The Sensory Quality and Volatile Profile of Dark Chocolate Enriched with Encapsulated Probiotic Lactobacillus plantarum Bacteria

Abstract

:1. Introduction

2. Materials and Methods

2.1. Strains and Culture Conditions

2.2. Encapsulation Process of Lactobacillus plantarum

2.3. Enumeration of Encapsulated Lactobacillus plantarum

2.4. Chocolate Production

2.5. Viability of Probiotic Bacteria

2.6. Chemical Analysis of Chocolate

2.7. Characterisation of Volatile Flavour Compounds by Head Space Gas Chromatography Mass Spectrometry

2.8. Sensory Analysis

2.9. Statistical Analysis

3. Results and Discussion

3.1. Cell Count of Spray Dried Probiotic Bacteria

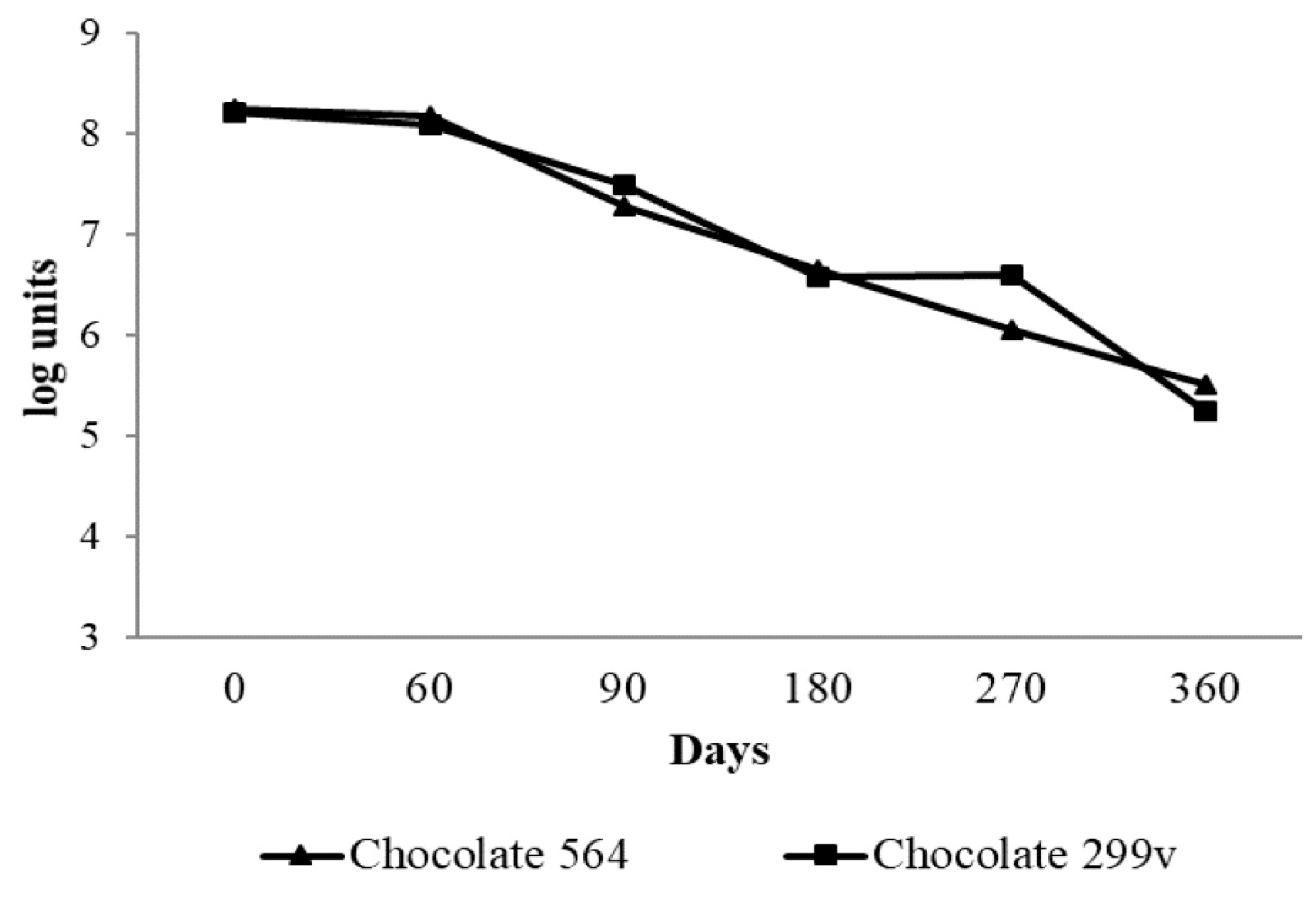

3.2. Viability of Probiotic Bacteria

3.3. Chemical Composition of Dark Chocolate

3.4. Volatile Analysis

3.5. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Crittiden, R.G.; Bennett, L.E. Cow’s Milk Allergy: A Complex Disorder. J. Am. Coll. Nutr. 2005, 24, 582–591. [Google Scholar] [CrossRef]

- Misselwitz, B.; Pohl, D.; Frühauf, H.; Fried, M.; Vavricka, S.R.; Fox, M. Lactose malabsorption and intolerance: Pathogenesis, diagnosis and treatment. United Eur. Gastroenterol. J. 2013, 1, 151–159. [Google Scholar] [CrossRef] [PubMed]

- Adamson, G.E.; Lazarus, S.A.; Mitchell, A.E.; Prior, R.L.; Cao, G.; Jacobs, P.H.; Kremers, B.G.; Hammerstone, J.F.; Rucker, R.B.; Ritter, K.A.; et al. HPLC method for the quantification of procyanidins in cocoa and chocolate samples and correlation to total antioxidant capacity. J. Agric. Food Chem. 1999, 47, 4184–4188. [Google Scholar] [CrossRef] [PubMed]

- Afoakwa, E.O.; Paterson, A.; Fowler, M.; Ryan, A. Flavor formation and character in cocoa and chocolate: A critical review. Crit. Rev. Food Sci. Nutr. 2008, 48, 840–857. [Google Scholar] [CrossRef] [PubMed]

- Hatano, T.; Miyatake, H.; Natsume, M.; Osakabe, N.; Takizawa, T.; Ito, H.; Yoshida, T. Proanthocyanidin glycosides and related polyphenols from cacao liquor and their antioxidant effects. Phytochemistry 2002, 59, 749–758. [Google Scholar] [CrossRef]

- Cooper, K.A.; Donovan, J.L.; Waterhouse, A.L.; Williamson, G. Cocoa and health: A decade of research. Br. J. Nutr. 2008, 99, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Keen, C.L.; Holt, R.R.; Polagruto, J.A.; Wang, J.F.; Schmitz, H.H. Cocoa flavanols and cardiovascular health. Phytochem. Rev. 2002, 1, 231–240. [Google Scholar] [CrossRef]

- Lippi, G.; Franchini, M.; Montagnana, M.; Favaloro, E.J.; Guidi, G.C.; Targher, G. Dark chocolate: Consumption for pleasure or therapy? J. Thromb. Thrombolysis 2009, 28, 482–488. [Google Scholar] [CrossRef] [PubMed]

- Smith, G. Benefits of flavanol-rich cocoa-derived products for mental well-being: A review. J. Funct. Foods 2013, 5, 10–15. [Google Scholar] [CrossRef]

- Possemiers, S.; Marzorati, M.; Verstraete, W.; Van de Wiele, T. Bacteria and chocolate: A successful combination for probiotic delivery. Int. J. Food Microbiol. 2010, 141, 97–103. [Google Scholar] [CrossRef] [PubMed]

- Briggs, M. Chocolate the Tasty Treat with a Dark Secret; Abbeydale Press: Leicester, UK, 2008. [Google Scholar]

- Lagorce, S. Chocolat; Octopus Publishing Group Ltd.: London, UK, 2008. [Google Scholar]

- Counet, C.; Callemien, D.; Ouwerx, C.; Collin, S. Use of Gas Chromatography-Olfactometry to Identify Key Odorant Compounds in Dark Chocolate. Comparison of Samples before and after Conching. J. Agric. Food Chem. 2002, 50, 2385–2391. [Google Scholar] [CrossRef] [PubMed]

- Magi, E.; Bono, L.; Di Carro, M. Characterization of cocoa liquors by GC-MS and LC-MS/MS: Focus on alkylpyrazines and flavanols. J. Mass Spectrom. 2012, 47, 1191–1197. [Google Scholar] [CrossRef] [PubMed]

- Cambrai, A.; Marcic, C.; Morville, S.; Houer, P.S.; Bindler, F.; Marchioni, E. Differentiation of Chocolates According to the Cocoa’s Geographical Origin Using Chemometrics. J. Agric. Food Chem. 2010, 58, 1478–1483. [Google Scholar] [CrossRef] [PubMed]

- Schwan, R.; Wheals, A. The microbiology of cocoa fermentation and its role in chocolate quality. Crit. Rev. Food Sci. Nutr. 2004, 44, 205–221. [Google Scholar] [CrossRef] [PubMed]

- Taylor, A.J. Food Flavor Technology; Sheffield Academic Press: Sheffield, UK, 2002. [Google Scholar]

- Ioannone, F.; Di Mattia, C.D.; De Gregorio, M.; Serg, M.; Serafini, M.; Sacchetti, G. Flavanols, proanthocyanidins and antioxidant activity changes during cocoa (Theobroma cacao L.) roasting as affected by temperature and time of processing. Food Chem. 2015, 174, 256–262. [Google Scholar] [CrossRef] [PubMed]

- Misnawi, S.J.; Jamilah, B.; Nazamid, S. Changes in polyphenol ability to produce astringency during roasting of cocoa liquor. J. Sci. Food Agric. 2005, 85, 917–924. [Google Scholar] [CrossRef]

- Afoakwa, E.O.; Paterson, A.; Fowler, M. Factors influencing rheological and textural qualities in chocolate—A review. Trends Food Sci. Technol. 2007, 18, 290–298. [Google Scholar] [CrossRef]

- Jantzen, M.; Gopel, A.; Beermann, C. Direct spray drying and microencapsulation of probiotic Lactobacillus reuteri from slurry fermentation with whey. J. Appl. Microbiol. 2013, 115, 1029–1036. [Google Scholar] [PubMed]

- Radulović, Z.; Petrović, T.; Nedović, V.; Dimitrijević, S.; Mirković, N.; Petrušić, M.; Paunović, D. Characterization of autochthonous Lactobacillus paracasei strains on potential probiotic ability. Mljekarstvo 2010, 60, 86–93. [Google Scholar]

- Radulović, Z.; Mirković, N.; Bogović-Matijašič, B.; Petrušić, M.; Petrović, T.; Manojlović, V.; Nedović, V. Quantification of Viable Spray-dried Potential Probiotic Lactobacilli using Real-Time PCR. Arch. Biol. Sci. 2012, 64, 1465–1472. [Google Scholar] [CrossRef]

- Laličić-Petronijević, J.; Popov-Raljić, J.; Obradović, D.; Radulović, Z.; Paunović, D.; Petrušić, M.; Pezo, L. Viability of probiotic strain Lactobacillus acidophilus NCFM® and Bifidobacteriumlactis HN019 and their impact on sensory and rheological properties of milk and dark chocolates during storage for 180 days. J. Func. Food 2015, 15, 541–550. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of Association of Official Analytical Chemists, 18th ed.; AOAC: Washington, DC, USA, 2005. [Google Scholar]

- Popov-Raljić, J.; Laličić-Petronijević, J. Sensory Properties and Color Measurements of Dietary Chocolates with Different Compositions during Storage for up to 360 Days. Sensors 2009, 9, 1996–2016. [Google Scholar] [CrossRef] [PubMed]

- ISO 8586-1. Sensory Analysis–General Guidance for the Selection, Training and Monitoring of Assessors–Part 1: Selected Assessors; International Organization for Standardization: Geneva, Switzerland, 1993. [Google Scholar]

- ISO 8586-2. Sensory Analysis–General Guidance for the Selection, Training and Monitoring of Assessors–Part 2: Experts; International Organization for Standardization: Geneva, Switzerland, 1994. [Google Scholar]

- Radulović, Z.; Miočinović, J.; Mirković, N.; Mirković, M.; Paunović, D.; Ivanović, M.; Seratlić, S. Survival of spray-dried and free-cells of potential probiotic Lactobacillus plantarum 564 in soft goat cheese. Anim. Sci. J. 2017, 88, 1849–1854. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations/World Health Organization. Report of a Joint FAO/WHO Expert Consultation on Evaluation of Health and Nutritional Properties of Probiotics in Food Including Powder Milk with Live Lactic Acid Bacteri; Food and Agriculture Organization: Cordoba, Argentina, 2001. [Google Scholar]

- Fooks, L.J.; Gibson, G.R. Probiotics as modulators of the gut flora. Br. J. Nutr. 2002, 88, 39–49. [Google Scholar] [CrossRef] [PubMed]

- Gibson, G.R.; Roberfroid, M.B. Dietary modulation of the human colonic microbiota: Introducing the concept of prebiotics. J. Nutr. 1995, 125, 1401–1412. [Google Scholar] [PubMed]

- Ouwehand, A.C.; Salminen, S.; Isolauri, E. Probiotics: An overview of beneficial effects. Antonie Van Leeuwenhoek 2002, 82, 279–289. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.K.; Salminen, S. Handbook of Probiotics and Prebiotics, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009. [Google Scholar]

- Lomer, M.C.; Parkes, G.C.; Sanderson, J.D. Review article: Lactose intolerance in clinical practice-myths and realities. Aliment. Pharmacol. Ther. 2008, 27, 93–103. [Google Scholar] [CrossRef] [PubMed]

- Prescott, S.L.; Björkstén, B. Probiotics for the prevention or treatment of allergic diseases. J. Allergy Clin. Immunol. 2007, 120, 255–262. [Google Scholar] [CrossRef] [PubMed]

- Prasad, J.; Gill, H.; Smart, J.; Gopal, P.K. Selection and characterization of Lactobacillus and Bifidobacterium strains for use as probiotics. Int. Dairy J. 1998, 8, 993–1002. [Google Scholar] [CrossRef]

- Milesi, M.M.; Vinderola, G.; Sabbag, N.; Meinardi, C.A.; Hynes, E. Influence on cheese proteolysis and sensory characteristic of non-starter lactobacilli strains with probiotic potential. Food Res. Int. 2009, 42, 1186–1196. [Google Scholar] [CrossRef]

- Mandal, S.; Hati, S.; Puniya, A.K.; Sinhg, R.; Singh, K. Development of Symbiotic Milk Chocolate Using Encapsulated Lactobacillus casei NCDC 298. J. Food Process. Preserv. 2012, 1, 1–7. [Google Scholar]

- Kurmann, J.A.; Rasic, J.L. The health potential of products containing bifidobacteria. In Therapeutic Properties of Fermented Milks; Robinson, R.K., Ed.; Elsevier Applied Sciences: London, UK, 1999; pp. 117–158. [Google Scholar]

- Kailaspathy, K.; Chin, J. Survival and therapeutic potential of probiotic organisms with reference to Lactobacillus acidophilus and Bifidobacterium spp. Immunol. Cell Biol. 2000, 78, 80–88. [Google Scholar] [CrossRef] [PubMed]

- Coman, M.M.; Cecchini, C.; Verdenelli, M.C.; Silvi, S.; Orpianesi, C.; Cresci, A. Functional food s as carrier for SYNBIO®, a probiotic bacteria combination. Int. J. Food Microbiol. 2012, 157, 346–352. [Google Scholar] [CrossRef] [PubMed]

- Gismondo, M.R.; Drago, L.; Lombardi, A. Review of probiotics available to modify gastrointestinal flora. Int. J. Antimicrob. Agents 1999, 12, 287–292. [Google Scholar] [CrossRef]

- Nicolas, J.Z.; Nedović, V. Encapsulation Technologies for Active Food Ingredients and Food Processing; Springer: New York, NY, USA; Dordrecht, The Netherland; Heidelberg, Germany; London, UK, 2009. [Google Scholar]

- Gibbs, B.F.; Kermasha, S.; Alli, I.; Mulligan, C.N. Encapsulation in the food industry: A review. Int. J. Food Sci. Nutr. 1999, 50, 213–224. [Google Scholar] [PubMed]

- Crittenden, R.; Weerakkody, R.; Sanguansri, L.; Augustin, M.A. Synbiotic microcapsules that enhance microbial viability during non-refrigerated storage and gastro-intestinal transit. Appl. Environ. Microbiol. 2006, 72, 2280–2282. [Google Scholar] [CrossRef] [PubMed]

- Gardiner, G.E.; O’Sullivan, E.; Kelly, J.; Auty, M.A.; Fitzgerald, G.F.; Collins, J.K.; Ross, R.P.; Stanton, C. Comparative survival rates of human-derived probiotic Lactobacillus paracasei and L. salivarius strains during heat treatment and spray drying. Appl. Environ. Microbiol. 2000, 66, 2605–2612. [Google Scholar] [CrossRef] [PubMed]

- Teanpaisan, R.; Chooruk, A.; Wannun, A.; Wichienchot, S.; Piwat, S. Survival rates of human-derived probiotic Lactobacillus paracasei SD1 in milk powder using spray drying. Songklanakarin J. Sci. Technol. 2012, 34, 241–245. [Google Scholar]

- Nebesny, E.; Zyzelewicz, D.; Motyl, I. Dark chocolate supplemented with Lactobacillus strains. Eur. Food Res. Technol. 2007, 225, 33–42. [Google Scholar] [CrossRef]

- Aragon-Alegro, L.C.; Aragon-Alegro, J.H.; Cardarelli, H.R.; Chiu, M.C.; Saad, S.M. Potentially probiotic and synbiotic chocolate mousse. LWT Food Sci. Technol. 2007, 40, 669–675. [Google Scholar] [CrossRef]

- Moros, J.; Inon, F.A.; Garrigues, S.; De la Guardia, M. Near-infrared diffuse reflectance spectroscopy and neural networks for measuring nutritional parameters in chocolate samples. Anal. Chim. Acta 2007, 584, 215–222. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, R.; Mortazavian, A.M.; Khosrokhavar, R.; Da Cruz, A.G. Probiotic ice cream: Viability of probiotic bacteria and sensory properties. Ann. Microbiol. 2011, 61, 411–424. [Google Scholar] [CrossRef]

| Basic Sensory Properties | Weight Coefficient | Score | Description of the Evaluated Property | |

|---|---|---|---|---|

| APPEARANCE | Form Colour Gloss Surface | 2.50 | 5 | Appropriate form; spotless colour; smooth, glossy surface; clear print |

| 4 | Insignificant deviation of form; spotless colour; smooth, glossy surface; less clear print | |||

| 3 | Deviations of form; lower quality colour; fingerprints on the surface; air bubbles; less clear print | |||

| 2 | More pronounced form deviations; partially white or grey surface; presence of cracks | |||

| 1 | Distorted form; grey or white surface; higher damages; bad print | |||

| TEXTURE | MEHANICAL PROPERTIES Structure Break Hardness Chewiness | 2.50 | 5 | Straight break, homogenous, fragile; homogenous structure; appropriate chewiness |

| 4 | Uneven break; homogenous structure; appropriate hardness; very good chewiness | |||

| 3 | Uneven break, air bubbles; inappropriate hardness; fat bloom appearance on the break; average chewiness | |||

| 2 | Uneven break; roughly-granular texture; fat bloom on the break; stickiness; chewiness satisfactory | |||

| 1 | Crumbling; texture roughly granular; fat bloom; very bad chewiness and very strong stickiness | |||

| SURFACE PROPERTIES Moisture Lubricity | 1.0 | 5 | Without surface extracted water/fat | |

| 4 | Slight separation of water/fat on the surface | |||

| 3 | Separation of water/fat on the surface | |||

| 2 | Clearly expressed separation of water/fat on the surface | |||

| 1 | Very pronounced separation of water/fat on the surface | |||

| OTHER DYNAMIC PROPERTIES Solubility | 0.5 | 5 | Inherent gradual solubility | |

| 4 | Slight deviation from the characteristic, gradual dissolution | |||

| 3 | Deviation from the characteristic, gradual dissolution | |||

| 2 | Clearly pronounced deviation from the characteristic, gradual dissolution | |||

| 1 | Very pronounced deviation from the characteristic, gradual dissolution—very slow or very fast solubility | |||

| AROMA | THE ODOUR | 4.00 | 5 | Appropriate; round; aromatic |

| 4 | Appropriate; less round; aromatic | |||

| 3 | Appropriate; less round; poorly aromatic | |||

| 2 | Not appropriate; sour; staled | |||

| 1 | Foreign odour; sour; staled; mouldy | |||

| THE TASTE | 7.00 | 5 | Appropriate; round; aromatic | |

| 4 | Appropriate; less round; aromatic | |||

| 3 | Poorly round; poorly aromatic | |||

| 2 | Slightly sour; not round | |||

| 1 | Foreign taste; sour; bitter | |||

| Compositional Parameters | Chemical Composition (g/100g) * | ||

|---|---|---|---|

| Control Variant | Chocolate 564 | Chocolate 299v | |

| Moisture | 0.82 ± 0.05 | 0.80 ± 0.05 | 0.81 ± 0.07 |

| Protein | 9.88 ± 0.08 | 9.86 ± 0.04 | 9.90 ± 0.06 |

| Lipids | 39.94 ± 0.07 | 39.94 ± 0.06 | 40.02 ± 0.09 |

| Carbohydrate | 24.85 ± 0.09 | 25.01 ± 0.1 | 24.84 ± 0.1 |

| Ash | 2.30 ± 0.04 | 2.33 ± 0.07 | 2.41 ± 0.07 |

| Volatile Compounds | CAS No. | Odour Descriptor | Control Variant | Chocolate 299v | Chocolate 564 |

|---|---|---|---|---|---|

| Abundance Levels * | |||||

| Aldehydes | |||||

| Isobutyraldehyde | 78-84-2 | Banana, malty, chocolate-like, cocoa | 9.34 × 108 a | 3.88 × 108 b | 6.87 × 108 ab |

| 3-Methyl-butanal | 590-86-3 | Malty, powerful, cheese, green, dark chocolate, cocoa | 1.05 × 109 a | 4.11 × 109 b | 4.57 × 109 b |

| Hexanal | 66-25-1 | Green, slightly fruity, lemon, herbal, grassy, tallow | 1.37 × 108 a | 4.28 × 108 b | 4.23 × 108 b |

| Benzaldehyde | 100-52-7 | Bitter almond, sweet cherry | 2.26 × 108 a | 3.84 × 108 a | 6.25 × 108 a |

| Nonanal | 124-19-6 | Green, citrus, fatty, floral | 4.02 × 108 a | 1.76 × 108 a | 1.72 × 108 a |

| Isodihydro-lavandulal | 35158-25-9 | Herbal, lavender, woody, green, blueberry, tomato | 1.33 × 108 a | 4.29 × 108 b | 4.51 × 108 b |

| Ethyl Vanillin | 121-32-4 | Sweet, creamy, vanillia, caramellic | 2.91 × 109 a | 2.85 × 109 a | 2.76 × 109 a |

| Alcohols | |||||

| Ethanol | 64-17-5 | Dry, dust | 1.88 × 109 a | 1.91 × 109 a | 1.82 × 109 a |

| 2,3-Butanediol | 513-85-9 | Fruity, creamy, buttery | 7.20 × 1010 a | 5.18 × 1010 a | 6.23 × 1010 a |

| 1,6-Heptadien-4-ol | 2883-45-6 | Unknown | 5.58 × 108 a | 2.28 × 108 a | 4.61 × 108 a |

| 2-Heptanol | 543-43-7 | Fresh lemon grass herbal sweet floral fruity green | 2.34 × 108 a | 0 b | 0 b |

| 2-Ethyl-1-hexanol | 104-76-7 | Animal, Cardboard | 2.20 × 108 a | 6.35 × 107 b | 2.32 × 107 b |

| Phenylethyl Alcohol | 60-12-8 | Unclean, rose, violet-like, honey, floral, spicy | 4.35 × 108 a | 3.84 × 108 a | 4.25 × 108 a |

| Ketones | |||||

| Acetone | 67-64-1 | Earthy, wood pulp, hay | 1.63 × 109 ab | 1.42 × 109 b | 1.89 × 109 a |

| Butanone | 78-93-3 | Buttery, sour milk, etheric | 1.10 × 109 a | 4.09 × 108 b | 5.35 × 108 b |

| Acetoin | 513-86-0 | Buttery, sour milk, caramel | 3.13 × 109 a | 1.33 × 109 a | 2.74 × 109 a |

| 2-Heptanone | 110-43-0 | Blue cheese, spicy, Roquefort | 7.51 × 108 a | 3.90 × 108 a | 1.58 × 108 a |

| Acetophenone | 98-86-2 | Almond, musty, glue, orange blossom, sweet | 1.18 × 108 a | 1.68 × 108 b | 1.88 × 108 b |

| 2-Nonanone | 821-55-6 | Malty, fruity, hot milk, smoked cheese | 8.12 × 108 a | 2.72 × 108 b | 3.93 × 108 b |

| Pyrazines | |||||

| 2-Ethyl-6-methylpyrazine | 13925-03-6 | Roasted potato | 7.93 × 107 a | 1.47 × 108 b | 1.55 × 108 b |

| Trimethylpyrazine | 14667-55-1 | Chocolate, earthy | 2.39 × 109 a | 3.09 × 109 b | 3.17 × 109 b |

| 3,6-Cocoa pyrazine | 13360-65-1 | Patato, cocoa, roasted nutty | 2.52 × 108 a | 2.68 × 108 a | 2.67 × 108 a |

| Tetramethyl-pyrazine | 1124-11-4 | Musty, nutty, chocolate, coffee, cocoa, lard, burnt | 6.00 × 109 a | 6.30 × 109 b | 6.51 × 109 b |

| 2-Methyl-3,5-diethylpyrazine | 18138-05-1 | Nutty, meaty, vegetable | 2.10 × 108 a | 1.52 × 108 b | 1.55 × 108 b |

| Lactones | |||||

| g-Butyrolactone | 96-48-0 | Creamy, oily, fatty nuances | 1.64 × 109 a | 6.26 × 108 a | 1.35 × 109 a |

| Pantolactone compound | 599-04-2 | Unknown | 1.63 × 108 a | 1.06 × 108 a | 7.88 × 107 a |

| d-Octenolactone | 16400-69-4 | Sweet, coconut-like | 1.47 × 108 a | 7.98 × 107 b | 7.46 × 107 b |

| Acids | |||||

| Acetic acid | 64-19-7 | Vinegar, peppers, green, fruity floral, sour | 8.07 × 109 a | 1.12 × 1010 a | 7.21 × 109 a |

| Isovaleric acid | 503-74-2 | Cheesy, sweaty, old socks, rancid, faecal, rotten fruit, goaty | 1.16 × 1010 a | 1.10 × 1010 a | 1.08 × 1010 a |

| 2-Methyl-butanoic acid | 116-53-0 | Fruity, waxy, sweaty-fatty acid | 3.01 × 109 a | 2.55 × 109 a | 2.59 × 109 a |

| Esters | |||||

| Isoamyl acetate | 123-92-2 | Banana, sweet, pear, apple peel | 0 a | 4.12 × 108 b | 4.32 × 108 b |

| Phenethyl acetate | 103-45-7 | Floral, rose-like | 2.45 × 108 a | 1.77 × 108 a | 1.95 × 108 a |

| Terpenes | |||||

| β-Pinene | 127-91-3 | Herbaceous | 2.61 × 108 a | 1.75 × 108 a | 3.52 × 108 a |

| α-Limonene | 138-86-3 | Citrus | 1.94 × 109 a | 4.32 × 108 b | 3.79 × 108 b |

| Phenols | |||||

| Phenol | 108-95-2 | Medicinal | 1.91 × 108 a | 5.83 × 107 a | 2.12 × 107 a |

| Furans | |||||

| 2-Pentylfuran | 3777-69-3 | Fruity, green, earthy, beany, vegetable, metallic | 2.21 × 107 a | 1.76 × 108 b | 1.83 × 108 b |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirković, M.; Seratlić, S.; Kilcawley, K.; Mannion, D.; Mirković, N.; Radulović, Z. The Sensory Quality and Volatile Profile of Dark Chocolate Enriched with Encapsulated Probiotic Lactobacillus plantarum Bacteria. Sensors 2018, 18, 2570. https://doi.org/10.3390/s18082570

Mirković M, Seratlić S, Kilcawley K, Mannion D, Mirković N, Radulović Z. The Sensory Quality and Volatile Profile of Dark Chocolate Enriched with Encapsulated Probiotic Lactobacillus plantarum Bacteria. Sensors. 2018; 18(8):2570. https://doi.org/10.3390/s18082570

Chicago/Turabian StyleMirković, Milica, Sanja Seratlić, Kieran Kilcawley, David Mannion, Nemanja Mirković, and Zorica Radulović. 2018. "The Sensory Quality and Volatile Profile of Dark Chocolate Enriched with Encapsulated Probiotic Lactobacillus plantarum Bacteria" Sensors 18, no. 8: 2570. https://doi.org/10.3390/s18082570