A Fiber Bragg Grating (FBG)-Enabled Smart Washer for Bolt Pre-Load Measurement: Design, Analysis, Calibration, and Experimental Validation

Abstract

:1. Introduction

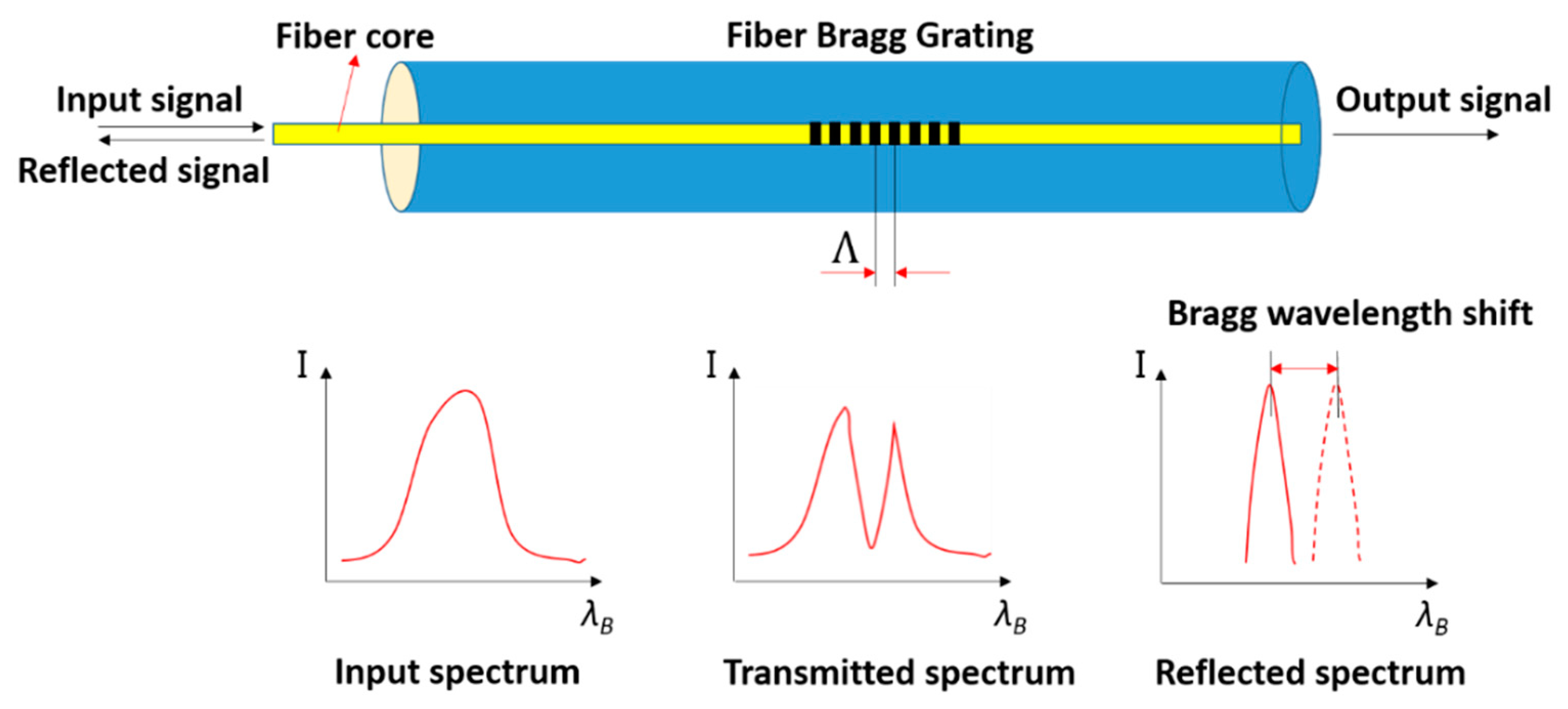

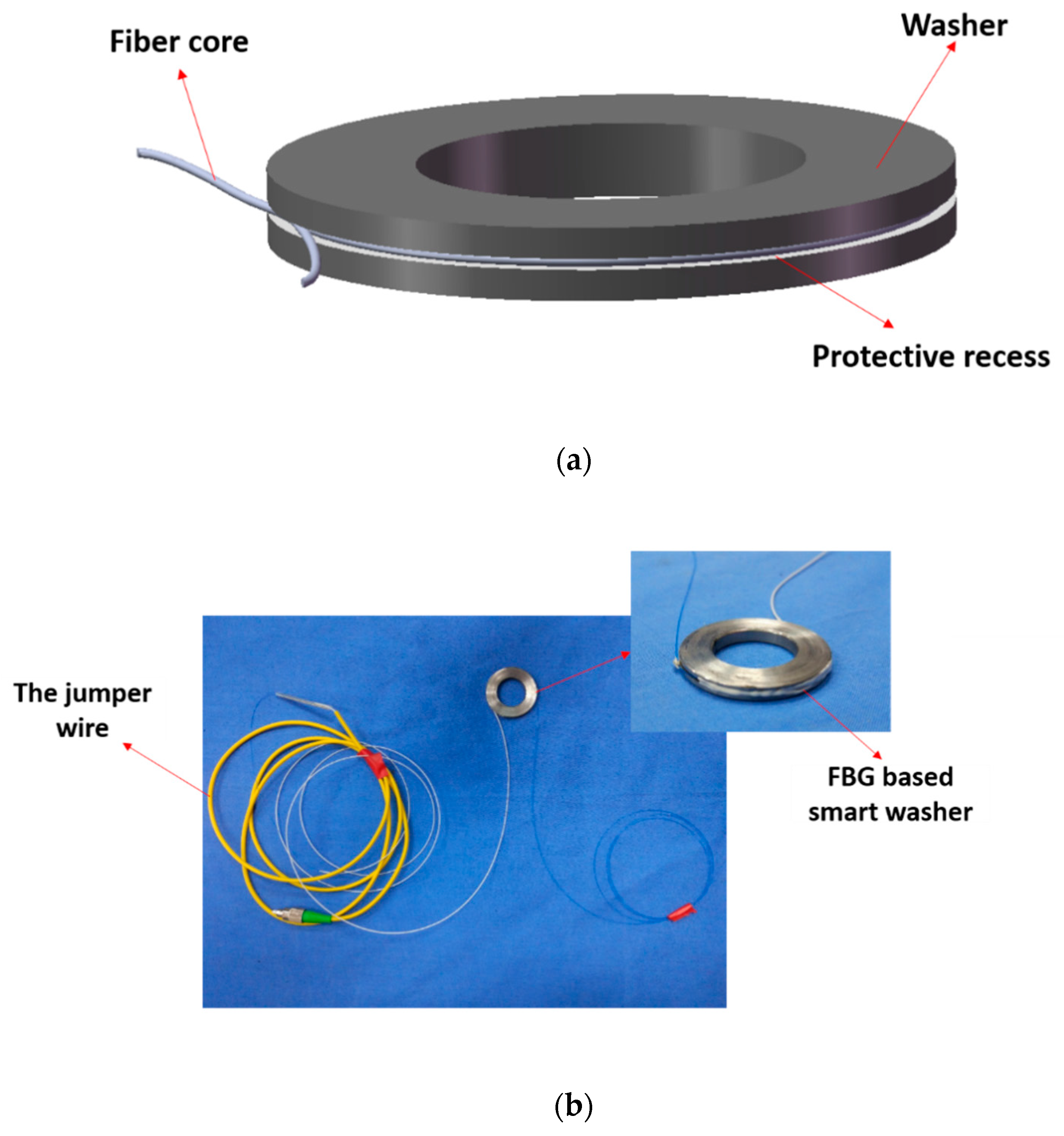

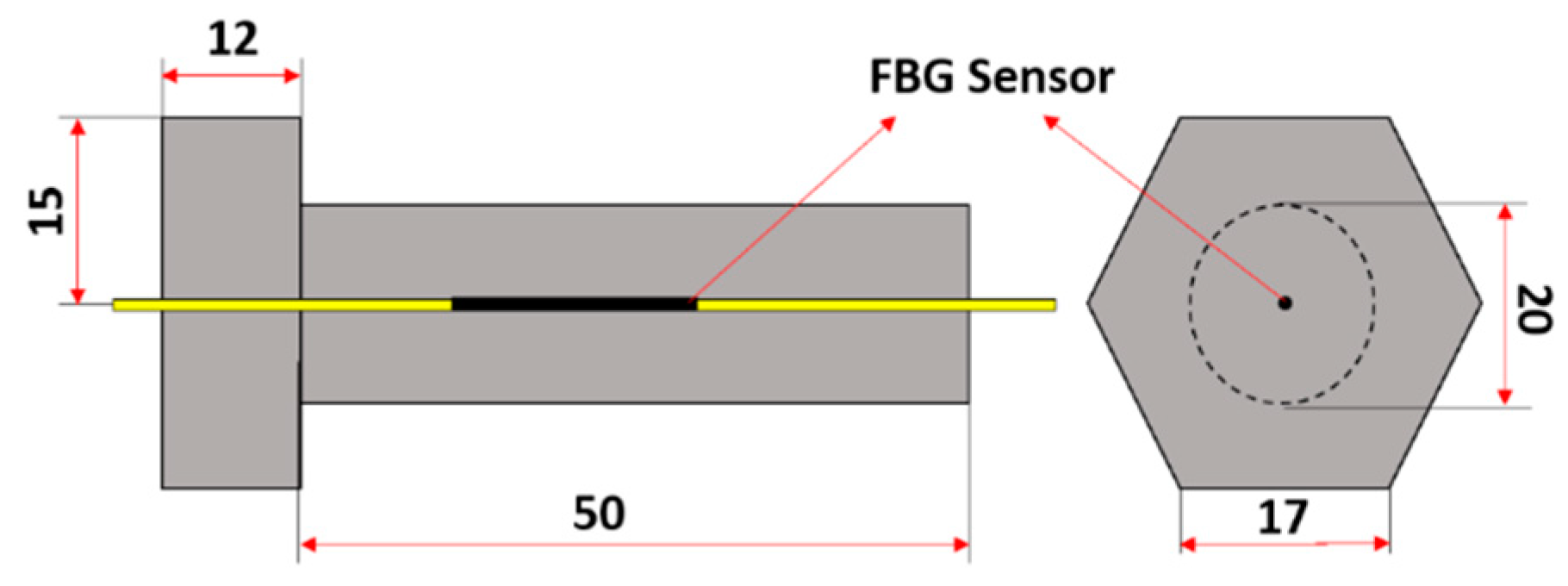

2. Fiber Bragg Grating (FBG)-Enabled Smart Washer: Principle and Design

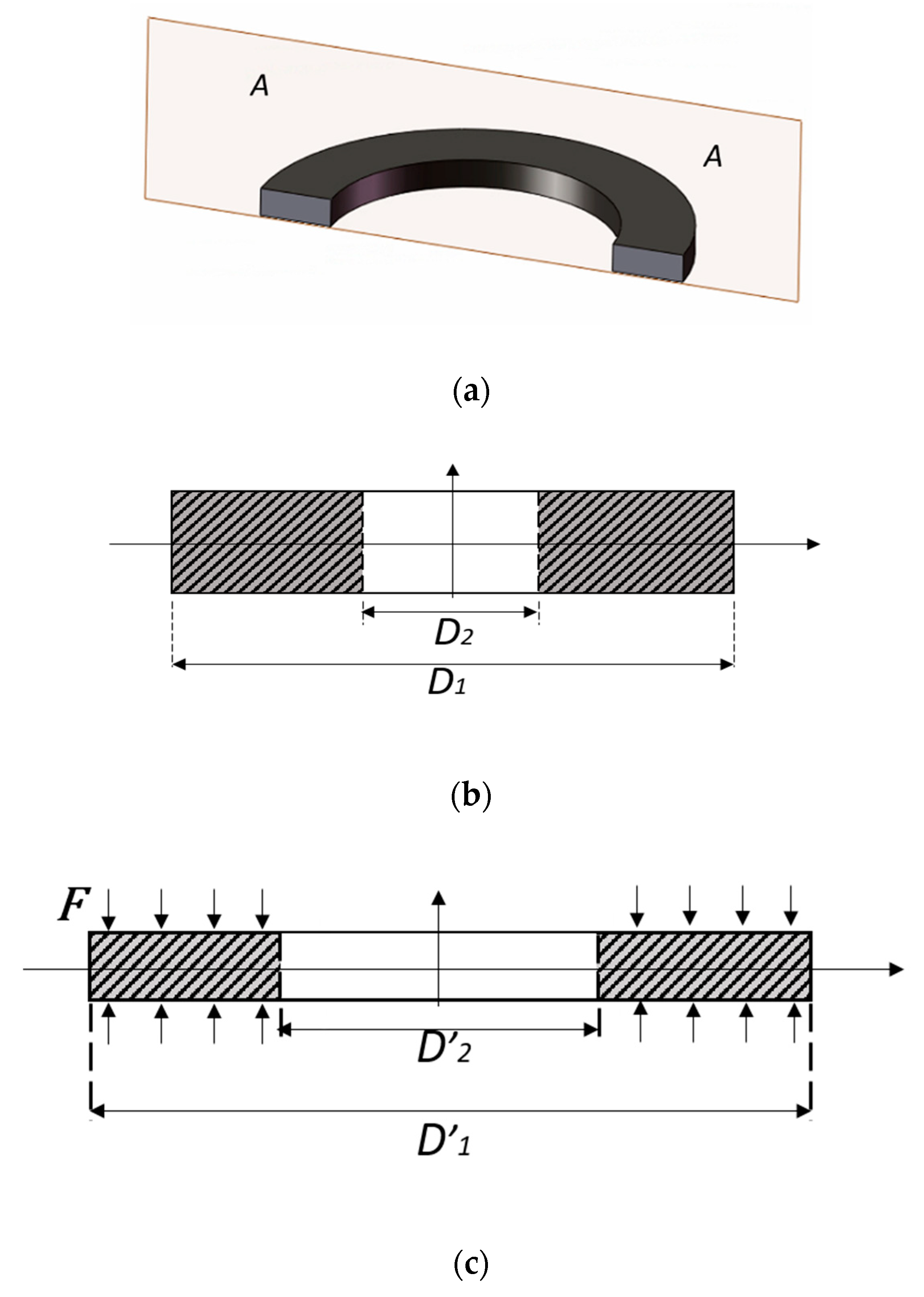

3. Smart Washer—An Analytical Model

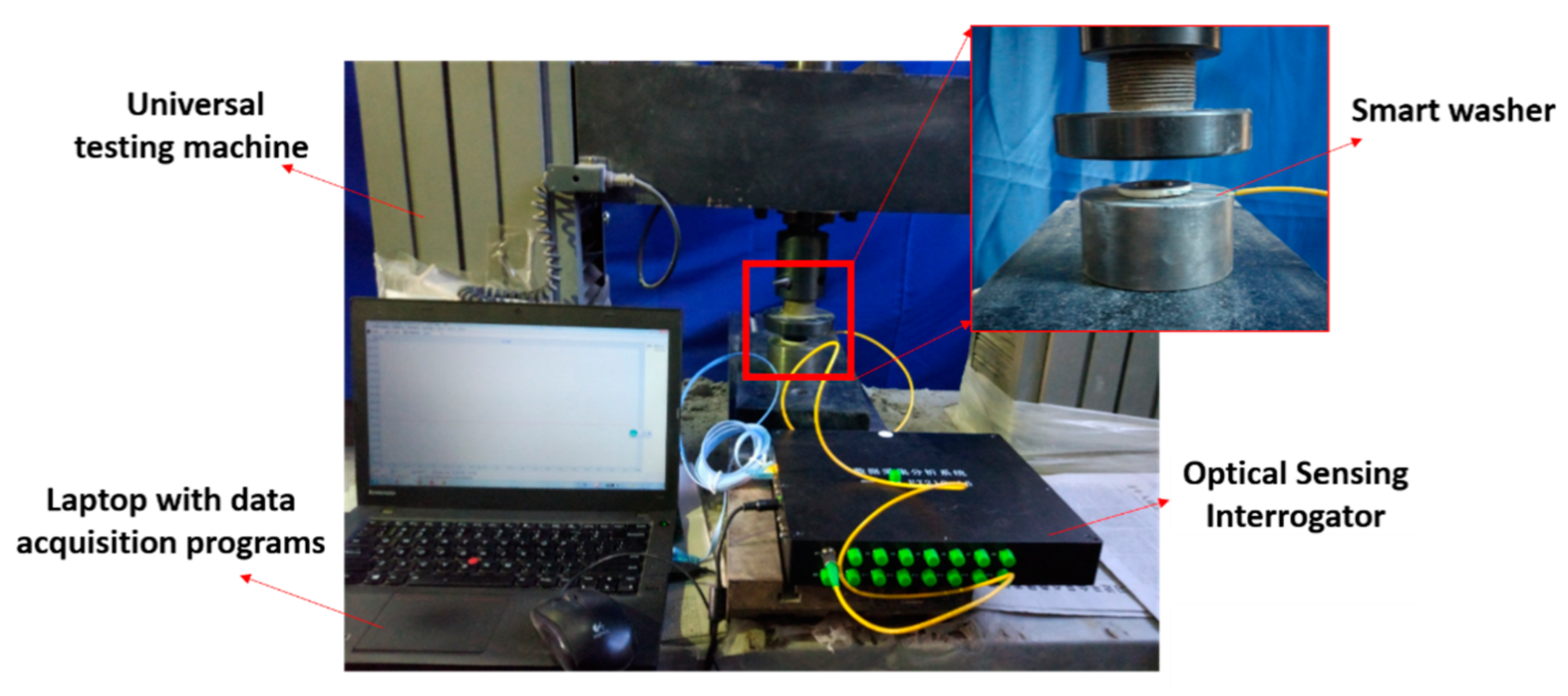

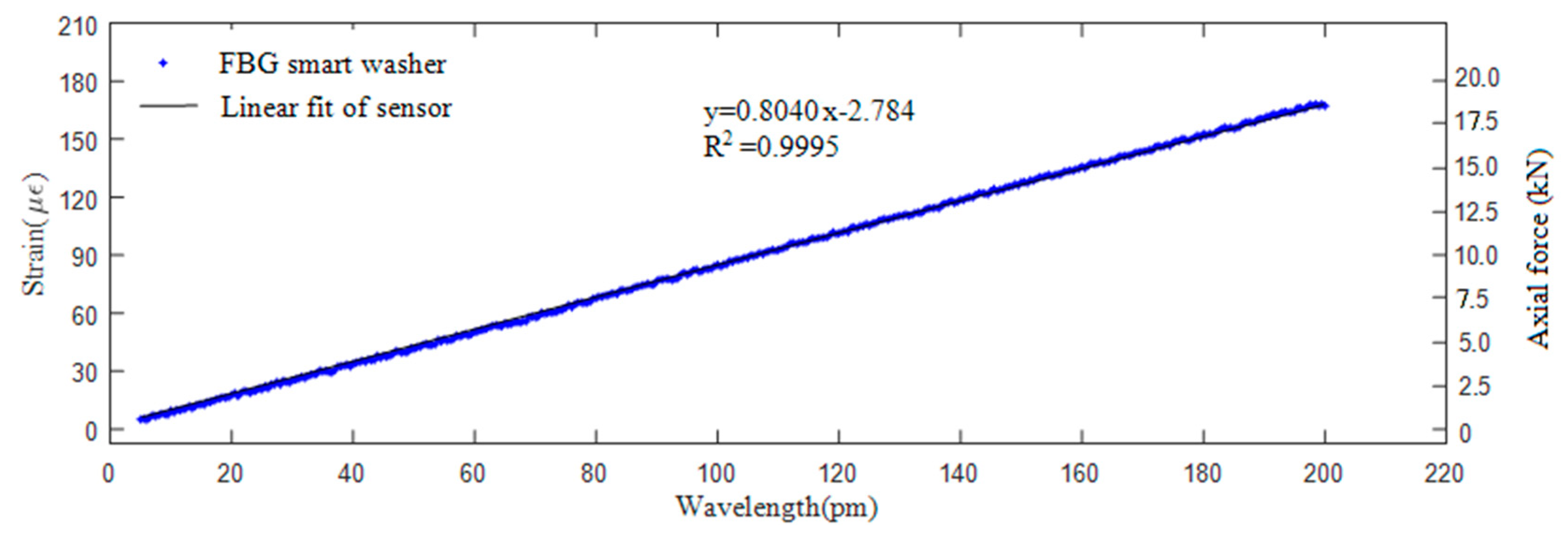

4. Smart Washer—Calibration

5. Bolt Looseness Monitoring Experiments Using Smart Washer

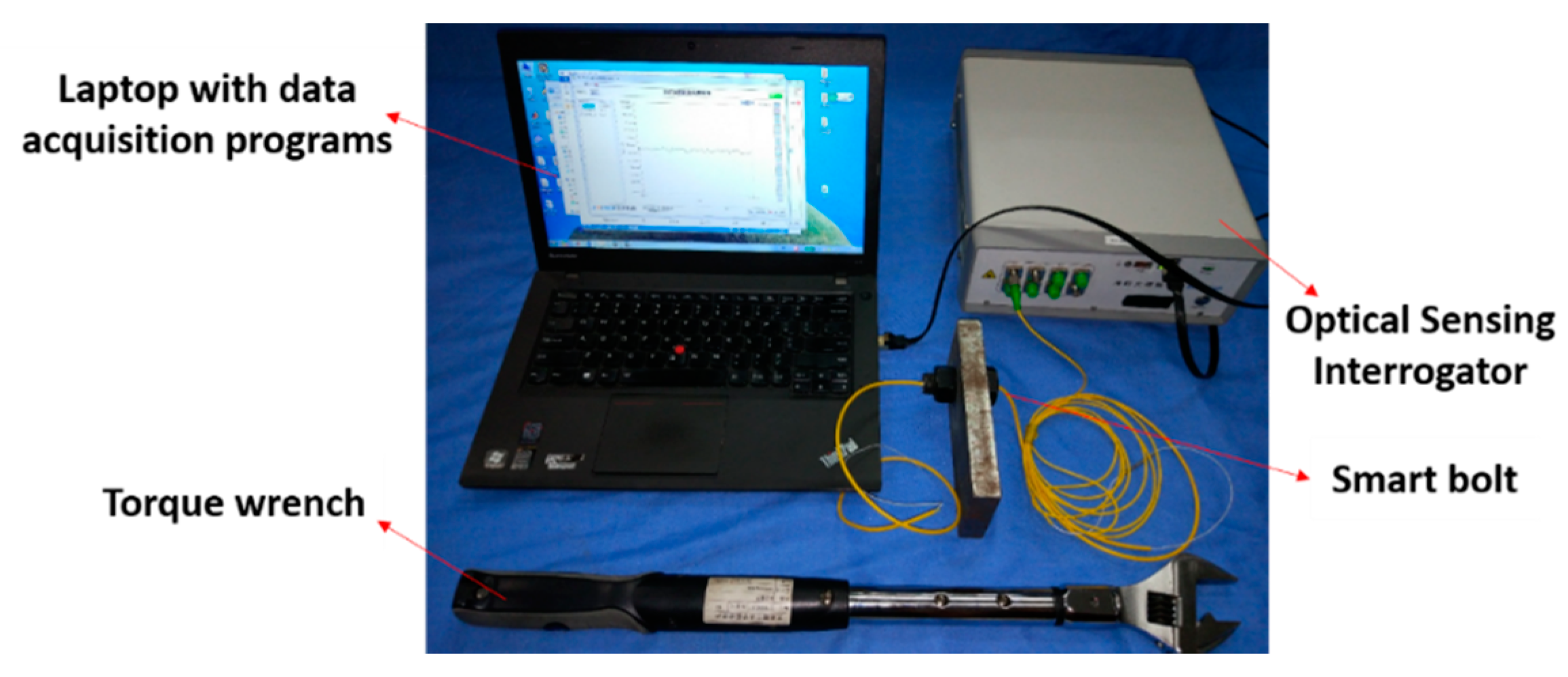

5.1. Experimental Setup

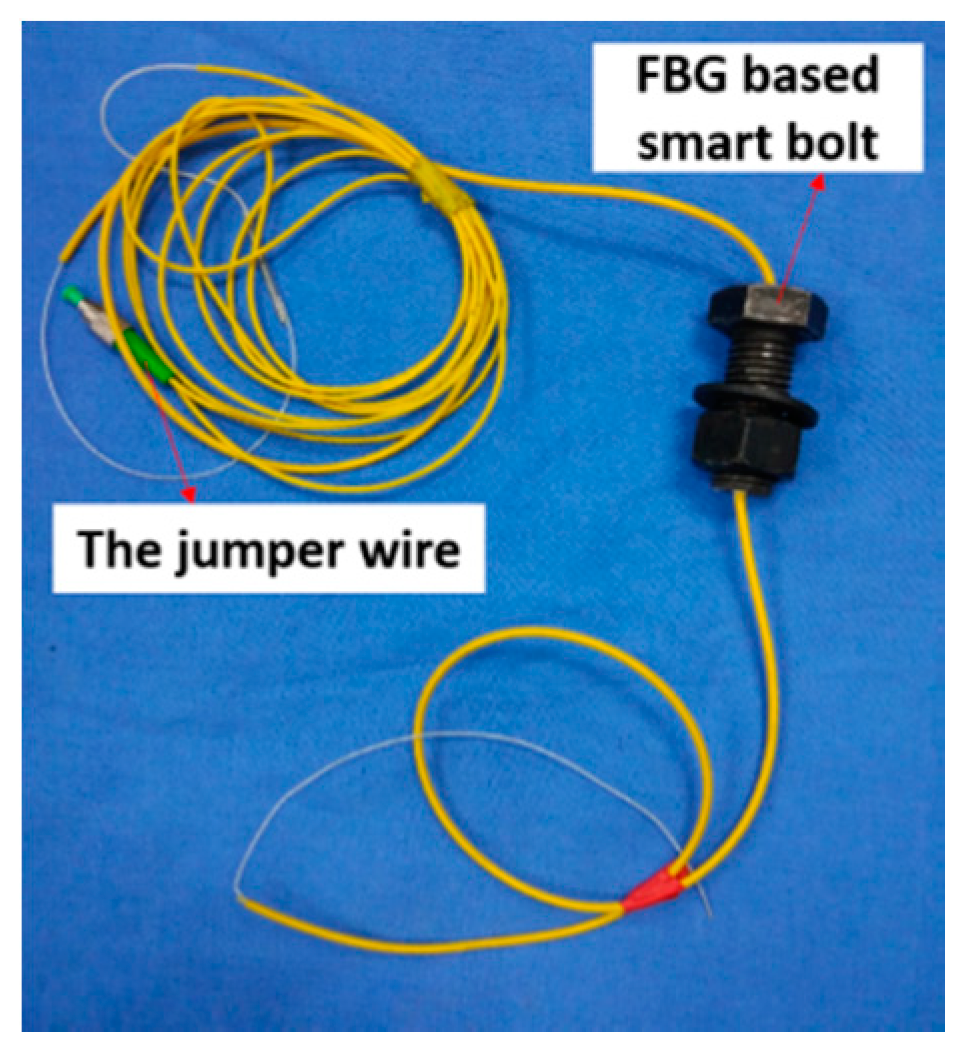

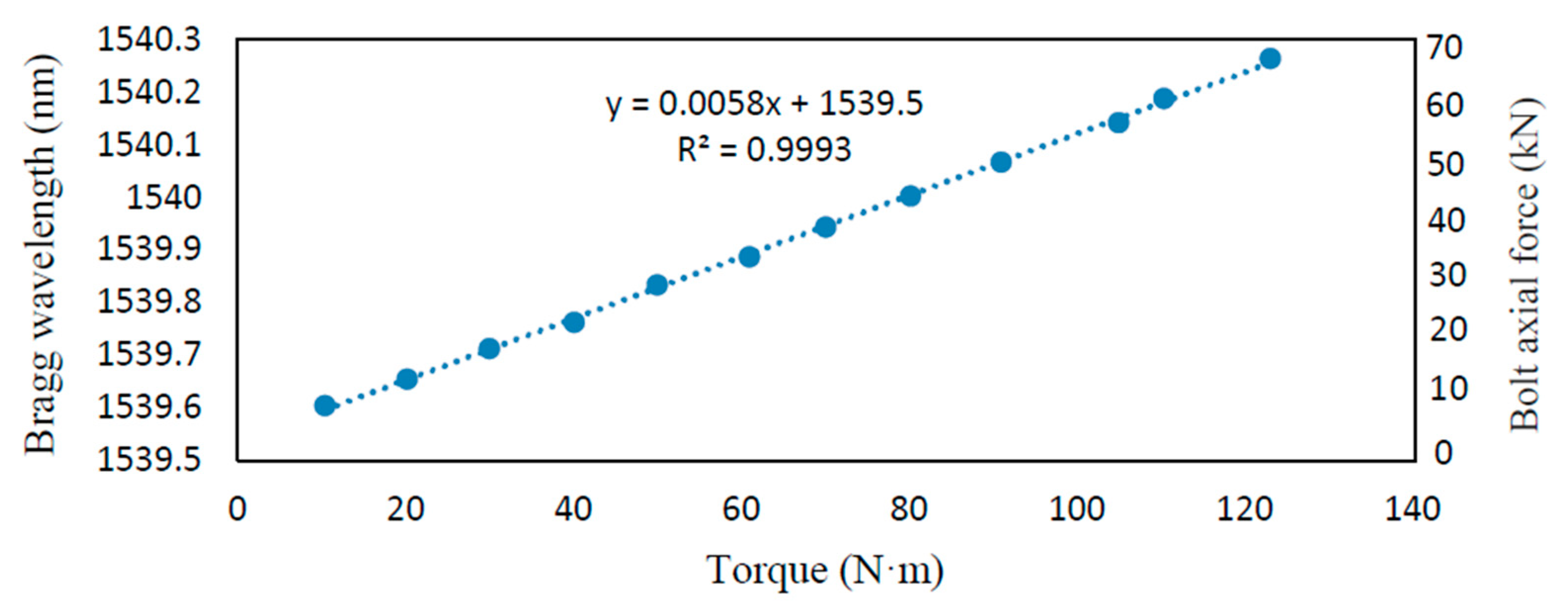

5.2. Relationship Between Pre-Load and External Torque with Help from a Smart Bolt

5.3. Quantitative Monitoring of Bolt Pre-Load Using an FBG-Based Smart Washer

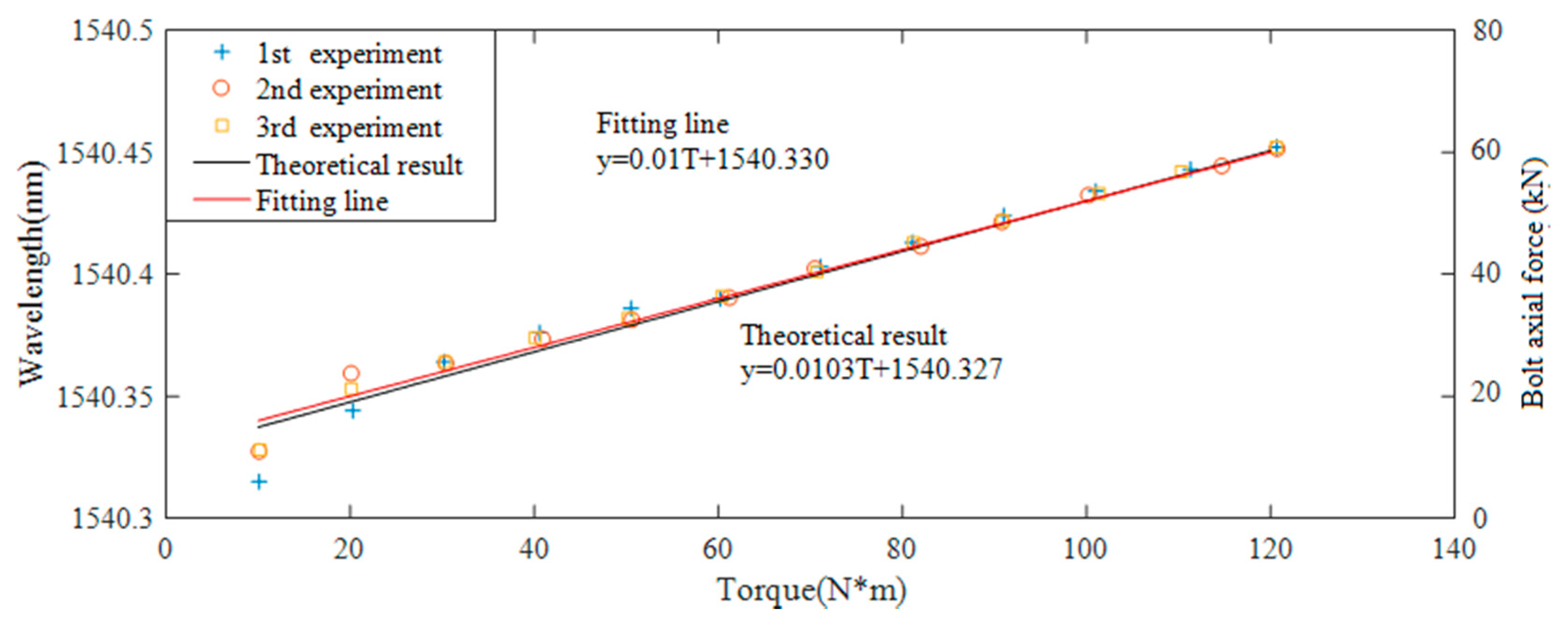

6. Validation between Theoretical and Experimental Results

7. Conclusions and Future Work

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Pines, D.; Aktan, A.E. Status of structural health monitoring of long-span bridges in the United States. Prog. Struct. Eng. Mater. 2002, 4, 372–380. [Google Scholar] [CrossRef]

- Yi, T.H.; Li, H.N.; Gu, M. Recent research and applications of GPS-based monitoring technology for high-rise structures. Struct. Contr. Health Monit. 2013, 20, 649–670. [Google Scholar] [CrossRef]

- Brownjohn, J.; Moyo, P.; Omenzetter, P.; Chakraborty, S. Lessons from monitoring the performance of highway bridges. Struct. Contr. Health Monit. 2005, 12, 227–244. [Google Scholar] [CrossRef] [Green Version]

- Mufti, A.A. Structural health monitoring of innovative Canadian civil engineering structures. Struct. Health Monit. 2002, 1, 89–103. [Google Scholar] [CrossRef]

- Wong, K.Y. Instrumentation and health monitoring of cable-supported bridges. Struct. Contr. Health Monit. 2004, 11, 91–124. [Google Scholar] [CrossRef]

- Du, G.; Kong, Q.; Zhou, H.; Gu, H. Multiple Cracks Detection in Pipeline Using Damage Index Matrix Based on Piezoceramic Transducer-Enabled Stress Wave Propagation. Sensors 2017, 17, 1812. [Google Scholar] [CrossRef] [PubMed]

- Kong, Q.; Robert, R.; Silva, P.; Mo, Y.L. Cyclic Crack Monitoring of a Reinforced Concrete Column under Simulated Pseudo-Dynamic Loading Using Piezoceramic-Based Smart Aggregates. Appl. Sci. 2016, 6, 341. [Google Scholar] [CrossRef]

- Shao, J.; Wang, T.; Yin, H.; Yang, D.; Li, Y. Bolt Looseness Detection Based on Piezoelectric Impedance Frequency Shift. Appl. Sci. 2016, 6, 298. [Google Scholar] [CrossRef]

- Yin, H.; Wang, T.; Yang, D.; Liu, S.; Shao, J.; Li, Y. A Smart Washer for Bolt Looseness Monitoring Based on Piezoelectric Active Sensing Method. Appl. Sci. 2016, 6, 320. [Google Scholar] [CrossRef]

- Xu, J.; Wang, C.; Li, H.; Zhang, C.; Hao, J.; Fan, S. Health Monitoring of Bolted Spherical Joint Connection Based on Active Sensing Technique Using Piezoceramic Transducers. Sensors 2018, 18, 1727. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Song, G.; Liu, S.; Li, Y.; Xiao, H. Review of bolted connection monitoring. Int. J. Distrib. Sens. Netw. 2013, 9, 871213. [Google Scholar] [CrossRef]

- Masataka, S.; Hasuo, Y.; Kanaya, A.; Ogura, Y.; Takishita, T.; Suzuki, Y. Development of ultrasonic axial bolting force inspection system for turbine bolts in thermal power plants. JSME Int. J. Solid Mech. Strength Mater. 1992, 35, 216–219. [Google Scholar]

- Yao, P.; Zheng, B.; Dawood, M.; Huo, L.; Song, G. Real time monitoring of spot-welded joints under service load using lead zirconate titanate (PZT) transducers. Smart Mater. Struct. 2017, 26, 035059. [Google Scholar] [CrossRef]

- Huo, L.; Chen, D.; Liang, Y.; Li, H.; Feng, X.; Song, G. Impedance based bolt pre-load monitoring using piezoceramic smart washer. Smart Mater. Struct. 2017, 26, 057004. [Google Scholar] [CrossRef]

- Yasui, H.; Kawashima, K. Acoustoelastic measurement of bolt axial load with velocity ratio method. In Proceedings of the 15th World Conference on Non-Destructive Testing, Rome, Italy, 15–21 October 2000; pp. 16–21. [Google Scholar]

- Wang, T.; Song, G.; Wang, Z.; Li, Y. Proof-of-concept study of monitoring bolt connection status using a piezoelectric based active sensing method. Smart Mater. Struct. 2013, 22, 087001. [Google Scholar] [CrossRef]

- Huo, L.; Chen, D.; Kong, Q.; Li, H.; Song, G. Smart washer—A piezoceramic-based transducer to monitor looseness of bolted connection. Smart Mater. Struct. 2017, 26, 025033. [Google Scholar] [CrossRef]

- Huo, L.; Wang, F.; Li, H.; Song, G. A fractal contact theory based model for bolted connection looseness monitoring using piezoceramic transducers. Smart Mater. Struct. 2017, in press. [Google Scholar] [CrossRef]

- Park, G.; Sohn, H.; Farrar, C.R.; Inman, D.J. Overview of piezoelectric impedance-based health monitoring and path forward. Shock Vib. Dig. 2003, 35, 451–463. [Google Scholar] [CrossRef]

- Yaowen, Y.; Bahador Sabet, D. Sub-Frequency Interval Approach in Electromechanical Impedance Technique for Concrete Structure Health Monitoring. Sensors 2010, 10, 11644–11661. [Google Scholar] [Green Version]

- Enrique, S.; Sun, R.; Ricardo, P. Damage Detection Based on Power Dissipation Measured with PZT Sensors through the Combination of Electro-Mechanical Impedances and Guided Waves. Sensors 2016, 16, 639. [Google Scholar] [Green Version]

- Fan, S.; Zhao, S.; Qi, B.; Kong, Q. Damage Evaluation of Concrete Column under Impact Load Using a Piezoelectric-Based EMI Technique. Sensors 2018, 18, 1591. [Google Scholar] [CrossRef] [PubMed]

- Liang, C.; Sun, F.; Rogers, C. Coupled electro-mechanical analysis of adaptive material systems-determination of the actuator power consumption and system energy transfer. J. Intell. Mater. Syst. Struct. 1997, 8, 335–343. [Google Scholar] [CrossRef]

- Park, G.; Cudney, H.H.; Inman, D.J. Feasibility of using impedance-based damage assessment for pipeline structures. Earthq. Eng. Struct. Dyn. 2001, 30, 1463–1474. [Google Scholar] [CrossRef]

- Park, G.; Cudney, H.H.; Inman, D.J. Impedance-based health monitoring of civil structural components. J. Infrastruct. Syst. 2000, 6, 153–160. [Google Scholar] [CrossRef]

- Lynch, J.P. A Summary Review of Wireless Sensors and Sensor Networks for Structural Health Monitoring. Shock Vib. Dig. 2006, 38, 91–128. [Google Scholar] [CrossRef]

- Perera, R.; Pérez, A.; García-Diéguez, M.; Zapico-Valle, J.L. Active Wireless System for Structural Health Monitoring Applications. Sensors 2017, 17, 2880. [Google Scholar] [CrossRef] [PubMed]

- Na, W.; Baek, J. Impedance-Based Non-Destructive Testing Method Combined with Unmanned Aerial Vehicle for Structural Health Monitoring of Civil Infrastructures. Appl. Sci. 2016, 7, 15. [Google Scholar] [CrossRef]

- Tennyson, R.; Coroy, T.; Duck, G.; Manuelpillai, G.; Mulvihill, P.; Cooper, D.J.; Smith, P.E.; Mufti, A.; Jalali, S. Fibre optic sensors in civil engineering structures. Can. J. Civ. Eng. 2000, 27, 880–889. [Google Scholar] [CrossRef]

- Li, H.-N.; Li, D.-S.; Song, G.-B. Recent applications of fiber optic sensors to health monitoring in civil engineering. Eng. Struct. 2004, 26, 1647–1657. [Google Scholar] [CrossRef]

- Tennyson, R.; Mufti, A.; Rizkalla, S.; Tadros, G.; Benmokrane, B. Structural health monitoring of innovative bridges in Canada with fiber optic sensors. Smart Mater. Struct. 2001, 10, 560–573. [Google Scholar] [CrossRef]

- Ecke, W.; Latka, I.; Willsch, R.; Reutlinger, A.; Graue, R. Fibre optic sensor network for spacecraft health monitoring. Meas. Sci. Technol. 2001, 12, 974. [Google Scholar]

- Zhou, Z.; He, J.; Huang, M.; He, J.; Chen, G. Casing pipe damage detection with optical fiber sensors: A case study in oil well constructions. Adv. Civ. Eng. 2010, 2010, 638967. [Google Scholar]

- Chong, S.Y.; Lee, J.-R.; Yun, C.-Y.; Sohn, H. Design of copper/carbon-coated fiber Bragg grating acoustic sensor net for integrated health monitoring of nuclear power plant. Nucl. Eng. Des. 2011, 241, 1889–1898. [Google Scholar] [CrossRef]

- Li, W.; Ho, S.C.M.; Luo, M.; Huynh, Q.; Song, G. Fiber optic macro-bend based sensor for detection of metal loss. Smart Mater. Struct. 2017, 26, 045002. [Google Scholar] [CrossRef]

- Khomenko, A.; Koricho, E.G.; Haq, M.; Cloud, G.L. Bolt tension monitoring with reusable fiber Bragg-grating sensors. J. Strain Anal. Eng. Des. 2015, 51, 101–108. [Google Scholar] [CrossRef]

- Khomenko, A.; Koricho, E.G.; Haq, M.; Cloud, G.L. Short-Term Preload Relaxation in Composite Bolted Joints Monitored with Reusable Optical Sensors. In Joining Technologies for Composites and Dissimilar Materials, Proceedings of the 2016 Annual Conference on Experimental and Applied Mechanics, Orlando, FL, USA, 6–9 June 2016; Springer: Berlin, Germany, 2016; pp. 115–123. [Google Scholar]

- Yeager, M.; Whitaker, A.; Todd, M. A method for monitoring bolt torque in a composite connection using an embedded fiber Bragg grating sensor. J. Intell. Mater. Syst. Struct. 2017. [Google Scholar] [CrossRef]

- Büyüköztürk, O.; Taşdemir, M.A. Nondestructive Testing of Materials and Structures; Springer Science & Business Media: Berlin, Germany, 2012; Volume 6. [Google Scholar]

- Majumder, M.; Gangopadhyay, T.K.; Chakraborty, A.K.; Dasgupta, K.; Bhattacharya, D.K. Fibre Bragg gratings in structural health monitoring—Present status and applications. Sens. Actuators A Phys. 2008, 147, 150–164. [Google Scholar] [CrossRef]

- Ren, L.; Feng, T.; Ho, M.; Jiang, T.; Song, G. A smart “shear sensing” bolt based on FBG sensors. Measurement 2018, 122, 240–246. [Google Scholar] [CrossRef]

- Bray, A.; Levi, R. Factors affecting the tightening characteristics of bolts. Exp. Mech. 1966, 6, 409–419. [Google Scholar] [CrossRef]

- Eccles, W. Design Guidelines for Torque Controlled Tightening of Bolted Joints; 0148-7191; SAE Technical Paper; SAE: Warrendale, PA, USA; Troy, MI, USA, 1993. [Google Scholar]

- Fukuoka, T.; Takaki, T. Mechanical behaviors of bolted joint during tightening using torque control. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 1998, 41, 185–191. [Google Scholar] [CrossRef]

- Sakai, T. The friction coefficient of fasteners. Bull. JSME 1978, 21, 333–340. [Google Scholar] [CrossRef]

- Motosh, N. Development of design charts for bolts preloaded up to the plastic range. J. Eng. Ind. 1976, 98, 849–851. [Google Scholar] [CrossRef]

- Jiang, Y.; Chang, J.; Lee, C.-H. An experimental study of the torque-tension relationship for bolted joints. Int. J. Mater. Prod. Technol. 2001, 16, 417–429. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.; Huo, L.; Li, H.; Song, G. A Fiber Bragg Grating (FBG)-Enabled Smart Washer for Bolt Pre-Load Measurement: Design, Analysis, Calibration, and Experimental Validation. Sensors 2018, 18, 2586. https://doi.org/10.3390/s18082586

Chen D, Huo L, Li H, Song G. A Fiber Bragg Grating (FBG)-Enabled Smart Washer for Bolt Pre-Load Measurement: Design, Analysis, Calibration, and Experimental Validation. Sensors. 2018; 18(8):2586. https://doi.org/10.3390/s18082586

Chicago/Turabian StyleChen, Dongdong, Linsheng Huo, Hongnan Li, and Gangbing Song. 2018. "A Fiber Bragg Grating (FBG)-Enabled Smart Washer for Bolt Pre-Load Measurement: Design, Analysis, Calibration, and Experimental Validation" Sensors 18, no. 8: 2586. https://doi.org/10.3390/s18082586