Buckling-Based Non-Linear Mechanical Sensor

Abstract

:1. Introduction

2. Materials and Methods

3. Results

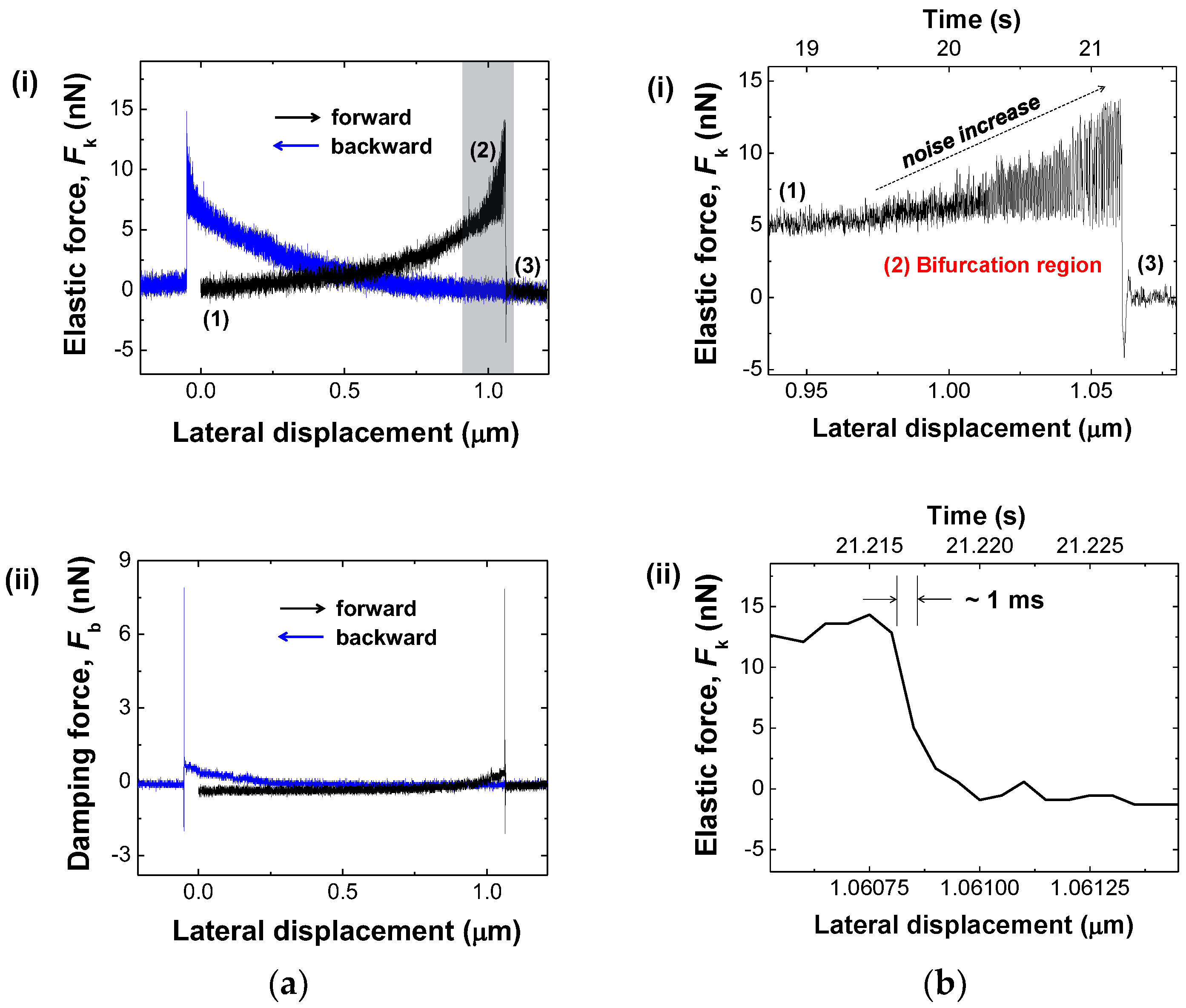

3.1. Sensitivity Increment at the Region of Bifurcation

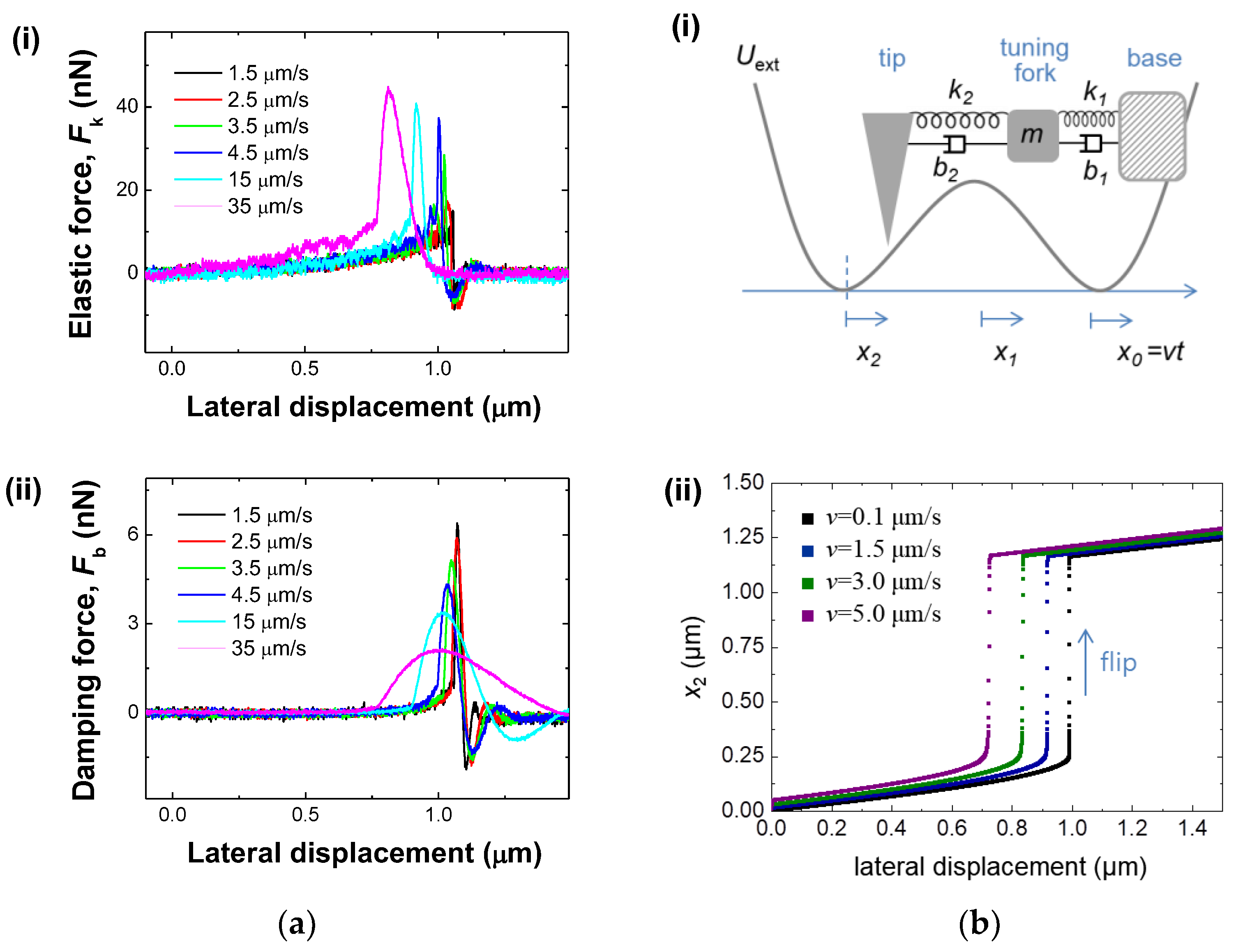

3.2. Characterization of the Non-Linear Sensor

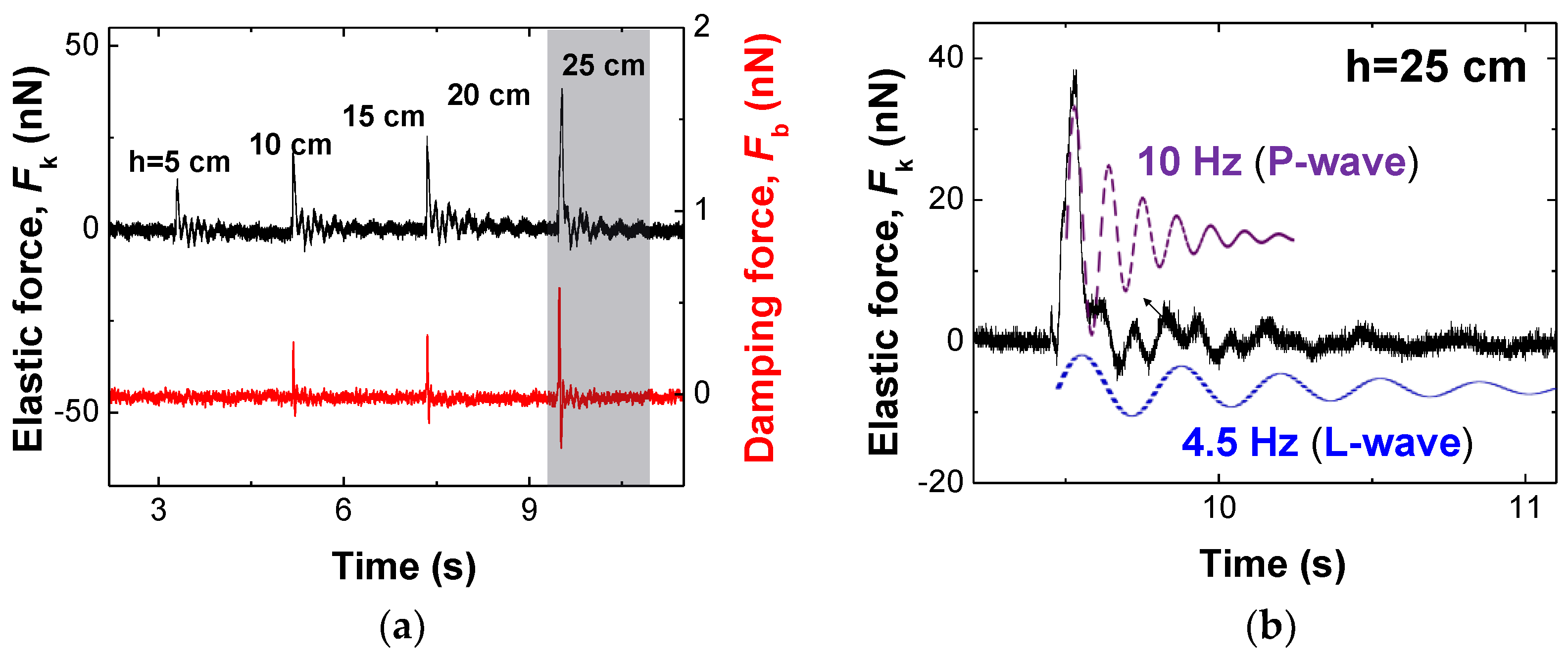

3.3. Demonstration of Senstive Mechnical Sensor

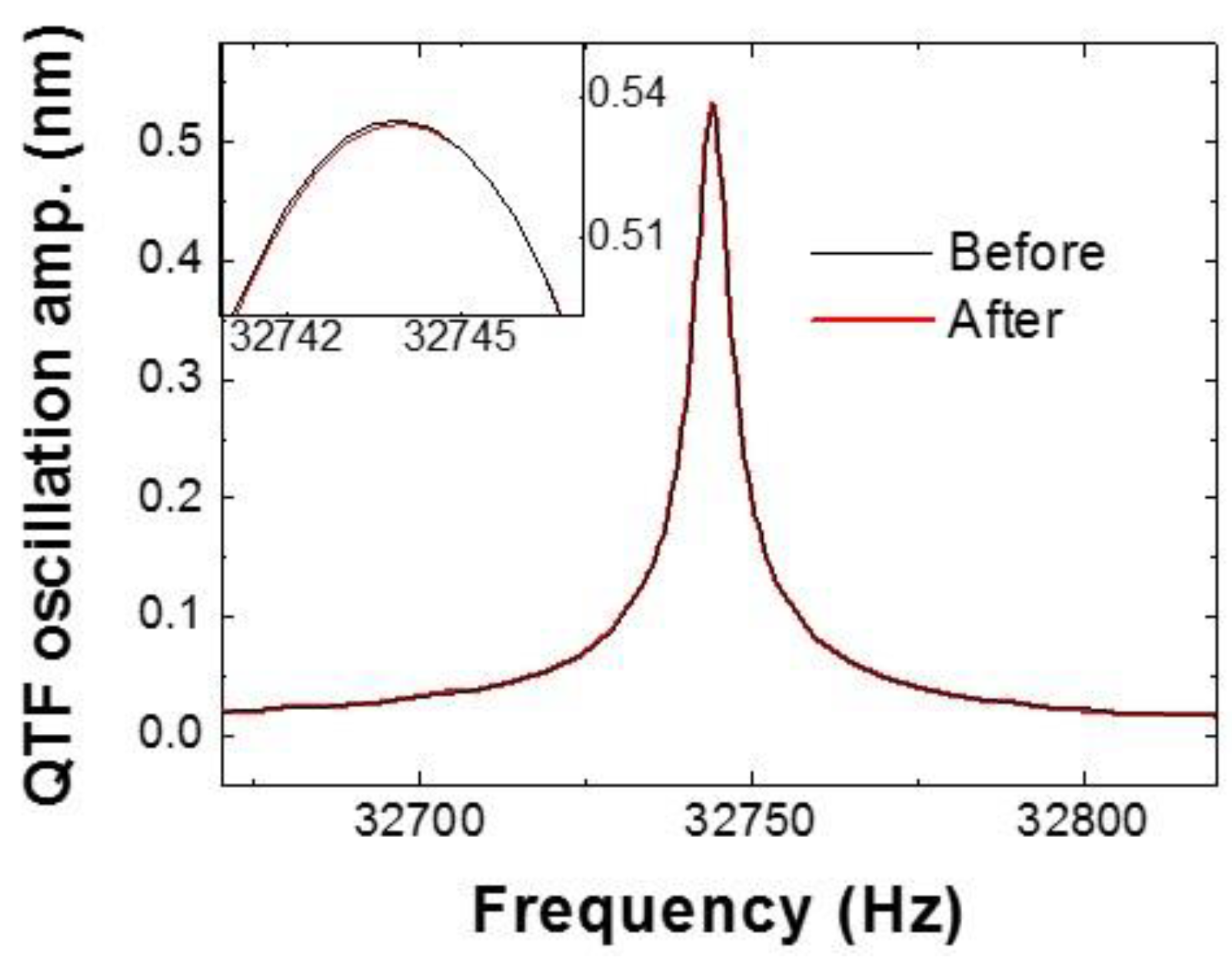

3.4. Reliability and Durability

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Euler, L. Additamentum I de curvis elasticis, methodus inveniendi lineas curvas maximi minimivi proprietate gaudentes. Opera Omnia I 1744, 24, 231–297. [Google Scholar]

- Chicurel, M.E.; Chen, C.S.; Ingber, D.E. Cellular control lies in the balance of forces. Curr. Opin. Cell Biol. 1998, 10, 232–239. [Google Scholar] [CrossRef]

- Falvo, M.R.; Clary, G.J.; Taylor, R.M.; Chi, V.; Brooks, F.P.; Washburn, S.; Superfine, R. Bending and buckling of carbon nanotubes under large strain. Nature 1997, 389, 582–584. [Google Scholar] [CrossRef] [PubMed]

- Grinfeld, M. The influence of mass forces on the critical thickness of pre-stressed He4 and solid epitaxial films. Europhys. Lett. 1993, 22, 723–728. [Google Scholar] [CrossRef]

- Kim, J.; Hanna, J.A.; Byun, M.; Santangelo, C.D.; Hayward, R.C. Designing responsive buckled surfaces by halftone gel lithography. Science 2012, 335, 1201–1205. [Google Scholar] [CrossRef] [PubMed]

- Cai, S.; Bertoldi, K.; Wang, H.; Suo, Z. Osmotic collapse of a void in an elastomer: Breathing, buckling and creasing. Soft Matter 2010, 6, 5770–5777. [Google Scholar] [CrossRef]

- Sanchez, T.; Chen, D.; DeCamp, S.J.; Heymann, M.; Dogic, Z. Spontaneous motion in hierarchically assembled active matter. Nature 2012, 491, 431–434. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cannon, D.F.; Edel, K.O.; Grassie, S.L.; Sawley, K. Rail defects: An overview. Fatigue Fract. Eng. Mater. Struct. 2003, 26, 865–887. [Google Scholar] [CrossRef]

- Swan, J.W.; Vasquez, P.A.; Furst, E.M. Buckling instability of self-assembled colloidal columns. Phys. Rev. Lett. 2014, 113, 138301. [Google Scholar] [CrossRef] [PubMed]

- Schroeder, C.M.; Babcock, H.P.; Shaqfeh, E.S.G.; Chu, S. Observation of polymer conformation hysteresis in extensional flow. Science 2003, 301, 1515–1519. [Google Scholar] [CrossRef] [PubMed]

- Becker, L.E.; Shelley, M.J. Instability of elastic filaments in shear flow yields first-normal-stress differences. Phys. Rev. Lett. 2001, 87, 198301. [Google Scholar] [CrossRef] [PubMed]

- Kachar, B.; Parakkal, M.; Kurc, M.; Zhao, Y.; Gillespie, P.G. High-resolution structure of hair-cell tip links. Proc. Natl. Acad. Sci. USA 2000, 97, 13336–13341. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, T.; Park, H.C.; Ahn, K.-H. Proposal for high sensitivity force sensor inspired by auditory hair cells. Appl. Phys. Lett. 2009, 95, 013702. [Google Scholar] [CrossRef]

- Omata, S.; Terunuma, Y. New tactile sensor like the human hand and its applications. Sens. Actuators A Phys. 1992, 35, 9–15. [Google Scholar] [CrossRef]

- Lanoye, R.; Vermeir, G.; Lauriks, W.; Kruse, R.; Mellert, V. Measuring the free field acoustic impedance and absorption coefficient of sound absorbing materials with a combined particle velocity-pressure sensor. J. Acoust. Soc. Am. 2006, 119, 2826–2831. [Google Scholar] [CrossRef]

- Bevly, D.M. Global positioning system (GPS): A low-cost velocity sensor for correcting inertial sensor errors on ground vehicles. J. Dyn. Sys. Meas. Control 2004, 126, 255–264. [Google Scholar] [CrossRef]

- Canuel, B.; Leduc, F.; Holleville, D.; Gauguet, A.; Fils, J.; Virdis, A.; Clairon, A.; Dimarcq, N.; Bordé, C.J.; Landragin, A.; et al. Six-axis inertial sensor using cold-atom interferometry. Phys. Rev. Lett. 2006, 97, 010402. [Google Scholar] [CrossRef] [PubMed]

- Lammerink, T.S.J.; Tas, N.R.; Elwenspoek, M.; Fluitman, J.H.J. Micro-liquid flow sensor. Sens. Actuators A Phys. 1993, 37–38, 45–50. [Google Scholar] [CrossRef]

- Kim, D.-H.; Lu, N.; Huang, Y.; Rogers, J.A. Materials for stretchable electronics in bioinspired and biointegrated devices. MRS Bull. 2012, 37, 226–235. [Google Scholar] [CrossRef]

- Kaltenbrunner, M.; Sekitani, T.; Reeder, J.; Yokota, T.; Kuribara, K.; Tokuhara, T.; Drack, M.; Schwödiauer, R.; Graz, I.; Bauer-Gogonea, S.; et al. An ultra-lightweight design for imperceptible plastic electronics. Nature 2013, 499, 458–463. [Google Scholar] [CrossRef] [PubMed]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef] [PubMed]

- Mannsfeld, S.C.B.; Tee, B.C.-K.; Stoltenberg, R.M.; Chen, C.V.H.-H.; Barman, S.; Muir, B.V.O.; Sokolov, A.N.; Reese, C.; Bao, Z. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.-Y.; Kim, T.-I.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef] [PubMed]

- Wielandt, E.; Streckeisen, G. The leaf-spring seismometer: Design and performance. Bull. Seismol. Soc. Am. 1982, 72, 2349–2367. [Google Scholar]

- Stuart-Watson, D.; Tapson, J. Simple force balance accelerometer/seismometer based on a tuning fork displacement sensor. Rev. Sci. Instrum. 2004, 75, 3045. [Google Scholar] [CrossRef]

- Given, D.D.; Cochran, E.S.; Heaton, T.; Hauksson, E.; Allen, R.; Hellweg, P.; Vidale, J.; Bodin, P. Technical Implementation Plan for the Shake Alert Production System—An Earthquake Early Warning System for the West Coast of the United States; Open-File Report 2014-1097; U.S. Geological Survey: Reston, VA, USA, 2014; pp. 1–25. [Google Scholar]

- An, S.; Kim, J.; Lee, K.; Kim, B.; Lee, M.; Jhe, W. Mechanical properties of the nanoscale molecular cluster of water meniscus by high-precision frequency modulation atomic force spectroscopy. Appl. Phys. Lett. 2012, 101, 053114. [Google Scholar] [CrossRef]

- Dykman, M.I.; Krivoglaz, M.A. Fluctuations in nonlinear systems near bifurcations corresponding to the appearance of new stable states. Phys. A Stat. Mech. Its Appl. 1980, 104, 480–494. [Google Scholar] [CrossRef]

- Vijay, R.; Devoret, M.H.; Siddiqi, I. Invited Review Article: The Josephson bifurcation amplifier. Rev. Sci. Instrum. 2009, 80, 111101. [Google Scholar] [CrossRef] [PubMed]

- An, S.; Hong, M.-H.; Kim, J.; Kwon, S.; Lee, K.; Lee, M.; Jhe, W. Quartz tuning fork-based frequency modulation atomic force spectroscopy and microscopy with all digital phase-locked loop. Rev. Sci. Instrum. 2012, 83, 113705. [Google Scholar] [CrossRef] [PubMed]

- Conley, W.G.; Krousgrill, C.M.; Raman, A. Stick-slip motions in the friction force microscope: Effects of tip compliance. Tribol. Lett. 2008, 29, 23–32. [Google Scholar] [CrossRef]

- Havskov, J.; Alguacil, G. Instrumentation in earthquake seismology. In Modern Approaches in Geophysics; Springer: New York, NY, USA, 2004; ISBN 1402029683. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, S.; Kim, B.; Kwon, S.; Moon, G.; Lee, M.; Jhe, W. Buckling-Based Non-Linear Mechanical Sensor. Sensors 2018, 18, 2637. https://doi.org/10.3390/s18082637

An S, Kim B, Kwon S, Moon G, Lee M, Jhe W. Buckling-Based Non-Linear Mechanical Sensor. Sensors. 2018; 18(8):2637. https://doi.org/10.3390/s18082637

Chicago/Turabian StyleAn, Sangmin, Bongsu Kim, Soyoung Kwon, Geol Moon, Manhee Lee, and Wonho Jhe. 2018. "Buckling-Based Non-Linear Mechanical Sensor" Sensors 18, no. 8: 2637. https://doi.org/10.3390/s18082637