Quantifying Grain-Size Variability of Metal Pollutants in Road-Deposited Sediments Using the Coefficient of Variation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data Sources and Study Sites

2.2. Analytical Methods and Quality Control

2.3. Estimation of the Heavy Metal Loads in the RDS Samples

2.4. Quantification of Grain-Size Class Variability in RDS

3. Results

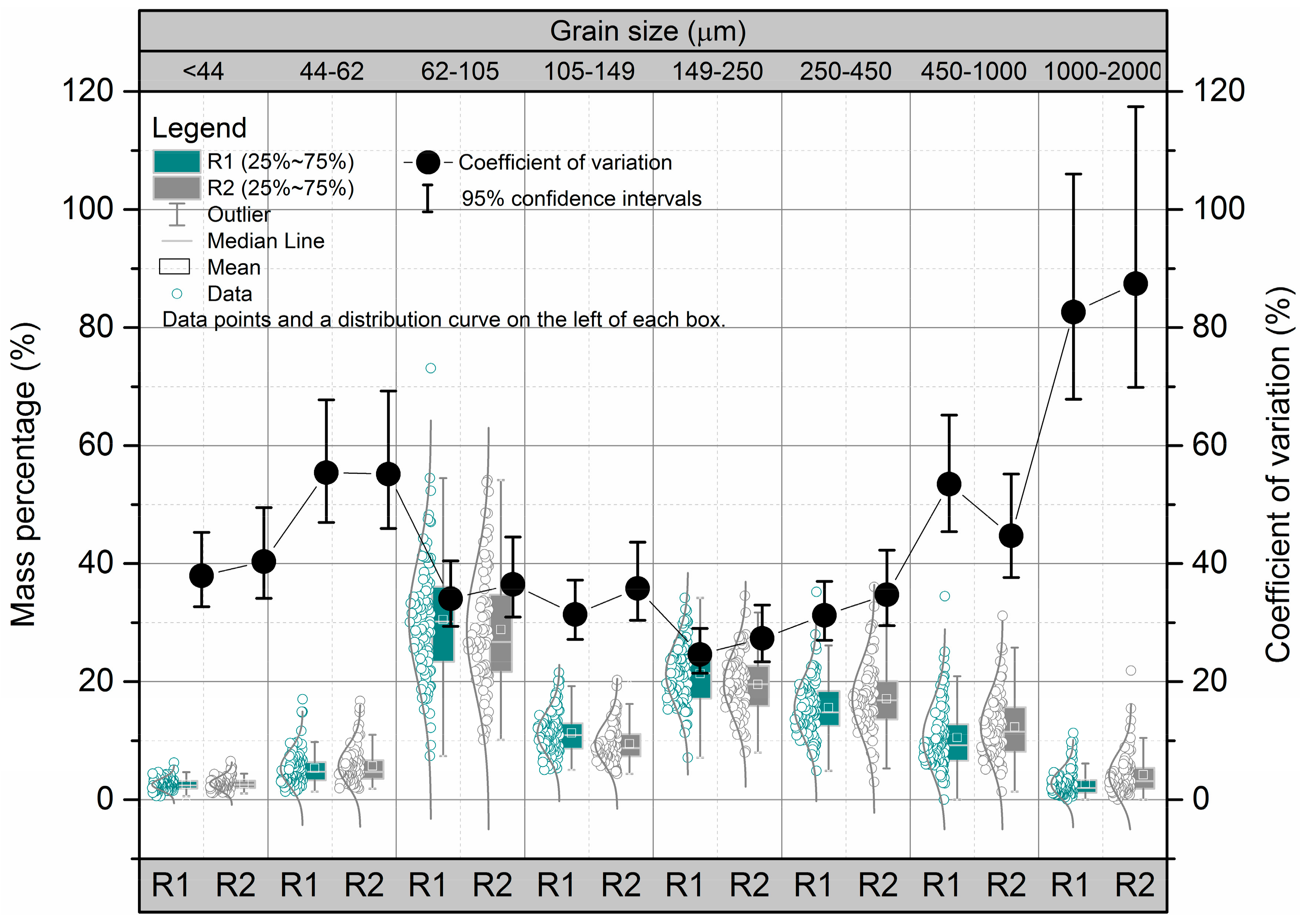

3.1. Grain-Size Class Variability in Terms of the Amounts or Mass Percentage Present

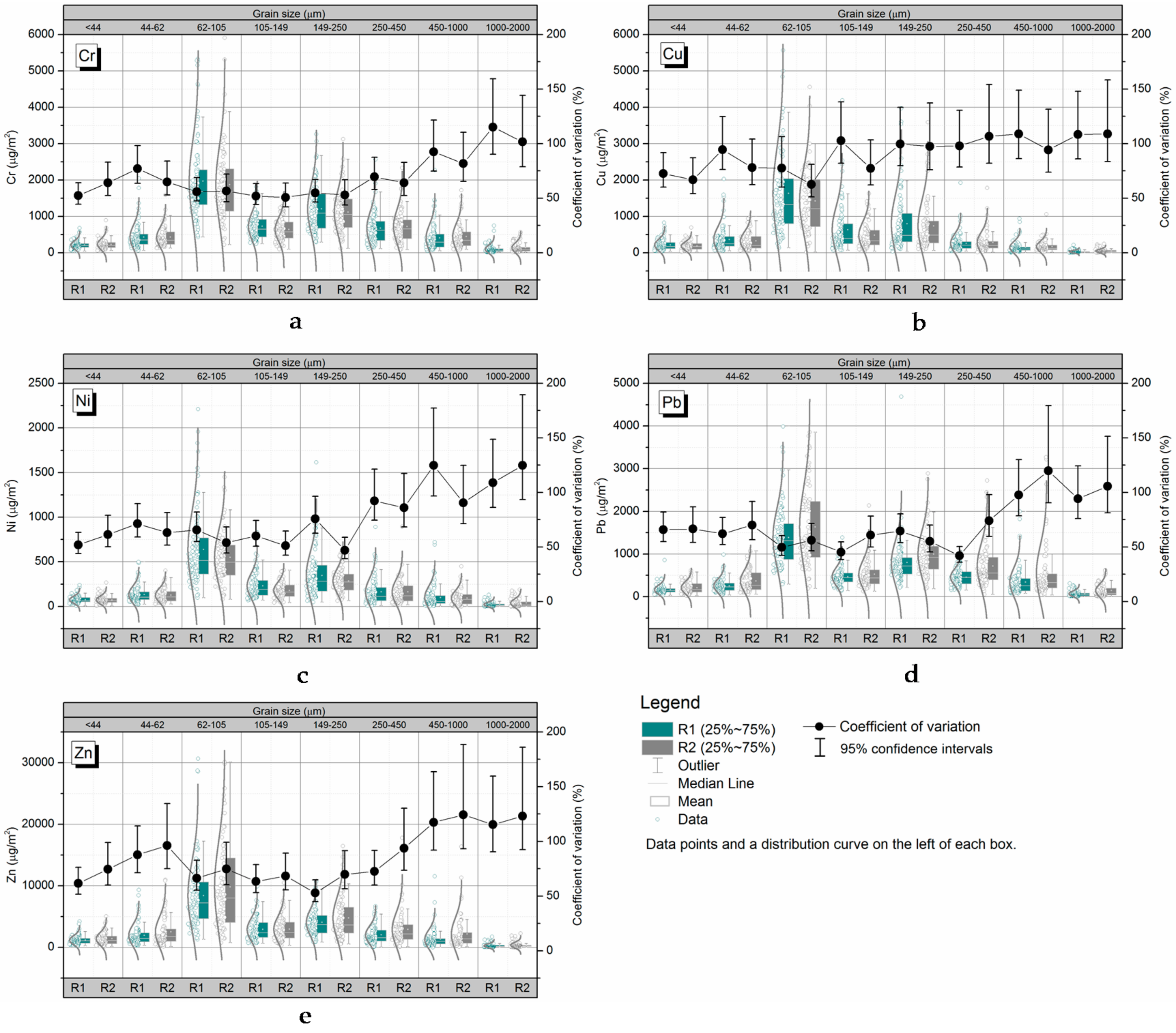

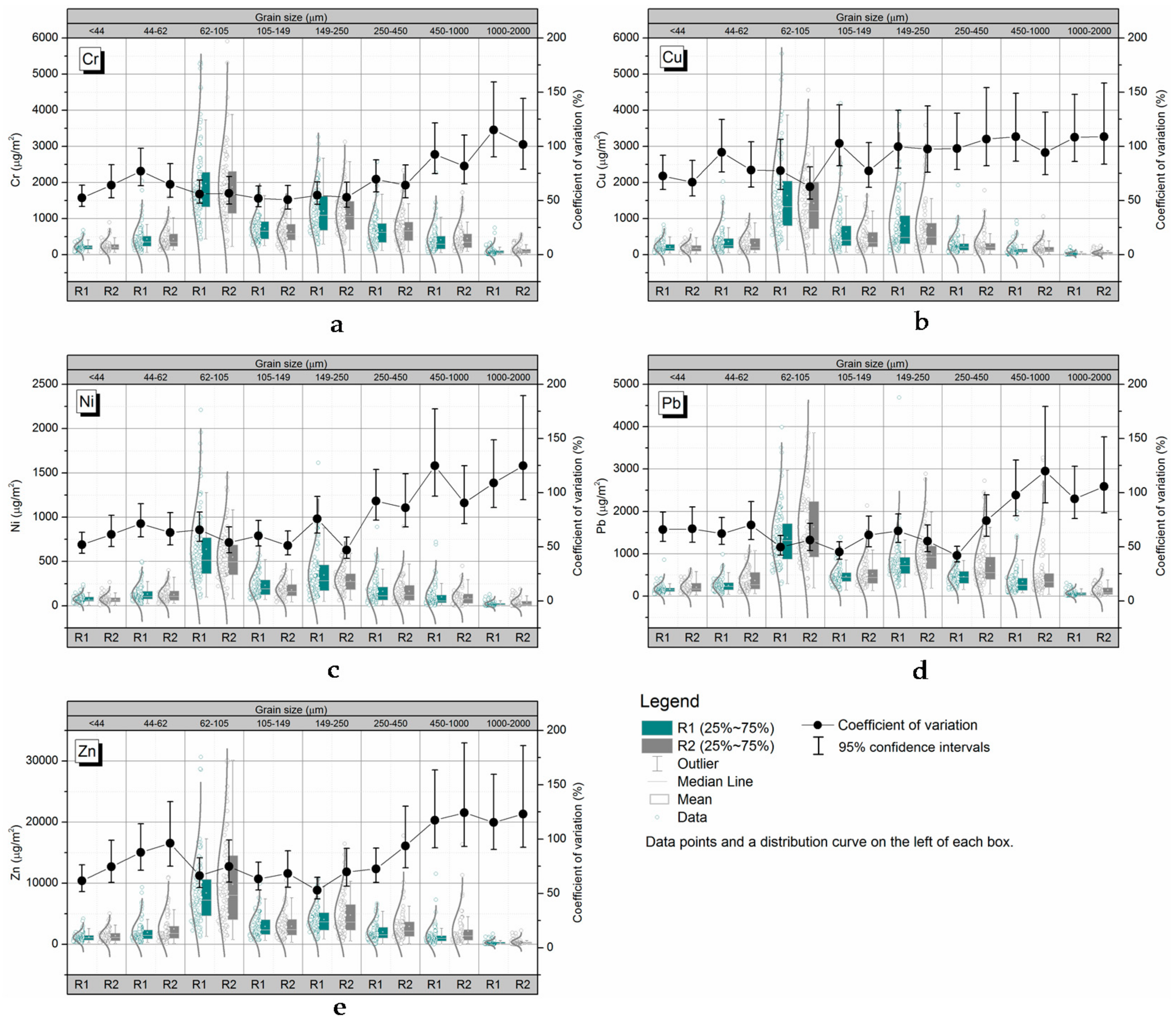

3.2. Grain-Size Class Variability in Terms of the Metal Concentrations Present

3.3. Grain-Size Class Variability in Terms of the Metal Loads Present

3.4. Grain-Size Class Variability in Terms of the GSFLoad Present

4. Discussion

4.1. Impact of Grain-Size Class Variability on Quantification of RDS Washoff Loads

4.2. Comparison of Different Measures Used to Quantify Grain-Size Class Variability

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lu, X.; Wang, L.; Lei, K.; Huang, J.; Zhai, Y. Contamination assessment of copper, lead, zinc, manganese and nickel in street dust of Baoji, NW China. J. Hazard. Mater. 2009, 161, 1058–1062. [Google Scholar] [CrossRef] [PubMed]

- Sutherland, R.A. Lead in grain size fractions of road-deposited sediment. Environ. Pollut. 2003, 121, 229–237. [Google Scholar] [CrossRef]

- Xiang, L.; Li, Y.; Yang, Z.; Shi, J. Influence of traffic conditions on polycyclic aromatic hydrocarbon abundance in street dust. J. Environ. Sci. Health A Toxic Hazard. Subst. Environ. Eng. 2010, 45, 339–347. [Google Scholar] [CrossRef] [PubMed]

- Adachi, K.; Tainosho, Y. Characterization of heavy metal particles embedded in tire dust. Environ. Int. 2004, 30, 1009–1017. [Google Scholar] [CrossRef] [PubMed]

- Gunawardana, C.; Goonetilleke, A.; Egodawatta, P.; Dawes, L.A.; Kokot, S. Source characterisation of road dust based on chemical and mineralogical composition. Chemosphere 2012, 87, 163–170. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gunawardana, C.; Egodawatta, P.; Goonetilleke, A. Role of particle size and composition in metal adsorption by solids deposited on urban road surfaces. Environ. Pollut. 2014, 184, 44–53. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, J.; Sansalone, J.J. Event-based size distributions of particulate matter transported during urban rainfall-runoff events. Water Res. 2008, 42, 2756–2768. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wang, J.; Hua, P.; Krebs, P. The qualitative and quantitative source apportionments of polycyclic aromatic hydrocarbons in size dependent road deposited sediment. Sci. Total Environ. 2015, 505, 90–101. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Li, X.; Wang, X. Heavy metal contents of road-deposited sediment along the urban-rural gradient around Beijing and its potential contribution to runoff pollution. Environ. Sci. Technol. 2011, 45, 7120–7127. [Google Scholar] [CrossRef] [PubMed]

- Amato, F.; Pandolfi, M.; Viana, M.; Querol, X.; Alastuey, A.; Moreno, T. Spatial and chemical patterns of PM10 in road dust deposited in urban environment. Atmos. Environ. 2009, 43, 1650–1659. [Google Scholar] [CrossRef]

- Chen, J.; Wang, W.; Liu, H.; Ren, L. Determination of road dust loadings and chemical characteristics using resuspension. Environ. Monitor. Assess. 2011, 184, 1693–1709. [Google Scholar] [CrossRef] [PubMed]

- Wijesiri, B.; Egodawatta, P.; Mcgree, J.; Goonetilleke, A. Process variability of pollutant build-up on urban road surfaces. Sci. Total Environ. 2015, 518, 434–440. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Li, X. Risk assessment of metals in road-deposited sediment along an urban-rural gradient. Environ. Pollut. 2013, 174, 297–304. [Google Scholar] [CrossRef] [PubMed]

- Wijesiri, B.; Egodawatta, P.; Mcgree, J.; Goonetilleke, A. Assessing uncertainty in pollutant build-up and wash-off processes. Environ. Pollut. 2016, 212, 48–56. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Robertson, D.; Taylor, K. Temporal variability of metal contamination in urban road-deposited sediment in Manchester, UK: Implications for urban pollution monitoring. Water Air Soil Pollut. 2007, 186, 209–220. [Google Scholar] [CrossRef]

- Charlesworth, S.; de Miguel, E.; Ordonez, A. A review of the distribution of particulate trace elements in urban terrestrial environments and its application to considerations of risk. Environ. Geochem. Health 2010, 33, 103–123. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deletic, A.; Orr, W. Pollution buildup on road surfaces. J. Environ. Eng. 2005, 131, 49–59. [Google Scholar] [CrossRef]

- Loganathan, P.; Vigneswaran, S.; Kandasamy, J. Road-deposited sediment pollutants: A critical review of their characteristics, source apportionment, and management. Crit. Rev. Environ. Sci. Technol. 2012, 43, 1315–1348. [Google Scholar] [CrossRef]

- Wang, M.; Bai, Y.; Chen, W.; Markert, B.; Peng, C.; Ouyang, Z. A GIS technology based potential eco-risk assessment of metals in urban soils in Beijing, China. Environ. Pollut. 2012, 161, 235–242. [Google Scholar] [CrossRef] [PubMed]

- Tessier, A.; Campbell, P.G.C.; Bisson, M. Sequential extraction procedure for the speciation of particulate trace metals. Anal. Chem. 1979, 51, 844–851. [Google Scholar] [CrossRef]

- Zhao, H.; Li, X.; Wang, X.; Tian, D. Grain size distribution of road-deposited sediment and its contribution to heavy metal pollution in urban runoff in Beijing, China. J. Hazard. Mater. 2010, 183, 203–210. [Google Scholar] [CrossRef] [PubMed]

- Fitch, P.; Lovell, M.; Davies, S.J.; Pritchard, T.; Harvey, P.K. An integrated and quantitative approach to petrophysical heterogeneity. Mar. Pet. Geol. 2015, 63, 82–96. [Google Scholar] [CrossRef]

- Kelley, K. Sample size planning for the coefficient of variation from the accuracy in parameter estimation approach. Behav. Res. Methods 2007, 39, 755–766. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Zhao, J.; Yin, C.; Li, X. Index models to evaluate the potential metal pollution contribution from washoff of road-deposited sediment. Water Res. 2014, 59, 71–79. [Google Scholar] [CrossRef] [PubMed]

- Bian, B.; Lin, C.; Wu, H.S. Contamination and risk assessment of metals in road-deposited sediments in a medium-sized city of China. Ecotoxicol. Environ. Saf. 2015, 112, 87–95. [Google Scholar] [CrossRef] [PubMed]

- Sansalone, J.J.; Ying, G. Partitioning and granulometric distribution of metal leachate from urban traffic dry deposition particulate matter subject to acidic rainfall and runoff retention. Water Res. 2008, 42, 4146–4162. [Google Scholar] [CrossRef] [PubMed]

- Shaw, S.B.; Parlange, J.Y.; Lebowitz, M.; Walter, M.T. Accounting for surface roughness in a physically-based urban wash-off model. J. Hydrol. 2009, 367, 79–85. [Google Scholar] [CrossRef]

- Wang, L.; Wei, J.; Huang, Y.; Wang, G.; Maqsood, I. Urban nonpoint source pollution buildup and washoff models for simulating storm runoff quality in the Los Angeles County. Environ. Pollut. 2011, 159, 1932–1940. [Google Scholar] [CrossRef] [PubMed]

- Liu, A.; Goonetilleke, A.; Egodawatta, P. Inherent errors in pollutant build-up estimation in considering urban land use as a lumped parameter. J. Environ. Qual. 2012, 41, 1690–1694. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Shi, A.; Zhang, X. Particle size distribution and characteristics of heavy metals in road-deposited sediments from Beijing Olympic Park. J. Environ. Sci.-China 2015, 32, 228–237. [Google Scholar] [CrossRef] [PubMed]

- Pal, S.K.; Wallis, S.G.; Arthur, S. Emission patterns of traffic-related metals and associated contamination in road deposited sediment. Int. J. Glob. Environ. Issues 2012, 12, 229–241. [Google Scholar] [CrossRef]

- Liu, A.; Liu, L.; Li, D.; Guan, Y. Characterizing heavy metal build-up on urban road surfaces: Implication for stormwater reuse. Sci. Total Environ. 2015, 515, 20–29. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K. Elemental chemistry and geochemical partitioning of heavy metals in road dust from Dhanbad and Bokaro regions, India. Environ. Earth Sci. 2010, 62, 1447–1459. [Google Scholar] [CrossRef]

- Vaze, J.; Chiew, F.H.S. Experimental study of pollutant accumulation on an urban road surface. Urban Water 2002, 4, 379–389. [Google Scholar] [CrossRef]

- Lake, L.W.; Jensen, J.L. A review of heterogeneity measures used in reservoir characterization. In Situ 1989, 15, 409–439. [Google Scholar]

| Study Site | Central Urban Area (UCA) | Central Suburban County Area (CSA) | Rural Town Area (RTA) | Rural Village Area (RVA) | Urban Village Area (UVA) |

|---|---|---|---|---|---|

| Areas containing main roads (R1) | 11 | 40 | 20 | 20 | 6 |

| Residential areas (R2) | 8 | 18 | 20 | 20 | 4 |

| Particle Size (μm) | Cr | Cu | Ni | Pb | Zn | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cv | Lc | Cv | Lc | Cv | Lc | Cv | Lc | Cv | Lc | |

| <44 | 33.3 | 0.183 | 53.8 | 0.286 | 33.3 | 0.178 | 36.5 | 0.197 | 47.6 | 0.252 |

| 44–62 | 35.6 | 0.190 | 58.2 | 0.310 | 38.8 | 0.212 | 34.8 | 0.188 | 50.9 | 0.271 |

| 62–105 | 40.1 | 0.218 | 69.8 | 0.356 | 51.1 | 0.267 | 35.0 | 0188 | 49.0 | 0.262 |

| 105–149 | 40.1 | 0.221 | 81.8 | 0.412 | 52.4 | 0.268 | 32.9 | 0.180 | 50.1 | 0.277 |

| 149–250 | 48.9 | 0.270 | 97.7 | 0.475 | 70.0 | 0.367 | 41.6 | 0.207 | 53.1 | 0.298 |

| 250–450 | 61.8 | 0.320 | 106.9 | 0.442 | 76.0 | 0.396 | 39.1 | 0.211 | 81.8 | 0.380 |

| 450–1000 | 86.8 | 0.375 | 59.3 | 0.320 | 95.0 | 0.465 | 92.8 | 0.370 | 122.0 | 0.468 |

| 1000–2000 | 90.0 | 0.401 | 84.32 | 0.386 | 114.4 | 0.514 | 90.9 | 0.359 | 127.8 | 0.557 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Wang, X.; Li, X. Quantifying Grain-Size Variability of Metal Pollutants in Road-Deposited Sediments Using the Coefficient of Variation. Int. J. Environ. Res. Public Health 2017, 14, 850. https://doi.org/10.3390/ijerph14080850

Zhao H, Wang X, Li X. Quantifying Grain-Size Variability of Metal Pollutants in Road-Deposited Sediments Using the Coefficient of Variation. International Journal of Environmental Research and Public Health. 2017; 14(8):850. https://doi.org/10.3390/ijerph14080850

Chicago/Turabian StyleZhao, Hongtao, Xiaoxue Wang, and Xuyong Li. 2017. "Quantifying Grain-Size Variability of Metal Pollutants in Road-Deposited Sediments Using the Coefficient of Variation" International Journal of Environmental Research and Public Health 14, no. 8: 850. https://doi.org/10.3390/ijerph14080850