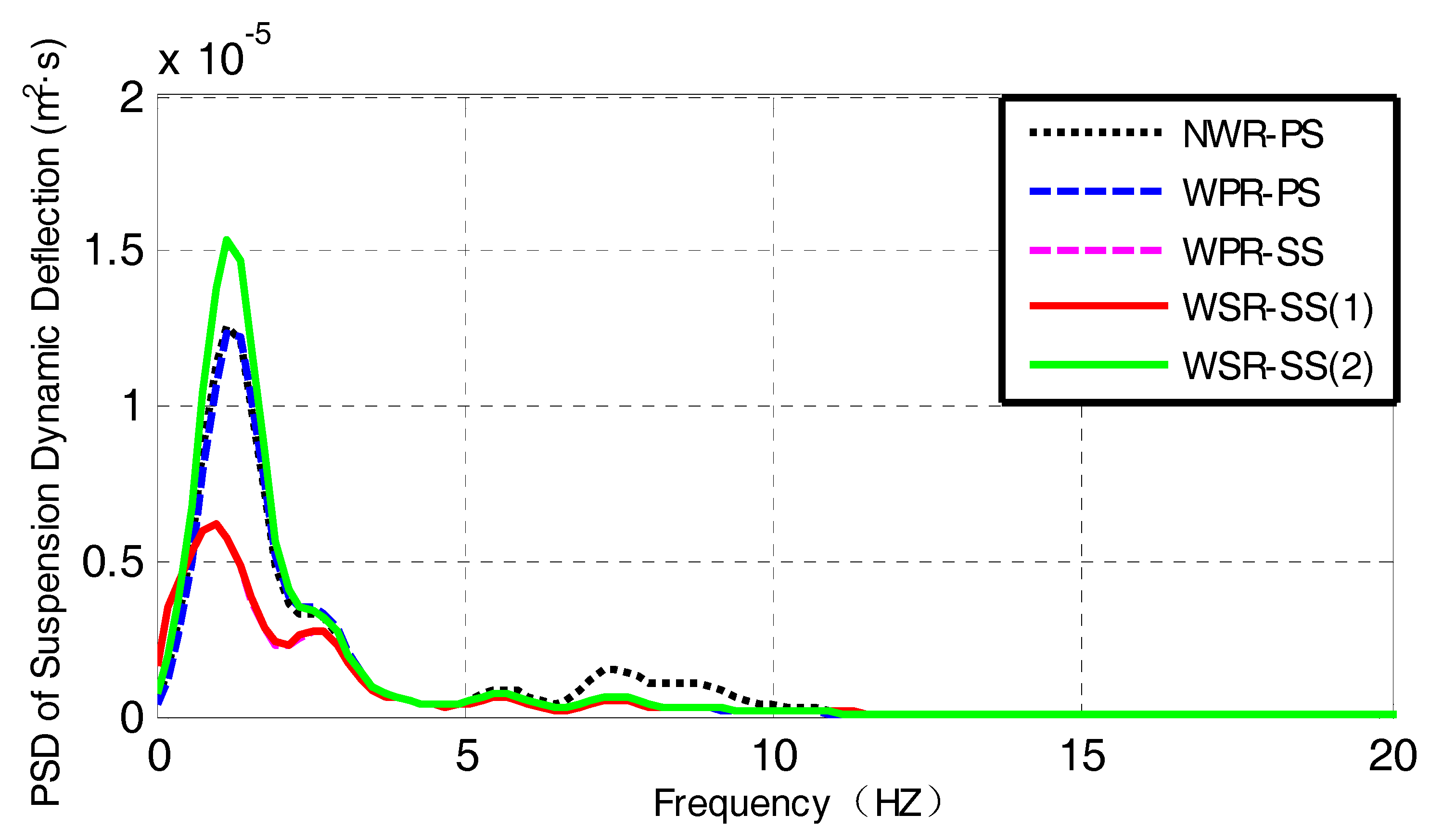

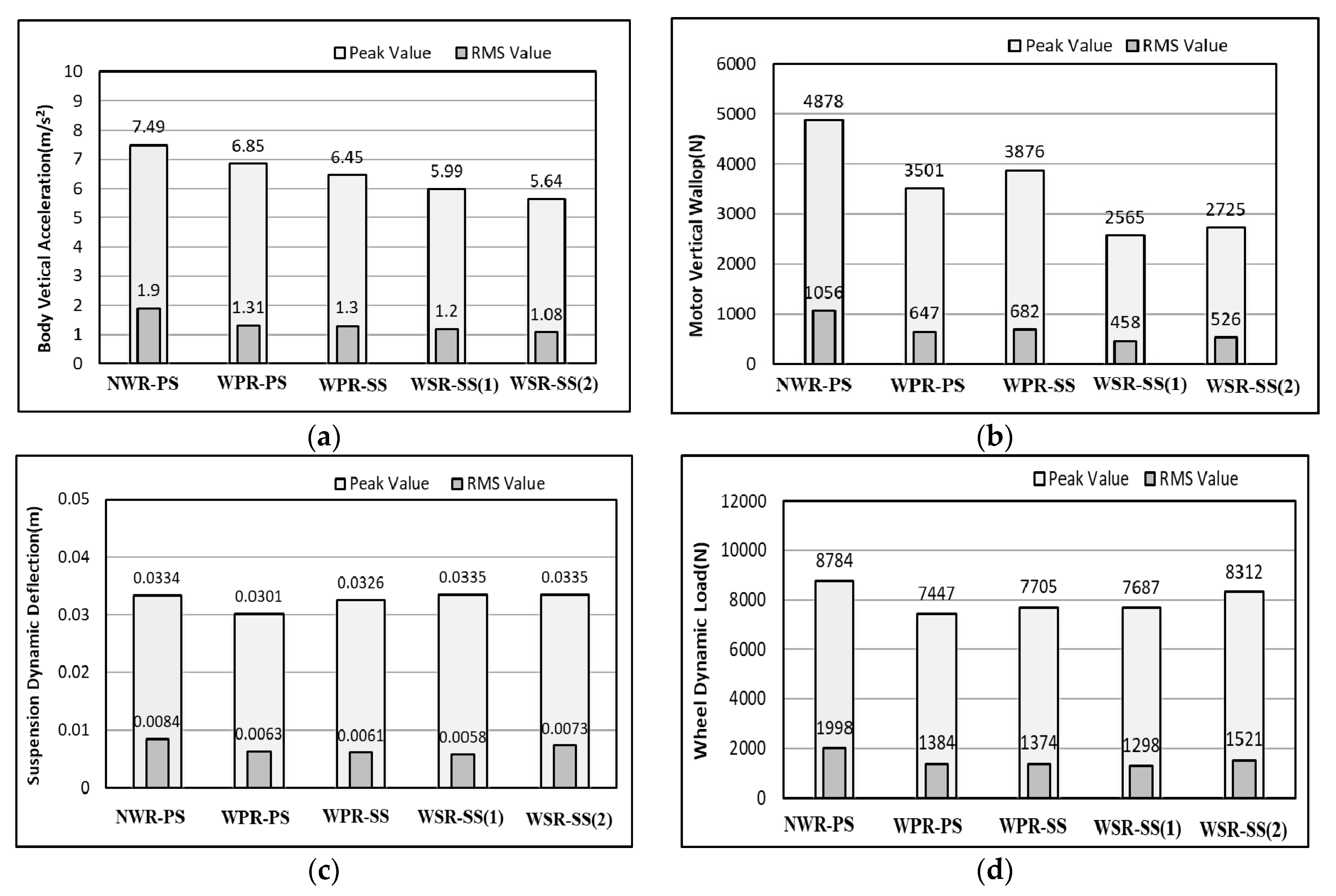

4.1. Simulation under Pavement Random Excitation

4.2. Simulation under Pavement Pulse Excitation

5. Conclusions

- (1)

- The proposed in-wheel vibration absorber consists of a spring, an annular rubber bushing, and a controllable damper. The spring and the rubber bushing to restrain the wheel vibration passively, and the controllable damper is controlled to further restrain the wheel and motor vibration adaptively.

- (2)

- Under typical driving conditions, the IPSO algorithm is utilized to determine the parameters of the in-wheel spring and rubber bushing. The in-wheel absorber with the matched parameters can effectively restrain the motor vibration under most conditions.

- (3)

- There are negative interaction effects between vehicle suspension and in-wheel absorber, which can be overcame by using LQR control of suspension force and fuzzy PID control of in-wheel damper force. The performance of the proposed control strategy has been examined through simulations under random pavement excitation and pavement pulse excitation conditions. The results show that the proposed LQR controller effectively improves vehicle ride comfort and the fuzzy PID controller further suppresses motor vibration and reduces motor vertical wallop as well.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yu, Z.; Feng, Y.; Xiong, L. Review on Vehicle Dynamics Control of Distributed Drive Electric Vehicle. J. Mech. Eng. 2013, 49, 105–114. [Google Scholar] [CrossRef]

- Yoshimura, M.; Fujimoto, H. Driving Torque Control Method for Electric Vehicle with In-Wheel Motors. IEEJ Trans. Ind. Appl. 2011, 131, 721–728. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Zhang, L.; Liu, M. Vehicle Stability Enhancement through Hierarchical Control for a Four-Wheel-Independently-Actuated Electric Vehicle. Energies 2017, 10, 947. [Google Scholar] [CrossRef]

- Watts, A.; Vallance, A.; Whitehead, A.; Hilton, C. The technology and economics of in-wheel motors. SAE Int. J. Passeng. Cars 2010, 3, 37–54. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, Y.; YU, E.; Rao, R.; Xie, J. Review of electric vehicle policies in China: Content summary and effect analysis. Renew. Sustain. Energy Rev. 2016, 70, 698–714. [Google Scholar] [CrossRef]

- Wang, R.; Chen, Y.; Feng, D.; Huang, X.; Wang, J. Development and performance characterization of an electric ground vehicle with independently actuated in-wheel motors. J. Power Sources 2011, 196, 3962–3971. [Google Scholar] [CrossRef]

- Chen, X.; Yin, J.; Wang, W.; Wu, L.; Tang, F. Approaches to diminish large unsprung mass negative effects of wheel side drive electric vehicles. J. Adv. Mech. Des. Syst. Manuf. 2016, 10, 1–2. [Google Scholar] [CrossRef]

- Wang, R.; Jing, H.; Yan, F.; Karimi, H.; Chen, N. Optimization and finite-frequency H∞ control of active suspensions in in-wheel motor driven electric ground vehicles. J. Franklin Inst. 2015, 352, 468–484. [Google Scholar] [CrossRef]

- Tan, D.; Lu, C. The Influence of the Magnetic Force Generated by the In-Wheel Motor on the Vertical and Lateral Coupling Dynamics of Electric Vehicles. IEEE Trans. Veh. Technol. 2016, 65, 4655–4668. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Sun, W.; Zheng, L. Effect of the Unbalanced Vertical Force of a Switched Reluctance motor on the Stability and the Comfort of an In-Wheel Motor Electric Vehicle. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2015, 229, 1569–1584. [Google Scholar] [CrossRef]

- Wang, Y.; Li, P.; Ren, G. Electric vehicles with in-wheel switched reluctance motors-Coupling effects between road excitation and the unbalanced radial force. J. Sound Vib. 2016, 372, 69–81. [Google Scholar] [CrossRef]

- Luo, Y.; Tan, D. A Research on the Hub-motor Driven Wheel Structure with a Novel Built-in Mounting System. Automot. Eng. 2013, 35, 1105–1110. [Google Scholar]

- Kacem, M.; Tounsi, S.; Neji, R. Determination of axial flux motor electrical parameters for electric vehicle. In Proceedings of the 2015 6th International Renewable Energy Congress, Sousse, Tunisia, 24–26 March 2015. [Google Scholar]

- Mahmoudi, A.; Rahim, N.; Ping, H. Axial-Flux Permanent-Magnet Motor Design For Electric Vehicle Direct Drive Using Sizing Equation And Finite Element Analysis. Prog. Electromagn. Res. 2012, 122, 467–496. [Google Scholar] [CrossRef]

- Nikam, S.; Vandana, R.; Fernandes, B. A High-Torque-Density Permanent-Magnet Free Motor for In-Wheel Electric Vehicle Application. IEEE Trans. Ind. Appl. 2012, 48, 2287–2295. [Google Scholar] [CrossRef]

- Takahashi, T.; Takemoto, M.; Ogasawara, S.; Hino, W.; Takezaki, K. Size and Weight Reduction of an In-wheel Axial-gap Motor Using Ferrite Permanent Magnets for Electric City Commuters. In Proceedings of the 18th International Conference on Electrical Machines and Systems, Pattaya, Thailand, 25–28 October 2015. [Google Scholar]

- Nagaya, G.; Wakao, Y.; Abe, A. Development of an in-wheel drive with advanced dynamic-damper mechanism. JSAE Rev. 2003, 4, 477–481. [Google Scholar] [CrossRef]

- Shao, X.; Naghdy, F.; Du, H. Reliable fuzzy H∞ control for active suspension of in-wheel motor driven electric vehicles with dynamic damping. Mech. Syst. Signal Process. 2017, 87, 365–383. [Google Scholar] [CrossRef]

- Luo, Y.; Tan, D. Study on the Dynamics of the In-Wheel Motor System. IEEE Trans. Veh. Technol. 2012, 61, 3510–3518. [Google Scholar]

- Oliveira, K.; Cesar, M.; Goncalves, J. Fuzzy based Control of a Vehicle Suspension System using a MR Damper. In Proceedings of the 12th Portuguese Conference on Automatic Control, Guimaraes, Portugal, 14–16 September 2017. [Google Scholar]

- Ma, Y.; Deng, Z.; Xie, D. Analysis and optimization of in-wheel motor suspension configuration. J. Cent. South Univ. 2014, 45, 3008–3013. [Google Scholar]

- Jin, L.; Yu, Y.; Fu, Y. Study on the ride comfort of vehicles driven by in-wheel motors. Adv. Mech. Eng. 2016, 8, 1–9. [Google Scholar] [CrossRef]

- Shen, D.; Ling, X.; Liu, J.; Wang, H. Modelling and Simulation of a Fuzzy PID Controller for Active Suspension System. In Proceedings of the 7th International Conference on Fuzzy Systems and Knowledge Discovery, Yantai, China, 10–12 August 2010. [Google Scholar]

- Kumar, V.; Rana, K.; Kumar, J.; Mishra, P. Self-tuned robust fractional order fuzzy PD controller for uncertain and nonlinear active suspension system. Neural Comput. Appl. 2017, 1–17. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J. Active steering Actuator Fault Detection for an automatically-steered electric ground vehicle. IEEE Trans. Veh. Technol. 2017, 66, 3685–3702. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, H.; Wang, J. Linear parameter-varying controller design for four-wheel independently actuated electric ground vehicles with active steering systems. IEEE Trans. Control Syst. Technol. 2014, 22, 1281–1296. [Google Scholar]

- Badri, P.; Amini, A.; Sojoodi, M. Robust fixed-order dynamic output feedback controller design for nonlinear uncertain suspension system. Mech. Syst. Signal Process. 2016, 80, 137–151. [Google Scholar] [CrossRef]

- Du, H.; Zhang, N. Fuzzy control for nonlinear uncertain electrohydraulic active suspensions with input constraint. IEEE Trans. Fuzzy Syst. 2009, 17, 343–356. [Google Scholar]

- Guo, D.; Hu, H.; Yi, J. Neural network control for a semi-active vehicle suspension with a magnetorheological damper. J. Vib. Control 2004, 10, 461–471. [Google Scholar] [CrossRef]

- Wang, R.; Song, Y.; Xue, Y.; Jing, H.; Hou, J.; Zhao, M. An optimal vibration control strategy for a vehicle’s active suspension based on improved cultural algorithm. Appl. Soft Comput. 2015, 28, 167–174. [Google Scholar] [CrossRef]

- Sun, W.; Gao, H.; Yao, B. Adaptive robust vibration control of full-car active suspension with electrohydraulic actuators. IEEE Trans. Control Syst. Technol. 2013, 21, 2417–2422. [Google Scholar] [CrossRef]

- Marinakis, Y.; Migdalas, A.; Sifaleras, A. A hybrid Particle Swarm Optimization-Variable Neighborhood Search algorithm for Constrained Shortest Path problems. Eur. J. Oper. Res. 2017, 261, 819–834. [Google Scholar] [CrossRef]

- Agarwalla, P.; Mukhopadhyay, S. Efficient player selection strategy based diversified particle swarm optimization algorithm for global optimization. Inf. Sci. 2017, 397, 69–90. [Google Scholar] [CrossRef]

- Tan, D.; Lu, C.; Ren, C. Optimal matching between the suspension and the rubber bushing of the in-wheel motor system. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 229, 758–769. [Google Scholar] [CrossRef]

| ECae | Eae | ||||||

|---|---|---|---|---|---|---|---|

| NB | NM | NS | Z | PS | PM | PB | |

| NB | PB | PB | PM | PM | PS | PS | Z |

| NM | PB | PB | PM | PM | PS | Z | Z |

| NS | PM | PM | PS | PS | Z | NS | NM |

| Z | PM | PS | PS | Z | NS | NM | NM |

| PS | PS | PS | Z | NS | NS | NM | NM |

| PM | Z | Z | NS | NM | NM | NM | NB |

| PB | Z | NS | NS | NM | NM | NB | NB |

| ECae | Eae | ||||||

|---|---|---|---|---|---|---|---|

| NB | NM | NS | Z | PS | PM | PB | |

| NB | NB | NB | NB | NM | NM | Z | Z |

| NM | NB | NB | NM | NM | NS | Z | Z |

| NS | NM | NM | NS | NS | Z | PS | PS |

| Z | NM | NS | NS | Z | PS | PS | PM |

| PS | NS | NS | Z | PS | PS | PM | PM |

| PM | Z | Z | PS | PM | PM | PB | PB |

| PB | Z | Z | PS | PM | PB | PB | PB |

| ECae | Eae | ||||||

|---|---|---|---|---|---|---|---|

| NB | NM | NS | Z | PS | PM | PB | |

| NB | NB | NB | NB | NM | NM | Z | Z |

| NM | NB | NB | NM | NM | MS | Z | Z |

| NS | NM | NM | NS | NS | Z | PS | PS |

| Z | NM | NS | NS | Z | PS | PS | PM |

| PS | NS | NS | Z | PS | PS | PM | PM |

| PM | Z | Z | PS | PM | PM | PB | PB |

| PB | Z | Z | PS | PM | PB | PB | PB |

| Parameters | Notation | Units | Value |

|---|---|---|---|

| 1/4 Body mass | ms | kg | 292 |

| Suspension stiffness | Ks | N/m | 17,000 |

| Suspension damping | Cs0 | N·S/m | 1317 |

| Vertical stiffness of tire | Kt | N/m | 241,600 |

| In-wheel spring stiffness | Ke | N/m | 2615 |

| In-wheel damper coefficient | Ce0 | N·S/m | 3226 |

| Mass of tire | mt | kg | 40 |

| Mass of motor stator | me1 | kg | 15 |

| Mass of motor rotor | me2 | kg | 30 |

| Bolts stiffness | Kr | N/m | 5,000,000 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Gu, F.; Zhang, Y. Ride Comfort Optimization of In-Wheel-Motor Electric Vehicles with In-Wheel Vibration Absorbers. Energies 2017, 10, 1647. https://doi.org/10.3390/en10101647

Liu M, Gu F, Zhang Y. Ride Comfort Optimization of In-Wheel-Motor Electric Vehicles with In-Wheel Vibration Absorbers. Energies. 2017; 10(10):1647. https://doi.org/10.3390/en10101647

Chicago/Turabian StyleLiu, Mingchun, Feihong Gu, and Yuanzhi Zhang. 2017. "Ride Comfort Optimization of In-Wheel-Motor Electric Vehicles with In-Wheel Vibration Absorbers" Energies 10, no. 10: 1647. https://doi.org/10.3390/en10101647