Evaluation of Flexible Force Sensors for Pressure Monitoring in Treatment of Chronic Venous Disorders

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sensors

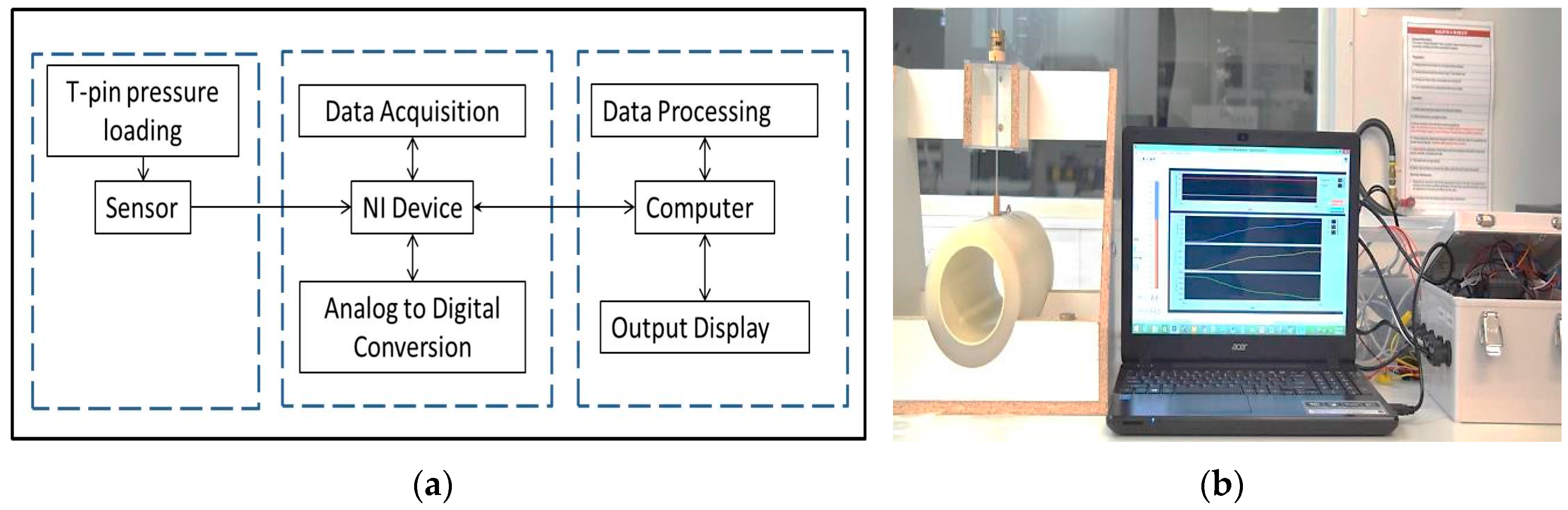

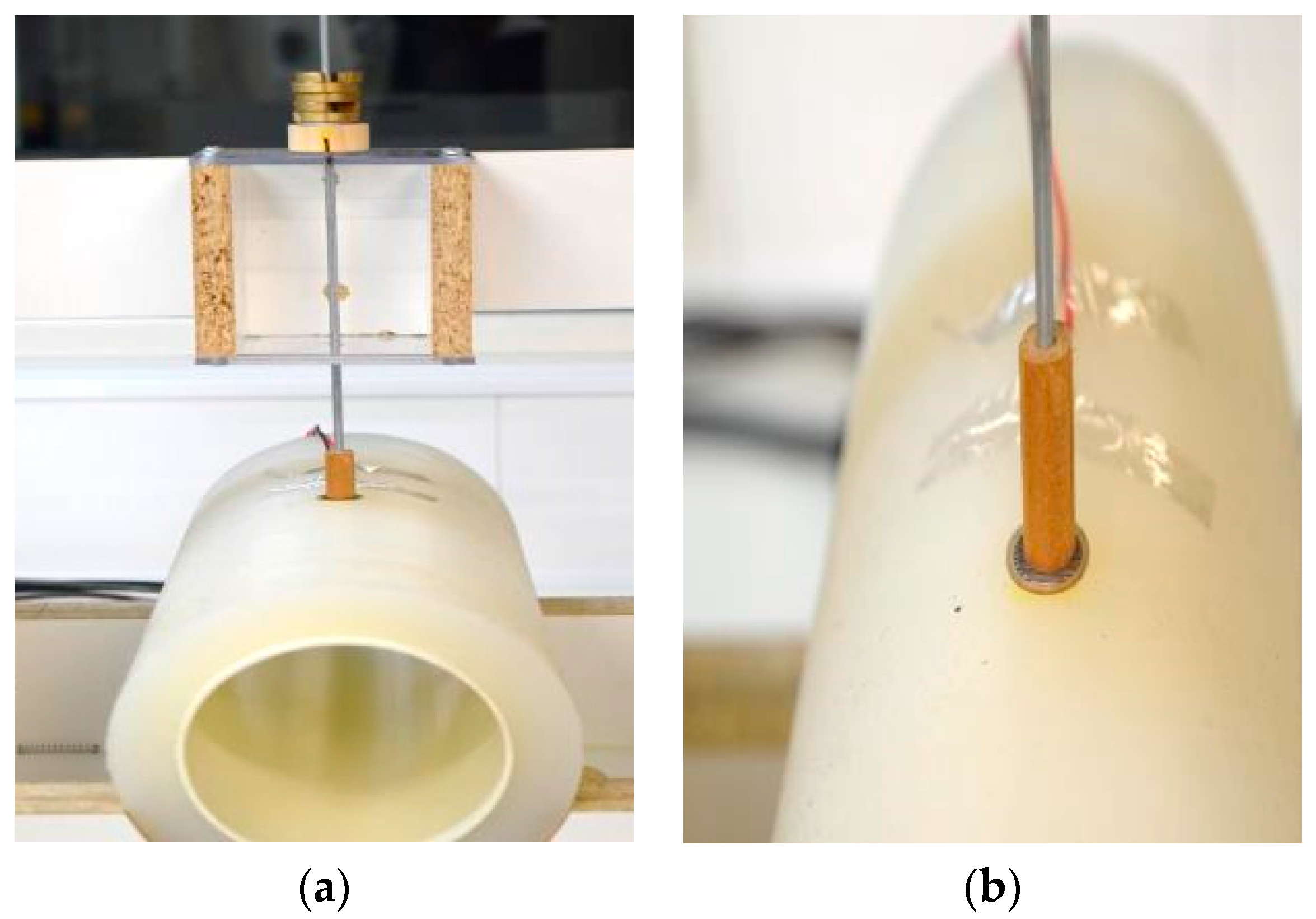

2.2. Experimental Setup

2.3. Method

2.3.1. Sensor Calibration

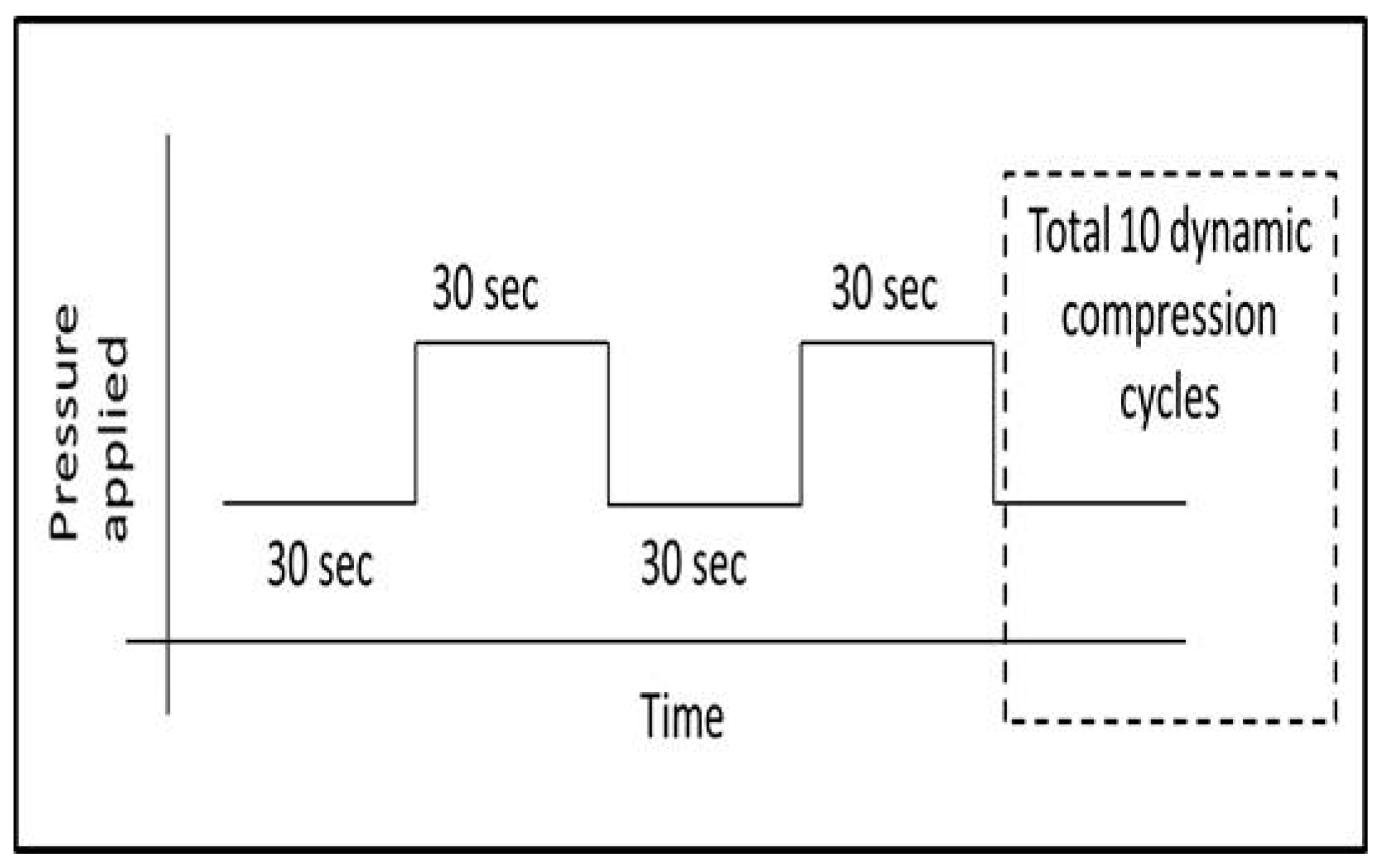

2.3.2. Loading Tests

2.4. Sensing Parameters and Data Analysis

3. Results

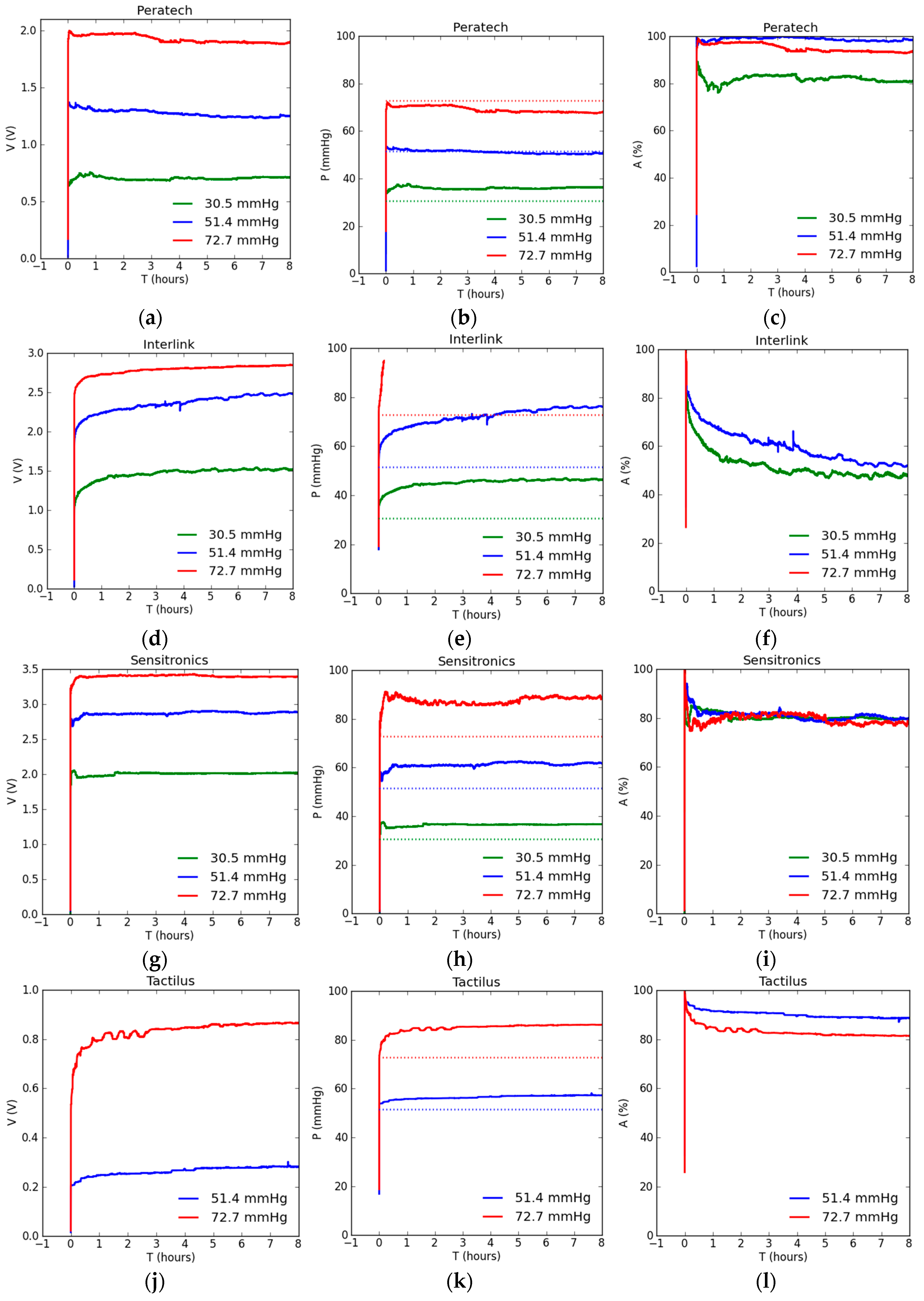

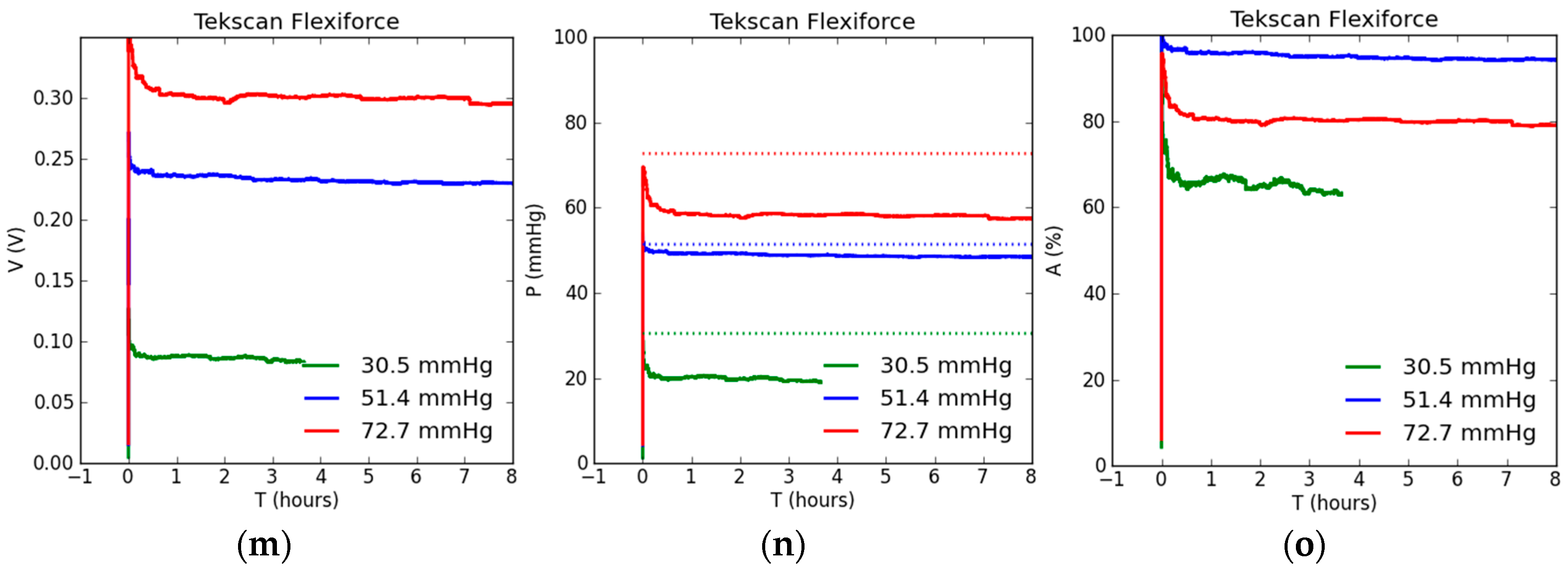

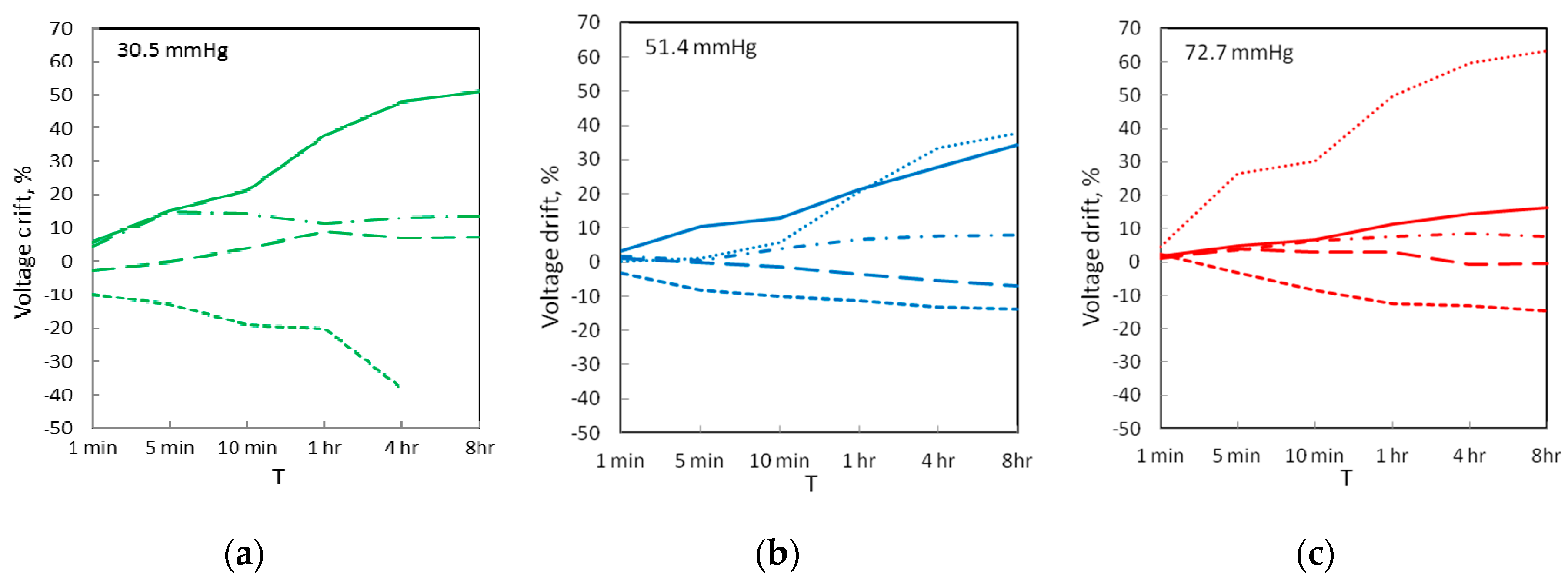

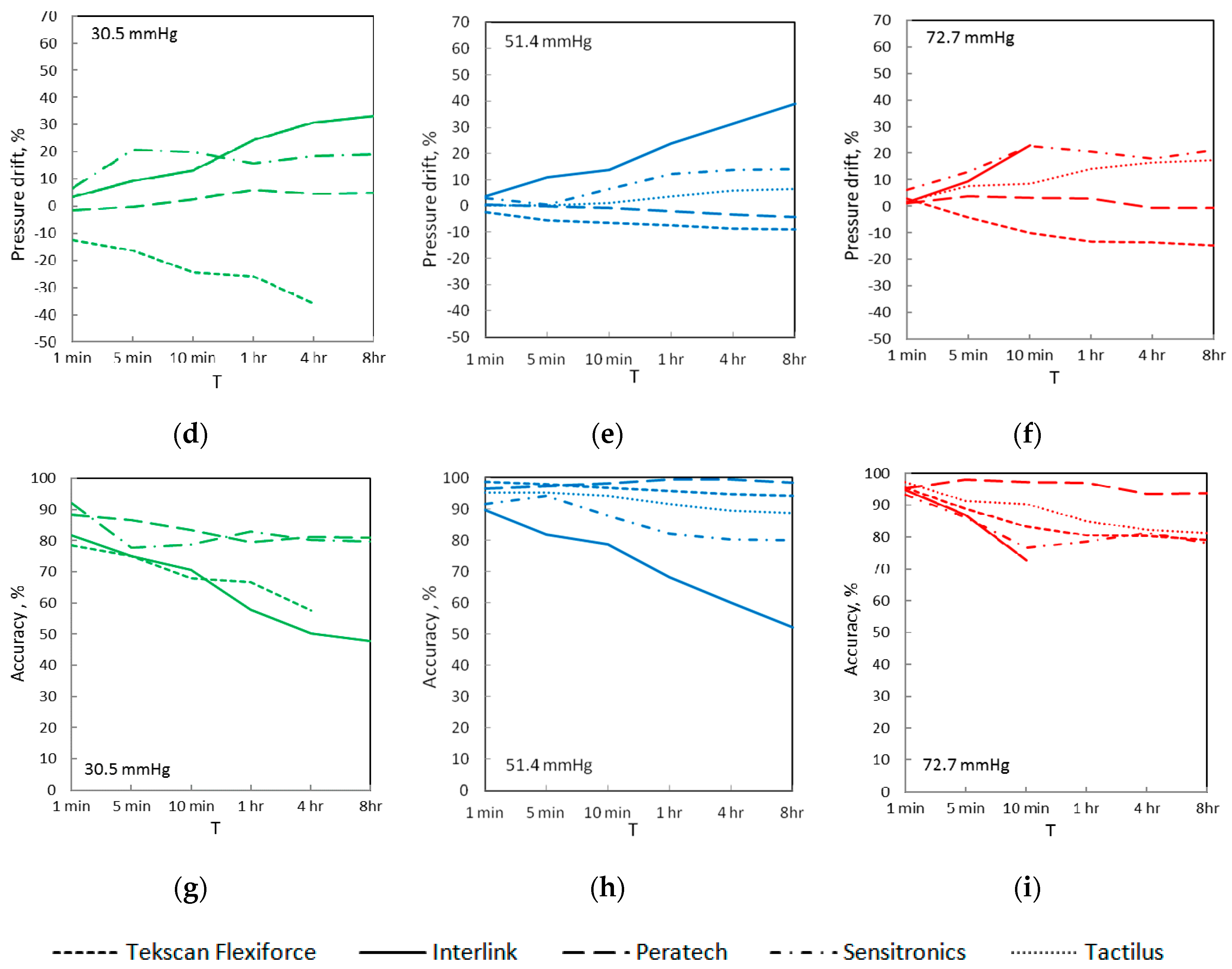

3.1. Static Evaluation

3.2. Dynamic Evaluation

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Finnie, A. Interface pressure measurements in leg ulcer management. Br. J. Nurs. 2000, 9, S8–S18. [Google Scholar] [CrossRef] [PubMed]

- Guex, J.J.; Avril, L.; Enrici, E.; Enriquez, E.; Lis, C.; Taïeb, C. Quality of life improvement in Latin American patients suffering from chronic venous disorder using a combination of ruscus aculeatus and hesperidin methyl-chalcone and ascorbic acid (quality study). Int. J. Angiol. 2010, 29, 525–532. [Google Scholar]

- Liu, R.; Guo, X.; Lao, T.T.; Little, T. A critical review on compression textiles for compression therapy: Textile-based compression interventions for chronic venous insufficiency. Text. Res. J. 2016, 87, 1121–1141. [Google Scholar] [CrossRef]

- Partsch, H.; Clark, M.; Bassez, S.; Benigni, J.P.; Becker, F.; Blazek, V.; Caprini, J.; Cornu-Thenard, A.; Hafner, J.; Flour, M. Measurement of lower leg compression in vivo: Recommendations for the performance of measurements of interface pressure and stiffness. Dermatol. Surg. 2006, 32, 224–233. [Google Scholar] [CrossRef] [PubMed]

- Principles of best practice: Compression in venous leg ulcers. In A Consensus Document: World Union of Wound Healing Societies; MEP Ltd.: London, UK, 2008.

- Medical Compression Hosiery—Quality Assurance; Technical rule Ral-GZ 387/1; Deutsches Institut für Gütesicherung und Kennzeichnung E.V. Beuth Verlag: Berlin, Germany, 2008; pp. 1–20.

- Partsch, H.; Clark, M.; Mosti, G.; Steinlechner, E.; Schuren, J.A.N.; Abel, M.; Benigni, J.-P.; Coleridge-Smith, P.; Cornu-ThÉNard, A.; Flour, M.; et al. Classification of compression bandages: Practical aspects. Dermatol. Surg. 2008, 34, 600–609. [Google Scholar] [CrossRef] [PubMed]

- Mosti, G.; Partsch, H. Compression stockings with a negative pressure gradient have a more pronounced effect on venous pumping function than graduated elastic compression stockings. Eur. J. Vasc. Endovasc. Surg. 2011, 42, 261–266. [Google Scholar] [CrossRef] [PubMed]

- Scurr, J.H.; Ibrahim, S.Z.; Faber, R.G.; Le Quesne, L.P. The efficacy of graduated compression stockings in the prevention of deep vein thrombosis. Br. J. Surg. 1977, 64, 371–373. [Google Scholar] [CrossRef] [PubMed]

- Flaud, P.; Bassez, S.; Counord, J.-L. Comparative in vitro study of three interface pressure sensors used to evaluate medical compression hosiery. Dermatol. Surg. 2010, 36, 1930–1940. [Google Scholar] [CrossRef] [PubMed]

- Partsch, B.; Partsch, H. Calf compression pressure required to achieve venous closure from supine to standing positions. J. Vasc. Surg. 2005, 42, 734–738. [Google Scholar] [CrossRef] [PubMed]

- Milic, D.J.; Zivic, S.S.; Bogdanovic, D.C.; Jovanovic, M.M.; Jankovic, R.J.; Milosevic, Z.D.; Stamenkovic, D.M.; Trenkic, M.S. The influence of different sub-bandage pressure values on venous leg ulcers healing when treated with compression therapy. J. Vasc. Surg. 2010, 51, 655–661. [Google Scholar] [CrossRef] [PubMed]

- Ferguson-Pell, M.; Hagisawa, S.; Bain, D. Evaluation of a sensor for low interface pressure applications. Med. Eng. Phys. 2000, 22, 657–663. [Google Scholar] [CrossRef]

- Mosti, G.; Rossari, S. The importance of measuring sub bandage pressure and presentation of new measuring device. Acta Vulnol. 2008, 6, 31–36. [Google Scholar]

- Damstra, R.J.; Partsch, H. Prospective, randomized, controlled trial comparing the effectiveness of adjustable compression velcro wraps versus inelastic multicomponent compression bandages in the initial treatment of leg lymphedema. J. Vasc. Surg. Venous Lymphat. Disord. 2013, 1, 13–19. [Google Scholar] [CrossRef] [PubMed]

- Lai, C.H.Y.; Li-Tsang, C.W.P. Validation of the Pliance X System in measuring interface pressure generated by pressure garment. Burns 2009, 35, 845–851. [Google Scholar] [CrossRef] [PubMed]

- Thomas, S. Practical limitations of two devices used for the measurement of sub-bandage pressure: Implications for clinical practice. J. Wound Care 2014, 23, 302–306. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Nie, B.; Zhai, C.; Cao, J.; Pan, J.; Chi, Y.-W.; Pan, T. Telemedical wearable sensing platform for management of chronic venous disorder. Ann. Biomed. Eng. 2016, 44, 2282–2291. [Google Scholar] [CrossRef] [PubMed]

- Mitrakos, V.; Macintyre, L.; Denison, F.; Hands, P.; Desmulliez, M. Design, manufacture and testing of capacitive pressure sensors for low-pressure measurement ranges. Micromachines 2017, 8, 41. [Google Scholar] [CrossRef]

- Parmar, S.; Bafekrpour, E.; Fuss, F.K.; Troynikov, O. Design and characterization of flexible pressure sensors for integration in smart medical textiles. In Proceedings of the 9th Textile Bioengineering and Informatics Symposium (TBIS 2016), Melbourne, Australia, 12–15 July 2016; pp. 1019–1027. [Google Scholar]

- Sepúlveda, A.; De Villoria, R.G.; Viana, J.; Pontes, A.; Wardle, B.; Rocha, L.A. Flexible pressure sensors: Modeling and experimental characterization. Procedia Eng. 2012, 47, 1177–1180. [Google Scholar] [CrossRef]

- Kumar, B.; Hu, J.; Pan, N. Smart medical stocking using memory polymer for chronic venous disorders. Biomaterials 2016, 75, 174–181. [Google Scholar] [CrossRef] [PubMed]

- Parmar, S.; Bafekrpour, E.; Fuss, F.K.; Troynikov, O. Evaluation of pressure sensors based on piezoresistive films for integration in smart medical textiles. In Proceedings of the 9th Textile Bioengineering and Informatics Symposium (TBIS 2016), Melbourne, Australia, 12–15 July 2016; Li, Y., Padhye, R., Eds.; Curran Associates, Inc.: Red Hook, NY, USA, 2016; pp. 951–958. [Google Scholar]

- Rabe, E.; Partsch, H.; Jünger, M.; Abel, M.; Achhammer, I.; Becker, F.; Cornu-Thenard, A.; Flour, M.; Hutchinson, J.; Ißberner, K.; et al. Guidelines for clinical studies with compression devices in patients with venous disorders of the lower limb. Eur. J. Vasc. Endovasc. Surg. 2008, 35, 494–500. [Google Scholar] [CrossRef] [PubMed]

- Partsch, H.; Flour, M.; Smith, P.C. Indications for compression therapy in venous and lymphatic disease consensus based on experimental data and scientific evidence. Under the auspices of the IUP. Int. J. Angiol. 2008, 27, 193–219. [Google Scholar]

- Komi, E.R.; Roberts, J.R.; Rothberg, S. Evaluation of thin, flexible sensors for time-resolved grip force measurement. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2007, 221, 1687–1699. [Google Scholar] [CrossRef]

- Peratech Holdco Ltd. Peratech QTC® SP200 Series Datasheet Single Point Sensors. Available online: https://www.peratech.com/assets/uploads/datasheets/Peratech-QTC-DataSheet-SP200-Series-Nov15.pdf (accessed on 17 July 2017).

- Interlink Electronics Inc. FSR 400 Series Data Sheet. Available online: https://www.interlinkelectronics.com/datasheets/Datasheet_FSR.pdf (accessed on 17 July 2017).

- Sensitronics Inc. Available online: http://www.sensitronics.com/products-half-inch-thru-mode-fsr.php (accessed on 17 July 2017).

- Sensor Products Inc. Tactilus Free from Sensor System. Available online: http://www.sensorprod.com/pdf/Tactilus-Free-Form.pdf (accessed on 17 July 2017).

- Tekscan Inc. Available online: https://www.tekscan.com/products-solutions/force-sensors/a301 (accessed on 17 July 2017).

- Almassri, A.M.; Abuitbel, M.B.; WanHasan, W.; Ahmad, S.A.; Sabry, A.H. In Real-time control for robotic hand application based on pressure sensor measurement. In Proceedings of the IEEE International Symposium on Robotics and Manufacturing Automation (ROMA), Kuala Lumpur, Malaysia, 15–16 December 2014; pp. 80–85. [Google Scholar]

- Ali, A.M.M.; Ambar, R.; Jamil, M.M.A.; Wahi, A.J.M.; Salim, S. Artificial hand gripper controller via smart glove for rehabilitation process. In Proceedings of the 2012 International Conference on Biomedical Engineering (ICoBE), Penang, Malaysia, 27–28 February 2012; pp. 300–304. [Google Scholar]

- Miqdad, A.; Suhairi, R.; Ali, A.M.M.; Roslan, N.F.; Aziz, P.D.A. Development of artificial hand gripper by using flex force sensor. In Proceedings of the 2014 4th International Conference on Engineering Technology and Technopreneuship (ICE2T), Kuala Lumpur, Malaysia, 27–29 August 2014; pp. 305–308. [Google Scholar]

- Wang, Y.-T.; Chen, Y.; Tsai, C.-L.; Chang, J.-H. Calibration of pressure sensors for hand grip measurement. In Proceedings of the 2016 ISBS Conference, Tsukuba, Japan, 18–22 July 2016. [Google Scholar]

- Schmidt, E.; Roberts, J.; Rothberg, S. Time-resolved measurements of grip force during a golf shot. Eng. Sport 6 2006, 57–62. [Google Scholar]

- Vecchi, F.; Freschi, C.; Micera, S.; Sabatini, A.M.; Dario, P.; Sacchetti, R. Experimental evaluation of two commercial force sensors for applications in biomechanics and motor control. In Proceedings of the 5th Annual Conference of International Functional Electrical Stimulation Society, Aalborg, Denmark, 18–20 June 2000. [Google Scholar]

- Bachus, K.N.; DeMarco, A.L.; Judd, K.T.; Horwitz, D.S.; Brodke, D.S. Measuring contact area, force, and pressure for bioengineering applications: Using Fuji Film and Tekscan systems. Med. Eng. Phys. 2006, 28, 483–488. [Google Scholar] [CrossRef] [PubMed]

- Polliack, A.; Sieh, R.; Craig, D.; Landsberger, S.; McNeil, D.; Ayyappa, E. Scientific validation of two commercial pressure sensor systems for prosthetic socket fit. Prosthet. Orthotic. Int. 2000, 24, 63–73. [Google Scholar] [CrossRef] [PubMed]

- Pirouzi, G.; Abu Osman, N.; Eshraghi, A.; Ali, S.; Gholizadeh, H.; Wan Abas, W. Review of the socket design and interface pressure measurement for transtibial prosthesis. Sci. World J. 2014, 2014, 849073. [Google Scholar] [CrossRef] [PubMed]

- Polliack, A.; Craig, D.; Sieh, R.; Landsberger, S.; McNeal, D. Laboratory and clinical tests of a prototype pressure sensor for clinical assessment of prosthetic socket fit. Prosthet. Orthotic. Int. 2002, 26, 23–34. [Google Scholar] [CrossRef] [PubMed]

- Dumbleton, T.; Buis, A.W.; McFadyen, A.; McHugh, B.F.; McKay, G.; Murray, K.D.; Sexton, S. Dynamic interface pressure distributions of two transtibial prosthetic socket concepts. J. Rehabil. Res. Dev. 2009, 46, 405–415. [Google Scholar] [CrossRef] [PubMed]

- Wilson, D.C.; Niosi, C.A.; Zhu, Q.A.; Oxland, T.R.; Wilson, D.R. Accuracy and repeatability of a new method for measuring facet loads in the lumbar spine. J. Biomech. 2006, 39, 348–353. [Google Scholar] [CrossRef] [PubMed]

- Hollinger, A.; Wanderley, M.M. Evaluation of commercial force-sensing resistors. In Proceedings of the International Conference on New Interfaces for Musical Expression, Paris, France, 4–8 June 2006. [Google Scholar]

- Lebosse, C.; Renaud, P.; Bayle, B.; de Mathelin, M. Modeling and evaluation of low-cost force sensors. IEEE Trans. Robot. 2011, 27, 815–822. [Google Scholar] [CrossRef]

- Lussey, D.; Peratech Ltd. UK Patent PCT/GB98/00206 (WO 98/33193), 1998.

- Bloor, D.; Donnelly, K.; Hands, P.; Laughlin, P.; Lussey, D. A metal–polymer composite with unusual properties. J. Phys. D Appl. Phys. 2005, 38, 2851. [Google Scholar] [CrossRef]

- Troynikov, O.; Ashayeri, E. 3D body scanning method for close-fitting garments in sport and medical applications. In Proceedings of the 47th Annual Conference of Human Factors and Ergonomics Society of Australia (HFESA), Crows Nest, Australia, 7–9 November 2011; pp. 11–16. [Google Scholar]

- Derler, S.; Spierings, A.B.; Schmitt, K.U. Anatomical hip model for the mechanical testing of hip protectors. Med. Eng. Phys. 2005, 27, 475–485. [Google Scholar] [CrossRef] [PubMed]

- Nawaz, N.; Troynikov, O.; Watson, C. Evaluation of surface characteristics of fabrics suitable for skin layer of firefighters’ protective clothing. Phys. Procedia 2011, 22, 478–486. [Google Scholar] [CrossRef]

- Troynikov, O.; Nawaz, N.; Vu, S. Evaluation of surface characteristics of inner layer fabrics suitable for structural firefighters’ clothing. Text. Res. J. 2012, 82, 1014–1025. [Google Scholar] [CrossRef]

| Sensor | Manufacturer | Sensing Area | Claimed Operating Range |

|---|---|---|---|

| QTC™ SP 200-10 | Peratech Holdco Ltd. | 10 mm | 0.1–20 N [27] |

| FSR® 402 | Interlink Electronics Inc. | 14.7 mm | ~0.2–20 N [28] |

| Half Inch ThruMode FSR | Sensitronics Inc. | 12.7 mm | 0.3–30 psi [29] |

| Tactilus® | Sensor Products Inc. | 12.5 mm | 0–400 psi [30] |

| Flexiforce® A 301 | Tekscan Inc. | 9.53 mm | 0–1 lb [31] |

| Disc | Applied Weight (g) | Calculated Pressure (mmHg) |

|---|---|---|

| t-pin platform | 16.64 | 17.63 |

| +Weight 1 | 18.97 | 20.10 |

| +Weight 2 | 28.80 | 30.51 |

| +Weight 3 | 38.66 | 40.96 |

| +Weight 4 | 48.53 | 51.42 |

| +Weight 5 | 58.57 | 62.05 |

| +Weight 6 | 68.62 | 72.70 |

| +Weight 7 | 78.69 | 83.37 |

| +Weight 8 | 88.75 | 94.03 |

| Sensor | Accuracy (%) | ||

|---|---|---|---|

| 30.5 mmHg | 51.4 mmHg | 72.7 mmHg | |

| Peratech | 83.7 | 98.1 | 95.6 |

| Interlink | 67.0 | 74.9 | - |

| Sensitronics | 84.3 | 87.2 | 84.9 |

| Tactilus | - | 92.8 | 89.5 |

| Tekscan Flexiforce | 70.4 | 96.4 | 85.8 |

| Sensor | Accuracy (%) | ||

|---|---|---|---|

| 30.5 mmHg | 51.4 mmHg | 72.7 mmHg | |

| Peratech | 94.8 ± 2.9 | 96.0 ± 2.1 | 96.0 ± 2.2 |

| Interlink | 97.7 ± 1.1 | 94.4 ± 1.7 | 88.3 ± 1.9 |

| Sensitronics | 90.8 ± 6.1 | 94.0 ± 3.1 | 92.6 ± 2.6 |

| Tactilus | - | 87.9 ± 3.8 | 90.3 ± 2.1 |

| Tekscan Flexiforce | 64.1 ± 7.4 | 89.4 ± 5.0 | 82.0 ± 4.1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parmar, S.; Khodasevych, I.; Troynikov, O. Evaluation of Flexible Force Sensors for Pressure Monitoring in Treatment of Chronic Venous Disorders. Sensors 2017, 17, 1923. https://doi.org/10.3390/s17081923

Parmar S, Khodasevych I, Troynikov O. Evaluation of Flexible Force Sensors for Pressure Monitoring in Treatment of Chronic Venous Disorders. Sensors. 2017; 17(8):1923. https://doi.org/10.3390/s17081923

Chicago/Turabian StyleParmar, Suresh, Iryna Khodasevych, and Olga Troynikov. 2017. "Evaluation of Flexible Force Sensors for Pressure Monitoring in Treatment of Chronic Venous Disorders" Sensors 17, no. 8: 1923. https://doi.org/10.3390/s17081923