Occurrence, Toxicity, and Analysis of Major Mycotoxins in Food

Abstract

:1. Introduction

2. Occurrence and Toxicity of Major Mycotoxins

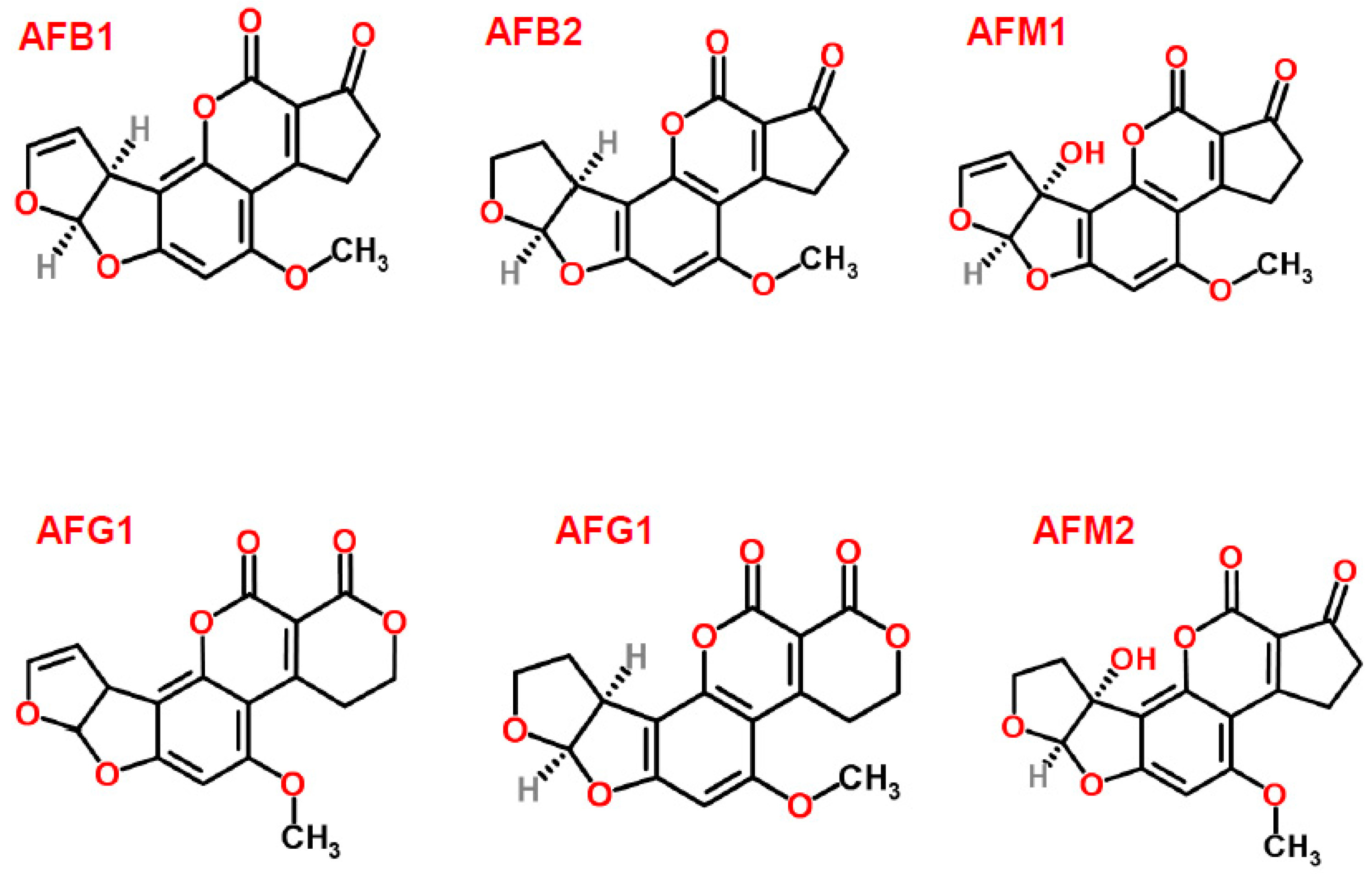

2.1. Aflatoxins

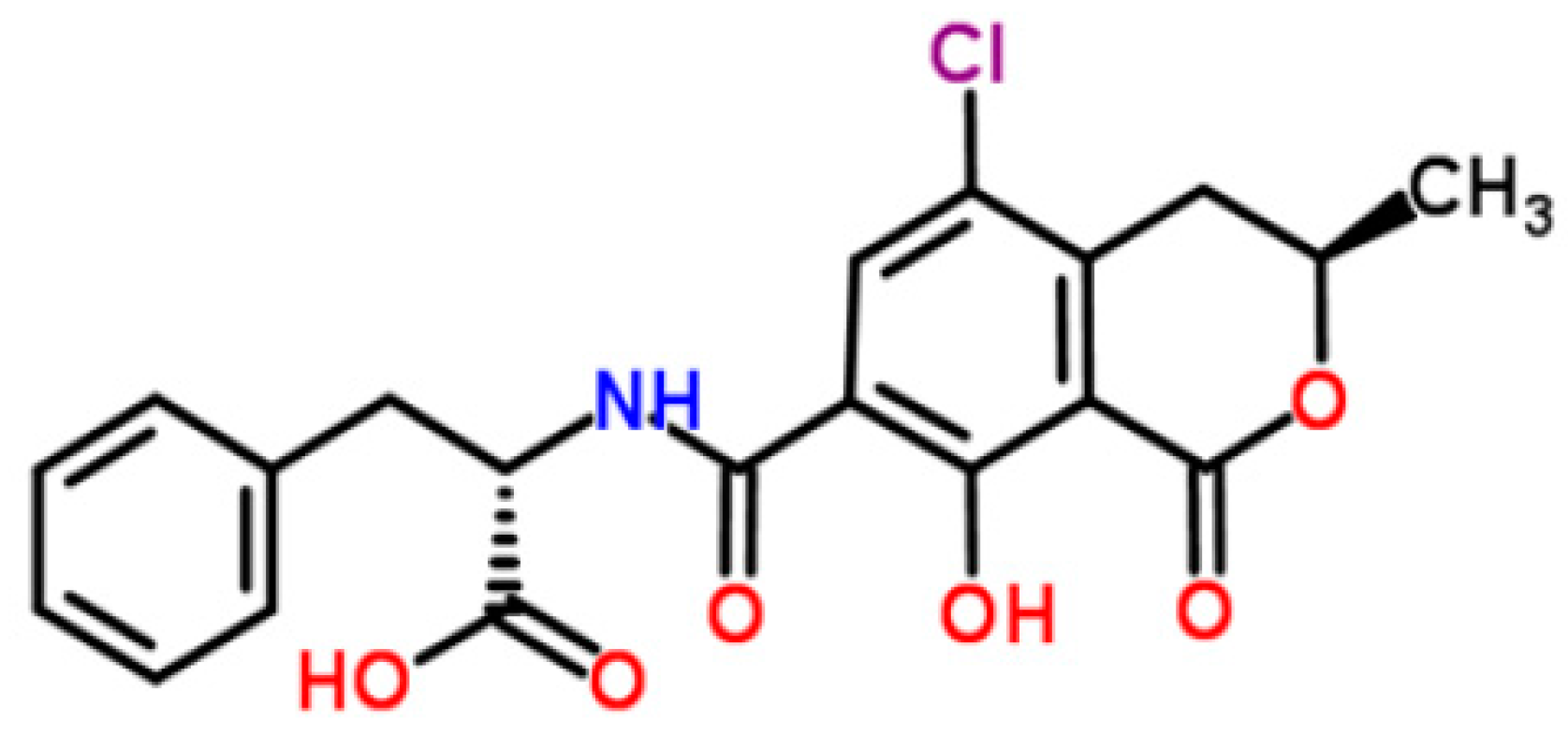

2.2. Ochratoxins

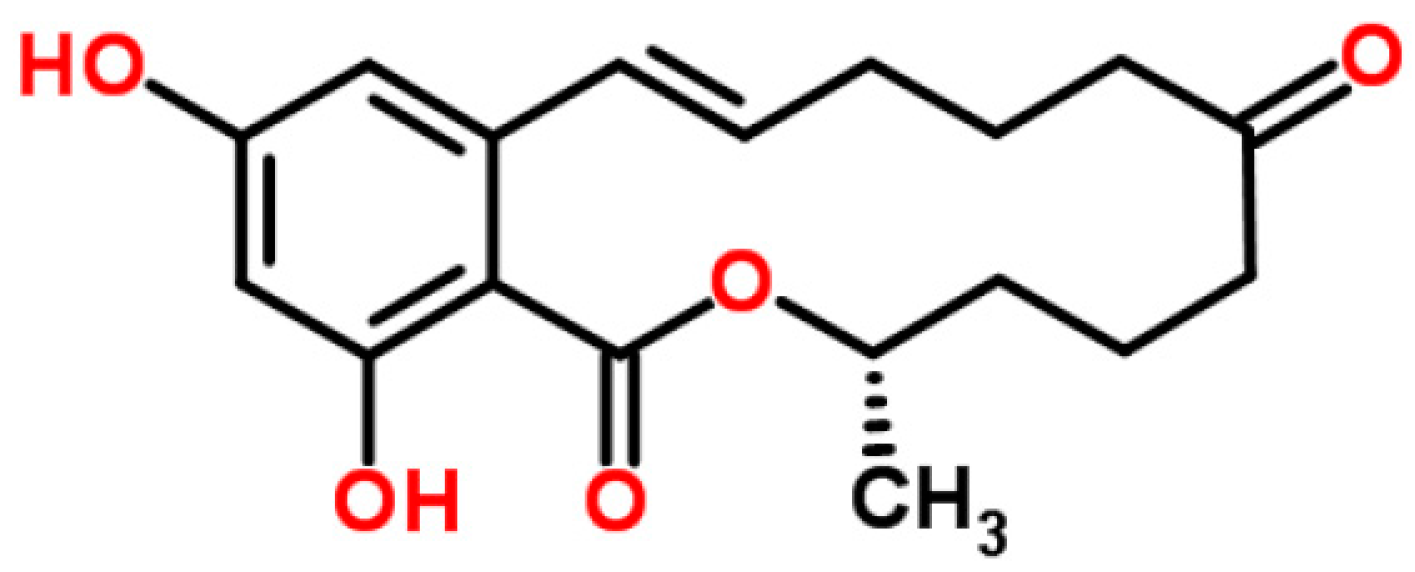

2.3. Zearalenone

2.4. Fumonisins

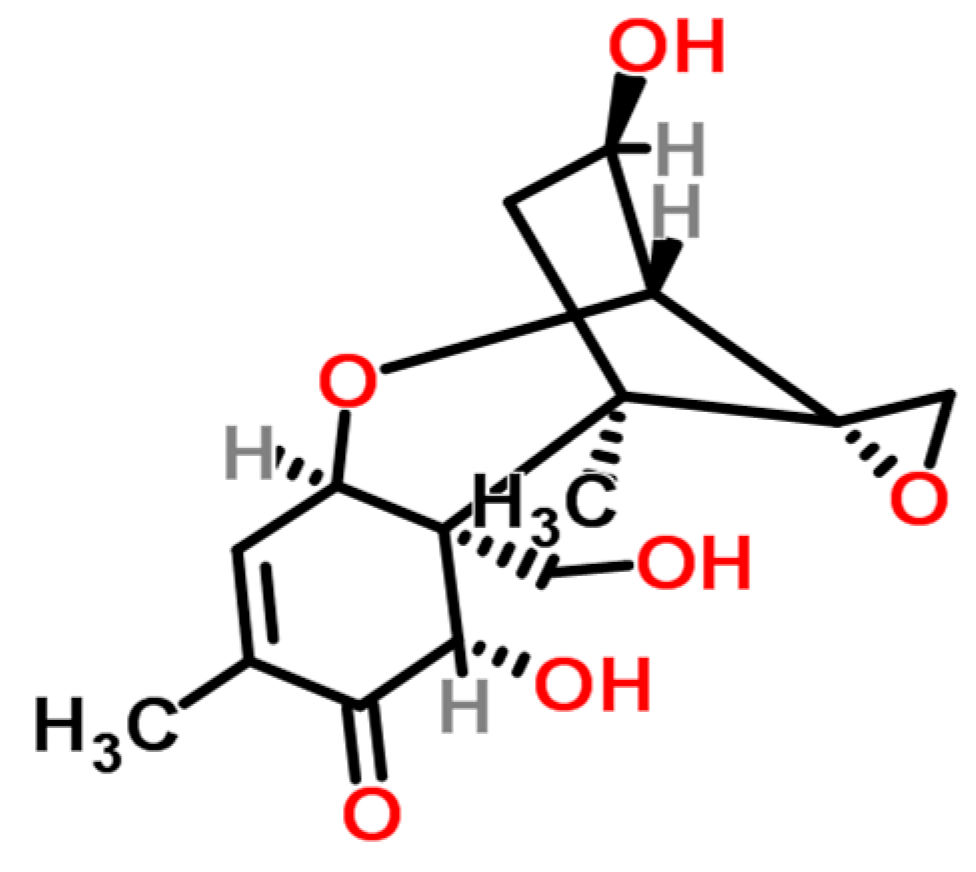

2.5. Trichothecenes

2.6. Patulin

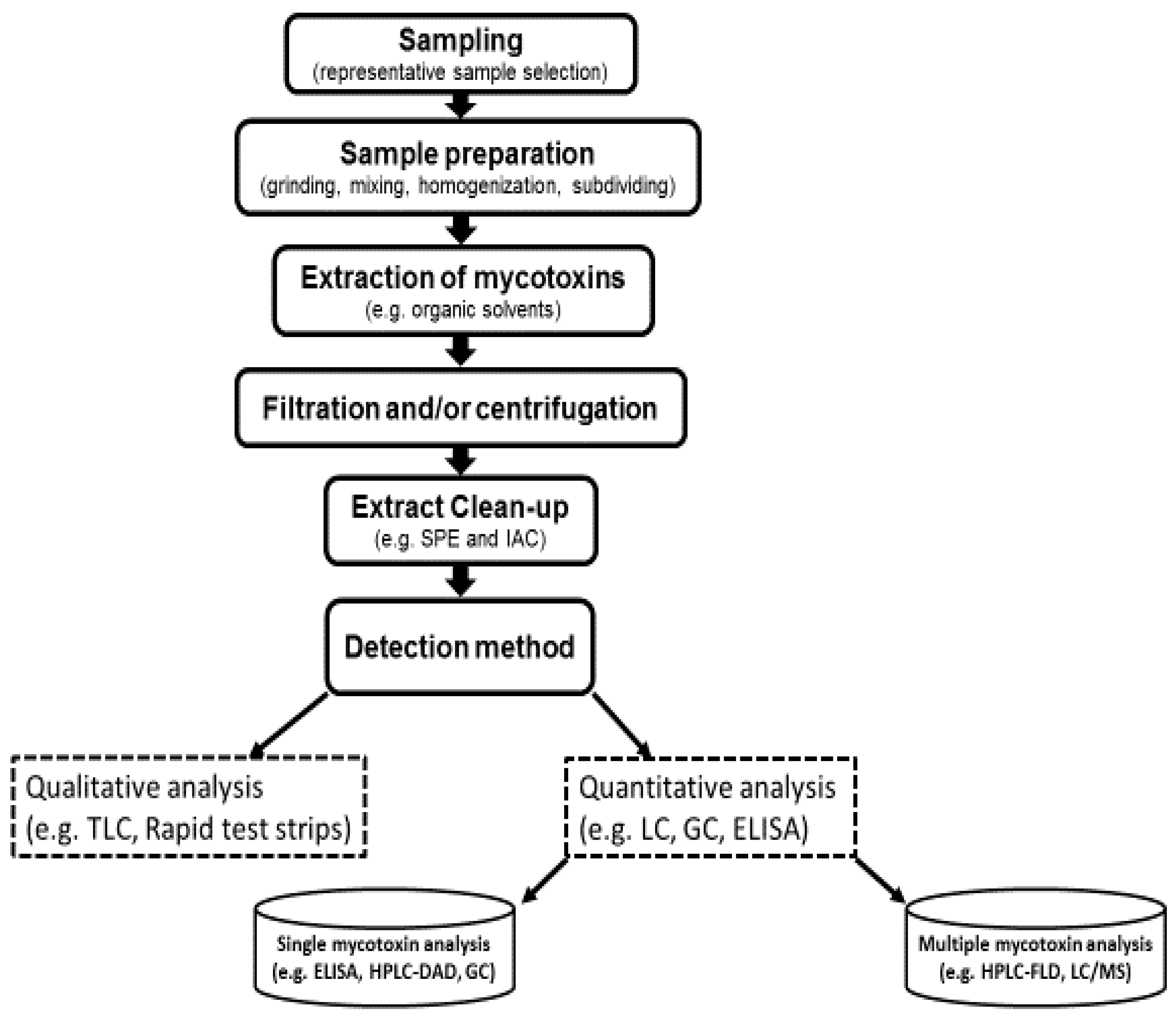

3. Analysis of Mycotoxins in Food

3.1. Sampling Tactics

3.2. Sample Preparation: Mycotoxin Extraction and Clean-Up

3.3. Analytical Methods

3.3.1. Chromatographic Techniques

3.3.2. Immunochemical Methods

3.3.3. Rapid Methods

3.3.4. Other Emerging Detection Technologies

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bennett, J.W. Mycotoxins, mycotoxicoses, mycotoxicology and mycopathologia. Mycopathologia 1987, 100, 3–5. [Google Scholar] [CrossRef] [PubMed]

- Sweeney, M.J.; Dobson, D.W. Mycotoxin production by Aspergillus, Fusarium and Penicillium species. Int. J. Food Microbiol. 1998, 43, 141–158. [Google Scholar] [CrossRef]

- Marin, S.; Ramos, A.J.; Cano-Sancho, G.; Sanchis, V. Mycotoxins: Occurrence, toxicology, and exposure assessment. Food Chem. Toxicol. 2013, 60, 218–237. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, T.; Hasegawa, A.; Yamamoto, S.; Lee, U.S.; Sugiura, Y.; Ueno, Y. Worldwide contamination of cereals by Fusarium mycotoxins nivalenol, deoxynivalenol and zearalenone. I. Survey of 19 countries. J. Agric. Food Chem. 1988, 36, 979–983. [Google Scholar] [CrossRef]

- Bennett, J.W.; Klich, M. Mycotoxins. Clin. Microbiol. Rev. 2003, 16, 497–516. [Google Scholar] [CrossRef] [PubMed]

- Boevre, M.; Mavungu, J.D.; Landshchoot, S.; Audenaert, K.; Eeckhout, M.; Maene, P. Natural occurrence of mycotoxins and their masked forms in food and feed products. World Mycotoxin J. 2012, 5, 207–219. [Google Scholar] [CrossRef]

- Pereira, V.L.; Fernandes, J.O.; Cunha, S.C. Mycotoxins in cereals and related foodstuffs: A review on occurrence and recent methods of analysis. Trends Food Sci. Technol. 2014, 36, 96–136. [Google Scholar] [CrossRef]

- Pitt, J.I. Toxigenic fungi: Which are important? Med. Mycol. 2000, 38, 17–22. [Google Scholar] [CrossRef] [PubMed]

- Richard, J.L. Some major mycotoxins and their mycotoxicoses—An overview. Int. J. Food Microbiol. 2007, 119, 3–10. [Google Scholar] [CrossRef] [PubMed]

- Hussein, H.S.; Brasel, J.M. Toxicity, metabolism, and impact of mycotoxins on humans and animals. Toxicology 2001, 167, 101–134. [Google Scholar] [CrossRef]

- Stoev, S.D. Food safety and increasing hazard of mycotoxin occurrence in foods and feeds. Crit. Rev. Food Sci. Nutr. 2013, 53, 887–901. [Google Scholar] [CrossRef] [PubMed]

- Mitchell, N.J.; Bowers, E.; Hurburgh, C.; Wu, F. Potential economic losses to the US corn industry from aflatoxin contamination. Food Addit. Contam. Part A 2016, 33, 540–550. [Google Scholar] [CrossRef] [PubMed]

- Ostry, V.; Malir, F.; Toman, J.; Grosse, Y. Mycotoxins as human carcinogens-the IARC Monographs classification. Mycotoxin Res. 2017, 33, 65–73. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wu, F. Global burden of aflatoxin-induced hepatocellular carcinoma: A risk assessment. Environ. Health Perspect. 2010, 118, 818–824. [Google Scholar] [CrossRef] [PubMed]

- Wu, F. Mycotoxin risk assessment for the purpose of setting international regulatory standards. Environ. Sci. Technol. 2004, 38, 4049–4055. [Google Scholar] [CrossRef] [PubMed]

- Krska, R.; Schubert-Ullrich, P.; Molinelli, A.; Sulyok, M.; MacDonald, S.; Crews, C. Mycotoxin analysis: An update. Food Addit. Contam. Part A 2008, 25, 152–163. [Google Scholar] [CrossRef] [PubMed]

- Turner, N.W.; Bramhmbhatt, H.; Szabo-Vezse, M.; Poma, A.; Coker, R.; Piletsky, S.A. Analytical methods for determination of mycotoxins: An update (2009–2014). Anal. Chim. Acta 2015, 901, 12–33. [Google Scholar] [CrossRef] [PubMed]

- Yazdanpanah, H. Mycotoxins: Analytical challenges. Iran. J. Pharm. Res. 2011, 10, 653–654. [Google Scholar] [PubMed]

- Shephard, G.S. Current Status of Mycotoxin Analysis: A Critical Review. J. AOAC Int. 2016, 99, 842–848. [Google Scholar] [CrossRef] [PubMed]

- Stroka, J.; Maragos, C.M. Challenges in the analysis of multiple mycotoxins. World Mycotoxin J. 2016, 9, 847–861. [Google Scholar] [CrossRef]

- Bhatnagar, D.; Cary, J.W.; Ehrlich, K.; Yu, J.; Cleveland, T.E. Understanding the genetics of regulation of aflatoxin production and Aspergillus flavus development. Mycopathologia 2006, 162, 155–166. [Google Scholar] [CrossRef] [PubMed]

- Chulze, S.N. Strategies to reduce mycotoxin levels in maize during storage: A review. Food Addit. Contam. Part A 2010, 27, 651–657. [Google Scholar] [CrossRef] [PubMed]

- Kaushik, G. Effect of processing on mycotoxin content in grains. Crit. Rev. Food Sci. Nutr. 2015, 55, 1672–1683. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Ryu, D. Worldwide Occurrence of Mycotoxins in Cereals and Cereal-Derived Food Products: Public Health Perspectives of Their Co-occurrence. J. Agric. Food Chem. 2017. [Google Scholar] [CrossRef] [PubMed]

- Moretti, A.; Logrieco, A.F.; Susca, A. Mycotoxins: An underhand food problem. Methods Mol. Biol. 2017, 1542, 3–12. [Google Scholar] [PubMed]

- Wilson, D.M.; Mubatanhema, W.; Jurjevic, Z. Biology and ecology of mycotoxigenic Aspergillus species as related to economic and health concerns. Adv. Exp. Med. Biol. 2002, 504, 3–17. [Google Scholar] [PubMed]

- Pitt, J.I.; Miller, J.D. A Concise History of Mycotoxin Research. J. Agric. Food Chem. 2016. [Google Scholar] [CrossRef] [PubMed]

- Krishnamachari, K.; Bhat, R.V.; Nagarajan, V.; Tilac, T. Investigations into an outbreak of hepatitis in Western India. Indian J. Med. Res. 1975, 63, 1036–1048. [Google Scholar] [PubMed]

- Prandini, A.; Tansini, G.; Sigolo, S.; Filippi, L.; Laporta, M.; Piva, G. On the occurrence of aflatoxin M1 in milk and dairy products. Food Chem. Toxicol. 2009, 47, 984–991. [Google Scholar] [CrossRef] [PubMed]

- Govaris, A.; Roussi, V.; Koidis, P.A.; Botsoglou, N.A. Distribution and stability of aflatoxin M1 during processing, ripening and storage of Telemes cheese. Food Addit. Contam. 2001, 18, 437–443. [Google Scholar] [CrossRef] [PubMed]

- Barbiroli, A.; Bonomi, F.; Benedetti, S.; Mannino, S.; Monti, L.; Cattaneo, T.; Iametti, S. Binding of Aflatoxin M1 to Different Protein Fractions in Ovine and Caprine Milk. J. Dairy Sci. 2007, 90, 532–540. [Google Scholar] [CrossRef]

- Robens, J.F.; Richard, J.L. Aflatoxins in animal and human health. Rev. Environ. Contam. Toxicol. 1992, 127, 69–94. [Google Scholar] [PubMed]

- Osweiler, G.D. Mycotoxins: Contemporary issues of food animal health and productivity. Vet. Clin. N. Am. Food Anim. Pract. 2000, 16, 511–530. [Google Scholar] [CrossRef]

- Mwanda, O.W.; Otieno, C.F.; Omonge, E. Acute aflatoxicosis: Case report. E. Afr. Med. J. 2005, 82, 320–324. [Google Scholar] [CrossRef]

- Pier, A.C. Major biological consequences of aflatoxicosis in animal production. J. Anim. Sci. 1992, 70, 3964–3967. [Google Scholar] [CrossRef] [PubMed]

- Duarte, S.C.; Pena, A.; Lino, C.M. A review on ochratoxin A occurrence and effects of processing of cereal and cereal derived food products. Food Microbiol. 2010, 27, 187–198. [Google Scholar] [CrossRef] [PubMed]

- Scudamore, K.A. Prevention of ochratoxin A in commodities and likely effects of processing fractionation and animal feeds. Food Addit. Contam. Part A 2005, 22, 17–25. [Google Scholar] [CrossRef] [PubMed]

- Magnoli, C.E.; Astoreca, A.L.; Chiacchiera, S.M.; Dalcero, A.M. Occurrence of ochratoxin A and ochratoxigenic mycoflora in corn and corn based foods and feeds in some South American countries. Mycopathologia 2007, 163, 249–260. [Google Scholar] [CrossRef] [PubMed]

- Mantle, P.G. Risk assessment and the importance of ochratoxins. Int. Biodeterior. Biodegradation 2002, 50, 143–146. [Google Scholar] [CrossRef]

- Heussner, A.H.; Bingle, L.E. Comparative Ochratoxin Toxicity: A Review of the Available Data. Toxins 2015, 7, 4253–4282. [Google Scholar] [CrossRef] [PubMed]

- Stoev, S.D.; Paskalev, M.; MacDonald, S.; Mantle, P.G. Experimental one year ochratoxin A toxicosis in pigs. Exp. Toxicol. Pathol. 2002, 53, 481–487. [Google Scholar] [CrossRef] [PubMed]

- Žanic-Grubišić, T.; Zrinski, R.; Ĉepelak, I.; Petrik, J.; Radić, B.; Pepeljnjak, S. Studies of ochratoxin A-induced inhibition of phenylalanine hydroxylase and its reversed by phenylalanine. Toxicol. Appl. Pharmacol. 2000, 167, 132–139. [Google Scholar] [CrossRef] [PubMed]

- Bhatnagar, D.; Yu, J.; Ehrlich, K.C. Toxins of filamentous fungi. Chem. Immunol. 2002, 81, 167–206. [Google Scholar] [PubMed]

- Yazar, S.; Omurtag, G.Z. Fumonisins, trichothecenes and zearalenone in cereals. Int. J. Mol. Sci. 2008, 9, 2062–2090. [Google Scholar] [CrossRef] [PubMed]

- Castelo, M.M.; Sumner, S.S.; Bullerman, L.B. Stability of fumonisins in thermally processed corn products. J. Food Prot. 1998, 161, 1030–1033. [Google Scholar] [CrossRef]

- Kowalska, K.; Habrowska-Górczyńska, D.E.; Piastowska-Ciesielska, A.W. Zearalenone as an endocrine disruptor in humans. Environ. Toxicol. Pharmacol. 2016, 48, 141–149. [Google Scholar] [CrossRef] [PubMed]

- Kallela, K.; Ettala, E. The oestrogenic Fusarium toxin (zearalenone) in hay as a cause of early abortions in the cow. Nord. Vet. Med. 1984, 36, 305–309. [Google Scholar] [PubMed]

- Rheeder, J.P.; Marasas, W.F.; Vismer, H.F. Production of fumonisin analogs by Fusarium species. Appl. Environ. Microbiol. 2002, 68, 2101–2105. [Google Scholar] [CrossRef] [PubMed]

- Reddy, K.R.N.; Nurdijati, S.B.; Salleh, B. An overview of plant-derived products on control of mycotoxigenic fungi and mycotoxins. Asian J. Plant Sci. 2010, 9, 126–133. [Google Scholar] [CrossRef]

- Li, F.; Jiang, D.; Zheng, F.; Chen, J.; Li, W. Fumonisins B1, B2 and B3 in corn products, wheat flour and corn oil marketed in Shandong province of China. Food Addit. Contam. Part B 2015, 8, 169–174. [Google Scholar] [CrossRef] [PubMed]

- Mazzoni, E.; Scandolara, A.; Giorni, P.; Pietri, A.; Battilani, P. Field control of Fusarium ear rot, Ostrinianubilalis (Hübner), and fumonisins in maize kernels. Pest Manag. Sci. 2011, 67, 458–465. [Google Scholar] [CrossRef] [PubMed]

- Ueno, Y. Trichothecenes- Chemical, Biological and Toxicological Aspects; Elsevier: Tokyo, Japan, 1983; pp. 135–146. [Google Scholar]

- Bottalico, A.; Perrone, G. Toxigenic Fusarium species and mycotoxins associated with head blight in small-grain cereals in Europe. Eur. J. Plant Pathol. 2002, 108, 611–624. [Google Scholar] [CrossRef]

- Yoshizawa, T. Natural occurrence of mycotoxins in small grain cereals (wheat, barley, rye, oats, sorghum, millet, rice). In Mycotoxins and Animal Foods; Smith, J.E., Henderson, R.S., Eds.; CRC: Boca Raton, FL, USA, 1991; pp. 301–324. [Google Scholar]

- Sobrova, P.; Adam, V.; Vasatkova, A.; Beklova, M.; Zeman, L.; Kizek, R. Deoxynivalenol and its toxicity. Interdiscip. Toxicol. 2010, 3, 94–99. [Google Scholar] [CrossRef] [PubMed]

- Pestka, J.J. Deoxynivalenol: Toxicity, mechanisms and animal health risks. Anim. Feed Sci. Technol. 2007, 137, 283–298. [Google Scholar] [CrossRef]

- Wannemacher, R.W.; Bunner, D.L.; Neufeld, H.A. Toxicity of trichothecenes and other related mycotoxins in laboratory animals. In Mycotoxins and Animal Foods; Smith, J.E., Henderson, R.S., Eds.; CRC: Boca Raton, FL, USA, 1991; pp. 499–552. [Google Scholar]

- Drusch, S.; Ragab, W. Mycotoxins in fruits, fruit juices, and dried fruits. J. Food Prot. 2003, 66, 1514–1527. [Google Scholar] [CrossRef] [PubMed]

- Harrison, M.A. Presence and stability of patulin in apple products: A review. J. Food Saf. 1989, 9, 147–153. [Google Scholar] [CrossRef]

- Moake, M.M.; Padilla-Zakour, O.I.; Worobo, R.W. Comprehensive review of patulin control methods in foods. Compr. Rev. Food Sci. Food Saf. 2005, 1, 8–21. [Google Scholar] [CrossRef]

- Yang, J.; Li, J.; Jiang, Y.; Duan, X.; Qu, H.; Yang, B.; Chen, F.; Sivakumar, D. Natural occurrence, analysis, and prevention of mycotoxins in fruits and their processed products. Crit. Rev. Food Sci. Nutr. 2014, 54, 64–83. [Google Scholar] [CrossRef] [PubMed]

- Puel, O.; Galtier, P.; Oswald, I.P. Biosynthesis and toxicological effects of patulin. Toxins 2010, 2, 613–631. [Google Scholar] [CrossRef] [PubMed]

- McKinley, E.R.; Carlton, W.W.; Boon, G.D. Patulin mycotoxicosis in the rat: Toxicology, pathology and clinical pathology. Food Chem. Toxicol. 1982, 20, 289–300. [Google Scholar] [CrossRef]

- Baert, K.; Devlieghere, F.; Flyps, H.; Oosterlinck, M.; Ahmed, M.M.; Rajković, A.; Verlinden, B.; Nicolaï, B.; Debevere, J.; De Meulenaer, B. Influence of storage conditions of apples on growth and patulin production by Penicillium expansum. Int. J. Food Microbiol. 2007, 119, 170–181. [Google Scholar] [CrossRef] [PubMed]

- Abnet, C.C. Carcinogenic Food Contaminants. Cancer Investig. 2007, 25, 189–196. [Google Scholar] [CrossRef] [PubMed]

- Van Emon, J.M. Bioanalytical methods for food contaminant analysis. J. AOAC Int. 2010, 93, 1681–1691. [Google Scholar] [PubMed]

- Whitaker, T.B. Detecting mycotoxins in agricultural commodities. Mol. Biotechnol. 2003, 23, 61–71. [Google Scholar] [CrossRef]

- Richard, J.L.; Bennett, G.A.; Ross, P.F.; Nelson, P.E. Analysis of naturally occurring mycotoxins in feedstuffs and food. J. Anim. Sci. 1993, 71, 2563–2574. [Google Scholar] [PubMed]

- Whitaker, T.B. Sampling foods for mycotoxins. Food Addit. Contam. 2006, 23, 50–61. [Google Scholar] [CrossRef] [PubMed]

- Ridgway, K.; Scientific, R. Sample preparation for food contaminant analysis. LC GC Eur. 2012, 25, 1–8. [Google Scholar]

- Scudamore, K.A. Bioactive Compounds in Foods; Gilbert, J., Enyuva, H.Z., Eds.; Blackwell Publishing Ltd.: Oxford, UK, 2008; pp. 134–172. [Google Scholar]

- Whitaker, T.B.; Johansson, A.S. Sampling uncertainties for the detection of chemical agents in complex food matrices. J. Food Prot. 2005, 68, 1306–1313. [Google Scholar] [CrossRef] [PubMed]

- Shephard, G.S. Determination of mycotoxins in human foods. Chem. Soc. Rev. 2008, 37, 2468–2477. [Google Scholar] [CrossRef] [PubMed]

- Krska, R. Performance of modern sample preparation techniques in the analysis of Fusarium mycotoxins in cereals. J. Chromatogr. A 1998, 815, 49–57. [Google Scholar] [CrossRef]

- Rahmani, A.; Jinap, S.; Soleimany, F. Qualitative and quantitative analysis of mycotoxins. Compr. Rev. Food Sci. Food Saf. 2009, 8, 202–251. [Google Scholar] [CrossRef]

- Turner, N.W.; Subrahmanyam, S.; Piletsky, S. Analytical methods for determination of mycotoxins: A review. Anal. Chim. Acta 2009, 632, 168–180. [Google Scholar] [CrossRef] [PubMed]

- Maragos, C.M.; Busman, M. Rapid and advanced tools for mycotoxin analysis: A review. Food Addit. Contam. Part A 2010, 27, 688–700. [Google Scholar] [CrossRef] [PubMed]

- Kralj Cigic, I.; Prosen, H. An overview of conventional and emerging analytical methods for the determination of mycotoxins. Int. J. Mol. Sci. 2009, 10, 62–115. [Google Scholar] [CrossRef] [PubMed]

- Spanjer, M.C.; Rensen, P.M.; Scholten, J.M. LC-MS/MS multi-method for mycotoxins after single extraction, with validation data for peanut, pistachio, wheat, maize, cornflakes, raisins and figs. Food Addit. Contam. Part A 2008, 25, 472–489. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Hu, R.; Zhang, Z.; Li, P.; Zhang, Q.; Wang, M. Development of a multiple immunoaffinity column for simultaneous determination of multiple mycotoxins in feeds using UPLC-MS/MS. Anal. Bioanal. Chem. 2016, 408, 6027–6036. [Google Scholar] [CrossRef] [PubMed]

- Saez, J.M.; Medina, A.; Gimeno-Adelantado, J.V.; Mateo, R.; Jimenez, M. Comparison of different sample treatments for the analysis of ochratoxin A in must, wine and beer by liquid chromatography. J. Chromatogr. A 2004, 1029, 125–133. [Google Scholar] [CrossRef] [PubMed]

- Koesukwiwat, U.; Sanguankaew, K.; Leepipatpiboon, N. Evaluation of a modified QuEChERS method for analysis of mycotoxins in rice. Food Chem. 2014, 153, 44–51. [Google Scholar] [CrossRef] [PubMed]

- Anastassiades, M.; Lehotay, S.J.; Stajnbaher, D.; Schenck, F.J. Fast and easy multiresidue method employing acetonitrile extraction/partitioning and “dispersive solid-phase extraction” for the determination of pesticide residues in produce. J. AOAC Int. 2003, 86, 412–431. [Google Scholar] [PubMed]

- Yogendrarajah, P.; Van Poucke, C.; De Meulenaer, B.; De Saeger, S. Development and validation of a QuEChERS based liquid chromatography tandem mass spectrometry method for the determination of multiple mycotoxins in spices. J. Chromatogr. A 2013, 1297, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Desmarchelier, A.; Tessiot, S.; Bessaire, T.; Racault, L.; Fiorese, E.; Urbani, A.; Chan, W.C.; Cheng, P.; Mottier, P. Combining the quick, easy, cheap, effective, rugged and safe approach and clean-up by immunoaffinity column for the analysis of 15 mycotoxins by isotope dilution liquid chromatography tandem mass spectrometry. J. Chromatogr. A 2014, 1337, 75–84. [Google Scholar] [CrossRef] [PubMed]

- Frenich, A.G.; Romero-González, R.; Gómez-Pérez, M.L.; Vidal, J.L. Multi-mycotoxin analysis in eggs using a QuEChERS-based extraction procedure and ultra-high pressure liquid chromatography coupled to triple quadrupole mass spectrometry. J. Chromatogr. A 2011, 1218, 4349–4356. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Li, F.; Chen, L.; Jiang, D. Quantitative analysis of 10 mycotoxins in wheat flour by ultrahigh performance liquid chromatography-tandem mass spectrometry with a modified QuEChERS strategy. J. Food Sci. 2016, 81, T2886–T2890. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Li, W.; Zhang, Y.; Hu, X.; Wu, L.; Wang, B. QuEChERS purification combined with ultrahigh-performance liquid chromatography tandem mass spectrometry for simultaneous quantification of 25 mycotoxins in cereals. Toxins 2016, 8, 375. [Google Scholar] [CrossRef] [PubMed]

- Romero-González, R.; Garrido Frenich, A.; Martínez Vidal, J.L.; Prestes, O.D.; Grio, S.L. Simultaneous determination of pesticides, biopesticides and mycotoxins in organic products applying a quick, easy, cheap, effective, rugged and safe extraction procedure and ultra-high-performance liquid chromatography-tandem mass spectrometry. J. Chromatogr. A 2011, 1218, 1477–1485. [Google Scholar] [CrossRef] [PubMed]

- Orata, F. Derivatization reactions and reagents for gas chromatography analysis. In Advanced Gas Chromatography e Progress in Agricultural, Biomedical and Industrial Applications, 1st ed.; Mohd, M.A., Ed.; InTech: Rijeka, Croatia, 2012; pp. 83–108. [Google Scholar]

- Laura, A.; Cristina, G.; Claudio, B. Mycotoxin detection. Curr. Opin. Biotechnol. 2016, 37, 120–126. [Google Scholar]

- Pascale, M. Detection methods for mycotoxins in cereal grains and cereal products. Matice Srpske za Prirodne Nauke 2009, 117, 15–25. [Google Scholar] [CrossRef]

- Kong, W.J.; Shen, H.H.; Zhang, X.F.; Yang, X.L.; Qiu, F.; Ouyang, Z.; Yang, M.-H. Analysis of zearalenone and a-zearalenol in 100 foods and medicinal plants determined by HPLC-FLD and positive confirmation by LC-MS-MS. J. Sci. Food Agric. 2013, 93, 1584–1590. [Google Scholar] [CrossRef] [PubMed]

- Rahmani, A.; Jinap, S.; Khatib, A.; Tan, C.P. Simultaneous determination of aflatoxins, ochratoxin A, and zearalenone in cereals using a validated RP-HPLC method and PHRED derivatization system. J. Liq. Chromatogr. Relat. Technol. 2013, 36, 600–617. [Google Scholar]

- Chan, D.; MacDonald, S.J.; Boughtflower, V.; Brereton, P. Simultaneous determination of aflatoxins and ochratoxin A in food using a fully automated immunoaffinity column clean-up and liquid chromatography–fluorescence detection. J. Chromatogr. A 2004, 1059, 13–16. [Google Scholar] [CrossRef] [PubMed]

- Trucksess, M.; Weaver, C.; Oles, C.; Fry, F.; Noonan, G.; Betz, J.; Rader, J. Determination of aflatoxins B1, B2, G1, and G2 and ochratoxin A in ginseng and ginger by multitoxin immunoaffinity column cleanup and liquid chromatographic quantitation: Collaborative study. J. AOAC Int. 2008, 91, 511–523. [Google Scholar] [PubMed]

- Gobel, R.; Lusky, K. Simultaneous determination of aflatoxins, ochratoxin A, and zearalenone in grains by new immunoaffinity column/liquid chromatography. J. AOAC Int. 2004, 87, 411–416. [Google Scholar] [PubMed]

- Rahmani, A.; Jinap, S.; Soleimany, F. Validation of the procedure for the simultaneous determination of aflatoxins ochratoxin A and zearalenone in cereals using HPLC-FLD. Food Addit. Contam. Part A 2010, 27, 1683–1693. [Google Scholar] [CrossRef] [PubMed]

- Ofitserova, M.; Nerkar, S.; Pickering, M.; Torma, L.; Thiex, N. Multiresidue mycotoxin analysis in corn grain by column high-performance liquid chromatography with postcolumn photochemical and chemical derivatization: Single-laboratory validation. J. AOAC Int. 2009, 92, 15–25. [Google Scholar] [PubMed]

- Lattanzio, V.M.T.; Solfrizzo, M.; Visconti, A. Determination of trichothecenes in cereals and cereal-based products by liquid chromatography-tandem mass spectrometry. Food Addit. Contam. Part A 2008, 25, 320–330. [Google Scholar] [CrossRef] [PubMed]

- Liao, C.; Lin, H.; Chiueh, L.; Shih, D.Y. Simultaneous quantification of aflatoxins, ochratoxin A and zearalenone in cereals by LC-MS/MS. J. Food Drug Anal. 2011, 19, 259–268. [Google Scholar]

- Li, P.; Zhang, Z.; Hu, X.; Zhang, Q. Advanced hyphenated chromatographic-mass spectrometry in mycotoxin determination: Current status and prospects. Mass Spectrom. Rev. 2013, 32, 420–452. [Google Scholar] [CrossRef] [PubMed]

- Chu, F.S. Recent studies on immunoassays for mycotoxin. In Immunoassays for Residue Analysis; Beier, R.C., Stanker, L.H., Eds.; American Chemical Society: Washington, DC, USA, 1996; pp. 294–313. [Google Scholar]

- Kos, J.; Janić Hajnal, E.; Jajić, I.; Krstović, S.; Mastilović, J.; Šarić, B.; Jovanov, P. Comparison of ELISA, HPLC-FLD and HPLC-MS/MS methods for determination of aflatoxin M1 in natural contaminated milk samples. Acta Chim. Slov. 2016, 63, 747–756. [Google Scholar] [CrossRef] [PubMed]

- Pittet, A. Modern methods and trends in mycotoxin analysis. Mitteilungen Lebensmitteluntersuchung Hygiene 2005, 96, 424–444. [Google Scholar]

- Yao, H.; Hruska, Z.; Diana Di Mavungu, J. Developments in detection and determination of aflatoxins. World Mycotoxin J. 2015, 8, 181–191. [Google Scholar] [CrossRef]

- Zheng, M.Z.; Richard, J.L.; Binder, J. A review of rapid methods for the analysis of mycotoxins. Mycopathologia 2006, 161, 261–273. [Google Scholar] [CrossRef] [PubMed]

- Goryacheva, I.Y.; De Saeger, S.; Eremin, S.A.; Van Peteghem, C. Immunochemical methods for rapid mycotoxin detection: Evolution from single to multiple analyte screening: A review. Food Addit. Contam. 2007, 24, 1169–1183. [Google Scholar] [CrossRef] [PubMed]

- Krska, R.; Molinelli, A. Rapid test strips for analysis of mycotoxins in food and feed. Anal. Bioanal. Chem. 2009, 393, 67–71. [Google Scholar] [CrossRef] [PubMed]

- Schneider, E.; Usleber, E.; Märtlbauer, E. Rapid detection of fumonisin B1 in corn-based food by competitive direct dipstick enzyme immunoassay/enzyme-linked immunofiltration assay with integrated negative control reaction. J. Agric. Food Chem. 1995, 43, 2548–2552. [Google Scholar] [CrossRef]

- Lattanzio, V.M.; Nivarlet, N.; Lippolis, V.; Della Gatta, S.; Huet, A.C.; Delahaut, P.; Granier, B.; Visconti, A. Multiplex dipstick immunoassay for semi-quantitative determination of Fusarium mycotoxins in cereals. Anal. Chim. Acta 2012, 718, 99–108. [Google Scholar] [CrossRef] [PubMed]

- Molinelli, A.; Grossalber, K.; Krska, R. A rapid lateral flow test for the determination of total type B fumonisins in maize. Anal. Bioanal. Chem. 2009, 395, 1309–1316. [Google Scholar] [CrossRef] [PubMed]

- De Saeger, S.; Van Peteghem, C. Dipstick enzyme immunoassay to detect Fusarium T-2 toxin in wheat. Appl. Environ. Microbiol. 1996, 62, 1880–1884. [Google Scholar] [PubMed]

- Sibanda, L.; De Saeger, S.; Bauters, T.G.M.; Nelis, H.J.; Van Peteghem, C. Development of a flow-through enzyme immunoassay and application in screening green coffee samples for ochratoxin A with confirmation by high-performance liquid chromatography. J. Food Prot. 2001, 64, 1597–1602. [Google Scholar] [CrossRef] [PubMed]

- Sibanda, L.; De Saeger, S.; Barna-Vetro, I.; Van Peteghem, C. Development of a solidphase cleanup and portable rapid flow-through enzyme immunoassay for the detection of ochratoxin A in roasted coffee. J. Agric. Food Chem. 2002, 50, 6964–6967. [Google Scholar] [CrossRef] [PubMed]

- Trullols, E.; Ruisanchez, I.; Rius, F.X.; Odena, M.; Feliu, M.T. Qualitative method for determination of aflatoxin B1 in nuts. J. AOAC Int. 2004, 87, 417–423. [Google Scholar] [PubMed]

- Urraca, J.L.; Benito-Peña, E.; Perez-Conde, C.; Moreno-Bondi, M.C.; Pestka, J.J. Analysis of zearalenone in cereal and swine feed samples using an automated flow-through immunosensor. J. Agric. Food Chem. 2005, 53, 3338–3344. [Google Scholar] [CrossRef] [PubMed]

- Pettersson, H.; Aberg, L. Near infrared spectroscopy for determination of mycotoxins in cereals. Food Control 2003, 14, 229–232. [Google Scholar] [CrossRef]

- Berardo, N.; Pisacane, V.; Battilani, P.; Scandolara, A.; Pietri, A.; Marocco, A. Rapid detection of kernel rots and mycotoxins in maize by near-infrared reflectance spectroscopy. J. Agric. Food Chem. 2005, 53, 8128–8134. [Google Scholar] [CrossRef] [PubMed]

- Kos, G.; Lohninger, H.; Krska, R. Development of a method for the determination of Fusarium fungi on corn using mid-infrared spectroscopy with attenuated total reflection and chemometrics. Anal. Chem. 2003, 75, 1211–1217. [Google Scholar] [CrossRef] [PubMed]

- De Girolamo, A.; Lippolis, V.; Nordkvist, E.; Visconti, A. Rapid and non-invasive analysis of deoxynivalenol in durum and common wheat by Fourier-Transform Near Infrared (FT-NIR) spectroscopy. Food Addit. Contam. Part A 2009, 26, 907–917. [Google Scholar] [CrossRef] [PubMed]

- Sieger, M.; Kos, G.; Sulyok, M.; Godejohann, M.; Krska, R.; Mizaikoff, B. Portable Infrared Laser Spectroscopy for On-site Mycotoxin Analysis. Sci. Rep. 2017, 7, 44028. [Google Scholar] [CrossRef] [PubMed]

- Maragos, C.M. Analysis of mycotoxins with capillary electrophoresis. Sem. Food Anal. 1998, 3, 353–373. [Google Scholar]

- Maragos, C.M.; Appell, M. Capillary electrophoresis of the mycotoxin zearalenone using cyclodextrin-enhanced fluorescence. J. Chromatogr. A 2007, 114, 252–257. [Google Scholar] [CrossRef] [PubMed]

- Corneli, S.; Maragos, C.M. Capillary electrophoresis with laser-induced fluorescence: Method for the mycotoxin ochratoxin A. J. Agric. Food Chem. 1998, 46, 3162–3165. [Google Scholar] [CrossRef]

- Giuseppe, V.; Del Roberta, S.; Lucia, M.; Maria, R.L.; Anna, S.; Sonia, S.; Giuseppe, M. Molecularly imprinted polymers: Present and future prospective. Int. J. Mol. Sci. 2011, 12, 5908–5945. [Google Scholar]

- Appell, M.; Mueller, A. Mycotoxin analysis using imprinted materials technology: Recent developments. J. AOAC Int. 2016, 99, 861–864. [Google Scholar] [CrossRef] [PubMed]

- Haupt, K. Imprinted polymers—Tailor-made mimics of antibodies and receptors. Chem. Commun. 2003, 2, 171–178. [Google Scholar] [CrossRef]

- Jodlbauer, J.; Maier, N.M.; Lindner, W. Towards ochratoxin A selective molecularly imprinted polymers for solid-phase extraction. J. Chromatogr. A 2002, 945, 45–63. [Google Scholar] [CrossRef]

- Zhou, S.N.; Lai, E.P.C.; Miller, J.D. Analysis of wheat extracts for ochratoxin A by molecularly imprinted solid-phase extraction and pulsed elution. Anal. Bioanal. Chem. 2004, 378, 1903–1906. [Google Scholar] [CrossRef] [PubMed]

- Weiss, R.; Freudenschuss, M.; Krska, R.; Mizaikoff, B. Improving methods of analysis for mycotoxins: Molecularly imprinted polymers for deoxynivalenol and zearalenone. Food Addit. Contam. 2003, 20, 386–395. [Google Scholar] [CrossRef] [PubMed]

- Visconti, A.; Lattanzio, V.M.T.; Pascale, M.; Haidukowski, M. Analysis of T-2 and HT-2 toxins in cereal grains by immunoaffinity clean-up and liquid chromatography with fluorescence detection. J. Chromatogr. A 2005, 1075, 151–158. [Google Scholar] [CrossRef] [PubMed]

- Maier, N.M.; Buttinger, G.; Welhartizki, S.; Gavioli, E.; Lindner, W. Molecularly imprinted polymer-assisted sample clean-up of ochratoxin A from red wine: Merits and limitations. J. Chromatogr. B 2004, 804, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Logrieco, A.; Arrigan, D.W.M.; Brengel-Pesce, K.; Siciliano, P.; Tothill, I. DNA arrays, electronic noses and tongues, biosensors and receptors for rapid detection of toxigenic fungi and mycotoxins: A review. Food Addit. Contam. 2005, 22, 335–344. [Google Scholar] [CrossRef] [PubMed]

- Bram van der, G.; Sabine, S.; Heidi, D.; Edwin, S.; Gerben, B.; Ton van, O.; Kees, K. Biosensors and multiple mycotoxin analysis. Food Control 2003, 14, 251–254. [Google Scholar] [CrossRef]

- Daly, S.J.; Keating, G.J.; Dillon, P.P.; Manning, B.M.; O’Kennedy, R.; Lee, H.A.; Morgan, M.R. Development of surface plasmon resonance-based immunoassay for aflatoxin B(1). J. Agric. Food Chem. 2000, 48, 5097–5104. [Google Scholar] [CrossRef] [PubMed]

- Tüdös, A.J.; Lucas-van den Bos, E.R.; Stigter, E.C.A. Rapid surface plasmon resonancebased inhibition assay of deoxynivalenol. J. Agric. Food Chem. 2003, 51, 5843–5848. [Google Scholar] [CrossRef] [PubMed]

- Wendy, A.; Anton, S. Fluorescence Polarization Assays in Small Molecule Screening. Expert Opin. Drug Discov. 2011, 6, 17–32. [Google Scholar]

- Maragos, C.M. Fluorescence polarization for mycotoxin determination. Mycotoxin Res. 2006, 22, 96–99. [Google Scholar] [CrossRef] [PubMed]

- Sheng, Y.J.; Eremin, S.; Mi, T.J.; Zhang, S.X.; Shen, J.Z.; Wang, Z.H. The development of a fluorescence polarization immunoassay for aflatoxin detection. Biomed. Environ. Sci. 2014, 27, 126–129. [Google Scholar] [PubMed]

- Shim, W.B.; Kolosova, A.Y.; Kim, Y.J.; Yang, Z.Y.; Park, S.J.; Eremin, S.A.; Lee, I.S.; Chung, D.H. Fluorescence polarization immunoassay based on a monoclonal antibody for the detection of ochratoxin A. Int. J. Food Sci. Technol. 2004, 39, 829–837. [Google Scholar] [CrossRef]

- Lippolis, V.; Pascale, M.; Visconti, A. Optimization of a fluorescence polarization immunoassay for rapid quantification of deoxynivalenol in durum wheat-based products. J. Food Prot. 2006, 69, 2712–2719. [Google Scholar] [CrossRef] [PubMed]

- Maragos, C.M.; Jolley, M.E.; Plattner, R.D.; Nasir, M.S. Fluorescence polarization as a means for determination of fumonisins in maize. J. Agric. Food Chem. 2001, 49, 596–602. [Google Scholar] [CrossRef] [PubMed]

- Chun, H.S.; Choi, E.H.; Chang, H.J.; Choi, S.W.; Eremin, S.A. A fluorescence polarization immunoassay for the detection of zearalenone in corn. Anal. Chim. Acta 2009, 639, 83–89. [Google Scholar] [CrossRef] [PubMed]

- Maragos, C.M.; Plattner, R.D. Rapid fluorescence polarization immunoassay for the mycotoxin deoxynivalenol in wheat. J. Agric. Food Chem. 2002, 50, 1827–1832. [Google Scholar] [CrossRef] [PubMed]

- Keshri, G.; Magan, N. Detection and differentiation between mycotoxigenic and non-mycotoxigenic strains of two Fusarium spp. using volatile production profiles and hydrolytic enzymes. J. Appl. Microbiol. 2000, 89, 825–833. [Google Scholar] [CrossRef] [PubMed]

- Feast, S. Potential application of electronic noses in cereals. Cereal Food World. 2001, 46, 159–161. [Google Scholar]

- Falasconi, M.; Gobbi, E.; Pardo, M.; Della Torre, M.; Sberveglieri, G. Detection of toxigenic strains of Fusarium verticillioides in corn by electronic olfactory systems. Sens. Actuators B 2005, 108, 250–257. [Google Scholar] [CrossRef]

- Olsson, J.; Börjesson, T.; Lundstedt, T.; Schnürer, J. Detection and quantification of ochratoxin A and deoxynivalenol in barley grains by GC-MS and electronic nose. Int. J. Food Microbiol. 2002, 72, 203–214. [Google Scholar] [CrossRef]

- Magan, N.; Evans, P. Volatiles as an indicator of fungal activity and differentiation between species, and the potential use of electronic nose technology for early detection of grain spoilage. J. Stored Prod. Res. 2000, 36, 319–340. [Google Scholar] [CrossRef]

- Campagnoli, A.; Cheli, F.; Savoini, G.; Crotti, A.; Pastori, A.G.; Dell’Orto, V. Application of an electronic nose to detection of aflatoxins in corn. Vet. Res. Commun. 2009, 33 (Suppl. 1), 273–275. [Google Scholar] [CrossRef] [PubMed]

| Mycotoxin | Fungal Species | Food Commodity | US FDA (µg/kg) | EU (EC 2006) (µg/kg) |

|---|---|---|---|---|

| Aflatoxins B1, B2, G1, G2 | Aspergillus flavus Aspergillus parasiticus | Maize, wheat, rice, peanut, sorghum, pistachio, almond, ground nuts, tree nuts, figs, cottonseed, spices | 20 for total | 2–12 for B1 4–15 for total |

| Aflatoxin M1 | Metabolite of aflatoxin B1 | Milk, milk Products | 0.5 | 0.05 in milk 0.025 in infant formulae and infant milk |

| Ochratoxin A | Aspergillus ochraceus Penicillium verrucosum Aspergillus carbonarius | Cereals, dried vine fruit, wine, grapes, coffee, cocoa, cheese | Not set | 2–10 |

| Fumonisins B1, B2, B3 | Fusarium verticillioides Fusarium proliferatum | Maize, maize, products, sorghum, asparagus | 2000–4000 | 200–1000 |

| Zearalenone | Fusarium graminearum Fusarium culmorum | Cereals, cereal products, maize, wheat, barley | Not set | 20–100 |

| Deoxynivalenol | Fusarium graminearum Fusarium culmorum | Cereals, cereal products | 1000 | 200–50 |

| Patulin | Penicillium expansum | Apples, apple juice, and concentrate | 50 | 10–50 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshannaq, A.; Yu, J.-H. Occurrence, Toxicity, and Analysis of Major Mycotoxins in Food. Int. J. Environ. Res. Public Health 2017, 14, 632. https://doi.org/10.3390/ijerph14060632

Alshannaq A, Yu J-H. Occurrence, Toxicity, and Analysis of Major Mycotoxins in Food. International Journal of Environmental Research and Public Health. 2017; 14(6):632. https://doi.org/10.3390/ijerph14060632

Chicago/Turabian StyleAlshannaq, Ahmad, and Jae-Hyuk Yu. 2017. "Occurrence, Toxicity, and Analysis of Major Mycotoxins in Food" International Journal of Environmental Research and Public Health 14, no. 6: 632. https://doi.org/10.3390/ijerph14060632