Novel Oversampling Technique for Improving Signal-to-Quantization Noise Ratio on Accelerometer-Based Smart Jerk Sensors in CNC Applications

Abstract

:1. Introduction

2. Theoretical Framework

2.1. Derivative of a Quantized Signal

2.2. Signal-to-Quantization Noise Ratio

2.3. SQNR Improvement by Oversampling

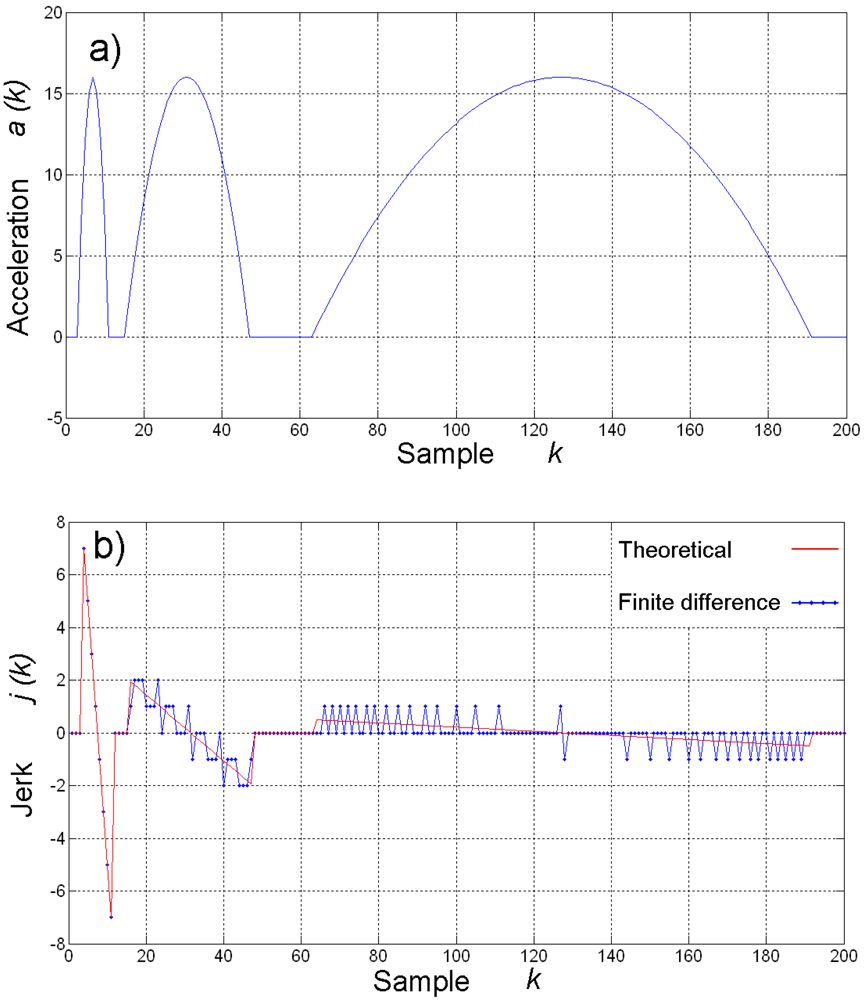

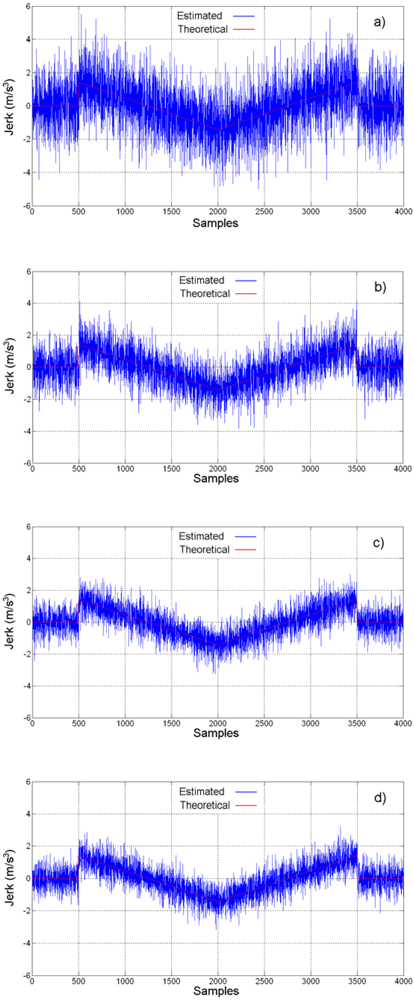

3. Simulation Results

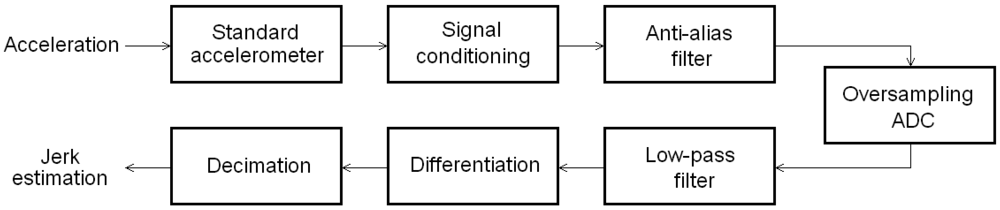

3.1. Signal Processing

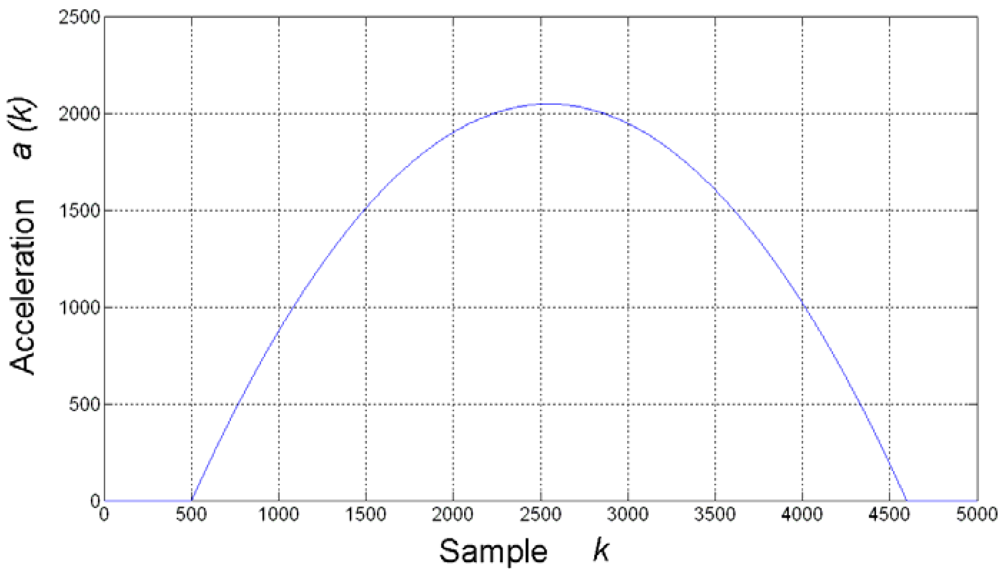

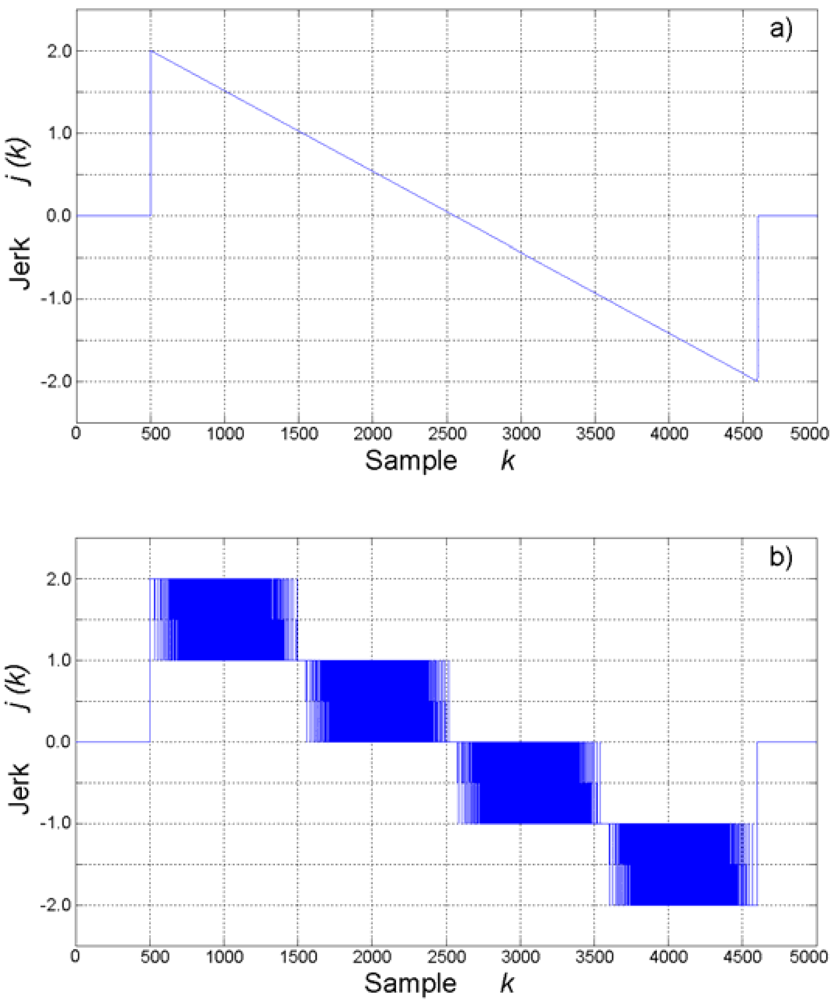

3.2. Study Case

4. Experimental Results

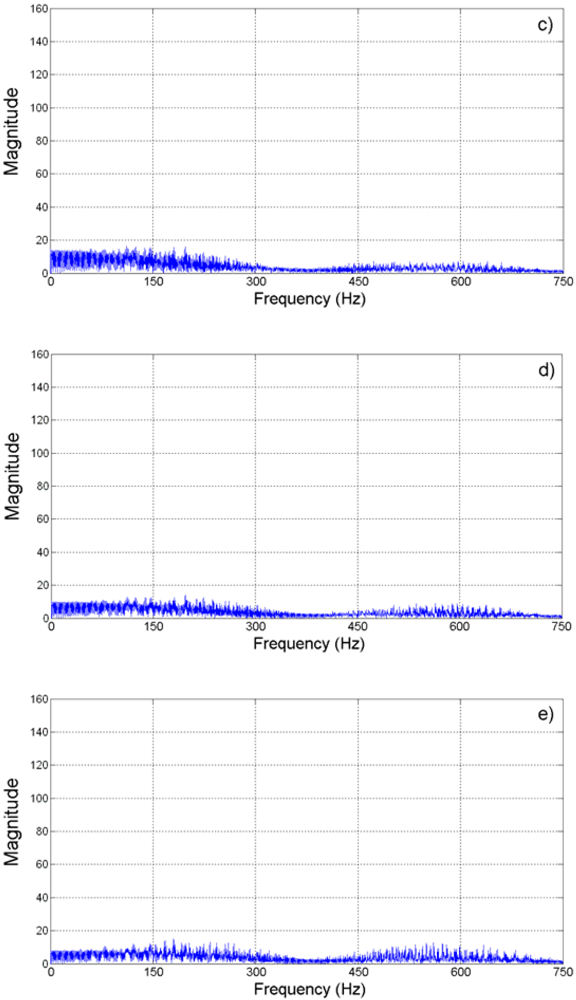

4.1. Instrumentation System

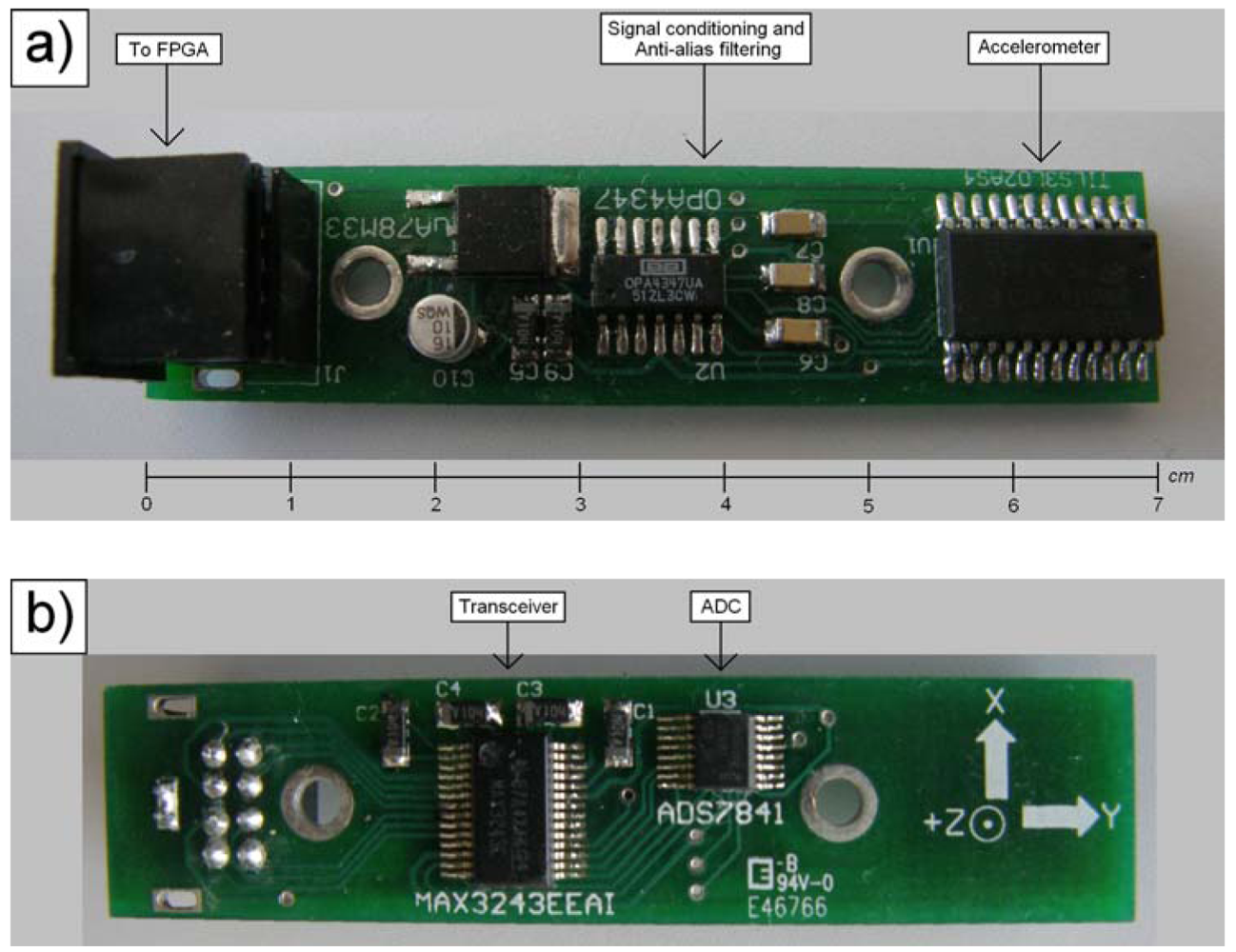

4.2. CNC Machine

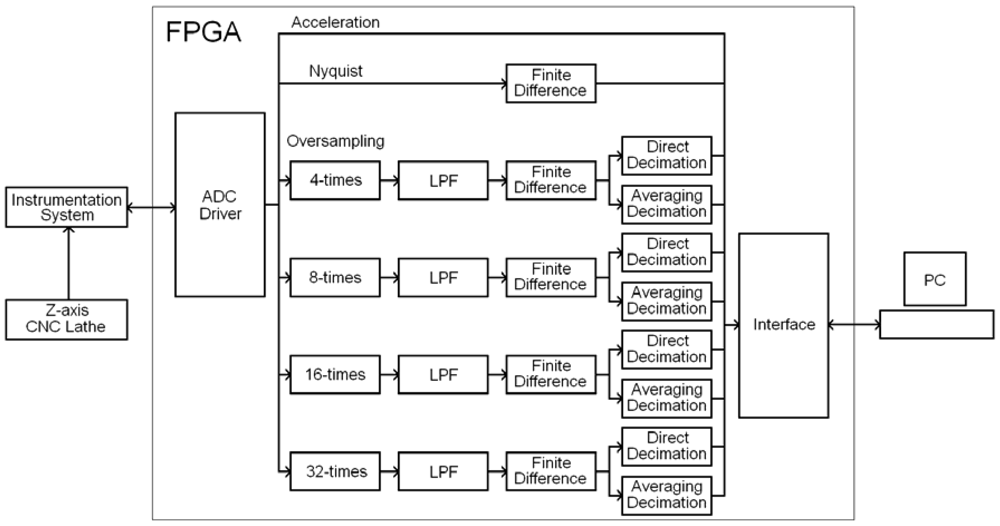

4.3. Signal Processing Unit

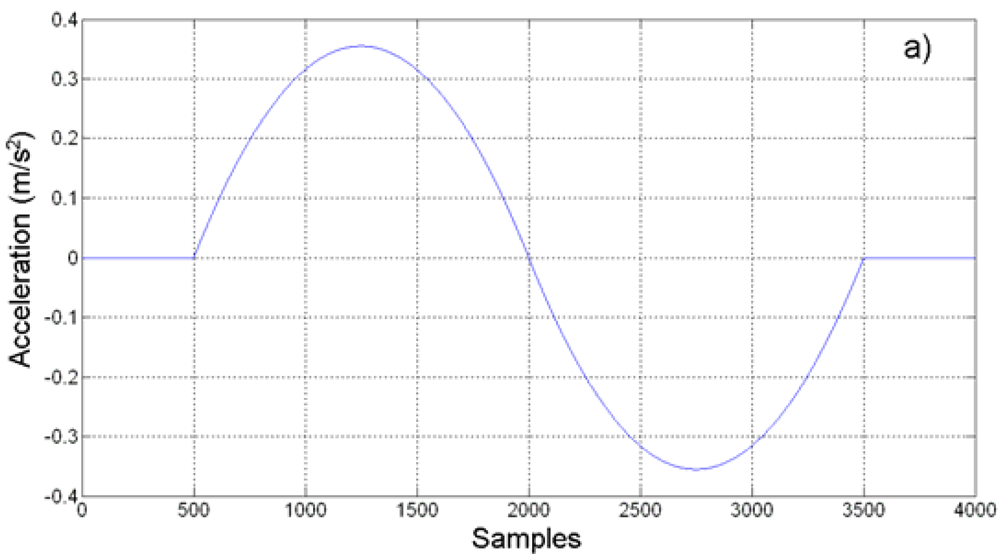

4.4. Acceleration Profile

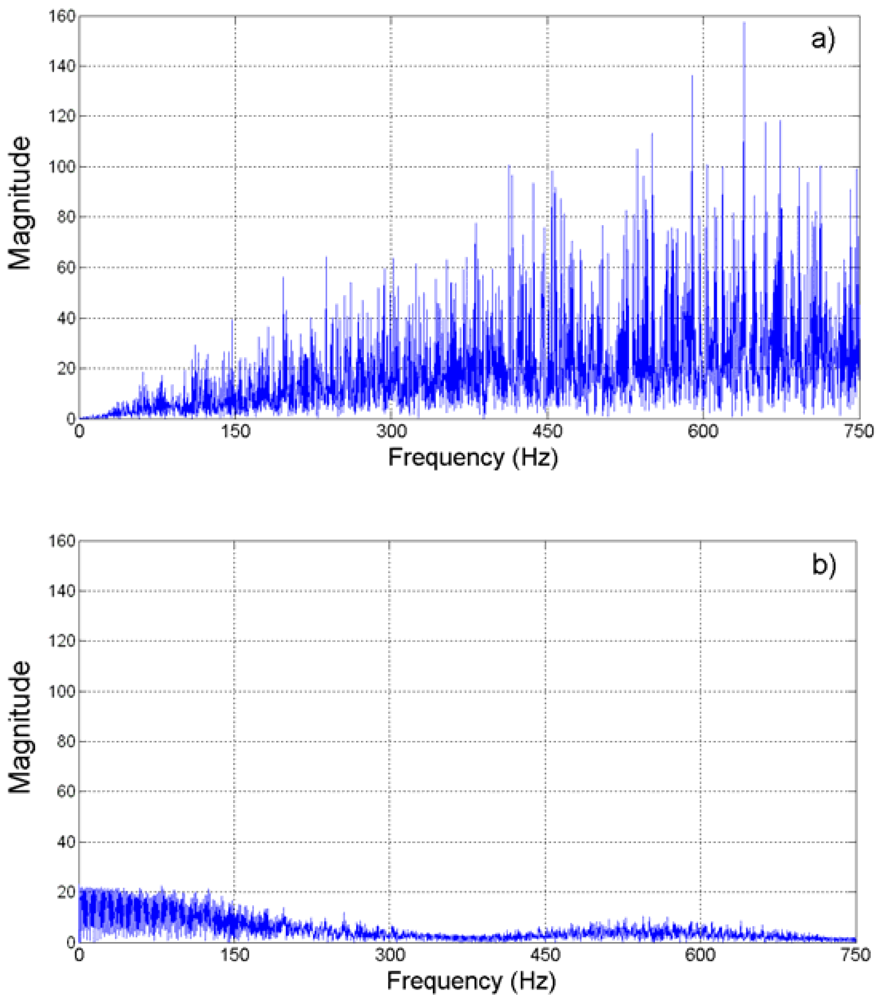

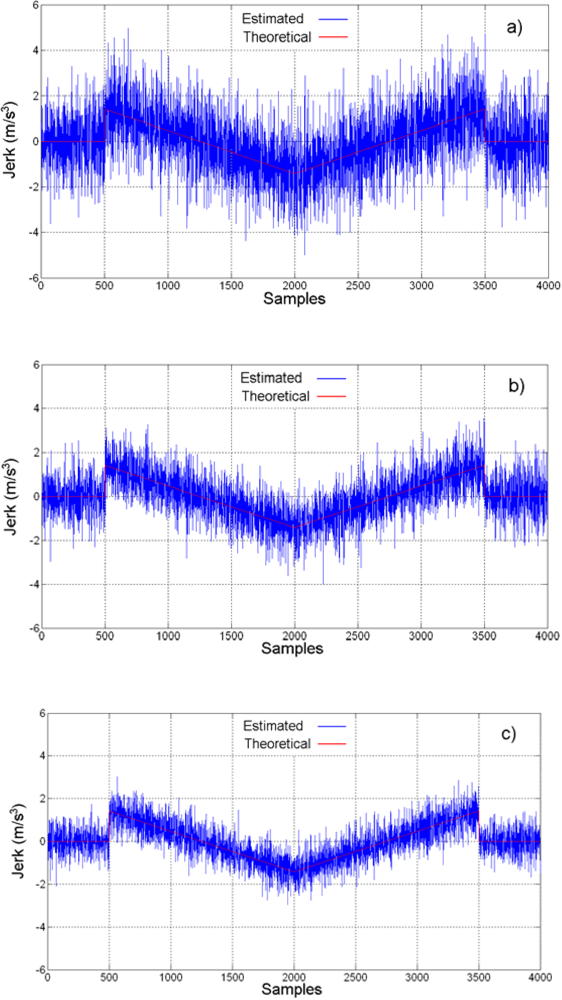

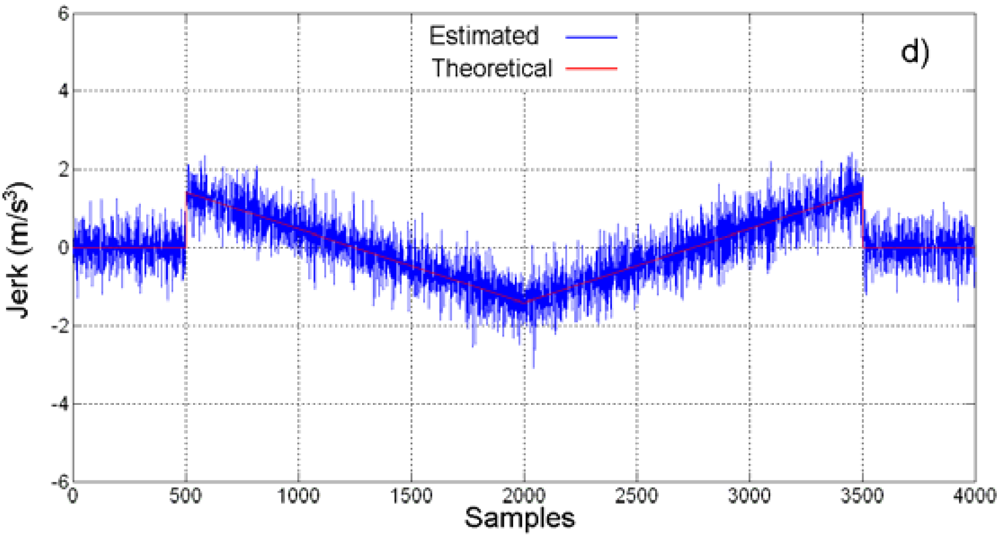

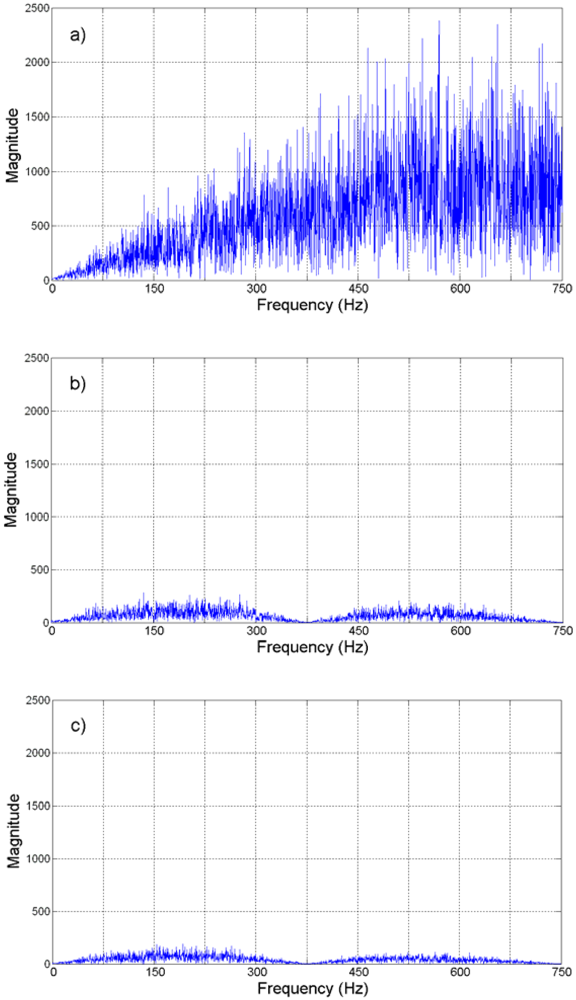

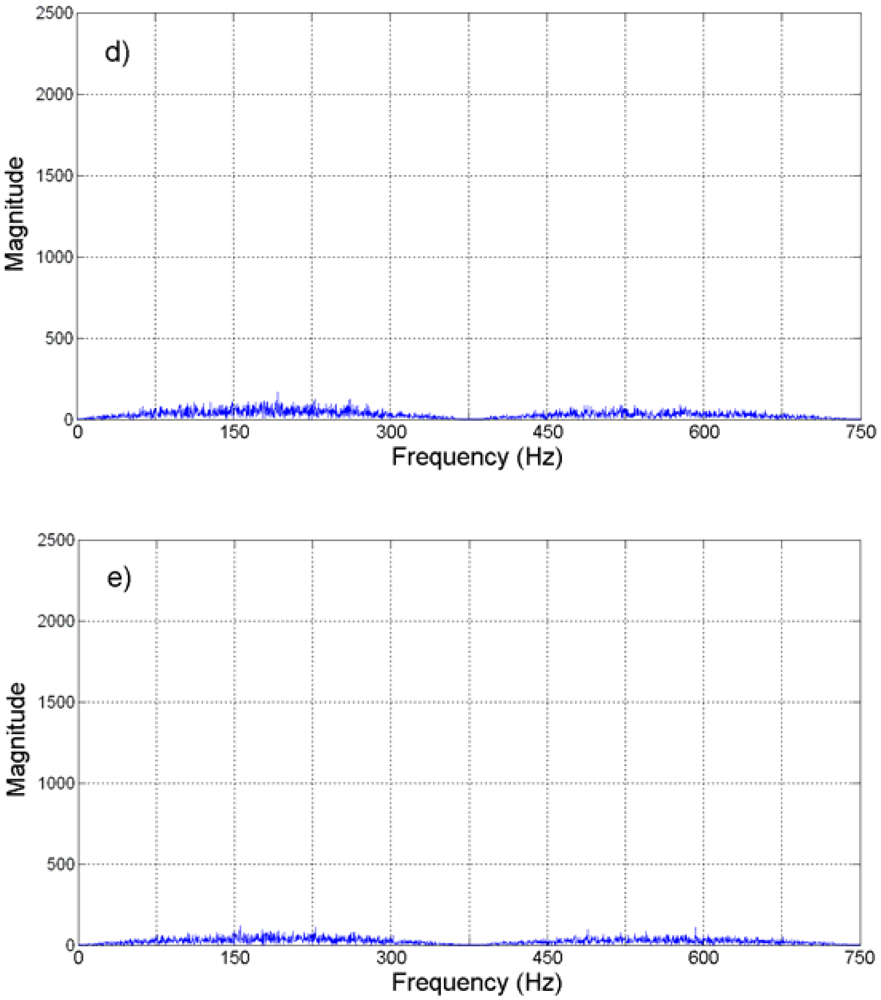

4.5. Results

4.6. Discussion

5. Conclusions

Acknowledgments

References and Notes

- Osornio-Rios, R.A.; Romero-Troncoso, R.J.; Herrera-Ruiz, G.; Castañeda-Miranda, R. FPGA implementation of higher degree polynomial acceleration profiles for peak jerk reduction in servomotors. Robot. Com-Int. Manuf. 2009, 25, 379–392. [Google Scholar]

- Erkorkmaz, K.; Altintas, Y. High speed CNC system design. Part I: jerk limited trajectory generation and quintic spline interpolation. Int. J. Mach. Tool. Manuf. 2001, 41, 1323–1345. [Google Scholar]

- Dong, J.; Ferreira, M.P.; Stori, J.A. Feed-rate optimization with jerk constraints for generating minimum-time trajectories. Int. J. Mach. Tool. Manuf. 2007, 47, 1941–1955. [Google Scholar]

- Mekid, S.; Pruschek, P.; Hernandez, J. Beyond intelligent manufacturing: A new generation of flexible intelligent NC machines. Mech. Mach. Theory 2009, 44, 466–476. [Google Scholar]

- Lorenzer, Th.; Weikert, S.; Bossoni, S.; Wegener, K. Modeling and evaluation tool for supporting decisions on the design of reconfigurable machine tools. J. Manuf. Syst. 2007, 26, 167–177. [Google Scholar]

- Nobuhiko, H.; Makoto, A.; Michihiko, T.; Takeshi, O. A study of piezoelectric jerk sensor (development of new sensor and treatment of jerk information). Nihon Kikai Gakkai Nenji Taikai Koen Ronbunshu 2005, 4, 247–248. [Google Scholar]

- Fujiyoshi, M.; Nonomura, Y.; Arai, F.; Fukuda, T. A new micro jerk sensor with viscous coupling. IEEE International Symposium on Micromechatronics and Human Science, Nagoya, Japan, Oct. 20-23, 2002; pp. 219–222.

- Chang, W.D.; Chang, D.M. Design of a higher-order digital differentiator using a particle swarm optimization approach. Mech. Syst. Signal Pr. 2008, 22, 233–247. [Google Scholar]

- De Santiago-Perez, J.J.; Osornio-Rios, R.A.; Romero-Troncoso, R.J.; Herrera-Ruiz, G.; Delgado-Rosas, M. DSP algorithm for the extraction of dynamics parameters in CNC machine tool servomechanisms from an optical incremental encoder. Int. J. Mach. Tool. Manuf. 2008, 48, 1318–1334. [Google Scholar]

- Morales-Velazquez, L.; Romero-Troncoso, R.J.; Osornio-Rios, R.A.; Cabal-Yepez, E. Sensorless jerk monitoring using an adaptive antisymmetric high- order FIR filter. Mech. Syst. Signal Pr. 2009, in press, available on-line. [Google Scholar] [CrossRef]

- Hernández, W. A survey on optimal signal processing techniques applied to improve the performance of mechanical sensors in automotive applications. Sensors 2007, 7, 84–102. [Google Scholar]

- Rivera, J.; Herrera, G.; Chacon, M.; Acosta, P.; Carrillo, M. Improved progressive polynomial algorithm for self-adjustment and optimal response in intelligent sensors. Sensors 2008, 8, 7410–7427. [Google Scholar]

- Frank, R. Understanding Smart Sensors; Artech House: Norwood, MA, USA, 2000. [Google Scholar]

- Samir, M. Further structural intelligence for sensors cluster technology in manufacturing. Sensors 2006, 6, 557–577. [Google Scholar]

- Hernández, W. Improving the responses of several accelerometers used in a car under performance tests by using Kalman filtering. Sensors 2001, 1, 38–52. [Google Scholar]

- Proakis, J.G.; Manolakis, D.K. Digital signal processing, Principles, Algorithms and Applications, 4th Ed. ed; Prentice-Hall: Englewood Cliffs, NJ, USA, 2006. [Google Scholar]

- STMicroelectronics Data Sheet LIS3L02AS4; STMicroelectronics Co.: Geneva, Switzerland, 2005.

- Texas Instruments Data Sheet ADS7841; Texas Instruments Inc.: Dallas, TX, USA, 2005.

- Altintas, Y. Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design; Cambridge University Press: Cambridge, UK, 2000; pp. 229–233. [Google Scholar]

| Oversampling rate (v) | 4 | 8 | 16 | 32 |

| SQNR improvement (dB) | 23.12 | 27.47 | 30.22 | 30.01 |

| Oversampling rate (v) | 4 | 8 | 16 | 32 |

|---|---|---|---|---|

| SQNR (dB) Direct decimation | 33.83 | 44.09 | 49.26 | 50.53 |

| SQNR (dB) Averaging decimation | 38.71 | 45.89 | 51.90 | 55.91 |

© 2009 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Rangel-Magdaleno, J.J.; Romero-Troncoso, R.J.; Osornio-Rios, R.A.; Cabal-Yepez, E. Novel Oversampling Technique for Improving Signal-to-Quantization Noise Ratio on Accelerometer-Based Smart Jerk Sensors in CNC Applications. Sensors 2009, 9, 3767-3789. https://doi.org/10.3390/s90503767

Rangel-Magdaleno JJ, Romero-Troncoso RJ, Osornio-Rios RA, Cabal-Yepez E. Novel Oversampling Technique for Improving Signal-to-Quantization Noise Ratio on Accelerometer-Based Smart Jerk Sensors in CNC Applications. Sensors. 2009; 9(5):3767-3789. https://doi.org/10.3390/s90503767

Chicago/Turabian StyleRangel-Magdaleno, Jose J., Rene J. Romero-Troncoso, Roque A. Osornio-Rios, and Eduardo Cabal-Yepez. 2009. "Novel Oversampling Technique for Improving Signal-to-Quantization Noise Ratio on Accelerometer-Based Smart Jerk Sensors in CNC Applications" Sensors 9, no. 5: 3767-3789. https://doi.org/10.3390/s90503767