A Real-Time Construction Safety Monitoring System for Hazardous Gas Integrating Wireless Sensor Network and Building Information Modeling Technologies

Abstract

:1. Introduction

2. Related Works

2.1. Localization and Safety Management

2.2. Facility and Environment Monitoring

2.3. Building & Infrastructure Monitoring

2.4. Resource Management and Optimization

2.5. Equipment Automation and Efficiency Enhancement

3. System Planning and Design

3.1. Requirements Analysis of Users

3.2. System Planning

3.3. System Analysis

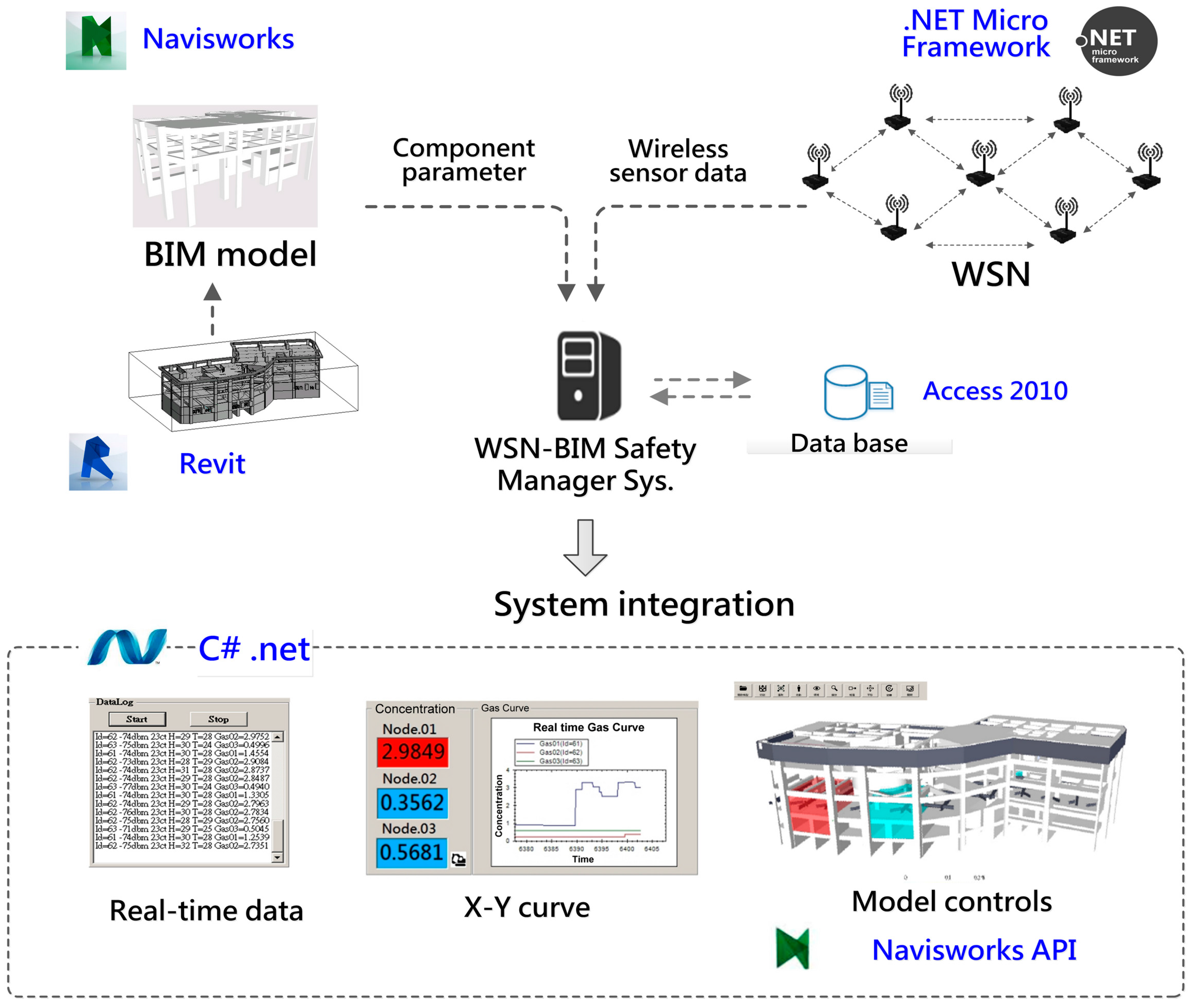

4. System Development

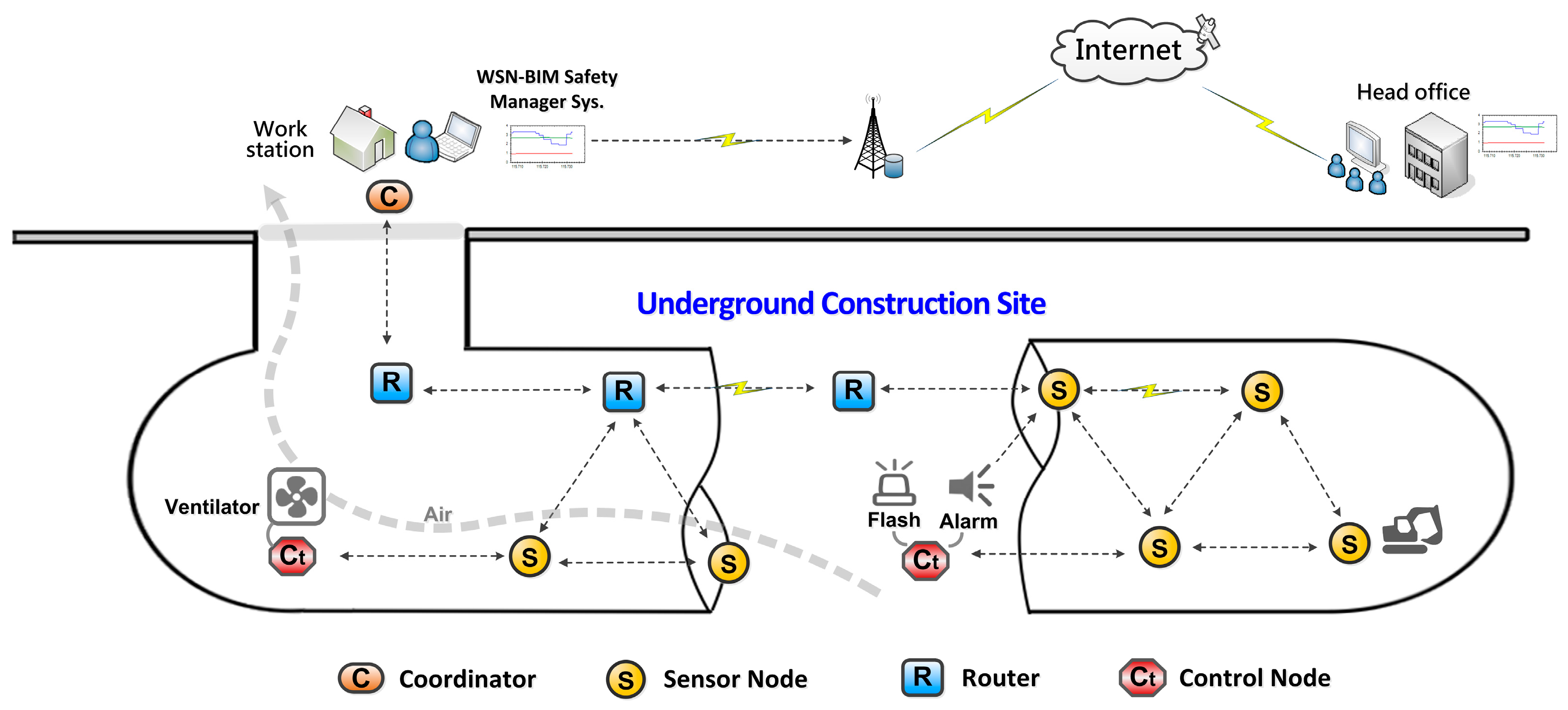

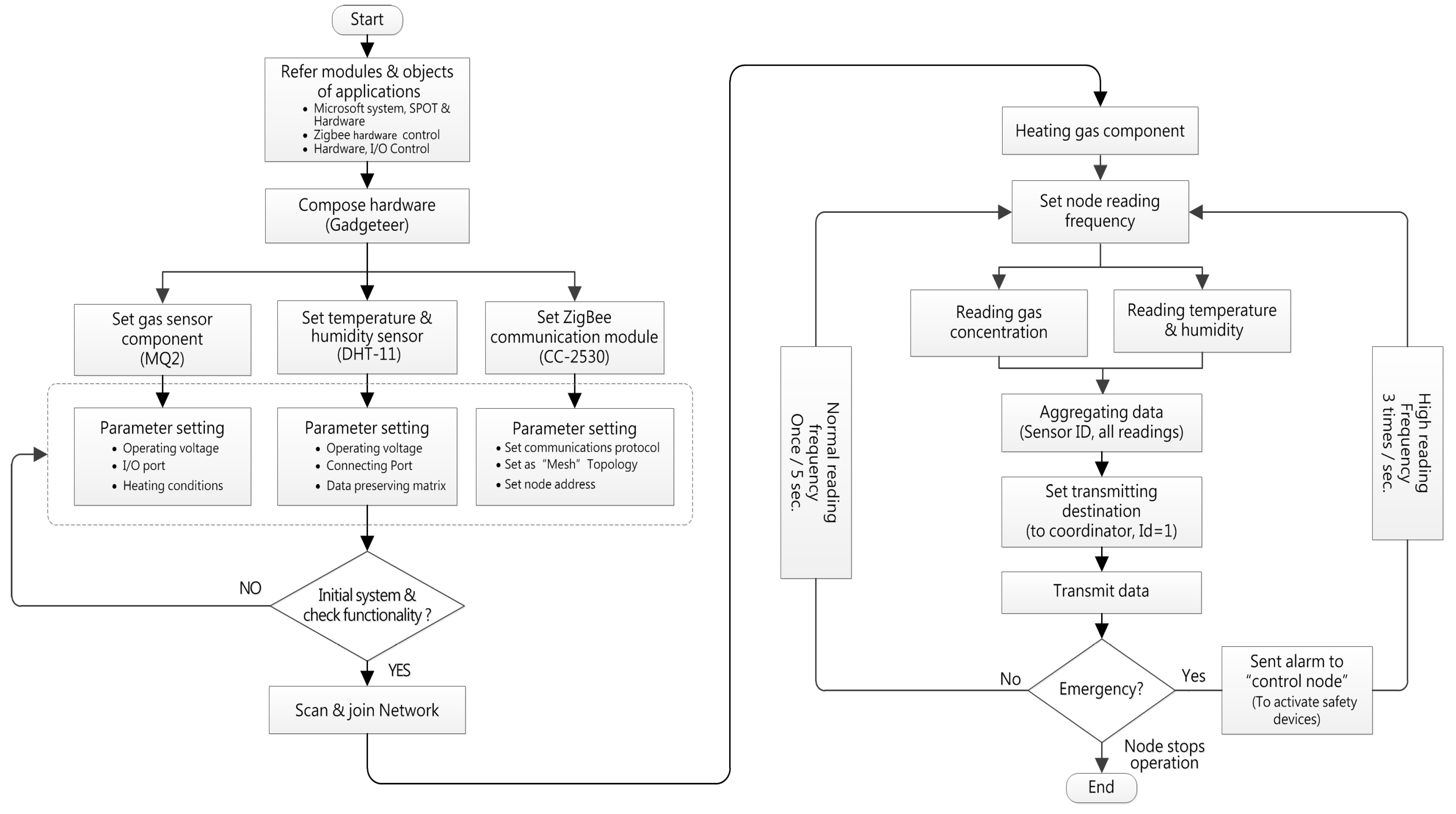

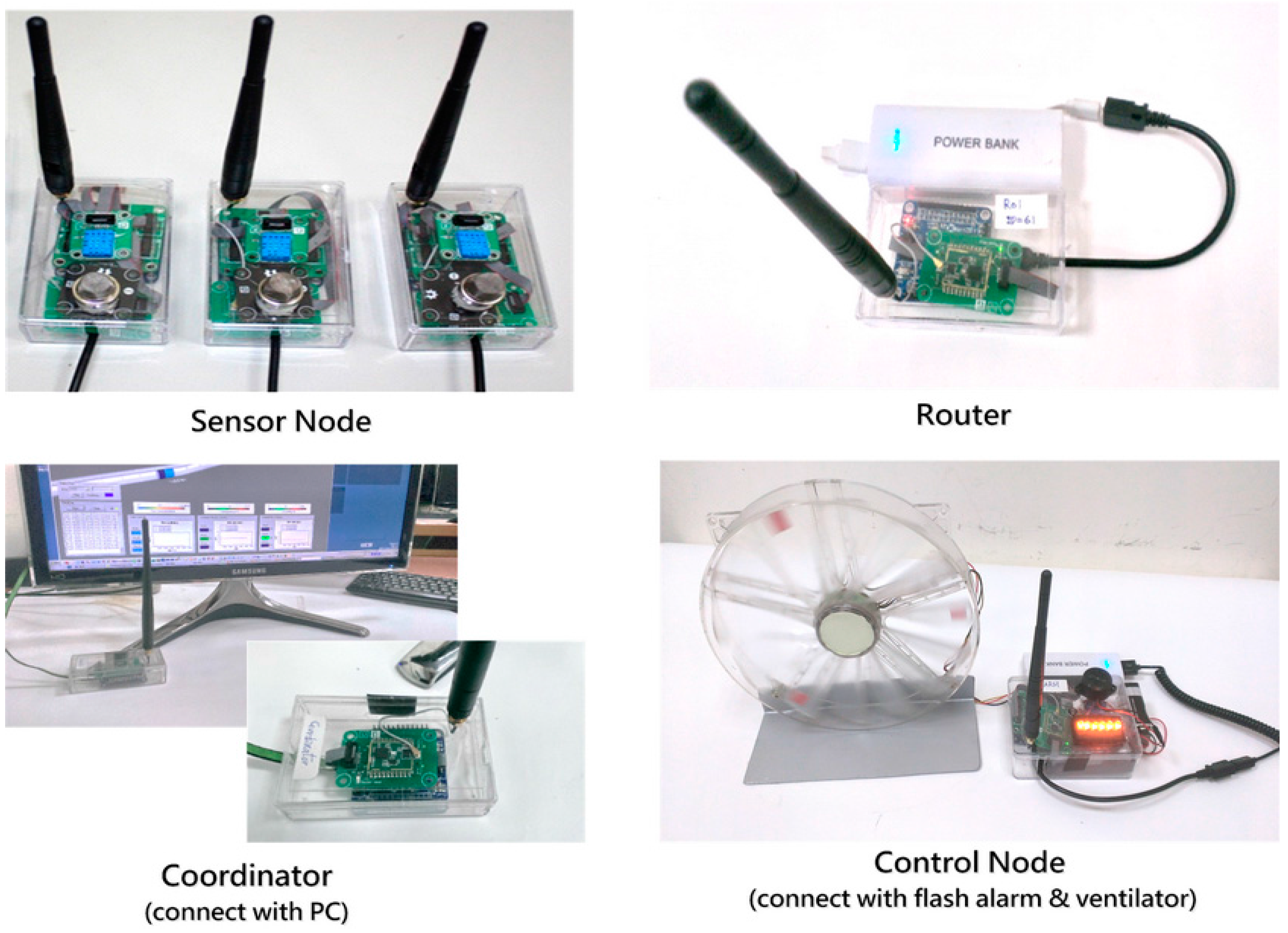

4.1. Network Topology and WSN Node Design

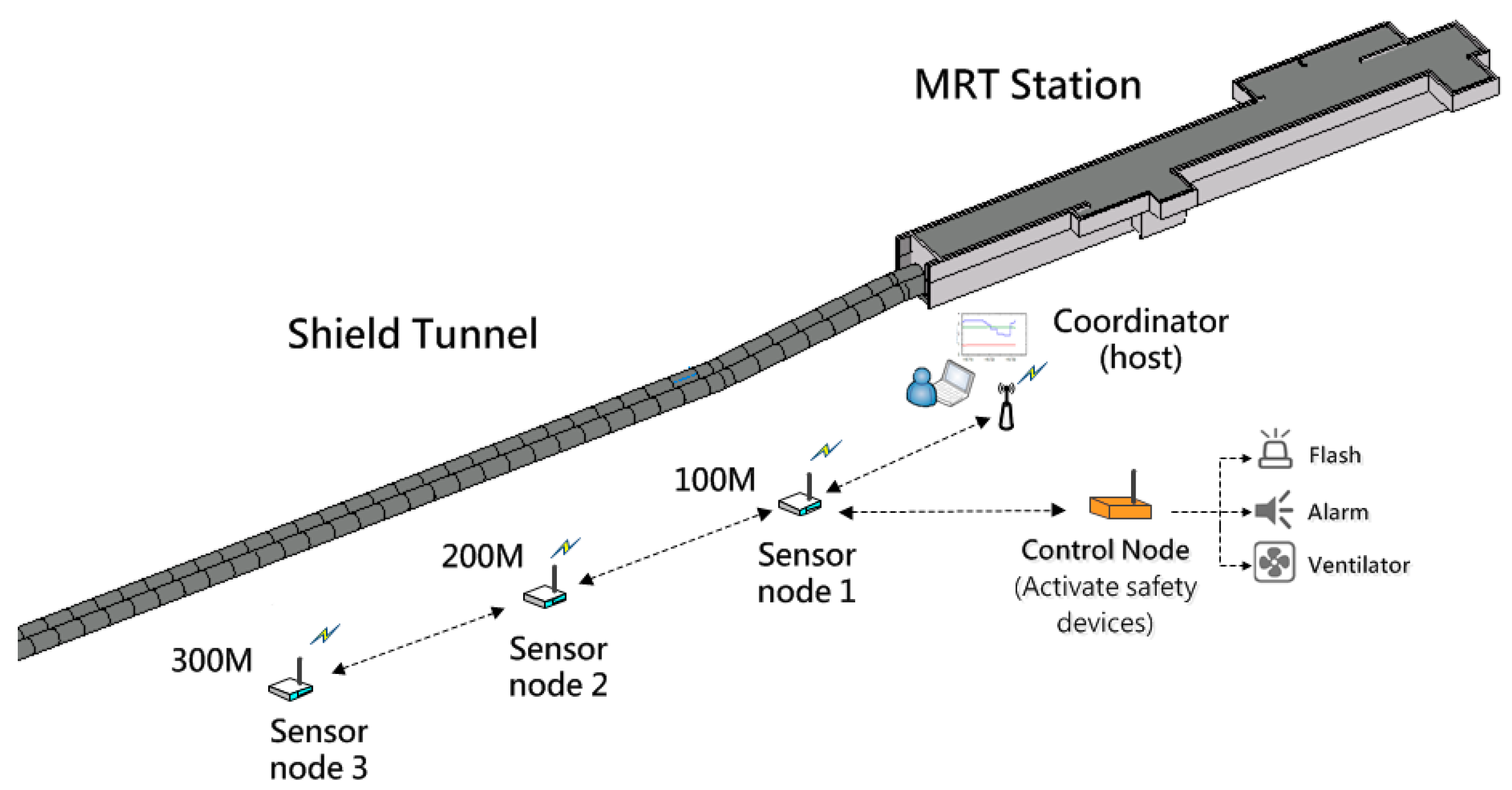

4.1.1. Network Topology

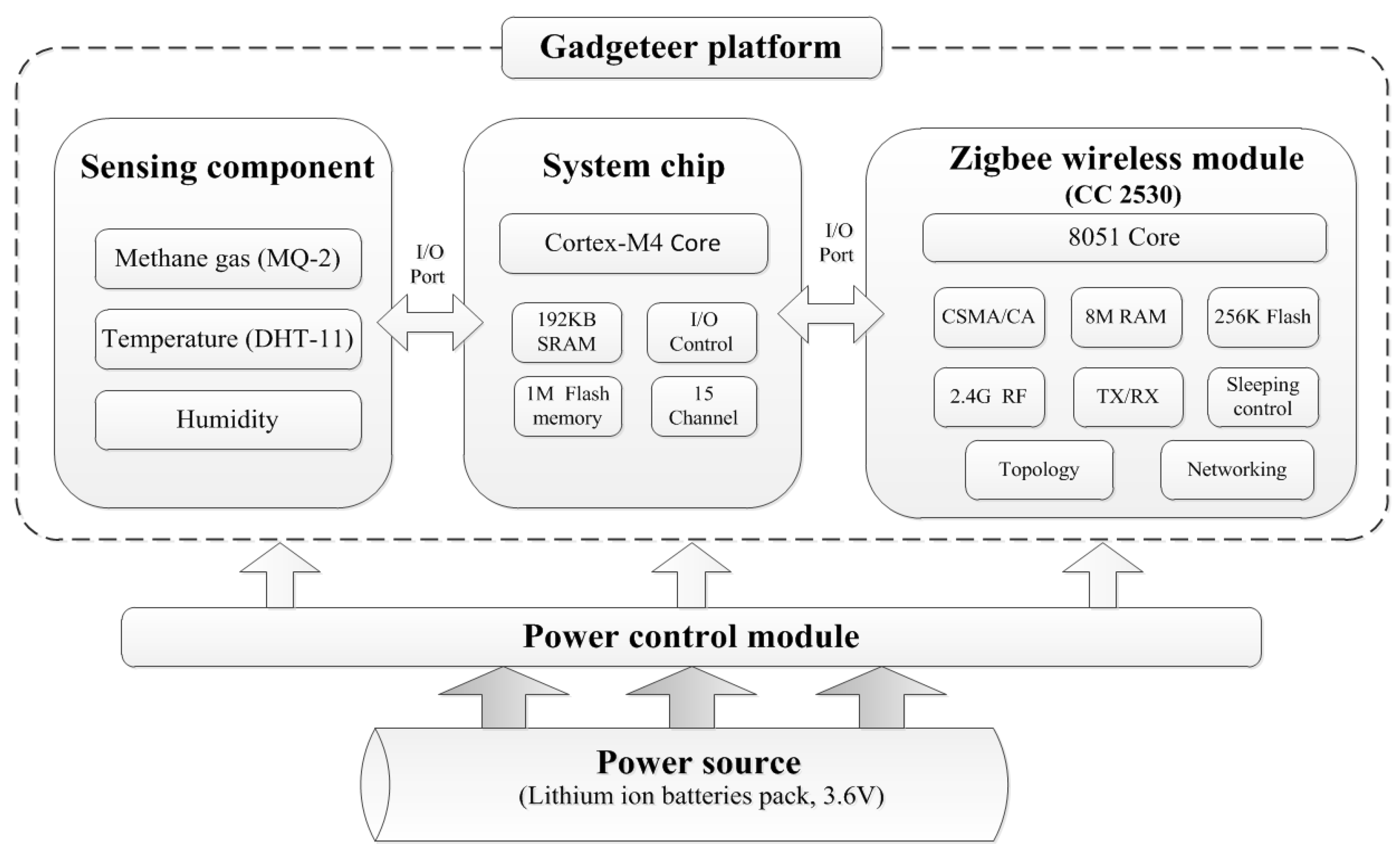

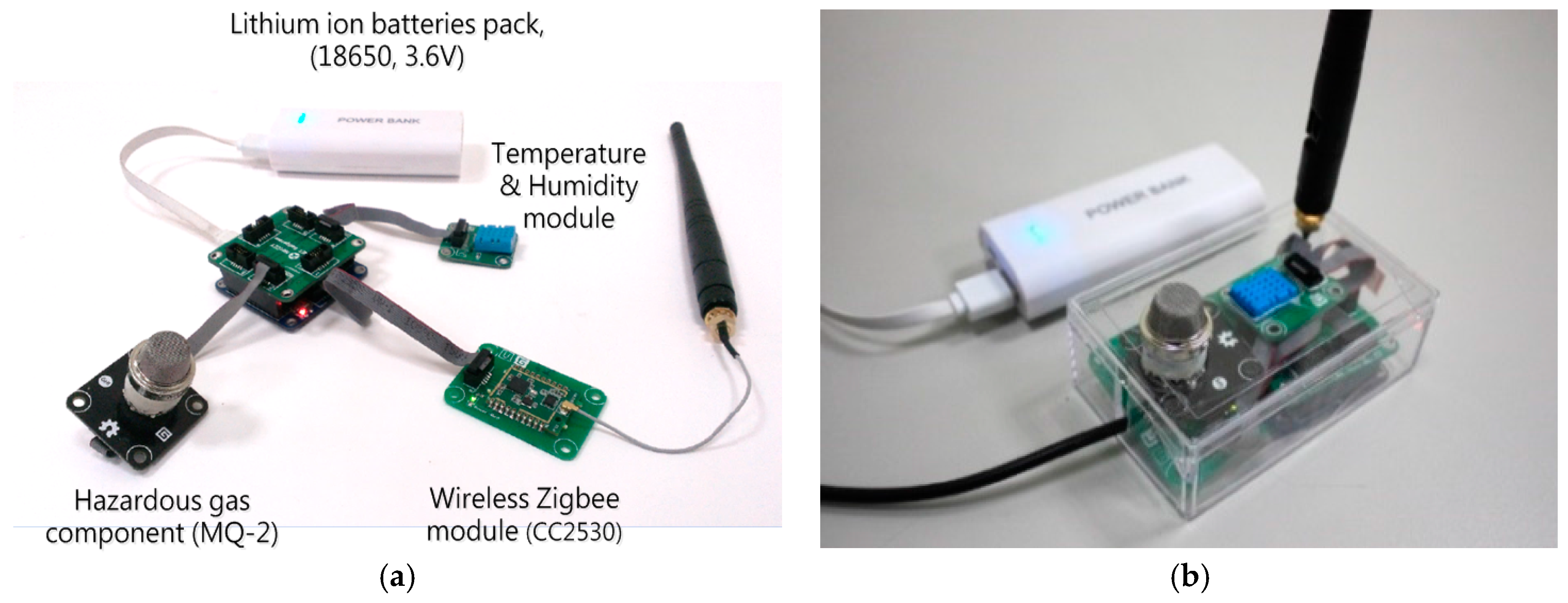

4.1.2. The Developments of WSN Node

Sensor Node Development

- (1)

- Gas sensor: a MQ-2sensing component [25] is used for detecting the methane gas concentration and transform it into a corresponding voltage for signal output.

- (2)

- Temperature and humidity sensor modules: DHT-11 [26] sensor modules which can detect the ambient temperature and humidity and then transform them into digital signal outputs are used.

- (3)

- System main board: Microsoft “Gadgeteer”, including an ARM Cortex-M4 core processor, was adopted as the hardware architecture of the embedded system.

- (4)

- Wireless transmission module: the detected data was transmitted through the Zigbee CC2530 wireless module [27]. The networking type of the module is debugged as a “mesh” topology.

- (5)

- Power supply module: composed by several 18650 lithium ion batteries and providing regular 3.6 V power for the operation of the sensor nodes.

Control Node Development

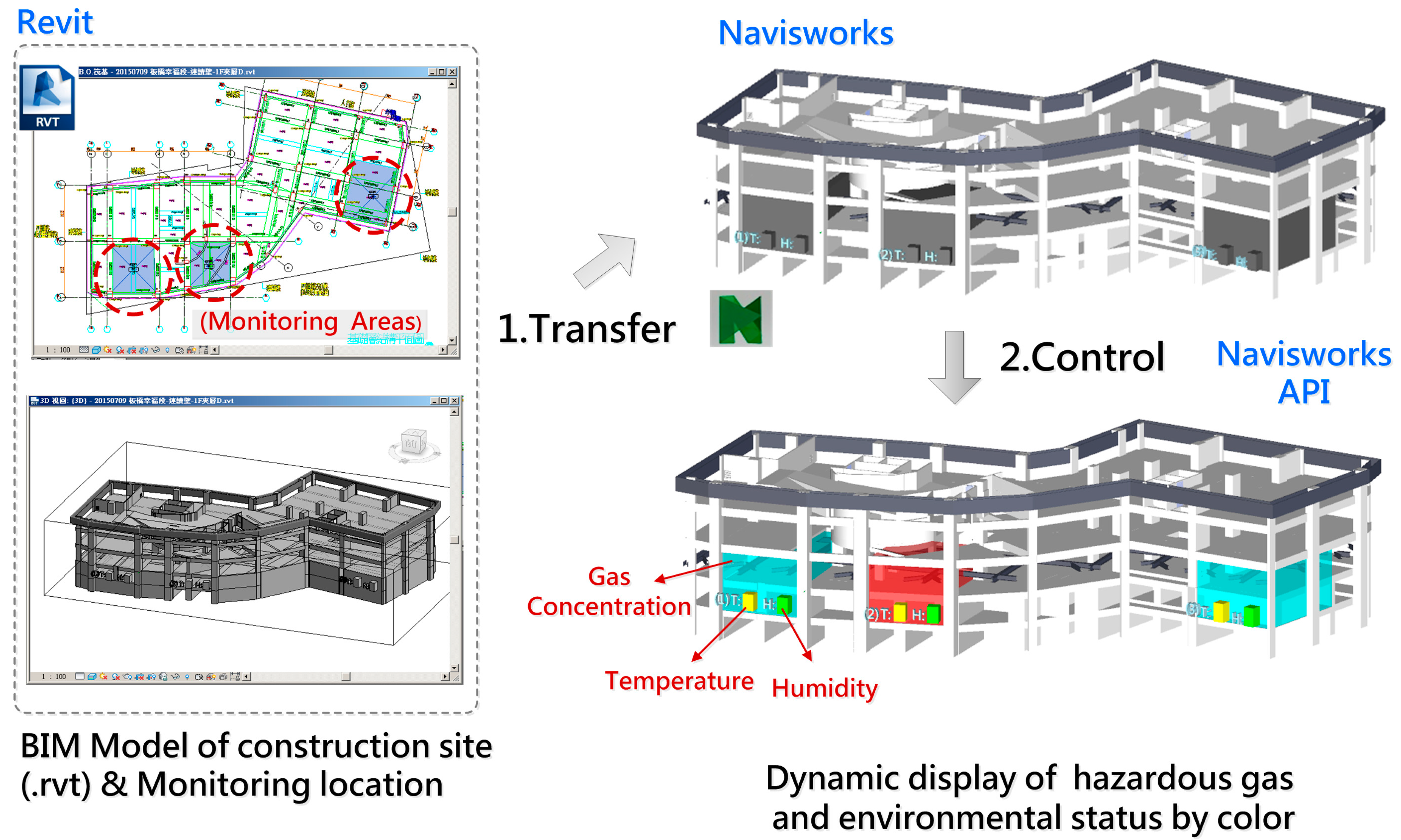

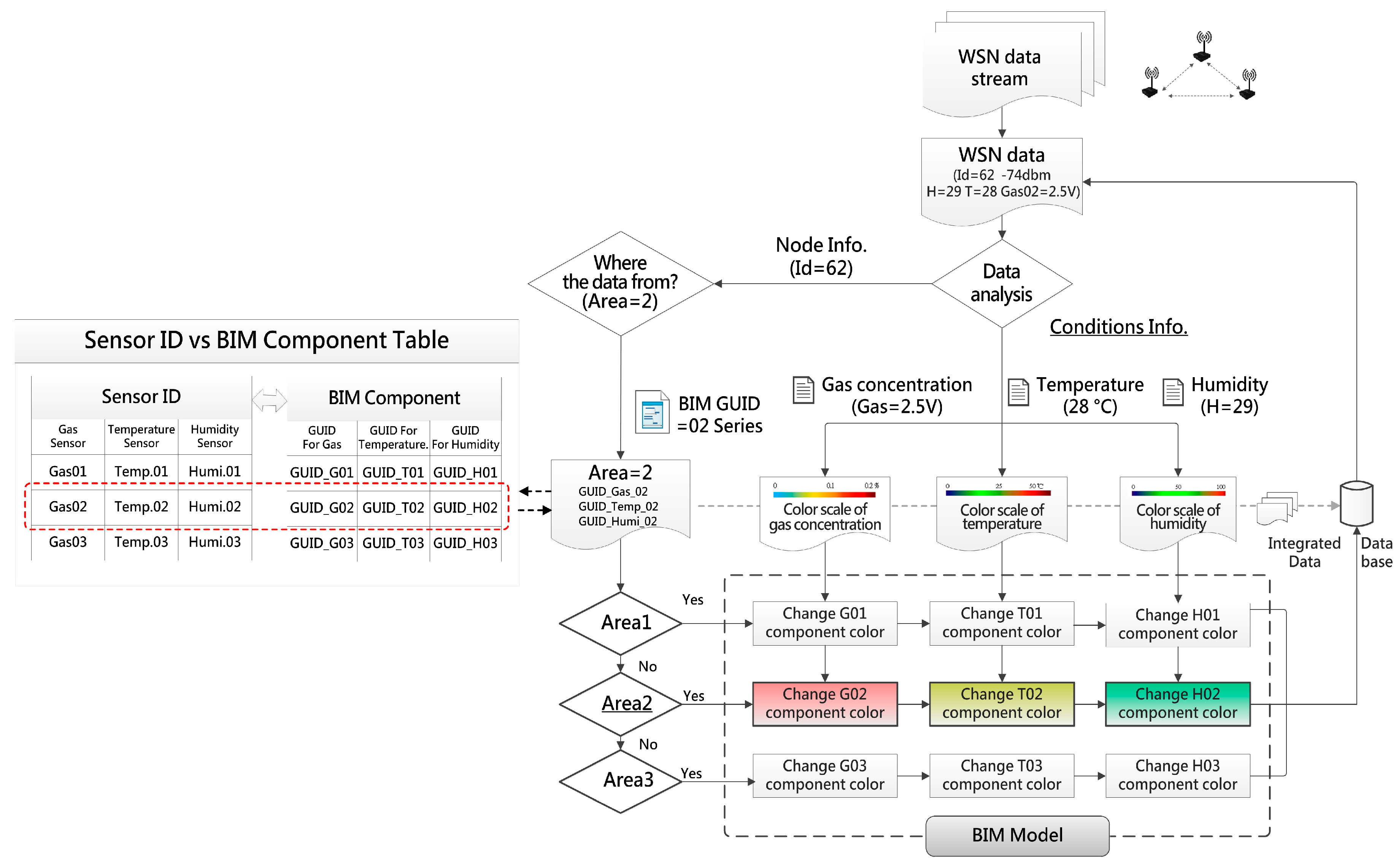

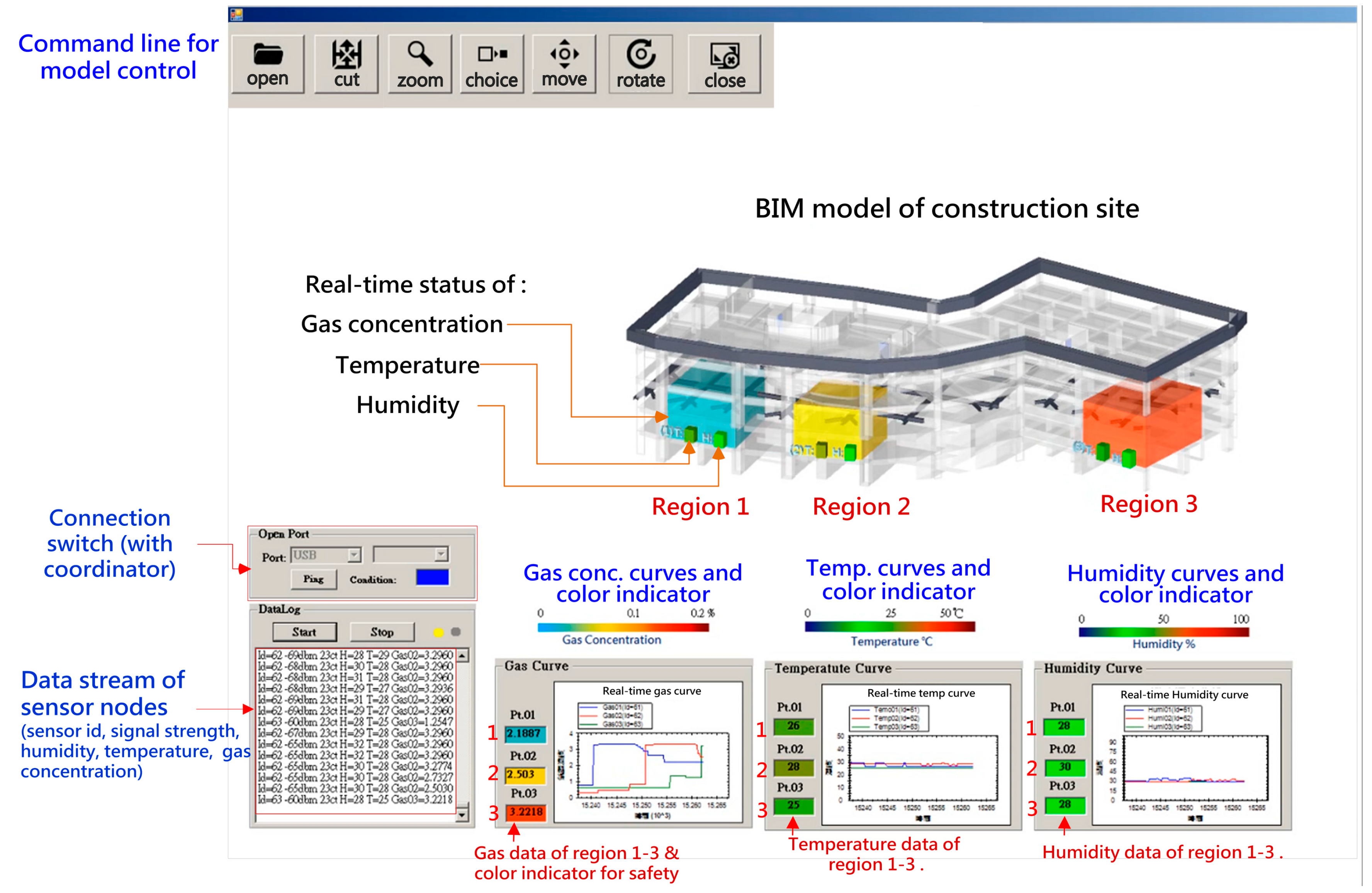

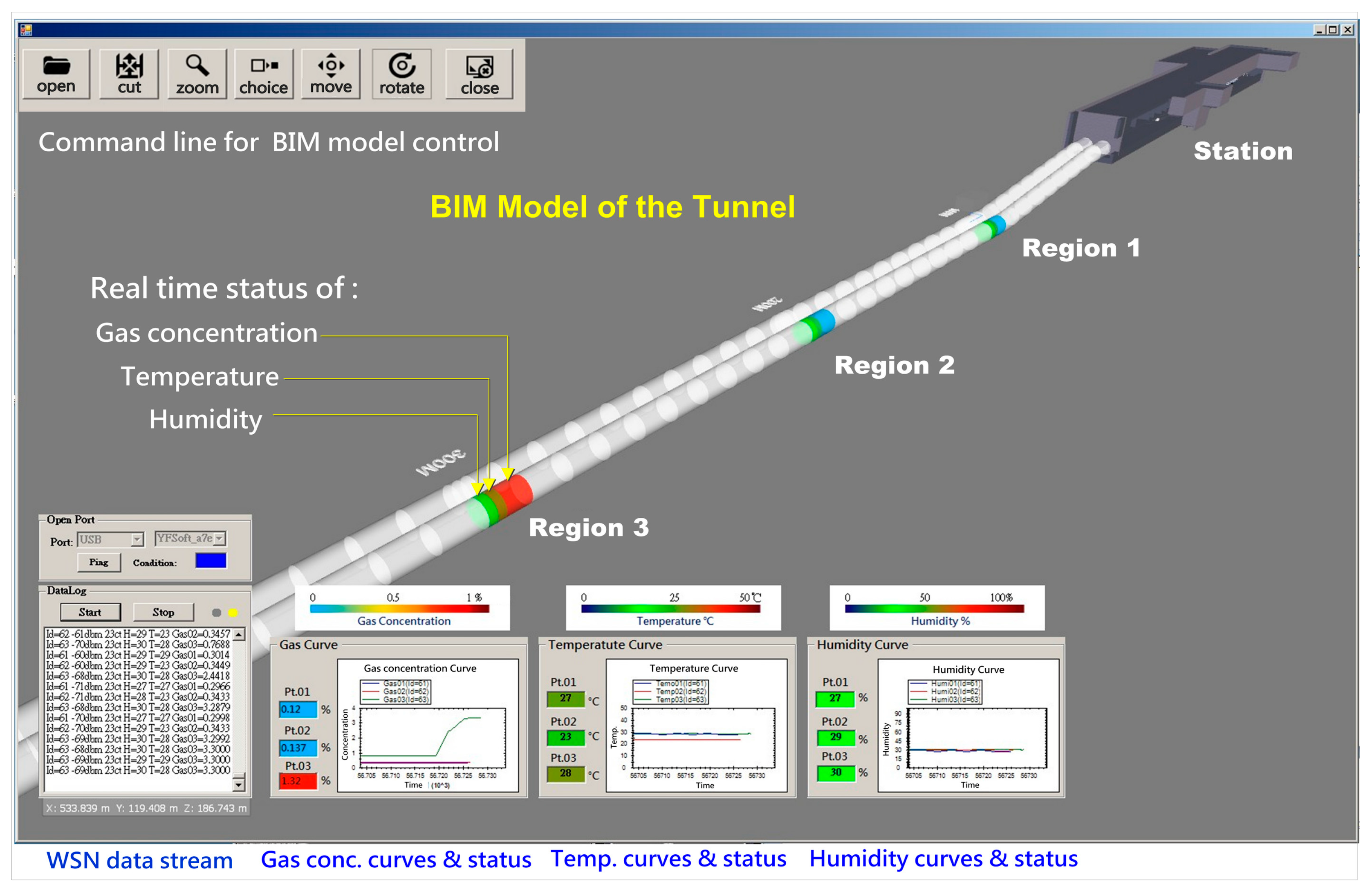

4.2. Establish and Control the BIM Model

4.2.1. BIM Model Establishment

4.2.2. BIM Model and Component Control

4.3. System Integration

5. Experiments

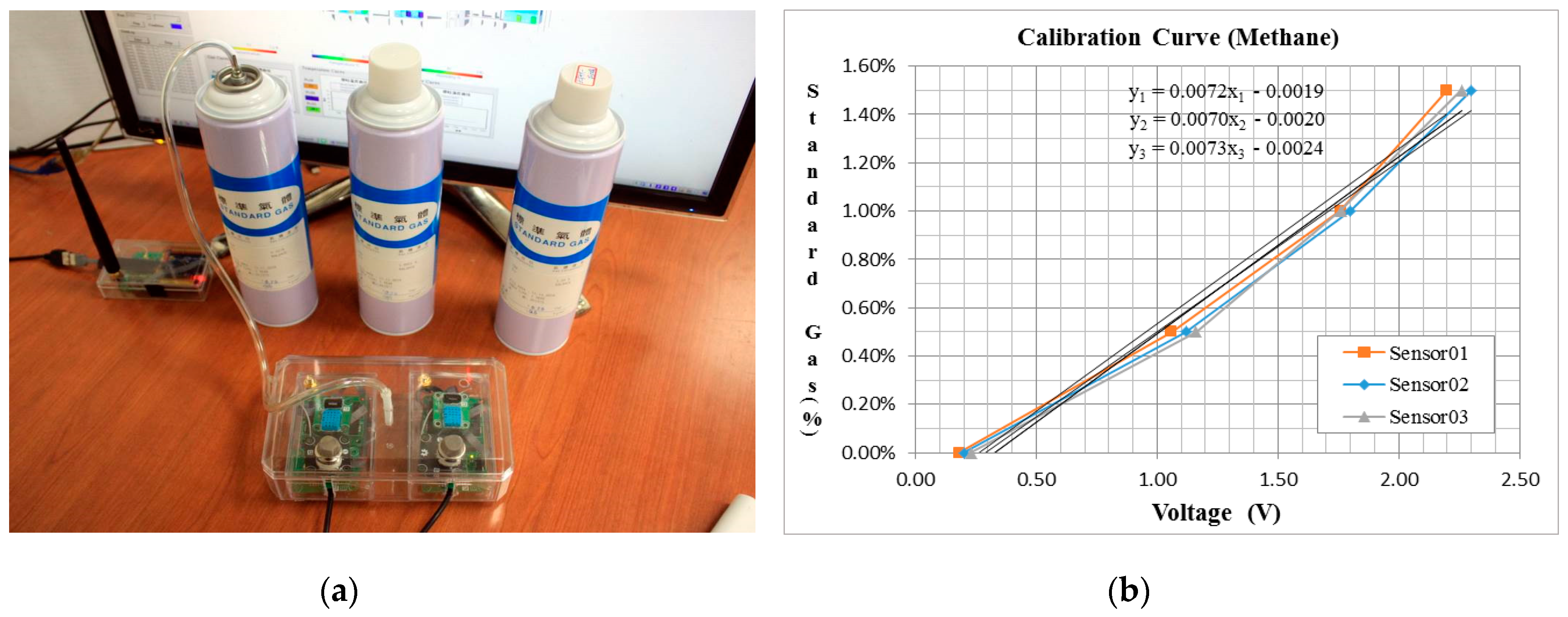

5.1. Sensor Node Calibration

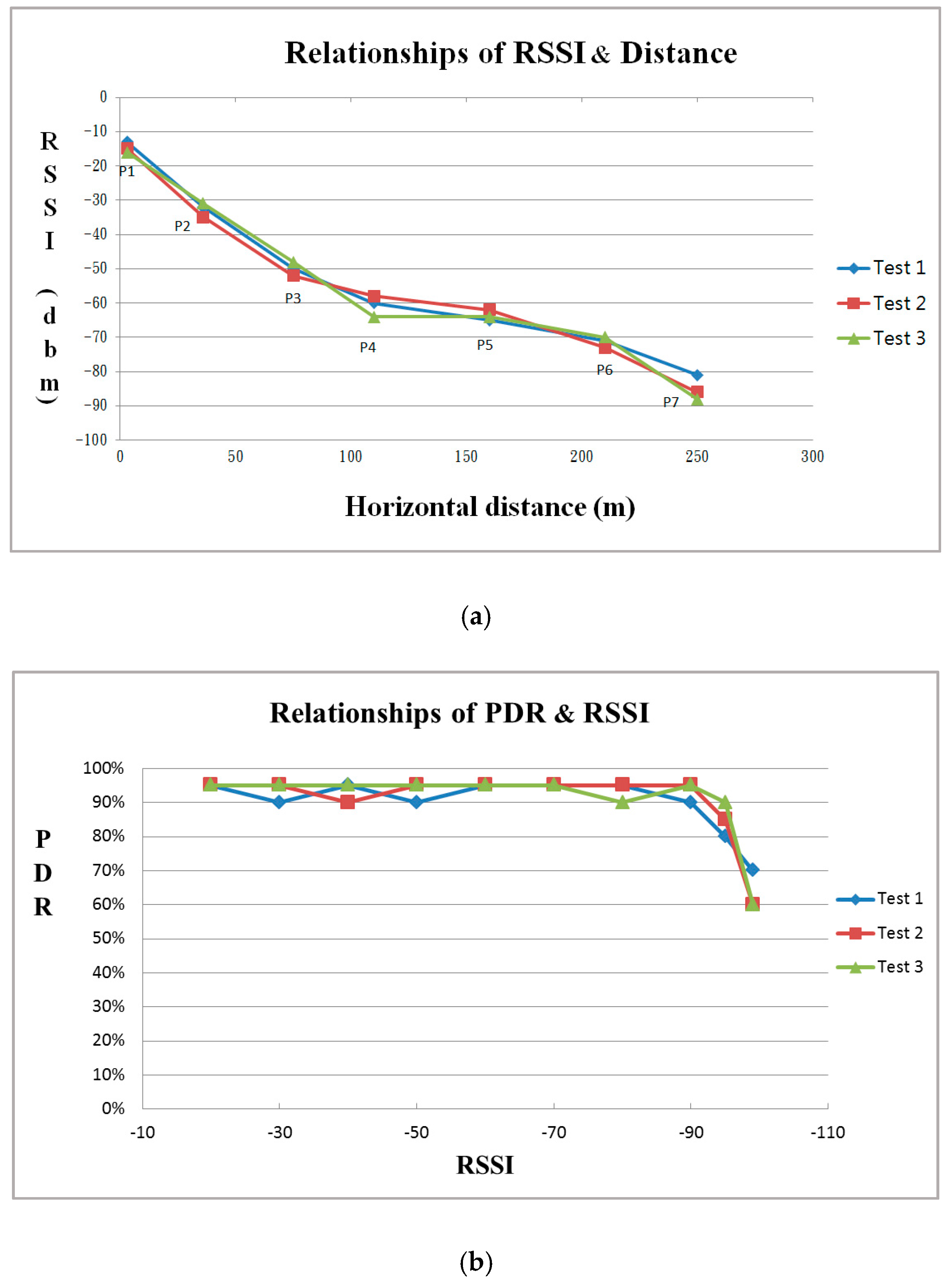

5.2. Node Performance Test

6. Case Study

6.1. Test Processes

6.1.1. Performance Test in Gas Detection

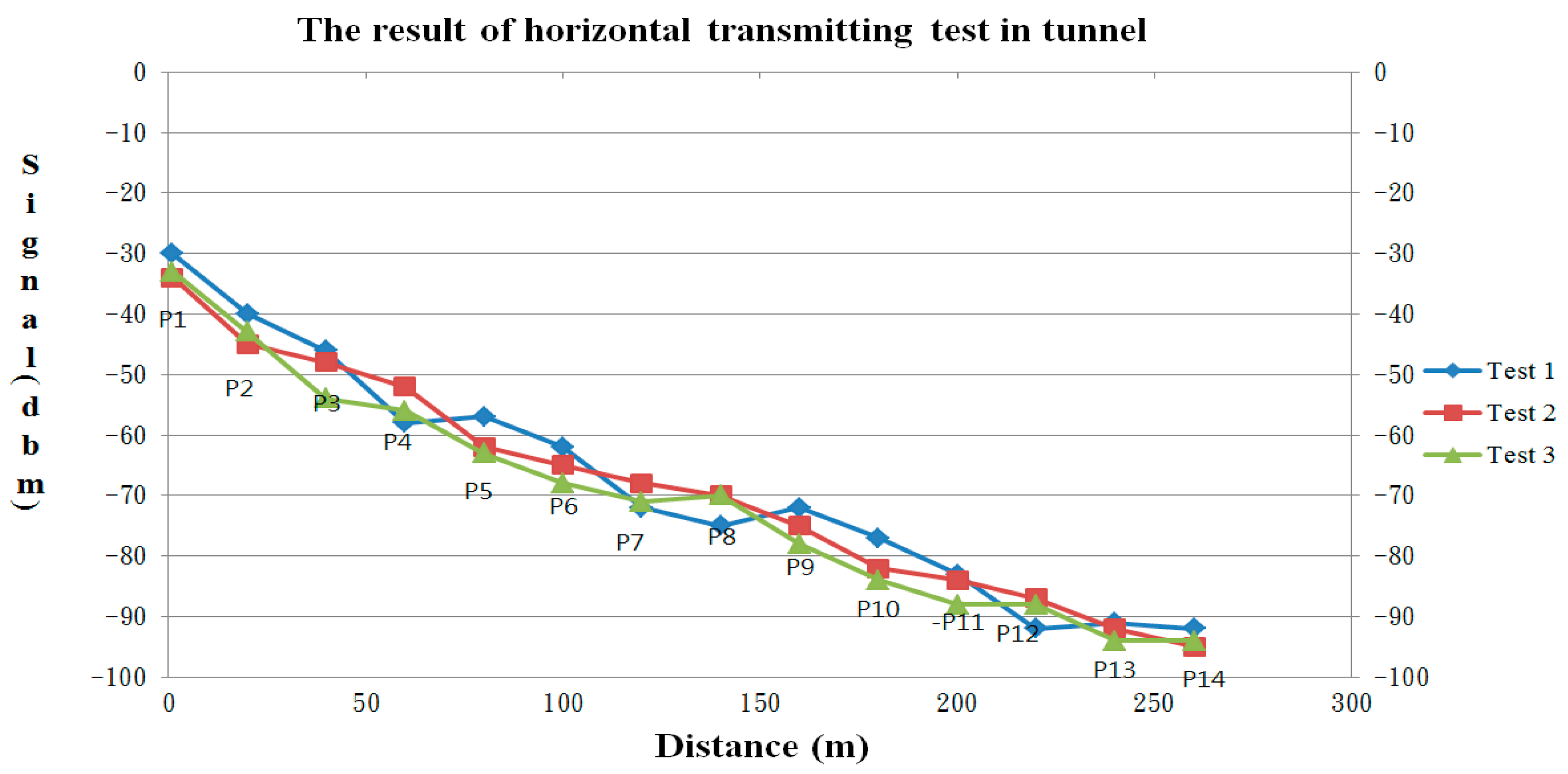

6.1.2. Signal Transmission Test

6.1.3. Interference Test of Sensor Node

6.2. Evaluation and Discussion

7. Conclusions and Suggestions

7.1. Conclusions

- Considering the characteristics of construction job sites, the network of “mesh” type topology within multi-hop and network auto-recovery capabilities is suitable for monitoring tasks in construction sites; “star” and “tree” type topologies networks may be limited by their shorter transmission distance and the communication may be interrupted by node failure.

- The WSN provides a remote way for monitoring and controlling hazards which eliminates the risk of human exposure to hazardous environments and enhances the human safety in monitoring tasks.

- Within the real-time safety status and spatial information displayed on the system model, the rescuer can determine the exact location of any event in advance, which is very important and helpful for rescue tasks in an emergency situation.

- The designed intelligent function enables the system to automatically actuate the ventilation and related safety devices when an abnormal situation is detected, which can decrease the hazardous gas accumulation, and prevent possible explosions and human injuries.

- The proposed system provides multi-condition monitoring information of several regions, which is helpful to judge the risk priorities of different regions (such as both high gas concentration and temperature conditions which are more dangerous than only one condition), and the information is useful for human evacuation and decision making.

- Compared with the “fixed” type monitoring system, WSNs not only can be quickly implemented and are free from wire maintenance, but the measuring locations can be changed or increased in number as demanded at any moment, the system is maneuverable and flexible, which meets the monitoring requirements of the construction environment.

7.2. Suggestions

- As the Navisworks application currently does not provide specific components for demonstration of the sensing status, the “room” component adopted to display the safety status in this study which may suffer from the hollow phenomenon when cutting the model. If the application can provide dedicated components for demonstrating the sensing conditions, that will be helpful to improve the display of monitoring tasks.

- The gas components show slightly different values in detection even with the same specification, which leads some degree of error in the measurements. It is recommended to add a calibration function to the system for each component, which will be helpful to improve the measurement accuracy.

- The power supply and the network lifetime are still the main limitations of the WSN system, especially the gas detection component has to be pre-heated before operation which will consume more power. It is suggested to increase the power supply capacity or introduce an external power supply.

- It is suggested to further increase the intelligent functions of system, for instance, the system may automatically derive an algorithm of the best evacuation route in fire emergency scenes by using the data returned by the WSN and the BIM spatial information, or estimate the influence on human health of low-dose hazardous gas exposures from long-term observed information.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Melzner, J.; Zhang, S.; Teizer, J.; Bargstädt, H.J. A case study on automated safety compliance checking to assist fall protection design and planning in building information models. Constr. Manag. Econ. 2013, 31, 661–674. [Google Scholar] [CrossRef]

- Occupational Safety and Health Administration. Confined Spaces. Available online: https://www.osha.gov/SLTC/confinedspaces/ (accessed on 9 September 2017).

- U.S. Department of Labor Bureau of Labor Statistics. National Census of Fatal Occupational Injuries. Available online: http://www.bls.gov/news.release/pdf/cfoi.pdf (accessed on 20 September 2017).

- Koehn, E.E.; Kothari, R.K.; Pan, C.S. Safety in developing countries: Professional and bureaucratic problems. J. Constr. Eng. Manag. 1995, 121, 261–265. [Google Scholar] [CrossRef]

- Elahi, A.; Gschwender, A. ZigBee Wireless Sensor and Control Network, 1st ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2009; ISBN 0137134851 9780137134854. [Google Scholar]

- Cerovsek, T. A review and outlook for a ‘Building Information Model’ (BIM): A multi-standpoint framework for technological development. Adv. Eng. Inform. 2011, 25, 224–244. [Google Scholar] [CrossRef]

- National Institute of Building Science (NIBS). Frequently Asked Questions about the National BIM Standard-United States. Available online: https://www.nationalbimstandard.org/faqs (accessed on 28 September 2017).

- Martínez-Aires, M.D.; López-Alonso, M.; Martínez-Rojas, M. Building information modeling and safety management: A systematic review. Saf. Sci. 2018, 101, 11–18. [Google Scholar] [CrossRef]

- FM systems, Brian Haines. What is the Internet of Things (IoT)? Available online: https://fmsystems.com/blog/does-bim-have-a-role-in-the-internet-of-things/ (accessed on 27 May 2017).

- Li, N.; Becerik-Gerber, B.; Krishnamachari, B.; Soibelman, L. A BIM centered indoor localization algorithm to support building fire emergency response operations. Autom. Constr. 2014, 42, 78–89. [Google Scholar] [CrossRef]

- Naticchia, B.; Vaccarini, M.; Carbonari, A. A monitoring system for real-time interference control on large construction sites. Autom. Constr. 2013, 29, 148–160. [Google Scholar] [CrossRef]

- Wu, W.; Yang, H.; Li, Q.; Chew, D. An integrated information management model for proactive prevention of struck-by-falling-object accidents on construction sites. Autom. Constr. 2013, 34, 67–74. [Google Scholar] [CrossRef] [Green Version]

- Ding, L.Y.; Zhou, C.; Deng, Q.X.; Luo, H.B.; Ye, X.W.; Ni, Y.Q.; Guo, P. Real-time safety early warning system for cross passage construction in Yangtze Riverbed Metro Tunnel based on the internet of things. Autom. Constr. 2013, 36, 25–37. [Google Scholar] [CrossRef]

- Ding, C.J.; Zhao, Y.H.; Zhang, M.L.; Fu, S.L. System design of harmful gas information collection based on ZigBee. Tianjin Gongye Daxue Xuebao 2012, 31, 74–77. [Google Scholar]

- Marzouk, M.; Abdelaty, A. BIM-based framework for managing performance of subway stations. Autom. Constr. 2014, 41, 70–77. [Google Scholar] [CrossRef]

- Riaz, Z.; Arslan, M.; Kiani, A.K.; Azhar, S. CoSMoS: A BIM and wireless sensor based integrated solution for worker safety in confined spaces. Autom. Constr. 2014, 45, 96–106. [Google Scholar] [CrossRef]

- Yang, X.; Ergan, S. Evaluation of visualization techniques for use by facility operators during monitoring tasks. Autom. Constr. 2014, 44, 103–118. [Google Scholar] [CrossRef]

- Hsieh, Y.M.; Lu, Y.S. Visualization system for field monitoring data and its effectiveness. Autom. Constr. 2012, 26, 54–68. [Google Scholar] [CrossRef]

- Chae, M.J.; Yoo, H.S.; Kim, J.Y.; Cho, M.Y. Development of a wireless sensor network system for suspension bridge health monitoring. Autom. Constr. 2012, 21, 237–252. [Google Scholar] [CrossRef]

- Liu, D.; Cui, B.; Liu, Y.; Zhong, D. Automatic control and real-time monitoring system for earth–rock dam material truck watering. Autom. Constr. 2013, 30, 70–80. [Google Scholar] [CrossRef]

- Zekavat, P.R.; Moon, S.; Bernold, L.E. Performance of short and long range wireless communication technologies in construction. Autom. Constr. 2014, 47, 50–61. [Google Scholar] [CrossRef]

- Cho, C.Y.; Kwon, S.; Shin, T.H.; Chin, S.; Kim, Y.S. A development of next generation intelligent construction liftcar toolkit for vertical material movement management. Autom. Constr. 2011, 20, 14–27. [Google Scholar] [CrossRef]

- Shin, T.H.; Chin, S.; Yoon, S.W.; Kwon, S.W. A service-oriented integrated information framework for RFID/WSN-based intelligent construction supply chain management. Autom. Constr. 2011, 20, 706–715. [Google Scholar] [CrossRef]

- Farahani, S. Zigbee Wireless Networks and Transceivers, 1st ed.; Newnes: Burlington, MA, USA, 2008; pp. 6–12. ISBN 0750683937. [Google Scholar]

- Hanwei Electronics, mq-2 Technical Data. Available online: http://www.haoyuelectronics.com/Attachment/MQ-2/MQ-2.pdf (accessed on 10 July 2017).

- D-Robotics. DHT11 Humidity & Temperature Sensor. Available online: http://www.micropik.com/PDF/dht11.pdf (accessed on 27 May 2017).

- Texas Instruments. CC2530, Second Generation System-on-Chip Solution for 2.4 GHz IEEE 802.15.4/RF4CE /ZigBee. Available online: http://www.ti.com/product/CC2530?utm_source=GOOGLE&utm_medium=cpc&utm_term=CC%202530&utm_campaign=CMCU_MCPI_TW_P_E_Technologies&utm_content=068f05f0-72e3-44ad-ba46-af411193b74c&gclid=Cj0KCQiAmITRBRCSARIsAEOZmr5Vp7Lt7sB1hArCg (accessed on 20 October 2017).

- Wikipedia Website. Application Programming Interface. Available online: https://en.wikipedia.org/wiki/Application_programming_interface (accessed on 10 October 2017).

| Layer | Description | Task |

|---|---|---|

| 1. Presentation Layer |

|

|

| 2. Application Layer |

|

|

| 3. Database Layer |

|

|

| 4. Sensor Layer |

|

|

| Item | Application /Software | Function |

|---|---|---|

| 1. Development of WSN nodes and the network system |

|

|

| 2. Building of the BIM model and processing |

|

|

| 3. Data processing |

|

|

| 4. Integration of BIM and WSN information |

|

|

| 5. Hazardous gas management information system |

|

|

| Name | Function |

|---|---|

| 1. Coordinator |

|

| 2. Sensor node |

|

| 3. Router |

|

| 4. Control node |

|

| Items | Description |

|---|---|

| 1. System performance |

|

| 2. Transmission distance test |

|

| 3. Router test |

|

| 4. System interference |

|

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheung, W.-F.; Lin, T.-H.; Lin, Y.-C. A Real-Time Construction Safety Monitoring System for Hazardous Gas Integrating Wireless Sensor Network and Building Information Modeling Technologies. Sensors 2018, 18, 436. https://doi.org/10.3390/s18020436

Cheung W-F, Lin T-H, Lin Y-C. A Real-Time Construction Safety Monitoring System for Hazardous Gas Integrating Wireless Sensor Network and Building Information Modeling Technologies. Sensors. 2018; 18(2):436. https://doi.org/10.3390/s18020436

Chicago/Turabian StyleCheung, Weng-Fong, Tzu-Hsuan Lin, and Yu-Cheng Lin. 2018. "A Real-Time Construction Safety Monitoring System for Hazardous Gas Integrating Wireless Sensor Network and Building Information Modeling Technologies" Sensors 18, no. 2: 436. https://doi.org/10.3390/s18020436