Modeling of BN Lifetime Prediction of a System Based on Integrated Multi-Level Information

Abstract

:1. Introduction

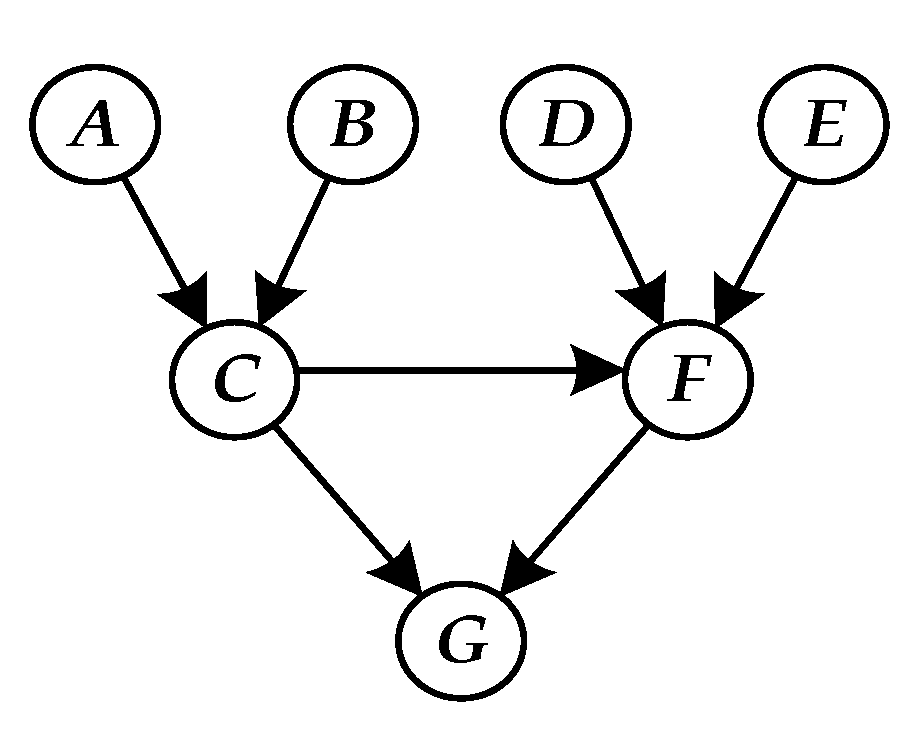

2. Overview of BN Model

- Determine node variables and their interpretation.

- Create a DAG with a directed edge connecting node variables.

- Create a CPT for non-root nodes.

3. Lifetime Prediction Method of Multi-level System Based on BN

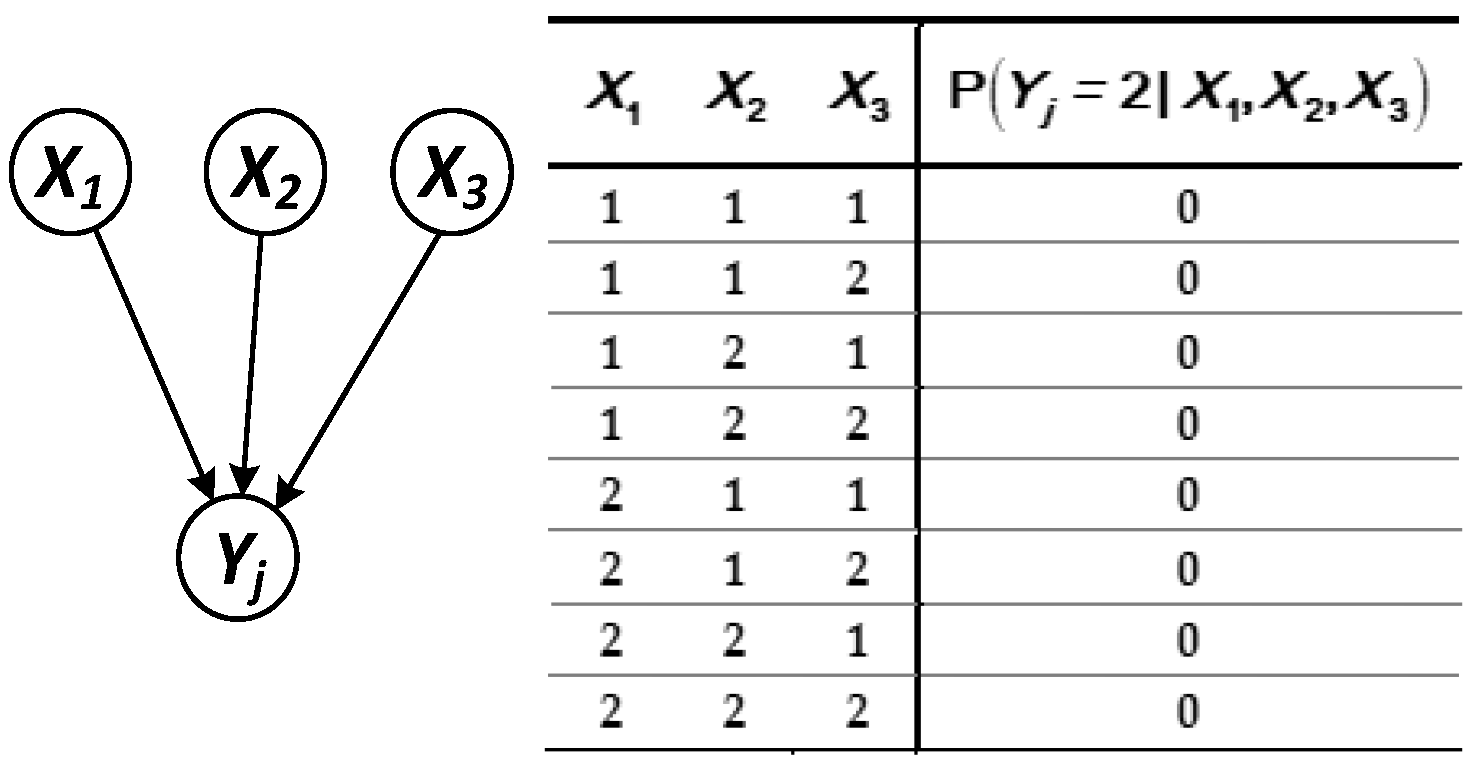

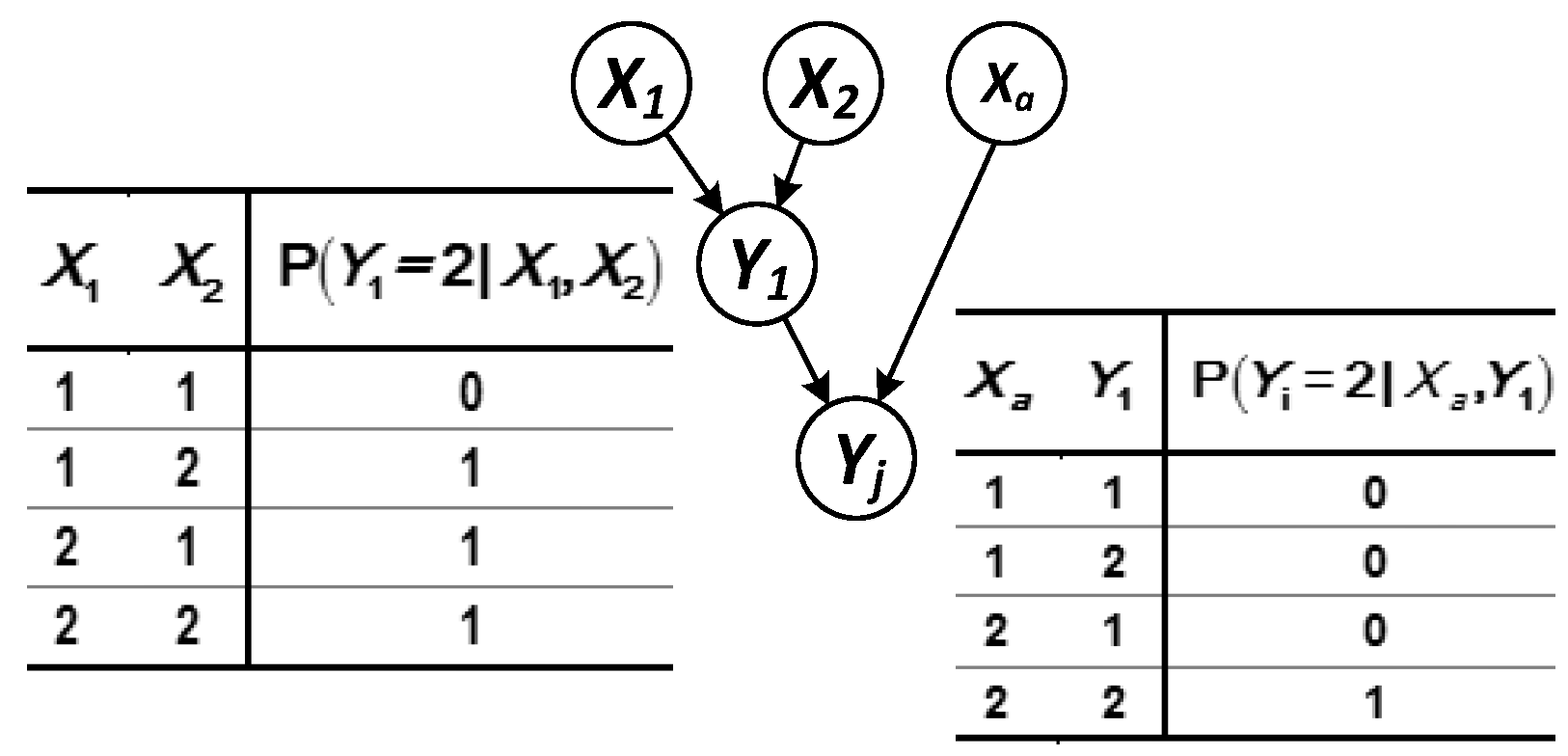

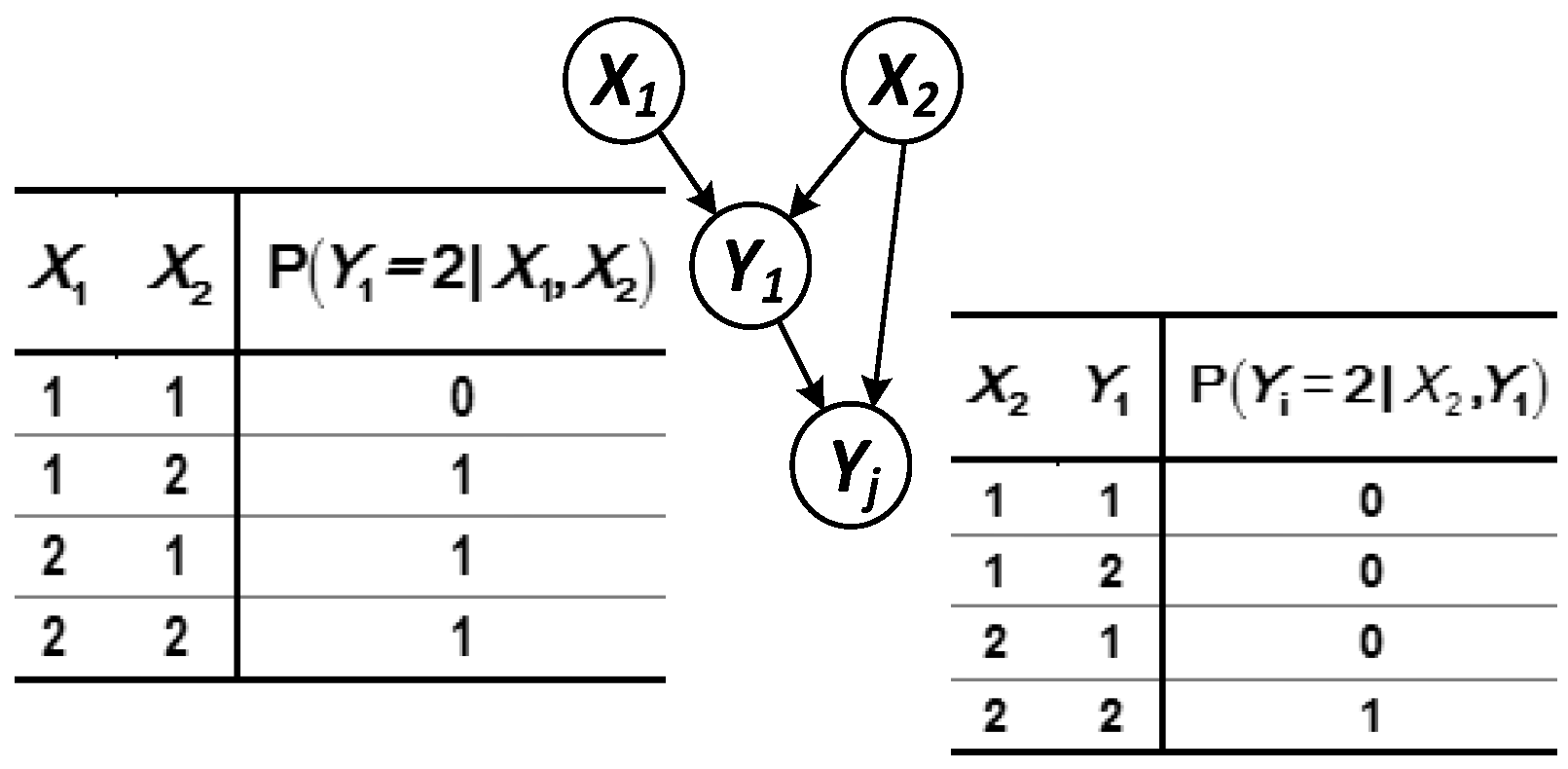

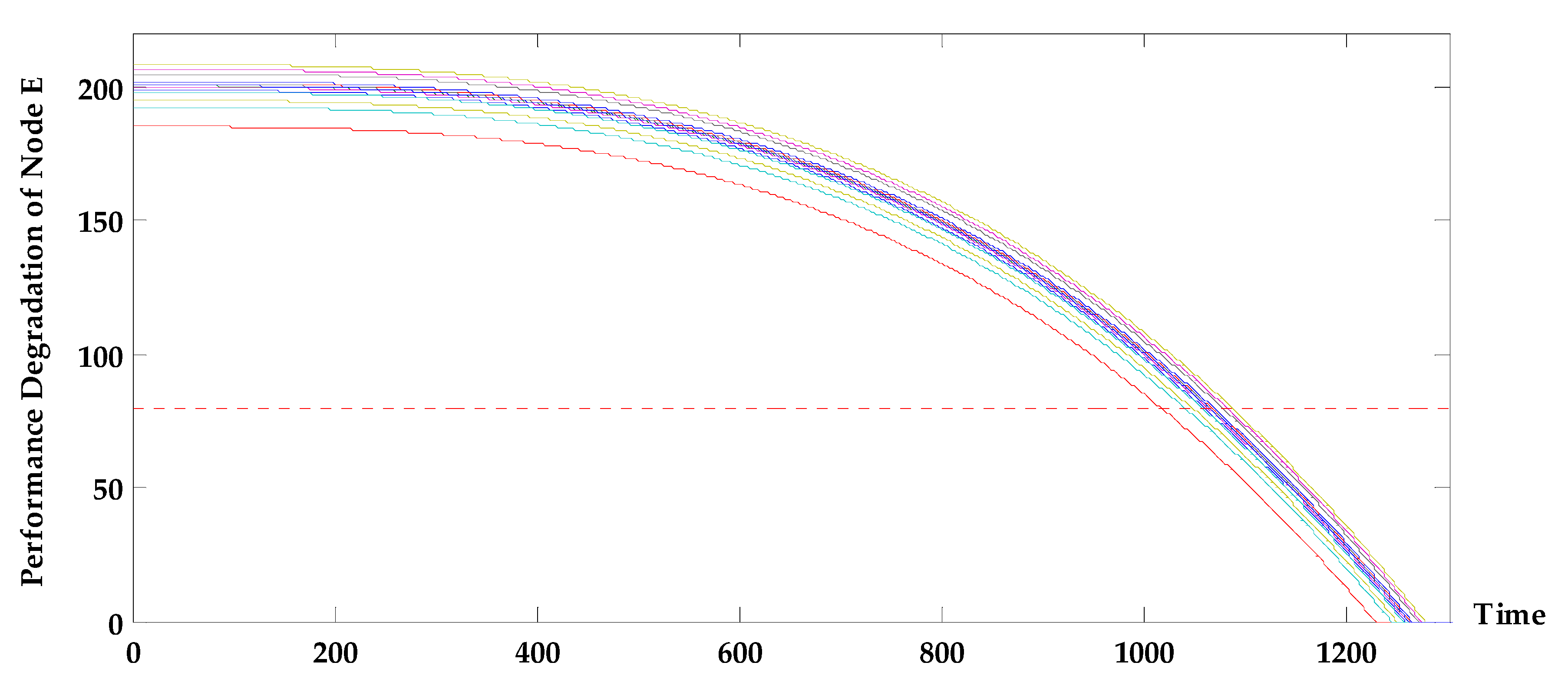

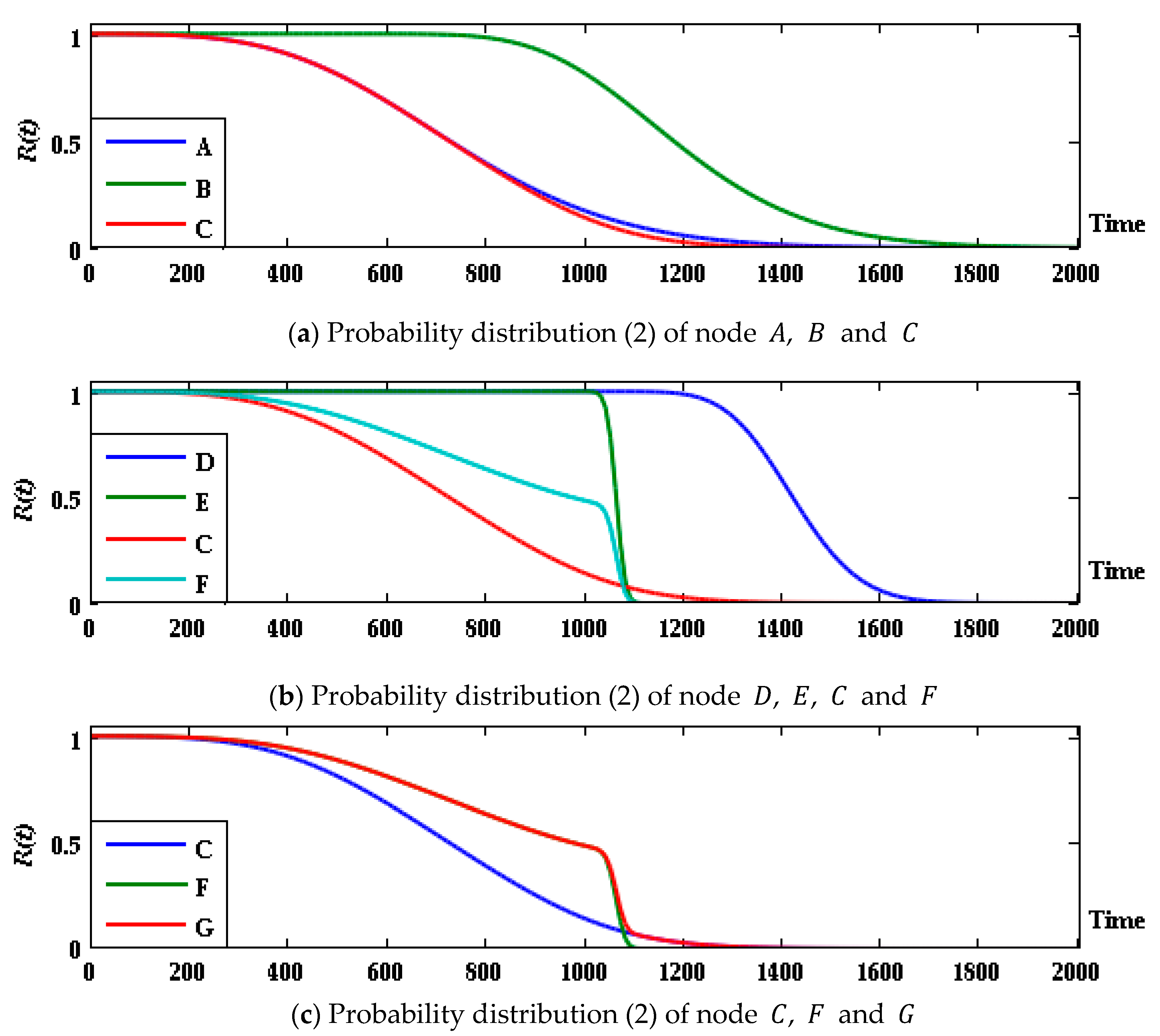

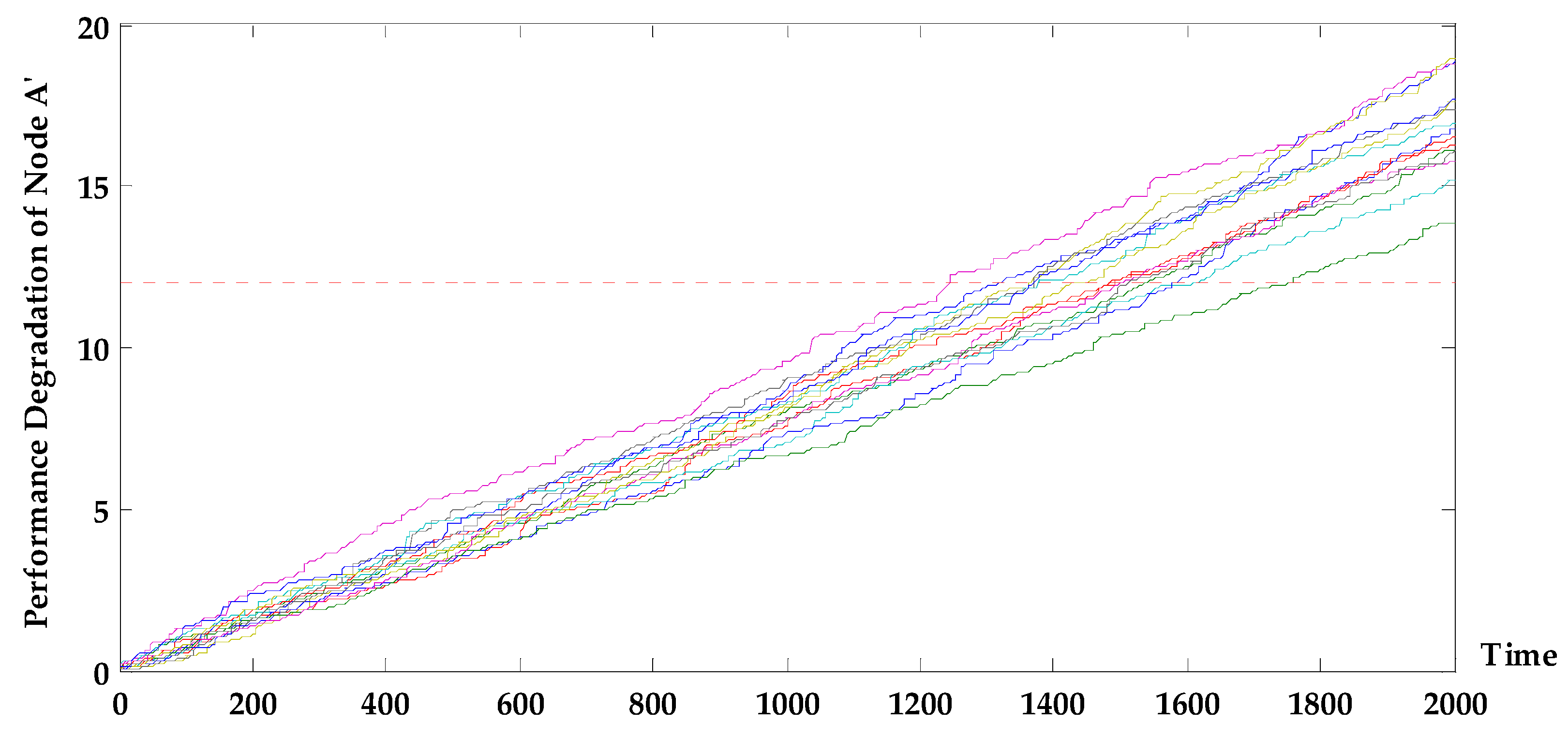

3.1. Prediction Model at Equipment Level

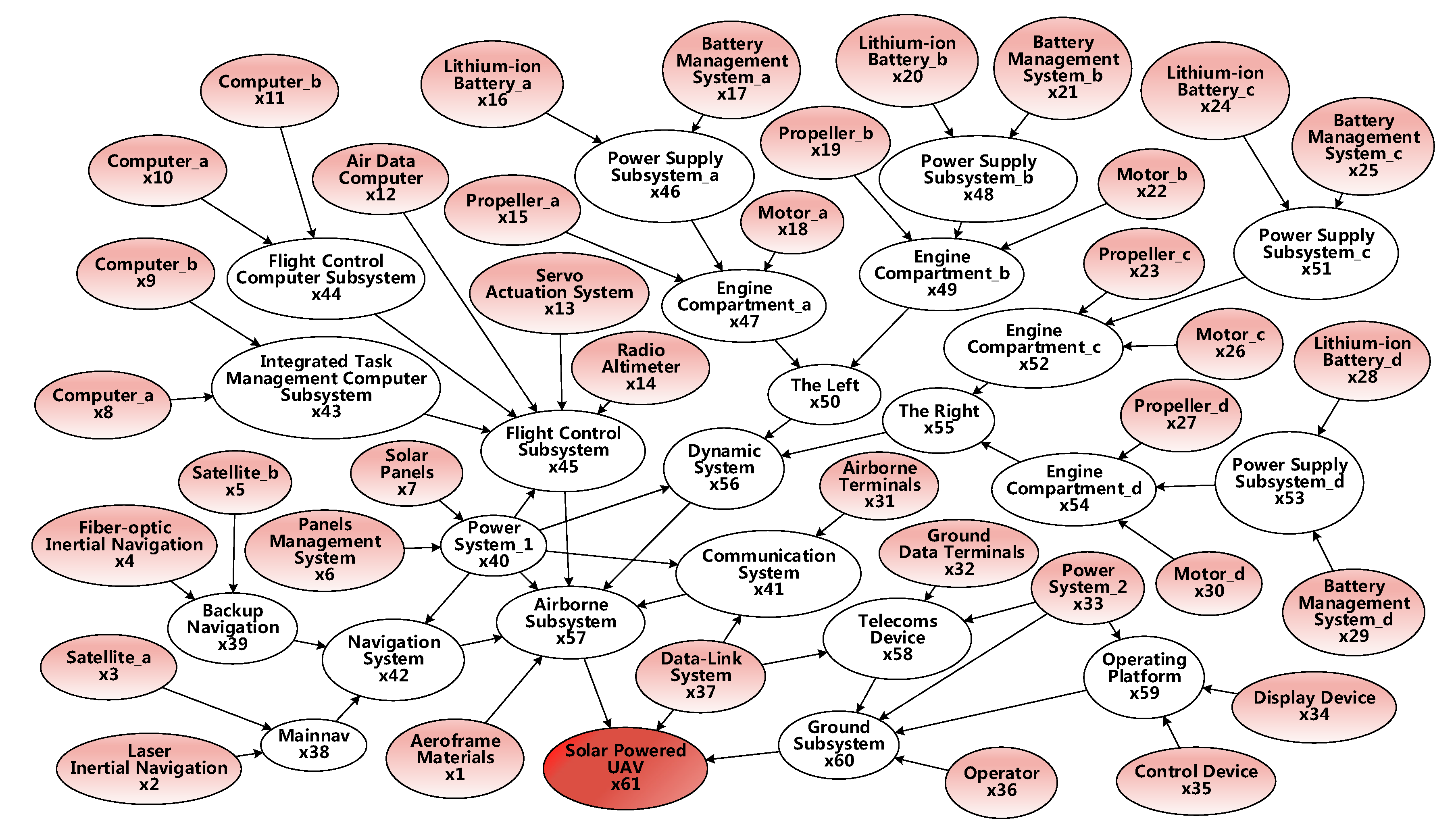

3.2. BN Prediction Modeling and Inference at System Level

- Obtain expert knowledge and structure and function information of similar products. Analyze the failure mode and mechanism through the system function-level method. Fault tree analysis is used for key faults to determine the equipment and mechanisms that affect system lifetime.

- Deploy sensors for key performance parameters of each device. Collect and process data.

- Based on the analysis of sensor data, the prediction model is established for each piece of equipment, and the prediction value of lifetime-related state probability is given.

- Combined with the system failure mechanism, the prediction value of state probability for the equipment involved is used as the prior probability for the root node.

- Combine system logic to form a DAG, and establish a non-root node CPT.

- The JT estimation algorithm is used to solve the joint probability of relevant nodes, to update the conditional probability values of each node, and to achieve the deduction of state probability of system nodes to complete the system prediction.

- The BN prediction model is still applicable, along with the updating of sensor data and correction of prediction model at equipment level. If the failure mechanism changes, the DAG and CPT should be corrected for the updated logical relationship; proceed to Step 3.

4. Modeling, Simulation, and Verification of System-Level BN Prediction

5. Application Case

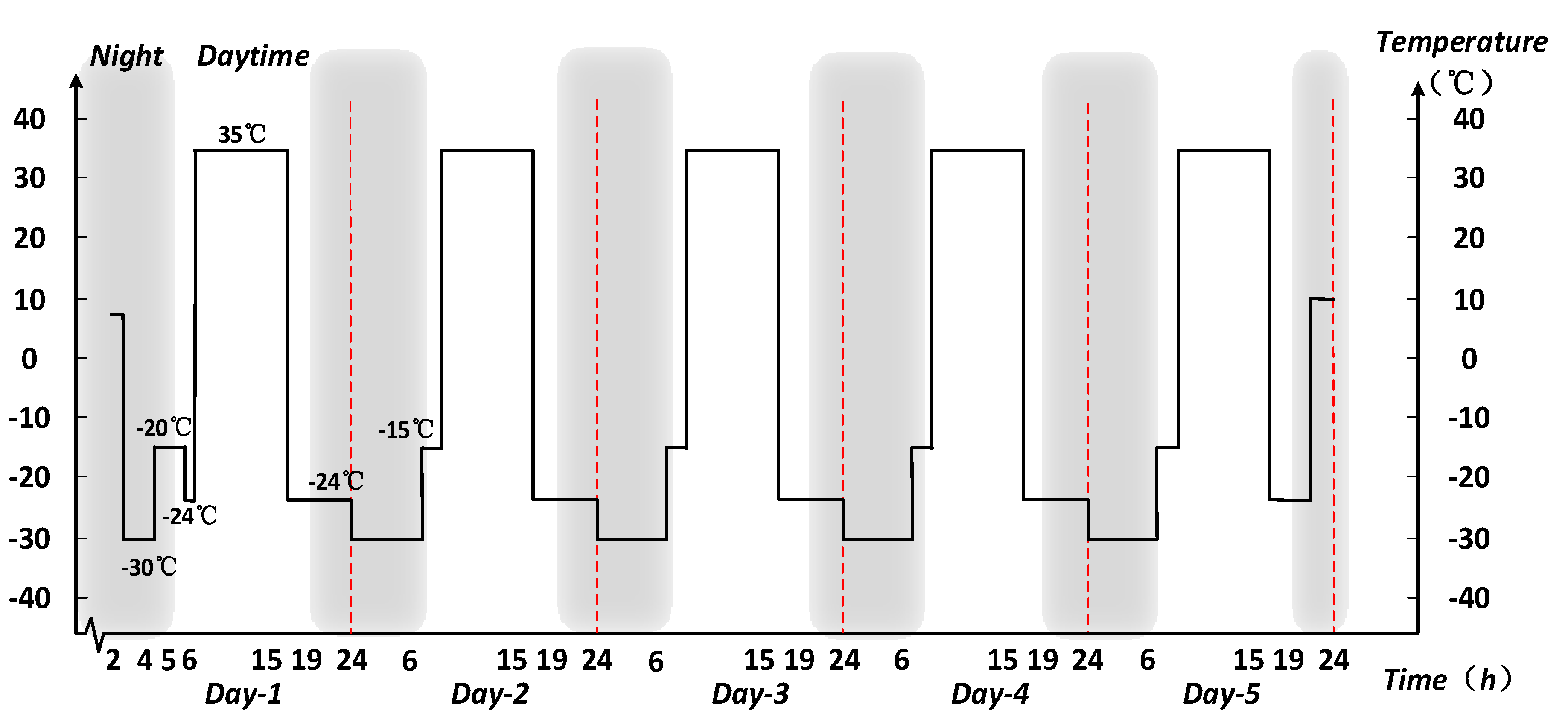

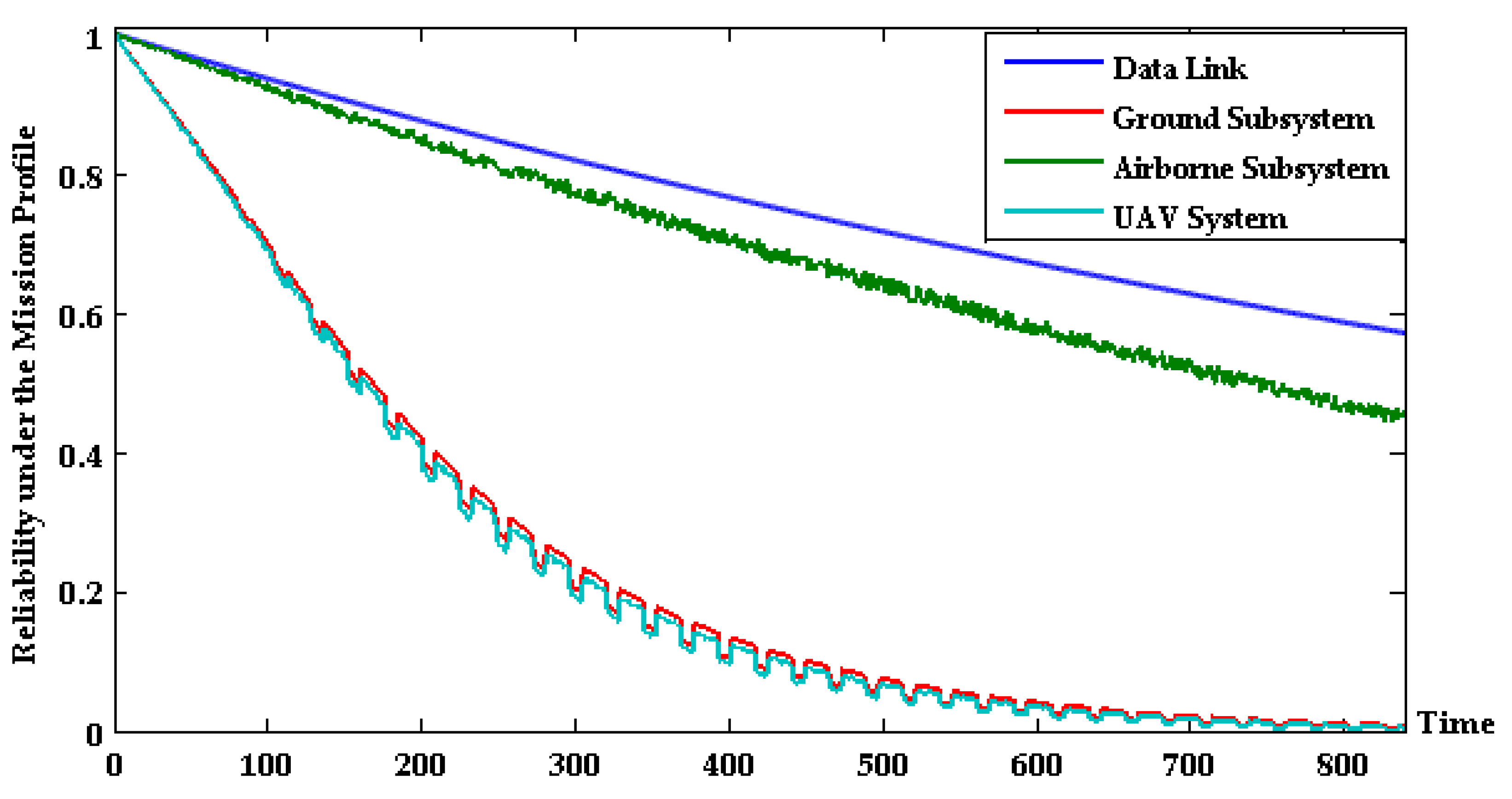

5.1. BN Lifetime Prediction of an Unmanned Solar-Powered System

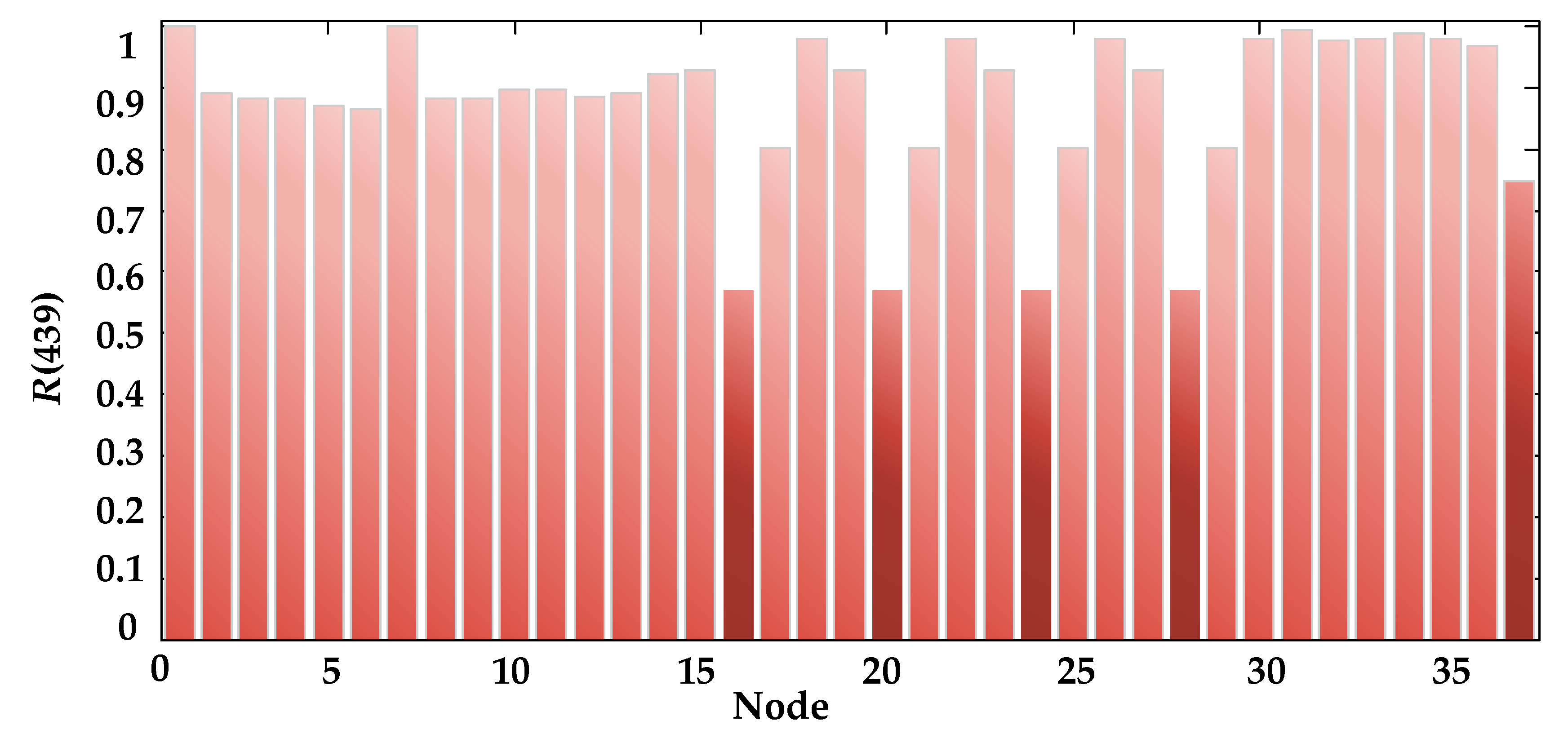

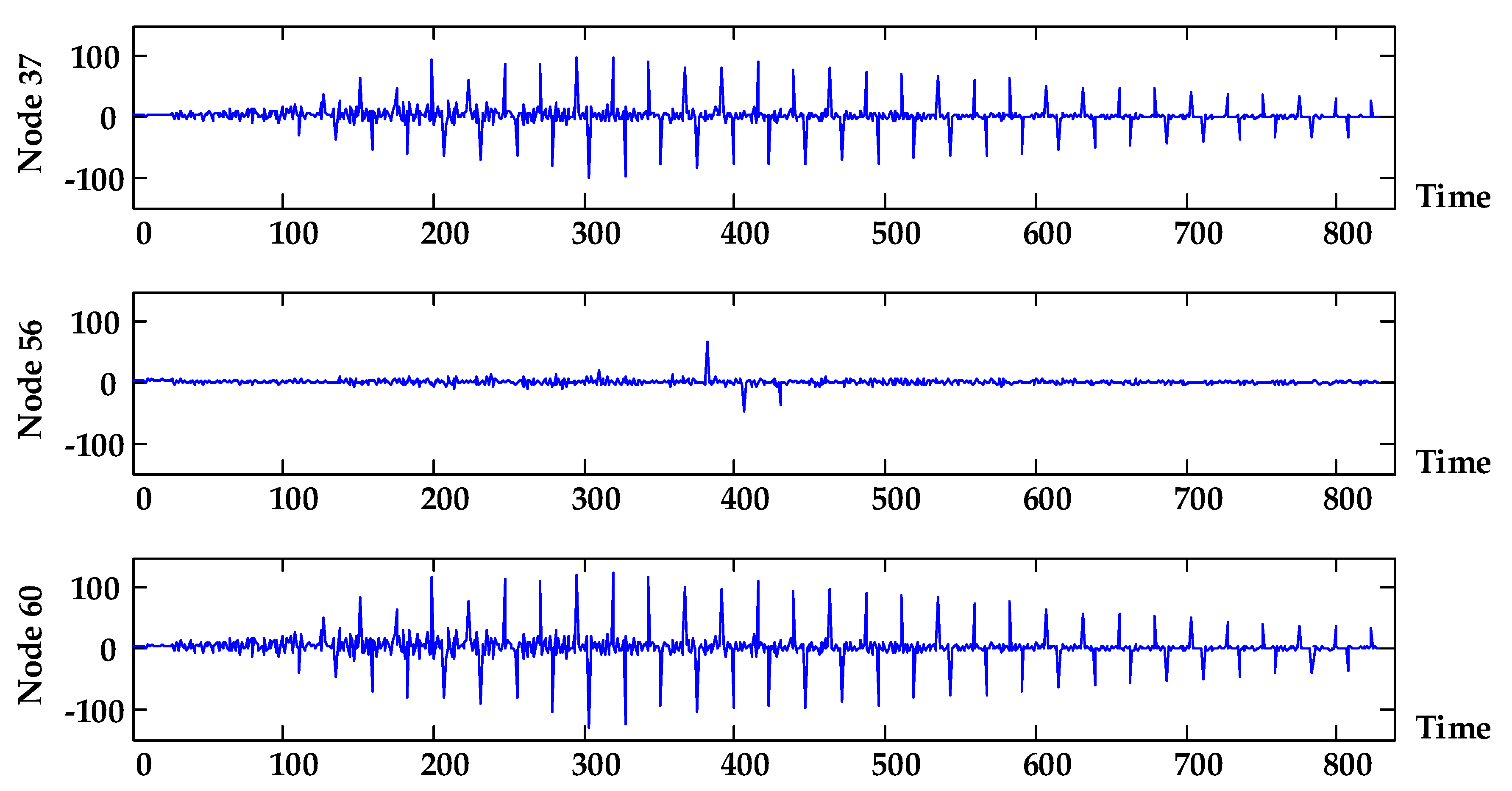

5.2. Analysis Based on the Prediction Results

6. Conclusions

- (1)

- By making full use of multi-sensor information, data association, and quantitative expression, integration and lifetime prediction can be achieved on multi-level, complex, dynamic, multi-source logic data.

- (2)

- The diversified life expectancy information of the model output is based on different aspects and complement each other, which provides comprehensive data support and theoretical guidance for design improvements and maintenance from system view and in the entire lifecycle process that considers a trade-off of economics, technology, risk, and effectiveness.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ge, Q.; Wei, Z.; Cheng, T.; Chen, S.; Wang, X. Flexible Fusion Structure-Based Performance Optimization Learning for Multisensor Target Tracking. Sensors 2017, 17, 1045. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Liu, J.; Hu, H.; Zhang, Y. Wearable Sensor-Based Human Activity Recognition Method with Multi-Features Extracted from Hilbert-Huang Transform. Sensors 2016, 16, 2048. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Feng, L.; Yang, A. Fusion Based on Visible Light Positioning and Inertial Navigation Using Extended Kalman Filters. Sensors 2017, 17, 1093. [Google Scholar]

- Rodger, J.A. Toward reducing failure risk in an integrated vehicle health maintenance system: A fuzzy multi-sensor data fusion Kalman filter approach for IVHMS. Expert Syst. Appl. 2012, 39, 9821–9836. [Google Scholar] [CrossRef]

- Jing, L.; Wang, T.; Zhao, M.; Wang, P. An Adaptive Multi-Sensor Data Fusion Method Based on Deep Convolutional Neural Networks for Fault Diagnosis of Planetary Gearbox. Sensors 2017, 17, 414. [Google Scholar] [CrossRef] [PubMed]

- Hsu, Y.L.; Chou, P.H.; Chang, H.C.; Lin, S.L.; Yang, S.C.; Su, H.Y.; Chang, C.C.; Cheng, Y.S.; Kuo, Y.C. Design and Implementation of a Smart Home System Using Multisensor Data Fusion Technology. Sensors 2017, 17, 1631. [Google Scholar] [CrossRef] [PubMed]

- Whitmore, G.A.; Schenkelberg, F. Modelling accelerated degradation data using Wiener diffusion with a time scale transformation. Lifetime Data Anal. 1997, 3, 27–45. [Google Scholar] [CrossRef] [PubMed]

- Bagdonavicius, V.; Nikulin, M.S. Estimation in degradation models with explanatory variables. Lifetime Data Anal. 2001, 7, 85–103. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.; Huang, H.L.; Das, D.; Pecht, M. Thermal reliability prediction and analysis for high-density electronic systems based on the Markov process. Microelectron. Reliab. 2016, 56, 182–188. [Google Scholar] [CrossRef]

- Ali, J.B.; Chebel-Morello, B.; Saidi, L.; Malinowski, S.; Fnaiech, F. Accurate Bearing remaining useful life prediction based on Weibull distribution and artificial neural network. Mech. Syst. Sig. Process. 2015, 56, 150–172. [Google Scholar]

- Alghassi, A.; Perinpanayagam, S.; Samie, M. Stochastic RUL Calculation Enhanced With TDNN-Based IGBT Failure Modeling. IEEE Trans. Reliab. 2016, 65, 558–573. [Google Scholar] [CrossRef]

- Son, J.; Zhou, S.; Sankavaram, C.; Sankavaram, C.; Du, X.; Zhang, Y. Remaining useful life prediction based on noisy condition monitoring signals using constrained Kalman filter. Reliab. Eng. Syst. Saf. 2016, 152, 38–50. [Google Scholar] [CrossRef]

- Li, K.; Wu, J.; Zhang, Q.; Su, L.; Chen, P. New Particle Filter Based on GA for Equipment Remaining Useful Life Prediction. Sensors 2017, 17, 696. [Google Scholar] [CrossRef] [PubMed]

- Qian, Y.N.; Yan, R.Q.; Gao, R.X. A multi-time scale approach to remaining useful life prediction in rolling bearing. Mech. Syst. Sig. Process. 2017, 83, 549–567. [Google Scholar] [CrossRef]

- Nguyen, K.A.; Do, P.; Grall, A. Multi-level predictive maintenance for multi-component systems. Reliab. Eng. Syst. Saf. 2015, 144, 83–94. [Google Scholar] [CrossRef]

- Zheng, X.; Fang, H. An integrated unscented kalman filter and relevance vector regression approach for lithium-ion battery remaining useful life and short-term capacity prediction. Reliab. Eng. Syst. Saf. 2015, 144, 74–82. [Google Scholar] [CrossRef]

- Khorasgani, H.; Biswas, G.; Sankararaman, S. Methodologies for system-level remaining useful life prediction. Reliab. Eng. Syst. Saf. 2016, 154, 8–18. [Google Scholar] [CrossRef]

- Coolen, F.P.A.; Coolen-Maturi, T. The structure function for system reliability as predictive (imprecise) probability. Reliab. Eng. Syst. Saf. 2016, 154, 180–187. [Google Scholar] [CrossRef] [Green Version]

- Jackson, C.; Mosleh, A. Bayesian inference with overlapping data: Reliability estimation of multi-state on-demand continuous life metric systems with uncertain evidence. Reliab. Eng. Syst. Saf. 2016, 145, 124–135. [Google Scholar] [CrossRef]

- George-Williams, H.; Patelli, E. A hybrid load flow and event driven simulation approach to multi-state system reliability evaluation. Reliab. Eng. Syst. Saf. 2016, 152, 351–367. [Google Scholar] [CrossRef]

- Meineri, E.; Dahlberg, C.J.; Hylander, K. Using Gaussian Bayesian Networks to disentangle direct and indirect associations between landscape physiography, environmental variables and species distribution. Ecol. Modell. 2015, 313, 127–136. [Google Scholar] [CrossRef]

- Pearl, J. Fusion, propagation, and structuring in belief networks. Artif. Intell. 1986, 29, 241–288. [Google Scholar] [CrossRef]

- Weber, P.; Medina-Oliva, G.; Simon, C.; Iung, B. Overview on Bayesian networks applications for dependability, risk analysis and maintenance areas. Eng. Appl. Artif. Intell. 2012, 25, 671–682. [Google Scholar] [CrossRef]

- Tien, I.; Kiureghian, A.D. Algorithms for Bayesian network modeling and reliability assessment of infrastructure systems. Reliab. Eng. Syst. Saf. 2016, 156, 134–147. [Google Scholar] [CrossRef]

- Price, L.C.; Peiris, H.V.; Frazer, J.; Easther, R. Designing and testing inflationary models with Bayesian networks. J. Cosmol. Astropart. Phys. 2016, 2016, 049. [Google Scholar] [CrossRef]

- Garvey, M.D.; Carnovale, S.; Yeniyurt, S. An analytical framework for supply network risk propagation: A Bayesian network approach. Eur. J. Oper. Res. 2015, 243, 618–627. [Google Scholar] [CrossRef]

- Cai, B.; Liu, H.; Xie, M. A real-time fault diagnosis methodology of complex systems using object-oriented Bayesian networks. Mech. Syst. Sig. Process. 2016, 80, 31–44. [Google Scholar] [CrossRef]

- Cai, B.; Liu, Y.; Fan, Q.; Zhang, Y.; Liu, Z.; Yu, S.; Ji, R. Multi-source information fusion based fault diagnosis of ground-source heat pump using Bayesian network. Appl. Energy 2014, 114, 1–9. [Google Scholar] [CrossRef]

- Khakzad, N. Application of dynamic Bayesian network to risk analysis of domino effects in chemical infrastructures. Reliab. Eng. Syst. Saf. 2015, 138, 263–272. [Google Scholar] [CrossRef]

- Tang, D.; Makis, V.; Jafari, L.; Yu, J. Optimal maintenance policy and residual life estimation for a slowly degrading system subject to condition monitoring. Reliab. Eng. Syst. Saf. 2015, 134, 198–207. [Google Scholar] [CrossRef]

- Cai, B.; Zhao, Y.; Liu, H.; Xie, M. A Data-Driven Fault Diagnosis Methodology in Three-Phase Inverters for PMSM Drive Systems. IEEE Trans. Power Electron. 2017, 32, 5590–5600. [Google Scholar] [CrossRef]

- Yontay, P.; Pan, R. A computational Bayesian approach to dependency assessment in system reliability. Reliab. Eng. Syst. Saf. 2016, 152, 104–114. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, L.; Ma, L.; Liang, W. An integrated safety prognosis model for complex system based on dynamic Bayesian network and ant colony algorithm. Expert Syst. Appl. 2011, 38, 1431–1446. [Google Scholar] [CrossRef]

- Li, N.; Feng, X.; Jimenez, R. Predicting rock burst hazard with incomplete data using Bayesian networks. Tunn. Undergr. Space Technol. 2017, 61, 61–70. [Google Scholar] [CrossRef]

- Kabir, G.; Demissie, G.; Sadiq, R.; Tesfamariam, S. Integrating failure prediction models for water mains: Bayesian belief network based data fusion. Knowl.-Based Syst. 2015, 85, 159–169. [Google Scholar] [CrossRef]

- Murphy, K. Bayesian Network Toolbox (BNT). Available online: http://www.cs.ubc.ca/murphyk/Software/BNT/bnt.html (accessed on 11 August 2017).

| F | T | F | T | F | T |

| 1 | 0 | 1 | 0 | 1 | 0 |

| 1 | 0 | 0 | 1 | 0 | 1 |

| 0 | 1 | 1 | 0 | 0 | 1 |

| 0 | 1 | 0 | 1 | 0 | 1 |

| Node | Description of Prediction Model | Lifetime Prediction Model |

|---|---|---|

| Exponential distribution | ||

| Weibull distribution | ||

| Wiener degradation process; Drift parameters are selected as the Arrhenius model | ||

| Degradation under cyclic stress |

| Node | Description of Prediction Model | Lifetime Prediction Model |

|---|---|---|

| Gamma process; Scale parameters are selected as the Arrhenius model | ||

| Wiener process |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wang, X.; Wang, L. Modeling of BN Lifetime Prediction of a System Based on Integrated Multi-Level Information. Sensors 2017, 17, 2123. https://doi.org/10.3390/s17092123

Wang J, Wang X, Wang L. Modeling of BN Lifetime Prediction of a System Based on Integrated Multi-Level Information. Sensors. 2017; 17(9):2123. https://doi.org/10.3390/s17092123

Chicago/Turabian StyleWang, Jingbin, Xiaohong Wang, and Lizhi Wang. 2017. "Modeling of BN Lifetime Prediction of a System Based on Integrated Multi-Level Information" Sensors 17, no. 9: 2123. https://doi.org/10.3390/s17092123