Novel Planar Electromagnetic Sensors: Modeling and Performance Evaluation

Abstract

:1. Introduction

- Power stations – nuclear and conventional power plants.

- Petro-chemical industry.

- Transportation – railways.

- Food industry - Quality assurance of food products.

- Medical sciences.

- Civil engineering - inspection of concrete structures, bridges, infrastructure due to aging problem.

- Aircraft - fatigue estimation in aircraft surface and other parts.

- Pipe inspection - Inspection of pipes and piping systems in industrial plants. The pipes are used for carrying oils, gases, waters, milks etc.

- Others.

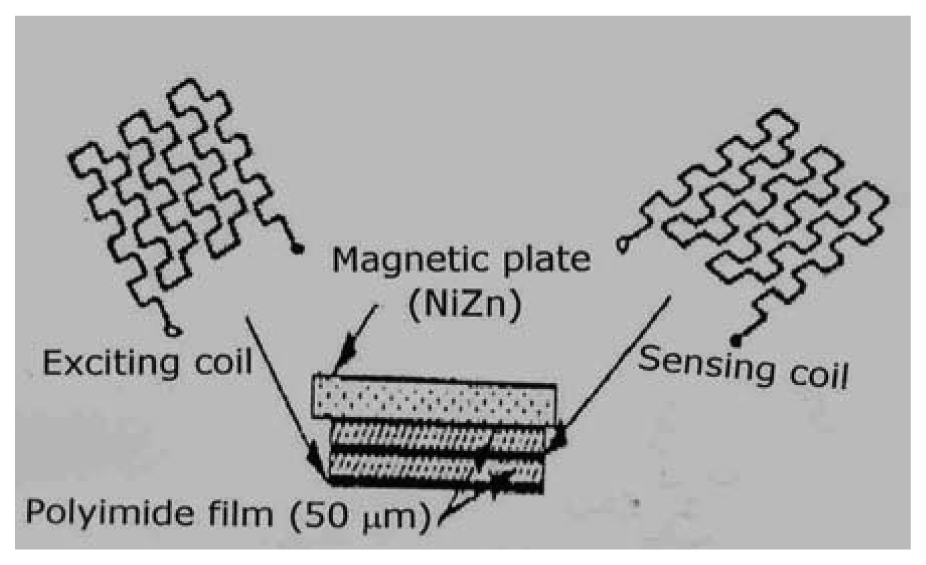

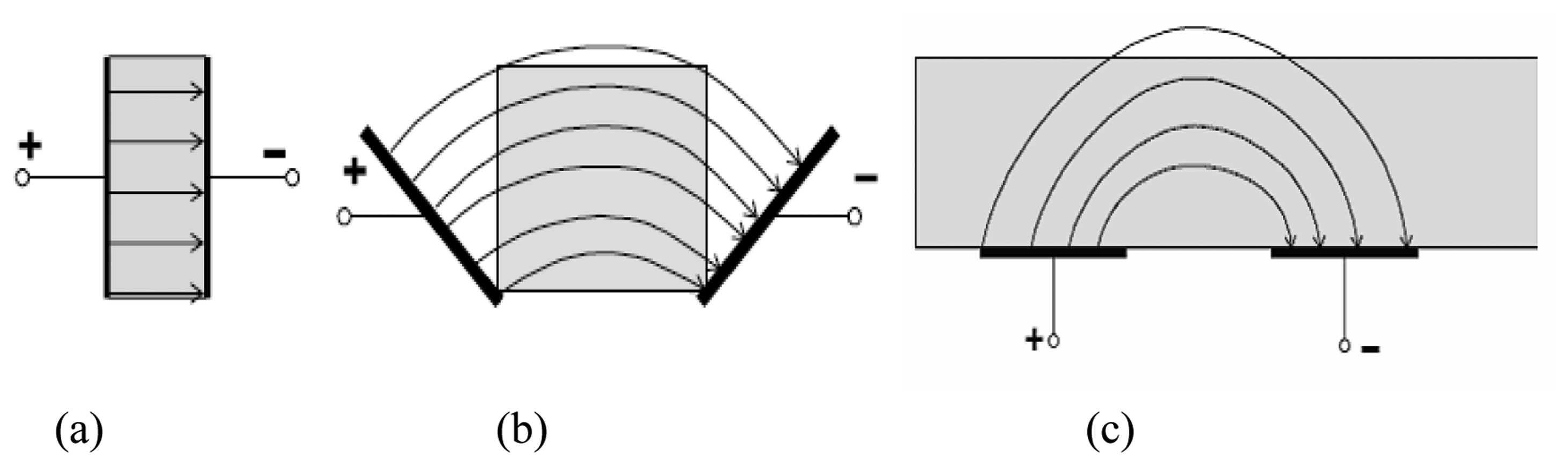

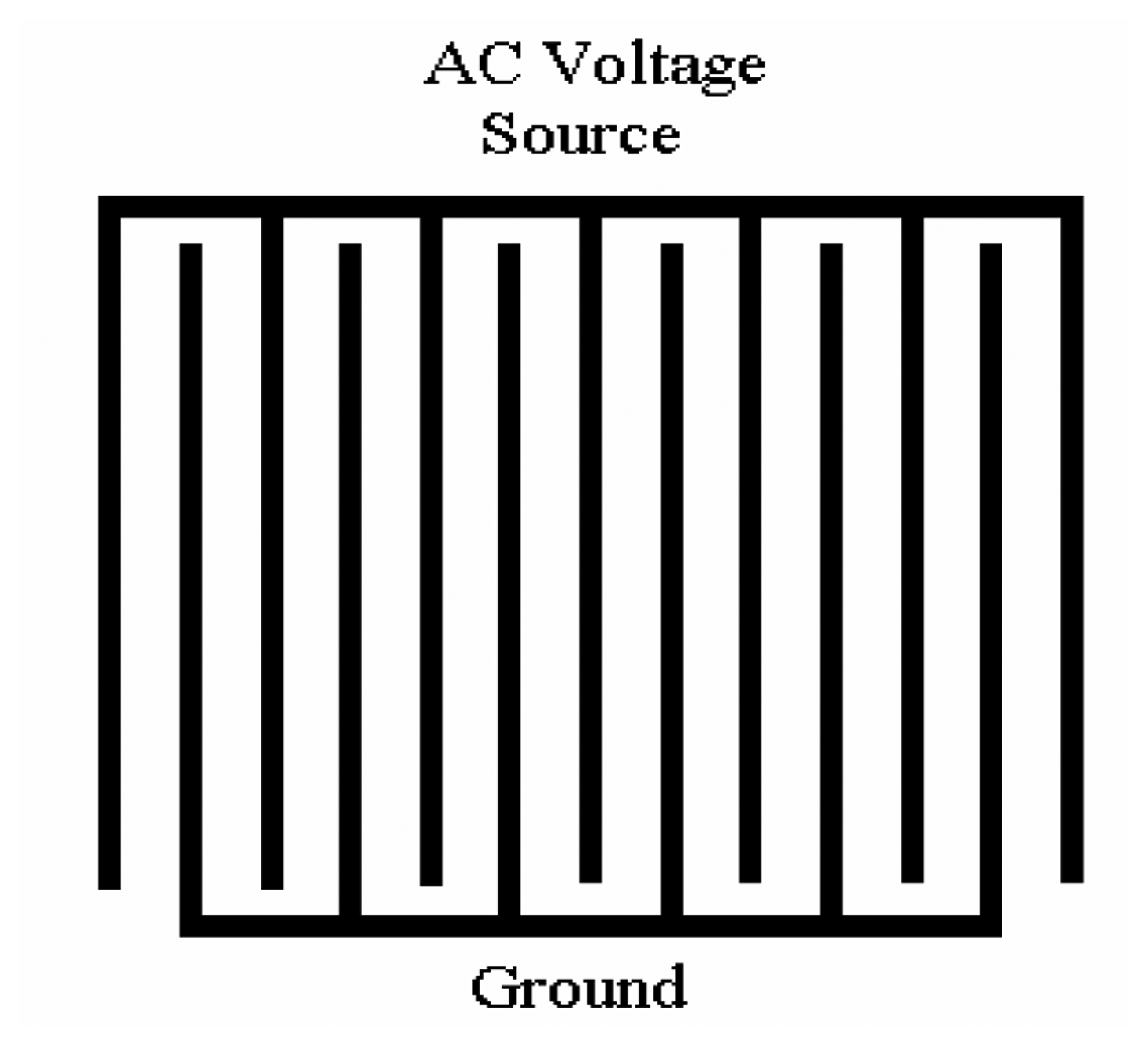

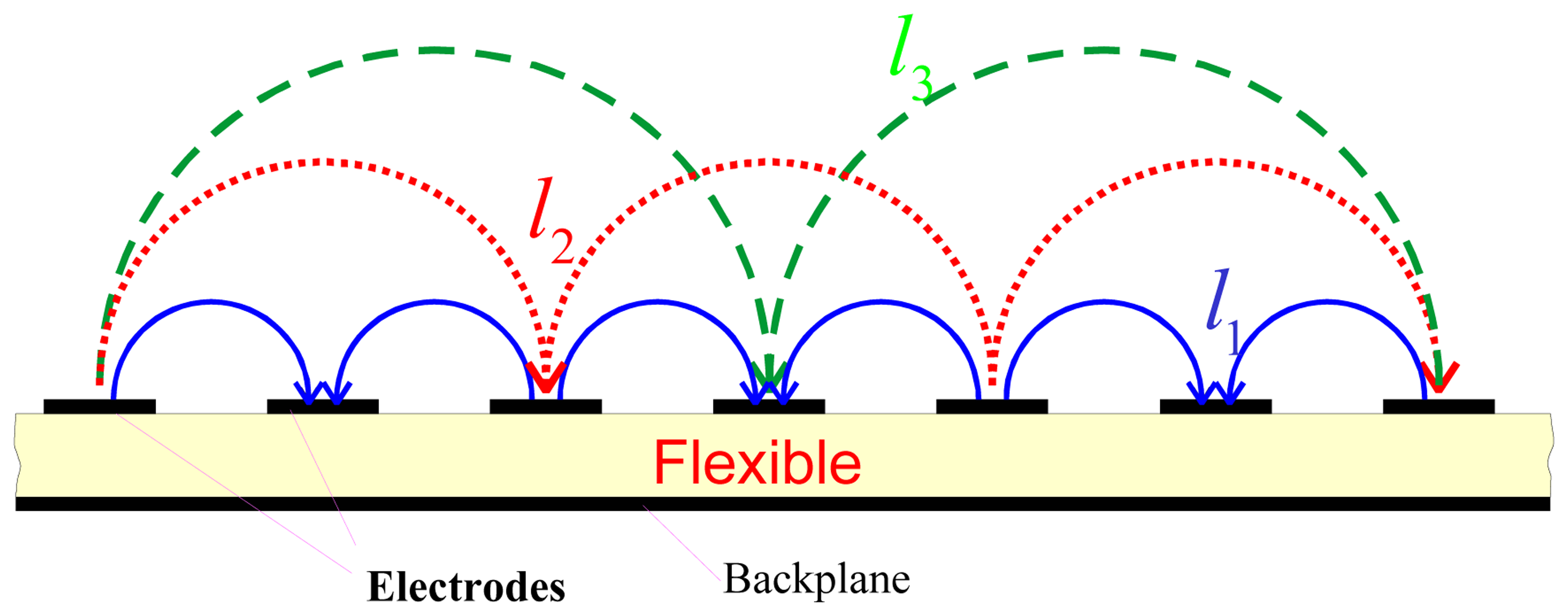

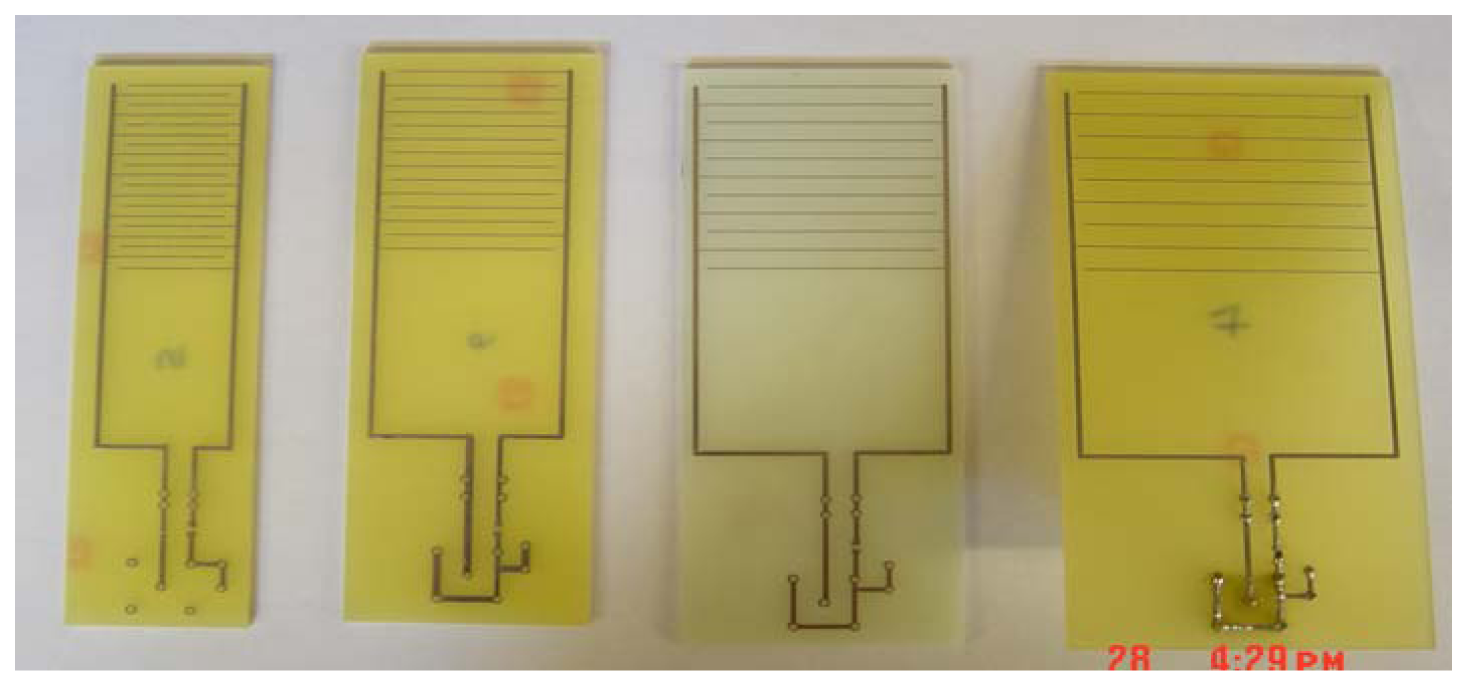

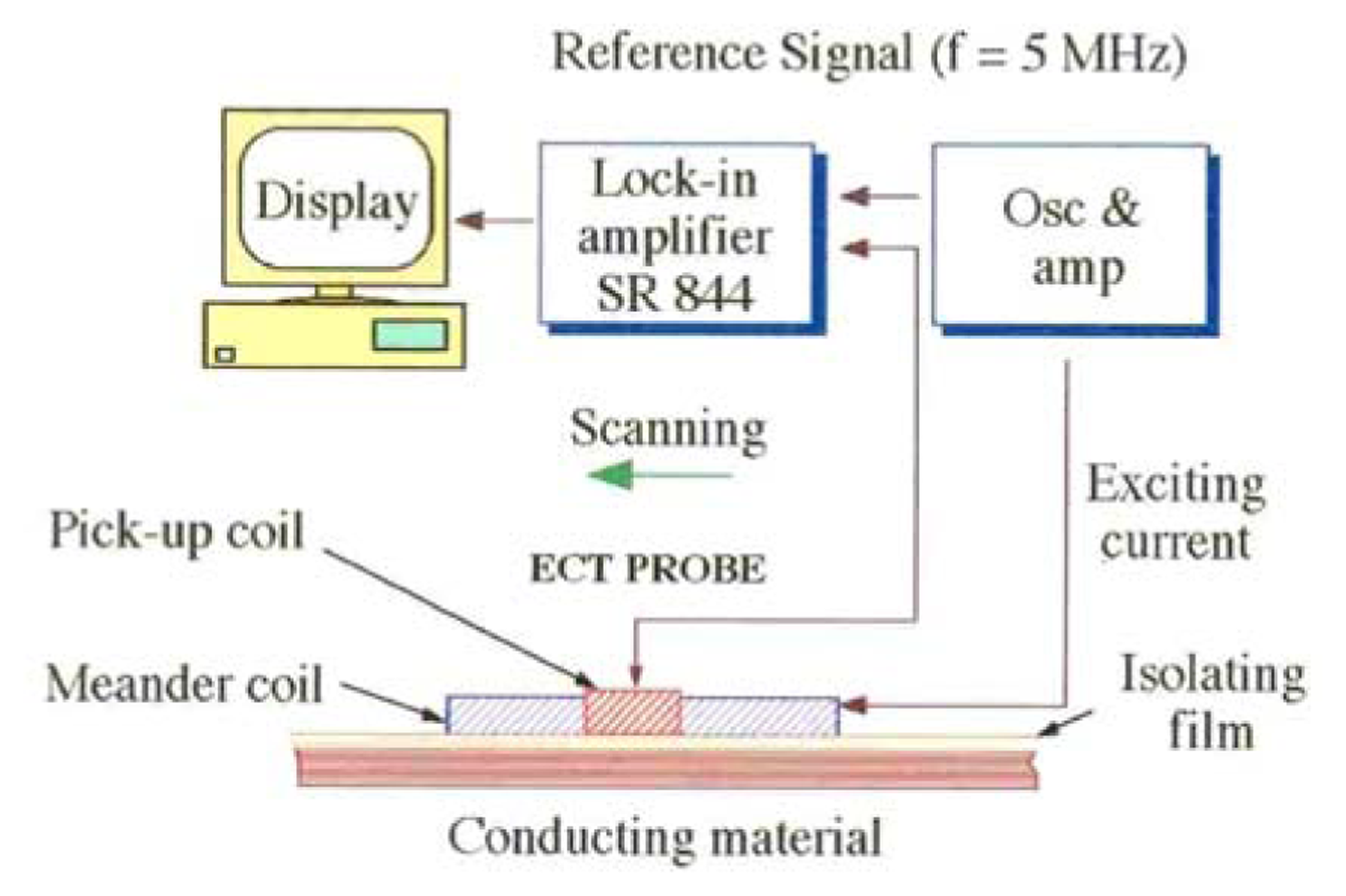

2. Configuration and Operating Principle of Planar Electromagnetic Sensors

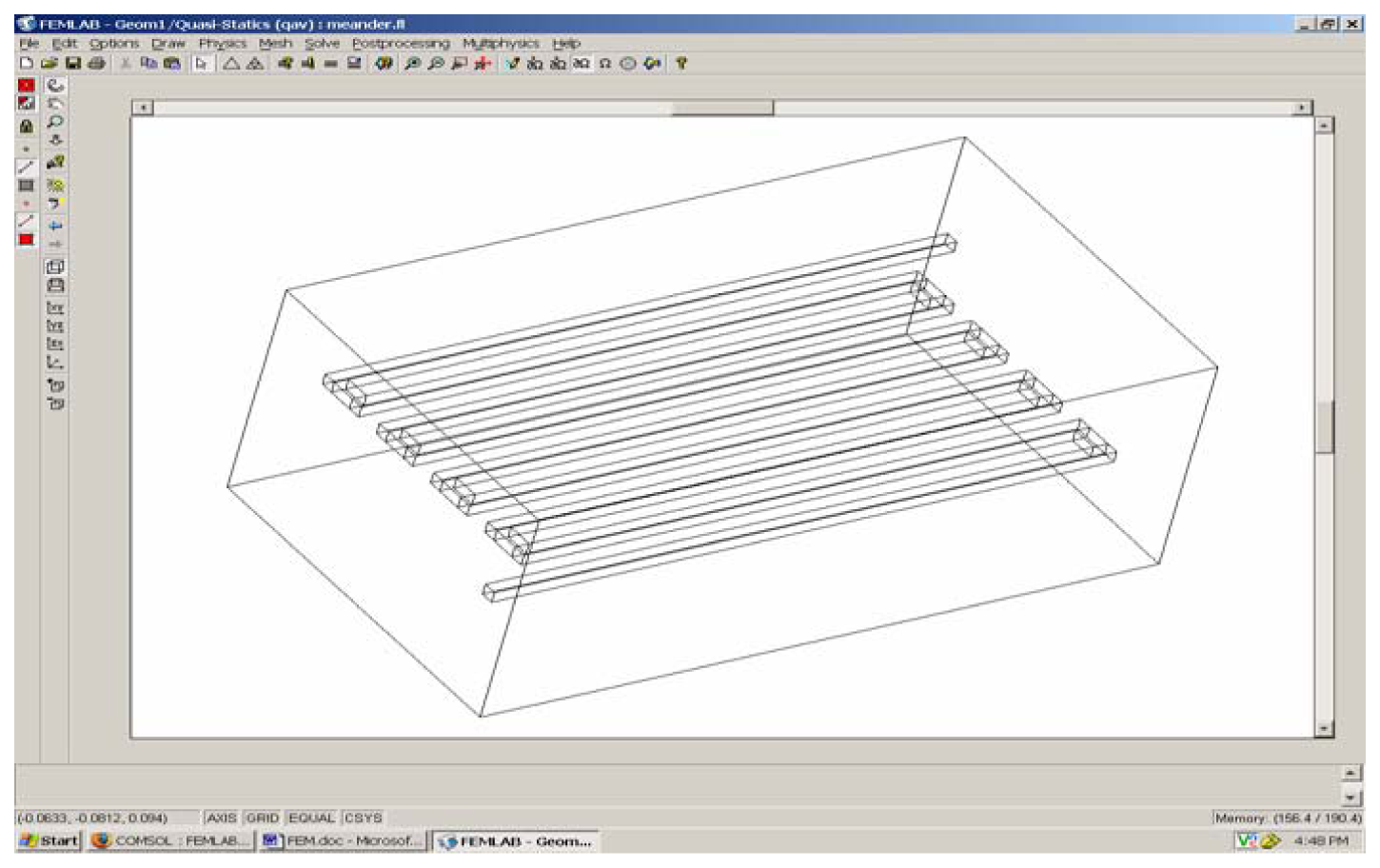

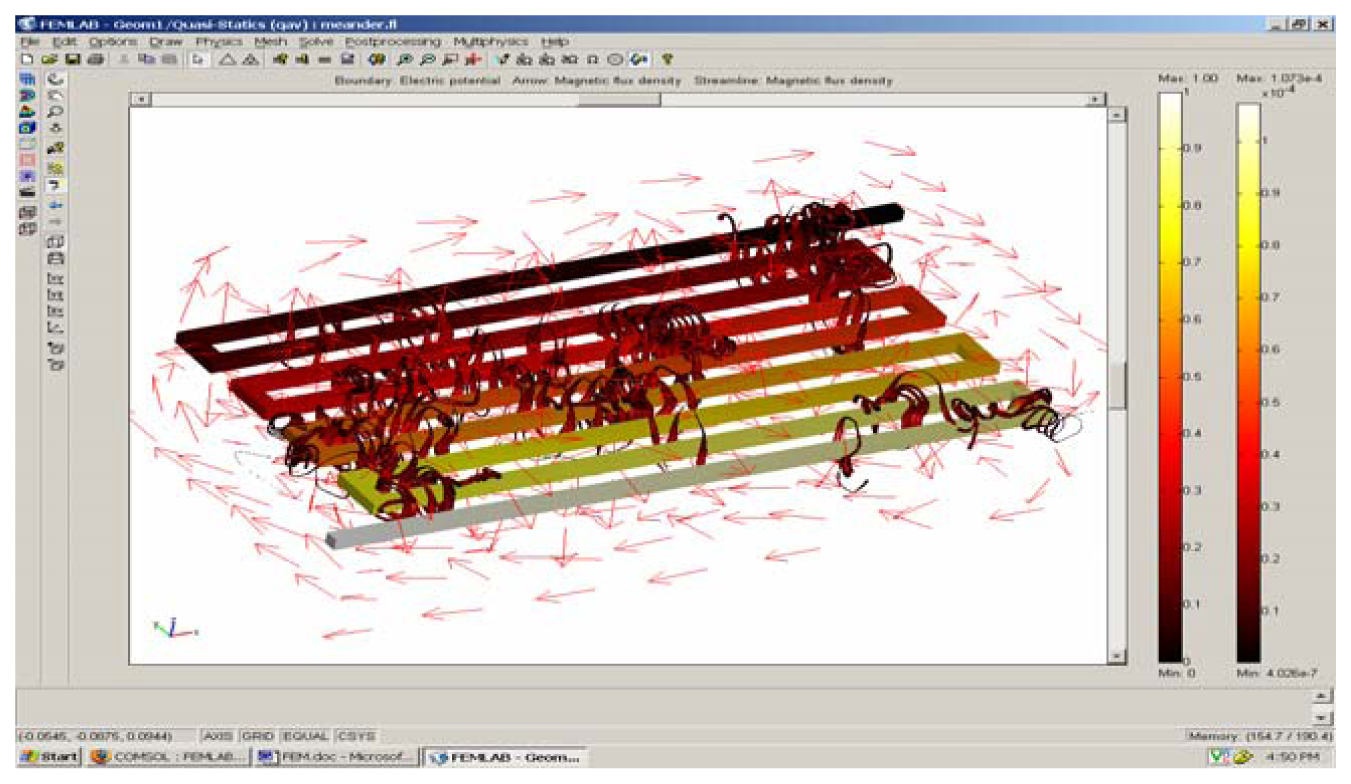

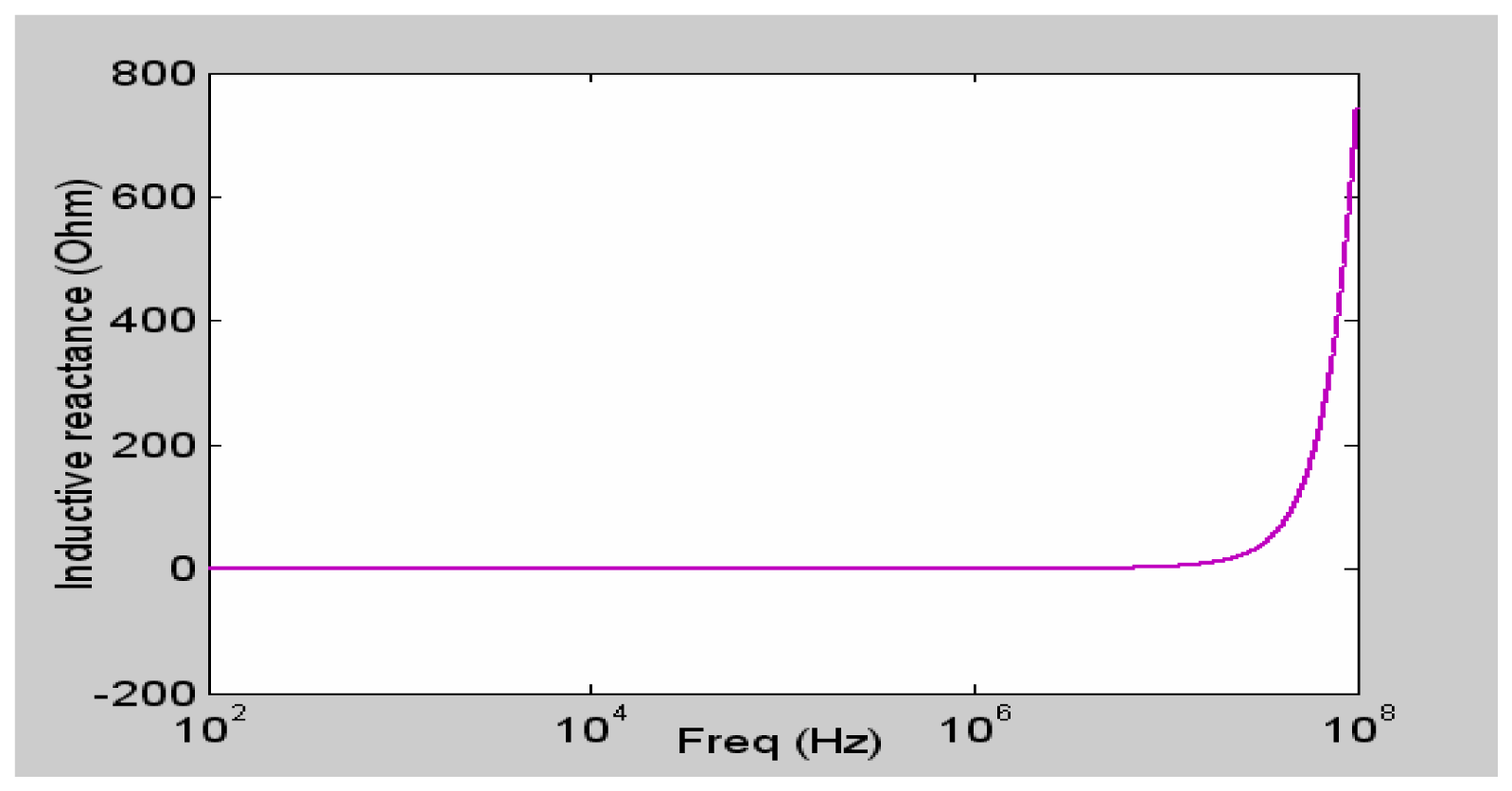

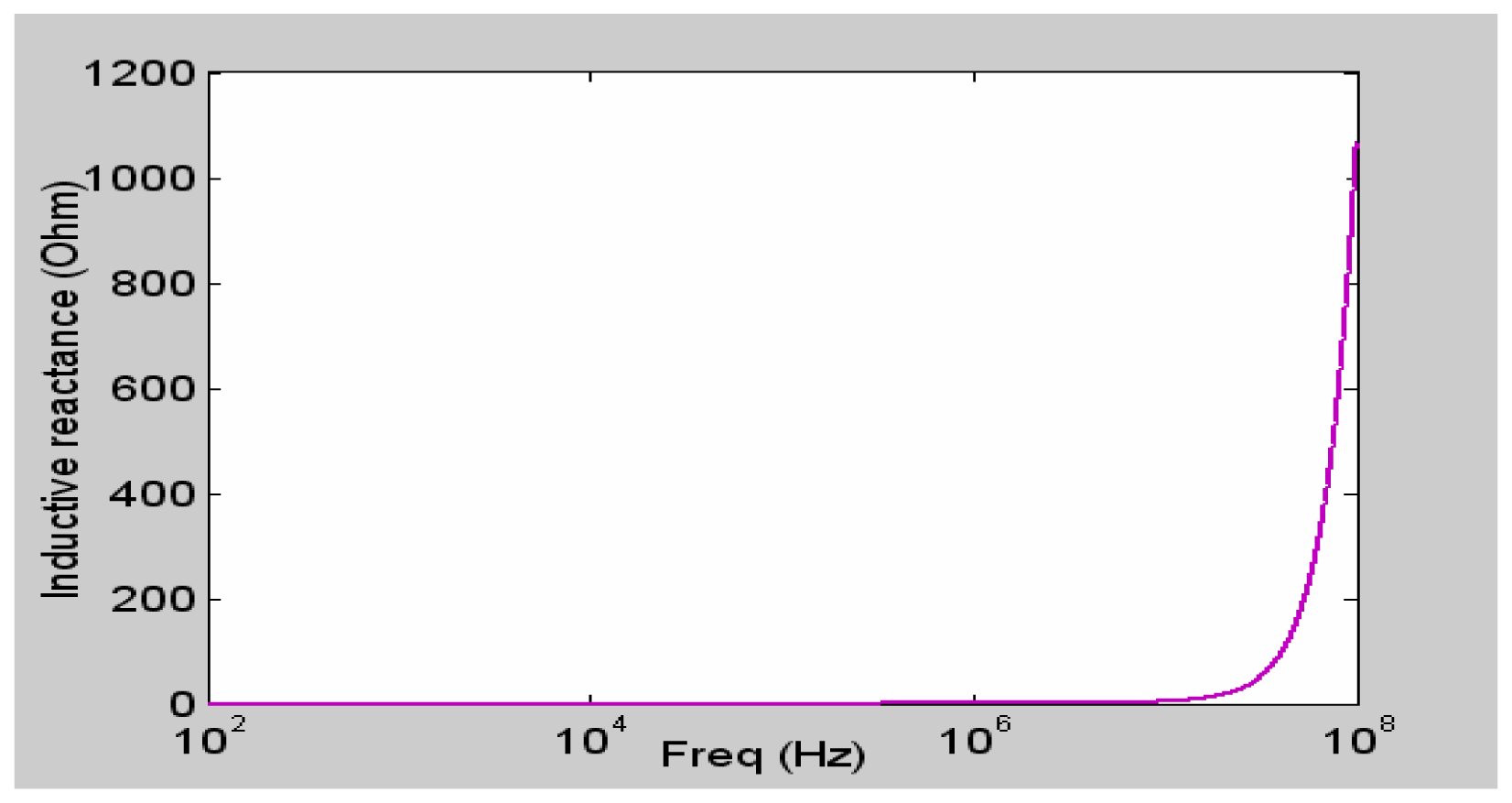

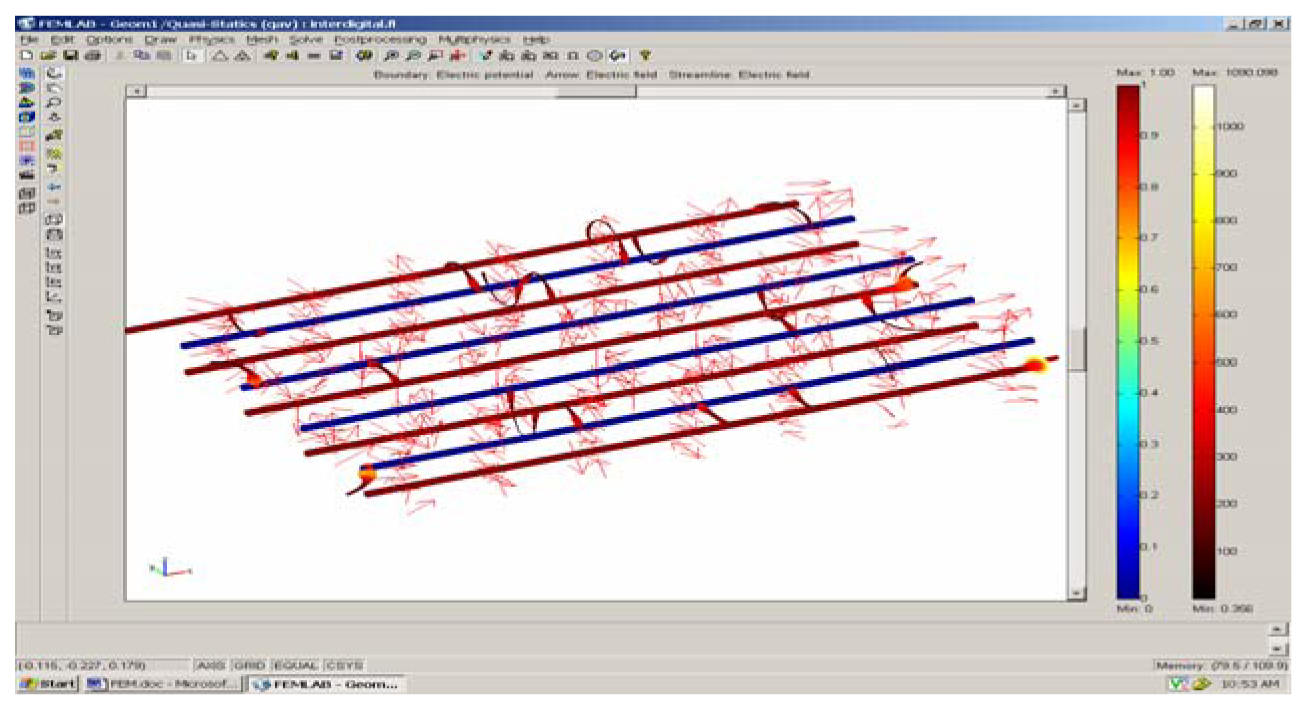

3. Analysis of planar sensors using finite element modeling software

4. Simulation Results

5. Applications of planar electromagnetic sensors

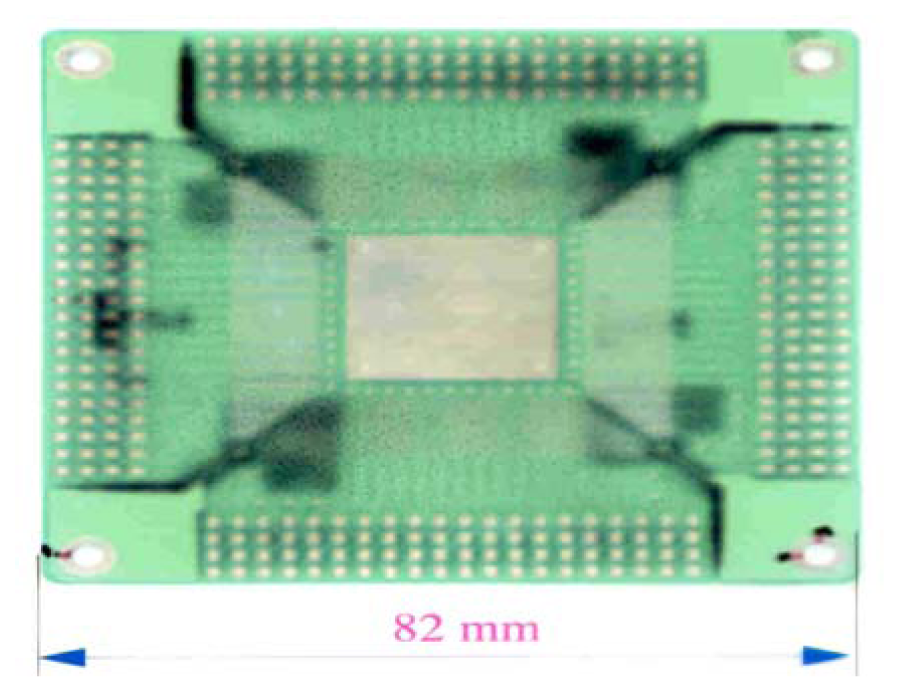

5.1. Inspection of printed circuit board

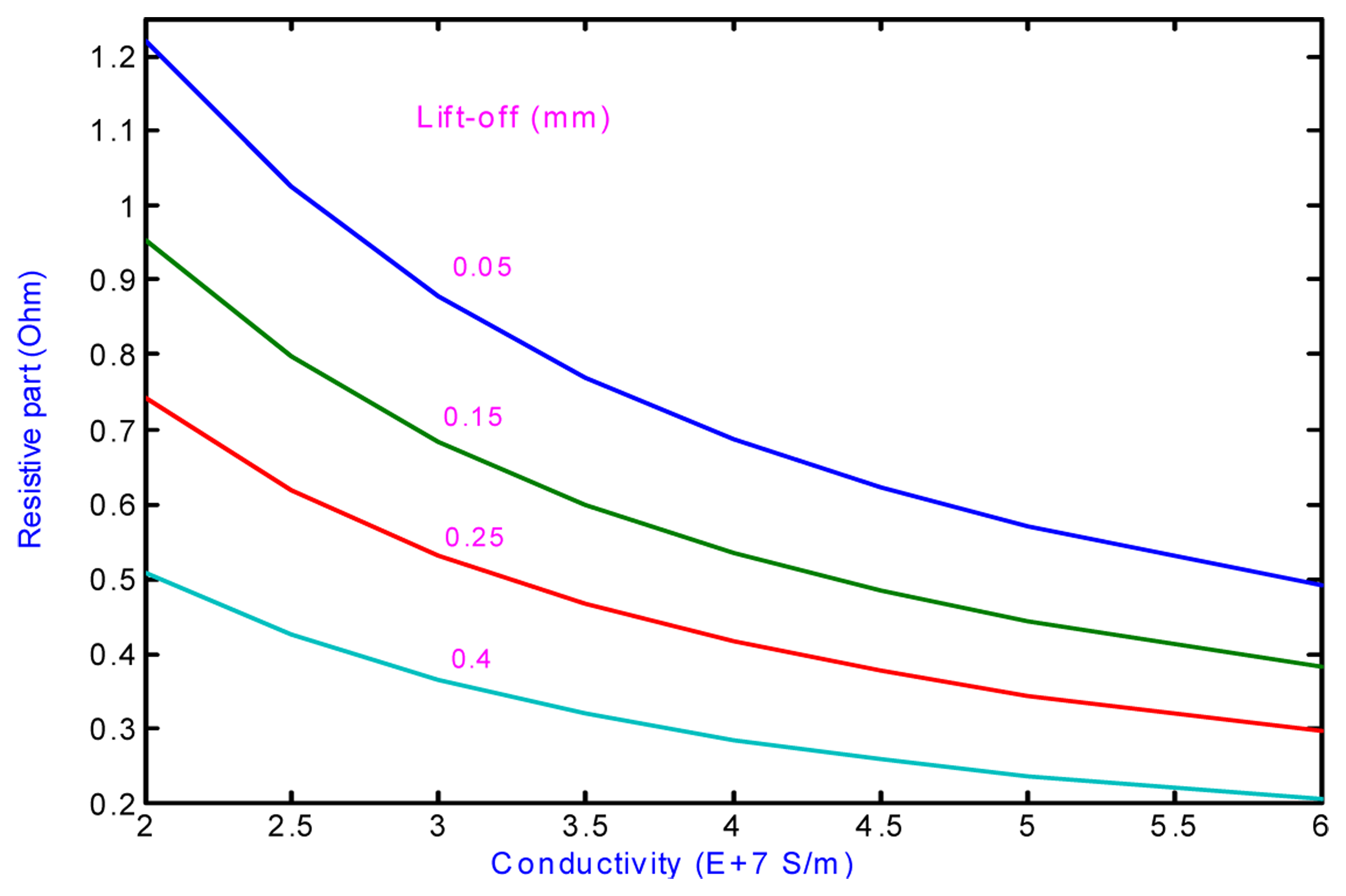

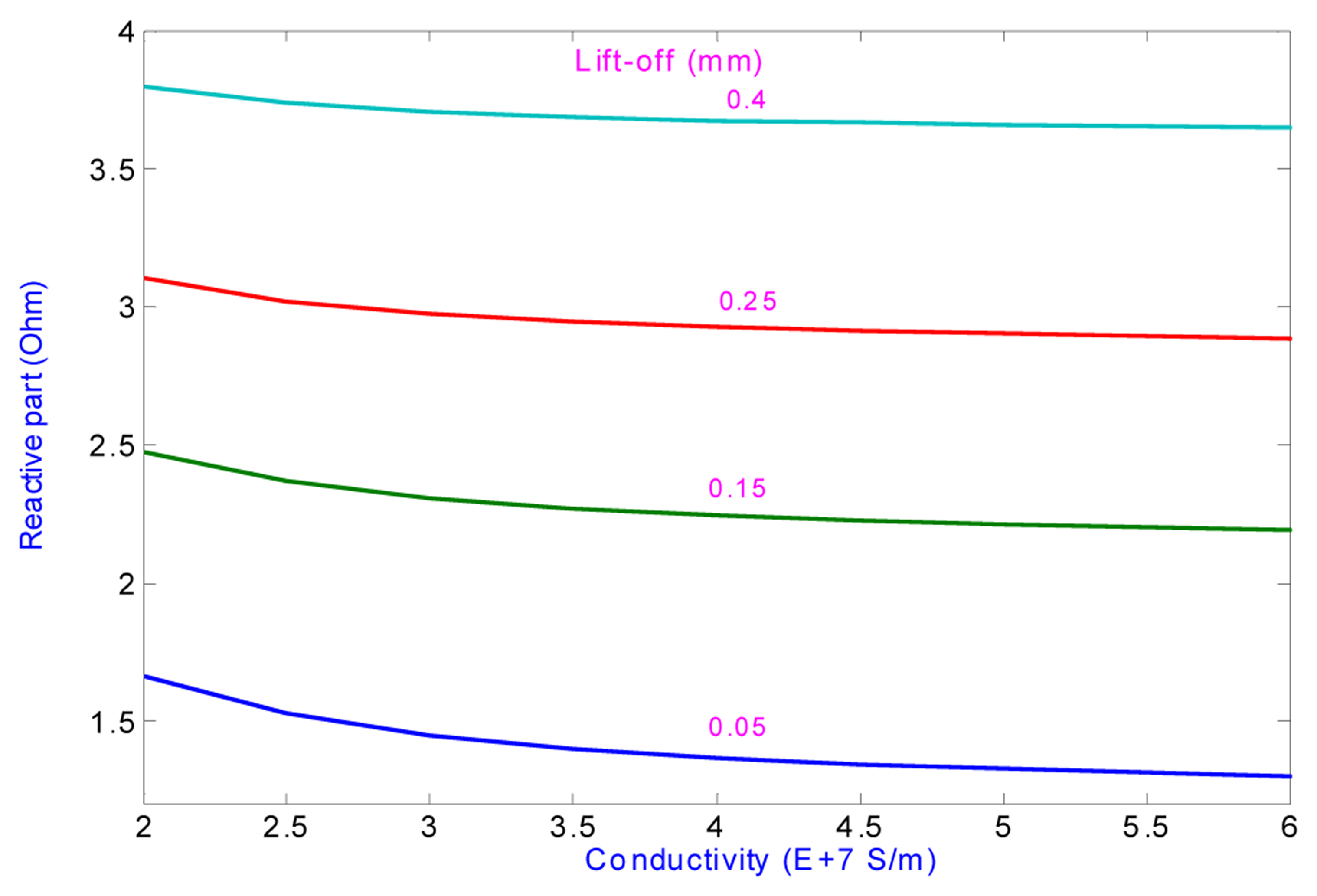

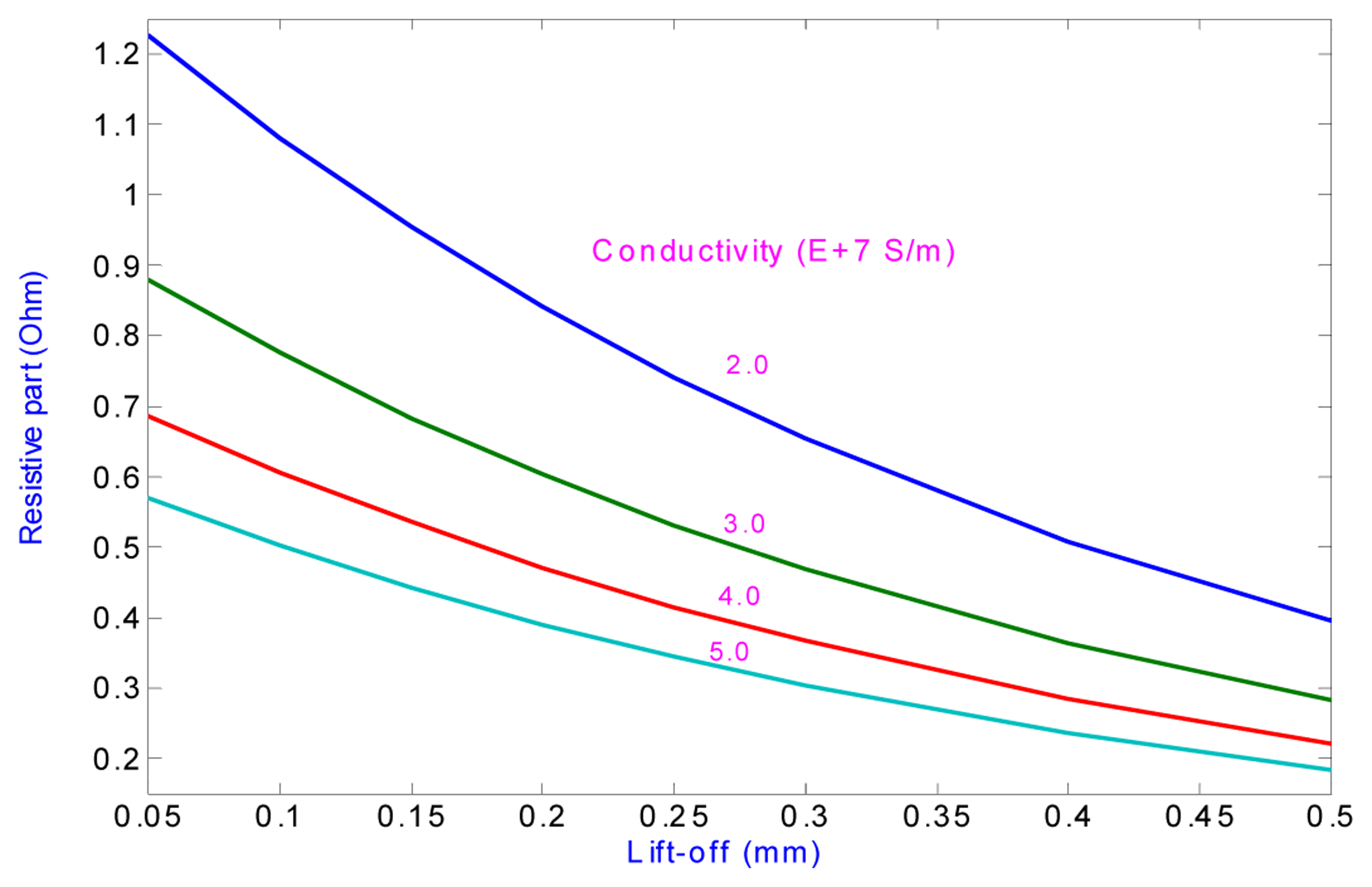

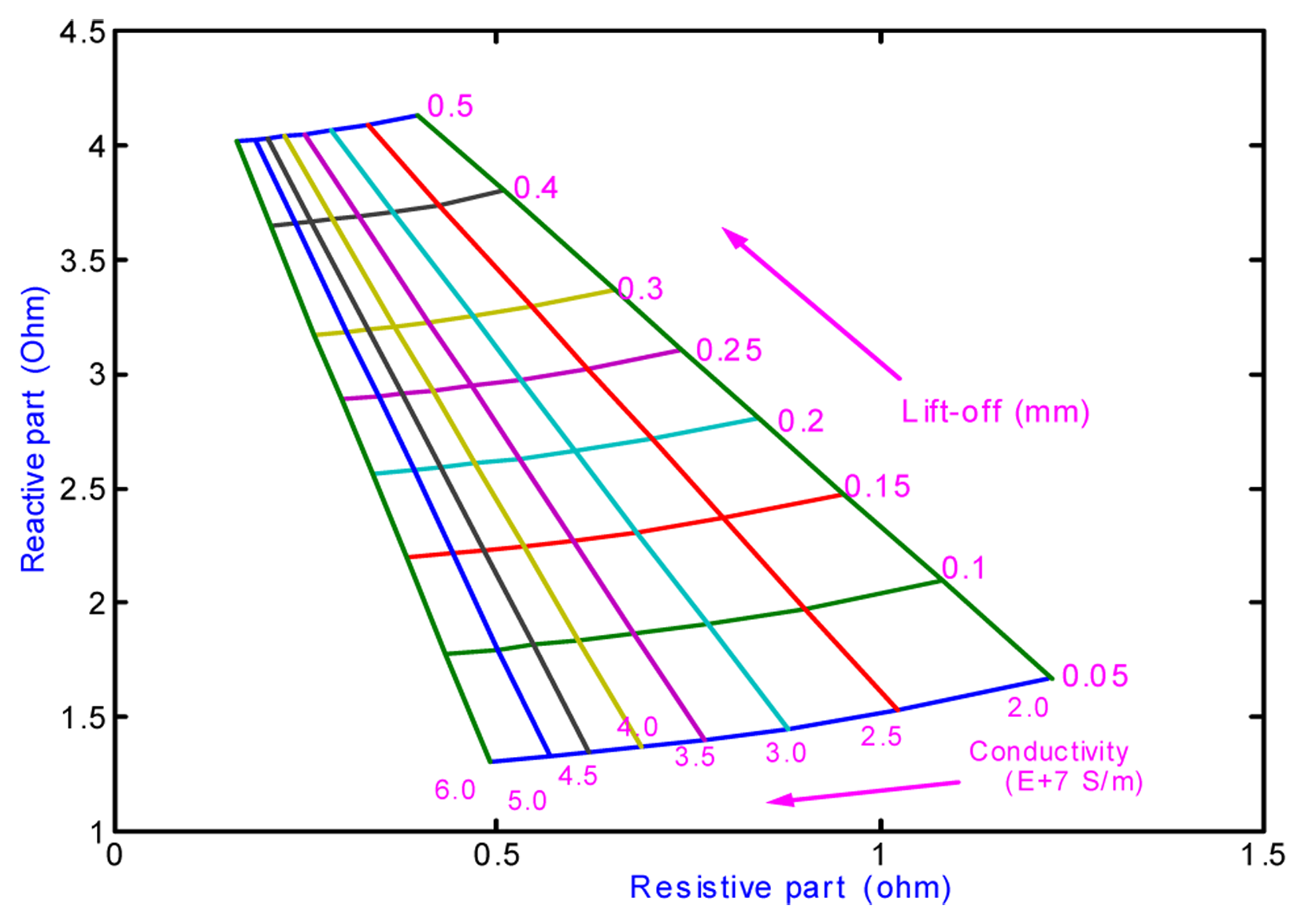

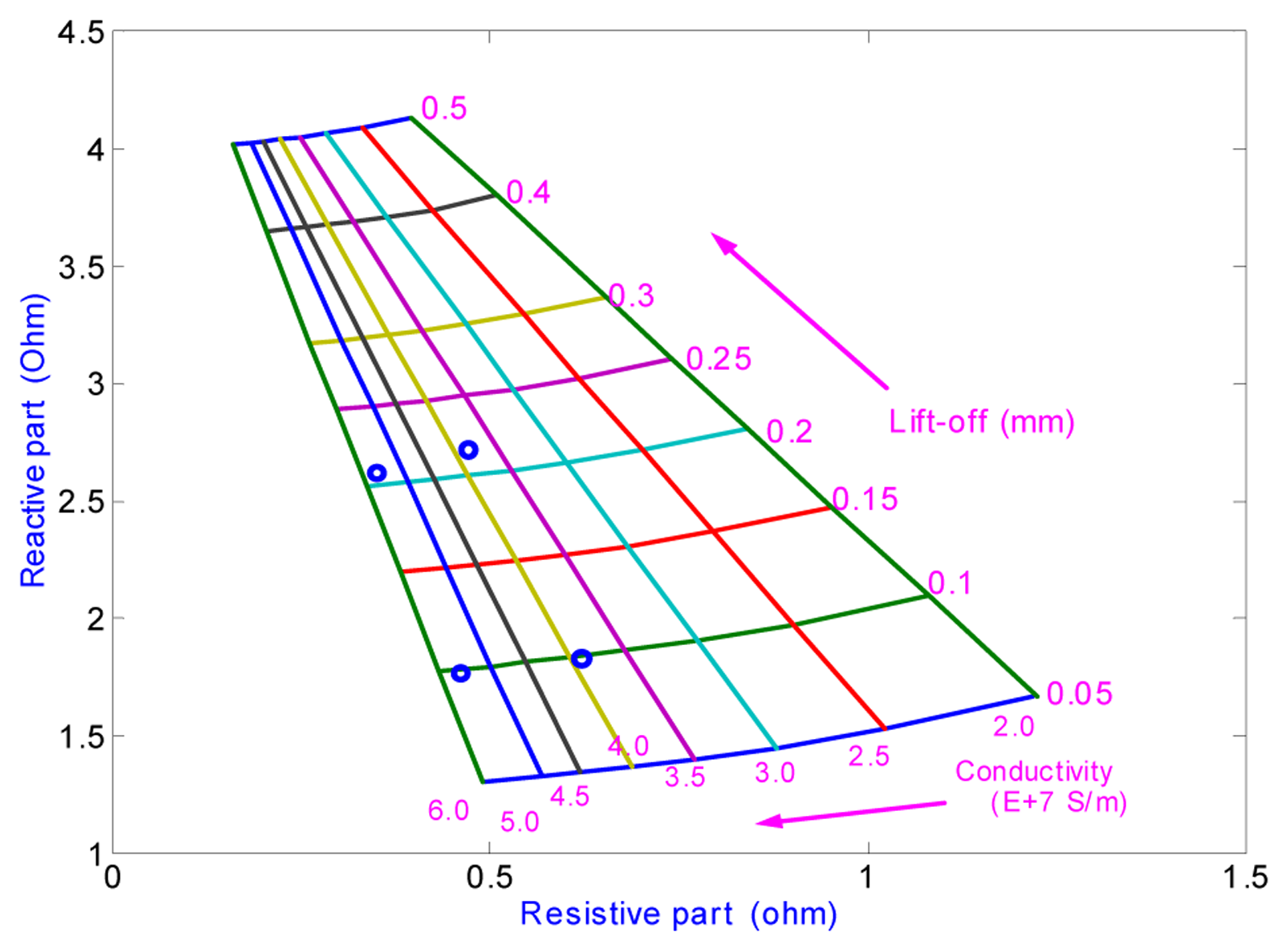

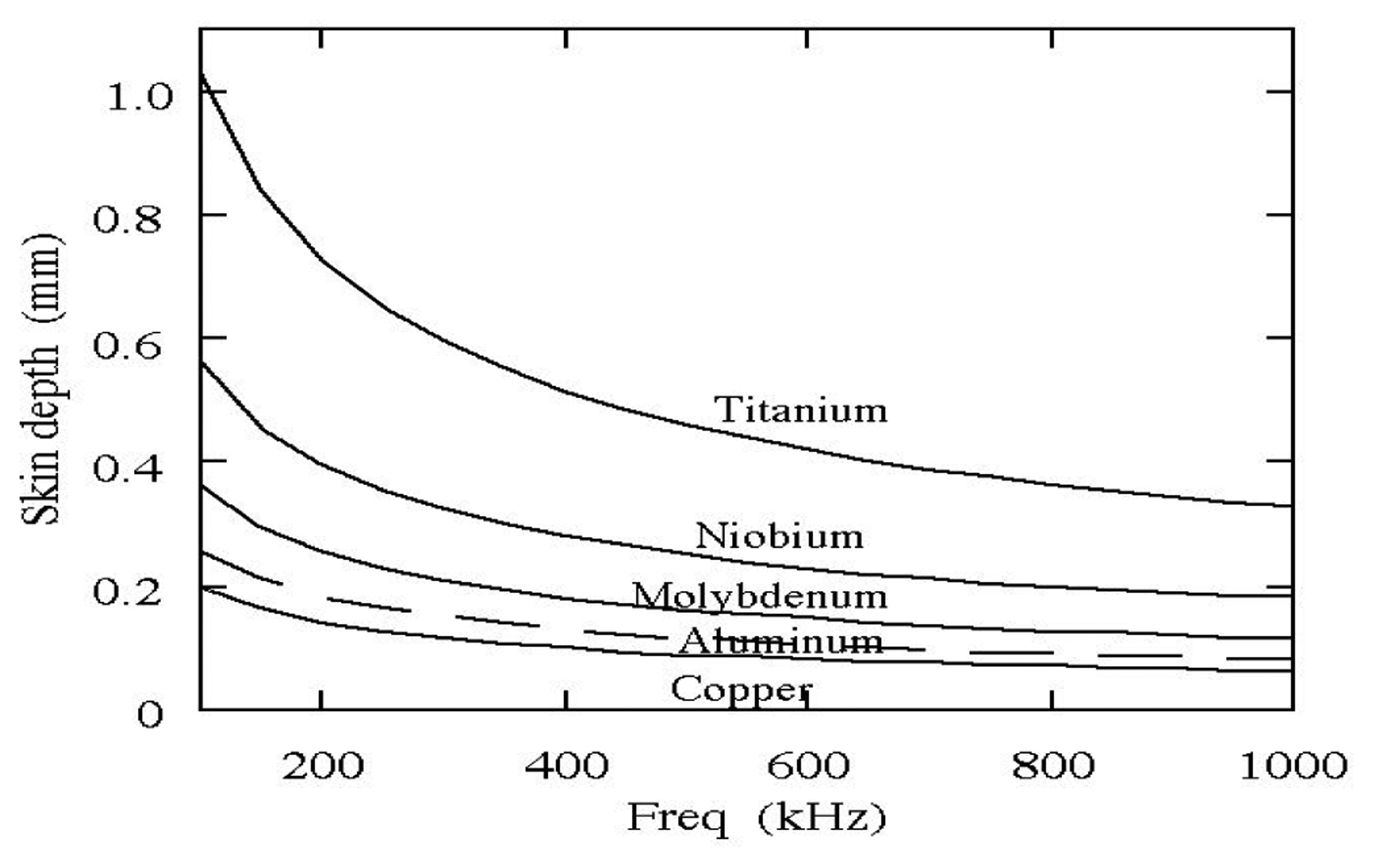

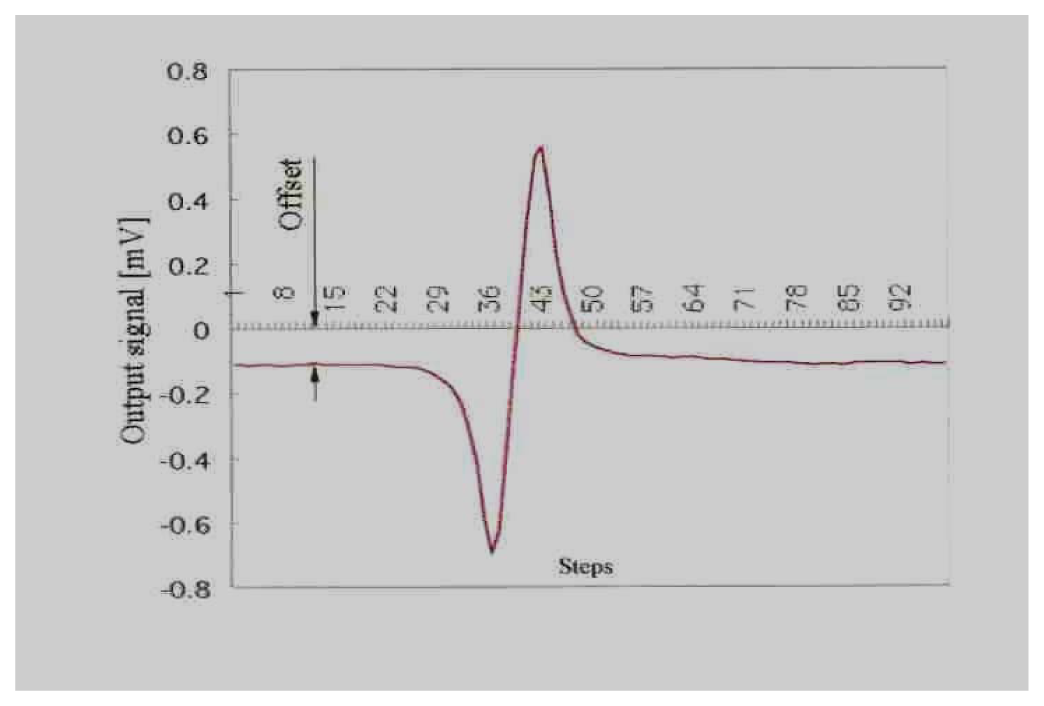

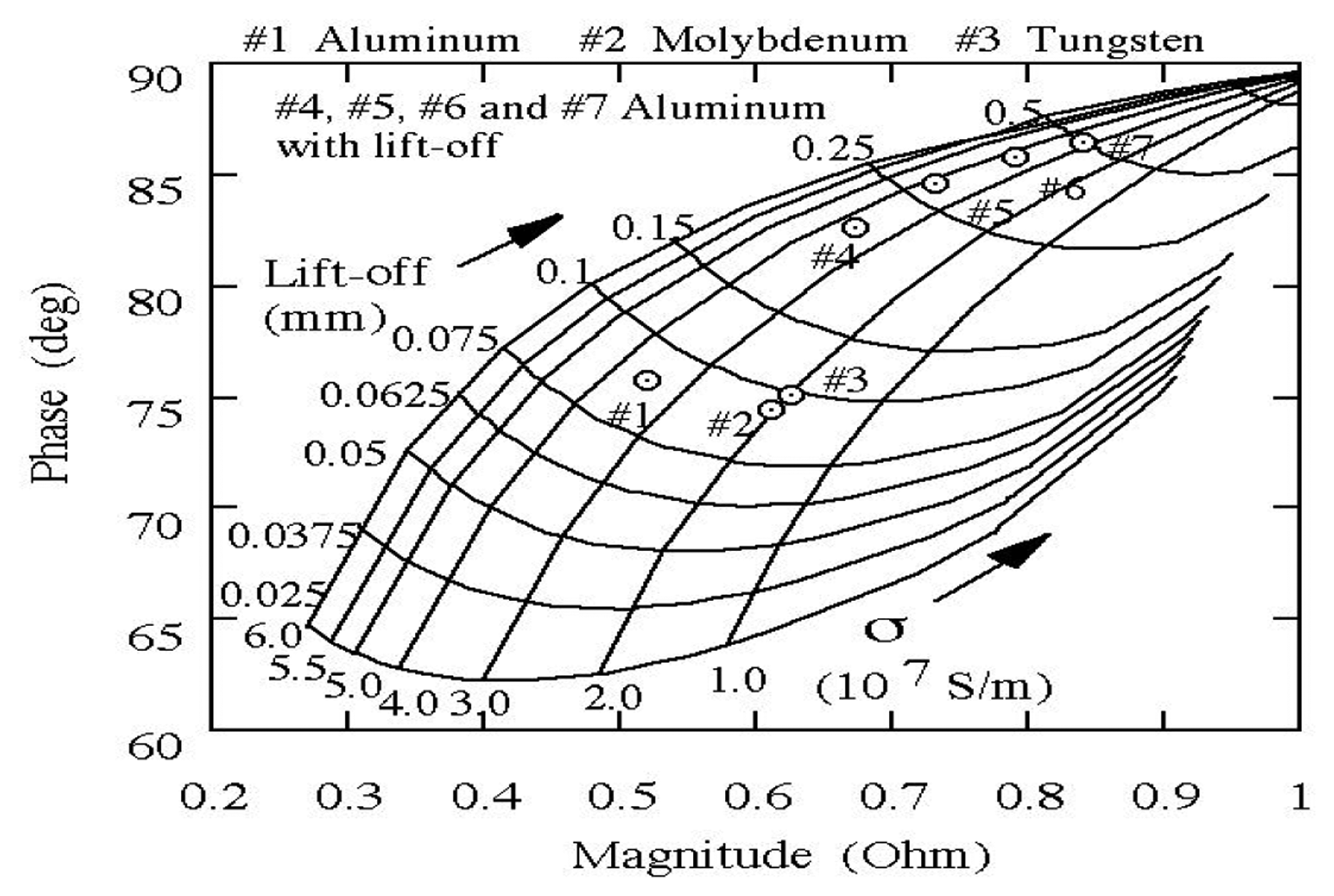

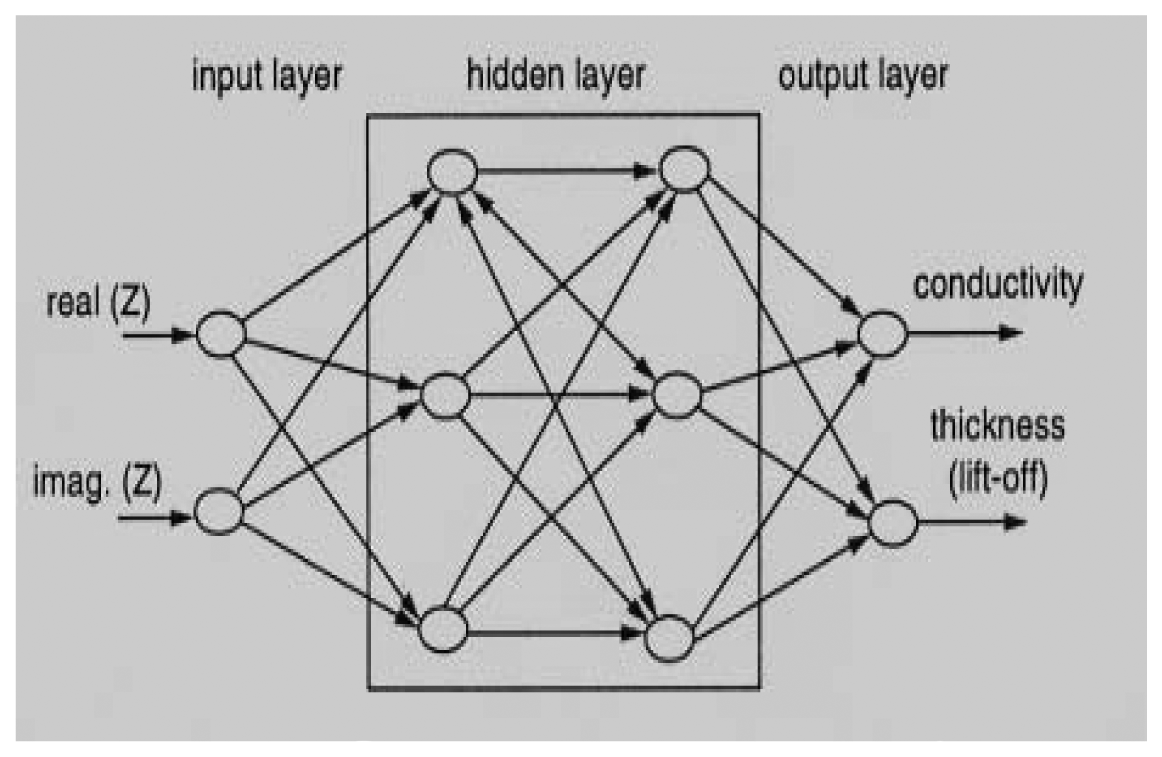

5.2. Estimation of near-surface material properties

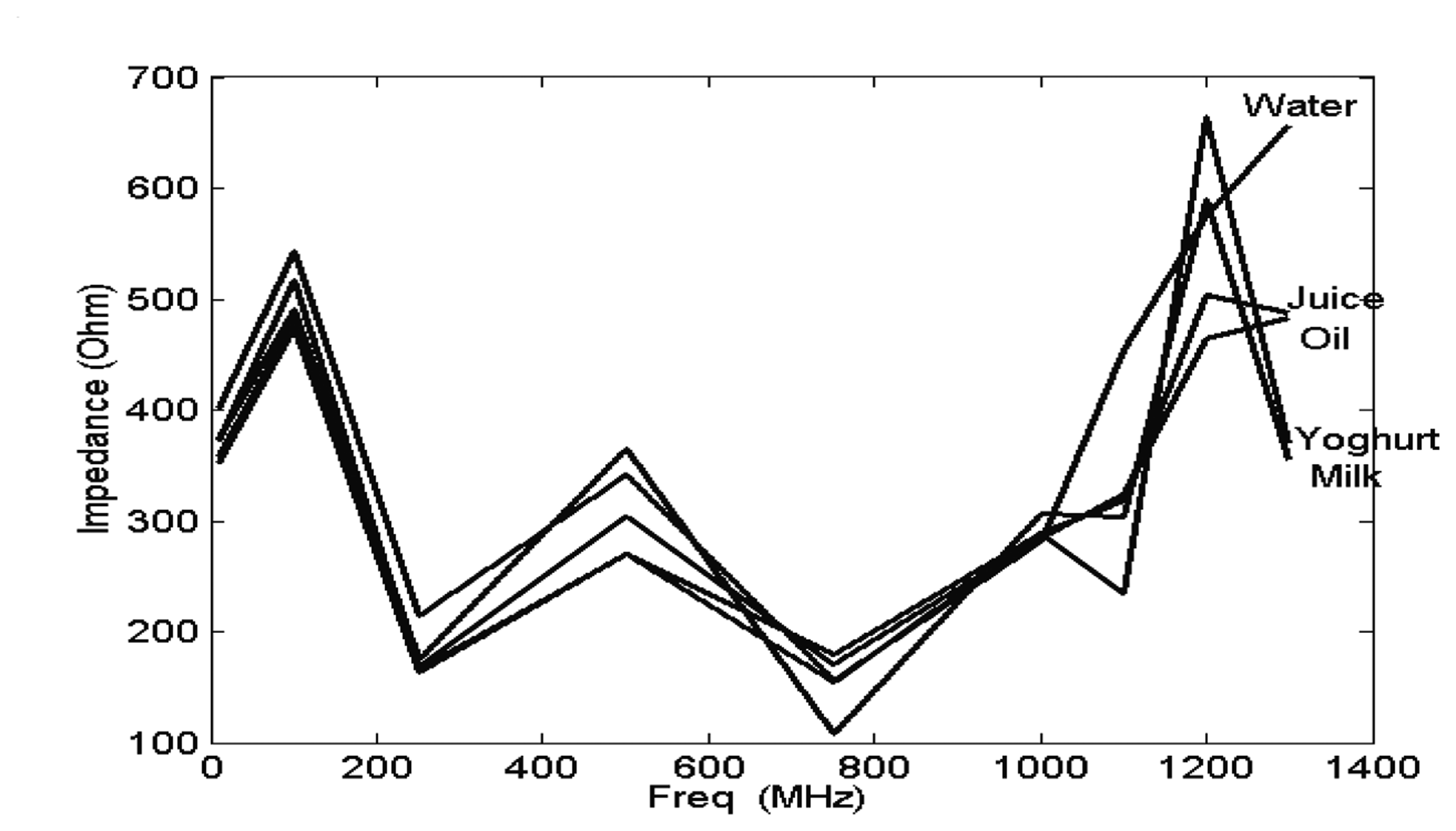

5.3. Preliminary investigation with milk

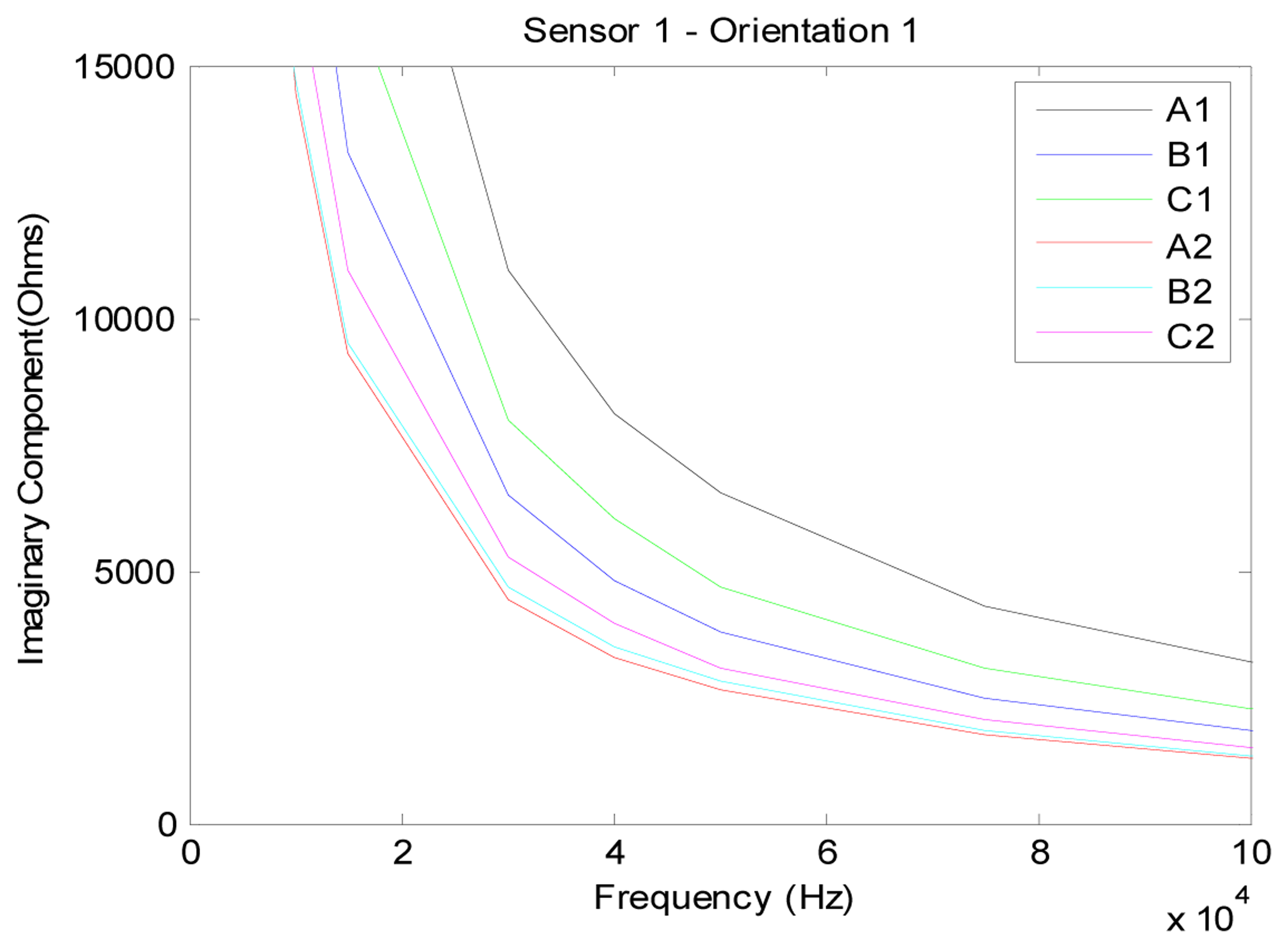

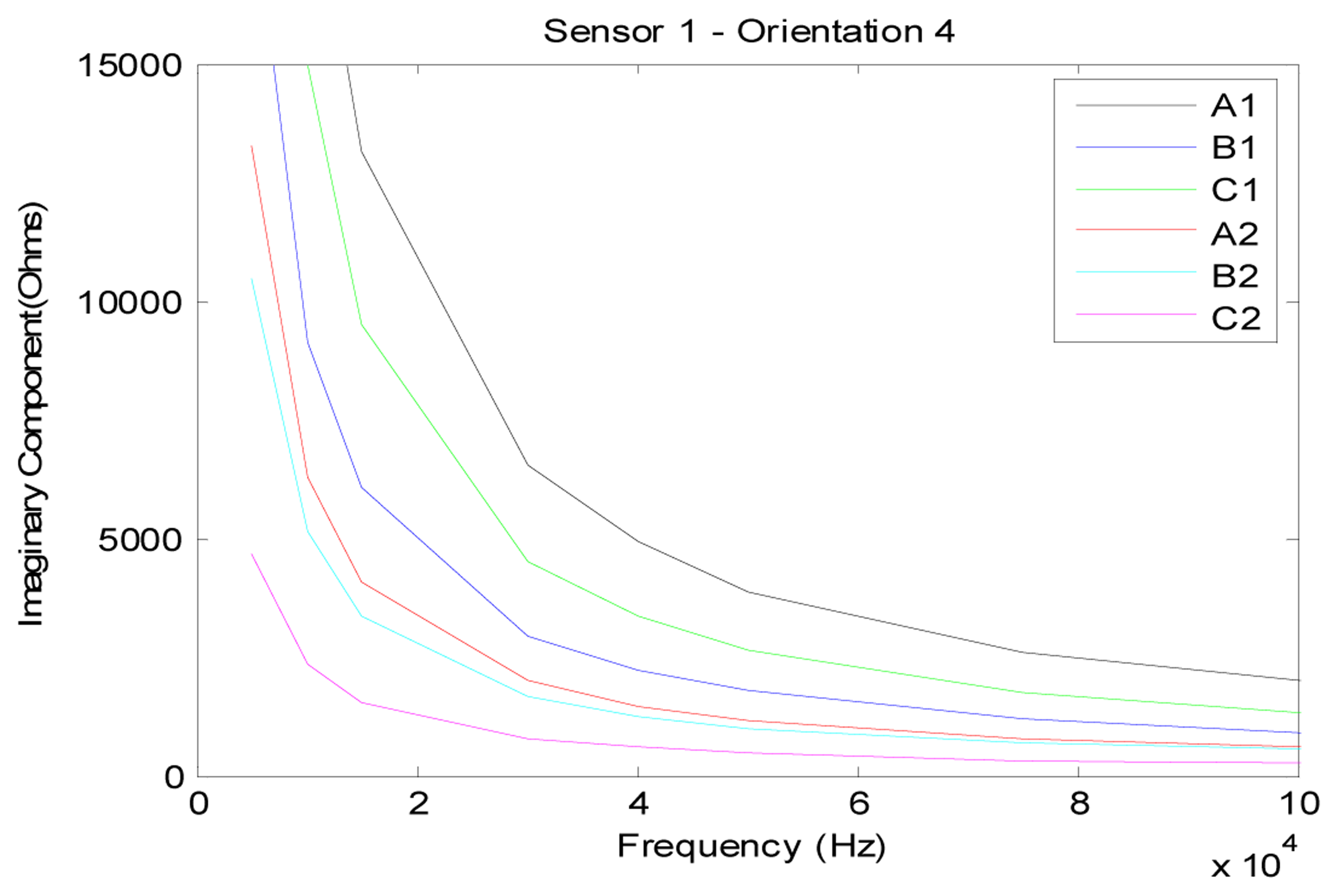

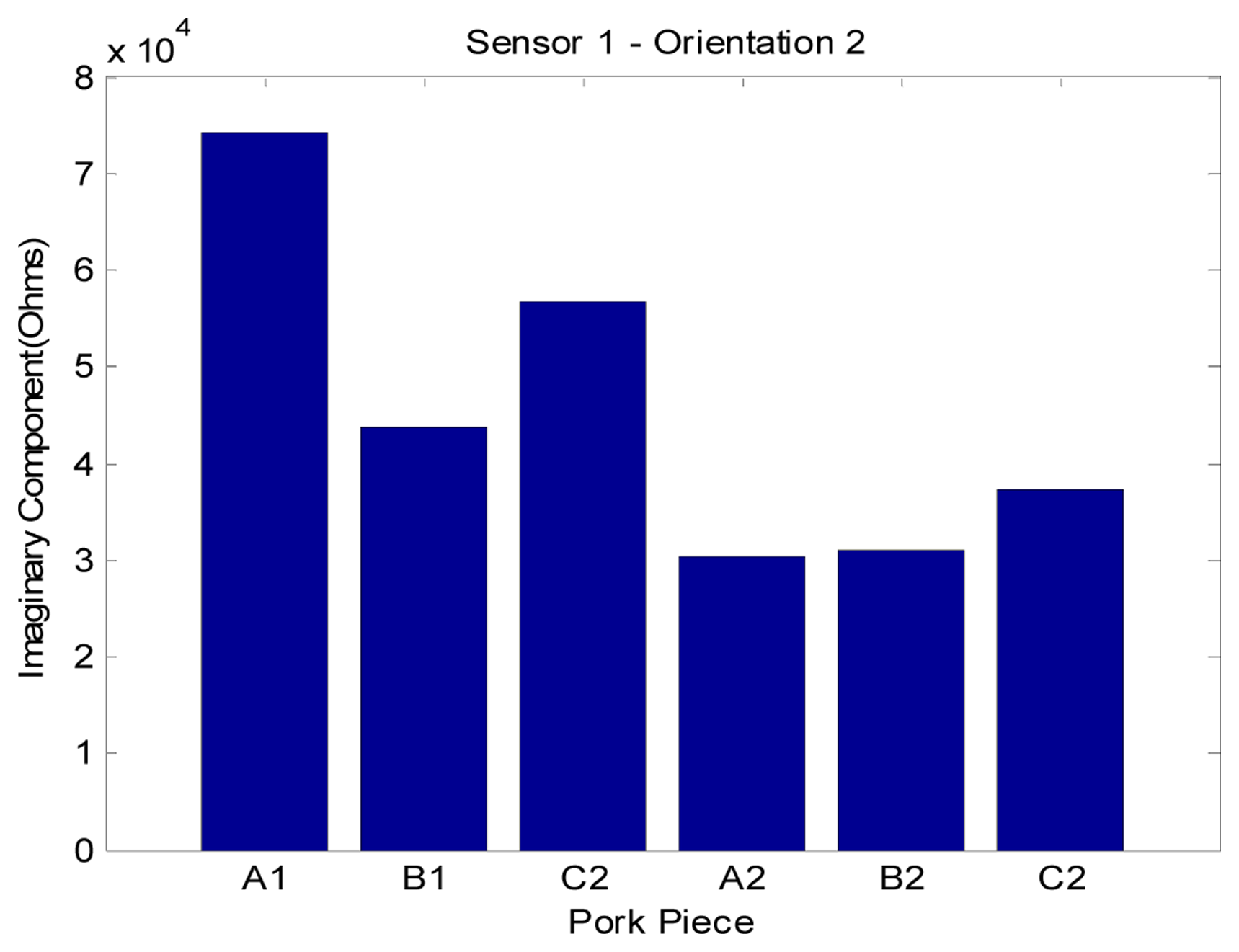

5.4. Electromagnetic interaction of planar interdigital sensor with pork belly cuts

- Orientation 1 = [skin side up, label at front] – as shown above

- Orientation 2 = [skin side up, label at back] – Rotate 180°

- Orientation 3 = [skin side down, label at front but underneath] – Flip over

- Orientation 4 = [skin side down, label at back underneath] - Rotate 180°

6. Conclusions

Acknowledgments

References

- Goldfine, N.J. Magnetometers for improved material characterization in aerospace application. Material Evaluation 1993, 396–405. [Google Scholar]

- Goldfine, N.J.; Clark, D.; Lovett, T. Material characterization using model based meandering winding eddy current testing (MW-ET). EPRI Topical workshop: Electromagnetic NDE applications in the Electric Power Industry 1995, 285–292. [Google Scholar]

- Goldfine, N.J. Conformable, meandering winding magnetometer (MWM) for flaw and material characterization in ferrous and nonferrous metals. ASME Pressure Vessels and Piping Conference, Proceeding on International Advancement in PVP Technology 1997, 431–439. [Google Scholar]

- Bi, Y.; Gobindaraju, M.R.; Jiles, D.C. The dependence of magnetic properties on fatigue in A533B nuclear pressure vessel steels. IEEE Transactions on Magnetics 1997, 33, 3928–3930. [Google Scholar]

- Shi, Y.; Jiles, D.C. Finite element analysis of the influence of a fatigue crack on magnetic properties of steel. Journal of Applied Physics 1998, 83, 6353–6355. [Google Scholar]

- Bi, Y.; Jiles, D.C. Dependence of magnetic properties on crack size in steels. IEEE Transactions on Magnetics 1998, 34, 2021–2023. [Google Scholar]

- Yamada, S.; Katou, M.; Iwahara, M.; Dawson, F.P. Eddy current testing probe composed on planar coils. IEEE Transactions on Magnetics 1995, 31, 3185–3187. [Google Scholar]

- Yamada, S.; Katou, M.; Iwahara, M.; Dawson, F.P. Defect images by planar ECT probe of Meander-Mesh coils. IEEE Transactions on Magnetics 1996, 32, 4956–4958. [Google Scholar]

- Yamada, S.; Fujiki, H.; Iwahara, M.; Mukhopadhyay, S.C.; Dawson, F.P. Investigation of printed wiring board testing by using planar coil type ECT probe. IEEE Transactions on Magnetics 1997, 33, 3376–3378. [Google Scholar]

- Mukhopadhyay, S.C.; Yamada, S.; Iwahara, M. Investigation of near-surface material properties using planar type meander coil. JSAEM Studies on Applied Electromagnetics and Mechanics 2001, 11, 61–69. [Google Scholar]

- Mukhopadhyay, S.C.; Yamada, S.; Iwahara, M. Evaluation of near- surface material properties using planar mesh type coils with post-processing from neural network model. International journal on Electromagnetic Nondestuctive Evaluation 2002, 23, 181–188. [Google Scholar]

- Mukhopadhyay, S.C.; Yamada, S.; Iwahara, M. Inspection of electroplated materials – performance comparison with planar meander and mesh type magnetic sensor. International journal of Applied Electromagnetics and Mechanics 2002, 15, 323–329. [Google Scholar]

- Mukhopadhyay, S.C. Quality inspection of electroplated materials using planar type micromagnetic sensors with post processing from neural network model. IEE Proceedings – Science, Measurement and Technology 2002, 149, 165–171. [Google Scholar]

- Mukhopadhyay, S.C.; Woolley, J.D.M.; Sen Gupta, G. Inspection of saxophone reeds employing a novel planar electromagntic sensing technique. Proceedings of 2005 International Instrumentation and Measurement Technology Conference. 2005, IEEE Catalog Number 05CH37627C, ISBN 0-7803-8880-1. 209–213. [Google Scholar]

- Mukhopadhyay, S.C.; Gooneratne, C.P.; Demidenko, S.; Sen Gupta, G. Low cost sensing system for dairy products quality monitoring. Proceedings of 2005 International Instrumentation and Measurement Technology Conference. 2005, IEEE Catalog Number 05CH37627C, ISBN 0-7803-8880-1. 244–249. [Google Scholar]

- Gooneratne, C.; Mukhopadhyay, S.C.; Purchas, R.; Sen Gupta, G. Interaction of planar electromagnetic sensors with pork belly cuts. Proceedings of 1st International Conference on Sensing Technology 2005, 519–526. [Google Scholar]

- Mukhopadhyay, S.C.; Yamada, S.; Iwahara, M. Experimental determination of optimum coil pitch for a planar mesh type micro-magnetic sensor. IEEE Transactions on Magnetics 2002, 38, 3380–3382. [Google Scholar]

- Mukhopadhyay, S.C.; Yamada, S.; Iwahara, M. Optimum coil pitch selection for planar mesh type micro-magnetic sensor for the estimation of near-surface material properties. JSAEM series on Applied Electromagnetics and Mechanics 2003, 14, 1–9. [Google Scholar]

- Mukhopadhyay, S.C. A novel planar mesh type micro-electromagnetic sensor: Part I - Model Formulation. IEEE Sensors Journal 2004, 4, 301–307. [Google Scholar]

- Mukhopadhyay, S.C. A novel planar mesh type micro-electromagnetic sensor: Part II – estimation of system properties. IEEE Sensors Journal 2004, 4, 308–312. [Google Scholar]

- Mamishev, A.; Sundara-Rajan, K.; Yang, F.; Du, Y.; Zahn, M. Interdigital sensors and transducers. Proceedings of the IEEE 2004, 92, 808–845. [Google Scholar]

- Fratticcioli, E.; Dionigi, M.; Sorrentino, R. A planar resonant sensor for the complex permittivity characterization of materials. IEEE MIT-S Digest 2002, 647–649. [Google Scholar]

- Toda, K.; Komatsu, Y.; Oguni, S.; Hashiguchi, S.; Sanemesa, I. Planar gas sensor combined with interdigitated array electrodes. Analytical Sciences 1999, 15, 87–89. [Google Scholar]

- Timmer, B.H.; Sparreboom, W.; Olthuis, W.; Bergveld, P.; van den Berg, A. Planar interdigitated conductivity sensors for low electrolyte concentrations. Proceedings of SeSens 2001, 878–883. [Google Scholar]

- Sundara-Rajan, K. Estimation of moisture content in paper pulp containing calcium carbonate using fringing field impedance spectroscopy. Appita Journal 2004, 413–419. [Google Scholar]

- Sundara-Rajan, K.; Byrd, L., II; Mamishev, A.V. Moisture content estimation in paper pulp using fringing field impedance spectroscopy. IEEE Sensors Journal 2003, 4, 378–383. [Google Scholar]

- FEMLAB. Finite Element Software. COMSOL 1994–2003. [Google Scholar]

- Taniguchi, T.; Nakamura, K.; Yamada, S.; Iwahara, M. An image synthesis method for eddy current testing based on extraction of defect orientation. Digest of IEEE Intermag conference 2002. GC-03. [Google Scholar]

- Ratnajeevan, S.; Hoole, H. Artificial neural network in the solution of inverse electromagnetic field problems. IEEE Transactions on Magnetics 1993, 29, 1931–1934. [Google Scholar]

- Enokizono, M.; Todaka, T.; Akita, M.; Nagata, S. Rotational magnetic flux sensor with neural network for non-destructive testing. IEEE Transactions on Magnetics 1993, 29, 3195–3197. [Google Scholar]

- Carlo, F.M.; Campolo, M. Location of plural defects in conductive plates via neural networks. IEEE transactions on Magnetics 1995, 31, 1765–1768. [Google Scholar]

- Enokizono, M.; Tsuchida, Y.; Chady, T. Crack size and shape determination by moving magnetic field type sensor. IEEE transactions on Magnetics 1998, 34, 1252–1254. [Google Scholar]

- Glorieux, C.; Moulder, J.C.; Bassart, J.; Thoen, J. The determination of electrical conductivity profiles using neural network inversion of multi-frequency eddy-current data. In Journal of Physics, D, Applied Physics; IOP Publishing Ltd.: UK, 1999; Volume 32, pp. 616–622. [Google Scholar]

- Chady, T.; Enokizono, M.; Sikora, R. Neural network models of eddy current multi-frequency systems for nondestructive testing. IEEE transactions on Magnetics 2000, 36, 1724–1727. [Google Scholar]

- Chady, T.; Enokizono, M.; Sikora, R.; Todaka, T.; Tsuchida, Y. Natural crack recognition using inverse neural model and multi-frequency eddy current method. IEEE transactions on Magnetics 2001, 37, 2797–2799. [Google Scholar]

- Allen, P.; Mcgeehin, B. Prediction of lean meat percentage in pigs using TOBEC. Proceedings of 43rd International Congress of Meat Science & Technology 1997, 254–255. [Google Scholar]

- Marchello, M.J.; Slanger, W.D.; Karlson, J.K. Bioelectrical impedance: fat content of beef and pork from different size grinds. Journal of Animal Science 1999, 77, 2464–2468. [Google Scholar]

- Schroeder, B.G.; Rust, R.E. Composition of pork bellies, compositional variations between and within animals and the relationship of various carcass measurements with chemical compositions of the belly. Journal of Animal Science 1974, 39, 1037–1044. [Google Scholar]

- Mitchell, A.D.; Scholz, A.M.; Wange, P.C.; Song, H. Body composition analysis of the pig by magnetic resonance imaging. Journal of Animal Science 2001, 79, 1800–1813. [Google Scholar]

- Sipahioglu, O.; Barringer, S.A.; Taub, I.; Yang, A.P.P. Characterization and modeling of dielectric properties of turkey meat. Journal of Food Science 2003, 68, 521–527. [Google Scholar]

- Tran, V.N.; Stuchly, S.S. Dielectric properties of beef liver, chicken and salmon at frequencies from 100 to 2500 MHz. Journal of Microwave Power 1987, 22, 29–33. [Google Scholar]

- Ryynanen, S. The Electromagnetic Properties of Food Materials: A Review of the Basic Principles. Journal of Food Engineering 1995, 26, 409–429. [Google Scholar]

| Sensor | Pitch (mm) | Length (mm) |

|---|---|---|

| 1 | 2 | 20 |

| 2 | 5 | 25 |

| 3 | 6 | 30 |

| 4 | 8 | 40 |

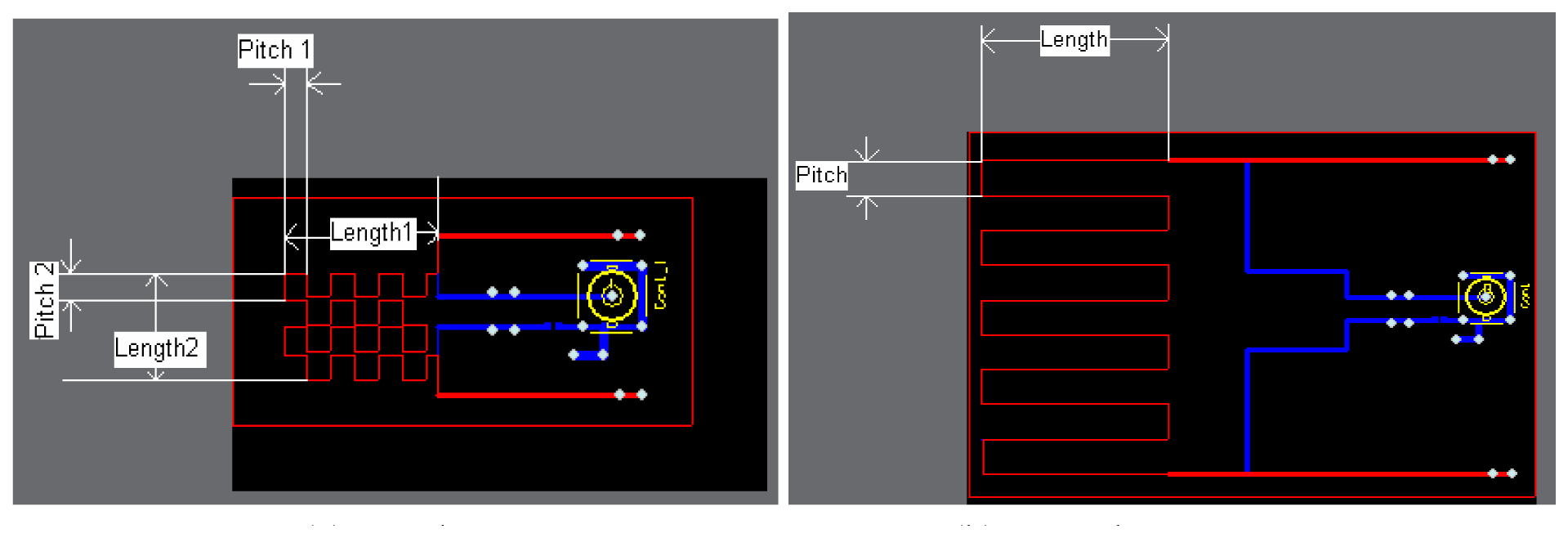

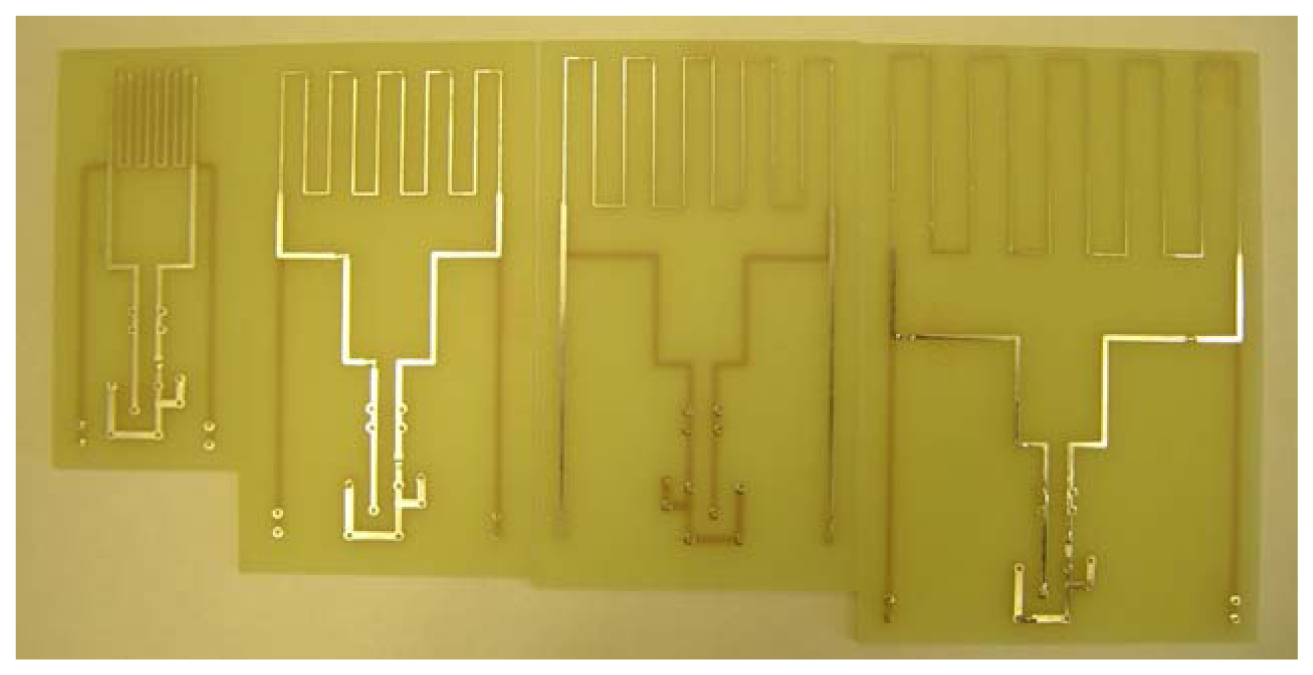

| Sensor | Pitch 1 (mm) | Pitch 2 (mm) | Length 1 (mm) | Length 2 (mm) |

|---|---|---|---|---|

| 1 | 2 | 2.5 | 10 | 10 |

| 2 | 3 | 3.5 | 14 | 14 |

| 3 | 3 | 3.5 | 20 | 14 |

| 4 | 4 | 5 | 27 | 18 |

| Sensor | Wavelength, λ (mm) | Length (mm) |

|---|---|---|

| 1 | 5 | 20 |

| 2 | 6 | 30 |

| 3 | 8 | 40 |

| 4 | 10 | 50 |

| Conductivity of Aluminum | From Grid System (S/m) | Neural Network Model (S/m) |

|---|---|---|

| With No lift-off | 3.6 E+7 | 3.53 E+7 |

| With 0.1 mm lift-off | 3.7 E+7 | 3.54 E+7 |

| With 0.2 mm lift-off | 3.8 E+7 | 3.53 E+7 |

| With 0.3 mm lift-off | 3.8 E+7 | 3.51 E+7 |

| With 0.4 mm lift-off | 3.4 E+7 | 3.49 E+7 |

| Sensor | Periodicity(cm) | Finger-length(cm) |

|---|---|---|

| 1 | 15 | 120 |

| 2 | 20 | 120 |

| 3 | 30 | 120 |

| Chemical Test | Sample A1 | Sample A2 | Sample B2 |

|---|---|---|---|

| 30.09 | 19.96 | 17.36 |

| Sample | Effective Permittivity (εeff) | Parameter of Index (Қ) |

|---|---|---|

| Orientation 1 | ||

| A1 | 2.7871 | 0.3588 |

| B1 | 4.7246 | 0.2117 |

| C1 | 3.6407 | 0.2747 |

| A2 | 6.1203 | 0.1634 |

| B2 | 6.0075 | 0.1665 |

| C2 | 4.9867 | 0.2005 |

| Orientation 2 | ||

| A1 | 2.7871 | 0.3588 |

| B1 | 4.7246 | 0.2117 |

| C1 | 3.6407 | 0.2747 |

| A2 | 6.1203 | 0.1634 |

| B2 | 6.0075 | 0.1665 |

| C2 | 4.9867 | 0.2005 |

| Orientation 3 | ||

| A1 | 4.9093 | 0.2037 |

| B1 | 10.8659 | 0.0920 |

| C1 | 6.2759 | 0.1593 |

| A2 | 14.0014 | 0.0714 |

| B2 | 17.7739 | 0.0563 |

| C2 | 40.1206 | 0.0249 |

| Orientation 4 | ||

| A1 | 4.9093 | 0.2037 |

| B1 | 10.8659 | 0.0920 |

| C1 | 6.2759 | 0.1593 |

| A2 | 14.0014 | 0.0714 |

| B2 | 17.7739 | 0.0563 |

| C2 | 40.1206 | 0.0249 |

| Sample | Parameter of Index (Қ) | Calculated Fat content | Calculated protein content |

|---|---|---|---|

| A1 | 0.3987 | 30.06 | 12.49 |

| A2 | 0.1633 | 18.74 | 16.28 |

| B1 | 0.2353 | 22.20 | 15.12 |

| B2 | 0.1644 | 18.80 | 16.26 |

| C1 | 0.3053 | 25.57 | 13.99 |

| C2 | 0.2005 | 20.53 | 15.68 |

© 2005 by MDPI ( http://www.mdpi.org). Reproduction is permitted for noncommercial purposes.

Share and Cite

Mukhopadhyay, S.C. Novel Planar Electromagnetic Sensors: Modeling and Performance Evaluation. Sensors 2005, 5, 546-579. https://doi.org/10.3390/s5120546

Mukhopadhyay SC. Novel Planar Electromagnetic Sensors: Modeling and Performance Evaluation. Sensors. 2005; 5(12):546-579. https://doi.org/10.3390/s5120546

Chicago/Turabian StyleMukhopadhyay, Subhas C. 2005. "Novel Planar Electromagnetic Sensors: Modeling and Performance Evaluation" Sensors 5, no. 12: 546-579. https://doi.org/10.3390/s5120546