Electromagnetic Acoustic Transducers for Robotic Nondestructive Inspection in Harsh Environments

Abstract

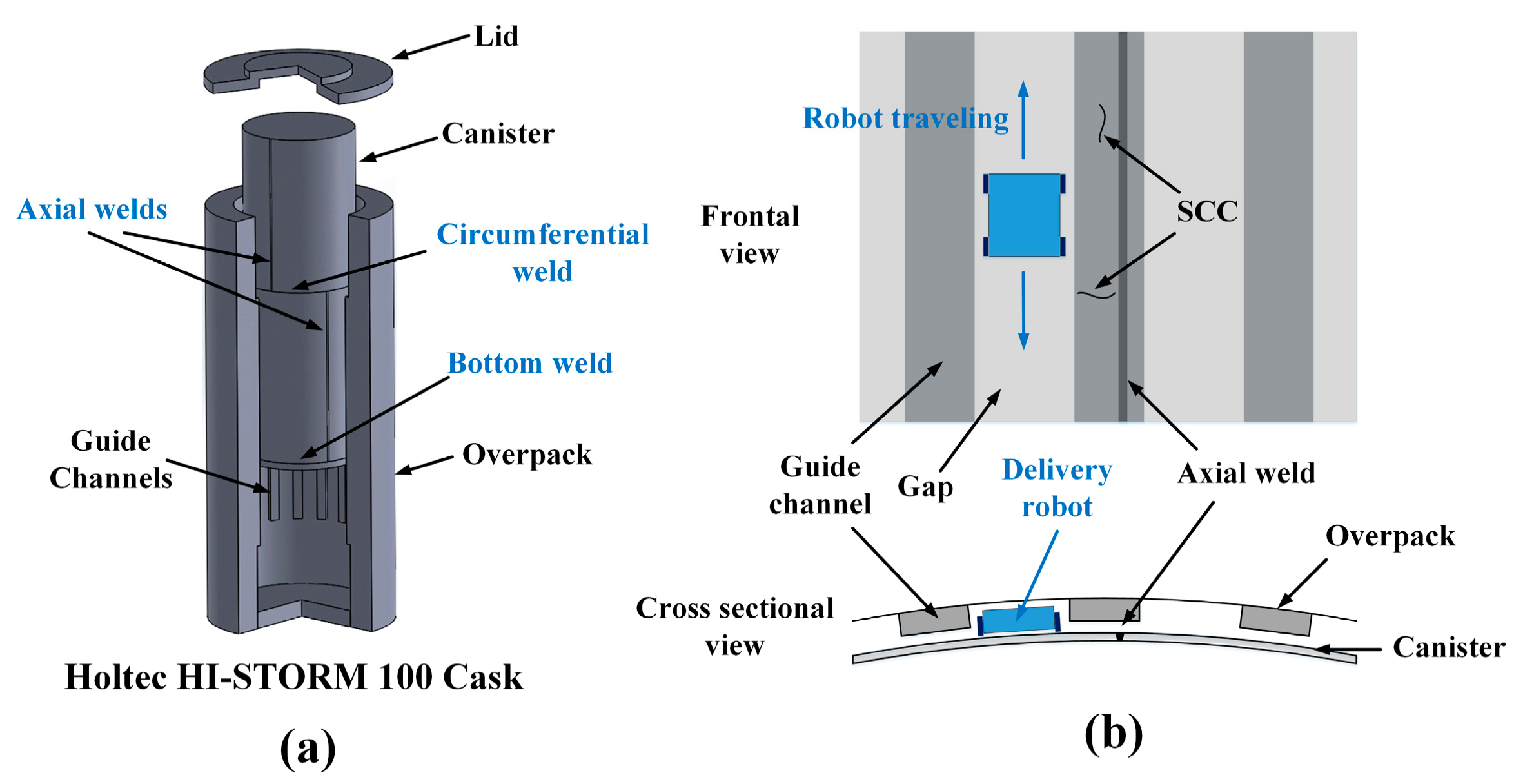

:1. Introduction

2. Development of Temperature and Radiation Tolerant EMATs

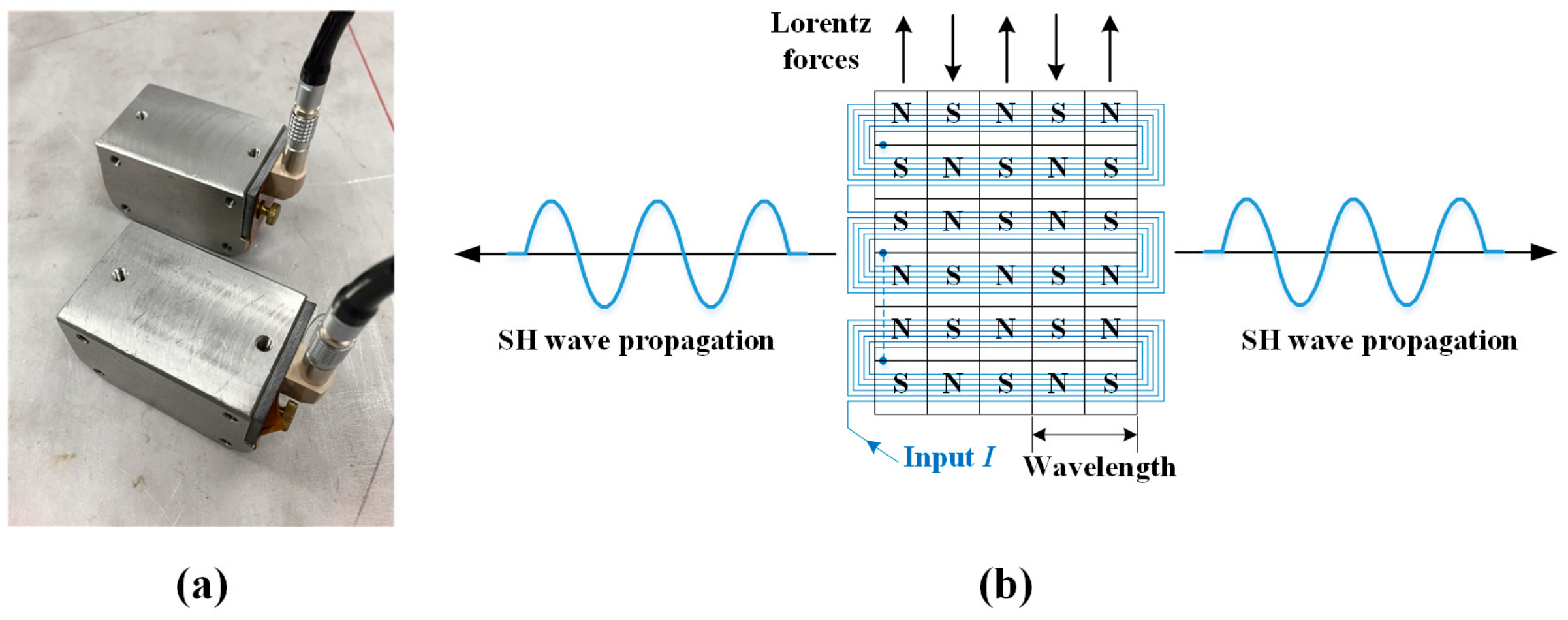

2.1. Periodic Permanent Magnet EMATs

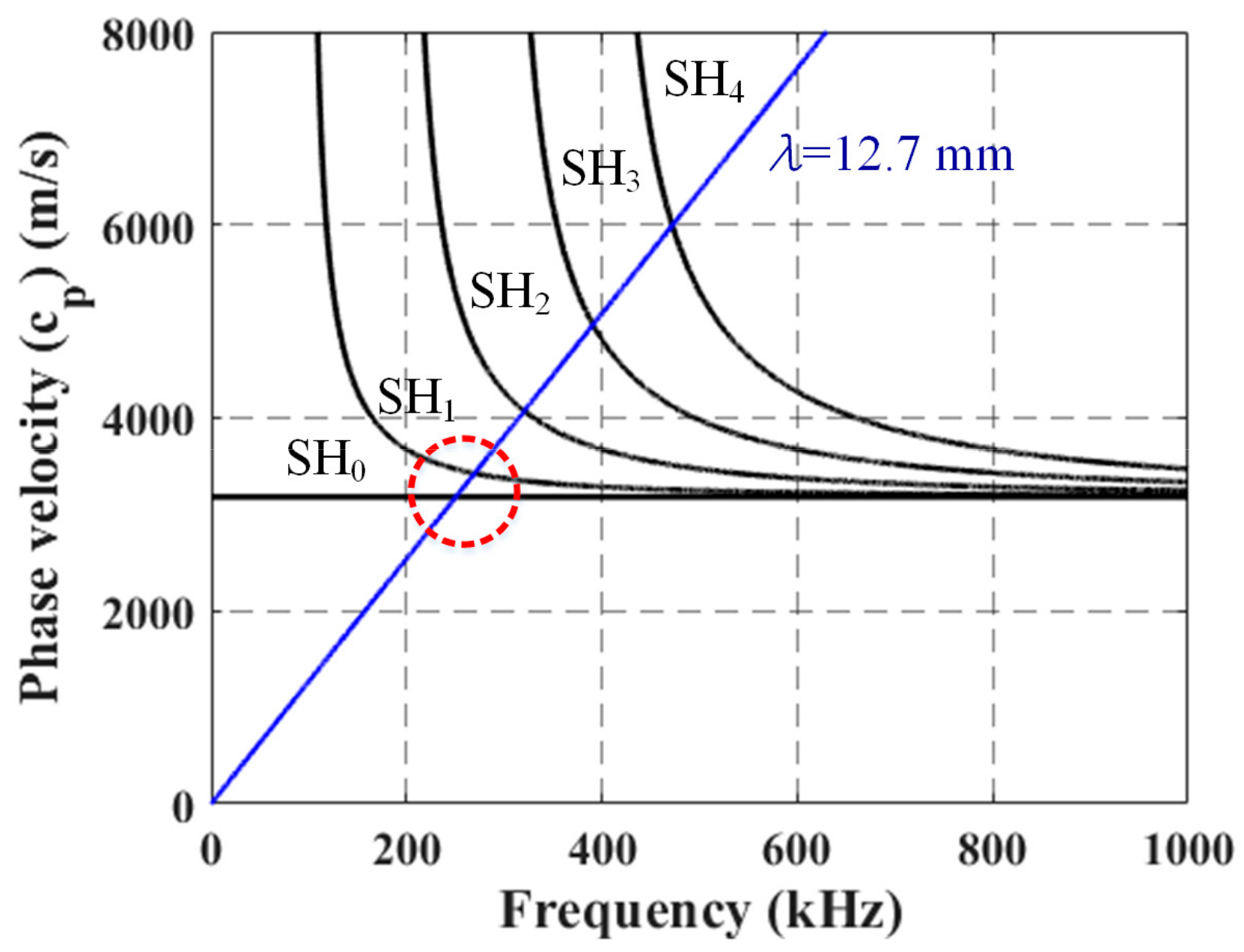

2.2. SH Mode Selection

2.3. Temperature and Radiation Tolerant EMAT Components

3. Experiments and Discussions of Results

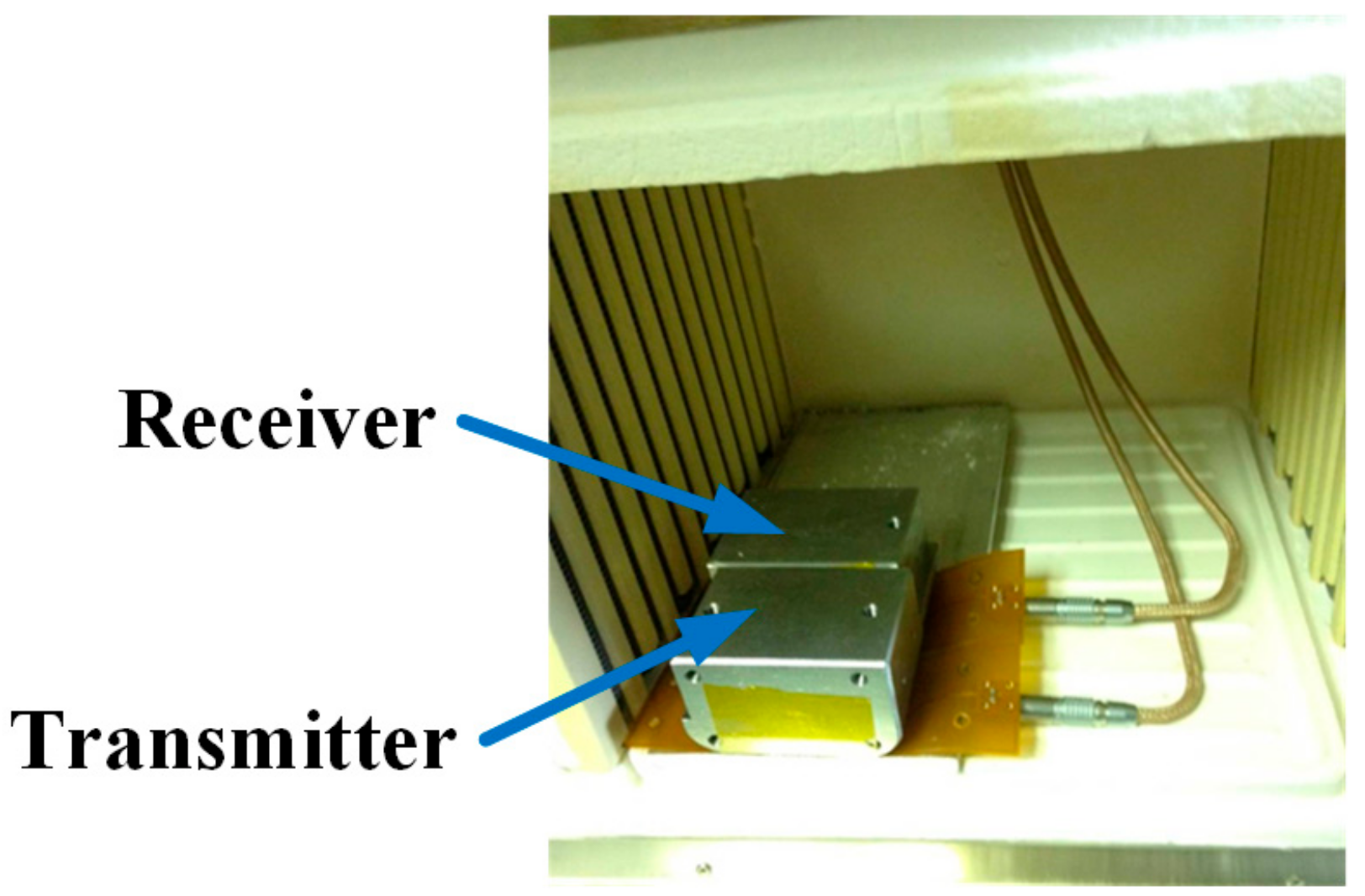

3.1. Elevated Temperature Tests

3.1.1. Electric Coil Impedance Change with Temperature

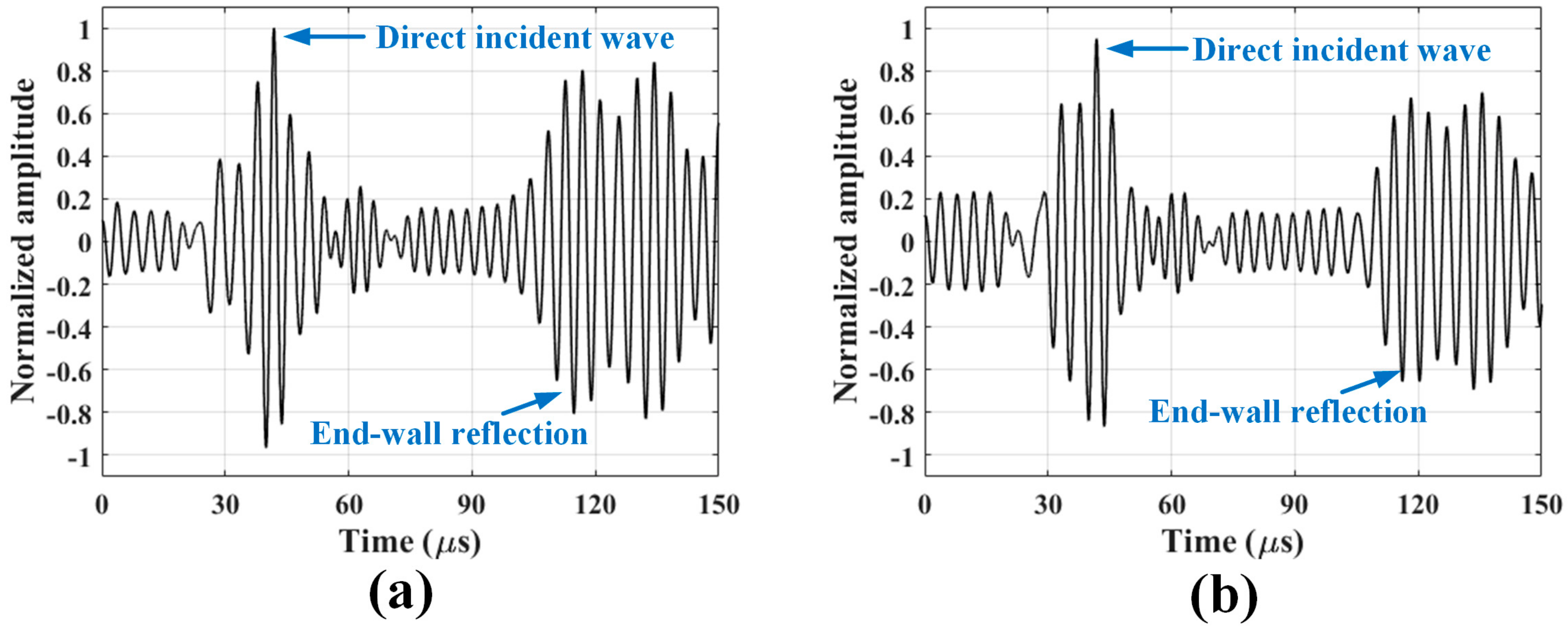

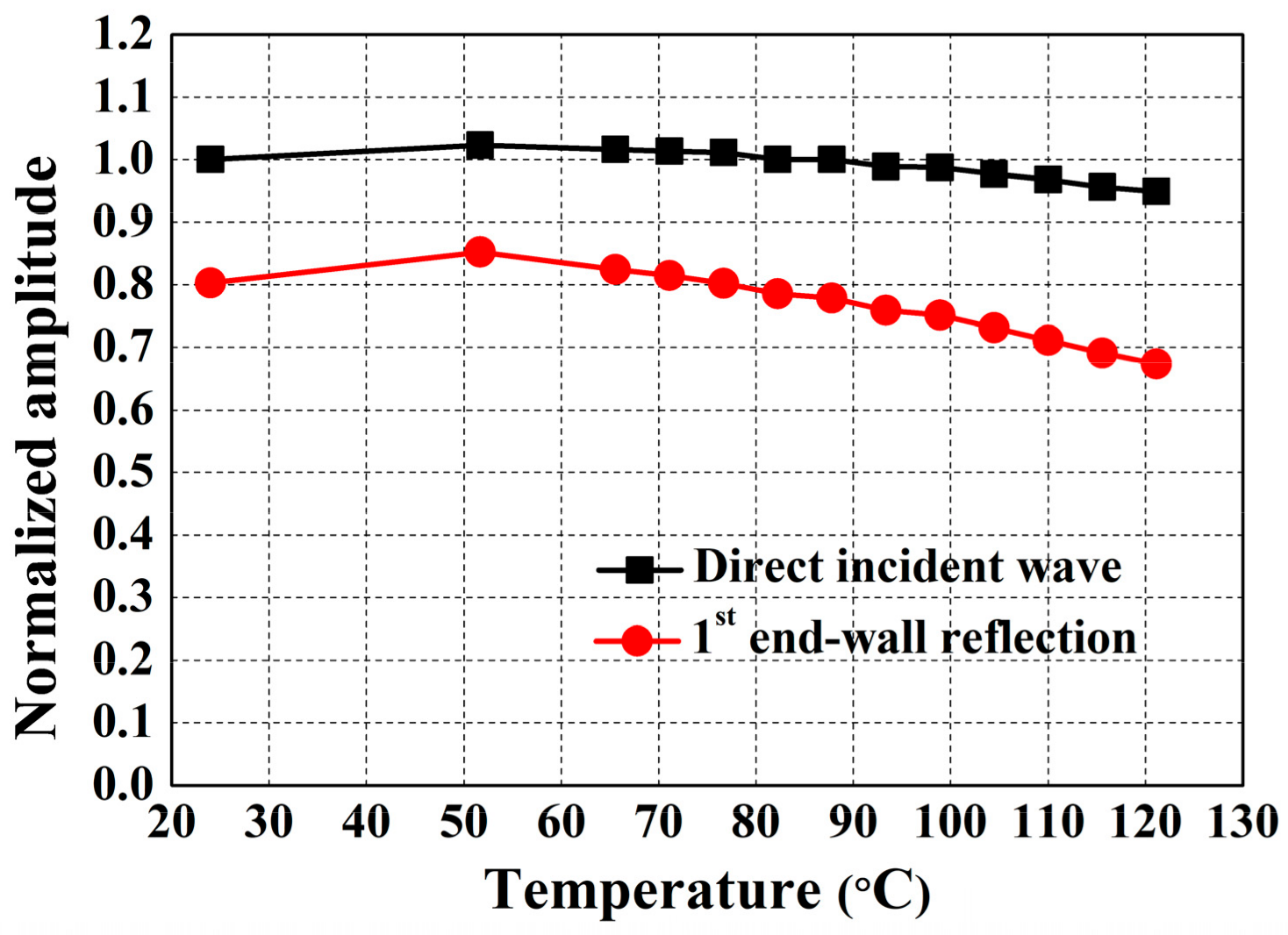

3.1.2. EMAT Performance as a Function of Temperature

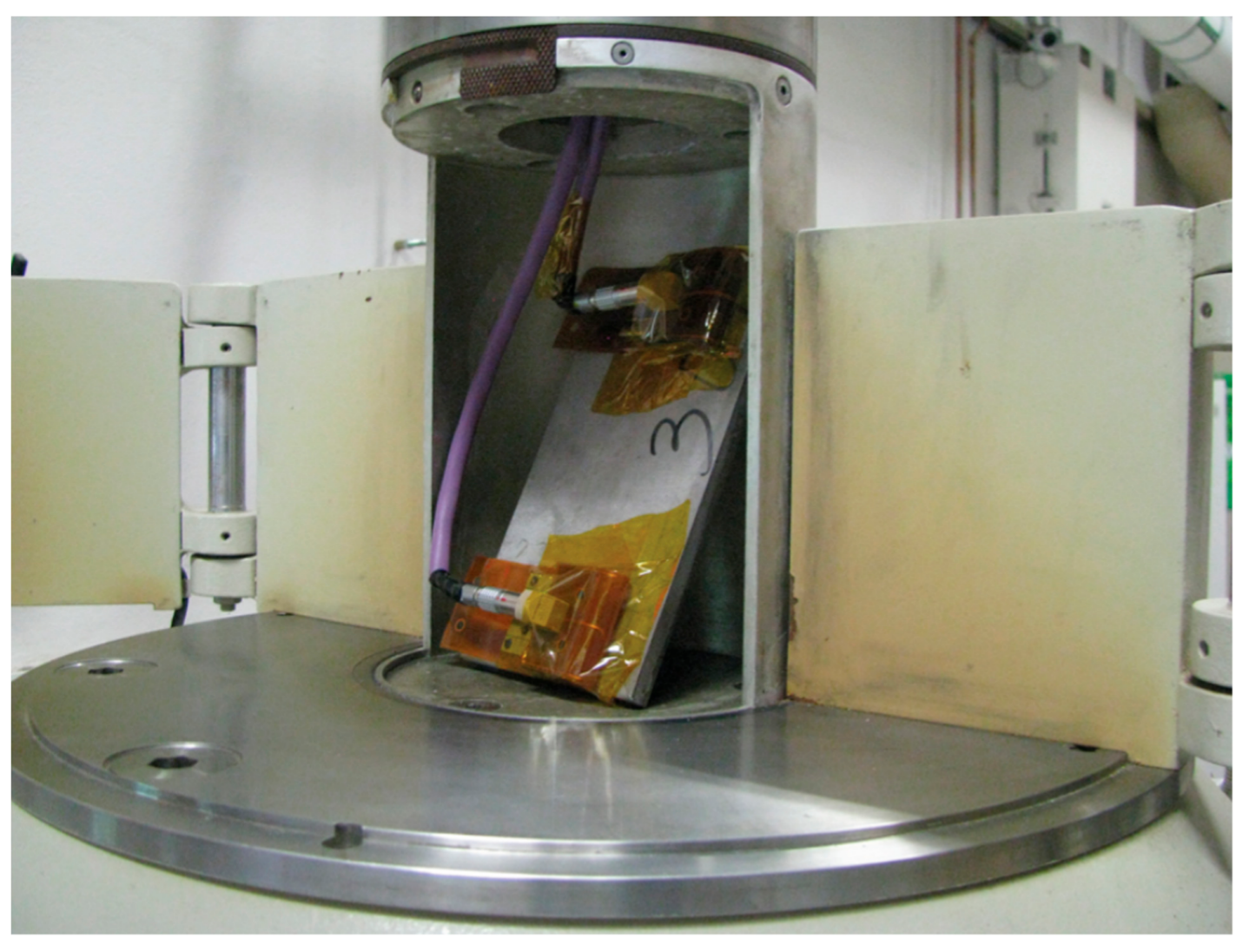

3.2. Gamma Radiation Tests

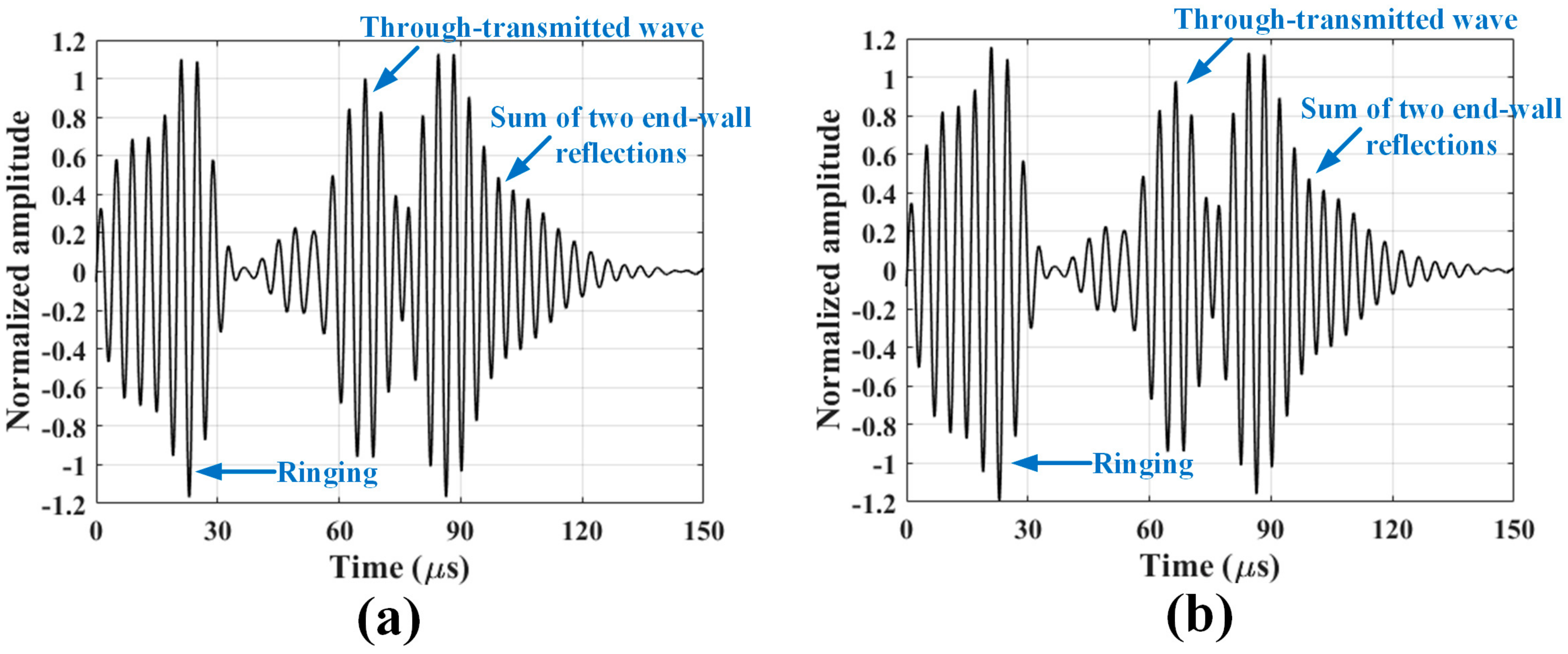

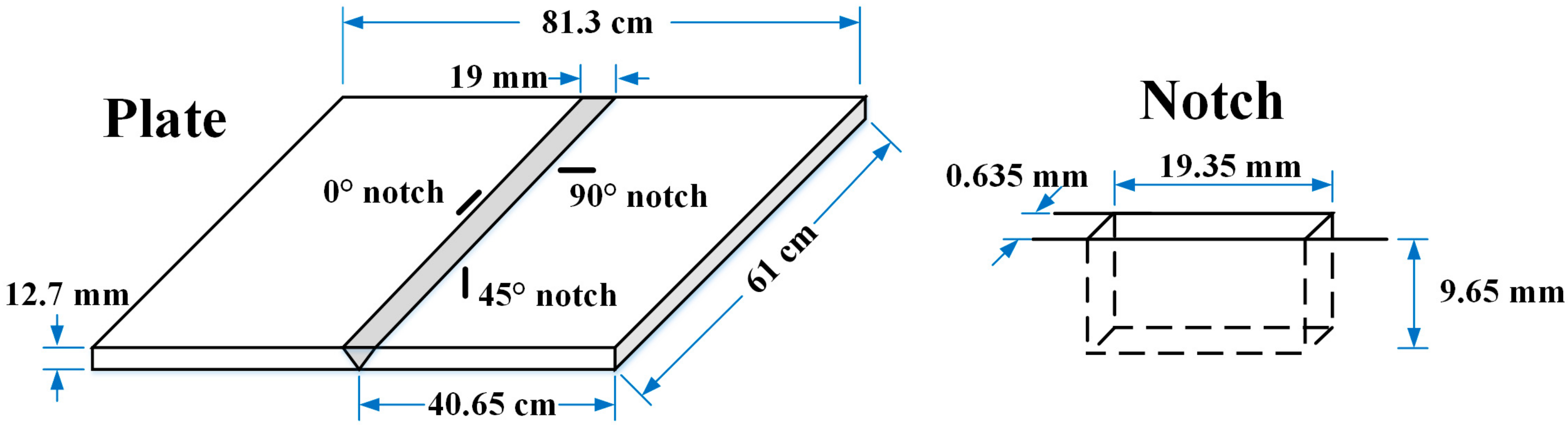

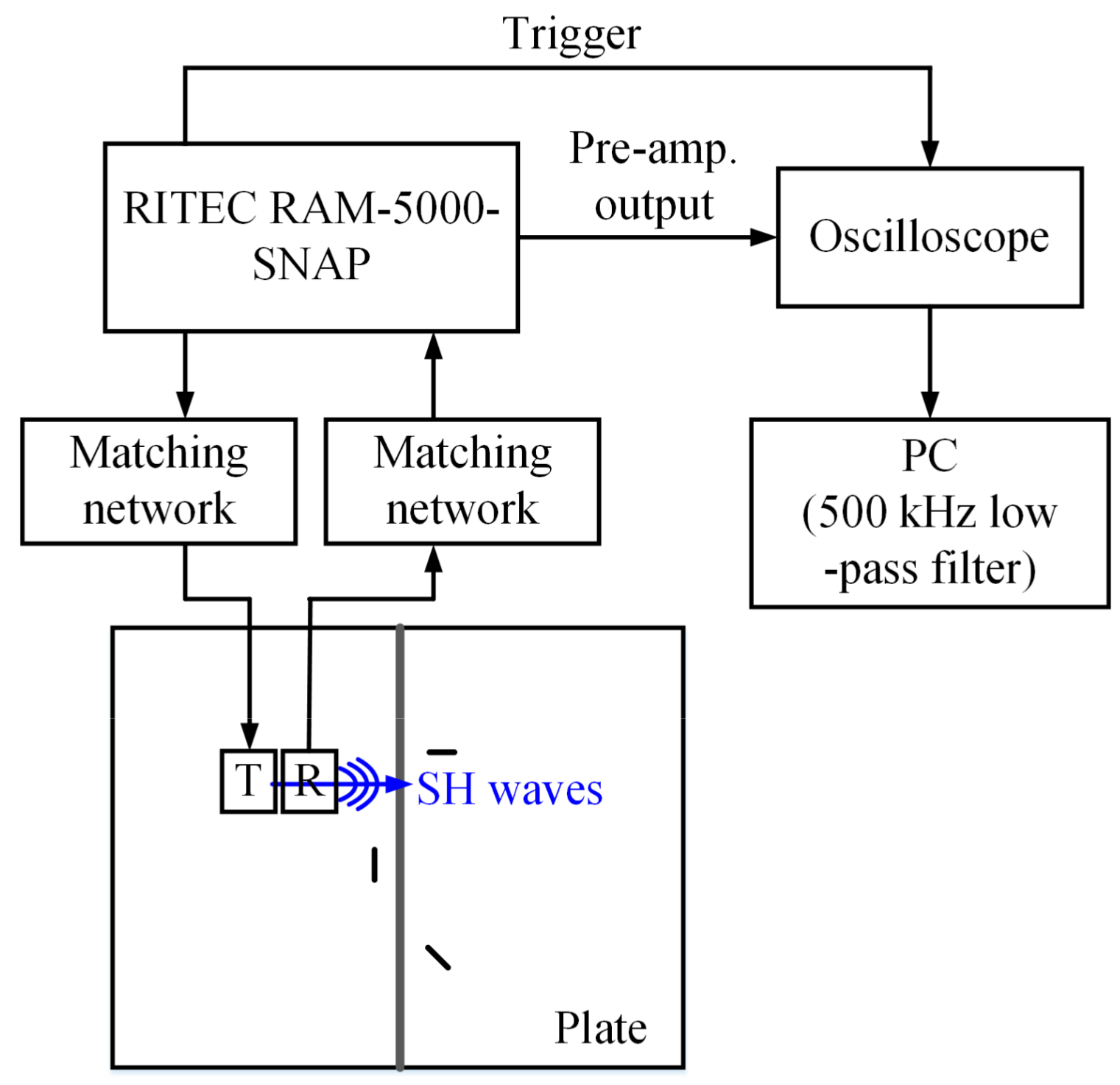

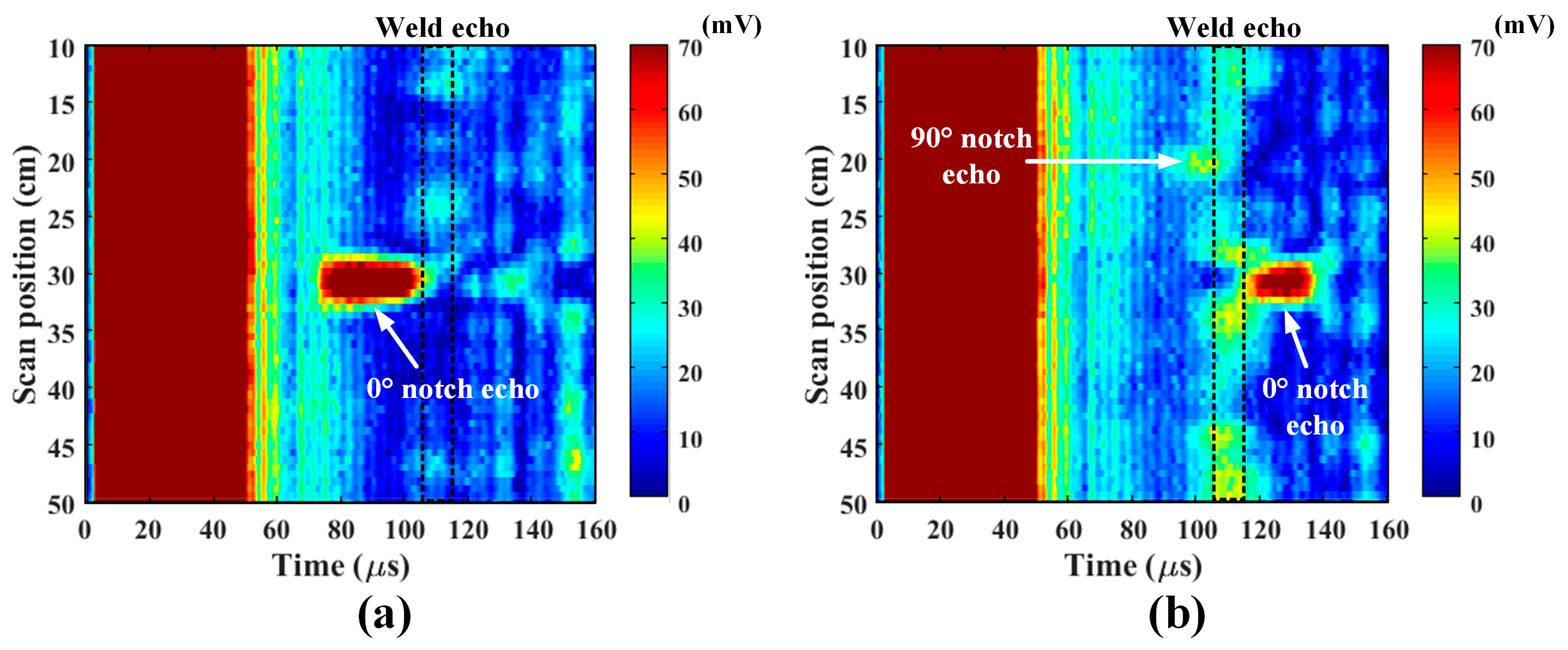

3.3. EMAT Capability to Detect Notches

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Meyer, R.M.; Pardini, A.F.; Cuta, J.M.; Adkins, H.E.; Casella, A.M.; Qiao, A.; Larche, M.; Diaz, A.A.; Doctor, S.R. NDE to Manage Atmospheric SCC in Canisters for Dry Storage of Spent Fuel: An Assessment; PNNL-22495; Pacific Northwest National Laboratory: Richland, WA, USA, 2013.

- Fuhr, K.; Gorman, J.; Broussard, J.; White, G. Failure Modes and Effects Analysis (FMEA) of Welded Stainless Steel Canisters for Dry Cask Storage Systems; EPRI Report 3002000815; Electric Power Research Institute: Palo Alto, CA, USA, 2013.

- Cho, H.; Choi, S.; Lissenden, C.J.; Lindsey, M.S. Electromagnetic acoustic transducer (EMAT) development for nondestructive inspection of spent nuclear fuel storage canisters. In Proceedings of the American Society of Mechanical Engineers (ASME) Pressure Vessls & Piping (PVP) Conference, Waikoloa, HI, USA, 16–20 July 2017. [Google Scholar]

- Choi, S.; Cho, H.; Lissenden, C.J. Selection of shear horizontal wave transducers for robotic nondestructive inspection in harsh environments. Sensors 2017, 17, 5. [Google Scholar] [CrossRef] [PubMed]

- Lissenden, C.J.; Choi, S.; Cho, H.; Motta, A.; Hartig, K.; Xiao, X.; Le Berre, S.; Brennan, S.; Reichard, K.; Leary, R.; et al. Toward robotic inspection of dry storage casks for spent nuclear fuel. J. Press. Vessel Technol. Trans. ASME 2017, 139, 031602. [Google Scholar] [CrossRef]

- Sindelar, R.L.; Duncan, A.J.; Dupont, M.E.; Lam, P.-S.; Louthan, M.R., Jr.; Skidmore, T.E. Materials Aging Issues and Aging Management for Extended Storage and Transportation of Spent Nuclear Fuel; NUREG/CR-7116, SRNL-STI-2011-00005; U.S. Nuclear Regulatory Commission: Washington, DC, USA, 2011.

- Caseres, L.; Mintz, T.S. Atmospheric Stress Corrosion Cracking Susceptibility of Welded and Unwelded 304, 304L, and 316L Austenitic Stainless Steels Commonly Used for Dry Cask Storage Containers Exposed to Marine Environments; NUREG/CR-7030; U.S. Nuclear Regulatory Commission: Washington, DC, USA, 2010.

- He, X.; Mintz, T.S.; Pabalan, R.; Miller, L.; Oberson, G. Assessment of Stress Corrosion Cracking Susceptibility for Austenitic Stainless Steels Exposed to Atmospheric Chloride and Non-Chloride Salts; NUREG/CR-7170; U.S. Nuclear Regulatory Commission: Washington, DC, USA, 2014.

- Chopra, O.K.; Diercks, D.R.; Fabian, R.R.; Han, Z.H.; Liu, Y.Y. Managing Aging Effects on Dry Cask Storage Systems for Extended Long-Term Storage and Transportation of Used Fuel Rev. 2; ANL-13/15, FCRD-UFD-2014-000476; U.S. Department of Energy: Washington, DC, USA, 2014.

- Xie, Y.; Zhang, J. Chloride-induced stress corrosion cracking of used nuclear fuel welded stainless steel canisters: A review. J. Nucl. Mater. 2015, 466, 85–93. [Google Scholar] [CrossRef]

- Meyer, R.M.; Pardini, A.F.; Hanson, B.D.; Sorenson, K.B. Review of NDE Methods for Detection and Monitoring of Atmospheric SCC in Welded Canisters for the Storage of Used Nuclear Fuel; PNNL-22158, FCRD-UFD-2013-000085; Pacific Northwest National Laboratory: Richland, WA, USA, 2013.

- Bakhtiari, S. Extended In-Situ and Real Time Monitoring Task 1: Monitoring Real Time Materials Degradation; ANL/NE-12/39; Argonne National Laboratory: Oak Ridge, TN, USA, 2012.

- Kunerth, D.C.; McJunkin, T.; McKay, M.; Bakhtiari, S. Inspection of Used Fuel Dry Storage Casks; INL/EXT-12-27119, FCRD-UFD-2012-000273; Idaho National Laboratory: Idaho Falls, ID, USA, 2012.

- Rose, J.L. Ultrasonic Guided Waves in Solid Media; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Rose, J.D. A baseline and vision of ultrasonic guided wave inspection potential. J. Press. Vessel Technol. Trans. ASME 2002, 124, 273–282. [Google Scholar] [CrossRef]

- Lowe, M.J.S.; Diligent, O. Low-freqeuncy reflection characteristics of the s0 Lamb wave from a rectrangular notch in a plate. J. Acoust. Soc. Am. 2002, 111, 64–74. [Google Scholar] [CrossRef] [PubMed]

- Chimenti, D.E. Guided waves in plates and their use in materials characterization. Appl. Mech. Rev. 1997, 50, 247–284. [Google Scholar] [CrossRef]

- Ratassepp, M.; Lowe, M.J.S.; Cawley, P.; Klauson, A. Scattering of the fundamental shear horizontal mode in a plate when incident at a through crack aligned in the propagation direction of the mode. J. Acoust. Soc. Am. 2008, 124, 2873–2882. [Google Scholar] [CrossRef] [PubMed]

- Hirao, M.; Ogi, H. Electromagnetic Acoustic Transducers: Noncontacting Ultrasonic Measurements Using EMATs, 2nd ed.; Springer Japan: Tokyo, Japan, 2017. [Google Scholar]

- Hanks, C.L.; Hamman, D.J. Radiation Effects Design Handbook: Section 3. Electrical Insulating Materials and Capacitors; NASA CR-1787; National Aeronautics and Space Administration: Washington, DC, USA, 1971.

- Searle, O.B.; Pfeiffer, R.H. Victrex poly(ethersulfone) (PES) and Victrex poly(etheretherketone) (PEEK). Polym. Eng. Sci. 1985, 25, 474–476. [Google Scholar] [CrossRef]

- K&J Magnetics, Inc. Available online: http://www.kjmagnetics.com (accessed on 29 November 2017).

| Components | Material | Function | Elevated Temperature (from the Vendors) | Gamma Radiation [20,21] |

|---|---|---|---|---|

| Rare earth magnets | NdFeB | Provide a static magnetic field | Operational temp.: 80 °C Curie temp.: 310 °C | - |

| Electrical coil substrate | Polyimide | Fixes coil position, which creates eddy currents | 200 °C | 1 × 106 krad |

| Housing | Stainless steel 316 | Encloses magnets and coil | 1400 °C | >1 × 106 krad |

| Epoxy adhesive | Novalac-based high temperature epoxy | Secures magnets in housing | 260 °C | 8.8 × 104 krad |

| Coil-fixation tape | Polyimide | Secures coil to magnets | 200 °C | 1 × 106 krad |

| Wear-resistant tape | PEEK | Protects both substrate and coil from wear damage and sets liftoff | 204 °C | 1 × 106 krad |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.; Cho, H.; Lindsey, M.S.; Lissenden, C.J. Electromagnetic Acoustic Transducers for Robotic Nondestructive Inspection in Harsh Environments. Sensors 2018, 18, 193. https://doi.org/10.3390/s18010193

Choi S, Cho H, Lindsey MS, Lissenden CJ. Electromagnetic Acoustic Transducers for Robotic Nondestructive Inspection in Harsh Environments. Sensors. 2018; 18(1):193. https://doi.org/10.3390/s18010193

Chicago/Turabian StyleChoi, Sungho, Hwanjeong Cho, Matthew S. Lindsey, and Cliff J. Lissenden. 2018. "Electromagnetic Acoustic Transducers for Robotic Nondestructive Inspection in Harsh Environments" Sensors 18, no. 1: 193. https://doi.org/10.3390/s18010193