Multi-Objective Analysis of a CHP Plant Integrated Microgrid in Pakistan

Abstract

:1. Introduction

2. Data Collection

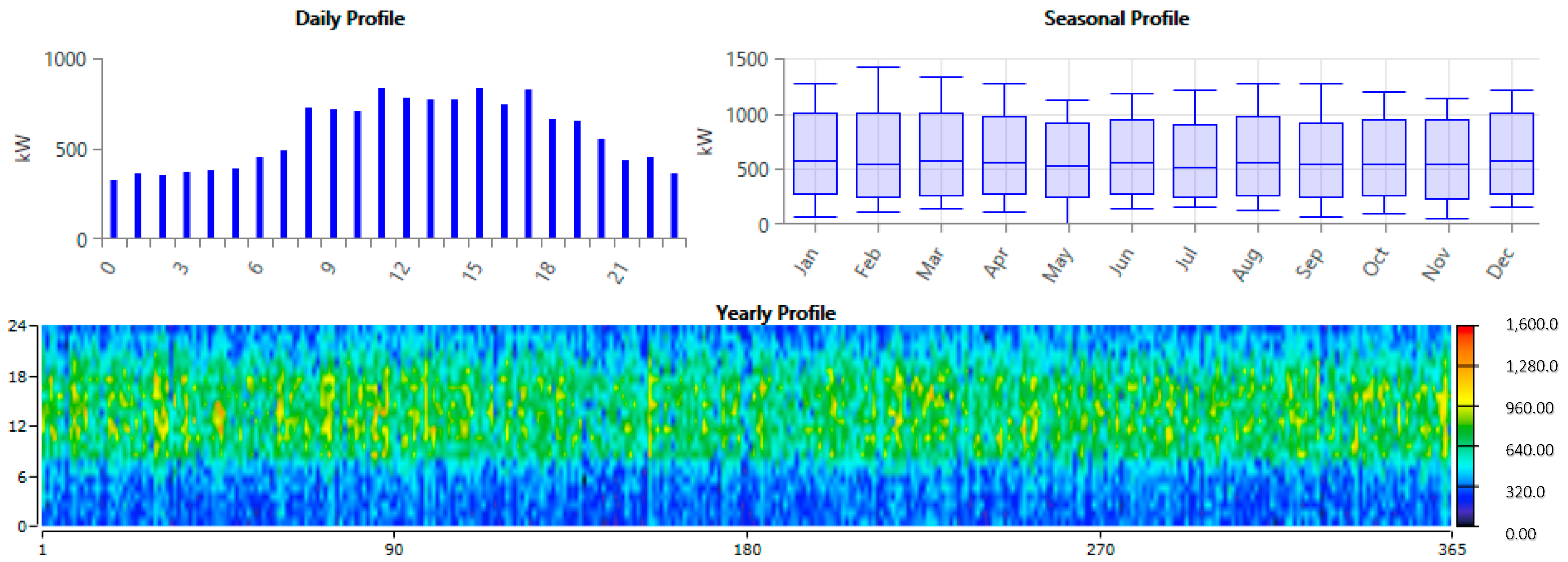

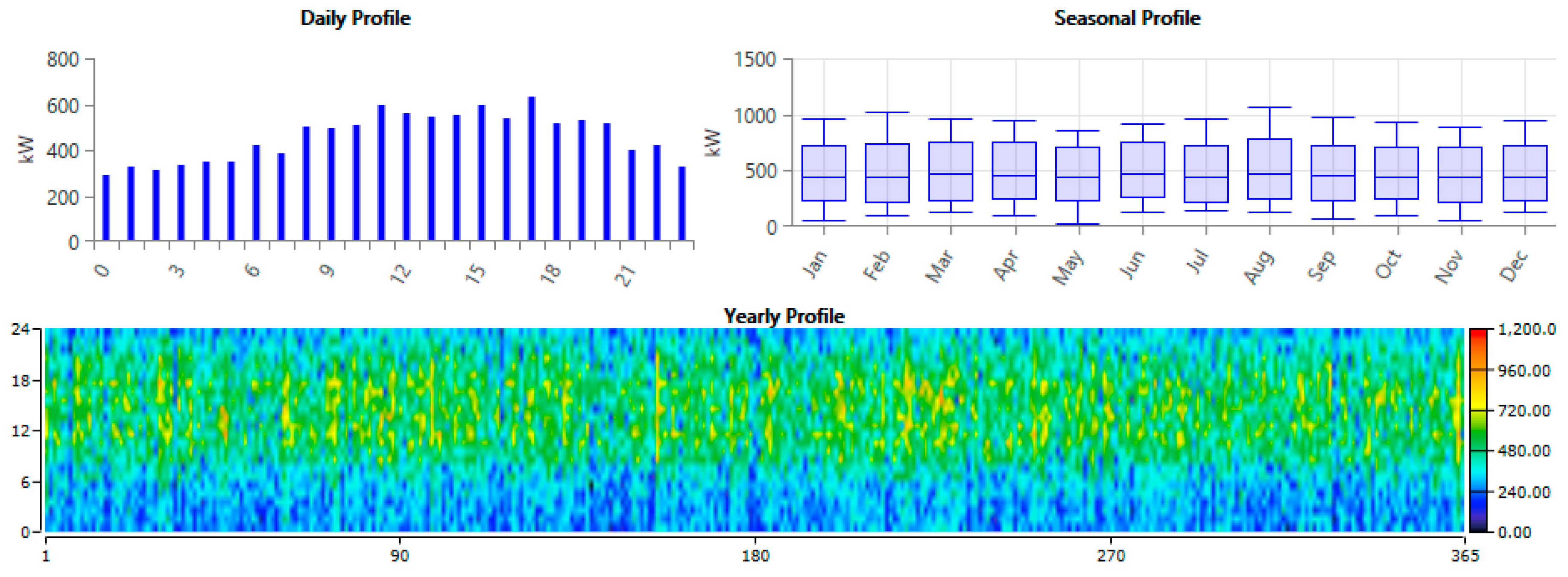

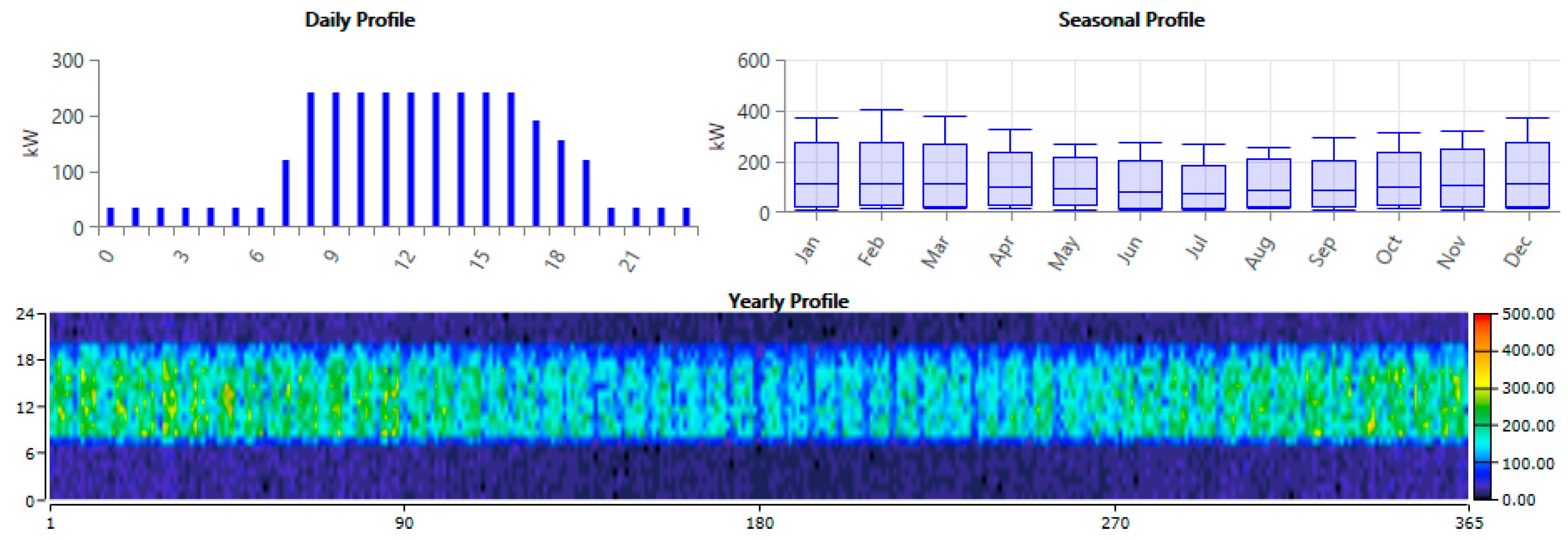

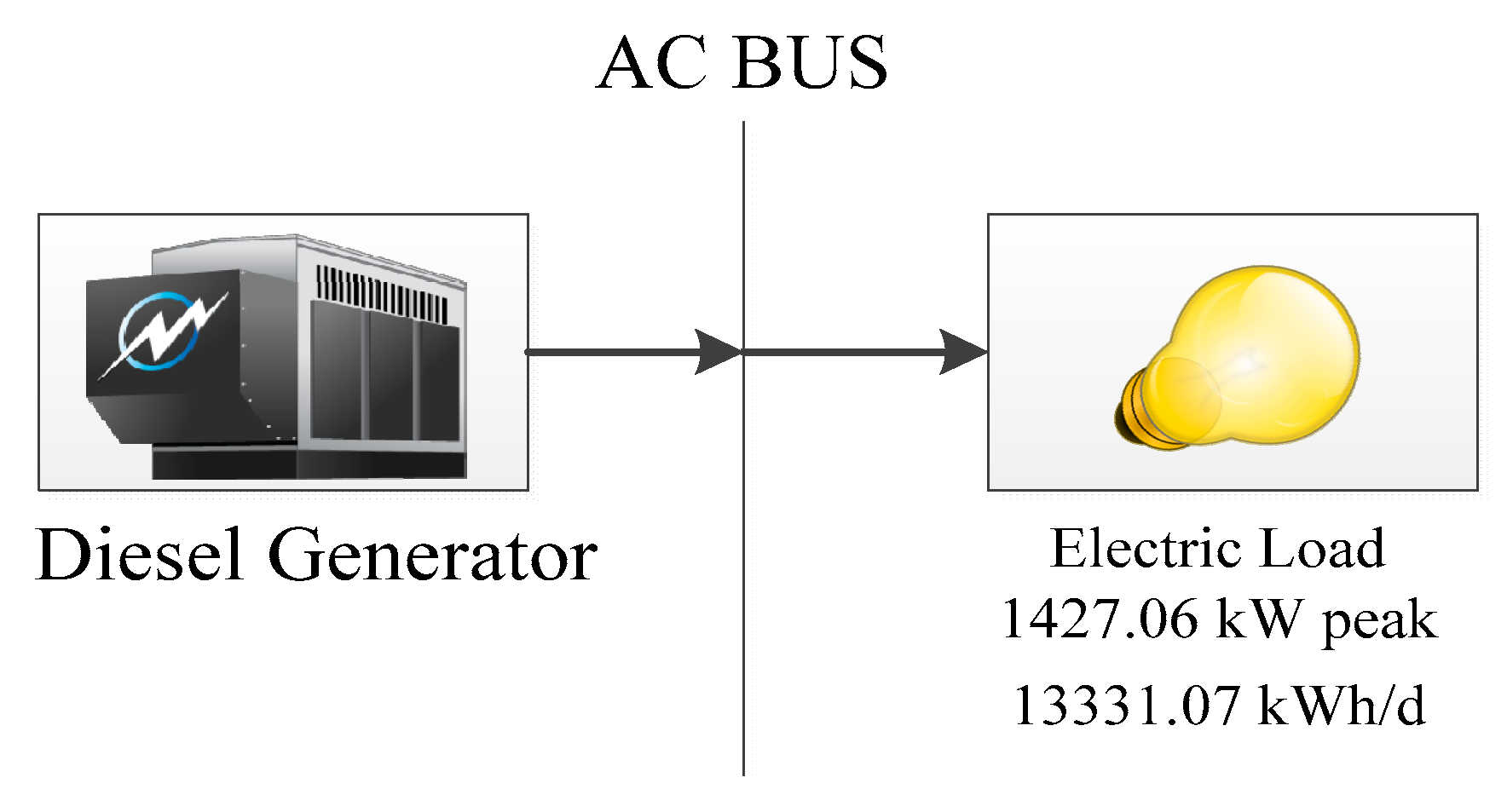

2.1. Load Profile

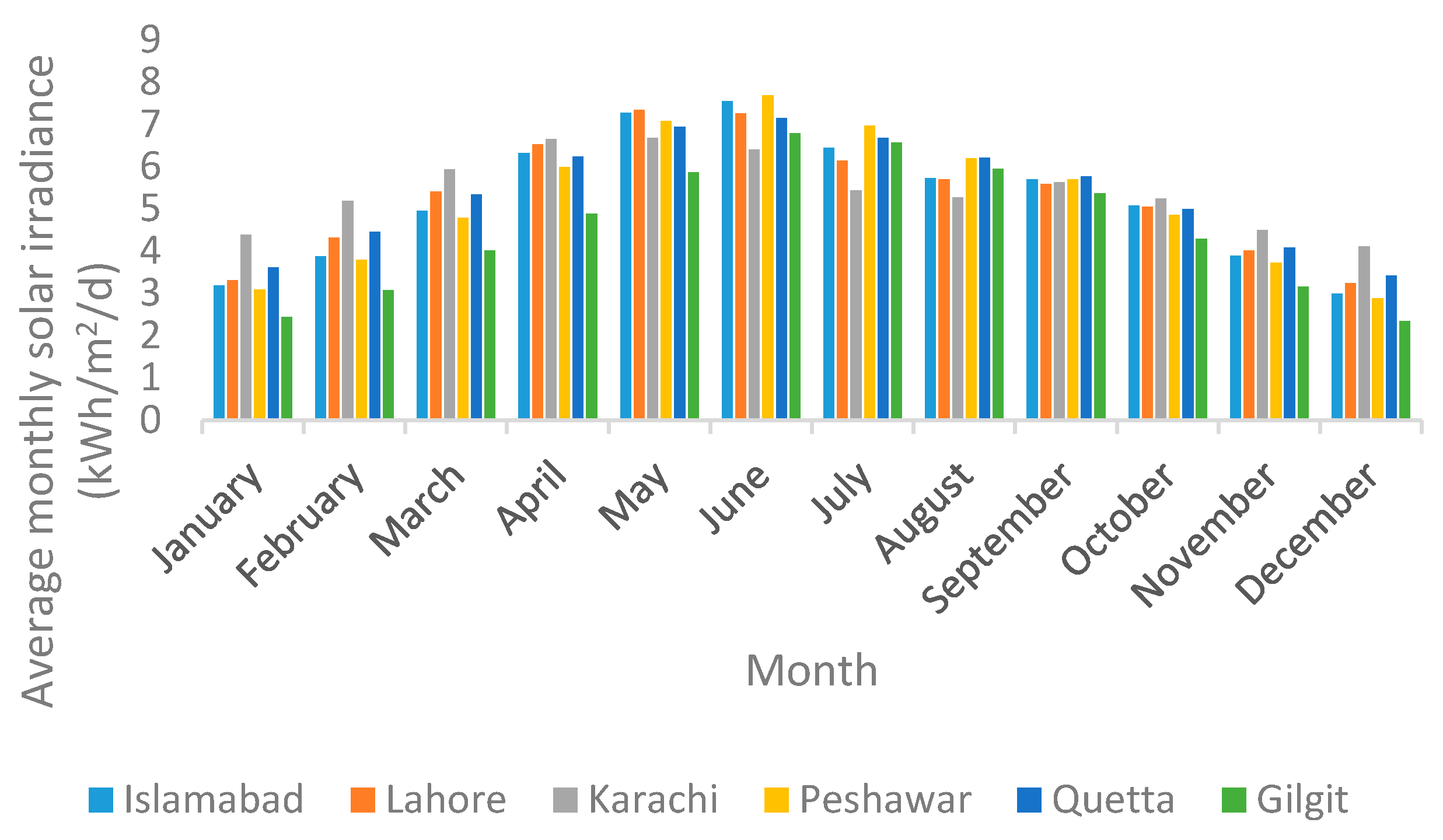

2.2. Solar Energy Resource

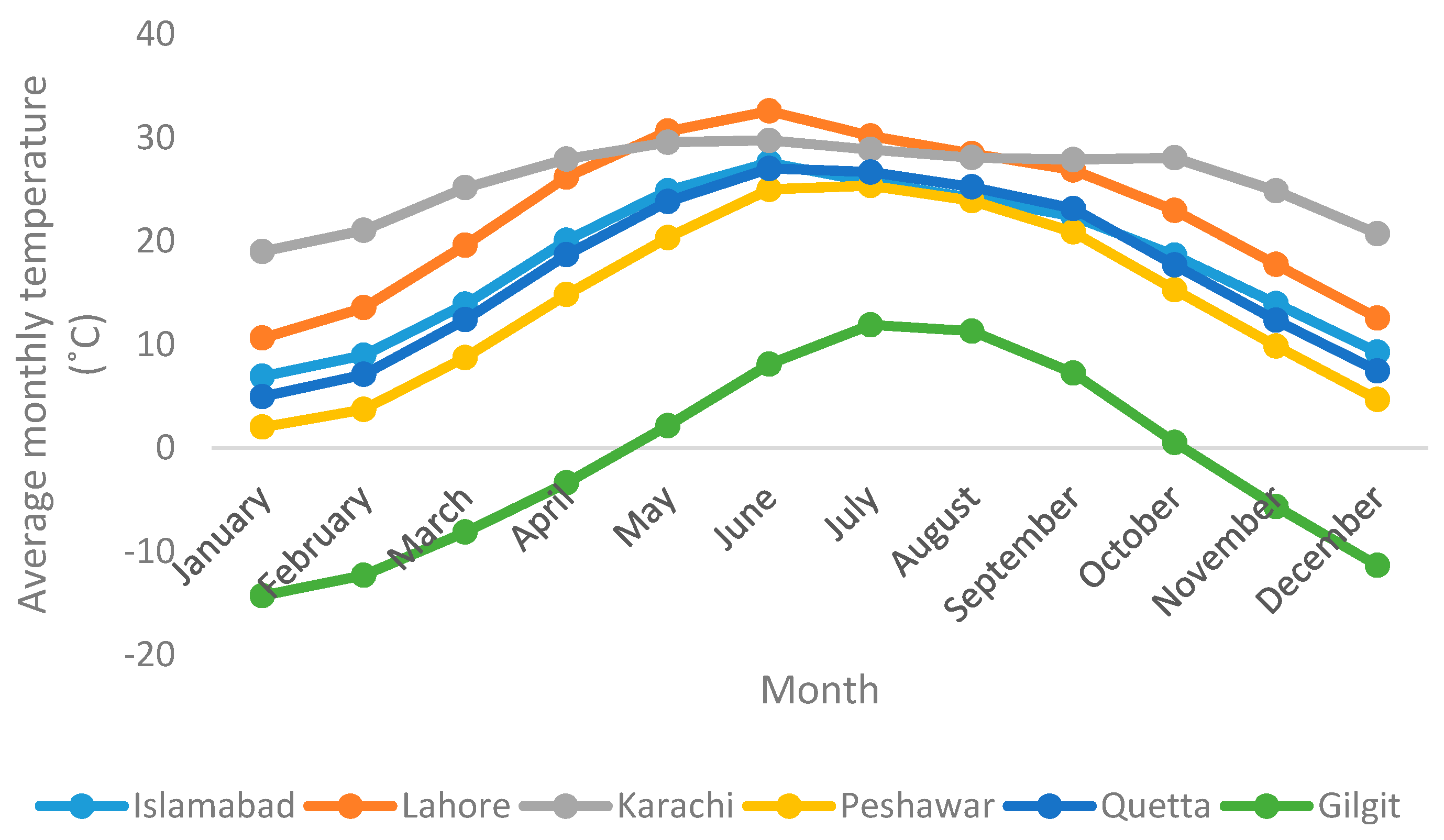

2.3. Temperature Resource

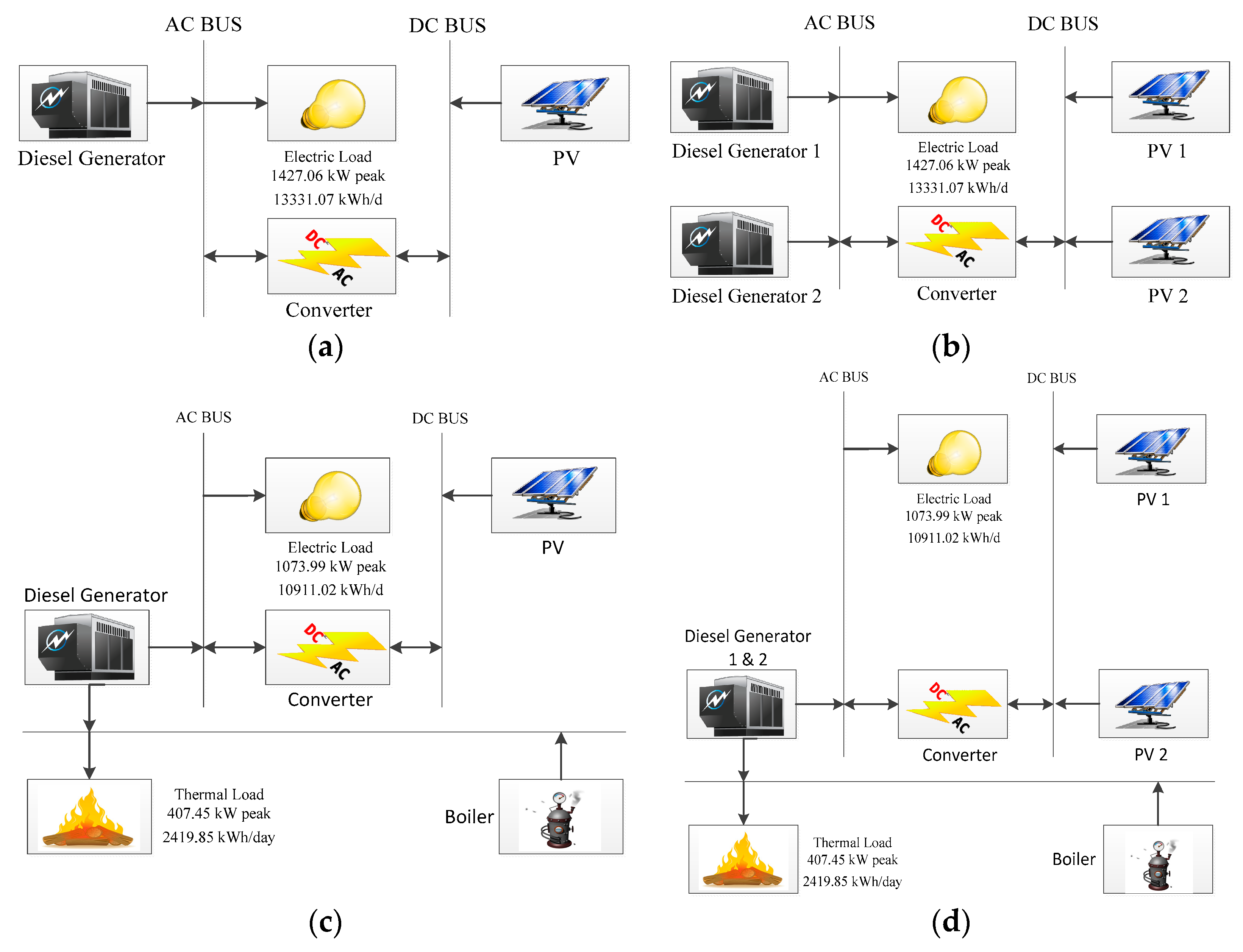

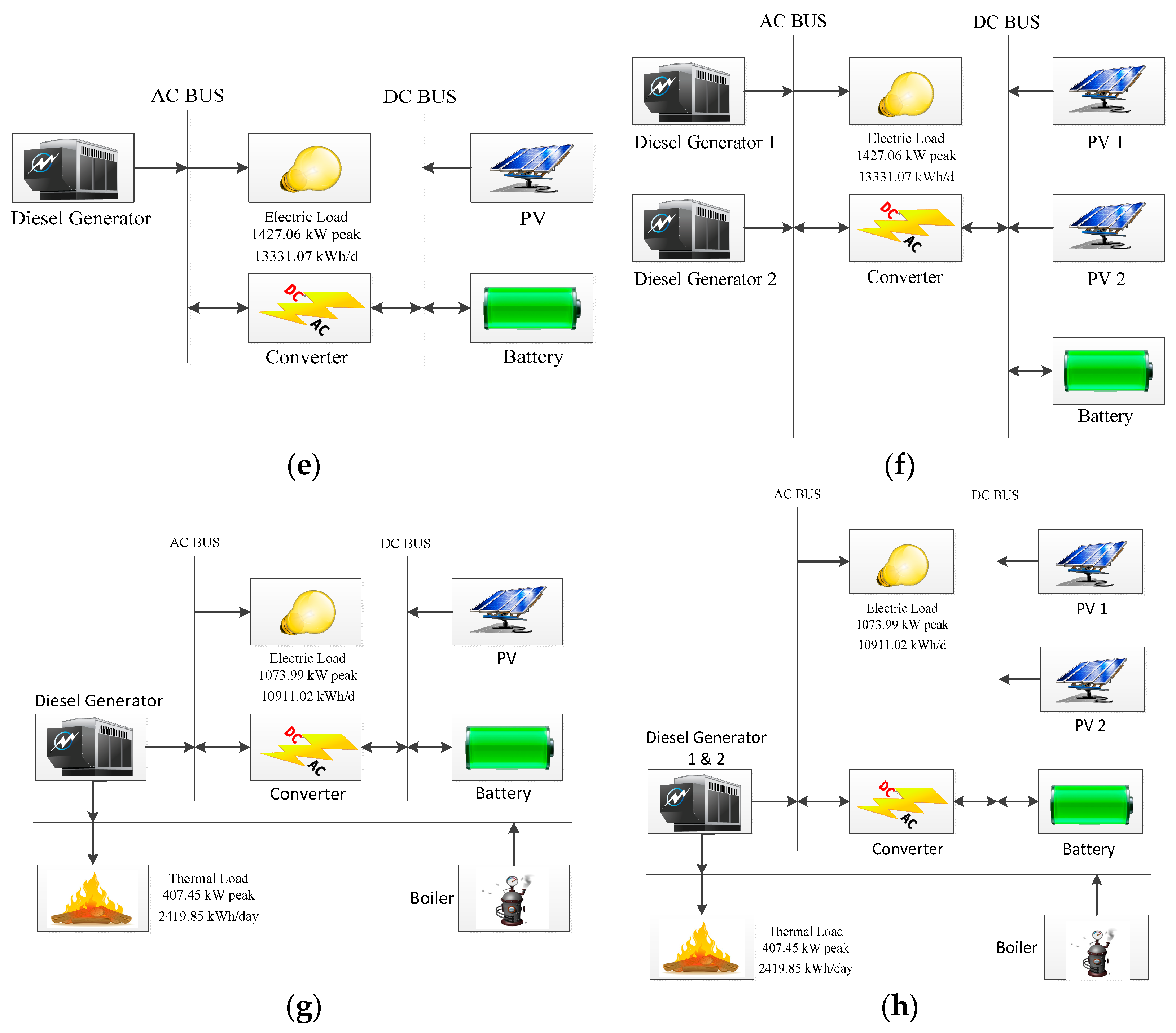

3. Microgrid Modelling

3.1. Multi-Objective Analysis Using HOMER Pro

3.2. Objective and Constraints

4. Results and Analysis

4.1. Graphical Representation

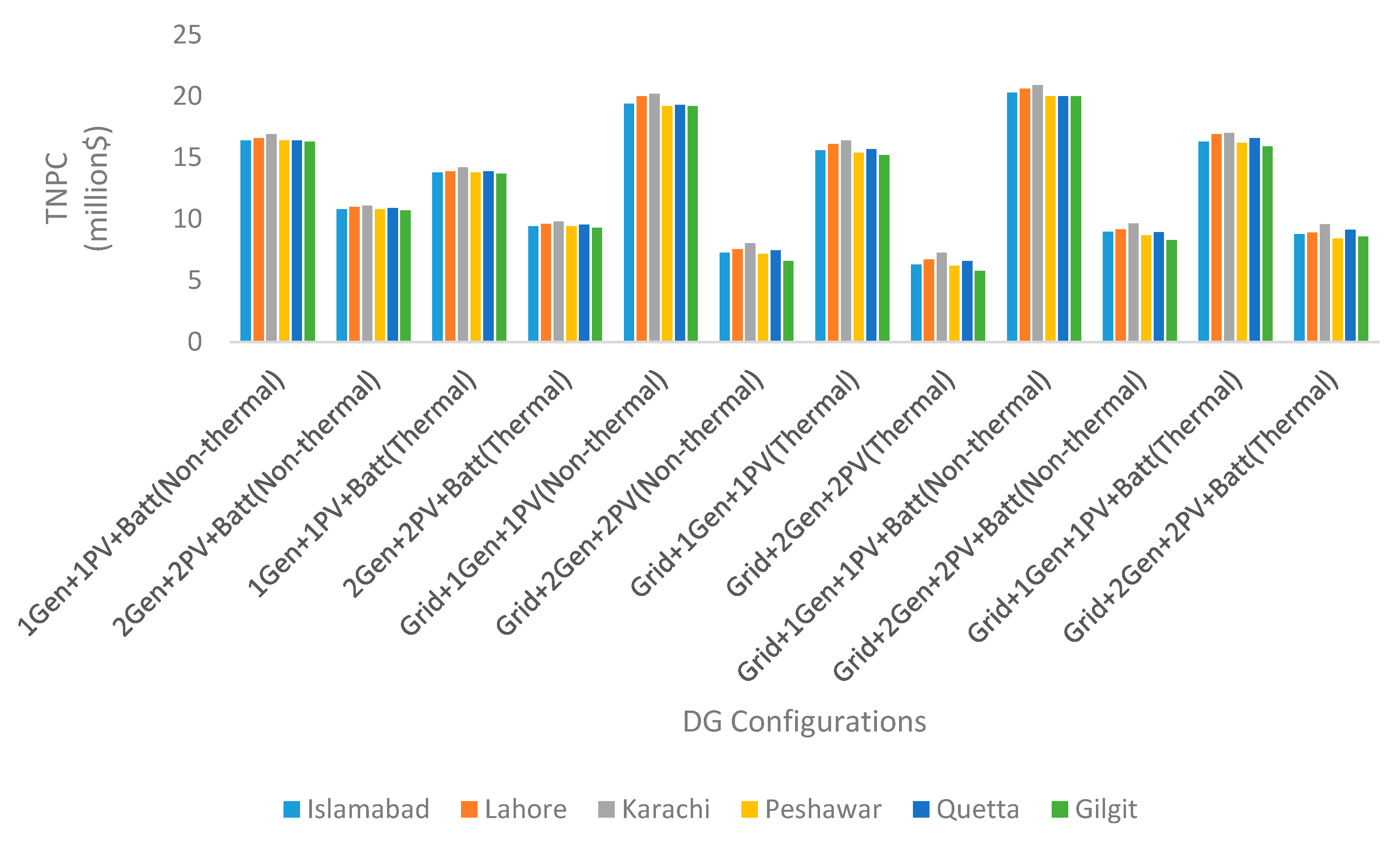

4.1.1. Total Net Present Cost

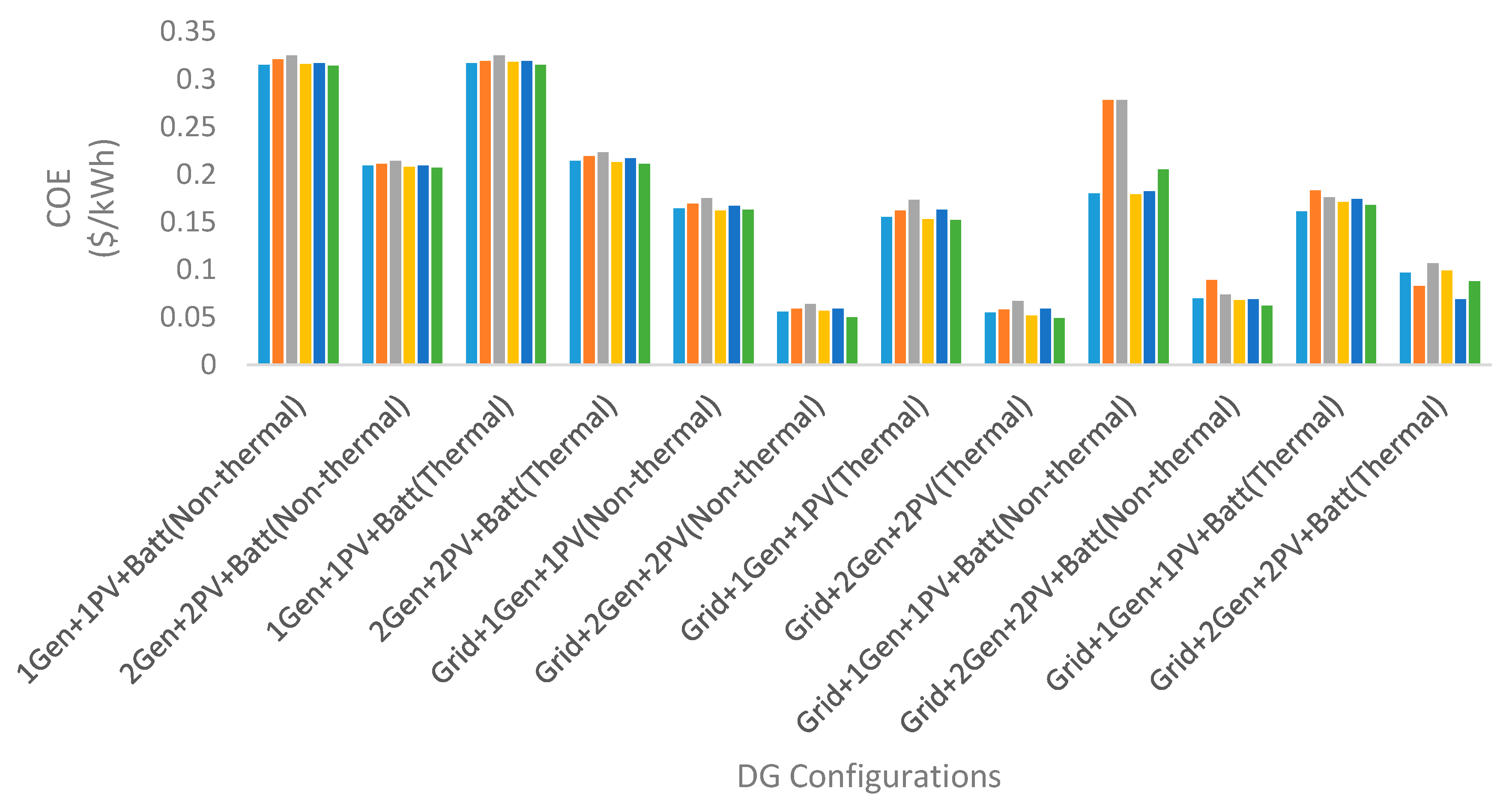

4.1.2. Cost of Generated Energy

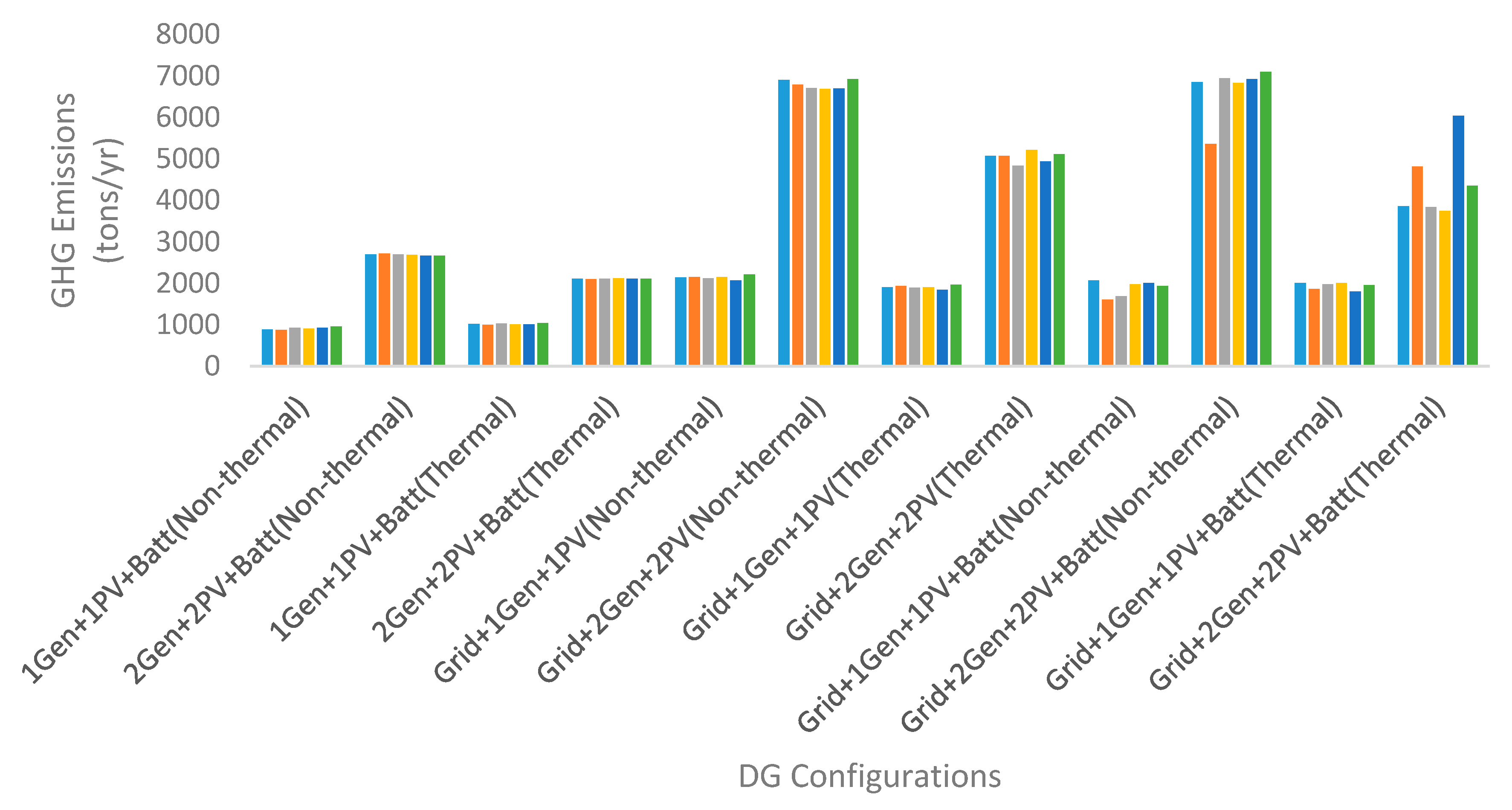

4.1.3. Greenhouse Gas Emissions

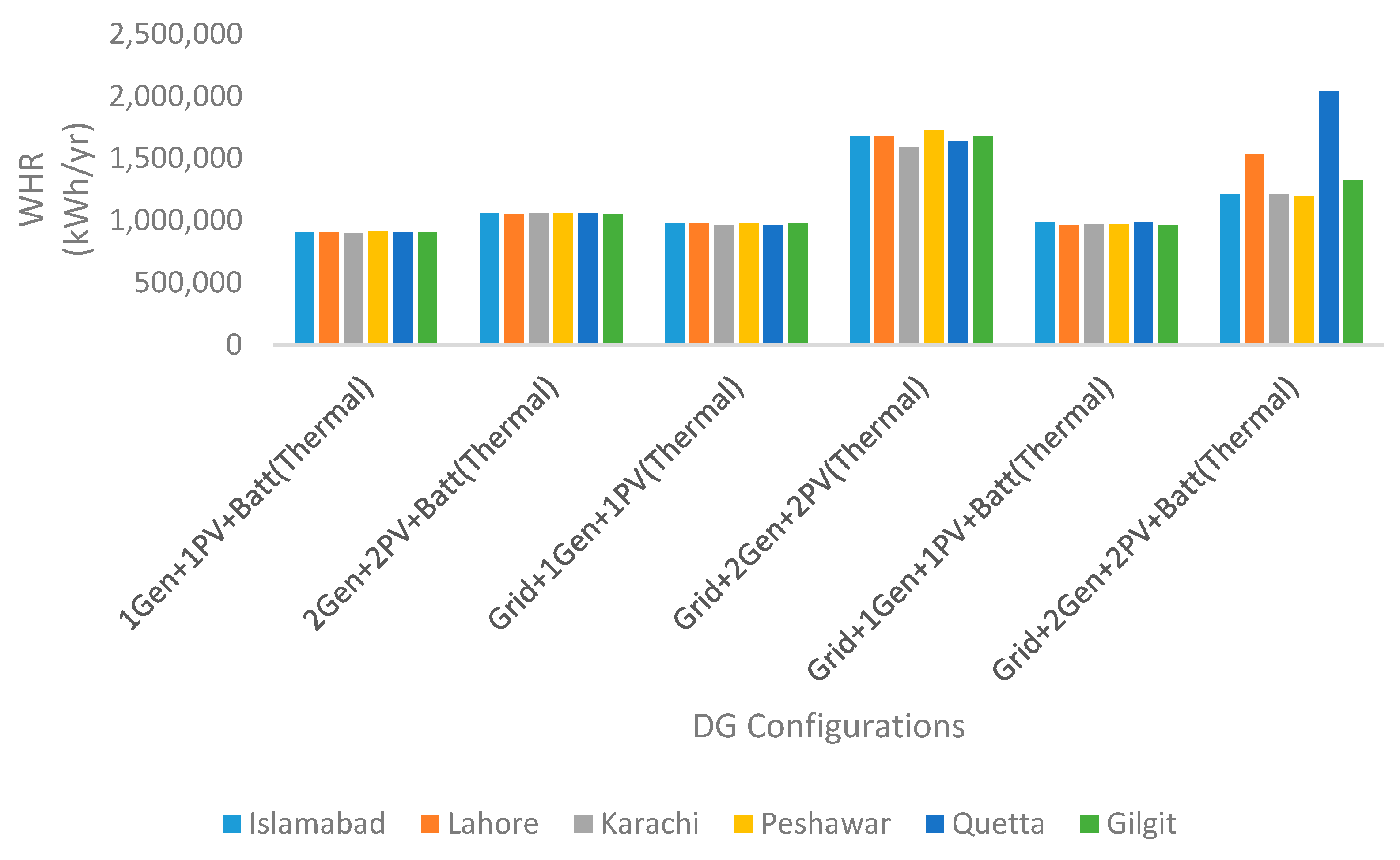

4.1.4. Waste Hear Recovery

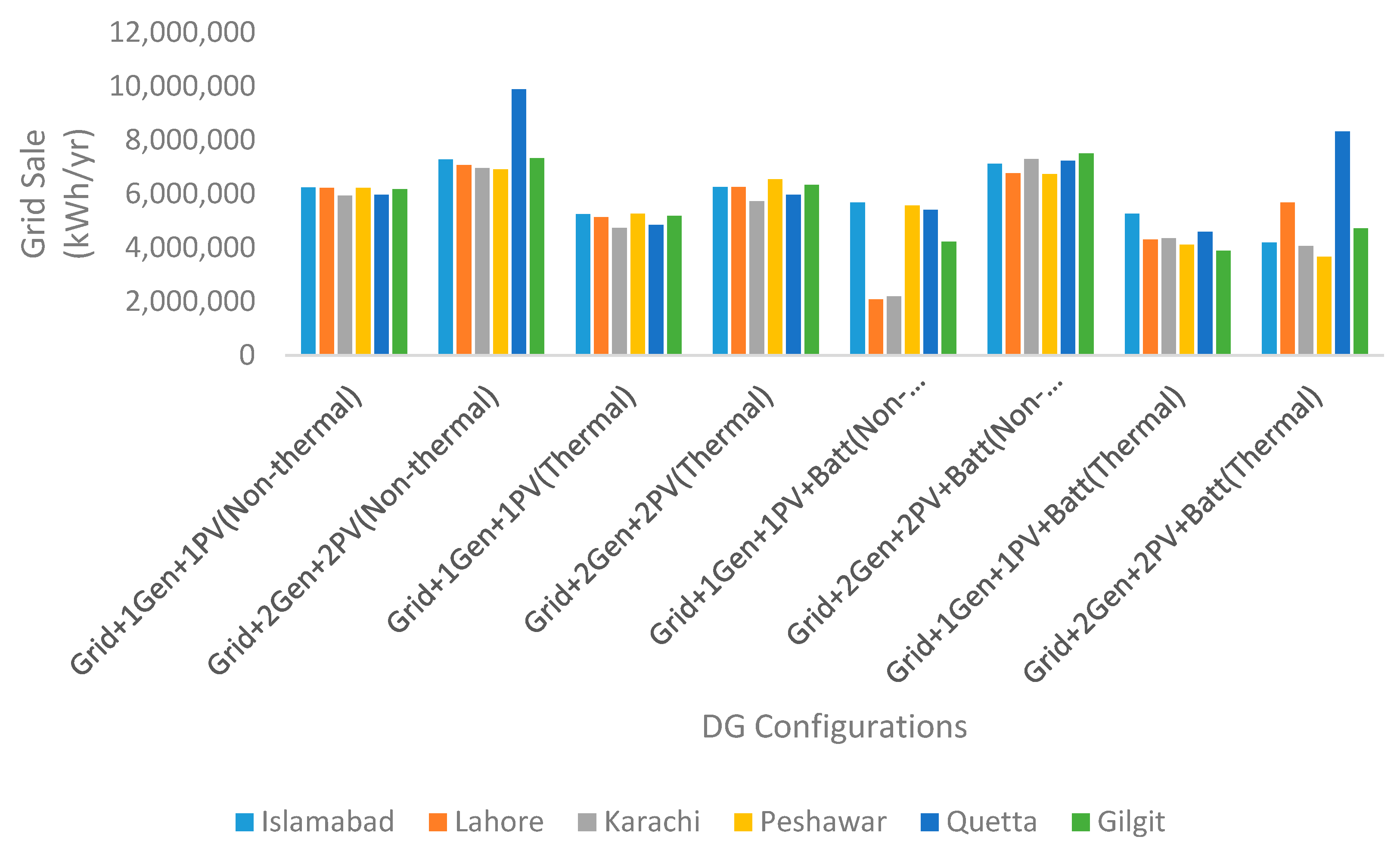

4.1.5. Grid Sales

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Diversifying Pakistan’s Energy Needs. Available online: http://naturalgasglobal.com/2016/06/20/diversifying-pakistans-energy-needs-a-case-of-natural-gas-lng (accessed on 20 June 2016).

- Dunya News. Available online: http://dunyanews.tv/en/Pakistan/285583-Electricity-shortfall-reaches-5500-MW-in-Pakistan (accessed on 18 December 2016).

- Tengfei, G.; Qiuxuan, W. Optimal design and feasibility analysis of a stand-alone hybrid CHP system-based on PV/Wind/gas turbine generator/VRB for a university in Hangzhou city. In Proceedings of the 2016 Chinese Control and Decision Conference (CCDC), Yinchuan, China, 28–30 May 2016; Volume 28, pp. 6187–6191. [Google Scholar]

- Adrain, B.D. Integration of Combined Heat and Power Generators into Small Buildings. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2006. [Google Scholar]

- Sreto, B.; Barry, N. Impact of combined heat and power plant on thermal and electrical energy supply for small and medium size enterprises. In Proceedings of the 42nd International Universities Power Engineering Conference, Brighton, UK, 4–6 September 2007; Volume 42, pp. 17–20. [Google Scholar]

- Plina, I.; Antans, S.; Olegs, L.; Maris, B. Combined heat and power plants towards efficient and flexible operation. In Proceedings of the IEEE 16th International Conference on Environment and Electrical Engineering (EEEIC), Florence, Italy, 7–10 June 2016; Volume 16. [Google Scholar]

- Colson, C.M.; Nehrir, M.H. Evaluating the Benefits of a hybrid solid oxide fuel cell combined heat and power plant for energy sustainability and emissions avoidance. IEEE Trans. Energy Convers. 2011, 26, 140–148. [Google Scholar] [CrossRef]

- Alexey, C.; Vladimir, M.; Alexander, A. Combined heat and power plants load distribution optimization. In Proceedings of the 45th International Universities Power Engineering Conference UPEC2010, Wales, UK, 31 August–3 September 2010; Volume 45. [Google Scholar]

- Michal, D.; Petr, H. Decomposition methods for operations scheduling problem in a combined heat and power plant. In Proceedings of the 10th International Conference on Environment and Electrical Engineering, Rome, Italy, 8–11 May 2011; Volume 10, pp. 1–4. [Google Scholar]

- Sekgogele, K.; Chowdhury, S.; Chowdhury, S.P. Technical and economic assessment of landfill gas-based CHP plants in South Africa. In Proceedings of the 46th International Universities’ Power Engineering Conference (UPEC), Soest, Germany, 5–8 September 2011; Volume 46, pp. 1–5. [Google Scholar]

- Vikas, C.; Anh-Tuan, D.; Baoduo, J.; Faryar, J.; Jack, B.; Ioannis, A.; Amit, C.; Andrew, A. Modeling and optimization of a combined cooling, heating and power plant system. In Proceedings of the 2012 American Control Conference (ACC), Montreal, QC, Canada, 27–29 June 2012. [Google Scholar]

- Ilija, B.B.; Rade, M.C. Optimal distributed generation planning at a local level—A review of Serbian renewable energy development. Renew. Sustain. Energy Rev. 2014, 39, 79–86. [Google Scholar]

- Liviu, R.; Mihai, P.M. Parallel operation of combined heat and power plants and wind farms. In Proceedings of the 2012 International Conference on Applied and Theoretical Electricity (ICATE), Craiova, Romania, 25–27 October 2012; pp. 1–4. [Google Scholar]

- Yuanhang, D.; Lei, C.; Yong, M.; Qun, C.; Kang, H.; Junhong, H.; Yiwei, Z.; Fei, X. Dispatch model of combined heat and power plant considering heat transfer process. IEEE Tarns. Sustain. Energy 2017, 8, 1225–1236. [Google Scholar]

- Ren, H.; Weisheng, Z.; Ken’ichi, N.; Weijun, G.; Qiong, W. Multi-onjective optimization for the operation of distributed energy systems considering economic and environmental aspects. Appl. Energy 2010, 87, 3642–3651. [Google Scholar] [CrossRef]

- Sreto, B. Planning algorithm for optimal combined heat & power generation plant connection in urban distribution network (UDN). In Proceedings of the 11th International Conference on the European Energy Market (EEM14), Krakow, Poland, 28–30 May 2014; Volume 11, pp. 1–7. [Google Scholar]

- Shekh, N.H.; Saiful, B. Waste heat recovery from exhaust of a diesel generator set using organic fluids. In Proceedings of the 10th International Conference on Mechanical Engineering, Dhaka, Bangladesh, 20–22 December 2013; Volume 10, pp. 439–444. [Google Scholar]

- Sreto, B. Combined heat & power plant connection into urban distribution network according to least cost technically acceptable principle. In Proceedings of the 50th International Universities Power Engineering Conference, Stoke on Trent, UK, 1–4 September 2015; Volume 50, pp. 1–6. [Google Scholar]

- Saint-Pierre, A.; Pierluigi, M. Techno-economic assessment of flexible combined heat and power plant with carbon capture and storage. In Proceedings of the 2014 Power Systems Computation Conference, Wroclaw, Poland, 18–22 August 2014; pp. 1–7. [Google Scholar]

- Constantin, S.; Nouredine, H.; Christophe, K.; Raphael, C. Combined heat and power plant optimization tool in a competitive energy market context. In Proceedings of the CIRED 2005—18th International Conference and Exhibition on Electricity Distribution, Turin, Italy, 6–9 June 2005; Volume 18. [Google Scholar]

- Eugen, H.; Mihai, G. Optimization of a combined cool, heat and power plant based on genetic algorithms and specialized software. In Proceedings of the 2014 International Conference and Exposition on Electrical and Power Engineering (EPE), Iasi, Romania, 16–18 October 2014; Volume 8, pp. 1030–1033. [Google Scholar]

- Daniel, S.; Felix, M. Increasing flexibility of combined heat and power plants with power-to-heat. In Proceedings of the 12th International Conference on the European Energy Market (EEM), Lisbon, Portugal, 19–22 May 2015; Volume 12, pp. 1–5. [Google Scholar]

- Buoro, D.; Casisi, M.; Nardi, D.A.; Pinamonti, P.; Reini, M. Multicriteria optimization of a distributed energy supply system for an industrial area. Energy 2013, 58, 128–137. [Google Scholar] [CrossRef]

- Somma, D.M.; Yan, B.; Bianco, N.; Graditi, G.; Luh, P.B.; Mongibello, L.; Naso, V. Multi-objective design optimization of distributed energy systems through cost and exergy assessments. Appl. Energy 2017, 204, 1299–1316. [Google Scholar] [CrossRef]

- Marialaura, D.S.; Bing, Y.; Nicola, B.; Peter, B.L.; Giorgio, G.; Luigi, M.; Vincenzo, N. Multi-objective operation optimization of a distributed energy system for a large-scale utility customer. Appl. Therm. Energy 2016, 101, 752–761. [Google Scholar]

- Zhang, G.; Cao, Y.; Cao, Y.; Li, D.; Wang, L. Optimal Energy Management for Microgrids with Combined Heat and Power (CHP) Generation Energy Storages and Renewable Energy Sources. Energies 2017, 10, 1288. [Google Scholar] [CrossRef]

- Li, P.; Wang, H.; Lv, Q.; Li, W. Combined Heat and Power Dispatch Considering Heat Storage of Both Buildings and Pipelines in District Heating System for Wind Power Integration. Energies 2017, 10, 893. [Google Scholar] [CrossRef]

- Zidan, A.; Gabbar, H. DG Mix and Energy Storage Units for Optimal Planning of Self-Sufficient Micro Energy Grids. Energies 2016, 9, 616. [Google Scholar] [CrossRef]

- Hussain, A.; Bui, V.; Kim, H.; Im, Y.; Lee, J. Optimal Energy Management of Combined Cooling Heat and Power in Different Demand Type Buildings Considering Seasonal Demand Variations. Energies 2017, 10, 789. [Google Scholar] [CrossRef]

- Alarcon-Rodriguez, A.; Ault, G.; Galloway, G. Multi-objective planning of distributed energy resources: A review of the state-of-the-art. Renew. Sustain. Energy Rev. 2010, 14, 1353–1566. [Google Scholar] [CrossRef]

- Di Somma, M.; Graditi, G.; Heydarian-Forushani, E.; Shafie-khah, M.; Siano, P. Stochastic optimal scheduling of distributed energy resources with renewables considering economic and environmental aspects. Renew. Energy 2018, 116, 272–287. [Google Scholar] [CrossRef]

- Maroufmashat, A.; Sattari, S.; Roshandel, R.; Fowler, M.; Elkamel, A. Multi-objective optimization for design and operation of distributed energy systems through the multi-energy hub network approach. Ind. Eng. Chem. Res. 2016, 55, 8950–8966. [Google Scholar] [CrossRef]

- Pakistan Bureau of Statistics. Available online: http://www.pbscensus.gov.pk/content/area-population-aadministrative-units (accessed on 23 August 2017).

- NASA Surface Meteorology and Solar Energy. Available online: https://eosweb.larc.nasa.gov/cgi-bin/sse/[email protected] (accessed on 2 January 2017).

- Tribune. Available online: https://www.tribune.com.pk/story/1357453/going-green-pakistan-1-9mw-solar-energy-potential/ (accessed on 17 March 2017).

- Fahd, D.; Hai, L.; Lijun, Z.; Salwa, A. An Environmentally-Friendly Tourist Village in Egypt Based on a Hybrid Renewable Energy System––Part One: What Is the Optimum City? Energies 2015, 8, 6926–6944. [Google Scholar]

- PAkBIZ. Available online: http://www.pakbiz.com/finance/petroleumprices/ (accessed on 3 January 2017).

- Pavan, Y.V.; Ravikumar, B. Renewable energy based microgrid system sizing and energy management for green buildings. J. Mod. Power Syst. Clean Energy 2015, 3, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Tom, L.; Paul, G.; Peter, L. Micropower system modeling with HOMER. Integr. Altern. Sour. Energy 2006, 379–418. [Google Scholar] [CrossRef]

- Homer Microgrid NEWS and Insight. Available online: http://microgridnews.com/homer-optimizer-a-faster-path-to-finding-least-cost-microgrid-options/ (accessed on 23 August 2017).

| Component | Capital Cost | Replacement Cost | O&M Cost | Life Time |

|---|---|---|---|---|

| PV module | 3000 $/kW | 2500 $/kW | 10 $/year | 20 years |

| Power converter | 800 $/kW | 600 $/kW | 5 $/year | 15 years |

| Battery | 300 $/kWh | 250 $/kWh | 10 $/year | 12,600 kWh |

| Diesel generator | 400 $/kW | 300 $/kW | 0.25 $/h | 15,000 h |

| Technical Details | Value |

|---|---|

| Derating factor | 80% |

| Ground reflection | 20% |

| Converter efficiency | 90% |

| Fuel cost | 0.75 $/L |

| Annual nominal interest rate | 8% |

| Project lifetime | 25 years |

| Emissions penalty | 20 $/ton |

| Capacity shortage penalty | 20 $/kWh |

| Component | Range |

|---|---|

| PV | 0–4000 kW |

| Diesel Generator | 0–2000 kW |

| Battery | 0–200 string size |

| Converter | 0–5000 kW |

| City | Sr. No. | DGs’ Configuration | DGen1 (kW) | DGen2 (kW) | PV1 (kW) | PV2 (kW) | Battery (kWh) | Converter (kW) |

|---|---|---|---|---|---|---|---|---|

| All Cities | CONVENTIONAL DIESEL ONLY SYSTEM | |||||||

| 1 | Diesel only system | 1570 | - | - | - | - | - | |

| Islamabad | ISOLATED SYSTEM | |||||||

| 1 | 1Gen + 1PV + Batt (without WHR) | 750 | - | 1388 | - | 2112 | 1179 | |

| 2 | 2Gen + 2PV + Batt (without WHR) | 300 | 550 | 50 | 891 | 816 | 720 | |

| 3 | 1Gen + 1PV + Batt (with WHR) | 600 | - | 1065 | - | 1536 | 889 | |

| 4 | 2Gen + 2PV + Batt (with WHR) | 300 | 500 | 62.5 | 910 | 480 | 696 | |

| GRID-CONNECTED SYSTEM | ||||||||

| 5 | Grid + 1Gen + 1PV (without WHR) | 1050 | - | 2766 | - | - | 1733 | |

| 6 | Grid + 2Gen + 2PV (without WHR) | 50 | 1350 | 644 | 1405 | - | 1343 | |

| 7 | Grid + 1Gen + 1PV (with WHR) | 850 | - | 2366 | - | - | 1521 | |

| 8 | Grid + 2Gen + 2PV (with WHR) | 50 | 1000 | 1053 | 1269 | - | 1492 | |

| 9 | Grid + 1Gen + 1PV + Batt (without WHR) | 1050 | - | 2698 | - | 1704 | 1727 | |

| 10 | Grid + 2Gen + 2PV + Batt (without WHR) | 550 | 1550 | 1023 | 1308 | 240 | 1110 | |

| 11 | Grid + 1Gen + 1PV + Batt (with WHR) | 900 | - | 2238 | - | 1224 | 1393 | |

| 12 | Grid + 2Gen + 2PV + Batt (with WHR) | 550 | 500 | 436 | 1384 | 1536 | 1201 | |

| Lahore | ISOLATED SYSTEM | |||||||

| 1 | 1Gen + 1PV + Batt (without WHR) | 750 | - | 1502 | - | 2112 | 1184 | |

| 2 | 2Gen + 2PV + Batt (without WHR) | 250 | 550 | 124 | 860 | 864 | 700 | |

| 3 | 1Gen + 1PV + Batt (with WHR) | 600 | - | 1146 | - | 1560 | 914 | |

| 4 | 2Gen + 2PV + Batt (with WHR) | 350 | 500 | 96.9 | 928 | 480 | 698 | |

| GRID-CONNECTED SYSTEM | ||||||||

| 5 | Grid + 1Gen + 1PV (without WHR) | 1050 | - | 2889 | - | - | 1733 | |

| 6 | Grid + 2Gen + 2PV (without WHR) | 50 | 1300 | 729 | 1386 | - | 1307 | |

| 7 | Grid + 1Gen + 1PV (with WHR) | 850 | - | 2354 | - | - | 1468 | |

| 8 | Grid + 2Gen + 2PV (with WHR) | 50 | 1000 | 976 | 1484 | - | 1515 | |

| 9 | Grid + 1Gen + 1PV + Batt (without WHR) | 750 | - | 1839 | - | 2184 | 809 | |

| 10 | Grid + 2Gen + 2PV + Batt (without WHR) | 400 | 850 | 319 | 1451 | 2208 | 1098 | |

| 11 | Grid + 1Gen + 1PV + Batt (with WHR) | 800 | - | 2133 | - | 1416 | 1501 | |

| 12 | Grid + 2Gen + 2PV + Batt (with WHR) | 250 | 850 | 2306 | 265 | 1032 | 1444 | |

| Karachi | ISOLATED SYSTEM | |||||||

| 1 | 1Gen + 1PV + Batt (without WHR) | 700 | - | 1448 | - | 1896 | 1233 | |

| 2 | 2Gen + 2PV + Batt (without WHR) | 300 | 550 | 50 | 1012 | 672 | 743 | |

| 3 | 1Gen + 1PV + Batt (with WHR) | 550 | - | 1169 | - | 1608 | 870 | |

| 4 | 2Gen + 2PV + Batt (with WHR) | 300 | 500 | 160 | 946 | 456 | 750 | |

| GRID-CONNECTED SYSTEM | ||||||||

| 5 | Grid + 1Gen + 1PV (without WHR) | 1000 | - | 2930 | - | - | 1733 | |

| 6 | Grid + 2Gen + 2PV (without WHR) | 50 | 1250 | 1316 | 880 | - | 1368 | |

| 7 | Grid + 1Gen + 1PV (with WHR) | 800 | - | 2313 | - | - | 1425 | |

| 8 | Grid + 2Gen + 2PV (with WHR) | 100 | 900 | 919 | 1533 | - | 1483 | |

| 9 | Grid + 1Gen + 1PV + Batt (without WHR) | 750 | - | 1863 | - | 2352 | 724 | |

| 10 | Grid + 2Gen + 2PV + Batt (without WHR) | 450 | 1550 | 1327 | 1239 | 240 | 1177 | |

| 11 | Grid + 1Gen + 1PV + Batt (with WHR) | 850 | - | 2280 | - | 1080 | 1423 | |

| 12 | Grid + 2Gen + 2PV + Batt (with WHR) | 500 | 500 | 804 | 1198 | 1192 | 1154 | |

| City | Sr. No. | DGs’ Configuration | DGen1 (kW) | DGen2 (kW) | PV1 (kW) | PV2 (kW) | Battery (kWh) | Converter (kW) |

|---|---|---|---|---|---|---|---|---|

| Peshawar | ISOLATED SYSTEM | |||||||

| 1 | 1Gen + 1PV + Batt (without WHR) | 750 | - | 1332 | - | 2160 | 1187 | |

| 2 | 2Gen + 2PV + Batt (without WHR) | 300 | 550 | 250 | 671 | 744 | 724 | |

| 3 | 1Gen + 1PV + Batt (with WHR) | 650 | - | 1075 | - | 1776 | 932 | |

| 4 | 2Gen + 2PV + Batt (with WHR) | 300 | 500 | 123 | 818 | 552 | 684 | |

| GRID-CONNECTED SYSTEM | ||||||||

| 5 | Grid + 1Gen + 1PV (without WHR) | 1050 | - | 2704 | - | - | 1724 | |

| 6 | Grid + 2Gen + 2PV (without WHR) | 50 | 1250 | 908 | 1023 | - | 1322 | |

| 7 | Grid + 1Gen + 1PV (with WHR) | 850 | - | 2356 | - | - | 1530 | |

| 8 | Grid + 2Gen + 2PV (with WHR) | 50 | 1050 | 1140 | 1242 | - | 1532 | |

| 9 | Grid + 1Gen + 1PV + Batt (without WHR) | 1000 | - | 2746 | - | 2064 | 1762 | |

| 10 | Grid + 2Gen + 2PV + Batt (without WHR) | 350 | 1550 | 586 | 1730 | 240 | 1123 | |

| 11 | Grid + 1Gen + 1PV + Batt (with WHR) | 850 | - | 1899 | - | 1032 | 1197 | |

| 12 | Grid + 2Gen + 2PV + Batt (with WHR) | 400 | 500 | 548 | 1251 | 624 | 957 | |

| Quetta | ISOLATED SYSTEM | |||||||

| 1 | 1Gen + 1PV + Batt (without WHR) | 700 | - | 1356 | - | 1920 | 1087 | |

| 2 | 2Gen + 2PV + Batt (without WHR) | 250 | 550 | 150 | 850 | 672 | 767 | |

| 3 | 1Gen + 1PV + Batt (with WHR) | 600 | - | 1089 | - | 1632 | 941 | |

| 4 | 2Gen + 2PV + Batt (with WHR) | 350 | 500 | 67.3 | 937 | 504 | 700 | |

| GRID-CONNECTED SYSTEM | ||||||||

| 5 | Grid + 1Gen + 1PV (without WHR) | 1000 | - | 2827 | - | - | 1731 | |

| 6 | Grid + 2Gen + 2PV (without WHR) | 50 | 1250 | 571 | 1503 | - | 1280 | |

| 7 | Grid + 1Gen + 1PV (with WHR) | 800 | - | 2313 | - | - | 1468 | |

| 8 | Grid + 2Gen + 2PV (with WHR) | 50 | 950 | 936 | 1399 | - | 1463 | |

| 9 | Grid + 1Gen + 1PV + Batt (without WHR) | 950 | - | 2657 | - | 1224 | 1570 | |

| 10 | Grid + 2Gen + 2PV + Batt (without WHR) | 450 | 1550 | 688 | 1688 | 240 | 1148 | |

| 11 | Grid + 1Gen + 1PV + Batt (with WHR) | 850 | - | 2493 | - | 1032 | 1573 | |

| 12 | Grid + 2Gen + 2PV + Batt (with WHR) | 450 | 1500 | 1631 | 1979 | 240 | 1735 | |

| Gilgit | ISOLATED SYSTEM | |||||||

| 1 | 1Gen + 1PV + Batt (without WHR) | 750 | - | 1150 | - | 2160 | 1189 | |

| 2 | 2Gen + 2PV + Batt (without WHR) | 400 | 550 | 106 | 749 | 672 | 731 | |

| 3 | 1Gen + 1PV + Batt (with WHR) | 650 | - | 937 | - | 1704 | 937 | |

| 4 | 2Gen + 2PV + Batt (with WHR) | 300 | 500 | 95.5 | 823 | 432 | 750 | |

| GRID-CONNECTED SYSTEM | ||||||||

| 5 | Grid + 1Gen + 1PV (without WHR) | 1050 | - | 2386 | - | - | 1735 | |

| 6 | Grid + 2Gen + 2PV (without WHR) | 50 | 1350 | 680 | 1160 | - | 1457 | |

| 7 | Grid + 1Gen + 1PV (with WHR) | 850 | - | 2025 | - | - | 1510 | |

| 8 | Grid + 2Gen + 2PV (with WHR) | 50 | 1000 | 1431 | 709 | - | 1574 | |

| 9 | Grid + 1Gen + 1PV + Batt (without WHR) | 1050 | - | 2225 | - | 1464 | 1186 | |

| 10 | Grid + 2Gen + 2PV + Batt (without WHR) | 500 | 1650 | 1017 | 1053 | 240 | 1265 | |

| 11 | Grid + 1Gen + 1PV + Batt (with WHR) | 850 | - | 1867 | - | 1320 | 1372 | |

| 12 | Grid + 2Gen + 2PV + Batt (with WHR) | 600 | 650 | 1075 | 1038 | 1584 | 1105 | |

| City | Sr. No. | DGs’ Configurations | TNPC (million$) | COE ($/kWh) | GHG Emissions (tons/year) | WHR (kWh/year) | Grid Sale (kWh/year) |

|---|---|---|---|---|---|---|---|

| All Cities | CONVENTIONAL DIESEL ONLY SYSTEM | ||||||

| 1 | Diesel only system | 50.4 | 0.9700 | 3595.017 | - | - | |

| Islamabad | ISOLATED SYSTEM | ||||||

| 1 | 1Gen + 1PV + Batt (Without WHR) | 16.4 | 0.315 | 886.650 | - | - | |

| 2 | 2Gen + 2PV + Batt (Without WHR) | 10.8 | 0.209 | 2694.932 | - | - | |

| 3 | 1Gen + 1PV + Batt (With WHR) | 13.8 | 0.317 | 1014.785 | 904,483 | - | |

| 4 | 2Gen + 2PV + Batt (With WHR) | 9.42 | 0.214 | 2112.380 | 1,056,847 | - | |

| GRID-CONNECTED SYSTEM | |||||||

| 5 | Grid + 1Gen + 1PV (Without WHR) | 19.4 | 0.164 | 2145.700 | - | 6,239,867 | |

| 6 | Grid + 2Gen + 2PV (Without WHR) | 7.25 | 0.056 | 6902.004 | - | 7,289,230 | |

| 7 | Grid + 1Gen + 1PV (With WHR) | 15.6 | 0.155 | 1905.514 | 976,228 | 5,245,573 | |

| 8 | Grid + 2Gen + 2PV (With WHR) | 6.29 | 0.055 | 5078.612 | 1,676,691 | 6,255,967 | |

| 9 | Grid + 1Gen + 1PV + Batt (Without WHR) | 20.3 | 0.180 | 2010.973 | - | 5,677,536 | |

| 10 | Grid + 2Gen + 2PV + Batt (Without WHR) | 8.95 | 0.070 | 6844.752 | - | 7,114,622 | |

| 11 | Grid + 1Gen + 1PV + Batt (With WHR) | 16.3 | 0.161 | 2068.991 | 987,366 | 5,259,435 | |

| 12 | Grid + 2Gen + 2PV + Batt (With WHR) | 8.77 | 0.097 | 3860.661 | 1,211,317 | 4,188,724 | |

| Lahore | ISOLATED SYSTEM | ||||||

| 1 | 1Gen + 1PV + Batt (Without WHR) | 16.6 | 0.321 | 875.618 | - | - | |

| 2 | 2Gen + 2PV + Batt (Without WHR) | 11.0 | 0.211 | 2712.651 | - | - | |

| 3 | 1Gen + 1PV + Batt (With WHR) | 13.9 | 0.319 | 1000.214 | 904,691 | - | |

| 4 | 2Gen + 2PV + Batt (With WHR) | 9.62 | 0.2190 | 2102.363 | 1,056,003 | - | |

| GRID-CONNECTED SYSTEM | |||||||

| 5 | Grid + 1Gen + 1PV (Without WHR) | 20.0 | 0.169 | 2154.424 | - | 6,231,266 | |

| 6 | Grid + 2Gen + 2PV (Without WHR) | 7.56 | 0.059 | 6783.642 | - | 7,081,981 | |

| 7 | Grid + 1Gen + 1PV (With WHR) | 16.1 | 0.162 | 1935.756 | 976,475 | 5,140,511 | |

| 8 | Grid + 2Gen + 2PV (With WHR) | 6.70 | 0.058 | 5069.349 | 1,677,087 | 6,258,396 | |

| 9 | Grid + 1Gen + 1PV + Batt (Without WHR) | 20.6 | 0.278 | 1608.812 | - | 2,079,787 | |

| 10 | Grid + 2Gen + 2PV + Batt (Without WHR) | 9.16 | 0.089 | 5361.747 | - | 6,769,393 | |

| 11 | Grid + 1Gen + 1PV + Batt (With WHR) | 16.9 | 0.183 | 1860.616 | 961,111 | 4,310,902 | |

| 12 | Grid + 2Gen + 2PV + Batt (With WHR) | 8.89 | 0.083 | 4817.334 | 1,538,487 | 5,688,099 | |

| Karachi | ISOLATED SYSTEM | ||||||

| 1 | 1Gen + 1PV + Batt (Without WHR) | 16.9 | 0.325 | 925.864 | - | - | |

| 2 | 2Gen + 2PV + Batt (Without WHR) | 11.1 | 0.214 | 2692.043 | - | - | |

| 3 | 1Gen + 1PV + Batt (With WHR) | 14.2 | 0.325 | 1024.433 | 900,601 | - | |

| 4 | 2Gen + 2PV + Batt (With WHR) | 9.81 | 0.223 | 2108.410 | 1,061,929 | - | |

| GRID-CONNECTED SYSTEM | |||||||

| 5 | Grid + 1Gen + 1PV (Without WHR) | 20.2 | 0.175 | 2115.538 | - | 5,941,478 | |

| 6 | Grid + 2Gen + 2PV (Without WHR) | 8.03 | 0.064 | 6708.314 | - | 6,969,520 | |

| 7 | Grid + 1Gen + 1PV (With WHR) | 16.4 | 0.173 | 1893.449 | 965,763 | 4,733,953 | |

| 8 | Grid + 2Gen + 2PV (With WHR) | 7.26 | 0.067 | 4838.588 | 1,591,449 | 5,736,755 | |

| 9 | Grid + 1Gen + 1PV + Batt (Without WHR) | 20.9 | 0.278 | 1688.857 | - | 2,197,825 | |

| 10 | Grid + 2Gen + 2PV + Batt (Without WHR) | 9.64 | 0.074 | 6944.456 | - | 7,296,741 | |

| 11 | Grid + 1Gen + 1PV + Batt (With WHR) | 17.0 | 0.176 | 1976.607 | 970,729 | 4,358,460 | |

| 12 | Grid + 2Gen + 2PV + Batt (With WHR) | 9.57 | 0.107 | 3840.075 | 1,210,031 | 4,071,456 | |

| City | Sr. No. | DGs’ Configurations | TNPC (million $) | COE ($/kWh) | GHG Emissions (tons/year) | WHR (kWh/year) | Grid Sale (kWh/year) |

|---|---|---|---|---|---|---|---|

| Peshawar | ISOLATED SYSTEM | ||||||

| 1 | 1Gen + 1PV + Batt (Without WHR) | 16.4 | 0.316 | 905.329 | - | - | |

| 2 | 2Gen + 2PV + Batt (Without WHR) | 10.8 | 0.208 | 2689.675 | - | - | |

| 3 | 1Gen + 1PV + Batt (With WHR) | 13.8 | 0.318 | 1005.361 | 910,638 | - | |

| 4 | 2Gen + 2PV + Batt (With WHR) | 9.40 | 0.213 | 2116.130 | 1,056,336 | - | |

| GRID-CONNECTED SYSTEM | |||||||

| 5 | Grid + 1Gen + 1PV (Without WHR) | 19.2 | 0.162 | 2151.258 | - | 6,222,348 | |

| 6 | Grid + 2Gen + 2PV (Without WHR) | 7.15 | 0.057 | 6680.821 | - | 6,909,362 | |

| 7 | Grid + 1Gen + 1PV (With WHR) | 15.4 | 0.153 | 1901.308 | 976,348 | 5,260,739 | |

| 8 | Grid + 2Gen + 2PV (With WHR) | 6.20 | 0.052 | 5210.133 | 1,724,241 | 6,547,619 | |

| 9 | Grid + 1Gen + 1PV + Batt (Without WHR) | 20.0 | 0.179 | 1979.710 | - | 5,564,821 | |

| 10 | Grid + 2Gen + 2PV + Batt (Without WHR) | 8.67 | 0.068 | 6833.651 | - | 6,738,256 | |

| 11 | Grid + 1Gen + 1PV + Batt (With WHR) | 16.2 | 0.171 | 2008.673 | 968,185 | 4,119,405 | |

| 12 | Grid + 2Gen + 2PV + Batt (With WHR) | 8.41 | 0.099 | 3744.682 | 1,199,142 | 3,658,048 | |

| Quetta | ISOLATED SYSTEM | ||||||

| 1 | 1Gen + 1PV + Batt (Without WHR) | 16.4 | 0.317 | 924.143 | - | - | |

| 2 | 2Gen + 2PV + Batt (Without WHR) | 10.9 | 0.209 | 2663.564 | - | - | |

| 3 | 1Gen + 1PV + Batt (With WHR) | 13.9 | 0.319 | 1011.226 | 905,825 | - | |

| 4 | 2Gen + 2PV + Batt (With WHR) | 9.54 | 0.217 | 2112.711 | 1,059,623 | - | |

| GRID-CONNECTED SYSTEM | |||||||

| 5 | Grid + 1Gen + 1PV (Without WHR) | 19.3 | 0.167 | 2064.567 | - | 5,966,449 | |

| 6 | Grid + 2Gen + 2PV (Without WHR) | 7.44 | 0.059 | 6693.132 | - | 9,879,361 | |

| 7 | Grid + 1Gen + 1PV (With WHR) | 15.7 | 0.163 | 1841.852 | 965,224 | 4,852,982 | |

| 8 | Grid + 2Gen + 2PV (With WHR) | 6.59 | 0.059 | 4939.342 | 1,634,352 | 5,962,893 | |

| 9 | Grid + 1Gen + 1PV + Batt (Without WHR) | 20.0 | 0.182 | 1801.340 | - | 5,405,521 | |

| 10 | Grid + 2Gen + 2PV + Batt (Without WHR) | 9.12 | 0.069 | 6917.252 | - | 7,241,042 | |

| 11 | Grid + 1Gen + 1PV + Batt (With WHR) | 16.6 | 0.174 | 2004.305 | 987,894 | 4,592,684 | |

| 12 | Grid + 2Gen + 2PV + Batt (With WHR) | 8.92 | 0.069 | 6041.482 | 2,040,282 | 8,322,268 | |

| Gilgit | ISOLATED SYSTEM | ||||||

| 1 | 1Gen + 1PV + Batt (Without WHR) | 16.3 | 0.314 | 959.355 | - | - | |

| 2 | 2Gen + 2PV + Batt (Without WHR) | 10.7 | 0.207 | 2669.885 | - | - | |

| 3 | 1Gen + 1PV + Batt (With WHR) | 13.7 | 0.315 | 1040.364 | 910,025 | - | |

| 4 | 2Gen + 2PV + Batt (With WHR) | 9.28 | 0.211 | 2107.538 | 1,055,539 | - | |

| GRID-CONNECTED SYSTEM | |||||||

| 5 | Grid + 1Gen + 1PV (Without WHR) | 19.2 | 0.163 | 2214.816 | - | 6,178,188 | |

| 6 | Grid + 2Gen + 2PV (Without WHR) | 6.60 | 0.050 | 6922.720 | - | 7,330,439 | |

| 7 | Grid + 1Gen + 1PV (With WHR) | 15.2 | 0.152 | 1969.277 | 975,359 | 5,193,023 | |

| 8 | Grid + 2Gen + 2PV (With WHR) | 5.79 | 0.049 | 5116.636 | 1,673,369 | 6,337,434 | |

| 9 | Grid + 1Gen + 1PV + Batt (Without WHR) | 20.0 | 0.205 | 1936.572 | - | 4,230,165 | |

| 10 | Grid + 2Gen + 2PV + Batt (Without WHR) | 8.57 | 0.062 | 7096.481 | - | 7,514,326 | |

| 11 | Grid + 1Gen + 1PV + Batt (With WHR) | 15.9 | 0.168 | 1952.439 | 962,808 | 3,895,477 | |

| 12 | Grid + 2Gen + 2PV + Batt (With WHR) | 8.30 | 0.088 | 4349.394 | 1,329,160 | 4,719,079 | |

| City | Sr. No. | Optimal Configuration | Objectives | ||||

|---|---|---|---|---|---|---|---|

| TNPC (million$) | COE ($/kWh) | GHG Emissions (tons/year) | WHR (kWh/year) | Grid Sales (kWh/year) | |||

| Gilgit | 1 | Grid + 2Gen + 2PV (With WHR) | 5.79 | 0.049 | 5116.636 | 1,673,369 | 6,337,434 |

| Lahore | 2 | 1Gen + 1PV + Batt (With WHR) | 13.9 | 0.319 | 1000.214 | 904,691 | - |

| Quetta | 3 | Grid + 2Gen + 2PV + Batt (With WHR) | 8.92 | 0.069 | 6041.482 | 2,040,282 | 8,322,268 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waqar, A.; Shahbaz Tanveer, M.; Ahmad, J.; Aamir, M.; Yaqoob, M.; Anwar, F. Multi-Objective Analysis of a CHP Plant Integrated Microgrid in Pakistan. Energies 2017, 10, 1625. https://doi.org/10.3390/en10101625

Waqar A, Shahbaz Tanveer M, Ahmad J, Aamir M, Yaqoob M, Anwar F. Multi-Objective Analysis of a CHP Plant Integrated Microgrid in Pakistan. Energies. 2017; 10(10):1625. https://doi.org/10.3390/en10101625

Chicago/Turabian StyleWaqar, Asad, Muhammad Shahbaz Tanveer, Jehanzeb Ahmad, Muhammad Aamir, Muneeb Yaqoob, and Fareeha Anwar. 2017. "Multi-Objective Analysis of a CHP Plant Integrated Microgrid in Pakistan" Energies 10, no. 10: 1625. https://doi.org/10.3390/en10101625