A Novel Single-Axis MEMS Tilt Sensor with a High Sensitivity in the Measurement Range from 0∘ to 360∘ †

Abstract

:1. Introduction

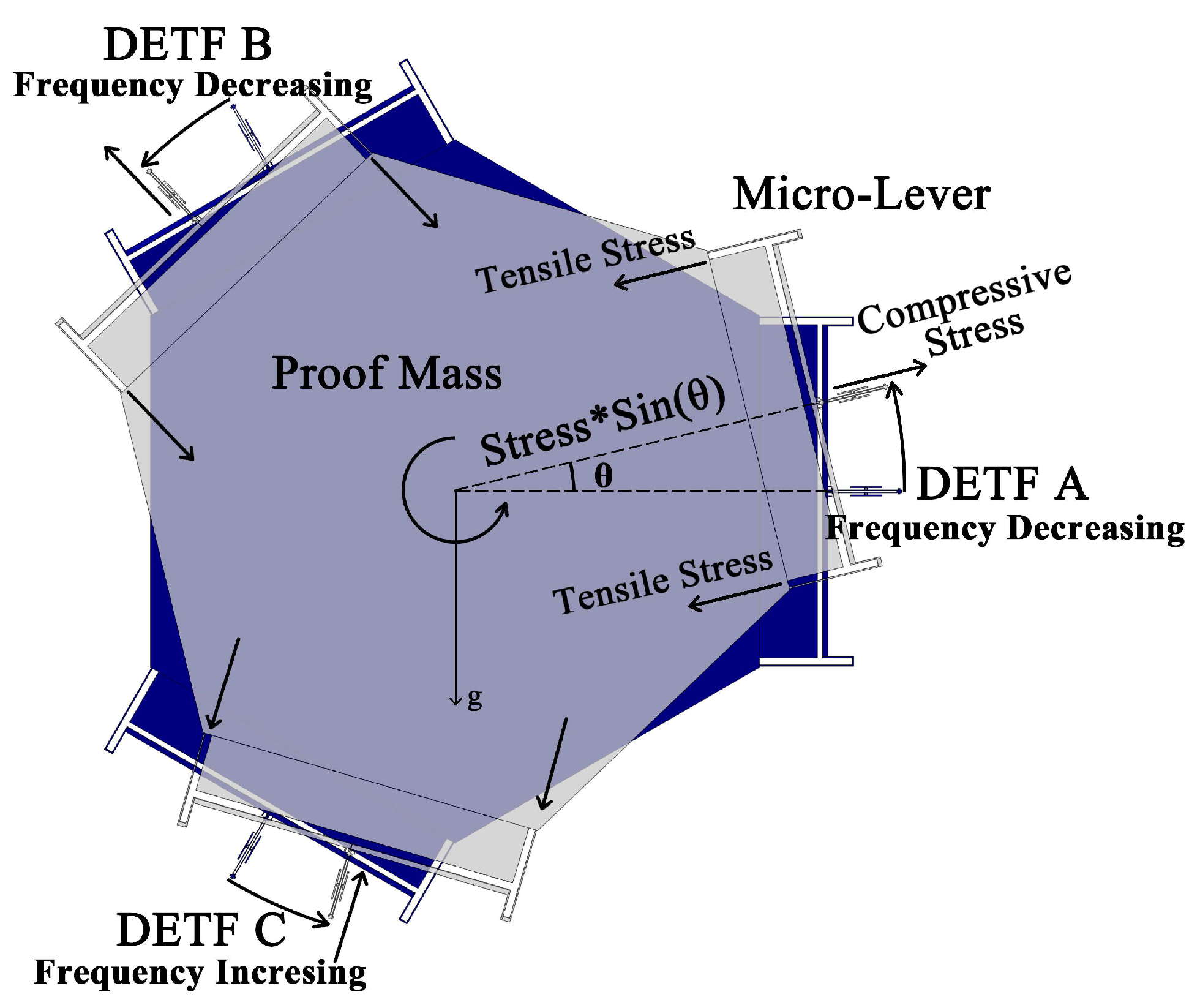

2. Sensing Principle and Structure Design

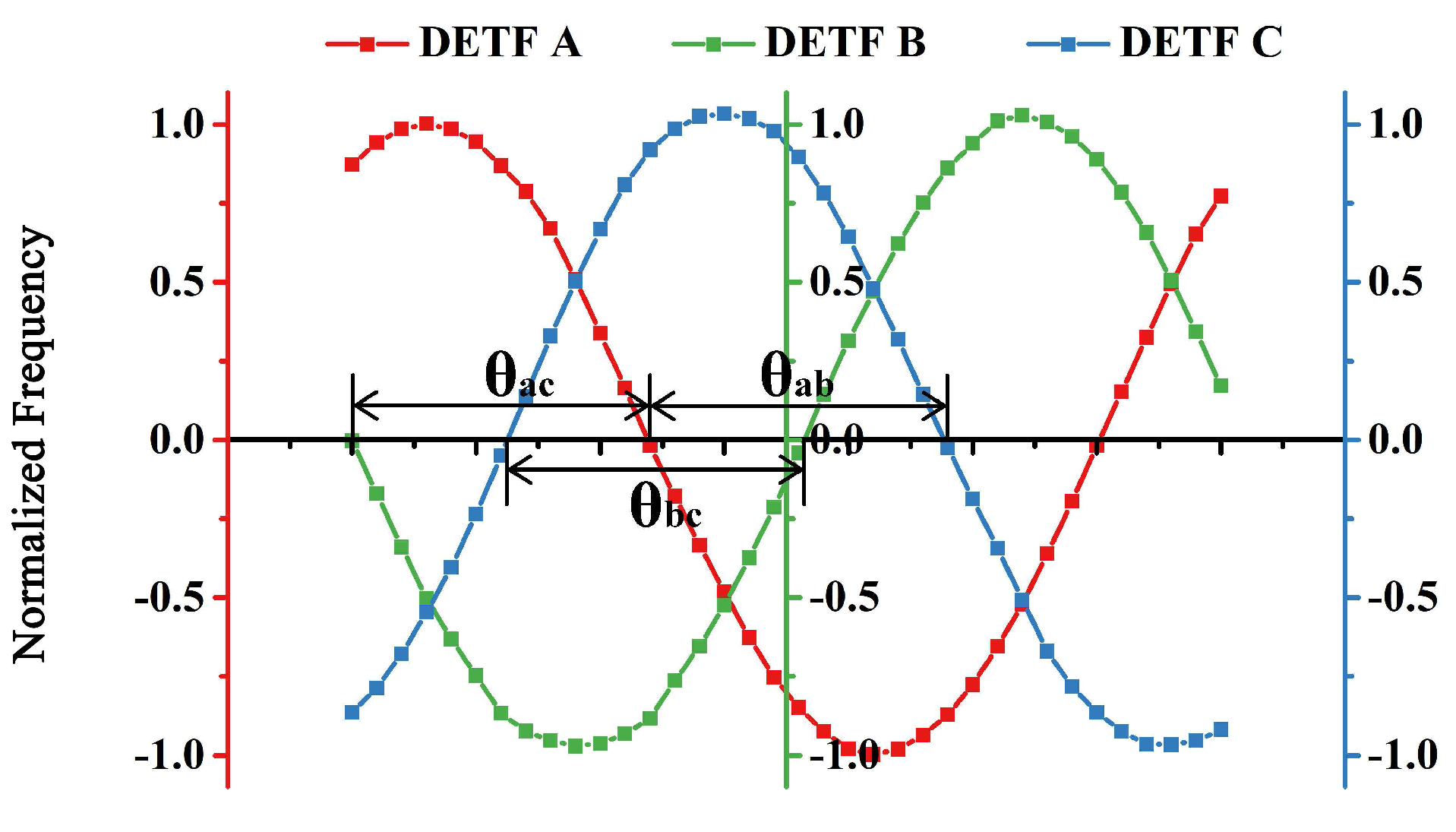

2.1. Sensing Principle

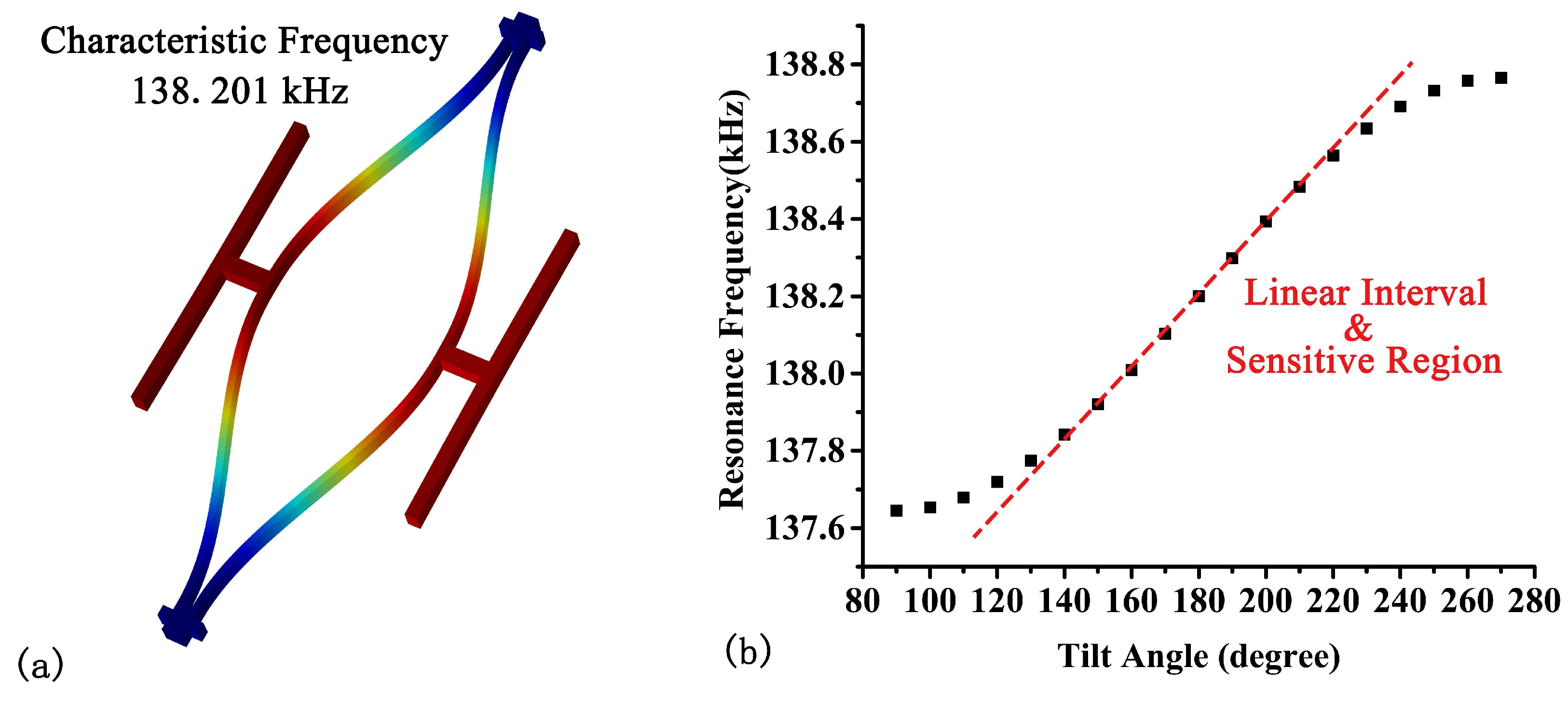

2.2. Sensor Design

2.3. Temperature Drift

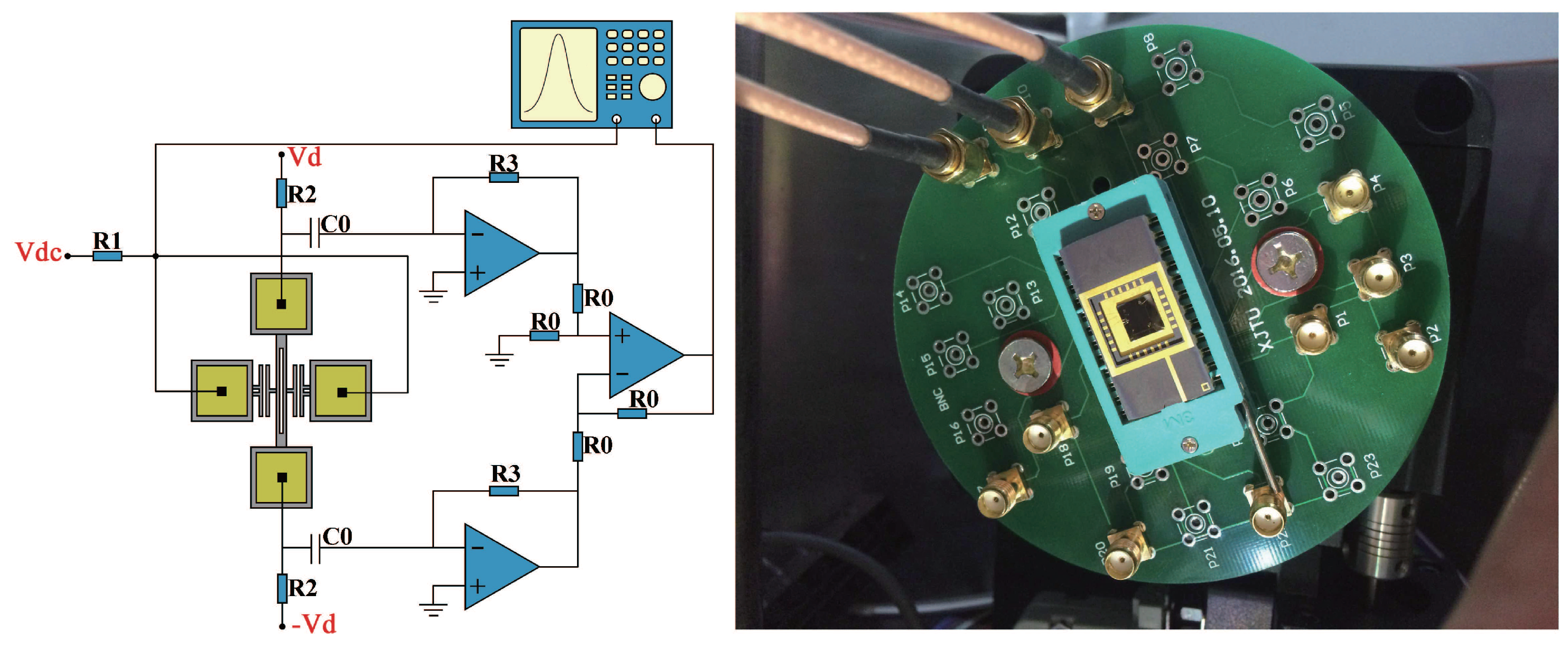

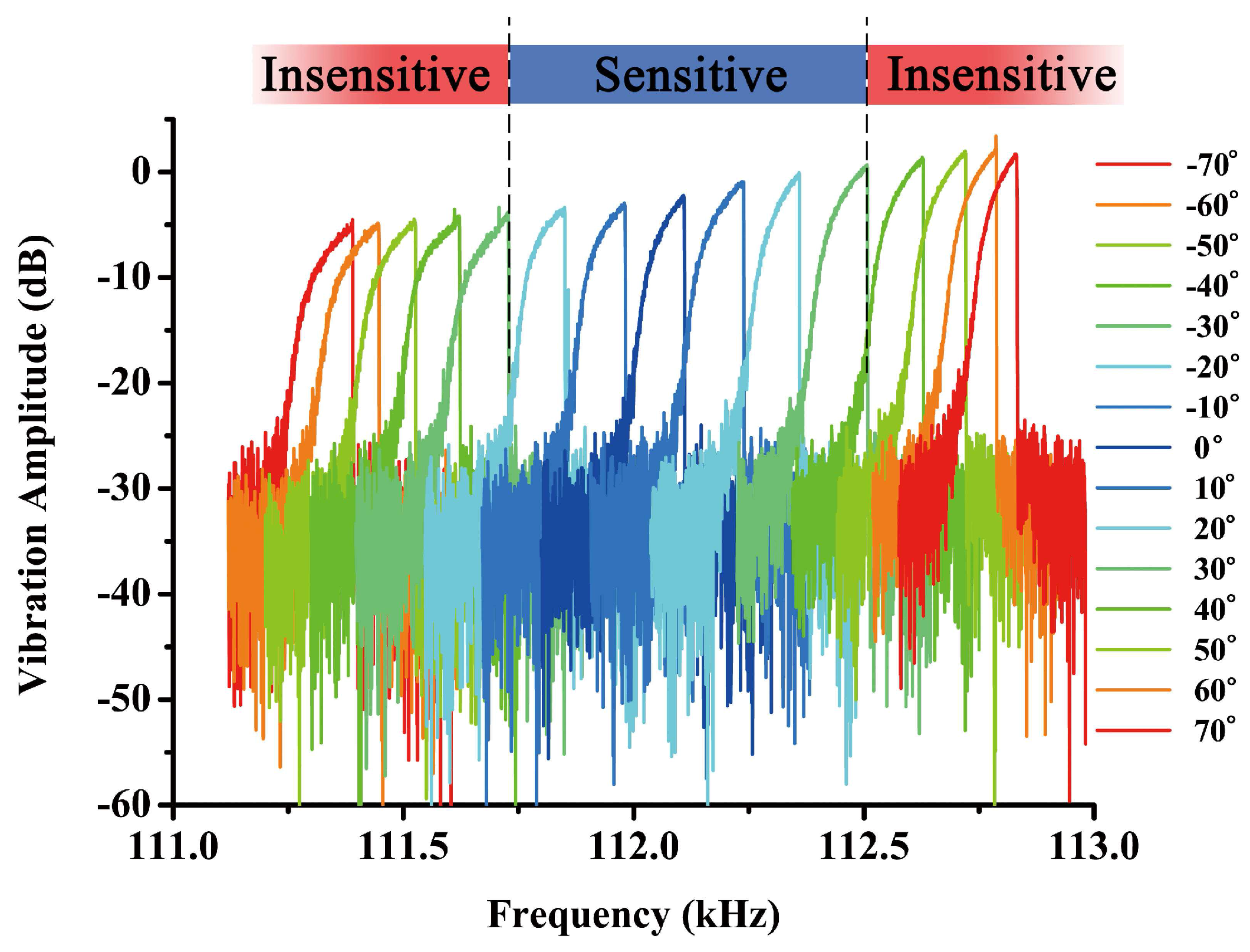

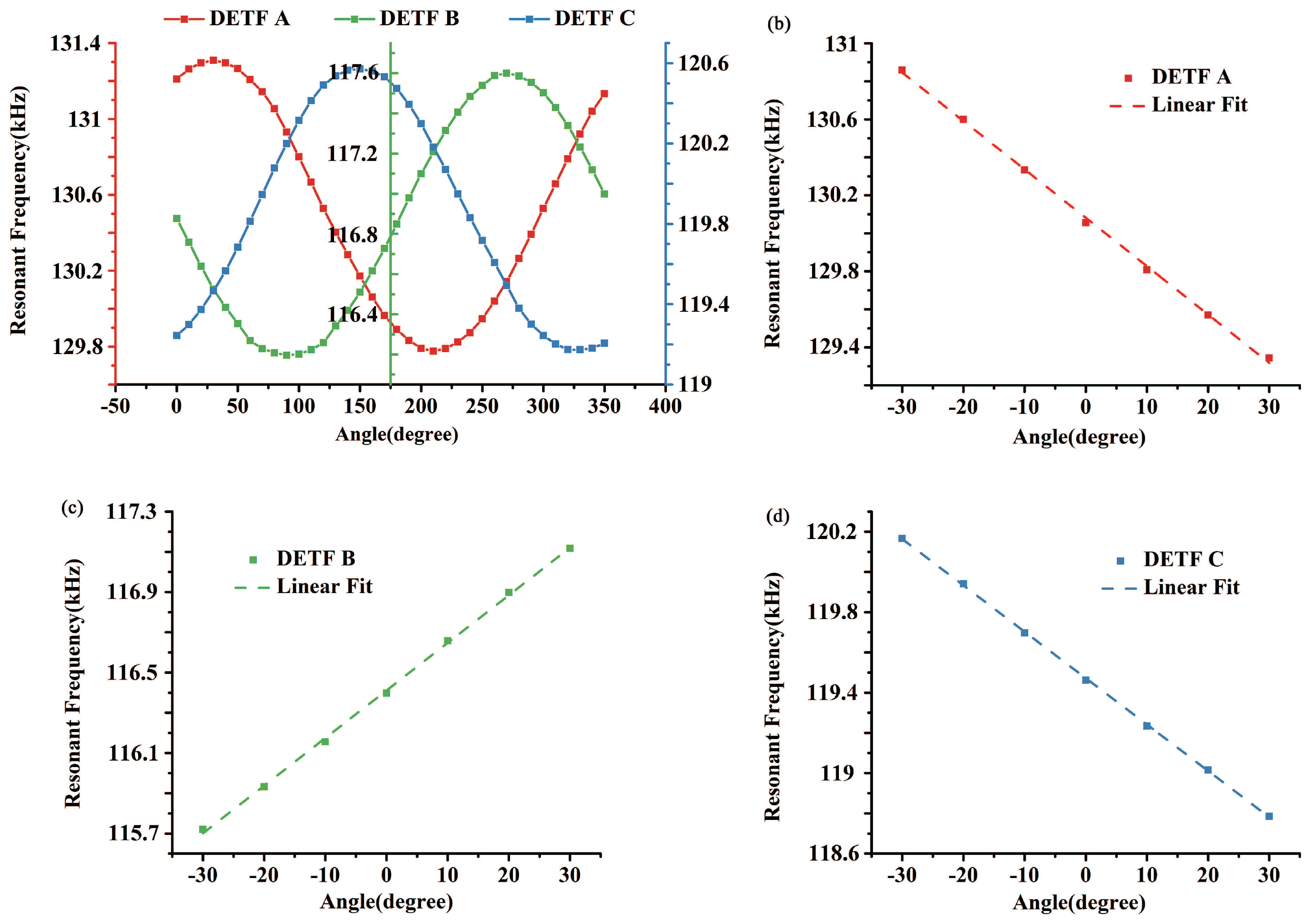

3. Experimental Results of Open-Loop Test

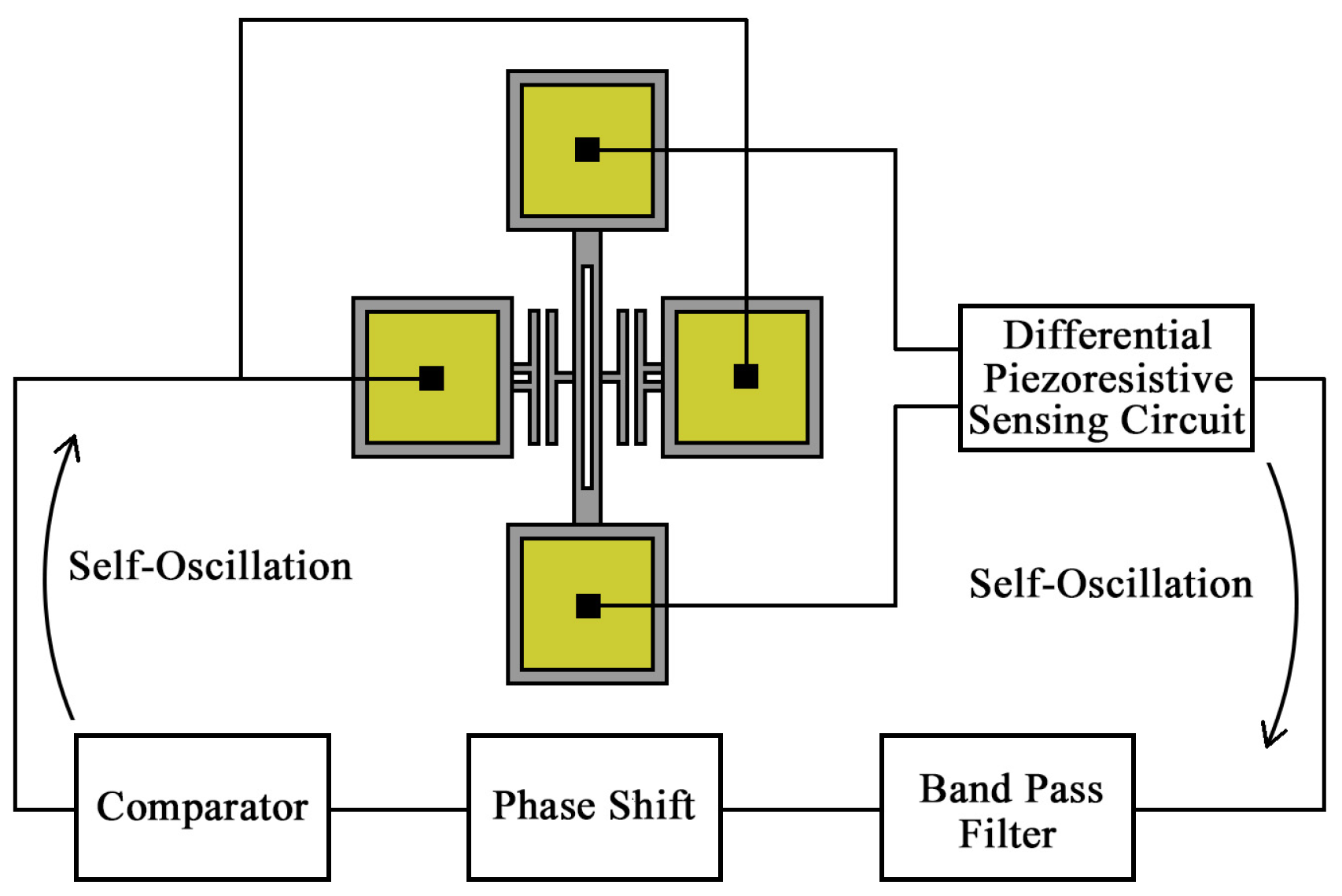

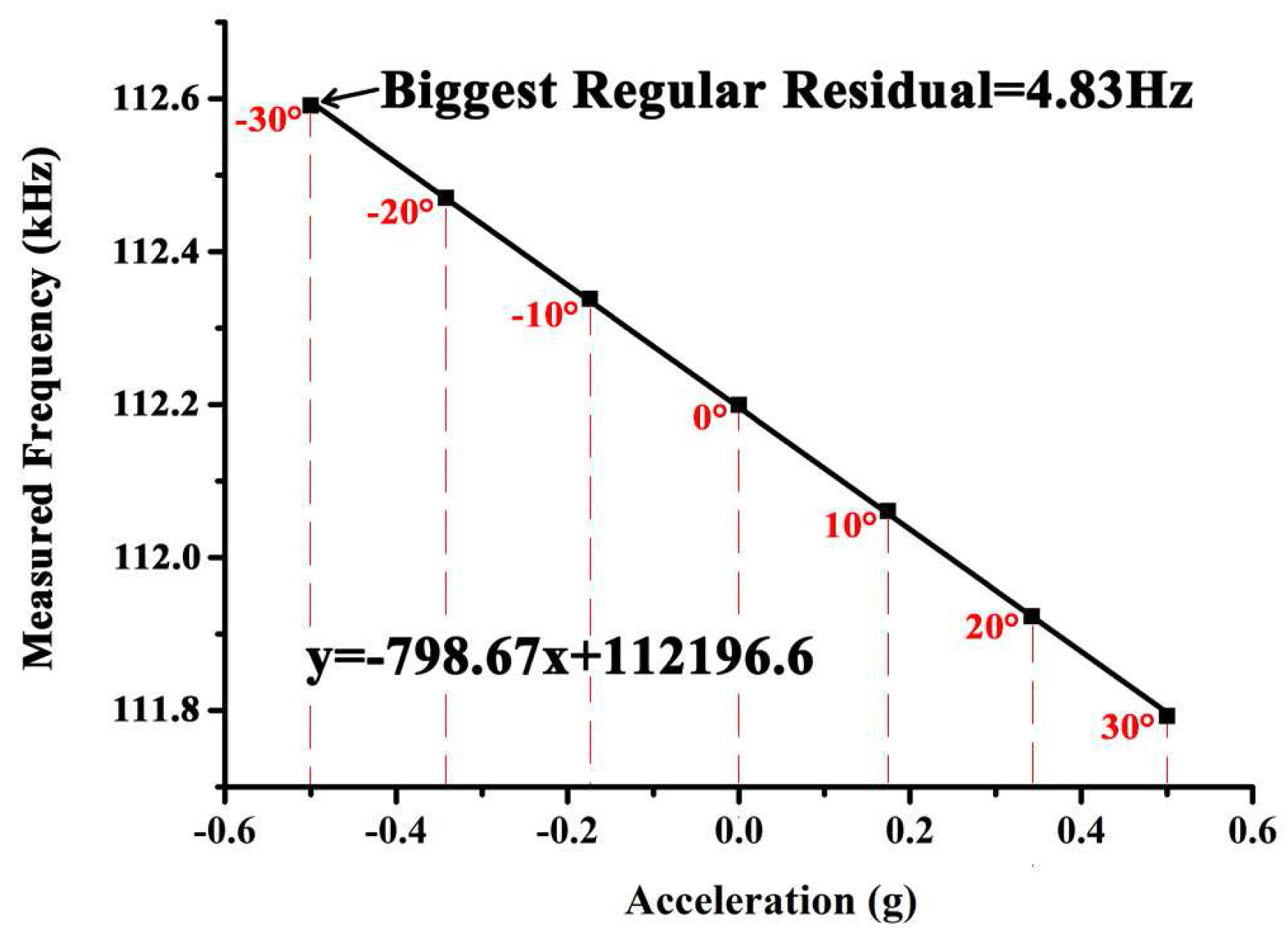

4. Experimental Results of Closed-Loop Test

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bajic, J.; Stupar, D.; Manojlovic, L.; Slankamenac, M.; Zivanov, M. A simple, low-cost, high-sensitivity fiber-optic tilt sensor. Sens. Actuators A 2012, 185, 33–38. [Google Scholar]

- Weng, Y.; Zhang, H.; Ren, J.; Wang, S.; Wei, X. Dynamic Performance of A Novel Tilting Angle Measurement System Using Three Accelerometers. In Proceedings of the 2016 IEEE Sensors, Orlando, FL, USA, 30 October–2 November 2016; pp. 940–942. [Google Scholar]

- Weng, Y.; Wang, S.; Zhang, H.; Gu, H.; Wei, X. A High Resolution Tilt Measurement System Based on Multi-accelerometers. Measurement 2017, 109, 215–222. [Google Scholar] [CrossRef]

- Chang, C.-T.; Tsai, M.-H.; Liu, Y.-C.; Sun, C.-M.; Fang, W. Design and implementation of an extremely large proof-mass COMS-MEMS capacitive tilt sensor for sensitivity and resolution improvement. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference (TRANSDUCERS), Beijing, China, 5–9 June 2011; pp. 1104–1107. [Google Scholar]

- Liu, H.; Pike, W.T. A micromachined angular-acceleration sensor for geophysical applications. Appl. Phys. Lett. 2016, 109, 173506. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, R. Micromachined Fluid Inertial Sensors. Sensors 2017, 17, 367. [Google Scholar]

- Hu, P.; Guo, J.; Tan, J. An Annular Planar-capacitive Tilt Sensor with a 360° Measurement Range. IEEE Trans. Ind. Electron. 2016, 63, 2469–2476. [Google Scholar]

- Zhang, W.; Zhu, H.; Lee, J.E.Y. Piezoresistive transduction in a double-ended tuning fork SOI MEMS resonator for enhanced linear electrical performance. IEEE Trans. Electron Devices 2015, 62, 1596–1602. [Google Scholar] [CrossRef]

- Zou, X.; Thiruvenkatanathan, P.; Seshia, A.A. A high-resolution micro-electro-mechanical resonant tilt sensor. Sens. Actuators A Phys. 2014, 220, 168–177. [Google Scholar] [CrossRef]

- Alves, F.S.; Dias, R.A.; Cabral, J.M.; Gaspar, J.; Rocha, L.A. High-Resolution MEMS Inclinometer Based on Pull-In Voltage. J. Microelectromech. Syst. 2012, 24, 931–939. [Google Scholar] [CrossRef]

- Sato, K.; Ono, A.; Tomikawa, Y. Experimental study of gyro sensor using double-ended tuning fork quartz resonator. In Proceedings of the 2004 IEEE International on Frequency Control Symposium and Exposition, Montreal, QC, Canada, 23–27 August 2004; pp. 575–578. [Google Scholar]

- Abdolvand, R.; Bahreyni, B.; Lee, J.E.Y.; Nabki, F. Micromachined resonators: A review. Micromachines 2016, 7, 160. [Google Scholar] [CrossRef]

- Li, C.; Zhao, Y.; Li, B.; Cheng, R.; Sun, D.; Han, C.; Zhao, Y. A micro-machined differential resonance accelerometer based on silicon on quartz method. Sens. Actuators A Phys. 2014, 253, 1–9. [Google Scholar] [CrossRef]

- Ding, H.; Zhao, J.; Ju, B.; Xie, J. A highly-sensitivity biaxial resonant accelerometer with two-stage microleverage mechanisms. J. Micromech. Microeng. 2016, 26, 015011. [Google Scholar] [CrossRef]

- Cheng, L.; Yue, W.; Shangchun, F.; Baoxi, K.; Chao, W. Design of a new differential silicon resonant accelerometer with dual proofmasses using two-stage microlever. In Proceedings of the 2015 IEEE on SENSORS, Busan, Korea, 1–4 November 2015. [Google Scholar]

- Zhao, C.; Wood, G.S.; Xie, J.; Chang, H.; Pu, S.; Kraft, M. A force sensor based on three weakly coupled resonators with ultrahigh sensitivity. Sens. Actuators A Phys. 2015, 232, 151–162. [Google Scholar] [CrossRef]

- Sawada, R.; Higurashi, E.; Ito, T.; Ishikawa, I. An accelerometer incorporating a laser microencoder for a wide measurable range. Sens. Actuators A Phys. 2007, 136, 161–167. [Google Scholar] [CrossRef]

- Łuczak, S.; Grepl, R.; Bodnicki, M. Selection of mems accelerometers for tilt measurements. J. Sens. 2017, 2017, 9796146. [Google Scholar] [CrossRef]

- Łuczak, S. Erratum to: Guidelines for tilt measurements realized by MEMS accelerometers. Int. J. Precis. Eng. Manuf. 2014, 15, 2011–2019. [Google Scholar] [CrossRef]

- Li, E.; Zhong, J.; Chang, H. Tilt sensor based on a dual-axis microaccelerometer with maximum sensitivity and minimum uncertainty in the full measurement range. IET Micro Nano Lett. 2017, 12, 866–870. [Google Scholar] [CrossRef]

- Wang, S.; Ren, J.; Zhang, T.; Weng, Y.; Jiang, Z.; Wei, X. A MEMS resonant tilt sensor with high sensitivity maintained in the whole 360° measurement range. In Proceedings of the 2016 IEEE on SENSORS, Orlando, FL, USA, 30 October–3 November 2016. [Google Scholar]

- Shin, D.D.; Ahn, C.H.; Chen, Y.; Christensen, D.L.; Flader, I.B.; Kenny, T.W. Environmentally robust differential resonant accelerometer in a wafer-scale encapsulation process. In Proceedings of the 2017 IEEE 30th International Conference on MICRO Electro Mechanical Systems, Las Vegas, NV, USA, 22–26 January 2017. [Google Scholar]

- Wei, X.; Seshia, A.A. Differential piezoresistive sensing in a bulk-mode micromechanical resonator. IET Micro Nano Lett. 2013, 8, 107–110. [Google Scholar] [CrossRef]

- Antonio, D.; Zanette, D.H.; López, D. Frequency stabilization in nonlinear micromechanical oscillators. Nat. Commun. 2012, 3, 806. [Google Scholar] [CrossRef] [PubMed]

- El-Sheimy, N.; Hou, H.; Niu, X. Analysis and modeling of inertial sensors using Allan variance. IEEE Trans. Instrum. Meas. 2008, 57, 140–149. [Google Scholar] [CrossRef]

- Chui, C.; Chen, G. Kalman Filtering With Real-Time Applications, 4th ed.; Springer: Berlin, Germany, 2009. [Google Scholar]

- Li, B.; Zhang, H.; Zhong, J.; Chang, H. A mode localization based resonant MEMS tilt sensor with a linear measurement range of 360°. In Proceedings of the 2016 IEEE 29th International Conference on MICRO Electro Mechanical Systems, Shanghai, China, 24–28 January 2016; pp. 938–941. [Google Scholar]

| Resonant beam length | 300 m |

| Resonant beam width | 3 m |

| Device thickness | 10 m |

| Die area | 5.5 mm × 5.5 mm |

| DETF A frequency | 151.815 kHz |

| DETF B frequency | 138.201 kHz |

| DETF C frequency | 138.211 kHz |

| Tilt Angle (degree) | Acceleration (g) | Frequency Data (Hz) | |||||

|---|---|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 4th | Average | Standard Deviation | ||

| −30 | −0.5 | 112,592.6 | 112,592 | 112,590.3 | 112,589.6 | 112,591.1 | 1.2 |

| −20 | −0.342 | 112,470.7 | 112,469.4 | 112,473.1 | 112,468.7 | 112,470.5 | 1.6 |

| −10 | −0.174 | 112,337.9 | 112,337.6 | 112,340.3 | 112,337 | 112,338.2 | 1.2 |

| 0 | 0 | 112,198.4 | 112,199.9 | 112,202 | 112,198.9 | 112,199.8 | 1.4 |

| 10 | 0.174 | 112,059.4 | 112.061.1 | 112,061.6 | 112,060.5 | 112,060.7 | 0.8 |

| 20 | 0.342 | 111,921.7 | 111,923.4 | 111,924.3 | 111,923.8 | 111,923.3 | 1.0 |

| 30 | 0.5 | 111,791.2 | 111,793.2 | 111,793.8 | 111,793.3 | 111,792.9 | 1.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Wei, X.; Weng, Y.; Zhao, Y.; Jiang, Z. A Novel Single-Axis MEMS Tilt Sensor with a High Sensitivity in the Measurement Range from 0∘ to 360∘. Sensors 2018, 18, 346. https://doi.org/10.3390/s18020346

Wang S, Wei X, Weng Y, Zhao Y, Jiang Z. A Novel Single-Axis MEMS Tilt Sensor with a High Sensitivity in the Measurement Range from 0∘ to 360∘. Sensors. 2018; 18(2):346. https://doi.org/10.3390/s18020346

Chicago/Turabian StyleWang, Shudong, Xueyong Wei, Yinsheng Weng, Yulong Zhao, and Zhuangde Jiang. 2018. "A Novel Single-Axis MEMS Tilt Sensor with a High Sensitivity in the Measurement Range from 0∘ to 360∘" Sensors 18, no. 2: 346. https://doi.org/10.3390/s18020346