Thermal Degradation, Mechanical Properties and Morphology of Wheat Straw Flour Filled Recycled Thermoplastic Composites

Abstract

:1. Introduction

2. Results and Discussion

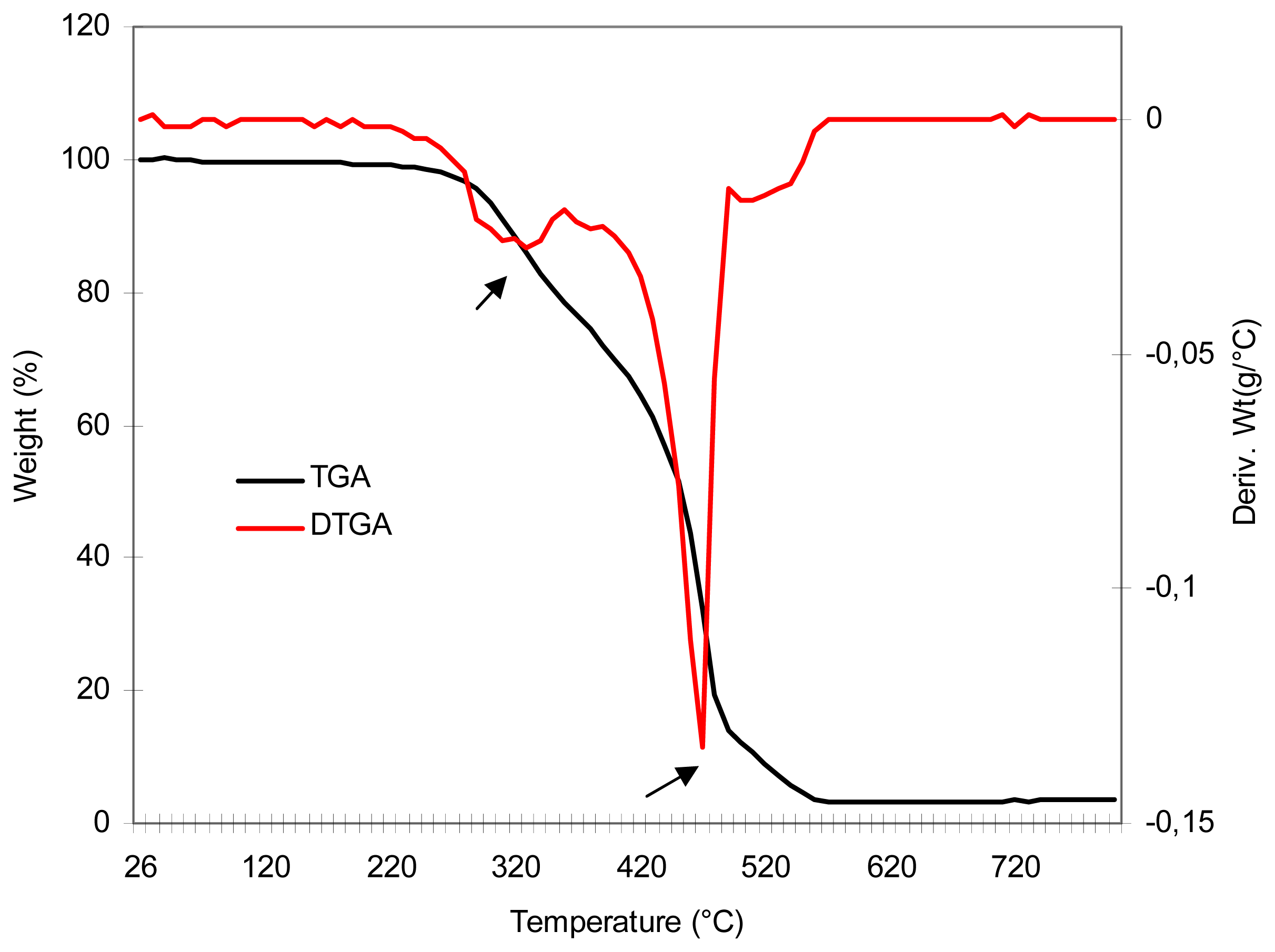

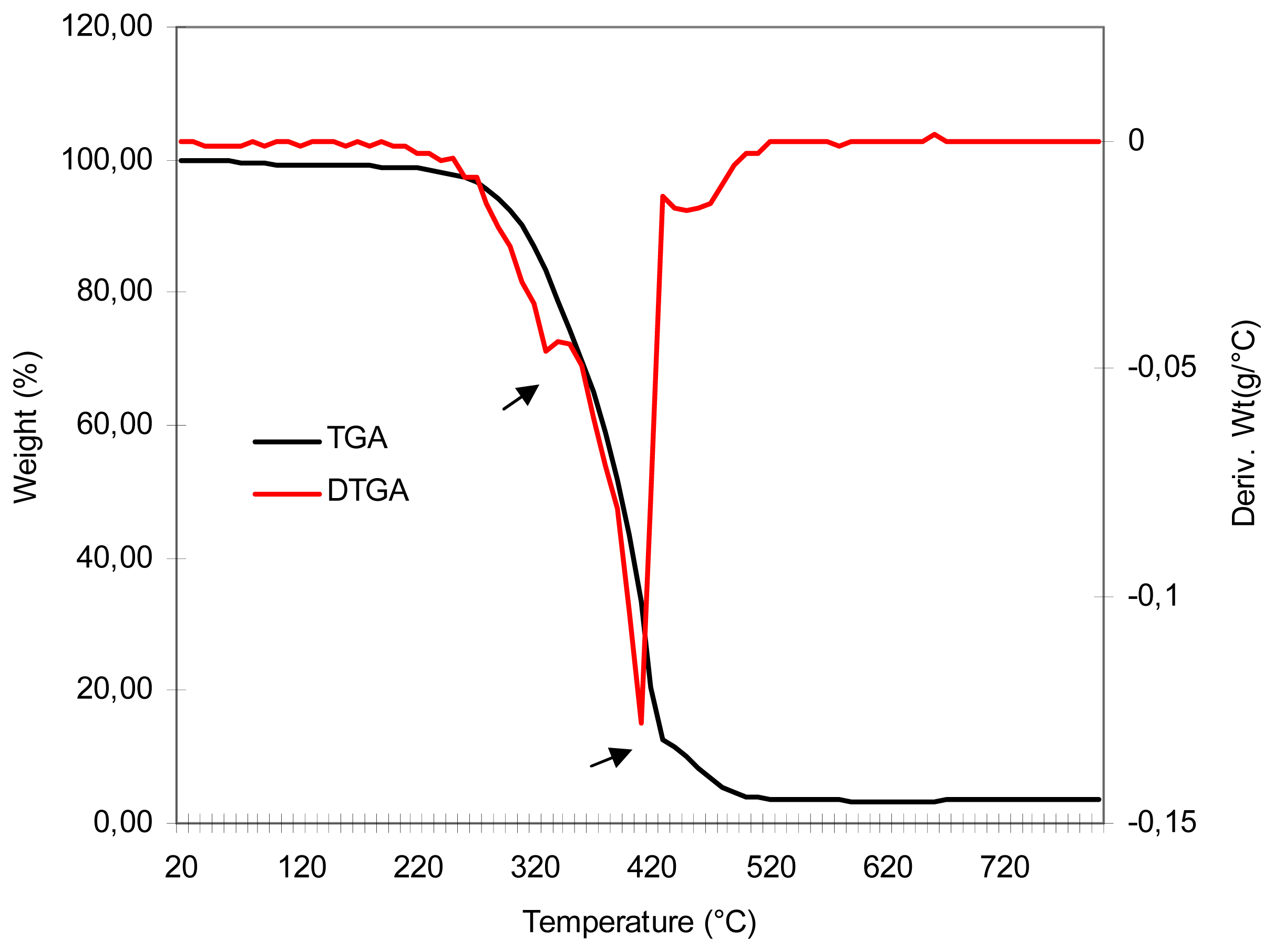

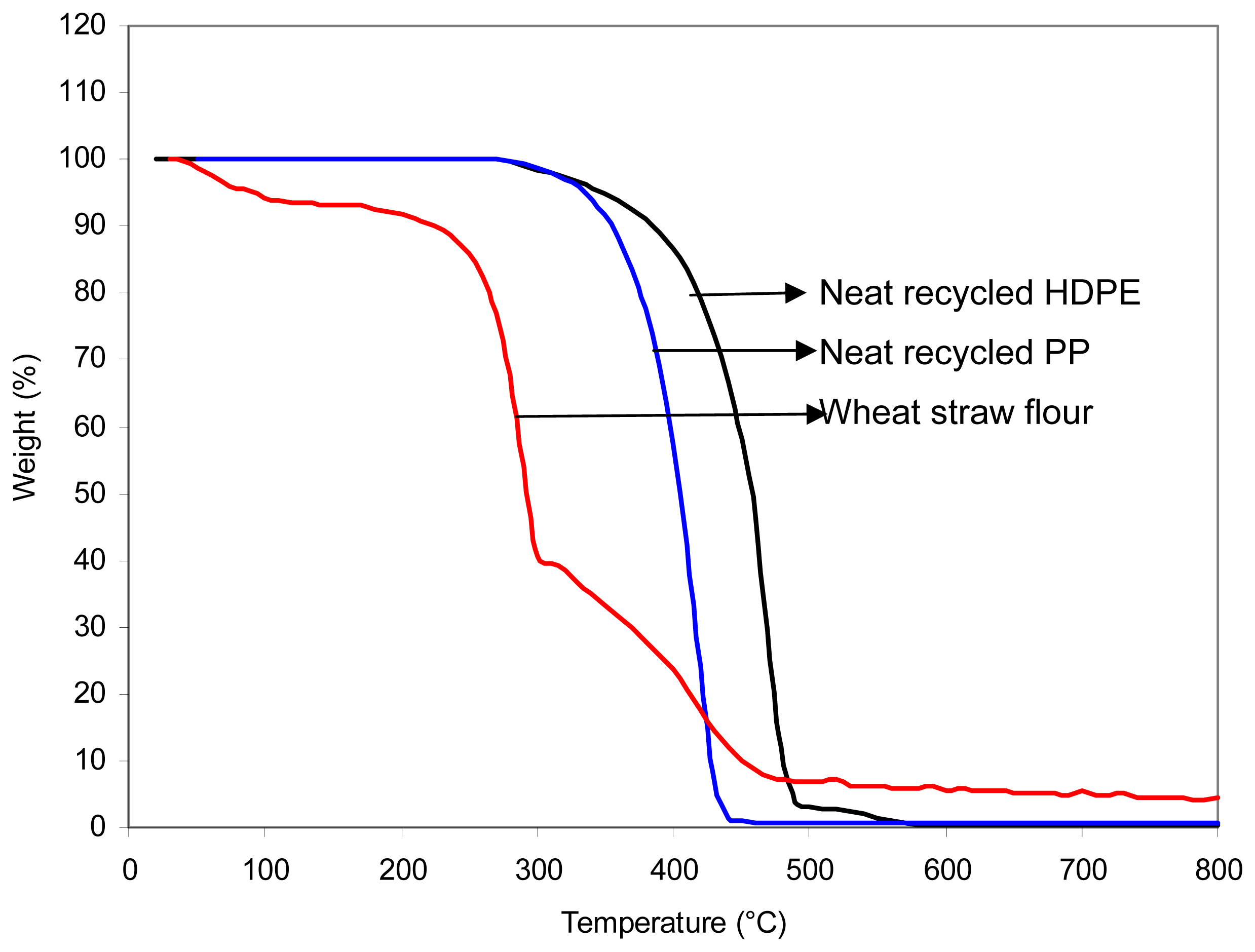

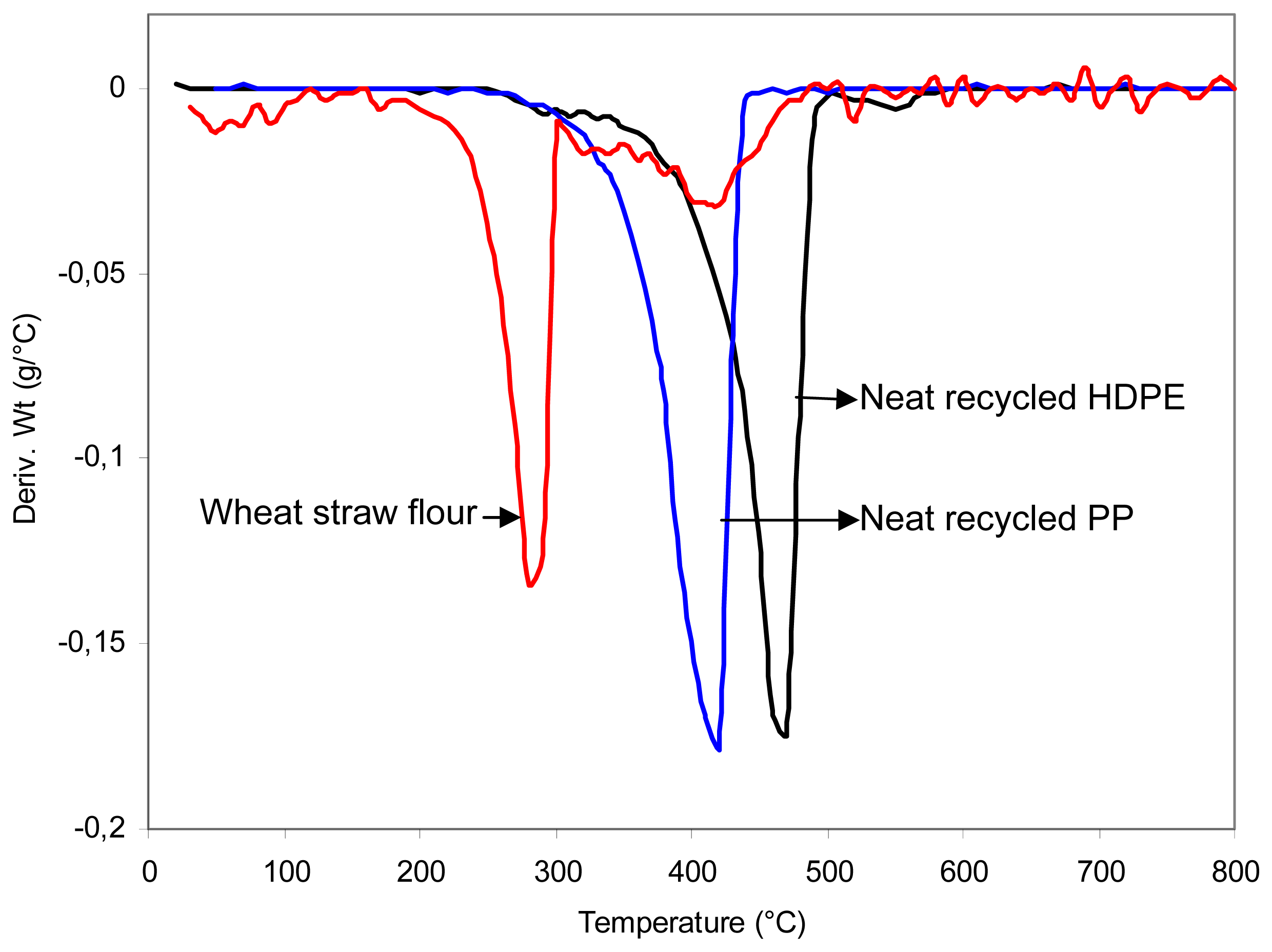

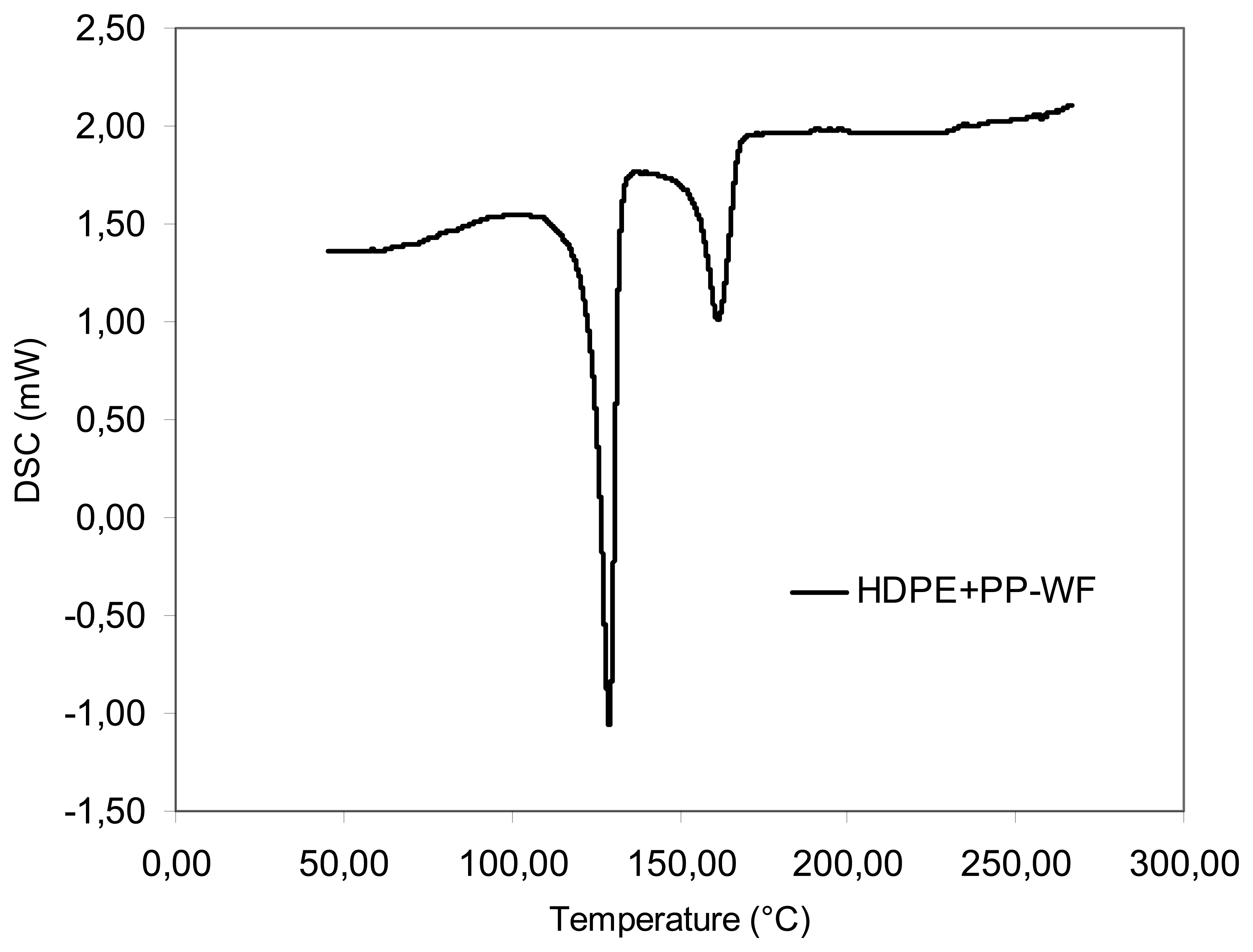

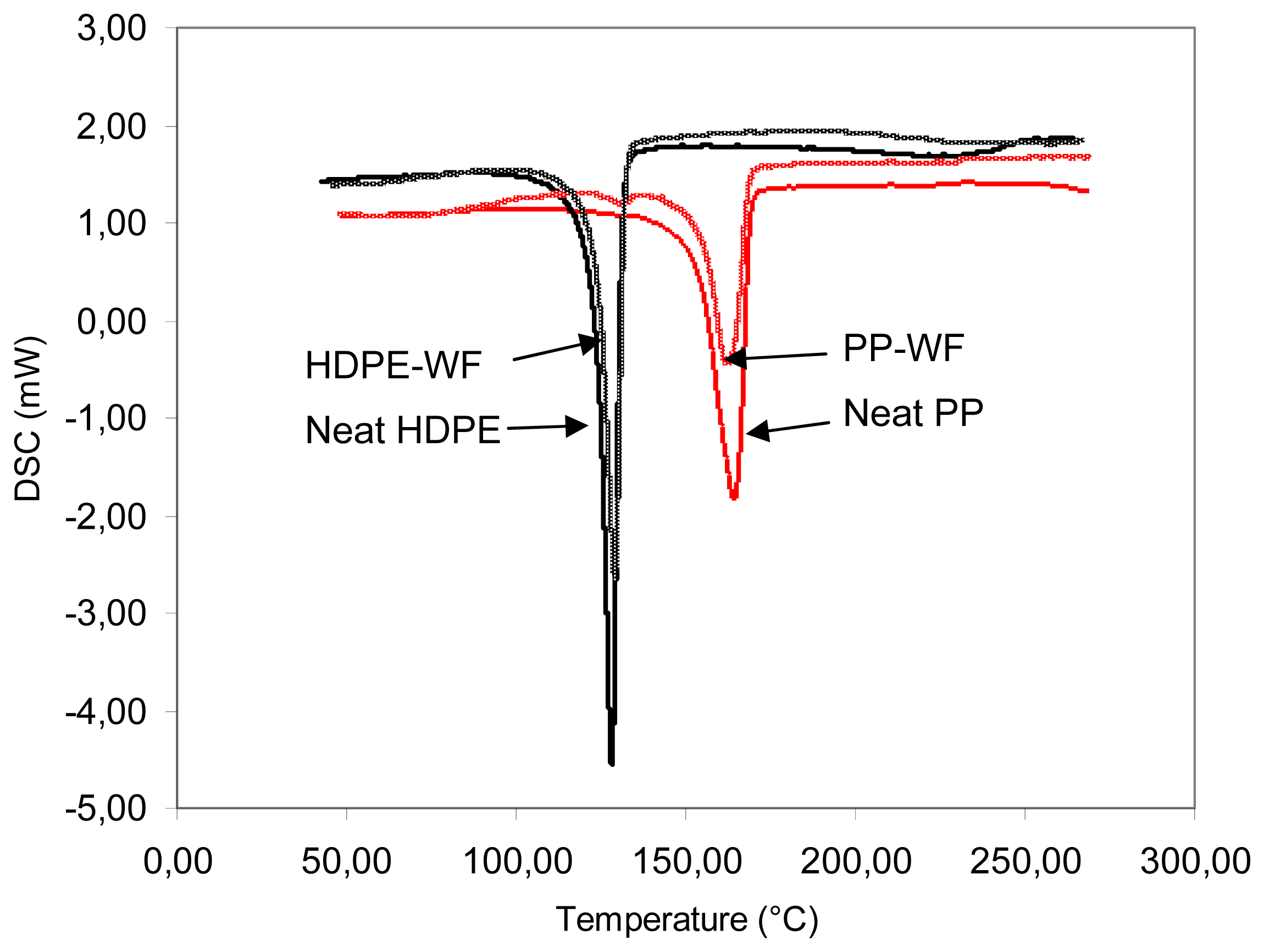

2.1. Thermogravimetric analysis (TGA) and Differential scanning calorimetry (DSC) results

2.2. Mechanical Properties

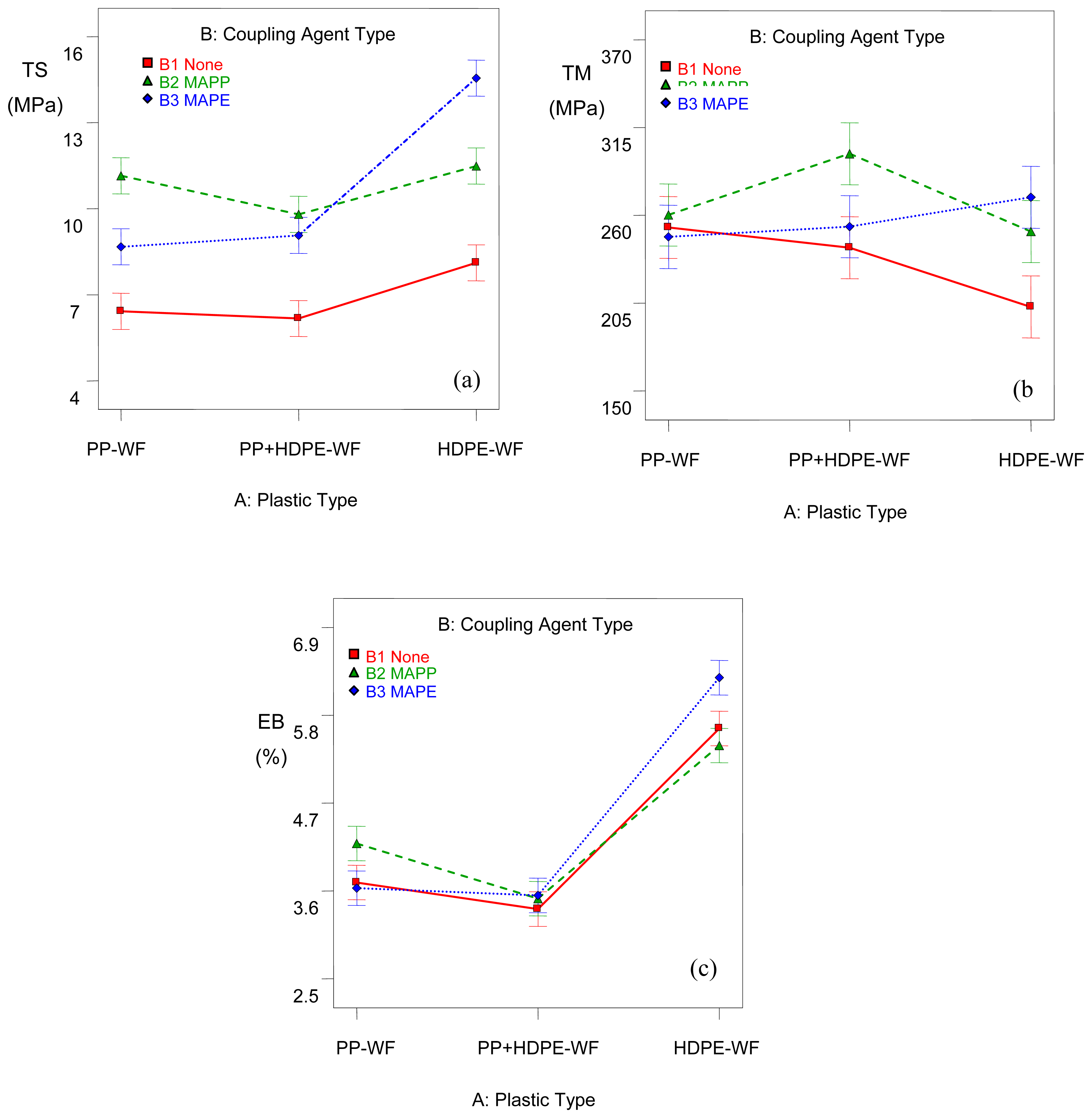

Tensile Properties

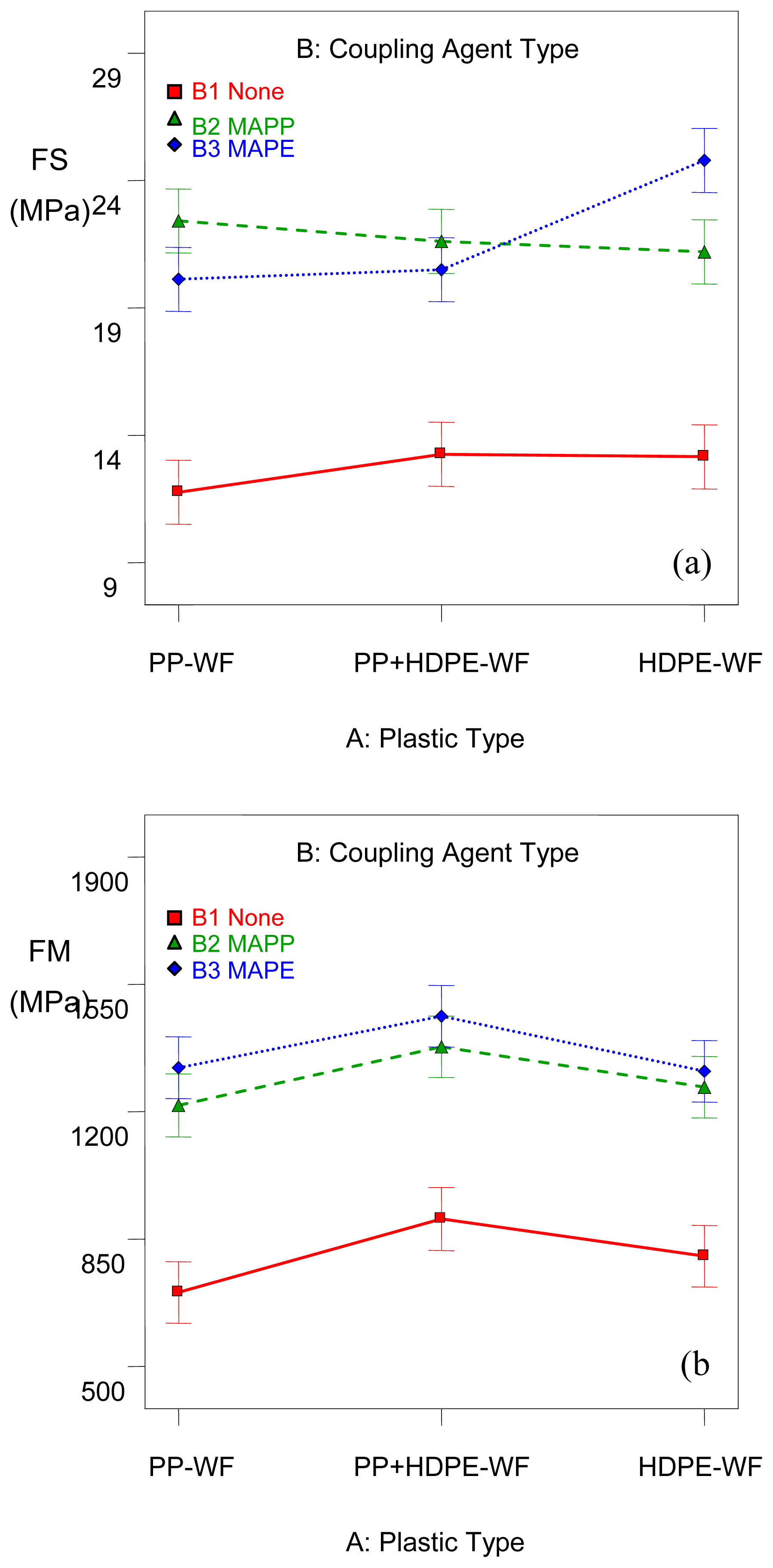

Flexural Properties

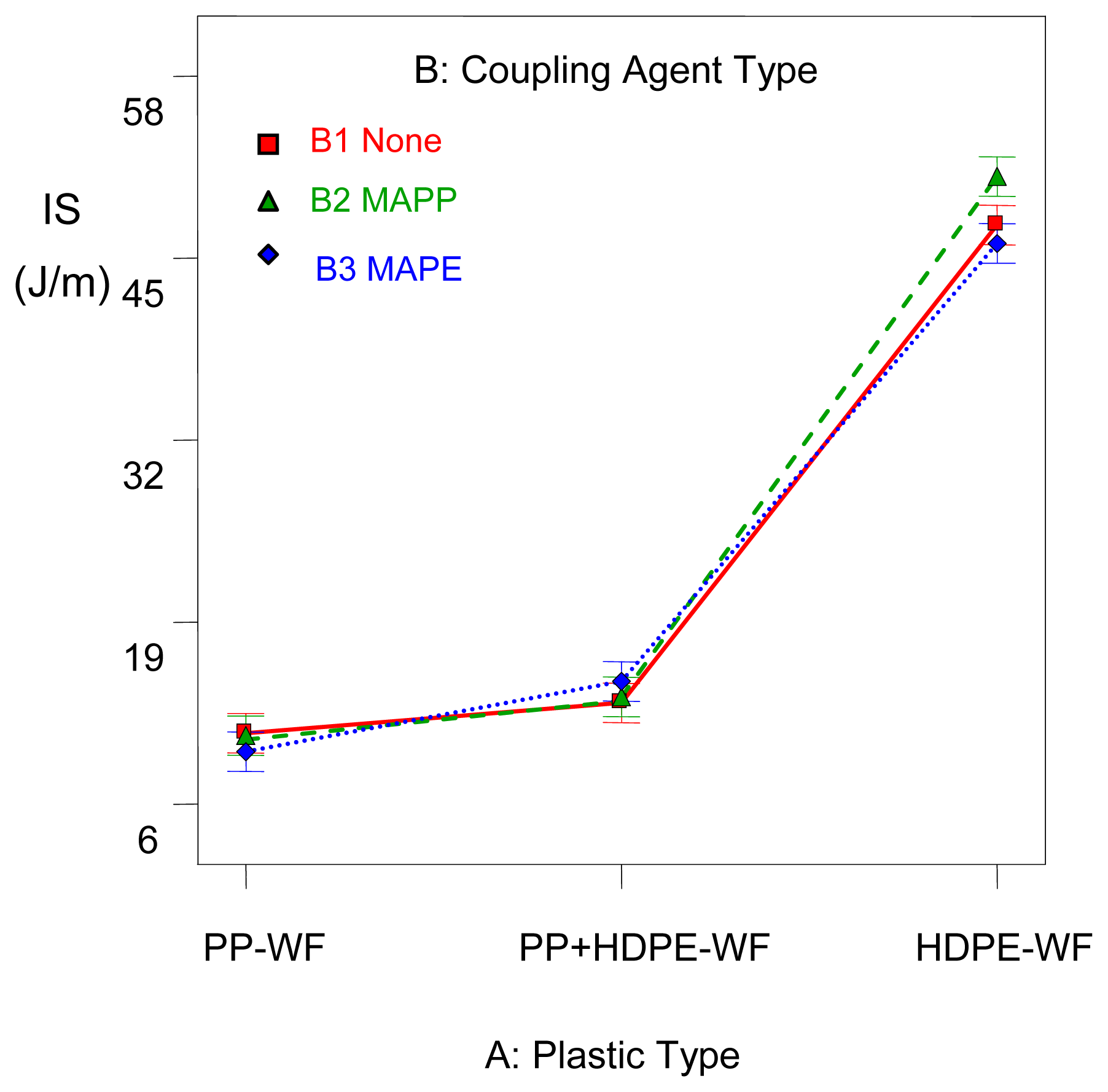

Impact Properties

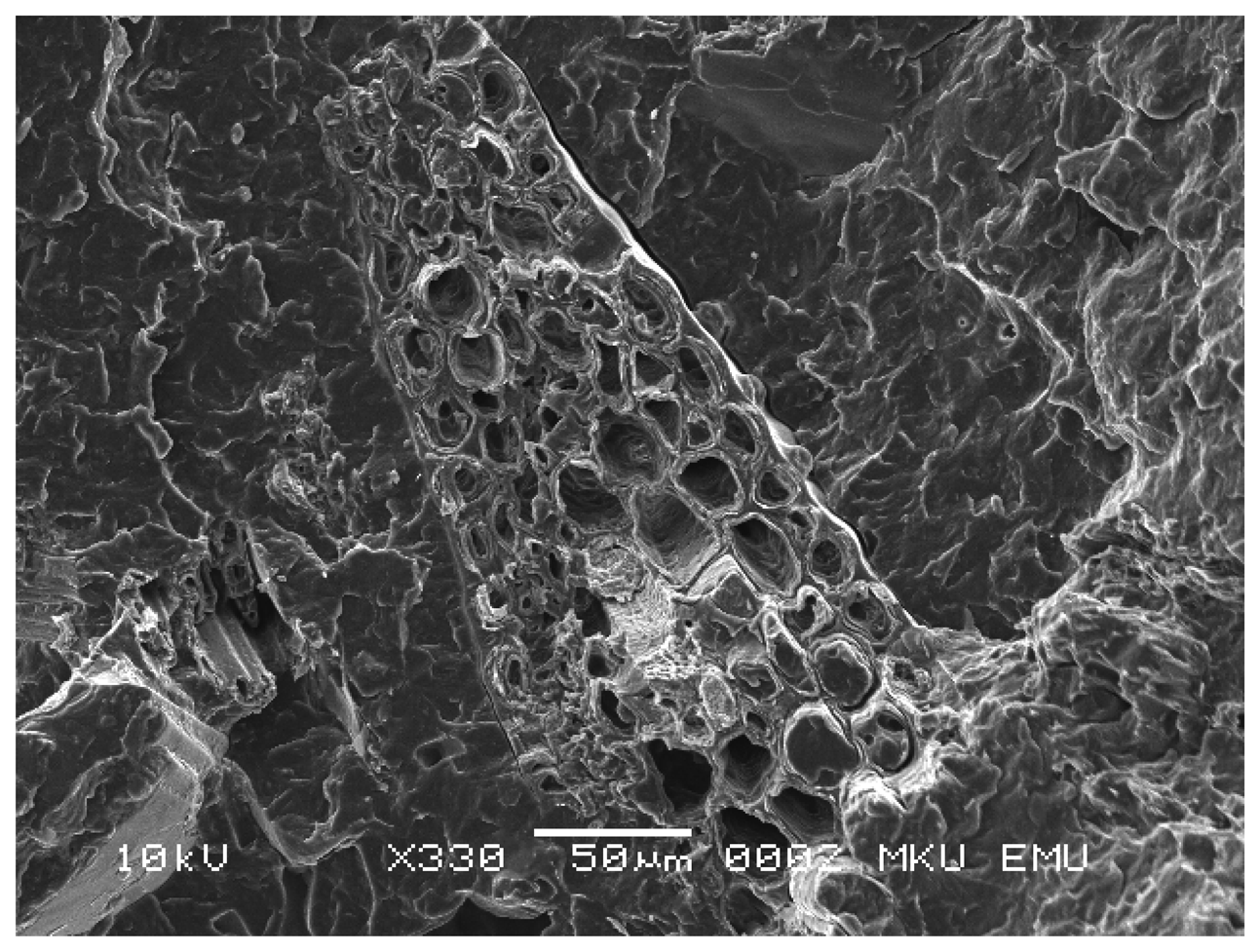

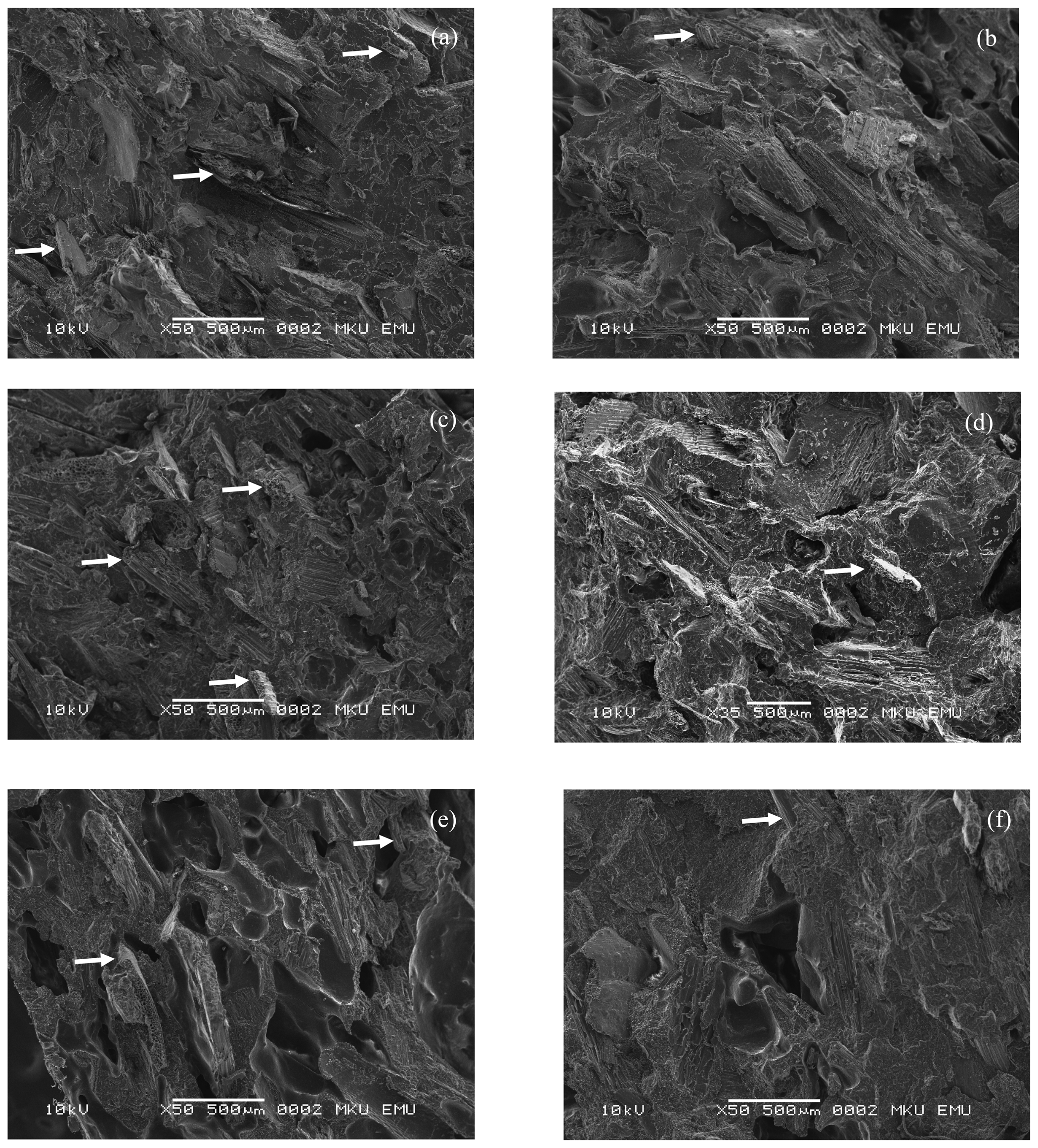

2.3. Morphology

3. Experimental Section

3.1. Materials

3.2. Composite Manufacturing

3.3. Thermogravimetry and Differential Scanning Calorimetry

3.4. Mechanical Property Testing

3.5. Scanning Electron Microscope

3.6. Statistical Analysis

Acknowledgments

References and Notes

- Clemons, C. Wood-plastic composites in the United States. The interfacing of two industries. Forest Prod. J. 2002, 52(6), 10–18. [Google Scholar]

- Caulfield, D.F.; Clemons, C.; Jacopson, R.E.; Rowell, R.M. Handbook of Wood Chemistry and Wood Composites; 2005; Taylor & Frandis: London, New York, Singapore; p. 365. [Google Scholar]

- La Mantia, F.P.; Morreale, M.; Ishak, Z.A. Processing and mechanical properties of organic filler-polypropylene composites. J. Appl. Polym. Sci. 2005, 96, 1906–1913. [Google Scholar]

- Mengeloglu, F.; Matuana, L.M.; King, J. Effects of impact modifiers on the properties of rigid PVC/wood-fiber composites. J. Vinyl. Addit. Techn. 2000, 6(3), 153–157. [Google Scholar]

- Mengeloglu, F.; Matuana, L.M. Mechanical properties of extrusion foamed rigid PVC/Wood-flour composites. J. Vinyl. Addit. Techn. 2003, 9(1), 26–31. [Google Scholar]

- Abu-Sharkh, B.F.; Kahraman, R.; Abbasi, S.H.; Hussein, I.A. Effect of epolene E-43 as a compatibilizer on the mechanical properties of palm fiber-poly(propylene) composites. J. Appl. Polym. Sci. 2004, 92, 2581–2592. [Google Scholar]

- Matuana, L.M.; Park, C.P.; Balatinecz, J.J. Cell morphology and property relationships of microcellular foamed PVC/Wood-fiber composites. Polym. Eng. Sci. 1998, 38, 1862–1872. [Google Scholar]

- Sanadi, A.R.; Caulfield, D.F.; Rowell, R.M. Reinforcing polypropylene with natural fibers. Plast. Eng. 1994, 4, 27–30. [Google Scholar]

- Chen, X.Y.; Guo, Q.P.; Mi, X.L. Bamboo fiber reinforced polypropylene composites: A study of the mechanical properties. J. Appl. Polym. Sci. 1998, 69, 1891–95. [Google Scholar]

- Gassan, J.; Bledzki, A.K. The influence of fiber surface treatment on the mechanical properties of jute—PP composites. Composites Part A 1997, 28A, 993–1000. [Google Scholar]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp sisal jute and kopak fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar]

- Joseph, K.; Pavithran, C.; Thomas, S. Influence of interfacial adhesion on the mechanical properties and fracture behaviour of short sisal fibre reinforced polymer composites. Eur. Polym. J. 1996, 32(10), 1243–1250. [Google Scholar]

- Sain, M.M.; Kokta, B.V. Effect of modified polypropylene on physical performance of saw dust filled polypropylene composite. J. Adv. Polym. Technol. 1993, 12(2), 167–183. [Google Scholar]

- Sain, M.; Li, H. High stiffness natural fiber-reinforced hybrid polypropylene composites. Polym.-Plast. Technol. Eng. 2003, 42(5), 853–862. [Google Scholar]

- Prasad, B.M.; Sain, M.M. Mechanical properties of thermally treated hemp fibers in inert atmosphere for potential composite reinforcement. Mater. Res. Innov. 2003, 7, 231–238. [Google Scholar]

- Vande Velde, K.; Keikens, P. Thermoplastic polymers; overview of several properties and their consequences in flax fiber reinforced composites. Polymer Testing 2001, 20, 885–893. [Google Scholar]

- Backiel, A. The fiber side of the equation. In Proc. Wood fiber-plastic composites; 1995; Madison, WI; pp. 3–7. [Google Scholar]

- Mengeloglu, F.; Alma, M.H. Bugday saplarının kompozit levha üretiminde kullanılması. KSU Fen ve Muhendislik Dergisi 2002, 5(2), 37–48. [Google Scholar]

- Fujimoto, M.; Taguchi, N.; Hatsutori, S. Manufacture of straw boards. Asignee: Oshinka Shinko KK. Patent, P.N.: JP 221007, I.D.:880914, 1988. [Google Scholar]

- Russell, B. Straw particleboard. Proc. of the 24thWashington State University international particleboard/composite materials symposium, Pullman, WA,, 1990; 1990; p. 264. [Google Scholar]

- Troger, F.; Pinke, G. Manufacture of boards glued with polymeric diphenylmethane-4,4-diisocyanate containing various proportions of straw. Holz als Roh- und Werkstoff 1988, 46(10), 389–395. [Google Scholar]

- Lathrop, E.C.; Naffziger, T.R.; Stivers, E.R. Boxboard from wheat straw to replace wood veneer in wirebound shipping containers. Tappi Journal 1951, 34(4), 145–152. [Google Scholar]

- Li, R. Wheat straw fiberboard production: treating straw with water, making pulp, vacuum drying, cutting edges, pressing, and scalding. Patent P.N.: CN 1055785, I.D.:911030, 1991. [Google Scholar]

- Wisniak, J.; Lauterback, A.; Vergara, P. The possible use of wheat straw and red mace for the manufacture of acoustical tile. Tappi 1962, 45, 226A–230A. [Google Scholar]

- Lathrop, E.C.; Naffziger, T.R. Evaluation of fibrous agricultural residues for structural building products. II. Fundamental studies on wheat straw fibers. Tappi 1949, 32(2), 91–96. [Google Scholar]

- Lathrop, E.C.; Naffziger, T.R. Evaluation of fibrous agricultural residues for structural building products. III. A process for the manufacture of high-grade products from wheat straw. Tappi 1949, 32(7), 319–330. [Google Scholar]

- Srivastava, A.C.; Gupta, R. Feasibility of using trash and straw as a thermal insulator. Biological Wastes 1990, 33(1), 63–65. [Google Scholar]

- Polis, C. Binding composition from gypsum plaster, lightweight granular aggregate, and wheat paste. Patent P.N.: US 3519450, I.D.: 700707, 1970. [Google Scholar]

- Cheng, Z.; Li, Z. Development of thermoplastic composites with mixed fillers. Suliao 1988, 17(5), 37–40. [Google Scholar]

- Hornsby, P.R.; Hinrichsen, E.; Tarverdi, K. Preparation and properties of polypropylene composites reinforced with wheat and flax straw fibers Part I. Fibre characterization. Journal of Material Science 1997, 32, 443–449. [Google Scholar]

- Mohini, S.; Panthapulakkal, S. Bioprocess preparation of wheat straw fibers and their characterization. Industrial Crops and Products 2006, 23, 1–8. [Google Scholar]

- Hornsby, P.R.; Hinrichsen, E.; Tarverdi, K. Preparation and properties of polypropylene composites reinforced with wheat and flax straw fibers Part II. Analysis of composite microstructure and mechanical properties. Journal of Material Science 1997, 32, 1009–1015. [Google Scholar]

- Panthapulakkal, S.; Zereshkian, A.; Sain, M. Preparation and characterization of wheat straw fibers for reinforcing applications in the injection molded thermoplastic composites. Bioresource Technolog 2006, 97, 265–272. [Google Scholar]

- Sanadi, A.R.; Young, R.A.; Clemons, C.; Rowel, R.M. Recycled newspaper fibers as reinforcing fillers in thermoplastics: Part I - Analysis of tensile and impact properties of polypropylene. J. Reinf. Plast. Comp. 1994, 13, 54–58. [Google Scholar]

- Sanadi, A.R.; Caulfield, D.F.; Rowell, R.M. Reinforcing polypropylene with natural fibers. Plast. Eng. 1994, 4, 27–30. [Google Scholar]

- Woodhams, R.T.; Thomas, G.; Rodgers, D.K. Wood fibers as reinforcing fillers for polyolefins. Polym. Eng. Sci. 1994, 24, 1166–1171. [Google Scholar]

- Matuana, L.M.; Balatinecz, J.J.; Park, C.B.; Sodhi, R.N.S. X-ray photoelectron spectroscopy study of silane-treated newsprint-fibers. Wood Sci. Technol. 1999, 33(4), 259–270. [Google Scholar]

- Coutinho, F.M.B.; Costa, T.H.S.; Carvalho, C.D.L. Polypropylene-wood fiber composites: Effect of treatment and mixing conditions on mechanical properties. J. Appl. Polym. Sci. 1998, 65, 1227–1235. [Google Scholar]

- Qiu, W.; Zhang, F.T.; Endo, T.; Hirotsu, T. Isocyanate as a compatibilizing agent on the properties of highly Crystalline cellulose/polypropylene composites. J. Mater. Sci. 2005, 40, 3607–3614. [Google Scholar]

- Qiu, W.; Zhang, F.T.; Endo, T.; Hirotsu, T. Milling-induced etherification between cellulose and maleated polypropylene. J. Appl. Polym. Sci. 2003, 91, 1703–1709. [Google Scholar]

- Jana, C.J.; Prieto, A. Natural fiber composites of high-temperature thermoplastics polymers: Effect of coupling agents. J. Appl. Polym. Sci. 2002, 86, 2168–2173. [Google Scholar]

- Lu, J.Z.; Wu, Q.; McNabb, H.S. Chemical coupling in wood fiber and polymer composites: A review of coupling and treatments. Wood Fiber Sci. 2000, 32(1), 88–104. [Google Scholar]

- Mengeloglu, F.; Kurt, R.; Gardner, D.J.; O'Neill, S. Mechanical properties of extruded high density polyethylene (HDPE)- and polypropylene (PP)- wood flour decking boards. Iran Polym. J. 2007, 16(7), 477–487. [Google Scholar]

- Yang, H.S.; Wolcott, M.P.; Kim, H.S.; Kim, S.; Kim, H.J. Effect of different compatibilizing agents on the mechanical properties of lignocellulosic material filled polyethylene bio-composites. Compos. Struct. 2007, 79, 369–375. [Google Scholar]

- Li, Q.; Matuana, L.M. Effectiveness of maleated and acryclic acid-functionalized polyolefin coupling agents for HDPE-wood-flour composites. J. Thermoplast. Compos. 2003, 16, 551–564. [Google Scholar]

- Lai, S.M.; Yeh, F.C.; Wang, Y.; Chan, H.C.; Shen, H.F. Comparative study of maleated polyolefins as compatibilizers for polyethylene/wood flour composites. J. Appl. Polym. Sci. 2003, 87, 487–496. [Google Scholar]

- Wang, Y.; Yeh, F.C.; Lai, S.M.; Chan, H.C.; Shen, H.F. Effectiveness of functionalized polyolefins as compatibilizers for polyethylene/wood flour composites. Polym. Eng. Sci. 2003, 43(4), 933–945. [Google Scholar]

- Sombatsompop, N.; Yotinwattanakumtorn, C.; Thongpin, C. Influence of type and concentration of maleic anhydride grafted polypropylene and impact modifiers on mechanical properties of PP/Wood sawdust composites. J. Appl. Polym. Sci. 2005, 97, 475–484. [Google Scholar]

- Chan, J.H.; Balke, S.T. The thermal degradation kinetics of polypropylene: Part II. Time-temperature superposition. Polym. Degrad. Stabil. 1997, 57(2), 127–134. [Google Scholar]

- ASTM D 6662. In Standard specification for polyolefin-based plastic lumber decking boards; Annual Book of ASTM Standards; West Conshohocken, P.A., 2007; Vol. 08, p. 03.

- ASTM D 790. In Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials; Annual Book of ASTM Standards; West Conshohocken, P.A., 2007; Vol. 08, p. 01.

- ASTM D 638. In Standard test methods for tensile properties of plastics; Annual Book of ASTM Standards; West Conshohocken, P.A., 2007; Vol. 08, p. 01.

- ASTM D 256. In Standard test methods for determining the izod pendulum impact resistance of plastics; Annual Book of ASTM Standards; West Conshohocken, P.A., 2007; Vol. 08, p. 01.

| Descriptions | Onset Temperature (°C) | Peak Temperature (°C) | Weight Loss (%) | Residue after 500 °C (%) | |

|---|---|---|---|---|---|

| Neat HDPE | 434.1 | 470.0 | 70.5 | 3.0 | |

| Neat PP | 377.0 | 420.5 | 76.0 | 0.7 | |

| Wheat-Straw-Flour | 178.5 | 280.0 | 32.3 | 7.0 | |

| 1stpeak | 2ndpeak | ||||

| HDPE-WF | 421.9 | 330.1 | 470.2 | 67.6 | 12.3 |

| PP-WF | 364.9 | 330.0 | 410.0 | 66.6 | 4.1 |

| HDPE+PP-WF | 373.4 | 330.1 | 440.0 | 68.0 | 7.6 |

| Descriptions | Onset Temperature (°C) | Melting Temperature (°C) | ||

|---|---|---|---|---|

| Neat HDPE | 107.2 | 128.5 | ||

| Neat PP | 130.8 | 164.8 | ||

| HDPE-WF | 105.6 | 129.3 | ||

| PP-WF | 142.12 | 163.4 | ||

| 1stpeak | 2ndpeak | 1stpeak | 2ndpeak | |

| HDPE+PP-WF | 109.4 | 140.7 | 129.4 | 162.5 |

| Specimen ID | Tensile Strength(MPa)1 | TensileModulus(MPa) | Elongationat Break(%) | FlexuralStrength(MPa) | FlexuralModulus(MPa) | ImpactStrength(J/m) | |

|---|---|---|---|---|---|---|---|

| HDPE-WF | None | 8.111 | 202.6 | 5.63 | 13.16 | 802.9 | 47.37 |

| (1.44)2 | (17.5) | (0.54) | (1.64) | (130.9) | (6.42) | ||

| MAPP | 11.49 | 249.8 | 5.42 | 21.20 | 1267.2 | 50.83 | |

| (1.38) | (72.9) | (0.71) | (1.92) | (133.1) | (2.86) | ||

| MAPE | 14.55 | 271.3 | 6.27 | 24.79 | 1311.1 | 46.04 | |

| (0.71) | (42.0) | (0.38) | (2.18) | (140.0) | (4.73) | ||

| PP- WF | None | 6.42 | 252.4 | 3.70 | 17.76 | 703.2 | 11.06 |

| (1.11) | (52.8) | (0.62) | (1.06) | (126.0) | (1.50) | ||

| MAPP | 11.15 | 260.3 | 4.19 | 22.41 | 1296.5 | 10.89 | |

| (1.85) | (36.9) | (0.20) | (3.20) | (291.6) | (1.71) | ||

| MAPE | 8.67 | 273.8 | 3.63 | 20.12 | 1320.9 | 9.74 | |

| (1.61) | (91.54) | (0.36) | (3.75) | (153.5) | (2.95) | ||

| HDPE/PP-WF | None | 6.17 | 239.7 | 3.37 | 13.25 | 969.6 | 13.22 |

| (1.93) | (39.5) | (0.70) | (3.94) | (323.2) | (1.26) | ||

| MAPP | 9.80 | 298.5 | 3.50 | 21.61 | 1378.1 | 13.66 | |

| (1.12) | (49.8) | (0.28) | (2.42) | (187.7) | (1.13) | ||

| MAPE | 9.07 | 252.9 | 3.54 | 20.50 | 1462.3 | 14.76 | |

| (1.14) | (17.8) | (0.26) | (3.73) | (313.1) | (1.29) | ||

| Dependent Variable | Source of variation | DF | SS | MS | F | P |

|---|---|---|---|---|---|---|

| Tensile Strength | A: Plastic Type | 2 | 163,26 | 81,63 | 40,87 | <0,001 |

| B: Coupling Agent Type | 2 | 302,19 | 151,09 | 75,65 | <0,001 | |

| Type | ||||||

| A*B | 4 | 90,96 | 22,74 | 11,39 | <0,001 | |

| Residual | 81 | 161,79 | 2,00 | |||

| Total | 89 | 718,20 | ||||

| Tensile Modulus | A: Plastic Type | 2 | 7593,94 | 3796,97 | 2,01 | 0,141 |

| B: Coupling Agent Type | 2 | 22479,56 | 11239.7 8 | 5,95 | 0,004 | |

| Type | ||||||

| A*B | 4 | 22169,16 | 5542,29 | 2,93 | 0,026 | |

| Residual | 81 | 151219,50 | 2695,302 | |||

| Total | 89 | 203844,2 7 | ||||

| Elongation at Break | A: Plastic Type | 2 | 91,70 | 45,85 | 194,8 6 | <0,001 |

| B: Coupling Agent Type | 2 | 0,91 | 0,45 | 1,93 | 0,152 | |

| A*B | 4 | 5,01 | 1,25 | 5,32 | <0,001 | |

| Residual | 81 | 19,06 | 0,24 | |||

| Total | 89 | 116,68 | ||||

| Dependent Variable | Source of variation | DF | SS | MS | F | P |

|---|---|---|---|---|---|---|

| Flexural Strength | A: Plastic Type | 2 | 43,27 | 21,64 | 2,71 | 0,073 |

| B: Coupling Agent Type | 2 | 1637,69 | 818,84 | 102,58 | <0,001 | |

| Type | ||||||

| A*B | 4 | 112,72 | 28,18 | 3,53 | 0,010 | |

| Residual | 81 | 646,57 | 7,98 | |||

| Total | 89 | 2440,25 | ||||

| Flexural Modulus | A: Plastic Type | 2 | 435600,72 | 2178000,00 | 6,12 | 0,003 |

| B: Coupling Agent Type | 2 | 5407873,71 | 2703000,00 | 75,98 | <0,001 | |

| Type | ||||||

| A*B | 4 | 30928,41 | 7732,10 | 0,22 | 0,928 | |

| Residual | 81 | 2811422,24 | 35580,08 | |||

| Total | 89 | 8766546,30 | ||||

| Dependent Variable | Source of variation | DF | SS | MS | F | P |

|---|---|---|---|---|---|---|

| Izod Impact Strength | A: Plastic Type | 2 | 25876,28 | 12938,14 | 1291,73 | <0,001 |

| B: Coupling Agent Type | 2 | 42,541 | 21,27 | 2,12 | 0,126 | |

| Type | ||||||

| A*B | 4 | 102,51 | 25,63 | 2,56 | 0,045 | |

| Residual | 81 | 811,31 | 10,02 | |||

| Total | 89 | 26832,64 |

| Descriptions | Licomont AR 504 (MAPP) | Licocene PE MA 4351 (MAPE) |

|---|---|---|

| Appearance | Yellowish fine grain | White fine grain |

| Softening point | 156°C | 123°C |

| Acid Value | 41 mg KOH/g | 43 mg KOH/g |

| Density at 23°C | 0.91 g/cm3 | 0.99 g/cm3 |

| Viscosity at 140 °C | 800 mPa.s | 300 mPa.s |

| Factors | Levels |

|---|---|

| Plastic Type | Recycled Polypropylene (PP) |

| Recycled High Density Polyethylene (HDPE) | |

| %50 PP + %50 HDPE (HDPE/PP) | |

| Coupling Agent Type (Maleated polyolefins) | None |

| Maleated anhydride grafted polypropylene (MAPP) | |

| Maleated anhydride grafted polyethylene (MAPE) | |

© 2008 by MDPI Reproduction is permitted for noncommercial purposes.

Share and Cite

Mengeloglu, F.; Karakus, K. Thermal Degradation, Mechanical Properties and Morphology of Wheat Straw Flour Filled Recycled Thermoplastic Composites. Sensors 2008, 8, 500-519. https://doi.org/10.3390/s8010500

Mengeloglu F, Karakus K. Thermal Degradation, Mechanical Properties and Morphology of Wheat Straw Flour Filled Recycled Thermoplastic Composites. Sensors. 2008; 8(1):500-519. https://doi.org/10.3390/s8010500

Chicago/Turabian StyleMengeloglu, Fatih, and Kadir Karakus. 2008. "Thermal Degradation, Mechanical Properties and Morphology of Wheat Straw Flour Filled Recycled Thermoplastic Composites" Sensors 8, no. 1: 500-519. https://doi.org/10.3390/s8010500