Modeling the Activated Sludge—Thickening Process in Secondary Settlers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sampling

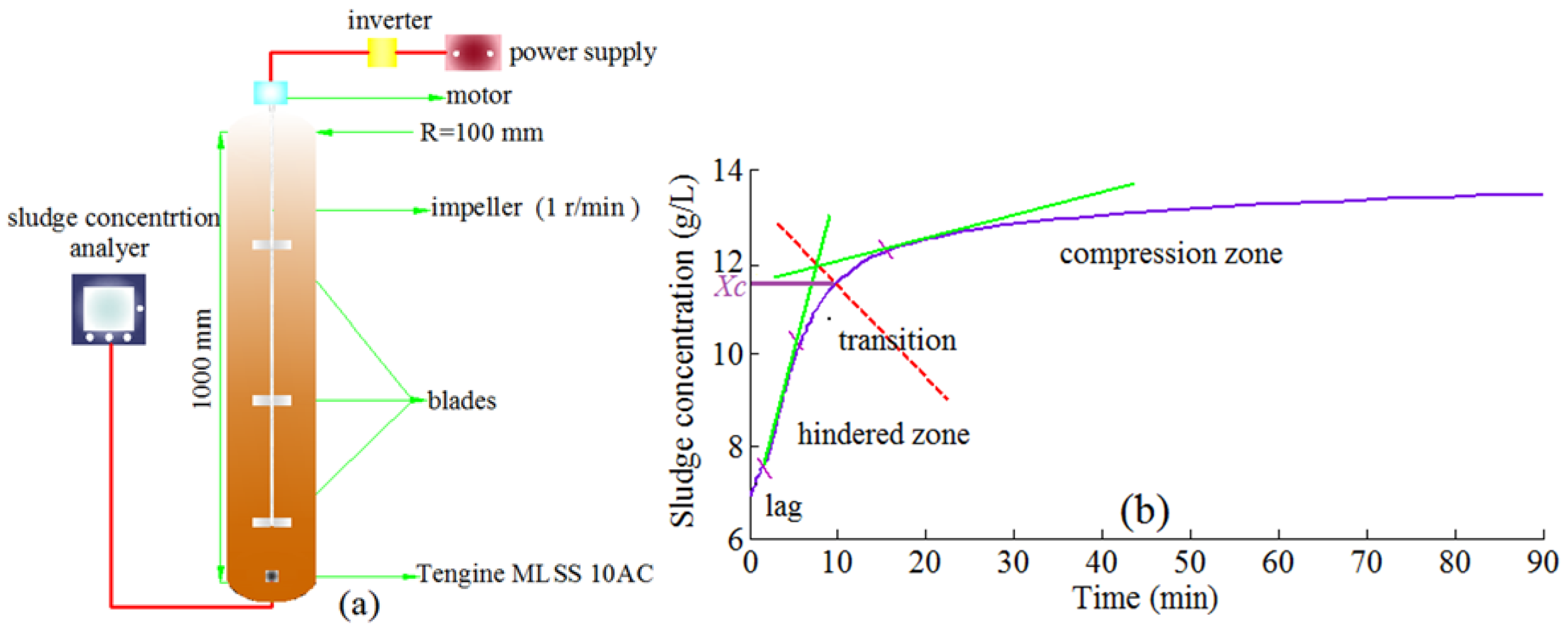

2.2. Sludge Thickening and Settling Tests

2.3. Model Development

2.3.1. Return Sludge Concentration Model

2.3.2. Sludge Compression Settling Model

2.4. Activated Sludge Fractal Dimensions

3. Results and Discussion

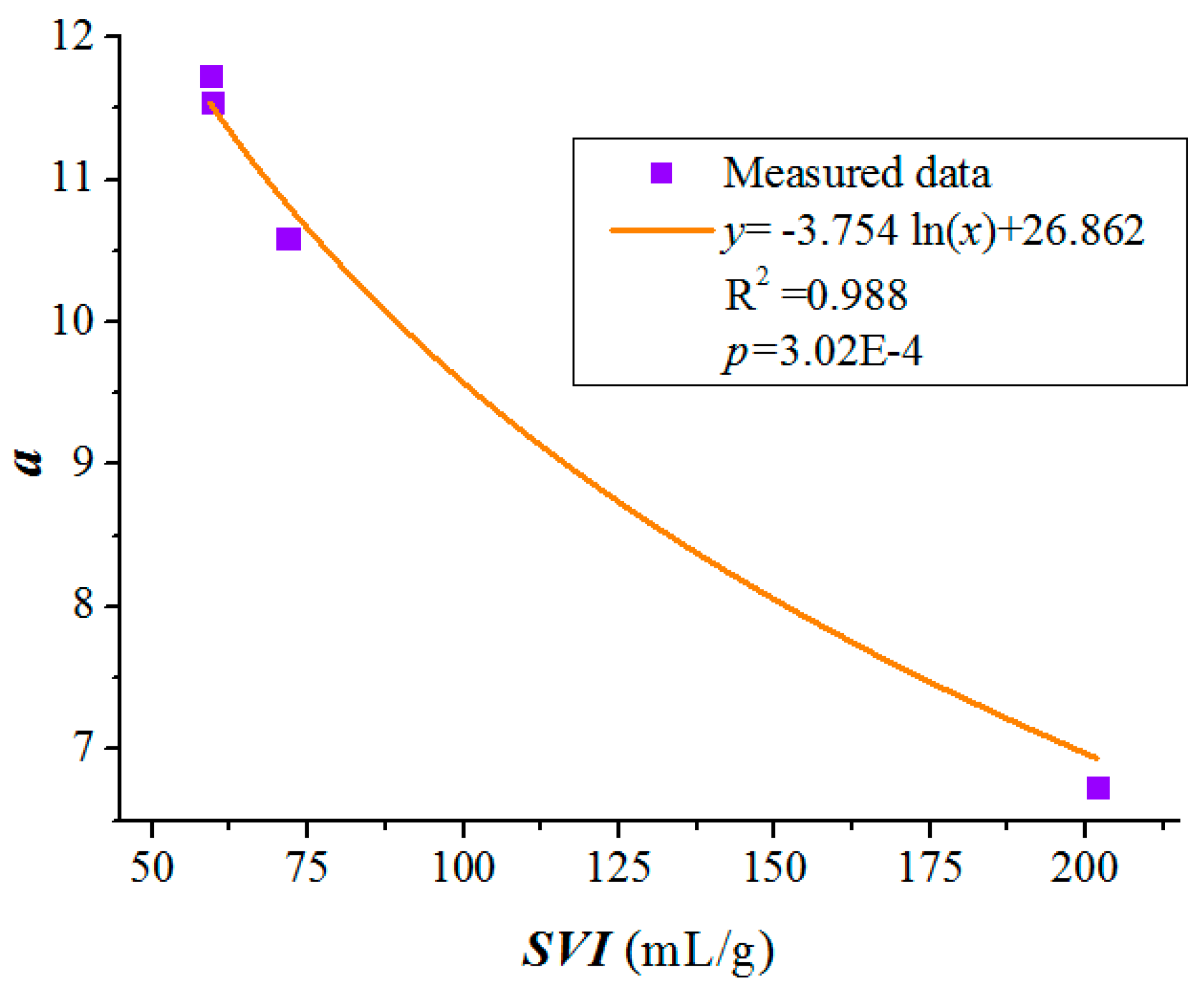

3.1. Model Calibration

| WWTP | SVI (mL/g) | a | b | R2 | p |

|---|---|---|---|---|---|

| 1 | 59.3 | 11.73 | 0.0496 | 0.88 | <0.001 |

| 2 | 59.6 | 11.54 | 0.0460 | 0.78 | <0.001 |

| 3 | 71.8 | 10.59 | 0.0500 | 0.86 | <0.001 |

| 4 | 201.8 | 6.74 | 0.0402 | 0.88 | <0.001 |

3.2. Model Validation

3.2.1. Return Activated Sludge Concentration Model Validation

3.2.2. New Sludge Compression Model Validation

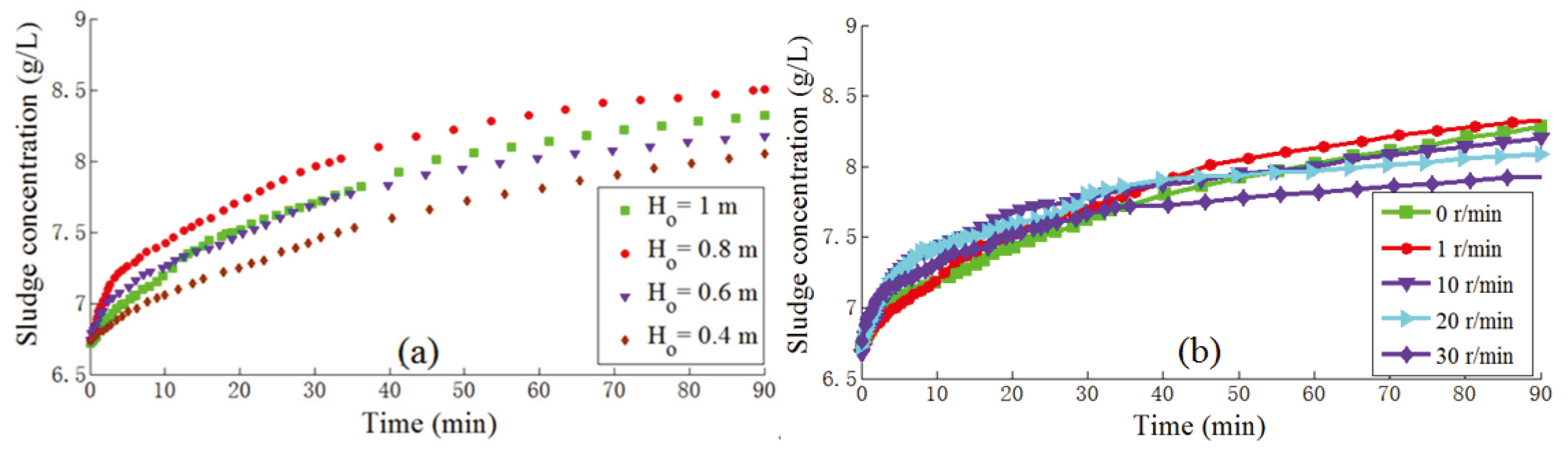

3.3. Factors Affecting the Sludge Thickening

3.3.1. Sludge Height

3.3.2. Stirring Rates

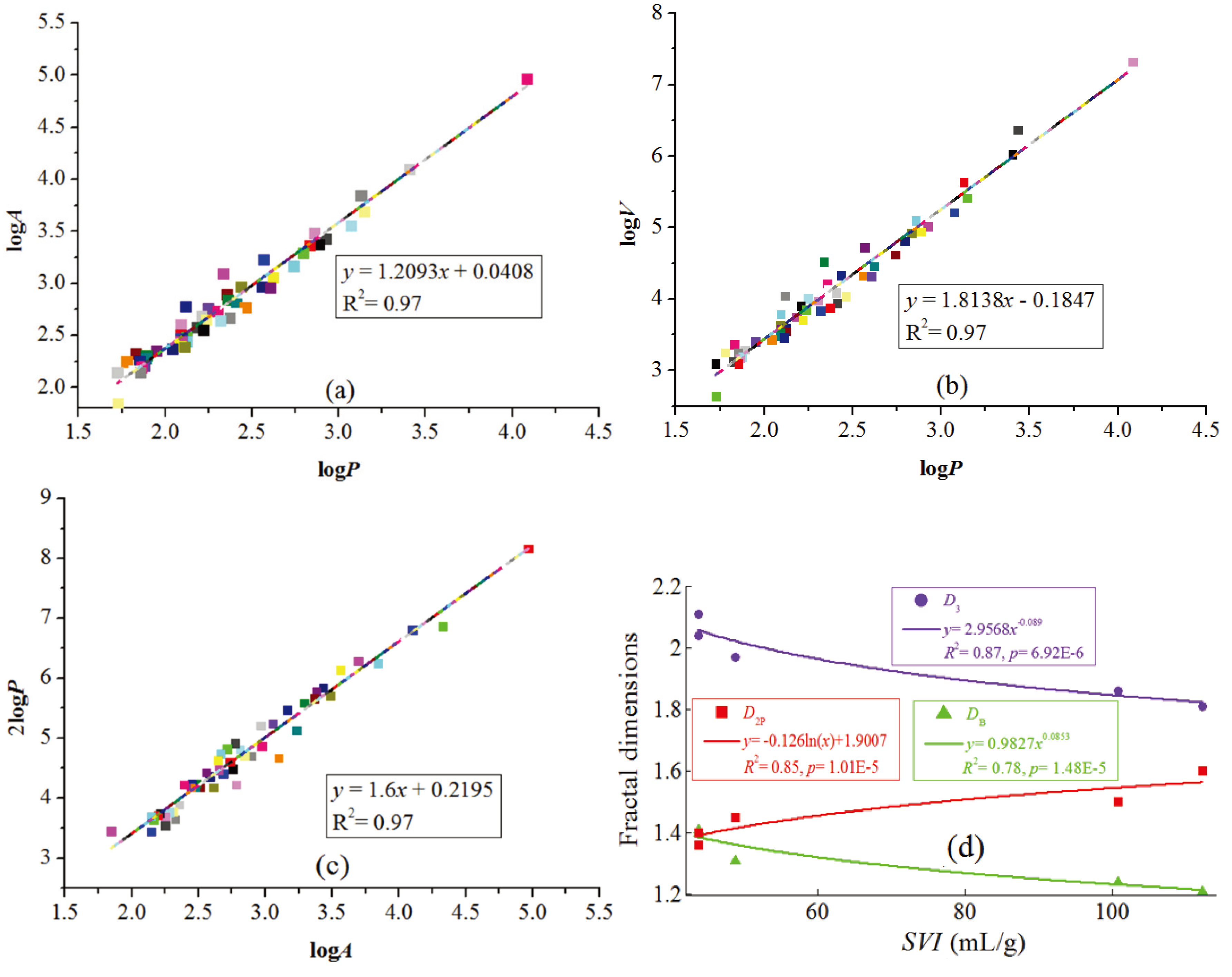

3.4. Activated Sludge Fractal Dimension

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- The National Urban Sewage Treatment Facilities Construction and Operation in the Fourth Quarter of 2014. Available online: http://www.mohurd.gov.cn/zcfg/jsbwj_0/jsbwjcsjs/201502/t20150217_220335.html (accessed on 11 October 2015).

- Narayanan, B.; Hough, S.G.; Ooten, R.J. New hypothesis for secondary clarifier performance under hydraulically limited conditions. Water Environ. Res. 2000, 72, 116–126. [Google Scholar] [CrossRef]

- Joannis, C.; Aumond, M.; Dauphin, S.; Ruban, G.; Deguin, A.; Bridoux, G. Modeling activated sludge mass transfer in a treatment plant. Water Sci. Technol. 1999, 39, 29–36. [Google Scholar] [CrossRef]

- Ekama, G.A.; Marais, P. Assessing the applicability of the 1D flux theory to full-scale secondary settling tank design with a 2D hydrodynamic model. Water Res. 2004, 38, 495–506. [Google Scholar] [CrossRef] [PubMed]

- Deininger, A.; Holthausen, E.; Wilderer, P.A. Velocity and solids distribution in circular secondary clarifiers: Full scale measurements and numerical modelling. Water Res. 1998, 32, 2951–2958. [Google Scholar] [CrossRef]

- De Clercq, J.; Devisscher, M.; Boonen, I.; Vanrolleghem, P.A.; Defrancq, J. A new one-dimensional clarifier model—Verification using full-scale experimental data. Water Sci. Technol. 2003, 47, 105–112. [Google Scholar] [PubMed]

- Kynch, G.J. A theory of sedimentation. Trans. Faraday Soc. 1952, 48, 166–176. [Google Scholar] [CrossRef]

- Vesilind, P.A. Design of prototype thickeners from batch settling tests. Water Sewage Works 1968, 115, 302–307. [Google Scholar]

- Li, D.H.; Ganczarczyk, J.J. Stroboscopic determination of settling velocity, size and porosity of activated sludge flocs. Water Res. 1987, 21, 257–262. [Google Scholar] [CrossRef]

- Takács, I.; Patry, G.G.; Nolasco, D.A. Dynamic model of the clarification-thickening process. Water Res. 1991, 25, 1263–1271. [Google Scholar] [CrossRef]

- Diehl, S.A. conservation law with point source and discontinuous flux function modelling continuous sedimentation. Siam. J. Appl. Math. 1996, 56, 388–419. [Google Scholar] [CrossRef]

- De Clercq, J.; Nopens, I.; Defrancq, J.; Vanrolleghem, P.A. Extending and calibrating a mechanistic hindered and compression settling model for activated sludge using in-depth batch experiments. Water Res. 2008, 42, 781–791. [Google Scholar] [CrossRef] [PubMed]

- Czysz, W.; Denne, A.; Rump, H. Technologie des eaux résiduaires: production, collecte, traitement et analyse des eaux résiduaires. Springer-Verlag: Paris, France, 1990. [Google Scholar]

- Giokas, D.L.; Kim, Y.; Paraskevas, P.A.; Paleologos, E.K.; Lekkas, T.D. A simple empirical model for activated sludge thickening in secondary clarifiers. Water Res. 2002, 36, 3245–3252. [Google Scholar] [CrossRef]

- Water Environment Federation. Standard Methods for the Examination of Water and Wastewater. Available online: http://www.mwa.co.th/download/file_upload/SMWW_1000-3000.pdf (accessed on 30 November 2015).

- Zhang, Y.K.; Wang, H.C.; Qi, L.; Liu, G.H.; He, Z.J.; Jiang, S.Z. Simple model of sludge thickening process in secondary settlers. Front. Env. Sci. Eng. 2015. [Google Scholar] [CrossRef]

- Zhang, D.J.; Li, Z.L.; Lu, P.L.; Zhang, T.; Xu, D.Y. A method for characterizing the complete settling process of activated sludge. Water Res. 2006, 40, 2637–2644. [Google Scholar] [CrossRef] [PubMed]

- Dick, R.I.; Vesilind, P.A. The sludge volume index: What is it? J. Water Pollut. Control. Fed. 1969, 41, 1285–1291. [Google Scholar]

- Hultman, B.; Hultgren, J. Deviations from the Kynch theory in thickening sludges from waste water treatment plants. Tribune du CEBEDEAU 1980, 33, 375–389. [Google Scholar]

- Roche, N.; Vaxelaire, J.; Prost, C. A simple empirical model for hindered settling in activated sludge clarifier. Water Environ. Res. 1995, 67, 775–780. [Google Scholar] [CrossRef]

- Jin, B.; Wilén, B.M.; Lant, P. A comprehensive insight into floc characteristics and their impact on compressibility and settleability of activated sludge. Chem. Eng. J. 2003, 95, 221–234. [Google Scholar] [CrossRef]

- Li, D.H.; Ganczarczyk, J. Fractal geometry of particle aggregates generated in water and wastewater treatment processes. Environ. Sci. Technol. 1989, 23, 1385–1389. [Google Scholar] [CrossRef]

- Wang, Y.L.; Lu, J.; Du, B.Y.; Baoyou, S.H. I.; Dongsheng, W.A.N.G. Fractal analysis of polyferric chloride-humic acid (PFC-HA) flocs in different topological spaces. J. Environ. Sci. 2009, 21, 41–48. [Google Scholar] [CrossRef]

- Li, Z.L.; Zhang, D.J.; Lu, P.L.; Zeng, S.W.; Yang, Y.H. Influencing factors of floc size distribution and fractal dimension of activated sludge. Environ. Sci. 2013, 34, 3975–3980. [Google Scholar]

- Wang, Y.L.; Dentel, S.K. The effect of high speed mixing and polymer dosing rates on the geometric and rheological characteristics of conditioned anaerobic digested sludge (ADS). Water Res. 2010, 44, 6041–6052. [Google Scholar] [CrossRef] [PubMed]

- Wilén, B.M.; Jin, B.; Lant, P. Impacts of structural characteristics on activated sludge floc stability. Water Res. 2003, 37, 3632–3645. [Google Scholar] [CrossRef]

- Chu, C.P.; Lee, D.J.; Peng, X.F. Structure of conditioned sludge flocs. Water Res. 2004, 38, 2125–2134. [Google Scholar] [CrossRef] [PubMed]

- Hyslip, J.P.; Vallejo, L.E. Fractal analysis of the roughness and size distribution of granular materials. Eng. Geol. 1997, 48, 231–244. [Google Scholar] [CrossRef]

- Zhao, Y.Q. Correlations between floc physical properties and optimum polymer dosage in alum sludge conditioning and dewatering. Chem. Eng. J. 2003, 92, 227–235. [Google Scholar] [CrossRef]

- Ekama, G.A.; Barnard, J.L.; Günthert, F.W.; Krebs, P.; McCorquodale, J.A.; Parker, D.S.; Wahlberg, E.J. Secondary Settling Tanks: Theory, Modelling, Design and Operation; International Association on Water Quality: England, UK, 1997; pp. 12–39. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yin, X.; He, Z.; Zhang, X.; Wen, Y.; Wang, H. Modeling the Activated Sludge—Thickening Process in Secondary Settlers. Int. J. Environ. Res. Public Health 2015, 12, 15449-15458. https://doi.org/10.3390/ijerph121214996

Zhang Y, Yin X, He Z, Zhang X, Wen Y, Wang H. Modeling the Activated Sludge—Thickening Process in Secondary Settlers. International Journal of Environmental Research and Public Health. 2015; 12(12):15449-15458. https://doi.org/10.3390/ijerph121214996

Chicago/Turabian StyleZhang, Yuankai, Xunfei Yin, Zhijiang He, Xiangjun Zhang, Yang Wen, and Hongchen Wang. 2015. "Modeling the Activated Sludge—Thickening Process in Secondary Settlers" International Journal of Environmental Research and Public Health 12, no. 12: 15449-15458. https://doi.org/10.3390/ijerph121214996