Visualization of Concrete Slump Flow Using the Kinect Sensor

Abstract

:1. Introduction

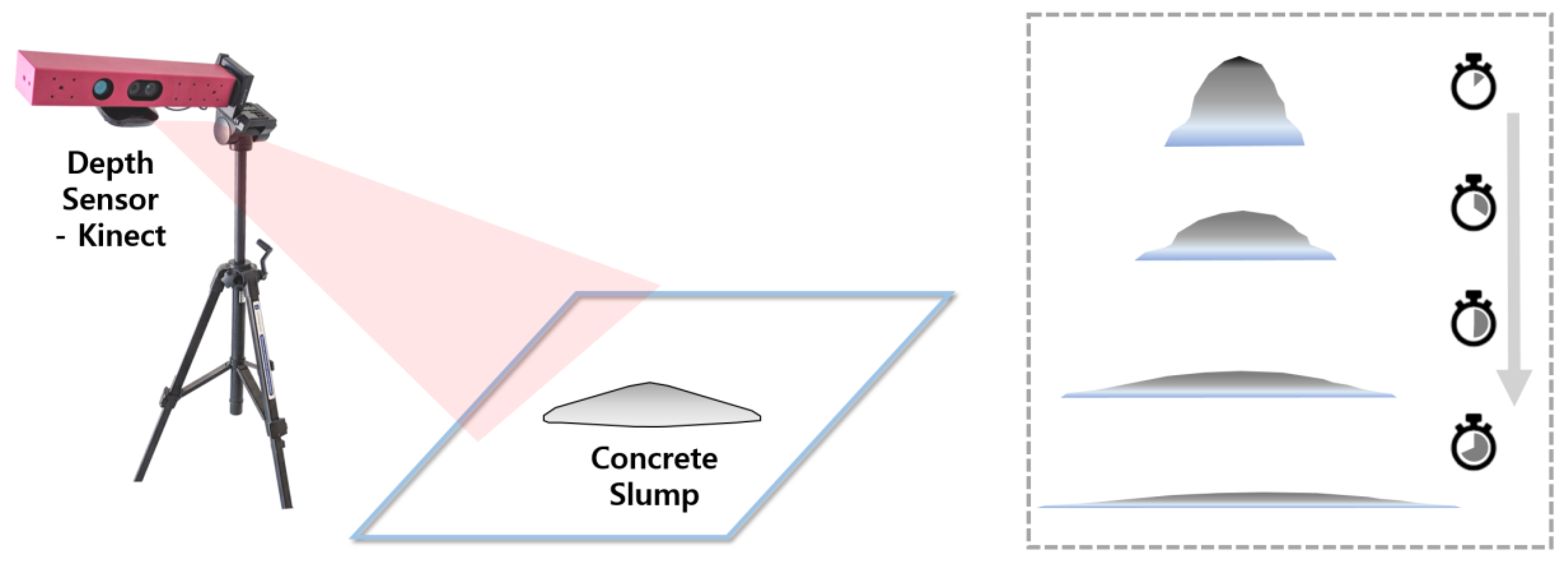

2. Data Processing Algorithm for the 4D Slump Test

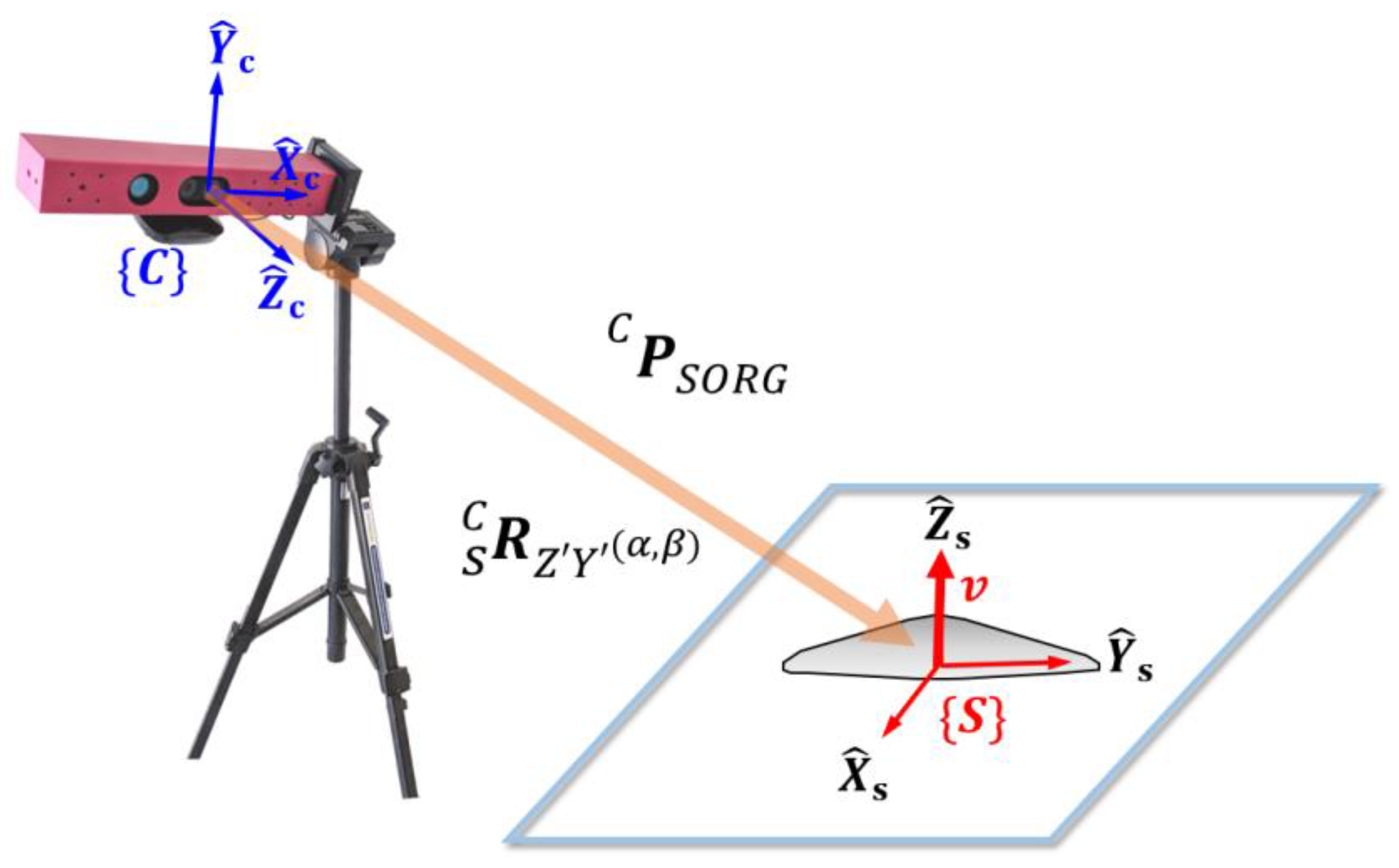

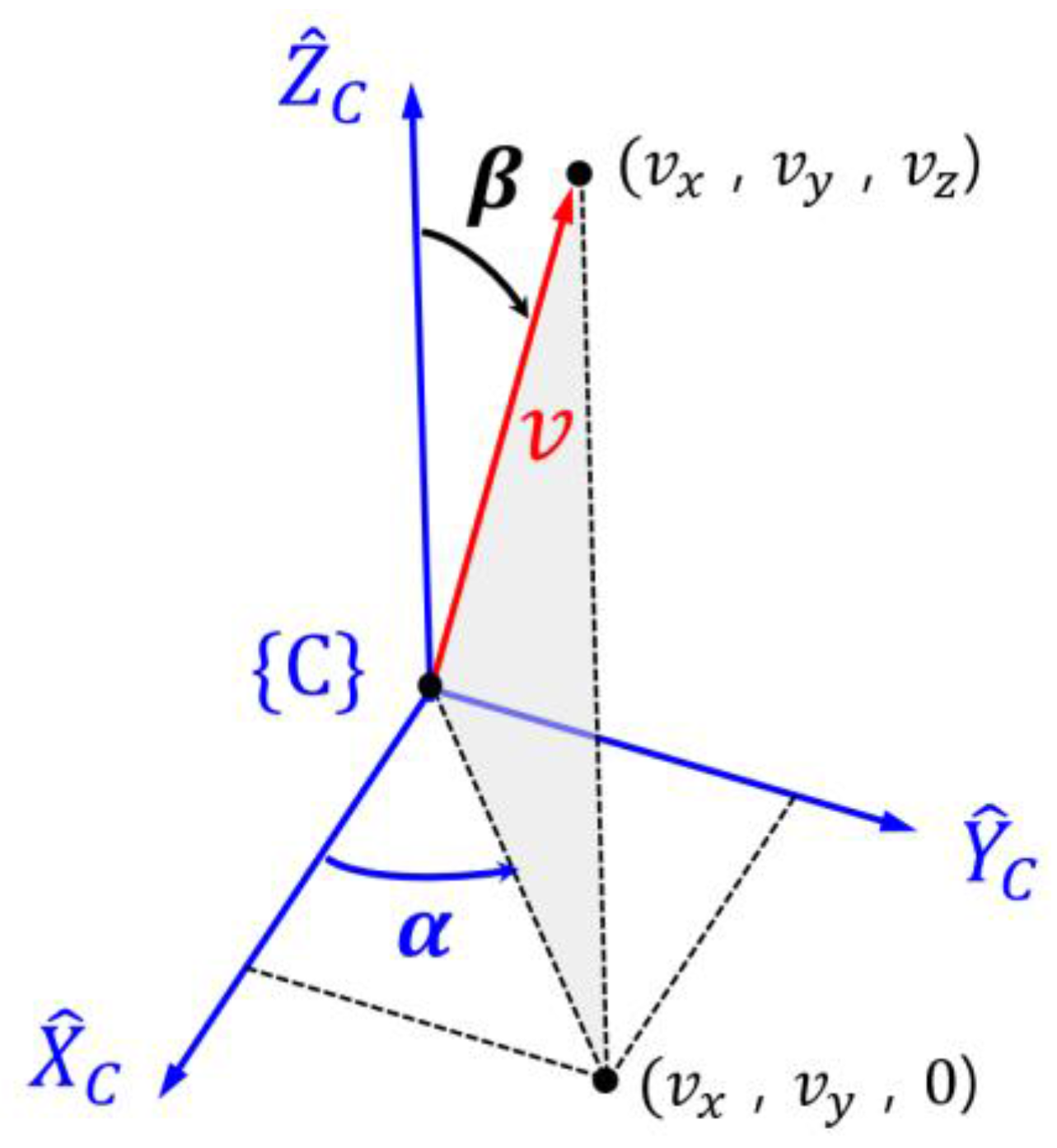

2.1. Representation of 3D Spatial Information at Camera Frame {C}

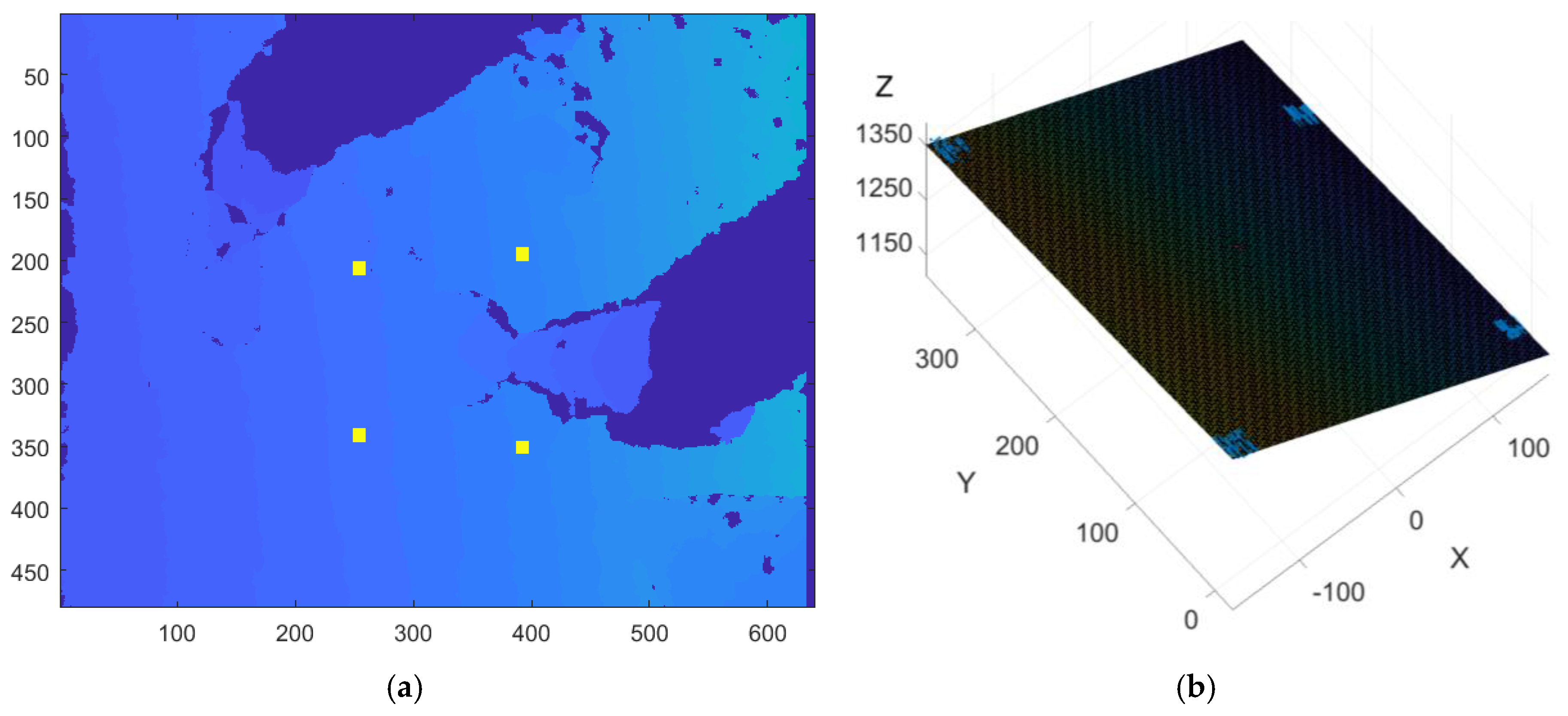

2.2. Determination of the Ground Plane Equation

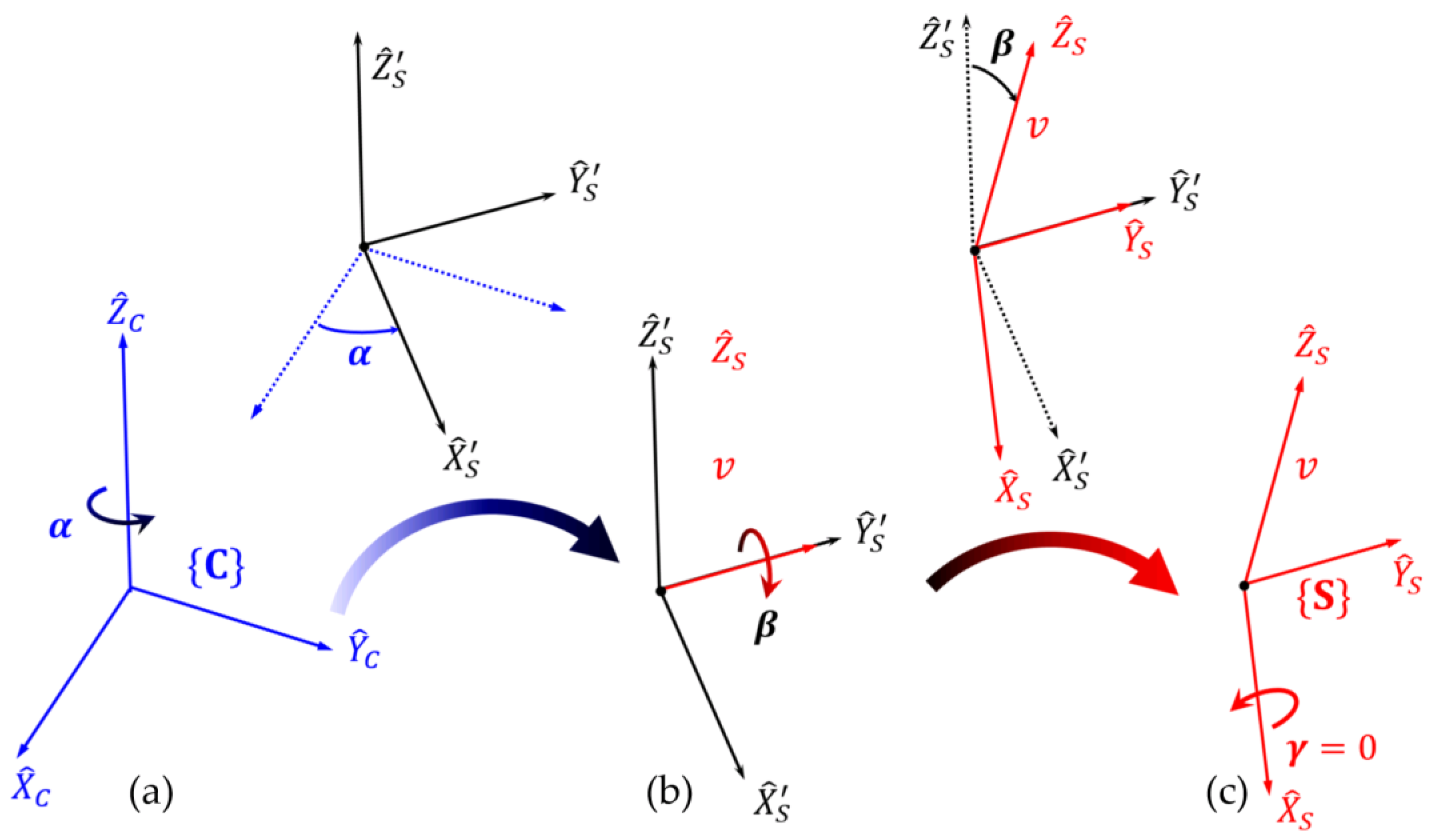

2.3. Coordinate Transformation from Camera Frame to Slump Frame

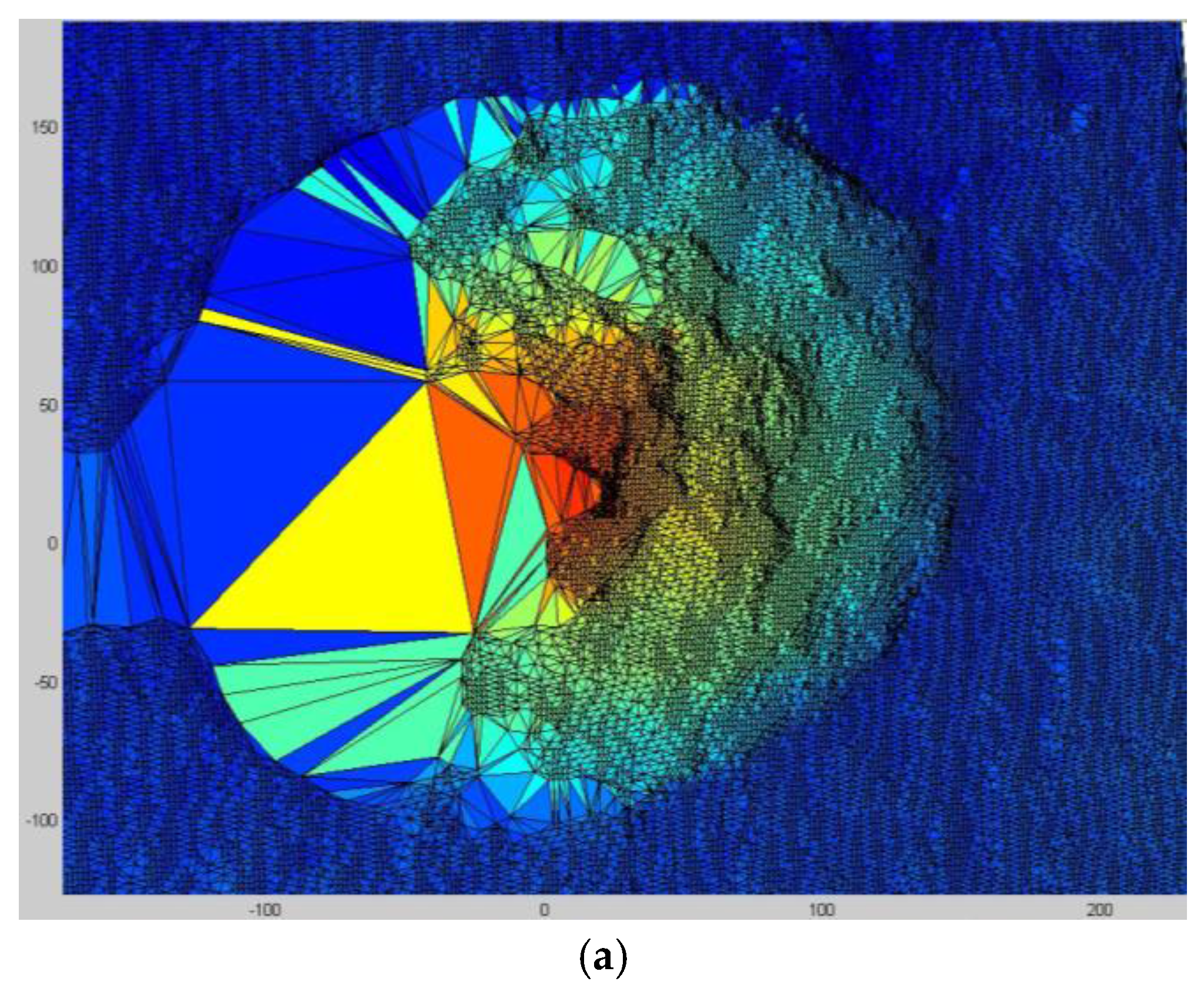

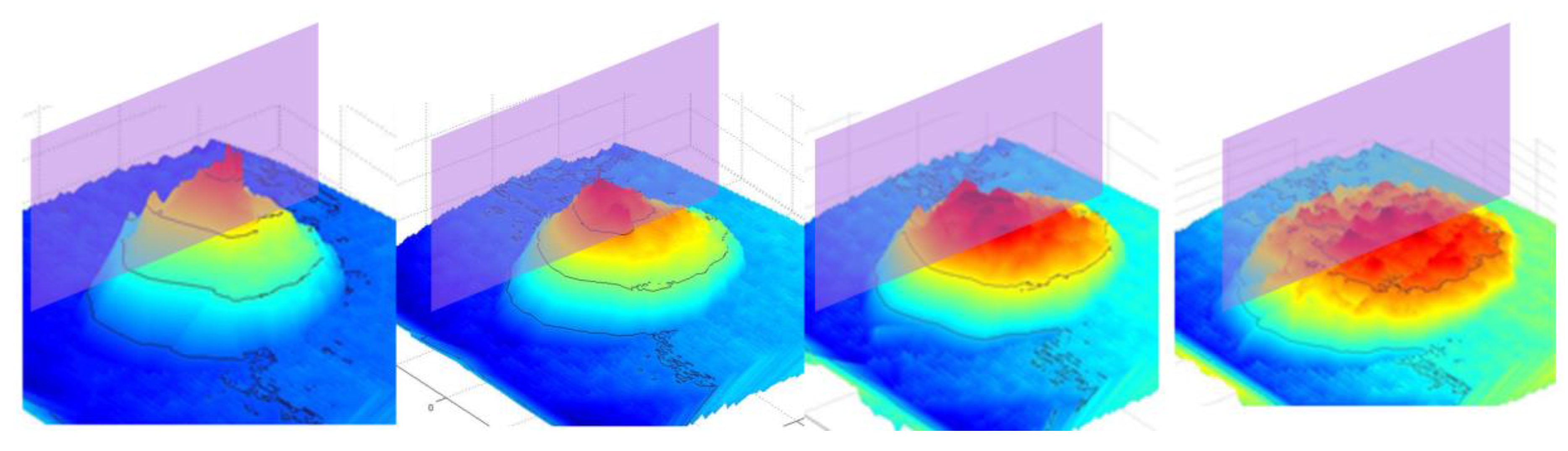

2.4. Reconstruction of 3D Surface for Concrete Slump

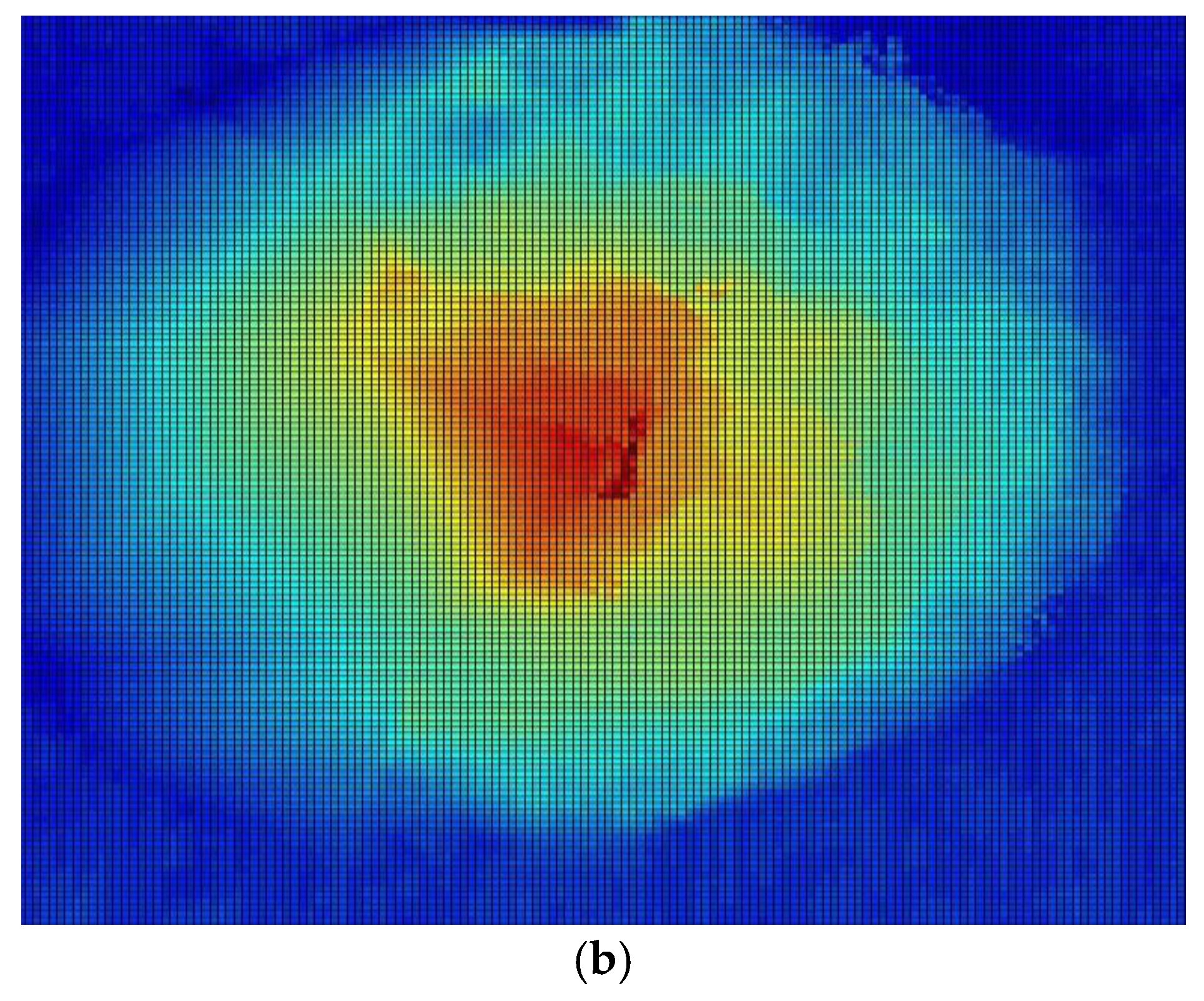

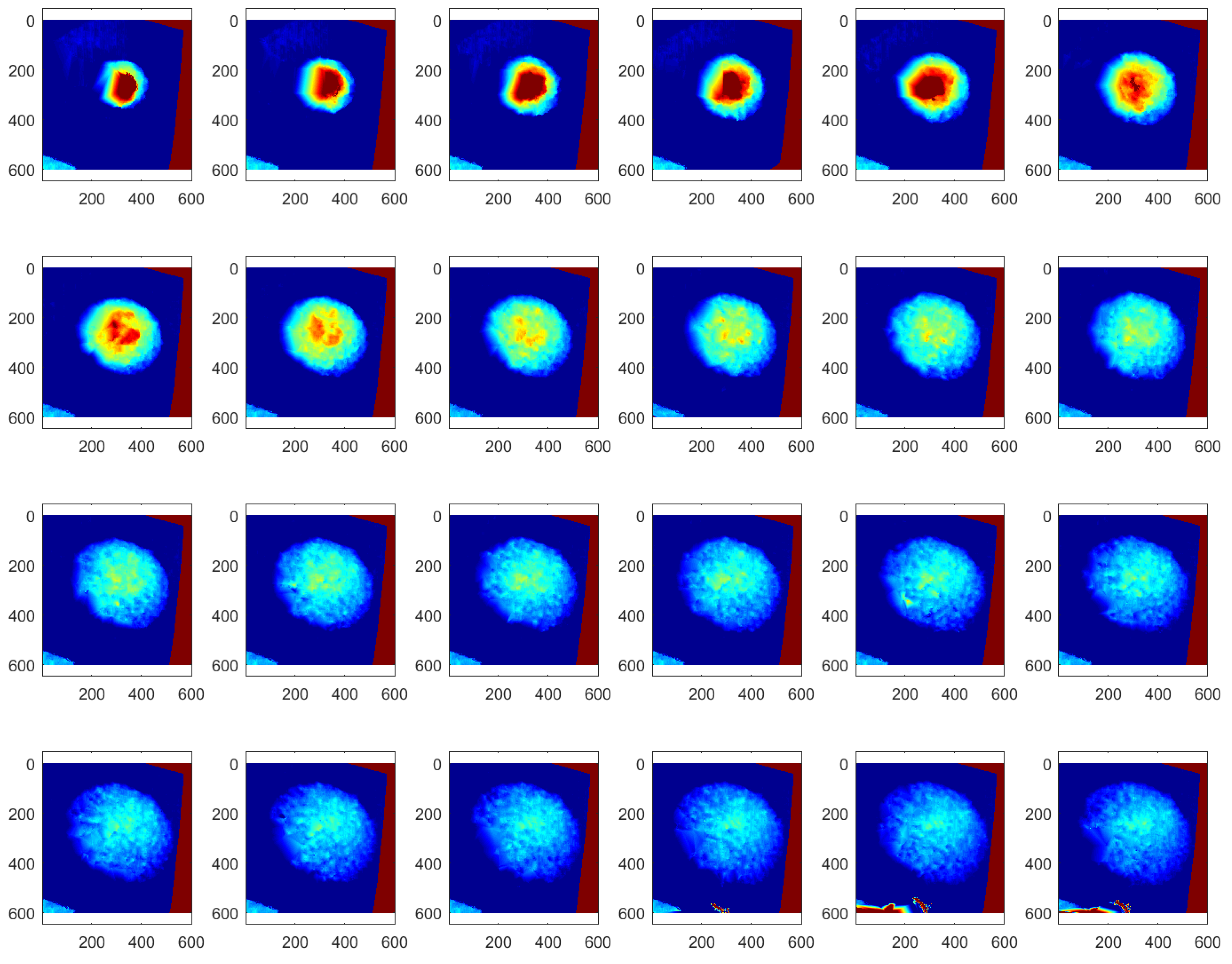

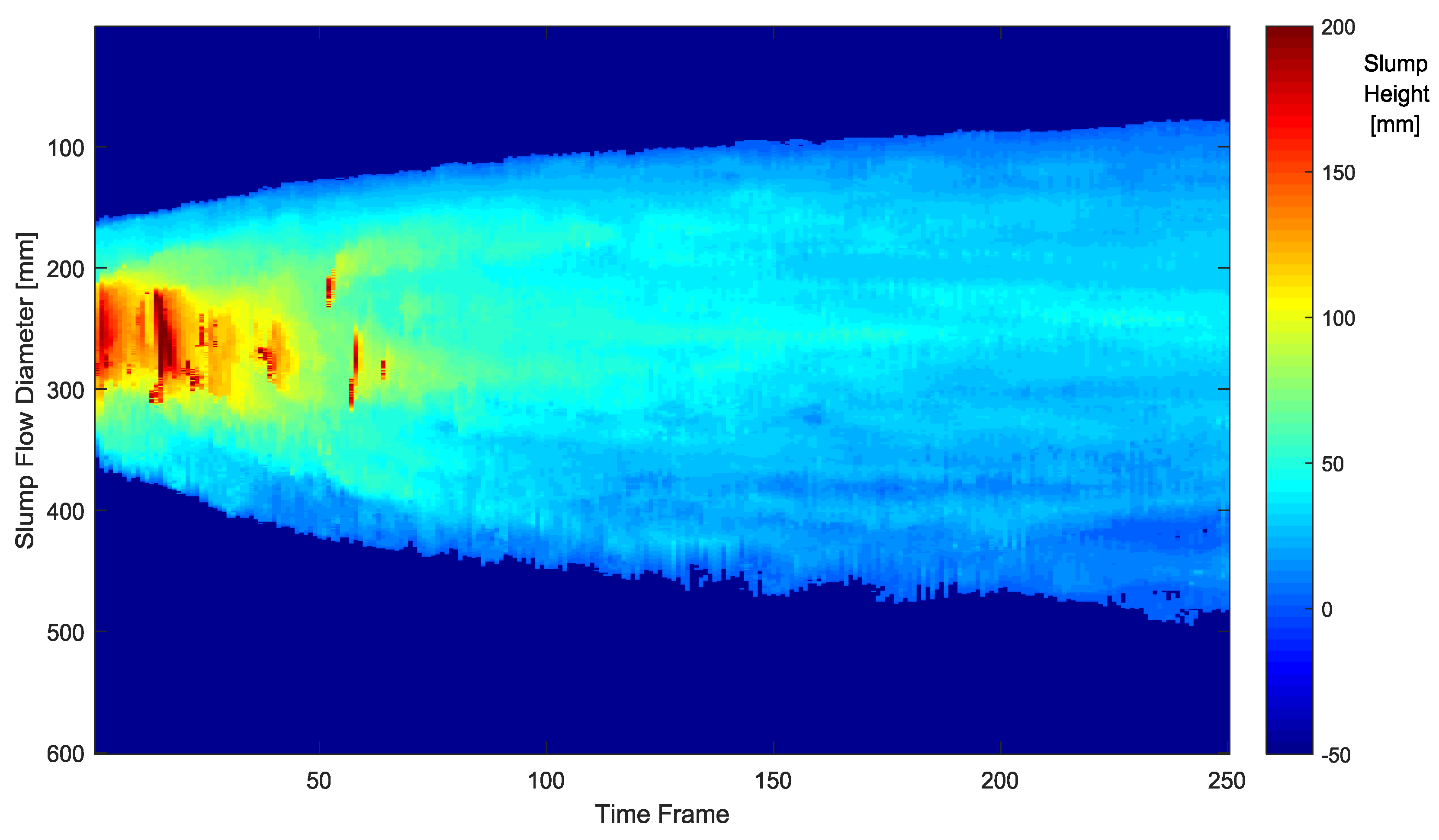

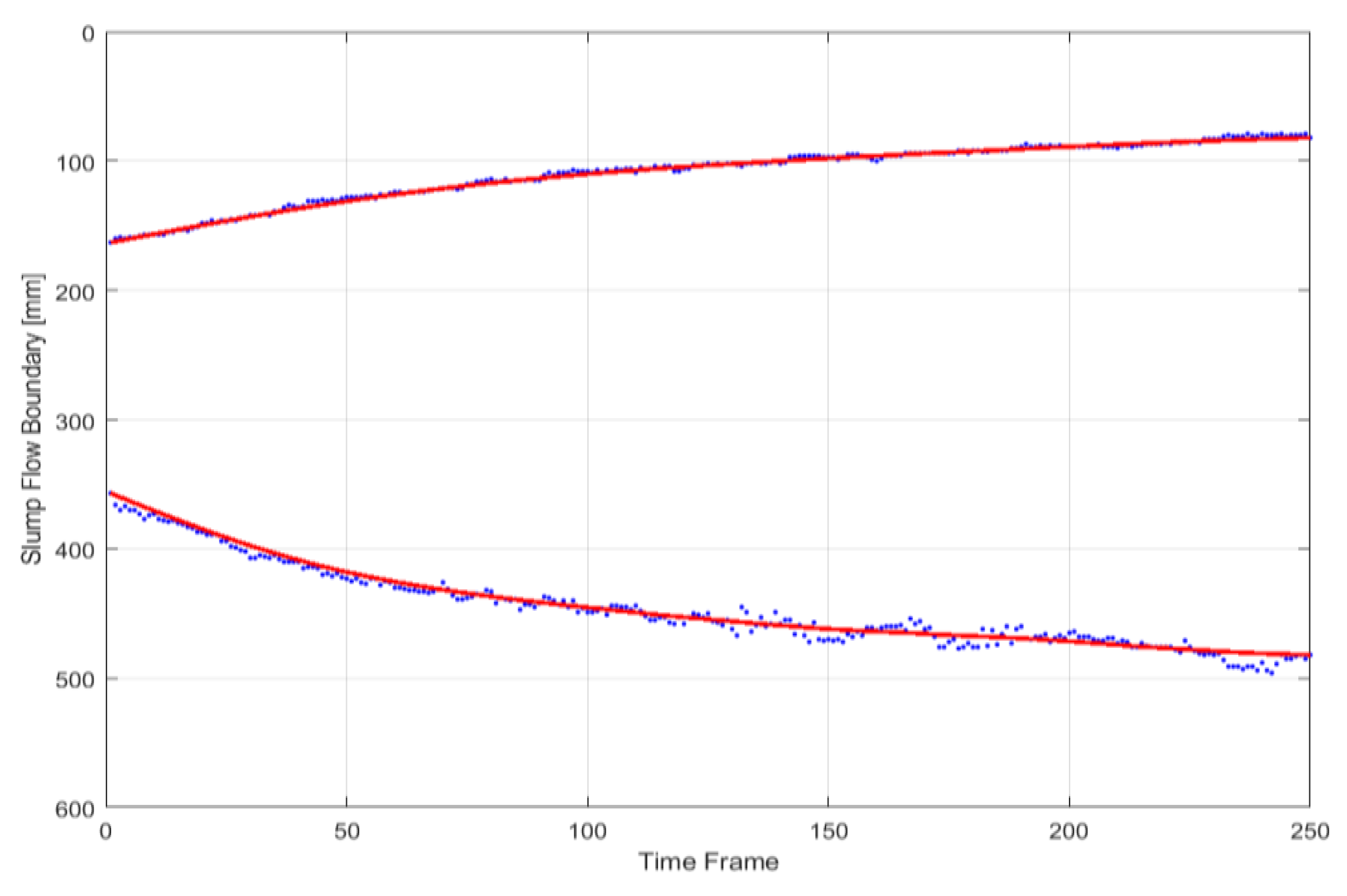

2.5. Cross-Section Extraction and Construction of a 4D Slump Image

3. Experimental Setup for the 4D Slump Test

3.1. Devices for the 4D Slump Test

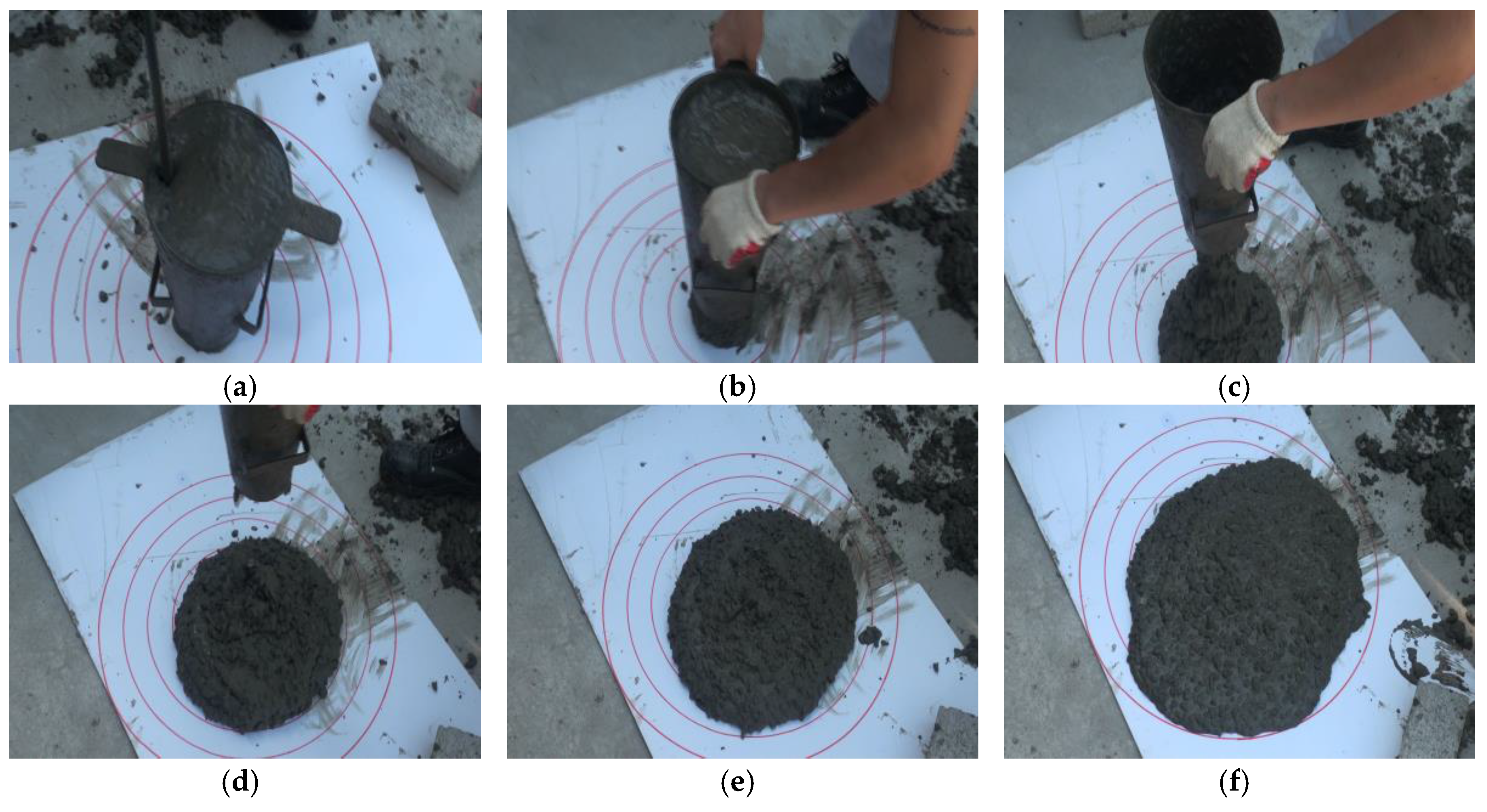

3.2. Test Material and Procedure

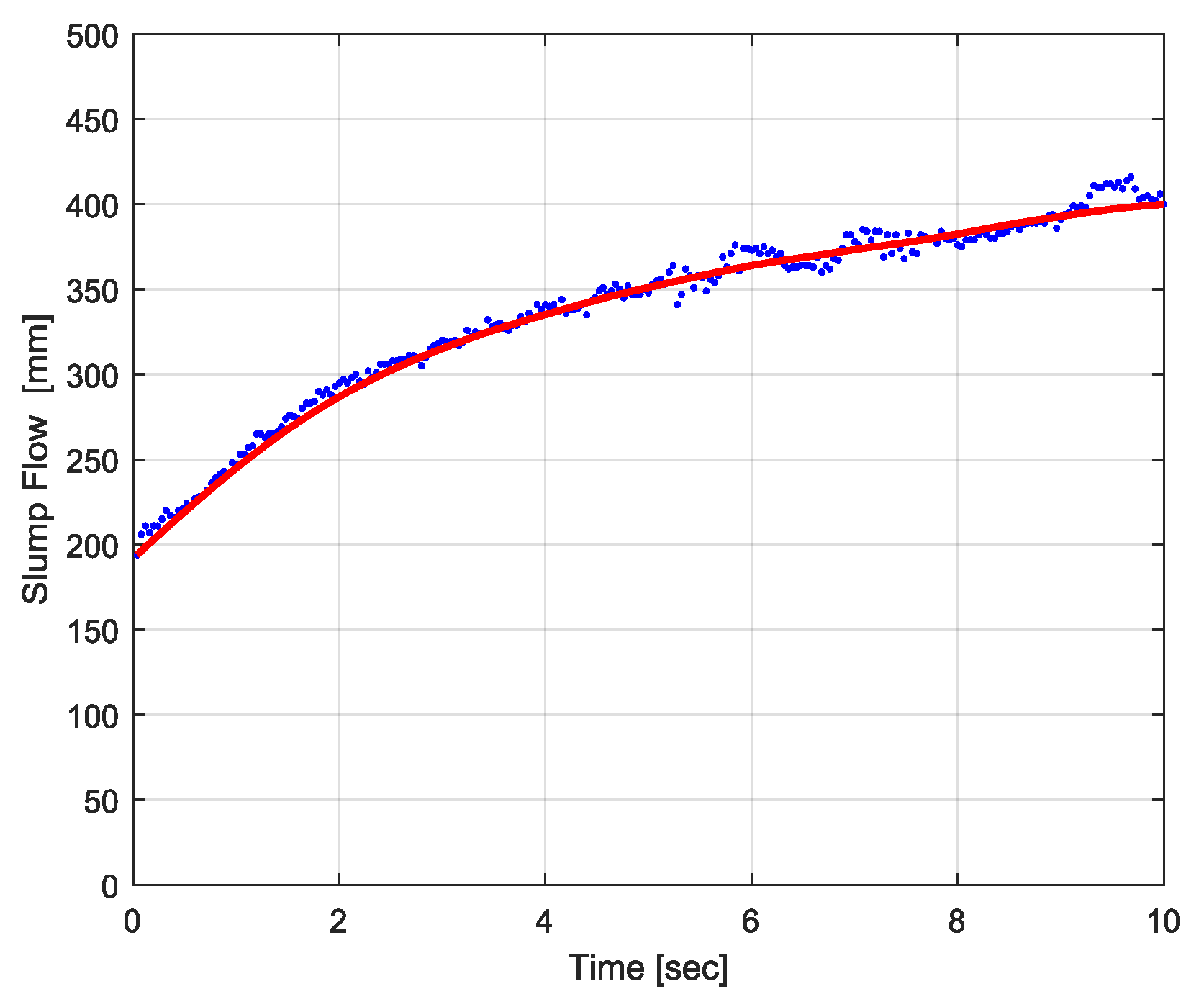

4. Experimental Results

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Koehler, E.P.; Fowler, D.W. Summary of Concrete Workability Test Methods; Research Report ICAR-105-1; International Center for Aggregates Research, University of Texas at Austin: Austin, TX, USA, 2003. [Google Scholar]

- Popovics, S. Fundamentals of Portland Cement Concrete: Fresh Concrete v. 1: Quantitative Approach; John Wiley & Sons Inc.: New York, NY, USA, 1982. [Google Scholar]

- Kwon, S.H.; Jang, K.P.; Kim, J.H.; Shah, S.P. State of the Art on Prediction of Concrete Pumping. Int. J. Concr. Struct. Mater. 2016, 10, 75–85. [Google Scholar] [CrossRef]

- Nehdi, M.L. Only Tall Things Cast Shadows: Opportunities, Challenges and Research Needs of Self-Consolidating Concrete in Super-Tall Buildings. Constr. Build. Mater. 2013, 48, 80–90. [Google Scholar] [CrossRef]

- Shin, S.W.; Yun, C.B.; Popovics, J.S.; Kim, J.H. Improved Rayleigh Wave Velocity Measurement for Nondestructive Early-Age Concrete Monitoring. Res. Nondestruct. Eval. 2007, 18, 45–68. [Google Scholar] [CrossRef]

- Başyiğit, C.; Çomak, B.; Kılınçarslan, Ş.; Serkan Üncü, İ. Assessment of Concrete Compressive Strength by Image Processing Technique. Constr. Build. Mater. 2012, 37, 526–532. [Google Scholar] [CrossRef]

- Rizzo, P.; Ni, X.; Nassiri, S.; Vandenbossche, J. A Solitary Wave-Based Sensor to Monitor the Setting of Fresh Concrete. Sensors 2014, 14, 12568. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lilliman, M. Control of Mortar Rheology for 3D Concrete Printing. Ph.D. Thesis, Department of Architecture, Building and Civil Engineering, Loughborough University, Loughborough, UK, 2017. [Google Scholar]

- Perrot, A.; Rangeard, D.; Pierre, A. Structural Built-Up of Cement-Based Materials Used for 3D-Printing Extrusion Techniques. Mater. Struct. 2016, 49, 1213–1220. [Google Scholar] [CrossRef]

- Jeon, K.-H.; Park, M.-B.; Kang, M.-K.; Kim, J.-H. Development of an Automated Freeform Construction System and its Construction Materials. In Proceedings of the 30th International Symposium on Automation and Robotics in Construction, Montréal, QC, Canada, 11–15 August 2013; pp. 1359–1365. [Google Scholar] [CrossRef]

- Khayat, K.H. Workability, Testing, and Performance of Self-Consolidating Concrete. ACI Mater. J. 1999, 96, 346–353. [Google Scholar] [CrossRef]

- Bartos, P.J.M.; Sonebi, M.; Tamimi, A.K. Workability and Rheology of Fresh Concrete: Compendium of Tests—Report of RILEM TC 145-WSM; RILEM Publications: Paris, France, 2002. [Google Scholar]

- ASTM C1611/C1611M-14. In Standard Test Method for Slump Flow of Self-Consolidating Concrete; ASTM International: West Conshohocken, PA, USA, 2014.

- Kurokawa, Y.; Tanigawa, Y.; Mori, H.; Komura, R. A Study on the Slump Test and Slump-Flow Test of Fresh Concrete. Trans. Jpn. Concr. Inst. 1994, 16, 25–32. [Google Scholar]

- ASTM C143/C143M-15a. In Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2015.

- Koehler, E.P.; Fowler, D.W.; Ferraris, C.F.; Amziane, S. A New, Portable Rheometer for Fresh Self-Consolidating Concrete. ACI Specif. Publ. 2006, 233, 97–116. [Google Scholar] [CrossRef]

- Kim, J.H.; Jang, H.R.; Yim, H.J. Sensitivity and Accuracy for Rheological Simulation of Cement-Based Materials. Comput. Concr. 2015, 15, 903–919. [Google Scholar] [CrossRef]

- Gao, J.; Fourie, A. Spread is Better: An Investigation of the Mini-Slump Test. Miner. Eng. 2015, 71, 120–132. [Google Scholar] [CrossRef]

- Smisek, J.; Jancosek, M.; Pajdla, T. 3D with Kinect. In Consumer Depth Cameras for Computer Vision: Research Topics and Applications; Fossati, A., Gall, J., Grabner, H., Ren, X., Konolige, K., Eds.; Springer: London, UK, 2013; pp. 3–25. [Google Scholar]

- El-laithy, R.A.; Huang, J.; Yeh, M. Study on the Use of Microsoft Kinect for Robotics Applications. In Proceedings of the 2012 IEEE/ION Position, Location and Navigation Symposium, Myrtle Beach, SC, USA, 23–26 April 2012; pp. 1280–1288. [Google Scholar]

- Park, J.-H.; Shin, Y.-D.; Bae, J.-H.; Baeg, M.-H. Spatial Uncertainty Model for Visual Features Using a Kinect™ Sensor. Sensors 2012, 12, 8640–8662. [Google Scholar] [CrossRef] [PubMed]

- Tannous, H.; Istrate, D.; Benlarbi-Delai, A.; Sarrazin, J.; Gamet, D.; Ho Ba Tho, M.; Dao, T. A New Multi-Sensor Fusion Scheme to Improve the Accuracy of Knee Flexion Kinematics for Functional Rehabilitation Movements. Sensors 2016, 16, 1914. [Google Scholar] [CrossRef] [PubMed]

- Qi, X.; Lichti, D.; El-Badry, M.; Chow, J.; Ang, K. Vertical Dynamic Deflection Measurement in Concrete Beams with the Microsoft Kinect. Sensors 2014, 14, 3293–3307. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, A.; Yulu Luke, C.; Mohammad, R.J.; Sami, F.M.; Wei-Men, S.; Uvais, A.Q. 3D Dynamic Displacement-Field Measurement for Structural Health Monitoring Using Inexpensive RGB-D Based Sensor. Smart Mater. Struct. 2017, 26, 125016. [Google Scholar] [CrossRef]

- Khan, F.; Bolhassani, M.; Kontsos, A.; Hamid, A.; Bartoli, I. Modeling and experimental implementation of infrared thermography on concrete masonry structures. Infrared Phys. Technol. 2015, 69, 228–237. [Google Scholar] [CrossRef]

- Freedman, B.; Shpunt, A.; Machline, M.; Arieli, Y. Depth Mapping Using Projected Patterns. U.S. Patent 8,493,496, 23 July 2013. [Google Scholar]

- Khoshelham, K.; Elberink, S.O. Accuracy and Resolution of Kinect Depth Data for Indoor Mapping Applications. Sensors 2012, 12, 1437–1454. [Google Scholar] [CrossRef] [PubMed]

- Darwish, W.; Tang, S.; Li, W.; Chen, W. A New Calibration Method for Commercial RGB-D Sensors. Sensors 2017, 17, 1204. [Google Scholar] [CrossRef] [PubMed]

- Craig, J.J. Introduction to Robotics: Mechanics and Control, 3rd ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2004. [Google Scholar]

- Fischler, M.A.; Bolles, A.R.C. Random Sample Consensus: A Paradigm for Model Fitting with Applications to Image Analysis and Automated Cartography. Commun. ACM 1981, 24, 381–395. [Google Scholar] [CrossRef]

- Amidror, I. Scattered Data Interpolation Methods for Electronic Imaging Systems: A Survey. J. Electron. Imaging 2002, 11, 157–176. [Google Scholar] [CrossRef]

- Kinect Sensor. Available online: https://msdn.microsoft.com/en-us/library/hh438998.aspx (accessed on 10 January 2018).

- Yang, L.; Zhang, L.; Dong, H.; Alelaiwi, A.; Saddik, A.E. Evaluating and Improving the Depth Accuracy of Kinect for Windows v2. IEEE Sens. J. 2015, 15, 4275–4285. [Google Scholar] [CrossRef]

- Fares, G. Effect of Slump Cone Orientation on the Slump Flow Time (T50) and Stability of Sustainable Self-Compacting Concrete Containing Limestone Filler. Constr. Build. Mater. 2015, 77, 145–154. [Google Scholar] [CrossRef]

- Ramsburg, P. The SCC Test: Inverted or Upright? Concr. Prod. 2003, 21, 34–38. [Google Scholar]

- Azzari, G.; Goulden, L.M.; Rusu, B.R. Rapid Characterization of Vegetation Structure with a Microsoft Kinect Sensor. Sensors 2013, 13, 2384–2398. [Google Scholar] [CrossRef] [PubMed]

| W/B | Water | C | FA | S | G | SP |

|---|---|---|---|---|---|---|

| 39% | 9.37% | 16.77% | 7.18% | 35.01% | 31.52% | 0.345% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-H.; Park, M. Visualization of Concrete Slump Flow Using the Kinect Sensor. Sensors 2018, 18, 771. https://doi.org/10.3390/s18030771

Kim J-H, Park M. Visualization of Concrete Slump Flow Using the Kinect Sensor. Sensors. 2018; 18(3):771. https://doi.org/10.3390/s18030771

Chicago/Turabian StyleKim, Jung-Hoon, and Minbeom Park. 2018. "Visualization of Concrete Slump Flow Using the Kinect Sensor" Sensors 18, no. 3: 771. https://doi.org/10.3390/s18030771