A Novel Damage Indicator Based on the Electromechanical Impedance Principle for Structural Damage Identification

Abstract

:1. Introduction

2. Fourth Voltage Statistical Moment-Based Damage Detection Method

2.1. Spectral Element Formulation for a Timoshenko Beam

2.1.1. The Intact Beam

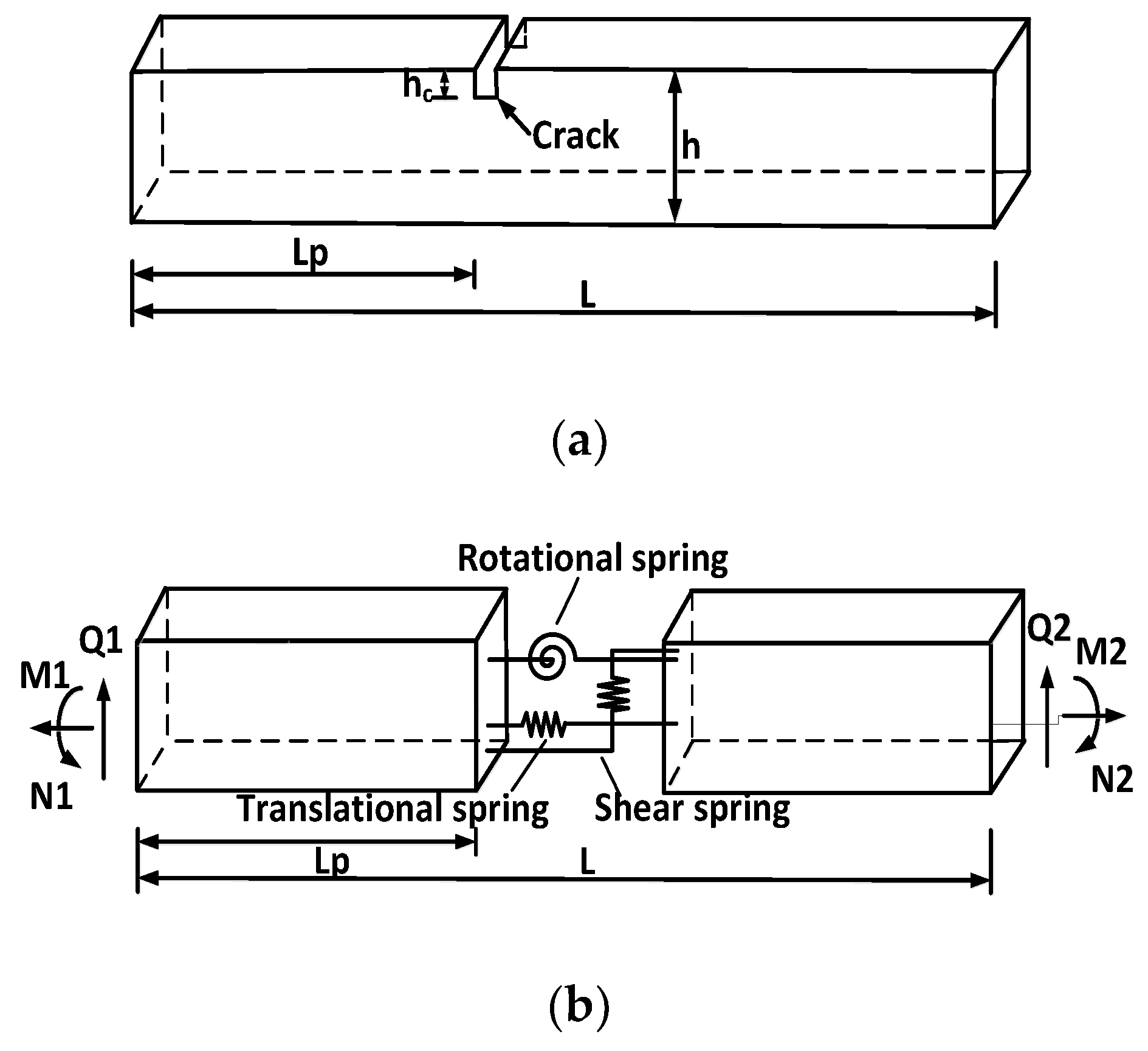

2.1.2. The Cracked Beam

2.2. Voltage Responses of the PZT Bonded on a Beam

2.3. Theory of Statistical Moment

2.4. Differential Evolution Algorithm

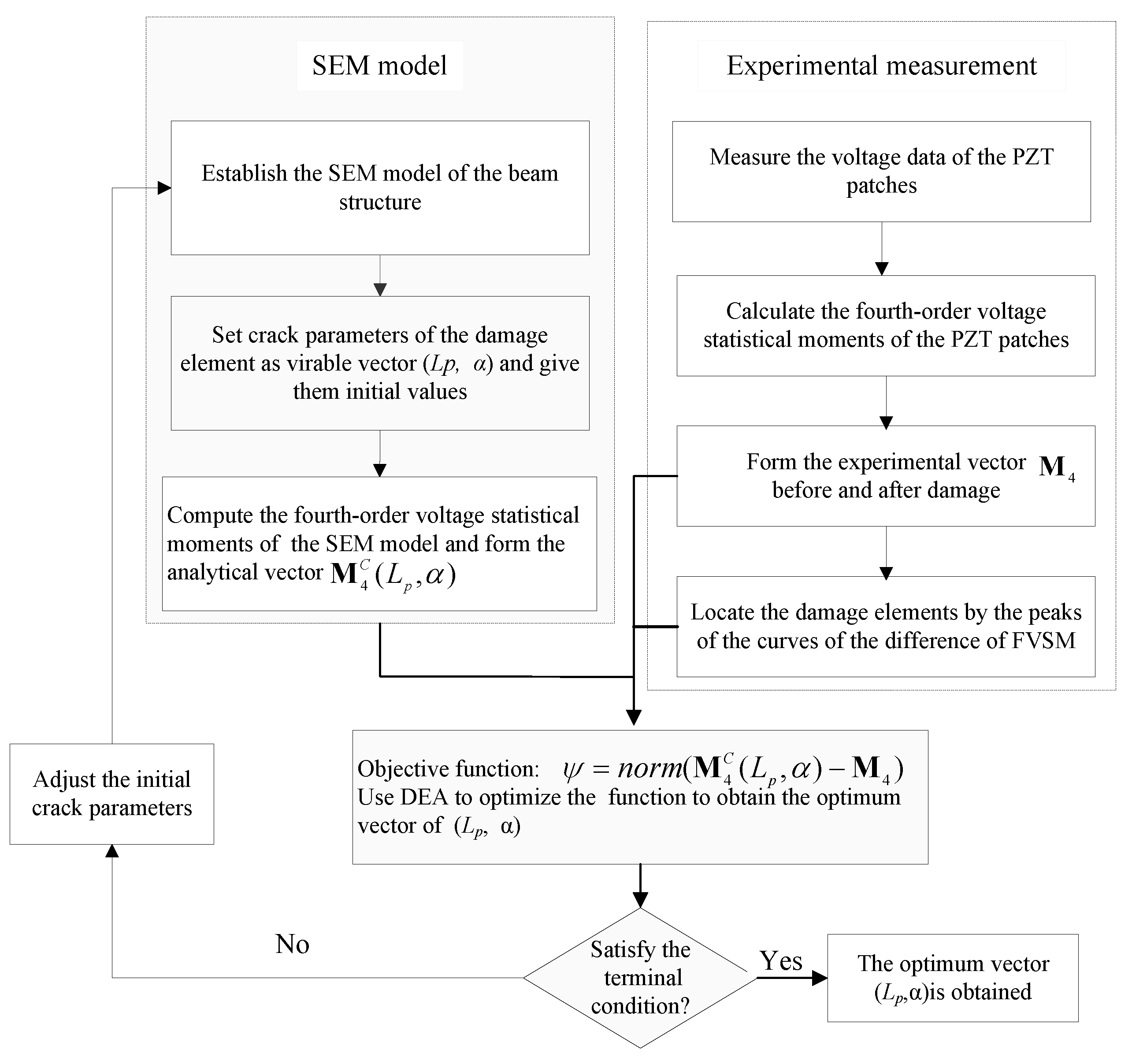

2.5. Two-Step Damage Detection Method

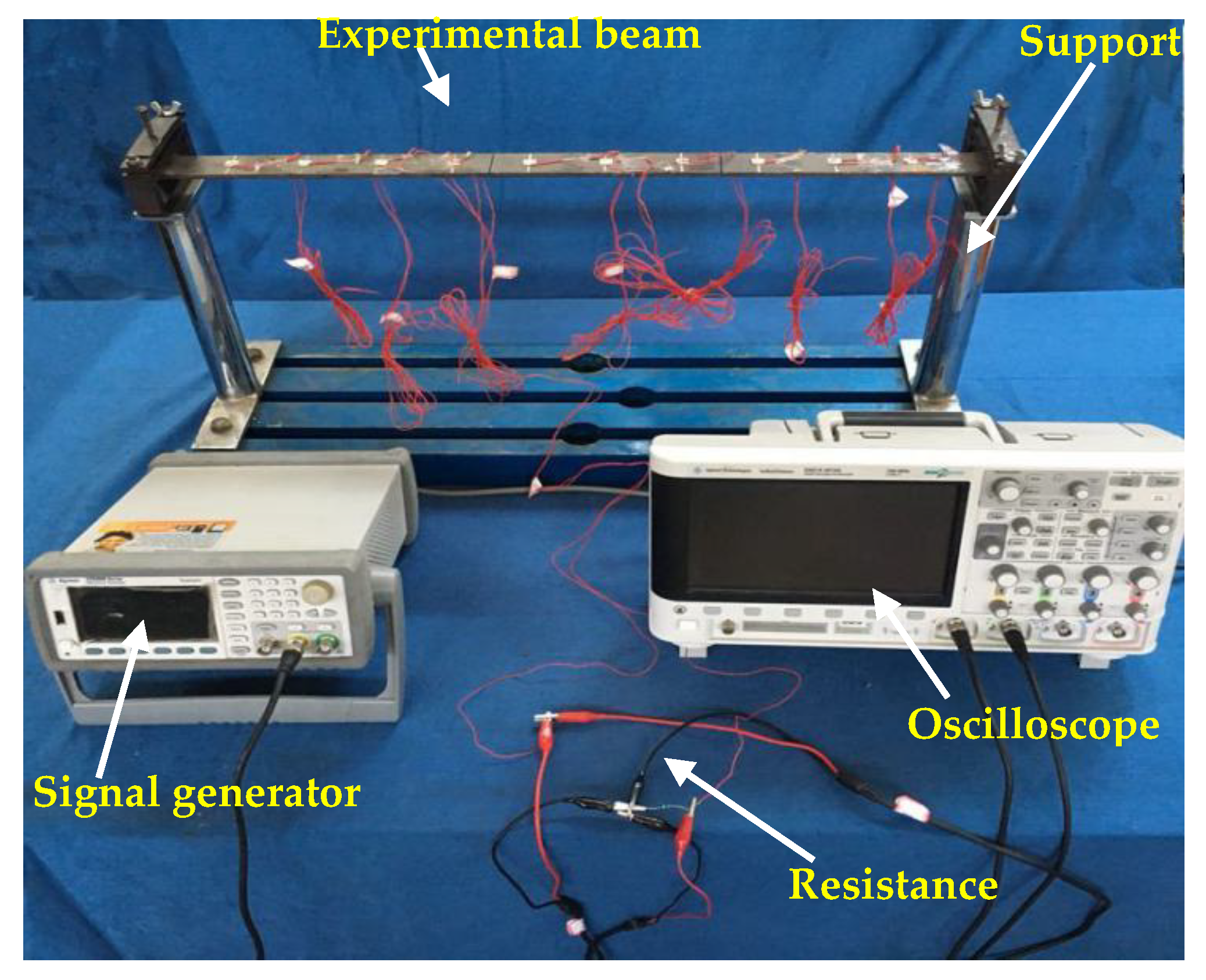

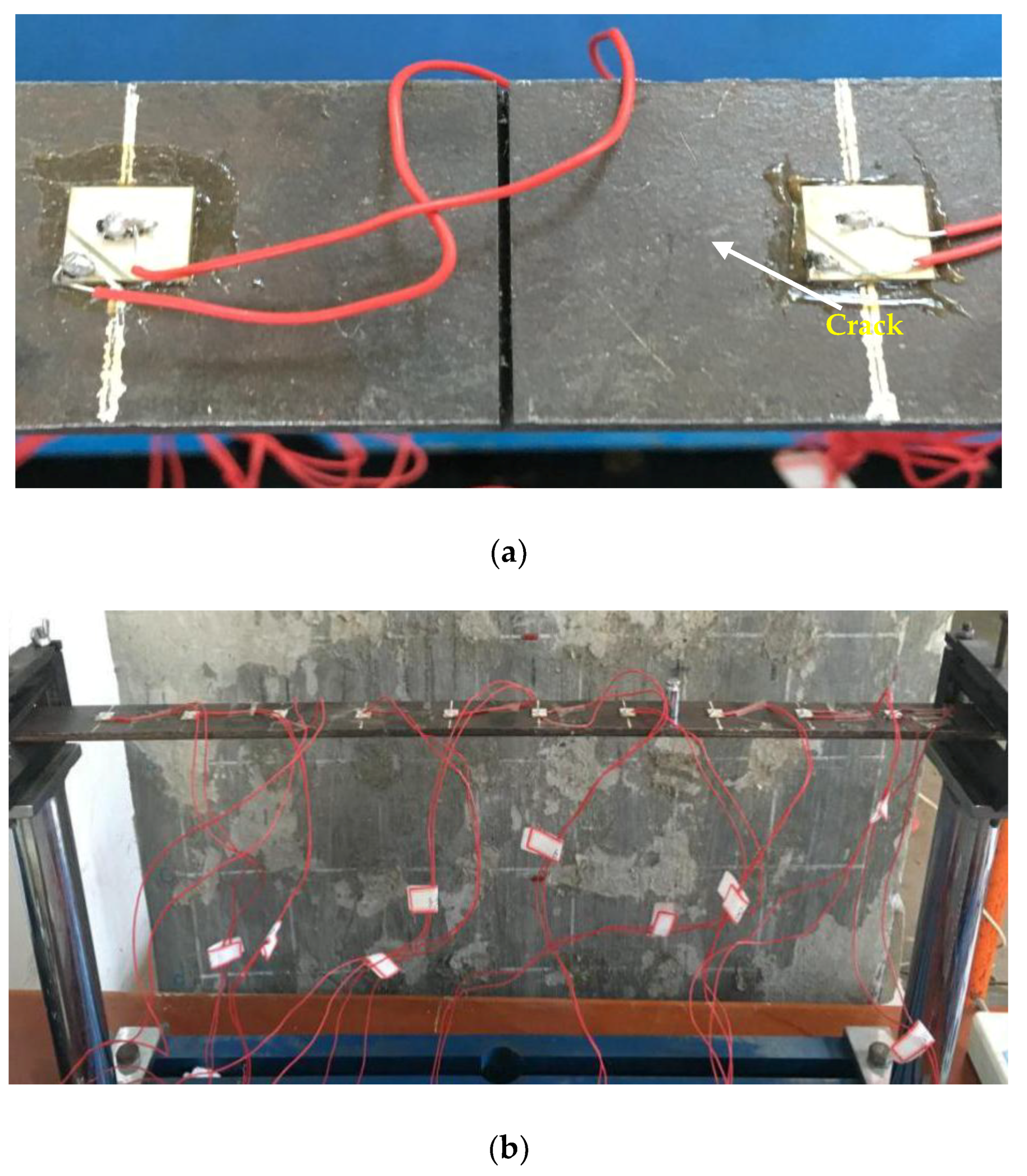

3. Experimental Setup

4. Experimental Results and Analysis

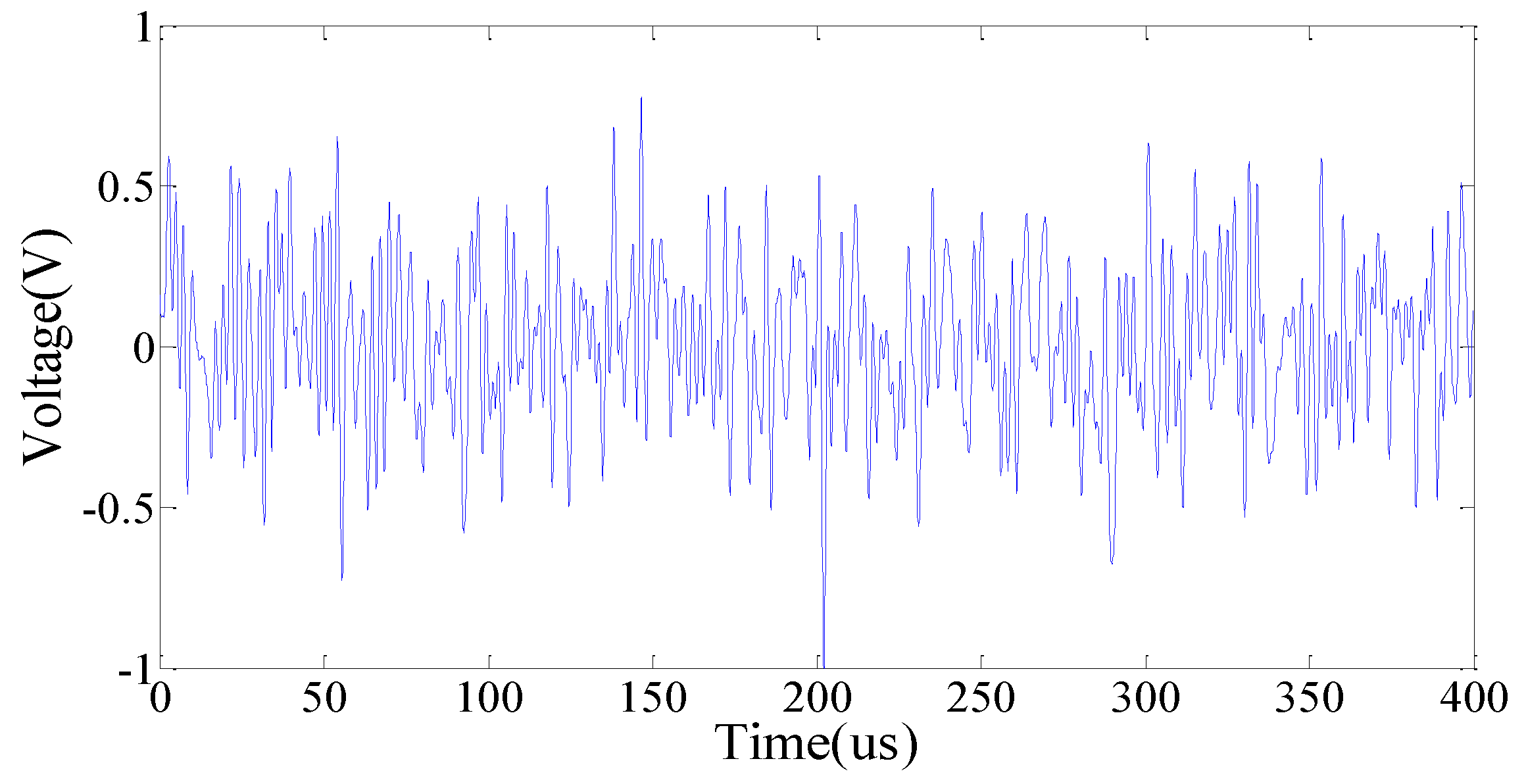

4.1. Comparison between the Experimental and Analytical Voltage Responses

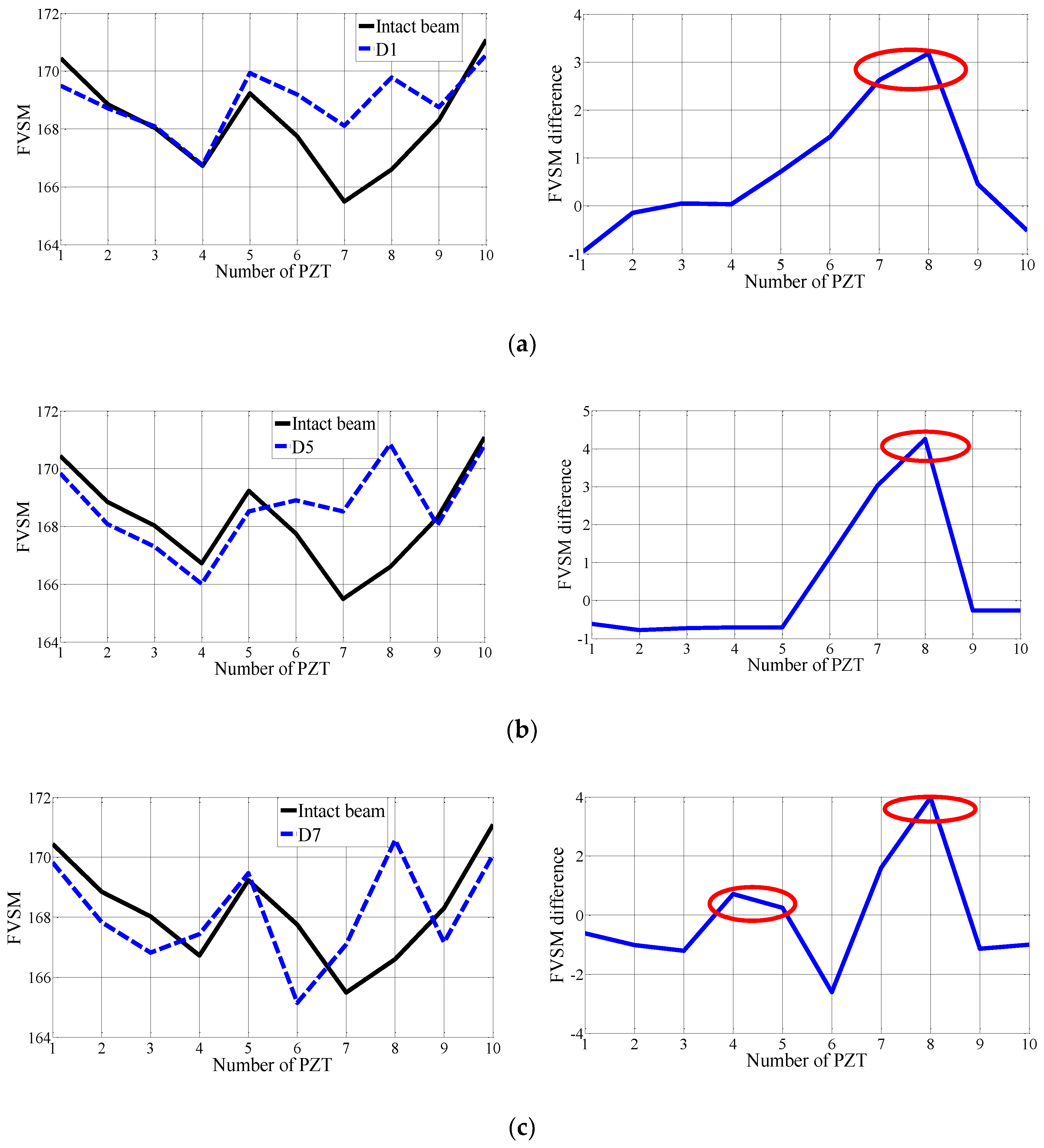

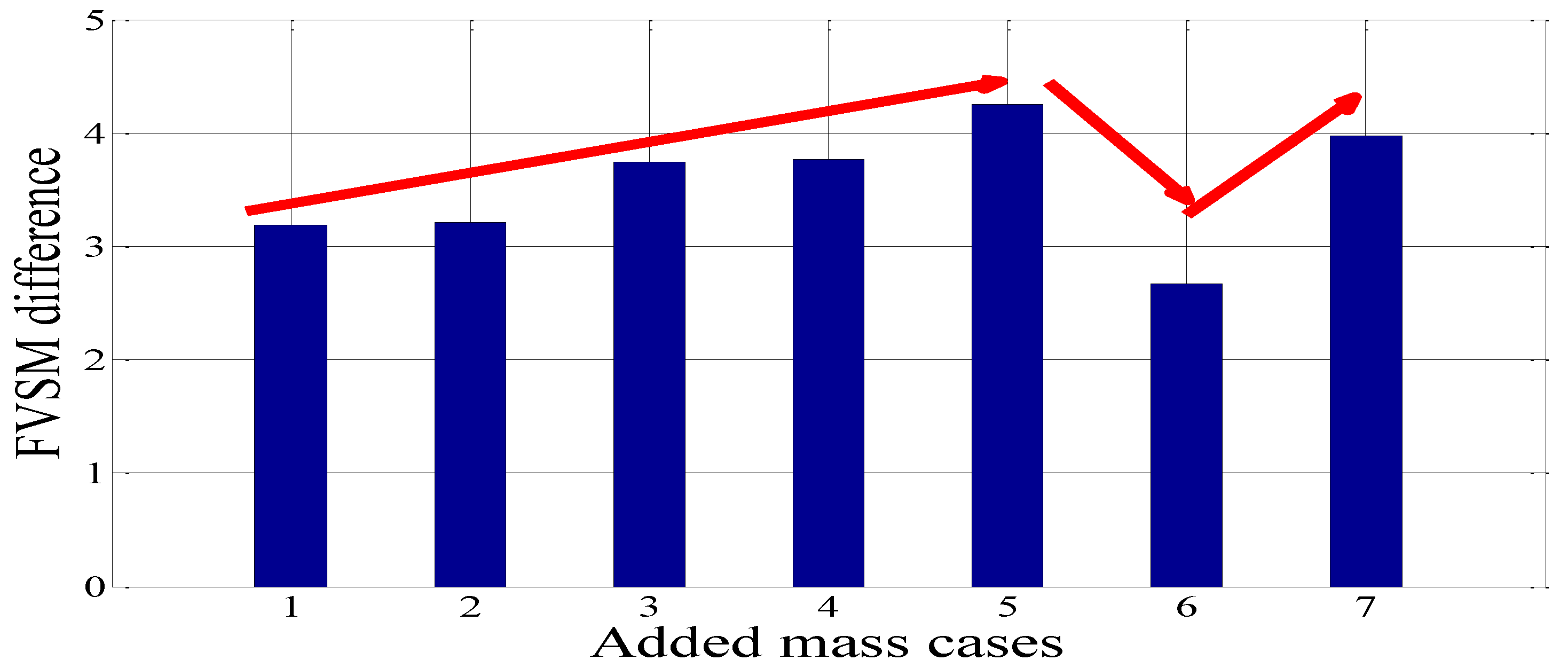

4.2. Damage Element Location in the Added Mass Experiment

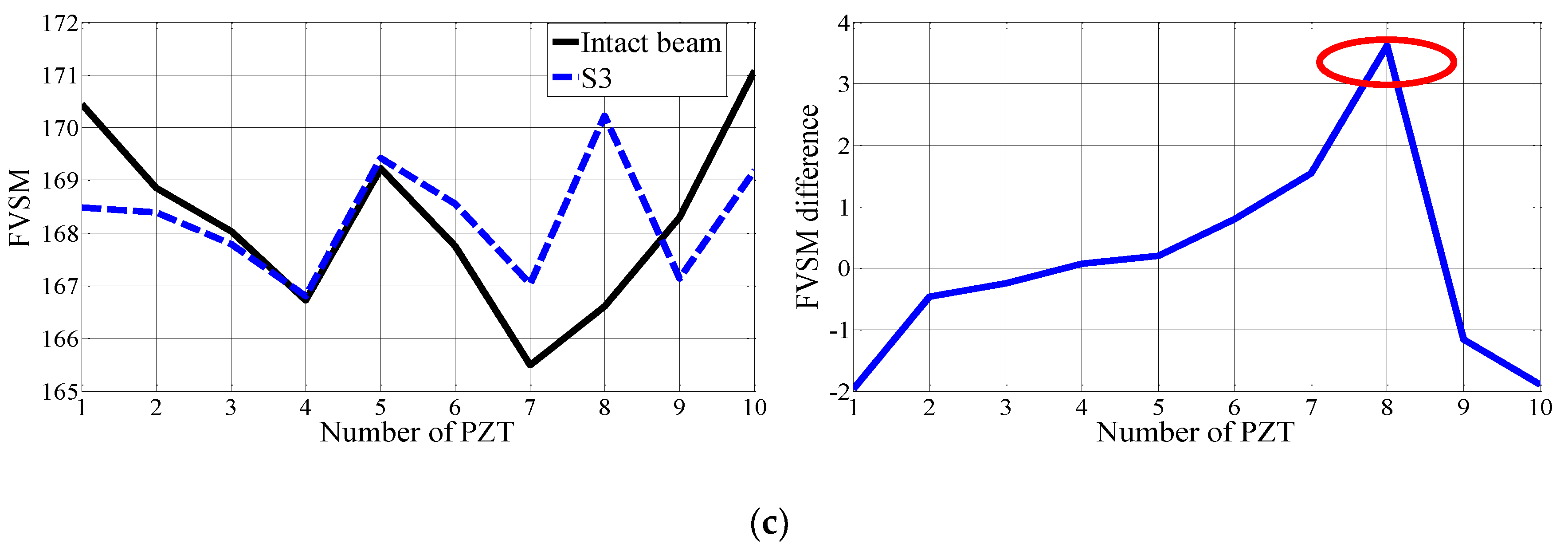

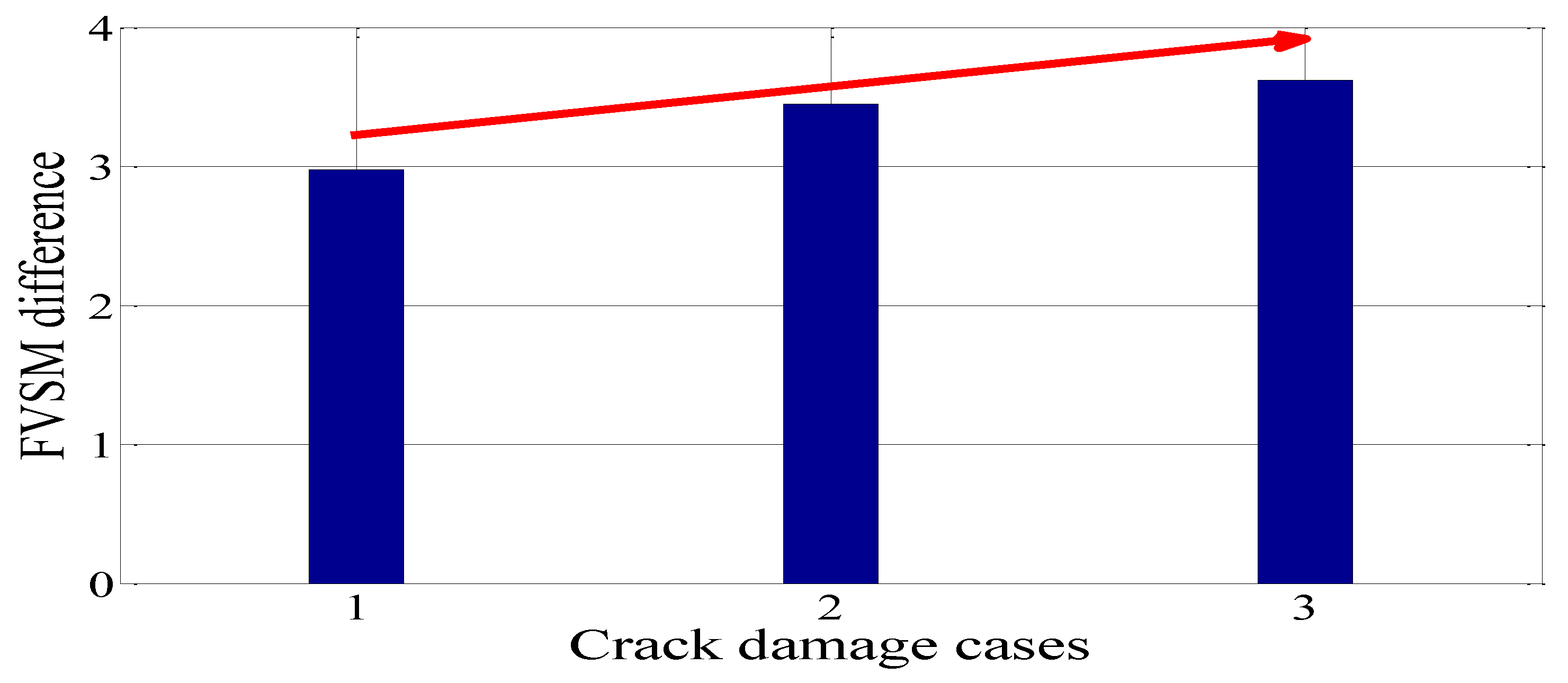

4.3. Damage Element Location in Crack Damage Experiment

4.4. Damage Quantification Based on the SEM and DEA

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Park, G.; Sohn, H.; Farrar, C.R.; Inman, D.J. Overview of piezoelectric impedance-based health monitoring and path forward. Shock Vib. Dig. 2003, 35, 451–463. [Google Scholar] [CrossRef]

- Bhalla, S.; Soh, C.K. Electromechanical impedance modeling for adhesively bonded piezo-transducers. J. Intell. Mater. Syst. Struct. 2004, 15, 955–972. [Google Scholar] [CrossRef]

- Lim, Y.Y.; Soh, C.K. Fatigue life estimation of a 1D aluminum beam under mode-I loading using the electromechanical impedance technique. Smart Mater. Struct. 2011, 20, 125001. [Google Scholar] [CrossRef]

- Wang, D.S.; Wang, Q.H.; Wang, H.; Zhu, H. Experimental study on damage detection in timber specimens based on an electromechanical impedance technique and RMSD-based Mahalanobis distance. Sensors 2016, 16, 1765. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Huo, L.S.; Chen, D.D.; Li, W.; Song, G. Impedance-based pre-stress monitoring of rock bolts using a piezoceramic-based smart washer—A feasibility study. Sensors 2017, 17, 250. [Google Scholar] [CrossRef] [PubMed]

- Huo, L.S.; Chen, D.D.; Liang, Y.B.; Li, H.; Feng, S.; Song, G. Impedance based bolt pre-load monitoring using piezoceramic smart washer. Smart Mater. Struct. 2017, 26, 057004. [Google Scholar] [CrossRef]

- Fan, S.L.; Zhao, S.Y.; Qi, B.X.; Kong, Q. Damage evaluation of concrete column under impact load using a piezoelectric-based EMI technique. Sensors 2018, 18, 1591. [Google Scholar] [CrossRef] [PubMed]

- Fan, S.L.; Li, W.J.; Kong, Q.Z.; Feng, Q.; Song, G. Monitoring of pin connection loosening using eletromechanical impedance: Numerical simulation with experimental verification. J. Intell. Mater. Syst. Struct. 2018, 29, 1964–1973. [Google Scholar] [CrossRef]

- Liang, C.; Sun, F.P.; Rogers, C.A. An impedance method for dynamic analysis of active material systems. J. Vib. Acoust. 1994, 116, 120–128. [Google Scholar] [CrossRef]

- Baptista, F.G.; Filho, J.V.; Inman, D.J. Real-time multi-sensors measurement system with temperature effects compensation for impedance-based structural health monitoring. Struct. Health Monit. 2012, 11, 173–186. [Google Scholar] [CrossRef]

- Na, W.S.; Park, K. A cost-effective impedance-based structural health monitoring technique for steel structures by monitoring multiple areas. J. Intell. Mater. Syst. Struct. 2017, 28, 154–162. [Google Scholar] [CrossRef]

- Li, J.C.; Lin, L.; Wu, D.; Li, X.M.; Lei, M.K. Elevated excitation voltage electrical impedance measurement system of electro-mechanical impedance-based structural health monitoring. Exp. Tech. 2016, 40, 381–390. [Google Scholar] [CrossRef]

- Silveira, R.Z.; Campeiro, L.M.; Baptista, F.G. Performance of three transducer mounting methods in impedance-based structural health monitoring applications. J. Intell. Mater. Syst. Struct. 2017, 28, 2349–2362. [Google Scholar] [CrossRef]

- Park, S.; Yun, C.B.; Roh, Y.; Lee, J.J. PZT-based active damage detection techniques for steel bridge components. Smart Mater. Struct. 2006, 15, 957–966. [Google Scholar] [CrossRef]

- Bhall, S.; Soh, C.K.; Liu, Z.X. Wave propagation approach for NDE using surface bonded piezoceramics. NDT E Int. 2005, 38, 143–150. [Google Scholar] [CrossRef]

- Divsholi, B.S.; Yang, Y.W. Health monitoring of steel structures using sub-frequency electromechanical impedance technique. J. Nondestruct. Eval. 2012, 31, 197–207. [Google Scholar] [CrossRef]

- Yang, Y.W.; Divsholi, B.S. Sub-frequency interval approach in electromechanical impedance technique for concrete structure health monitoring. Sensors 2010, 10, 11644–11661. [Google Scholar] [CrossRef] [PubMed]

- Sevillano, E.; Sun, R.; Gil, A.; Perera, R. Interfacial crack-induced debonding identification in FRP-strengthened RC beams from PZT signatures using hierarchical clustering analysis. Compos. Part B Eng. 2016, 87, 322–335. [Google Scholar] [CrossRef]

- Filho, J.V.; Baptista, F.G.; Inman, D.J. Time-domain analysis of piezoelectric impedance-based structural health monitoring using multilevel wavelet decomposition. Mech. Syst. Signal Process. 2011, 25, 1550–1558. [Google Scholar] [CrossRef]

- Silva, S.D.; Júnior, M.D.; Junior, V.L. Structural health monitoring in smart structures through time series analysis. Struct. Health Monit. 2008, 7, 231–244. [Google Scholar] [CrossRef]

- Xu, B.; Giurgiutiu, V. Development of DSP-based electromechanical (E/M) impedance analyzer for active structural health monitoring. In Proceedings of the Smart Structures and Materials 2006: Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, San Diego, CA, USA, 5 April 2006. [Google Scholar]

- Peairs, D.M.; Park, G.; Inman, D.J. Improving accessibility of the impedance-based structural health monitoring method. J. Intell. Mater. Syst. Struct. 2004, 15, 129–139. [Google Scholar] [CrossRef]

- Neto, R.M.; Steffen, V.; Rade, D.A.; Gallo, C.A.; Palomino, L.V. A low-cost electromechanical impedance-based SHM architecture for multiplexed piezoceramic actuators. Struct. Health Monit. 2011, 10, 391–402. [Google Scholar] [CrossRef]

- Xu, B.; Giurgiutiu, V. A low-cost and field portable electromechanical (E/M) impedance analyzer for active structural health monitoring. In Proceedings of the 5th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 15–17 September 2005; pp. 634–644. [Google Scholar]

- Cortez, N.E.; Filho, J.V.; Baptista, F.G. A new microcontrolled structural health monitoring system based on the electromechanical impedance principle. Struct. Health Monit. 2013, 12, 14–22. [Google Scholar] [CrossRef]

- Mascarenas, D.L.; Todd, M.D.; Park, G.; Farrar, C.R. Development of an impedance-based wireless sensornode for structural health monitoring. Smart Mater. Struct. 2007, 16, 2137. [Google Scholar] [CrossRef]

- Perera, R.; Pérez, A.; García-Diéguez, M.; Zapico-Valle, J.L. Active wireless system for structural health monitoring applications. Sensors 2017, 17, 2880. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.S.; Li, Z.; Zhu, H.P. A new three-dimensional electromechanical impedance model for an embedded dual-PZT transducer. Smart Mater. Struct. 2016, 25, 1–12. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, Y.L.; Xia, Y.; Li, J. A new statistical moment-based structural damage detection method. Struct. Eng. Mech. 2008, 30, 445–466. [Google Scholar] [CrossRef]

- Xu, Y.L.; Zhang, J.; Li, J.; Xia, Y. Experimental investigation on statistical moment-based structural damage detection method. Struct. Health Monit. 2009, 8, 555–571. [Google Scholar] [CrossRef]

- Xiang, W.; Wang, D.S.; Zhu, H.P. Damage identification in a plate structure based on strain statistical moment. Adv. Struct. Eng. 2014, 17, 1639–1655. [Google Scholar] [CrossRef]

- Wang, D.S.; Xiang, W.; Zhu, H.P. Damage identification in beam type structures based on strain statistical moment using a two-step method. J. Sound Vib. 2014, 333, 745–760. [Google Scholar] [CrossRef]

- Wang, D.S.; Chen, Z.; Xiang, W.; Zhu, H. Experimental investigation of damage identification in beam structures based on the strain statistical moment. Adv. Struct. Eng. 2017, 20, 747–758. [Google Scholar] [CrossRef]

- Wang, D.S.; Zhou, P.; Jin, T.; Zhu, H. Damage identification for beam structures using the laplace transform-based spectral element method and strain statistical moment. J. Aerosp. Eng. 2018, 31, 04018016. [Google Scholar] [CrossRef]

- Alamdari, M.M.; Rakotoarivelo, T.; Khoa, N. A spectral-based clustering for structural health monitoring of the Sydney Harbour Bridge. Mech. Syst. Signal Process. 2017, 87, 384–400. [Google Scholar] [CrossRef]

- Doyle, J.F.; Farris, T.N. A spectrally formulated finite element for wave propagation in 3-D frame structures. Int. J. Anal. Exp. Modal Anal. 1990, 5, 223–237. [Google Scholar]

- Lee, U. Vibration analysis of one-dimensional structures using the spectral transfer matrix method. Eng. Struct. 2000, 22, 681–690. [Google Scholar] [CrossRef]

- Lee, U.; Lee, J. Spectral-element method for Levy-type plates subject to dynamic loads. J. Eng. Mech. 1999, 125, 243–247. [Google Scholar] [CrossRef]

- Krawczuk, M. Application of spectral beam finite element with a crack and iterative search technique for damage detection. Finite Elem. Anal. Des. 2002, 38, 537–548. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, H.; Zhu, X.Q. Damage spectral element for condition assessment of one-dimensional waveguide. In Proceedings of the 4th International Conference on Steel & Composite Structures (ICSCS’10), Sydney, Australia, 21–23 July 2010. [Google Scholar]

- Wang, Y.; Hao, H. Damage identification of steel beams using local and global methods. Adv. Struct. Eng. 2012, 15, 807–824. [Google Scholar] [CrossRef]

- Sun, R.; Sevillano, E.; Perera, R. Debonding detection of FRP strengthened concrete beams by using impedance measurements and an ensemble PSO adaptive spectral model. Compos. Struct. 2015, 125, 374–387. [Google Scholar] [CrossRef] [Green Version]

- Sun, R.; Sevillano, E.; Perera, R. Identification of intermediate debonding damage in FRP-strengthened RC beams based on a multi-objective updating approach and PZT sensors. Compos. Part B 2017, 109, 248–258. [Google Scholar] [CrossRef]

- Doyle, J.F. Wave Propagation in Structures, 2nd ed.; Springer: New York, NY, USA, 1997. [Google Scholar]

- Wang, D.S.; Song, H.Y.; Zhu, H.P. Electromechanical impedance analysis on piezoelectric smart beam with a crack based on spectral element method. Math. Probl. Eng. 2015, 2015, 1–13. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Minimizing the real functions of the ICEC’96 contest by differential evolution. In Proceedings of the IEEE Conference on Evolution Computation, Nagoya, Japan, 20–22 May 1996; pp. 842–844. [Google Scholar]

- Storn, R.; Price, K. Differential evolution—A simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Price, K. Differential evolution vs. the functions of the 2nd ICEO. In Proceedings of the IEEE International Conference on Evolution Computation, Indianapolis, IN, USA, 13–16 April 1997; pp. 153–157. [Google Scholar]

| Geometrical Parameters | Value | Physical Parameters | Value |

|---|---|---|---|

| Length (mm) | 660 | Elastic modulus (Pa) | 2.1 × 1011 |

| Width of section (mm) | 37.8 | Poisson’s ratio | 0.3 |

| Height of section (mm) | 5.6 | Density (kg/m3) | 7800 |

| Section type | Rectangle |

| Symbol | Name | Value |

|---|---|---|

| Length | 10 mm | |

| Width | 10 mm | |

| Thickness | 0.5 mm | |

| Density | 7860 kg/m3 | |

| Young’s modulus | 60.16 GPa | |

| Mechanical loss factor | 0.0005 | |

| Dielectric constant | 1.311 × 10−8 F/m | |

| Dielectric loss factor | 0.025 | |

| Piezoelectric constant | −1.43 × 10−10 m/V |

| Cases | Element 5 | Element 8 | Cases | Element 8 | |

|---|---|---|---|---|---|

| D1 | – | 10 g | S1 | 1 mm cut | |

| D2 | – | 20 g | S2 | 2 mm cut | |

| D3 | – | 50 g | S3 | 3 mm cut | |

| D4 | – | 100 g | |||

| D5 | – | 200 g | |||

| D6 | 50 g | 50 g | |||

| D7 | 200 g | 200 g |

| PZT1 | PZT2 | PZT3 | PZT4 | PZT5 | PZT6 | PZT7 | PZT8 | PZT9 | PZT10 |

|---|---|---|---|---|---|---|---|---|---|

| 0.916 | 0.964 | 0.989 | 0.995 | 0.991 | 0.996 | 0.982 | 0.986 | 0.978 | 0.984 |

| Damage Cases | Preset Damage (Lp, α) | Identified Damage (Lp, α) | Relative Error (%) | Time Cost (s) |

|---|---|---|---|---|

| S1 | 0.03, 0.1786 | 0.025, 0.1742 | 16.7, 2.5 | 4898 |

| S2 | 0.03, 0.3571 | 0.028, 0.3194 | 6.7, 10.5 | 5032 |

| S3 | 0.03, 0.5357 | 0.028, 0.5018 | 6.7, 6.3 | 5136 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, P.; Wang, D.; Zhu, H. A Novel Damage Indicator Based on the Electromechanical Impedance Principle for Structural Damage Identification. Sensors 2018, 18, 2199. https://doi.org/10.3390/s18072199

Zhou P, Wang D, Zhu H. A Novel Damage Indicator Based on the Electromechanical Impedance Principle for Structural Damage Identification. Sensors. 2018; 18(7):2199. https://doi.org/10.3390/s18072199

Chicago/Turabian StyleZhou, Pin, Dansheng Wang, and Hongping Zhu. 2018. "A Novel Damage Indicator Based on the Electromechanical Impedance Principle for Structural Damage Identification" Sensors 18, no. 7: 2199. https://doi.org/10.3390/s18072199