1. Introduction

Structural stress distribution is a critical and directly-measurable parameter to evaluate structural safety [

1] in which monitoring and prediction of the stress distribution of real-world structures is key to the application of structural health monitoring. A stress development prediction method was proposed to predict the stress development trend and provide a deterioration assessment for existing bridges [

1]. Long-term monitoring data of dynamic strain were used for fatigue life assessment of steel bridges, where the strain measurement data from the Tsing Ma Bridge were used to verify the method [

2]. The maximum stress of beam structures was measured during monitoring, and it was compared with the allowable stress and used to assess structural safety [

3]. For such stress prediction methods, the critical problem is that the number of the sensors for stress monitoring is limited, although there is some research on the optimal placement of sensors to control the number of sensors in a reasonable range and ensure that the sensors provide the greatest efficiency. This is because the installation of sensor systems is expensive. Zhang proposed an optimal multi-type sensor placement method to reconstruct the structural responses. The method considered the measurement of structural response and was limited to a few locations [

4]. In other words, sensors are arranged only on some key components, and then the stress of the entire structure is identified by the analysis method.

Based on the limited number of stress measurements, the prediction methods for stress distribution were researched and developed. A sensor-free stress estimation model was proposed to estimate the stress distribution of steel beam structures. The model considered the uncertain loads to which the building structure was exposed [

5]. A Gaussian particle filtering algorithm was used to predict the dynamic extreme stress based on the monitoring data [

6]. A Kalman filter method with a dynamic model of the structure was used to estimate the power spectral density of stresses at unmeasured locations based on the measurements at the limited locations [

7]. A model-based state estimator was proposed to predict the stress measurements at arbitrary locations in the structure based on acceleration measurements [

8,

9,

10]. Pattern identification was used to estimate the structural stresses based on stress measurements and displacement measurements [

11]. Xu validated the effectiveness and practicability of the proposed multi-type sensor placement and response reconstruction method according to the good agreement of the reconstructed multi-type responses between the numerical studies and the experimental investigations [

12]. Lu proposed an improved pattern recognition method, which selected more than one best pattern and used weighting parameters to obtain the synthesized estimated stress values [

11]. Zhang presented a restoring method for spatial structural stress monitoring. That method can avoid the missing data using correlation among the measuring points [

13]. It is obvious that stress monitoring is important for the structural safety assessment, and there is much research regarding the structural safety assessment using stress measurements and the prediction method for the stress values at the sensor-free placements. However, such methods just considered how to realize the stress prediction, where the prediction processes were all concentrated; in other words, such methods may be unusable if the measurements were partially missed or the central data-processing centre breaks down.

Some research has been based on function dispersion. Smarsly proposed an analytical redundancy approach to decentralized sensor fault detection by using artificial neural networks [

14]. Sim presented a decentralized data aggregation approach for system identification based on the random decrement technique, which was used for wireless sensor networks and demonstrated its effectiveness by the accuracy of estimated modal properties and wireless data communication [

15]. Lynch developed intelligent data-processing nodes by setting a signal-processing algorithm into sensors. This approach has been applied in the Alamosa Canyon Bridge in New Mexico [

16]. Leng divided petroleum pipe software into two subsystems: a data management system and a data analysis system. The two systems work concurrently to complete a second pre-processing, data storage, and data analysis [

17]. Gao [

18] established a powerful structural health monitoring hardware platform and identified stress by a kind of distributed data acquisition system called ‘small concentrated’. Inaudi [

19] introduced the monitoring of data standard management considering the difficulty in storing mass data. The research developed the decentralized functions in condensing mass measurements, data acquisition, and data pre-processing, where the effectiveness has already been proved partially. Furthermore, the structural health monitoring methods should be developed based on such decentralized functions to reduce the potential risks caused by sensor failure and to improve the operation efficiency caused by function concentration.

A stress prediction method in distributed processes is proposed. It is based on the limited stress measurements and pattern recognition method. The aim of the proposed method is to develop a stress prediction method that can be adaptive to the distributed sensor networks accompanying the decentralized functions. Here, we first propose a distributed algorithm based on pattern recognition, where the number of sensors and patterns is considered. Furthermore, simulation of the shell-like structure is performed to verify the effectiveness of the proposed method. In addition, measurements of a real-world structure are used to prove the proposed method by considering noise influences.

2. Distributed Algorithm Based on Pattern Recognition

Compared with only one pattern library using all the measurements, there are multiple pattern libraries that recognize stress in monitoring positions to achieve distributed operation. If one pattern library is simply being divided into some subparts, it can be helpful for improving the calculation efficiency, but not for precise recognition.

In this paper, the process of a distributed computing method based on pattern recognition is to establish multiple pattern libraries to recognize the same single pattern, and there are still two improved aspects: (1) information optimised from different pattern libraries, which is the optimization of the number of sensors, and (2) an optimal amount of fusion patterns chosen during a distributed-computing process and final fusion computation. The steps to the method are as follows: (1) sensors are divided into m subgroups; therefore, there will be subpattern-recognizing libraries and subtesting libraries; (2) for each subpattern recognition library and subtesting library, the optimal number of sensors is chosen for the calculation and fusion algorithm patterns; and (3) optimised fusion algorithm patterns are gathered into one total pattern library. Then, the stress prediction of unknown positions based on distributed computing and the pattern recognition method can be completed.

2.1. Measurements and Response to Be Recognized

The measurements collected from sensors can be represented as

:

where

is the time series of the measurement collected from the

th sensor.

The response to be recognized can be represented as .

2.2. Distributed Subsets of Measurements

The measurements

can be divided into

subsets of measurements, which can be represented as

,

,…,

,…,

. The subset of measurements

is represented as:

where

;

is the number of measurements in the

th subset of measurements.

is the

th measurements in the

th subset of measurements.

2.3. Pattern Recognition Based on a Subset of Measurements

2.3.1. Sequenced Responses Based on the Correlation

The finite-element model of the structure is built first. It is used to calculate the structural responses at the locations of sensors and the location to be recognized. The calculated structural responses at the location of sensors and location to be recognized are represented as

and

, respectively, which has

time steps and can be used to give the correlations between the responses at the location of sensors and the response at the location to be recognized. The correlation between the response at the location of sensors and the response at the location to be recognized is represented as

:

The responses included in the

th subsets

can be sequenced by the value of correlation

. The sequenced measurements

can be represented as

:

where

.

2.3.2. Error Analysis on Different Numbers of Sensors and Patterns

The input of the traditional pattern recognition method is , and the output of the traditional pattern recognition method is .

If the number of sensors is considered, the input of the advanced pattern recognition method can be

,

,…,

,…,

, respectively:

where

;

represents the number of sensors in

th subset.

If the number of recognized patterns is considered, the output of the advanced pattern recognition method can be

,

,…,

,…,

, respectively:

where

;

represents the number of well-matched patterns, and

represents the

th well-matched pattern.

The approach degree between well-matched patterns and pattern to be recognized is represented by vector

:

If the number of patterns is considered, the output of the advanced pattern recognition method can be

,

,…,

,…,

, respectively:

The recognition error with the different number of sensors and the different number of patterns can be represented as:

where

is the determined number of sensors, and

is the determined number of patterns.

The input of such a best pattern library for the

th subset of measurements is:

The output of such a best pattern library for the

th subset of measurements is:

The predicted value for the pattern to be recognized is:

The predicted values using subsets of measurements can be given as , ,…, ,…, , respectively.

2.4. Pattern Recognition Based on Gross Sets of Measurements

The gross set of measurements based on the input of each best pattern library for

subsets of measurements can be represented as:

The predicted value by considering the best number of sensors and patterns is:

where

and

are the best number of sensors and patterns when the gross set of measurements is used.

3. The Simulation on the Stress Recognition of Shell-Like Structures

3.1. The Main Parameters of Shell-Like Structures

The finite-element model is built based on the Schwedler shell-like structure [

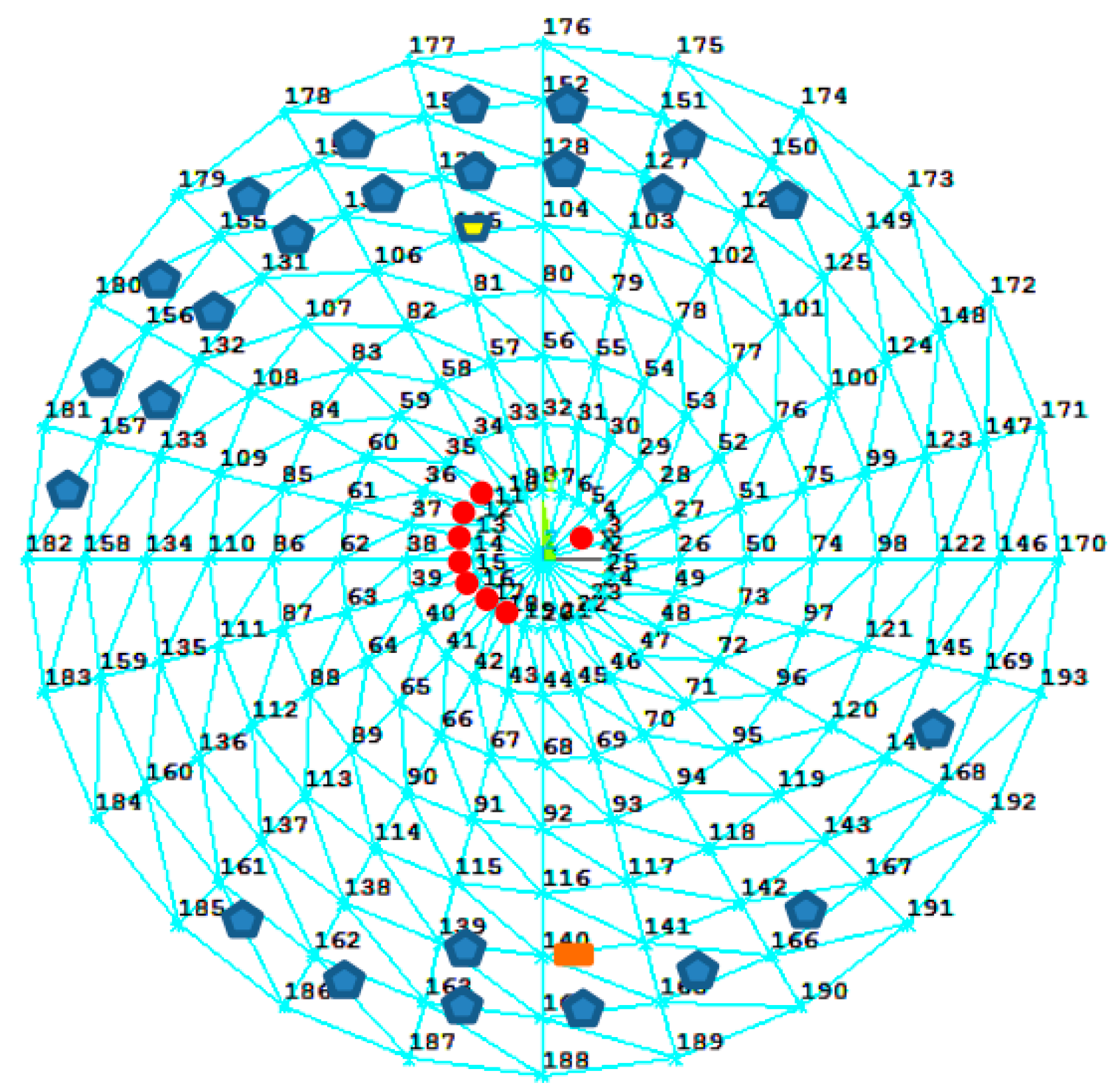

20], which is shown in

Figure 1. The shell-like structure is 50 m long, 50 m wide, and 7.5 m high. The uniform mass is 200 Kg/m

2. The material of the steel members is Q235, the elastic modulus is

, the Poisson ratio is 0.3, and the damping ratio is 0.02 in Rayleigh damping. The section of the member in the radial direction is

133

4, while the section of the members in the circle direction and diagonal direction is

127

3. The Poisson ratio

is 0.3. The type of support is a fixed-hinge support.

In this finite-element method calculation, the Karman spectrum is selected to simulate the along-wind fluctuating wind spectrum, while the calculation equation proposed by Panofsky is selected to simulate the vertical-wind fluctuating wind spectrum. The formulas are shown below:

where

is the fluctuated wind power spectrum,

is the average wind speed at the height of z,

is the fluctuated angular frequency,

is the roughness coefficient on the ground,

,

is the roughness length, and

is the Kaman constant.

3.2. Layout of Sensors

A variable coefficient (VC), a kind of parameter used for measuring and reflecting discrete levels of a set of data, is used to determine the placement of sensors, which is represented as:

where

is the VC of the items of components,

is the standard deviation of the items of components, and

is the average value of the items of components.

A time-domain dynamic analysis of this finite-element method is carried out by setting a fluctuating wind load whose average speed reaches 15 m/s. The total loading time is 10 min and 6000 substeps. For each step, the combined stresses of axial stress and bending stress in Y+ at 1/4 length of the members are extracted. According to the values of VC with descending order, the first 26 members are chosen to locate the sensors and extract the stresses; the number of the members are 153, 152, 154, 168, 151, 155, 150, 129, 128, 156, 130, 127, 149, 164, 163, 131, 165, 162, 126, 161, 166, 132, 105, 140, 157, and 139. According to the value of VC with descending order, the first eight points are chosen to extract the displacements, and the number of the members are 2, 12, 13, 14, 15, 16, 17, and 18.

Considering the values of VC, stress changing, and average stress, the members with No. 105 and No. 140 are selected as the stress of members to be identified, which are denoted as Position A and Position B, respectively. Those positions, the members for extracting stresses, and the points for extracting displacements are shown in

Figure 2.

3.3. Pattern Sets and Subsets of Measurement

A fluctuated wind load whose average value increases from 5 m/s to 50 m/s (5 m/s for each step) is simulated for the finite-element method analysis. In addition, the stresses and displacements are extracted from the finite-element method every 0.1 s, and the total analysis time is 10 min; that is, the stresses and displacements extracted from the finite-element method analysis are 6000 time steps. Furthermore, the data are separated into the pattern library, testing library, and observed library. The stress and displacement responses from the first time step and those in every three time steps are the data in the pattern library; there are a total of 15,000 patterns. The stress and displacement responses from the second time step and those in every 120 time steps are the data in the testing library; there are a total of 500 patterns. The stress and displacement responses from the third time step and those in every 600 time steps are the data in the observed library, and there are 100 patterns. The subsets of measurement are given in

Table 1.

3.4. Determination of the Optimal Number of Sensors and Patterns

There are four subsets of measurement, while the determination of the optimal number of sensors and patterns is illustrated using Subset 1.

(1) The correlation between the responses of the points in No. 1 subset of measurement and the stresses of Position A can be calculated by Equation (4), sorted and shown in

Table 2.

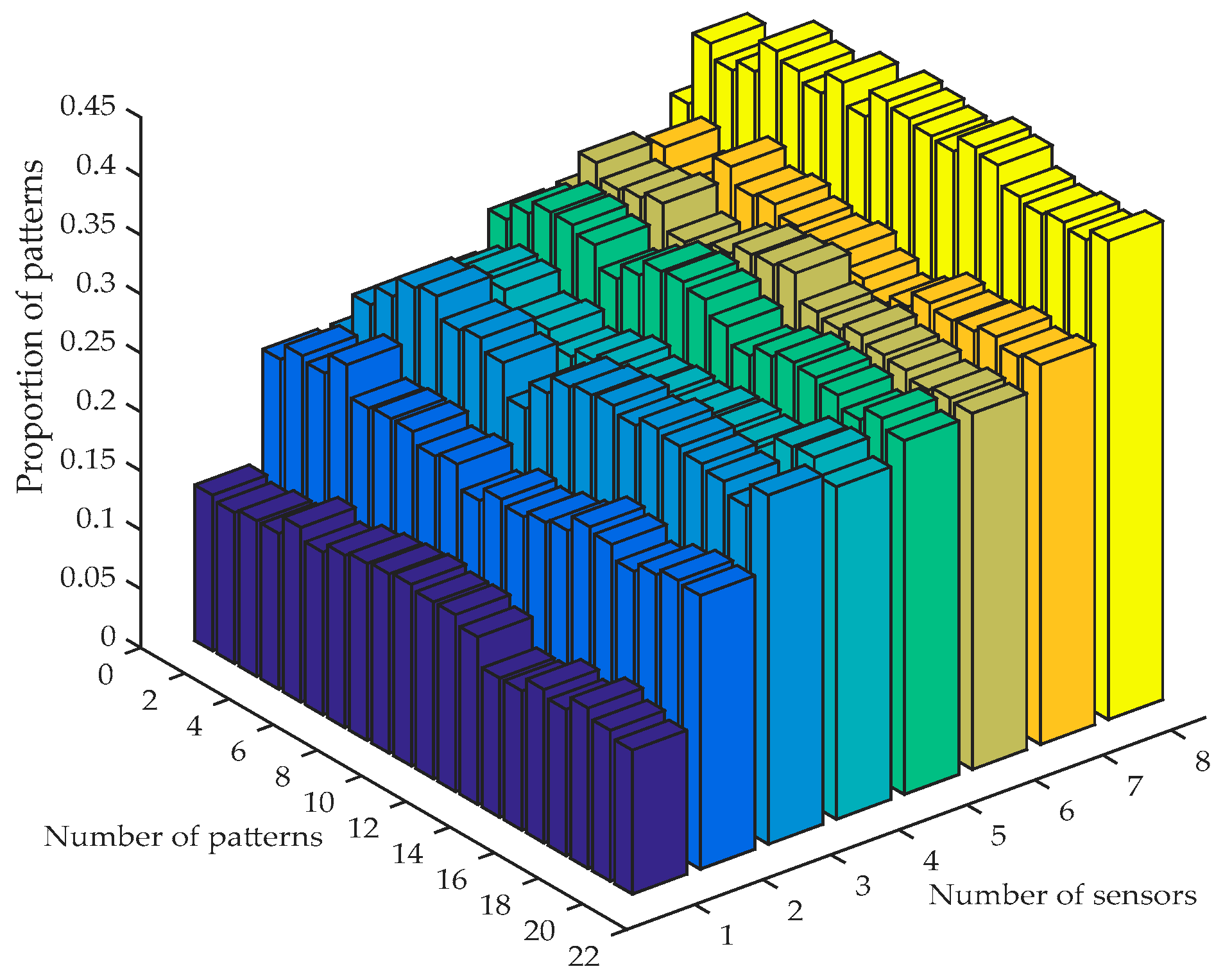

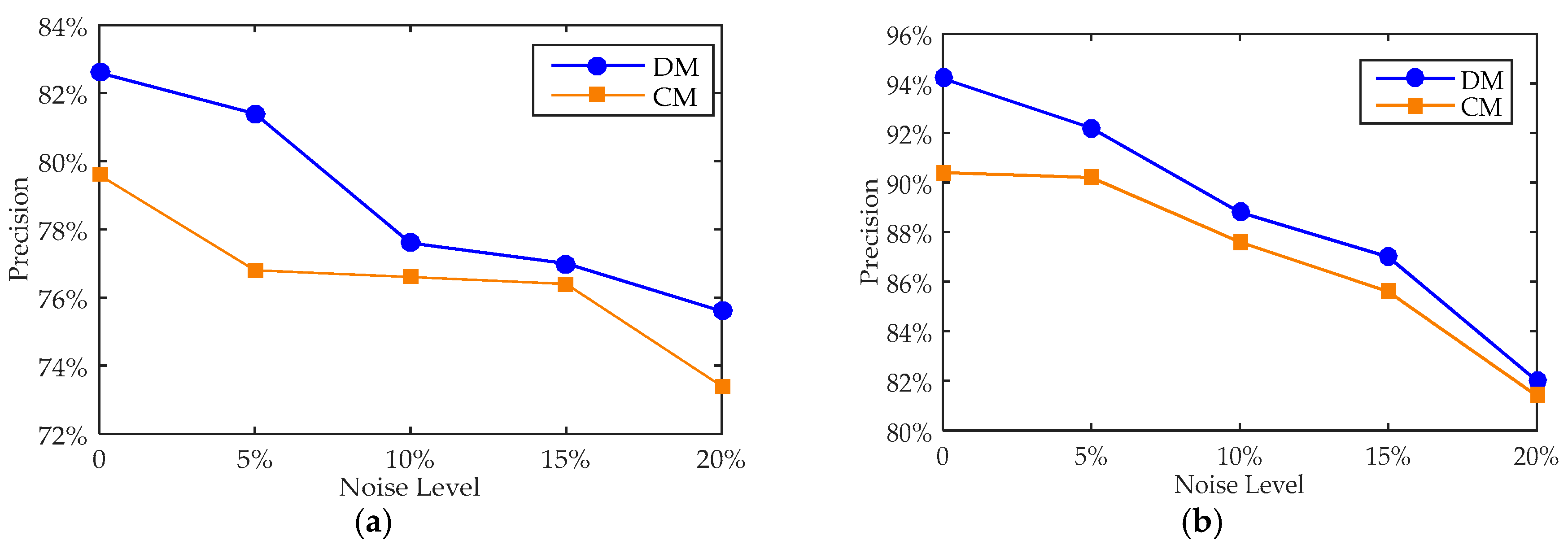

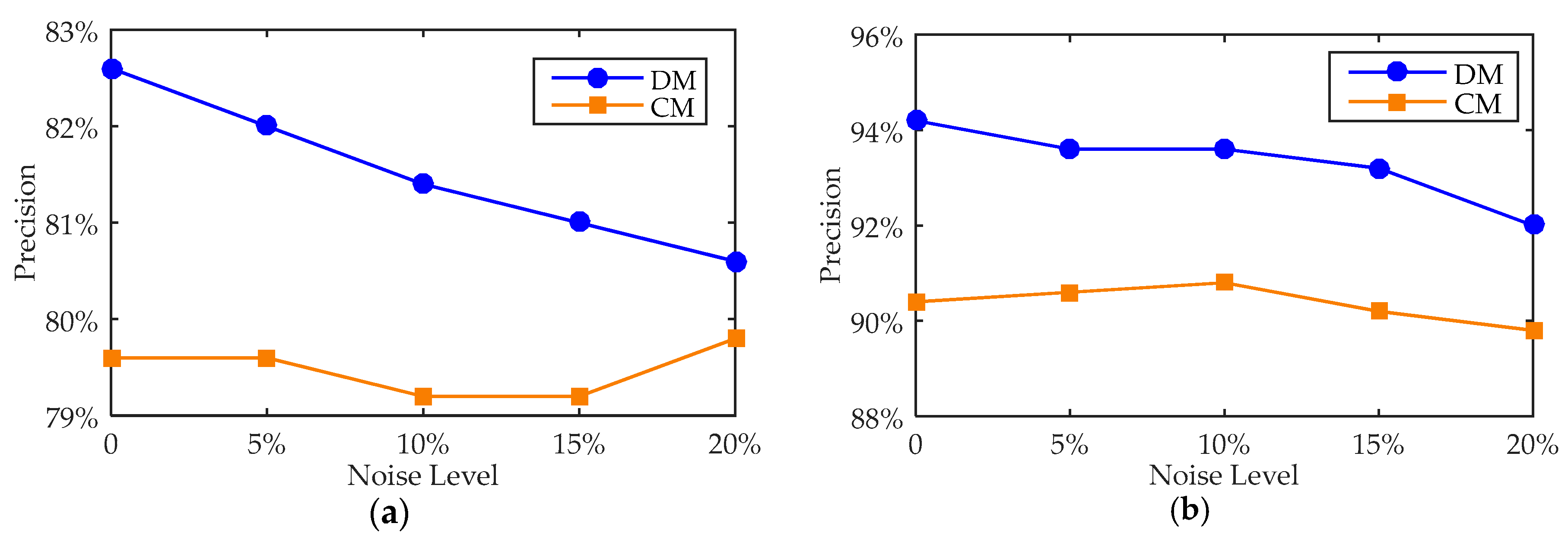

(2) The scenarios with different numbers of sensors and patterns are calculated, the pattern with the stress error of Position A less than 15% is signed, and the property of such a pattern is shown in

Figure 3.

(3) There are five optimal combinations including the number of sensors and patterns through

Figure 3, which are listed in

Table 3. By comparing the five combinations in different error ranges, the fourth scenario is chosen as the optimal parameter for identify the stress of Position A. For all the four subsets of measurement, the optimal parameter for identifying the stress of Position A and Position B can be also obtained and are shown in

Table 4 and

Table 5. According to the determination process of the number of sensors, recognition parameters in two positions with the whole pattern libraries can be determined, and they are listed in

Table 6.

represents the locations of the displacement sensors,

represents the locations of the displacement sensors,  represents the locations of the strain sensors,

represents the locations of the strain sensors,  represents Position A, and

represents Position A, and  represents Position B.

represents Position B.

represents the locations of the displacement sensors,

represents the locations of the displacement sensors,  represents the locations of the strain sensors,

represents the locations of the strain sensors,  represents Position A, and

represents Position A, and  represents Position B.

represents Position B.