Enhanced Strain Measurement Range of an FBG Sensor Embedded in Seven-Wire Steel Strands

Abstract

:1. Introduction

2. Seven-Wire Steel Strand with an Embedded FBG Sensor

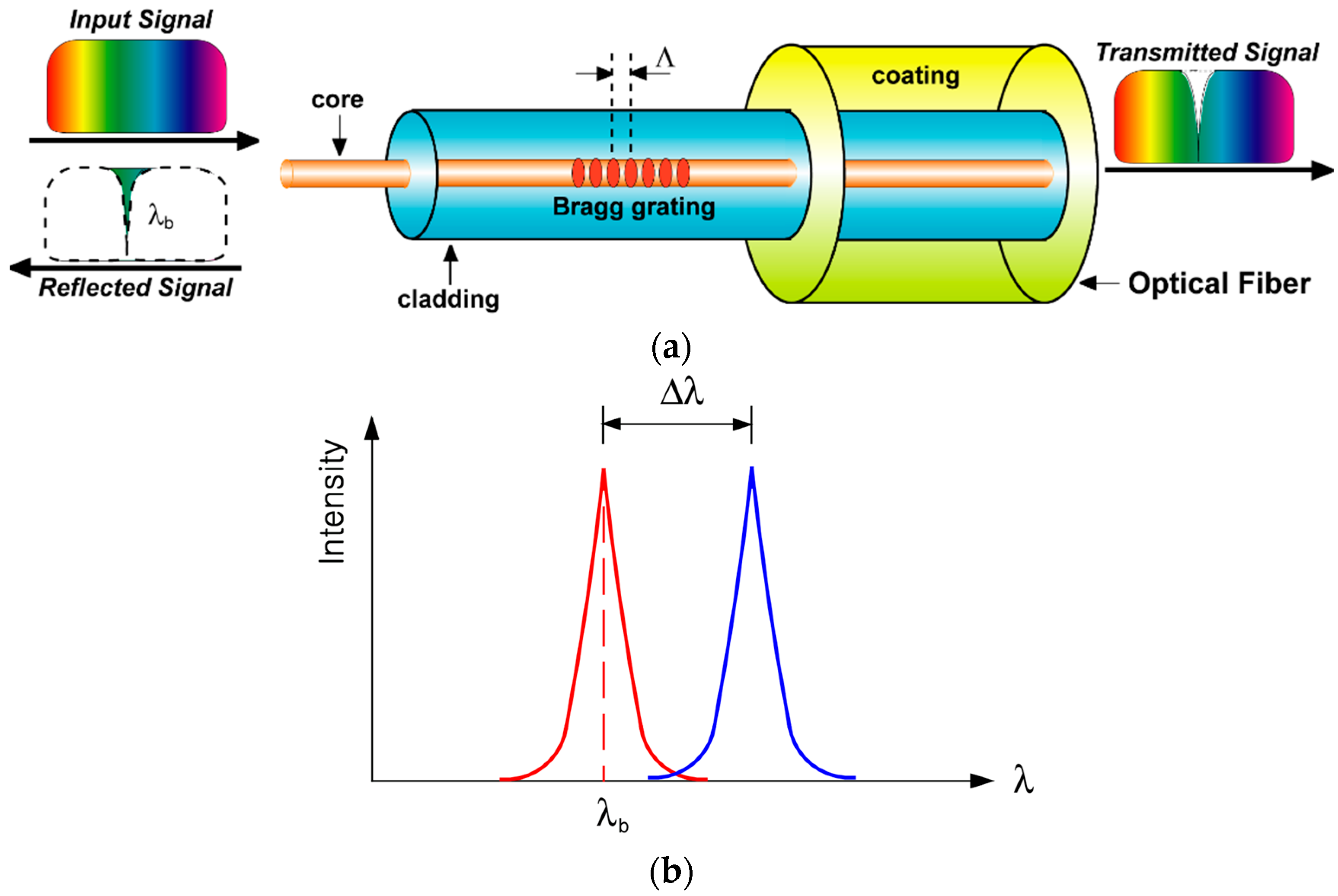

2.1. FBG Sensor

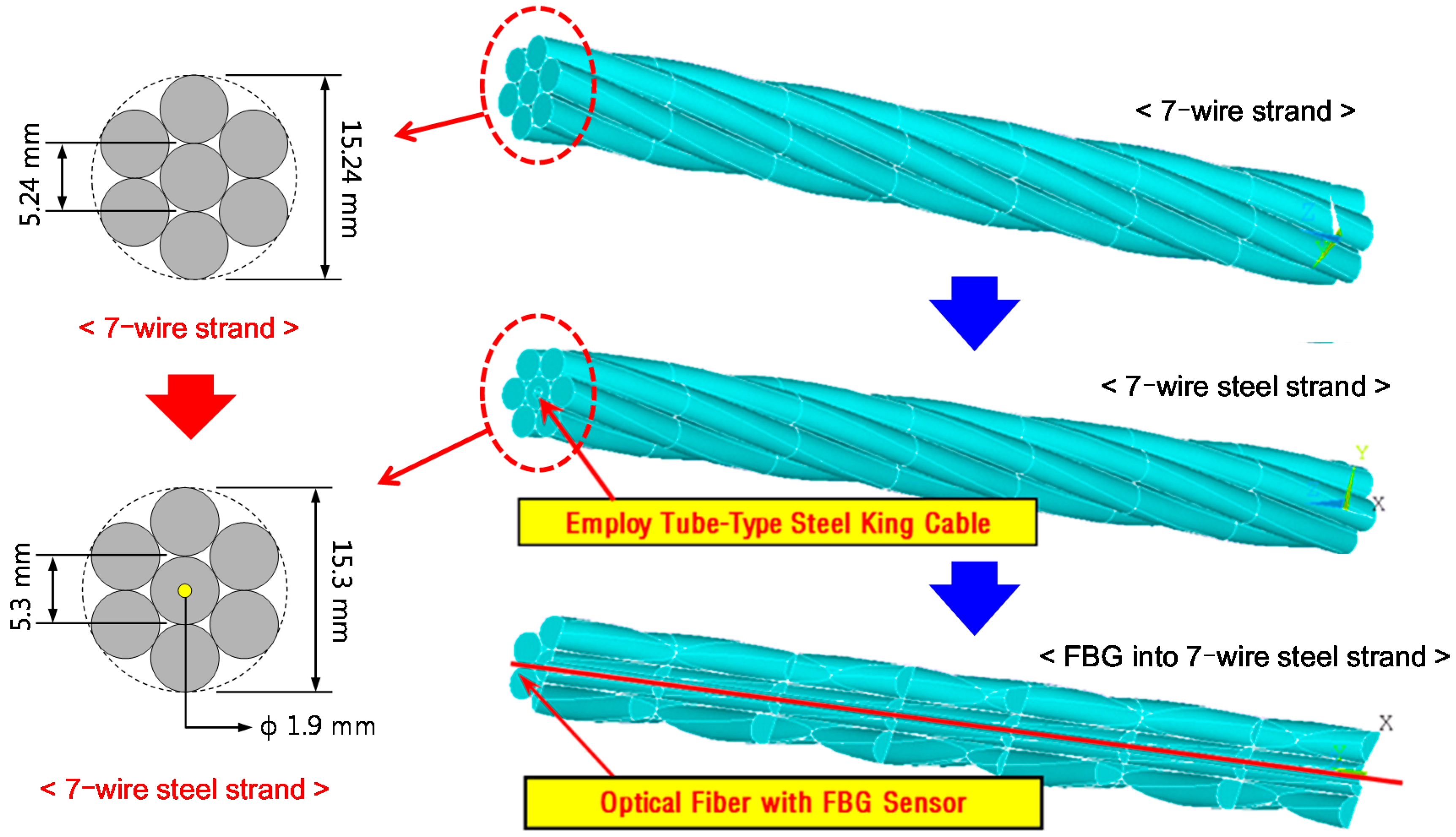

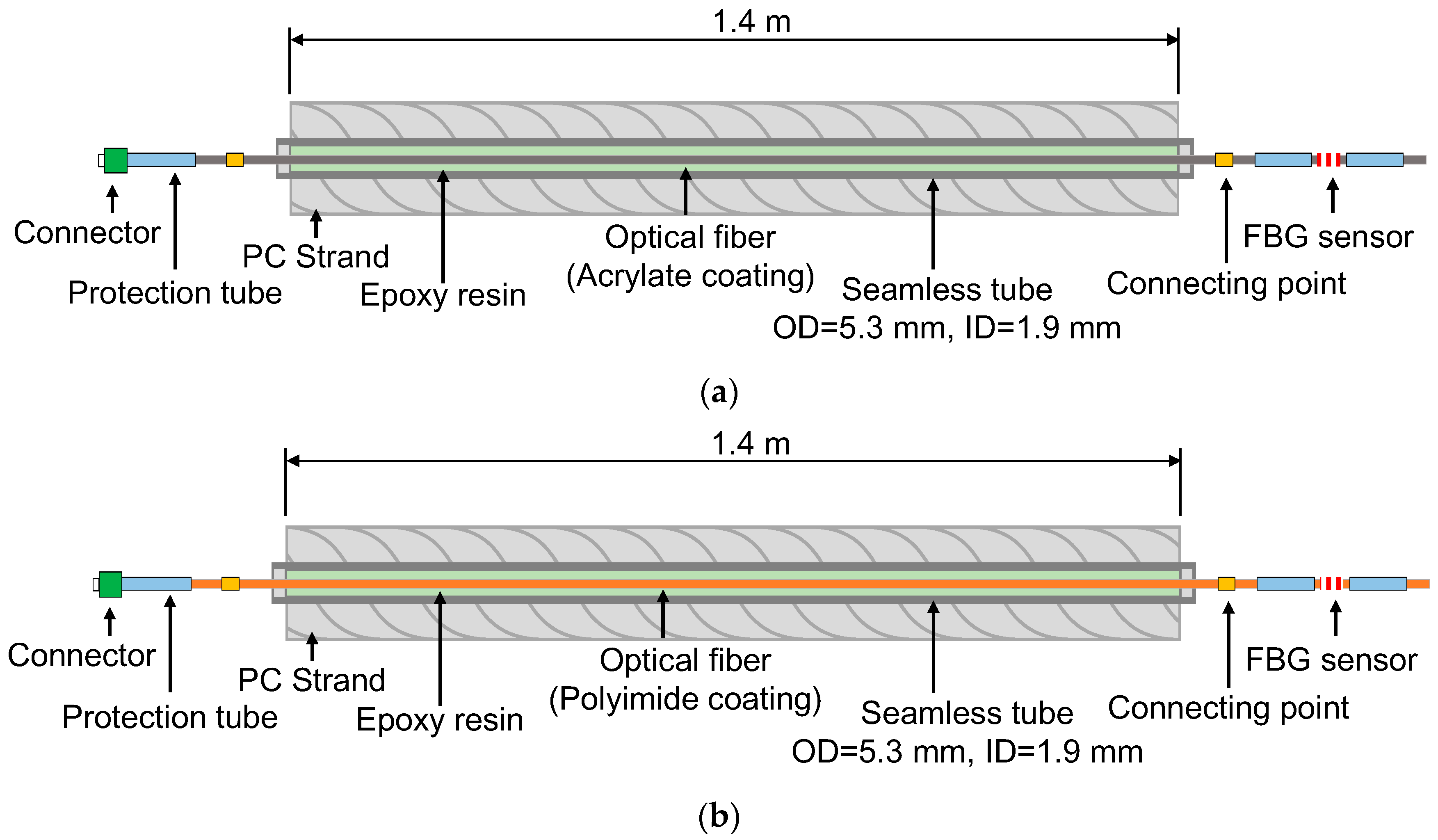

2.2. Structure of the Seven-Wire Steel Strand with an Embedded FBG Sensor

3. Limitations and Performance Enhancements of FBG Sensors Embedded in Seven-Wire Steel Strands

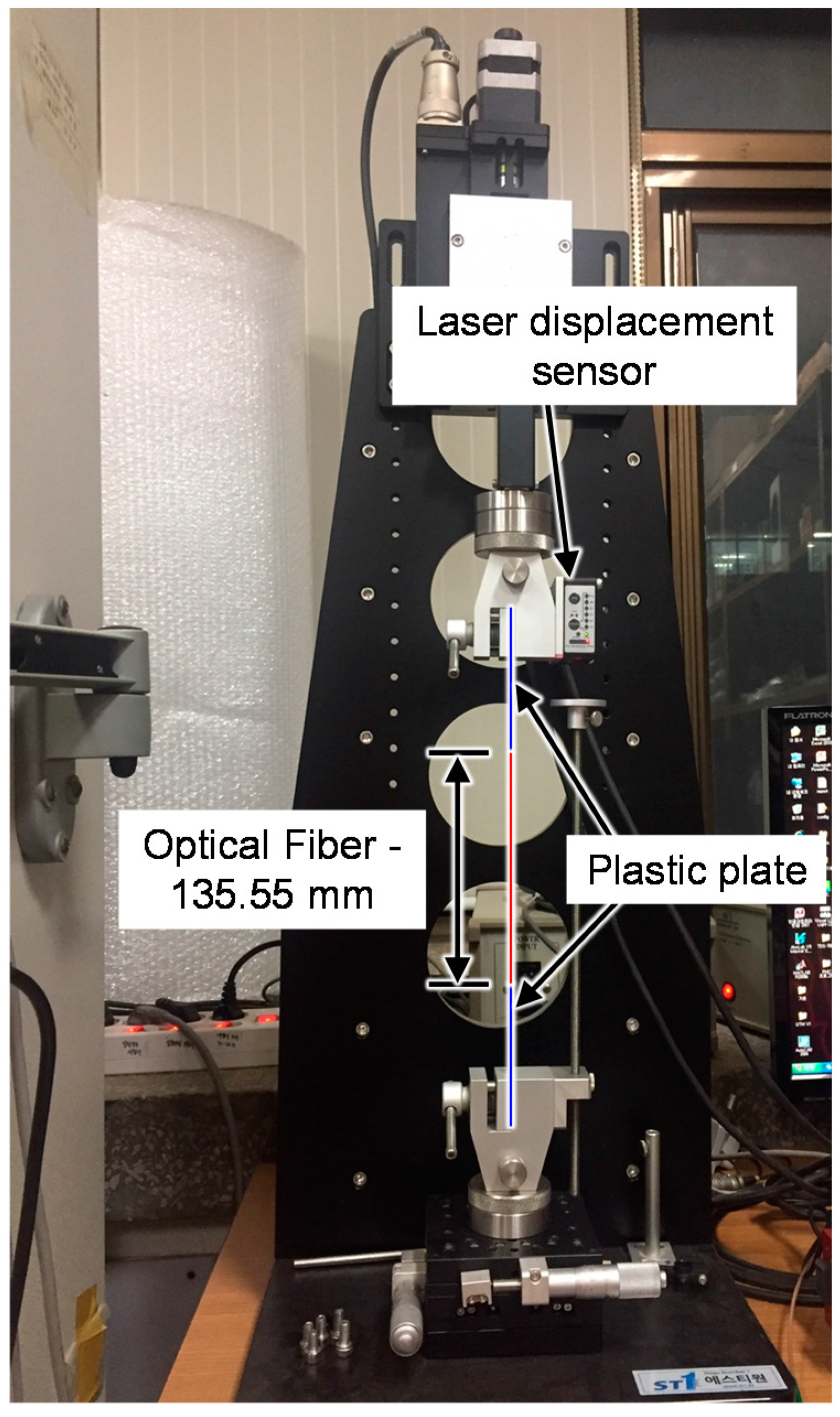

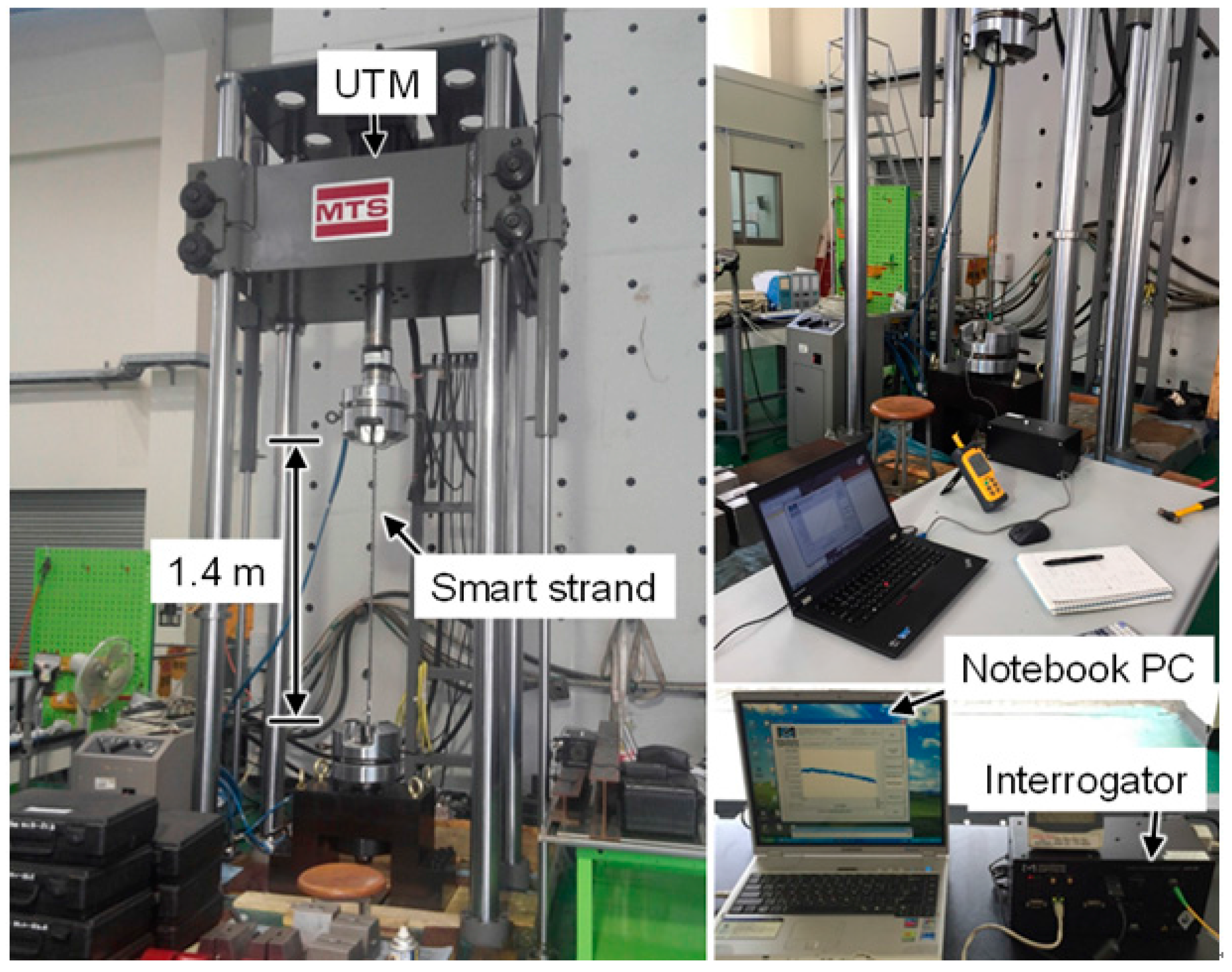

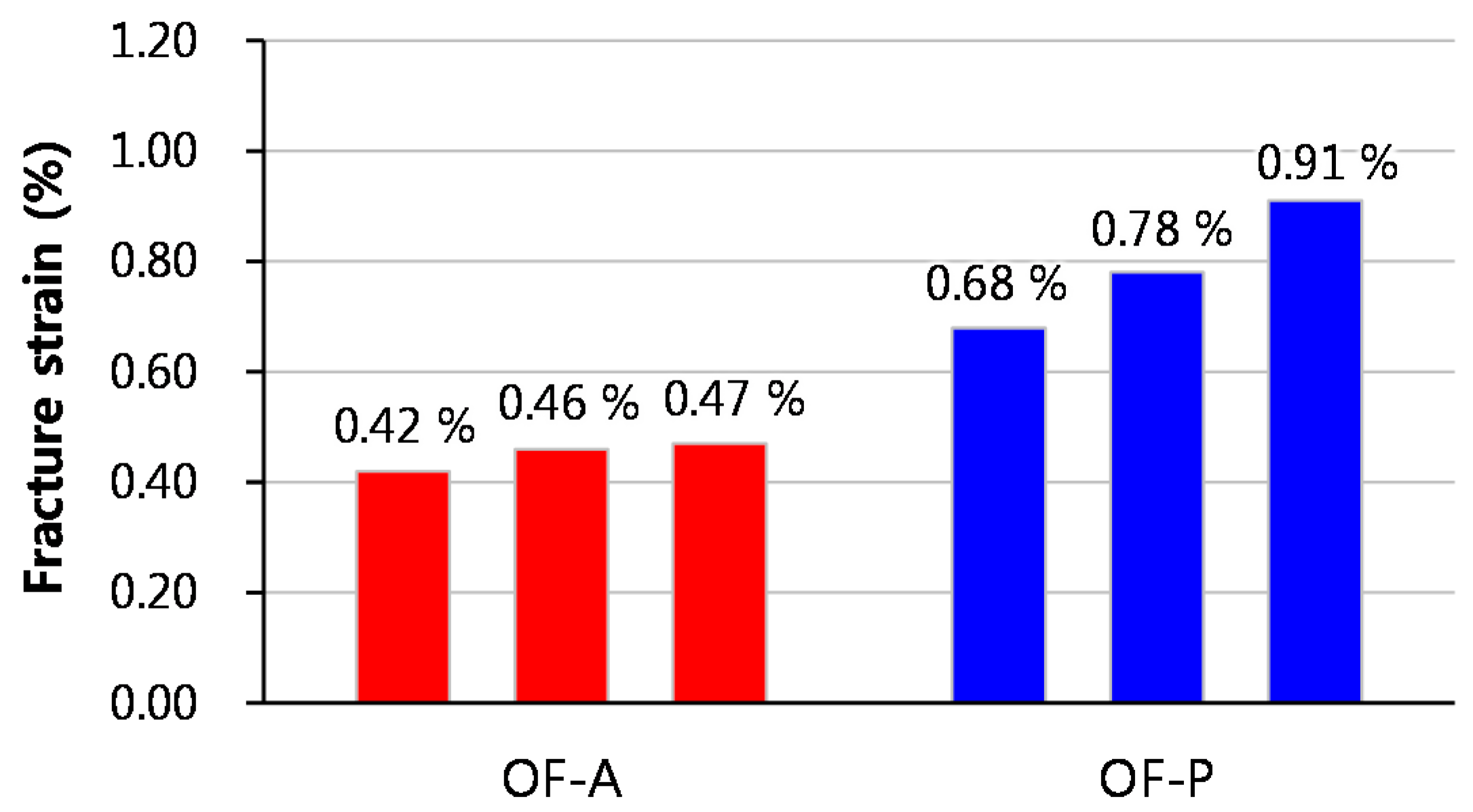

3.1. Effect of the Coating Type on the Maximum Strain Measurement Range of Optical Fiber

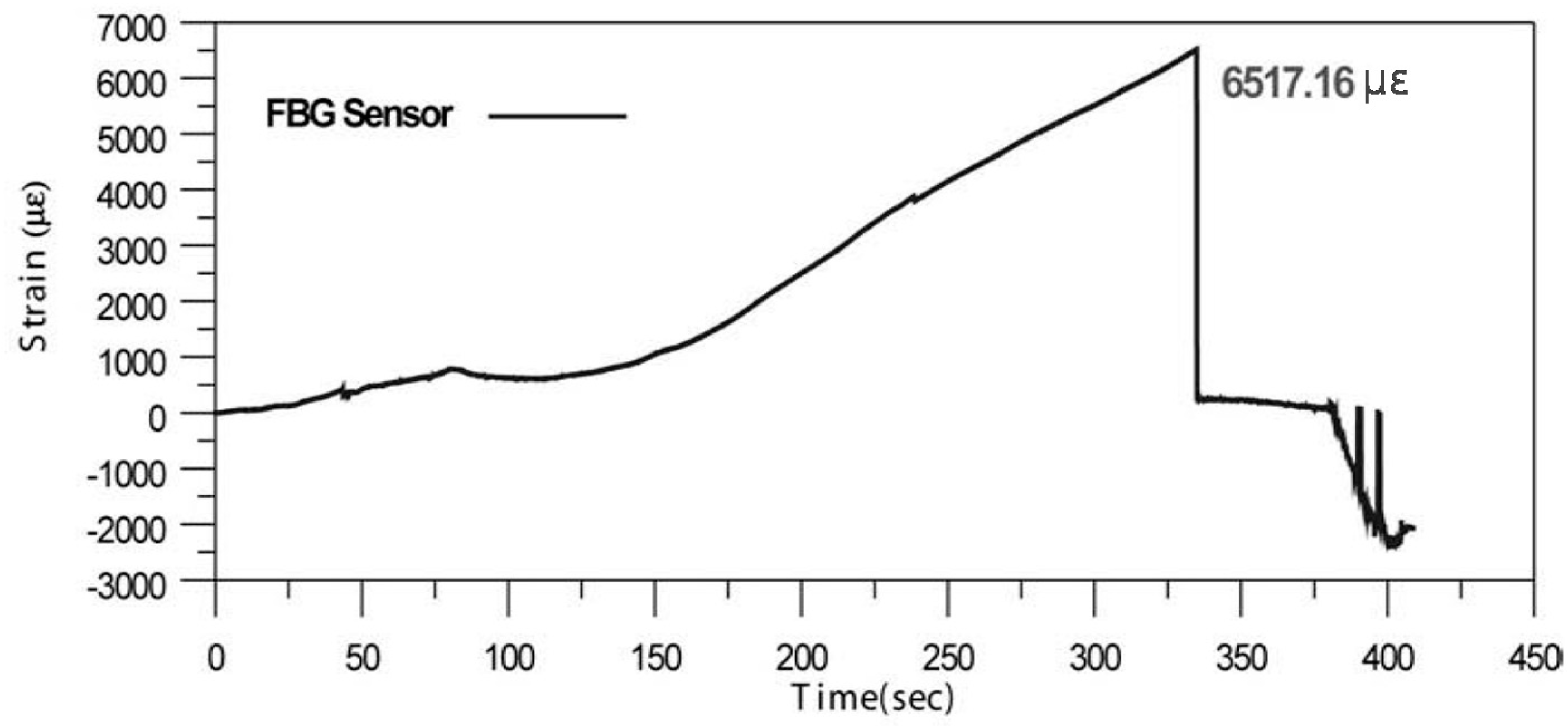

3.2. Effect of the Coating Type on the Maximum Strain Measurement Range of an Optical Fiber Embedded in a Strand

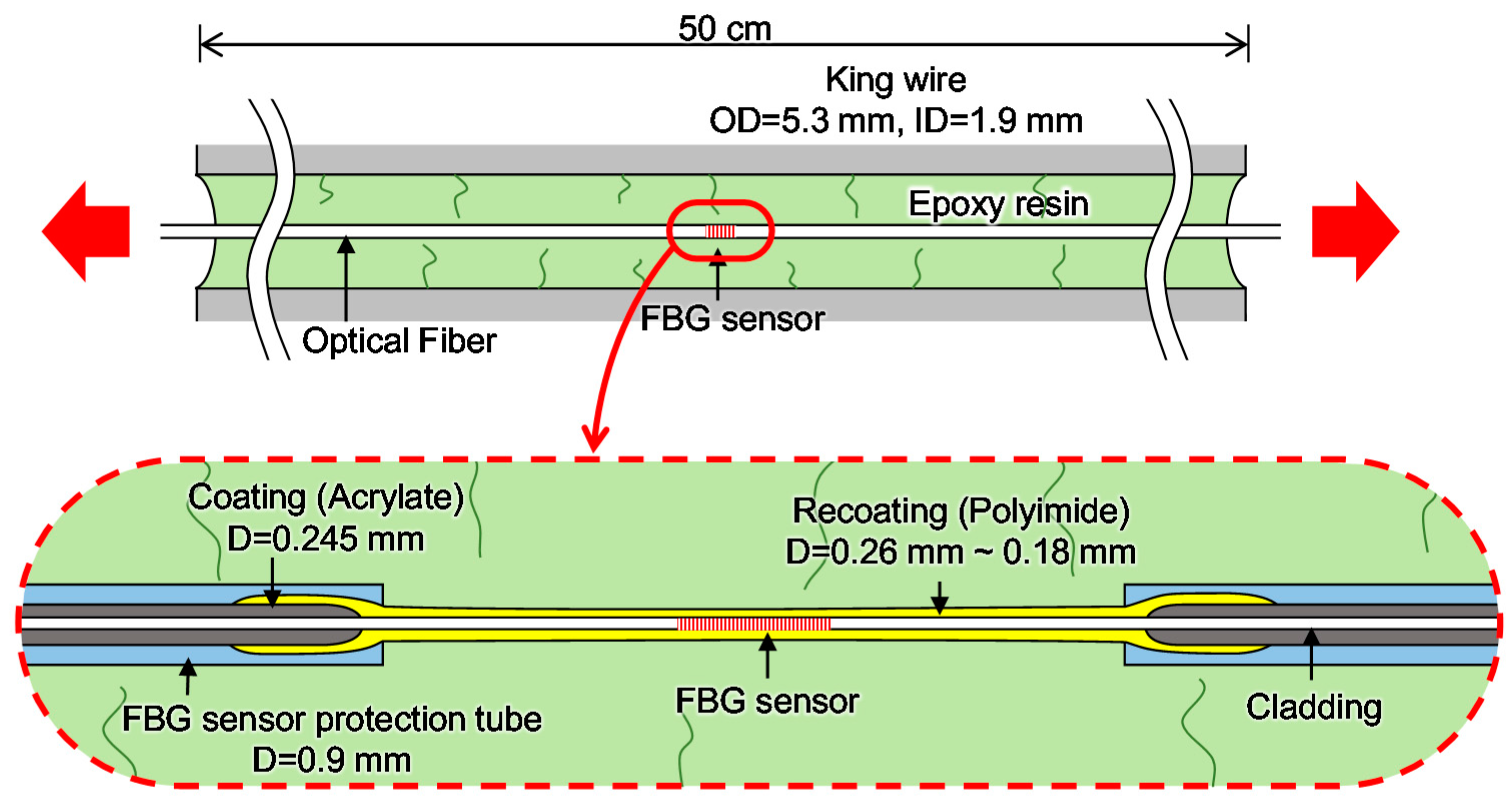

3.3. Enhancement Method of the Maximum Strain Measurement Range

3.4. Validation of the Proposed Method

4. Conclusions

- The fracture strain of an optical fiber recoated with acrylate was 0.45%. On the other hand, the fracture strain of an optical fiber recoated with polyimide was 0.79%, which is 75% higher than that of the optical fiber recoated with acrylate. From these test results, it was confirmed that the fracture strain of optical fibers can be increased by recoating the optical fibers with polyimide.

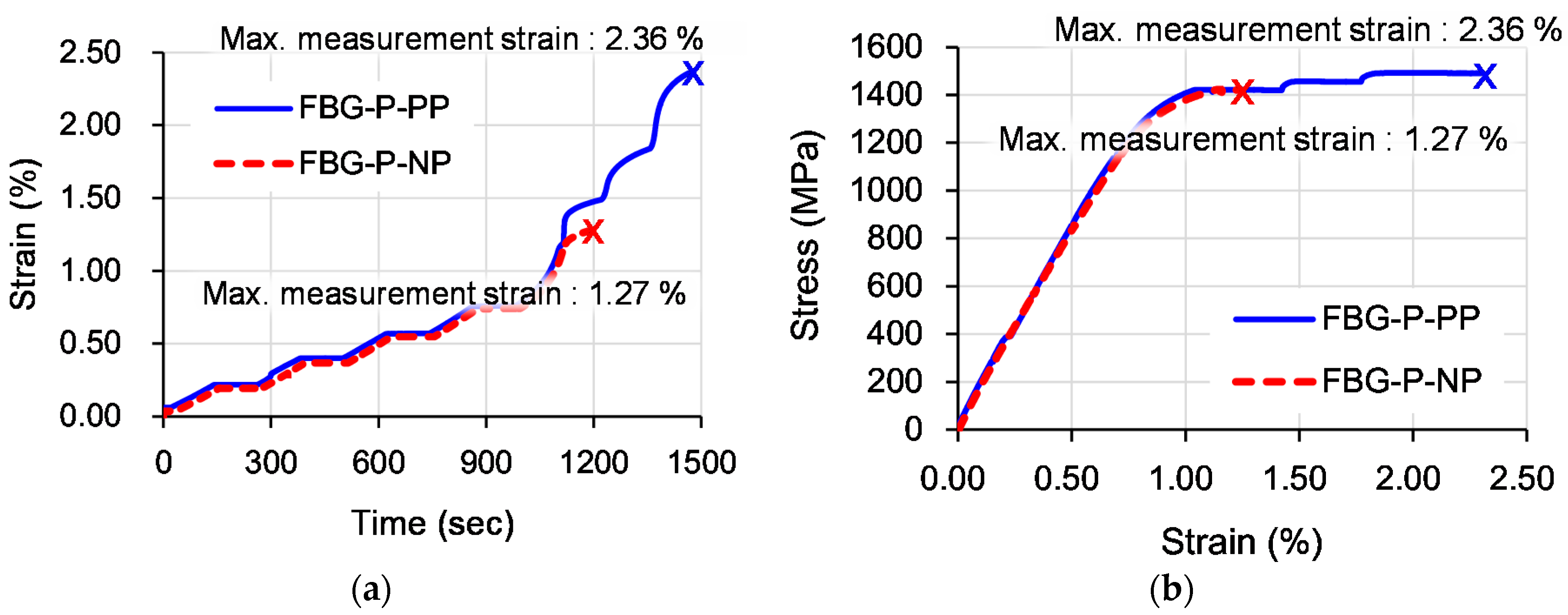

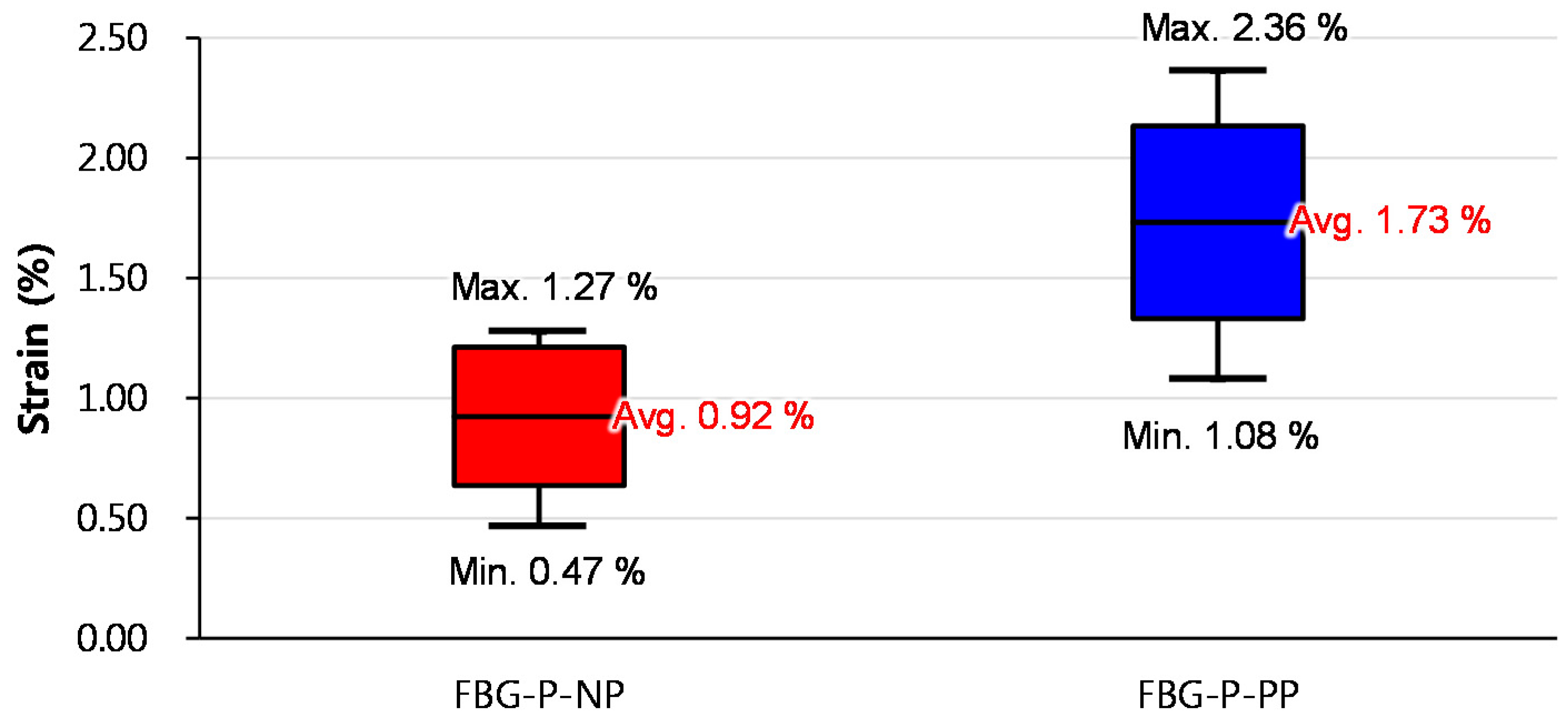

- The maximum strain measurement range of a normal FBG sensor embedded in a strand was 0.92%. On the other hand, the maximum strain measurement range of the new FBG sensor, which was protected by the polyimide tube, embedded in a strand was 1.73%, which was 88% higher than that of the normal FBG sensor.

- All steel strand specimens adopting the new FBG sensing system, in which the optical fiber was recoated with polyimide and the FBG sensor was protected by the polyimide tube, showed higher maximum strain measurement ranges which exceeded 1.0%, which is the yield strain of the steel strands used, with measurement possible up to a strain level of 2.36%. Therefore, the new FBG sensing technique can be effectively applied to monitor the strain on strands in PSC structures.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jang, S.; Jo, H.; Cho, S.; Mechitov, K.; Rice, J.A.; Sim, S.-H.; Jung, H.-J.; Yun, C.-B.; Spencer, B.F., Jr.; Agha, G. Structural health monitoring of a cable-stayed bridge using smart sensor technology: Deployment and evaluation. Smart Struct. Syst. 2010, 6, 439–459. [Google Scholar] [CrossRef]

- Kim, J.; Kim, H.; Kim, Y.; Park, Y. Tension monitoring of a prestressing strand for concrete bridge using in-tendon FBG sensors. In Proceedings of the Fifth International Conference on Bridge Maintenance, Safety and Management, Philadelphia, PA, USA, 11–15 July 2010; p. 93. [Google Scholar]

- Ko, J.; Ni, Y. Technology developments in structural health monitoring of large-scale bridges. Eng. Struct. 2005, 27, 1715–1725. [Google Scholar] [CrossRef]

- Ou, J.; Li, H. Structural health monitoring in mainland China: Review and future trends. Struct. Health Monit. 2010, 9, 219–231. [Google Scholar]

- Sumitro, S.; Jarosevic, A.; Wang, M.L. Elasto-Magnetic Sensor Utilization on Steel Cable Stress Measurement. In Proceedings of the First FIB Congress, Osaka, Japan, 13–19 October 2002; pp. 13–19. [Google Scholar]

- Watkins, S.E. Smart bridges with fiber-optic sensors. IEEE Instrum. Meas. Mag. 2003, 6, 25–30. [Google Scholar] [CrossRef]

- Ye, X.; Su, Y.; Han, J. Structural health monitoring of civil infrastructure using optical fiber sensing technology: A comprehensive review. Sci. World J. 2014, 2014, 652329. [Google Scholar] [CrossRef] [PubMed]

- Chan, T.H.; Yu, L.; Tam, H.-Y.; Ni, Y.-Q.; Liu, S.; Chung, W.; Cheng, L. Fiber Bragg grating sensors for structural health monitoring of Tsing Ma bridge: Background and experimental observation. Eng. Struct. 2006, 28, 648–659. [Google Scholar] [CrossRef]

- Kim, Y.-S.; Sung, H.-J.; Kim, H.-W.; Kim, J.-M. Monitoring of tension force and load transfer of ground anchor by using optical FBG sensors embedded tendon. Smart Struct. Syst. 2011, 7, 303–317. [Google Scholar] [CrossRef]

- Li, H.-N.; Li, D.-S.; Song, G.-B. Recent applications of fiber optic sensors to health monitoring in civil engineering. Eng. Struct. 2004, 26, 1647–1657. [Google Scholar] [CrossRef]

- López-Higuera, J.M.; Cobo, L.R.; Incera, A.Q.; Cobo, A. Fiber optic sensors in structural health monitoring. J. Lightwave Technol. 2011, 29, 587–608. [Google Scholar] [CrossRef]

- Mufti, A.A. Structural health monitoring of innovative Canadian civil engineering structures. Struct. Health Monit. 2002, 1, 89–103. [Google Scholar] [CrossRef]

- Rizkalla, S.; Tadros, G. First smart highway bridge in Canada. Concr. Int. 1994, 16, 42–44. [Google Scholar]

- Udd, E. Fiber optic smart structures. Proc. IEEE 1996, 84, 884–894. [Google Scholar] [CrossRef]

- Werneck, M.M.; Allil, R.; Ribeiro, B.; de Nazaré, F. A guide to fiber Bragg grating sensors. In Current Trends in Short-and Long-Period Fibre Gratings; InTech: Rijeka, Croatia, 2013; pp. 1–24. [Google Scholar]

- Kim, S.T.; Park, Y.; Park, S.Y.; Cho, K.; Cho, J.-R. A sensor-type PC strand with an embedded FBG sensor for monitoring prestress forces. Sensors 2015, 15, 1060–1070. [Google Scholar] [CrossRef]

- Maaskant, R.; Alavie, T.; Measures, R.; Tadros, G.; Rizkalla, S.; Guha-Thakurta, A. Fiber-optic Bragg grating sensors for bridge monitoring. Cem. Concr. Compos. 1997, 19, 21–33. [Google Scholar] [CrossRef]

- Majumder, M.; Gangopadhyay, T.K.; Chakraborty, A.K.; Dasgupta, K.; Bhattacharya, D.K. Fibre Bragg gratings in structural health monitoring—Present status and applications. Sens. Actuators A Phys. 2008, 147, 150–164. [Google Scholar] [CrossRef]

- Moyo, P.; Brownjohn, J.; Suresh, R.; Tjin, S. Development of fiber Bragg grating sensors for monitoring civil infrastructure. Eng. Struct. 2005, 27, 1828–1834. [Google Scholar] [CrossRef]

- Zhou, Z.; Graver, T.W.; Hsu, L.; Ou, J. Techniques of advanced FBG sensors: Fabrication, demodulation, encapsulation and their application in the structural health monitoring of bridges. Pac. Sci. Rev. 2003, 5, 116–121. [Google Scholar]

- Kim, J.-M.; Kim, Y.-S.; Kim, H.-W.; Seo, D.-N.; Yun, C.-B. Development of smart tendon instrumented with optical FBG sensors. In Proceedings of the Computational Structural Engineering Institute Conference, Seoul, Korea, 12–13 April 2007; pp. 33–38. [Google Scholar]

- Kim, J.-M.; Kim, H.-W.; Choi, S.-Y.; Park, S.-Y. Measurement of prestressing force in pretensioned UHPC deck using a fiber optic FBG sensor embedded in a 7-wire strand. J. Sens. 2016, 2016, 8634080. [Google Scholar] [CrossRef]

- Kim, J.-M.; Kim, H.-W.; Park, Y.-H.; Yang, I.-H.; Kim, Y.-S. FBG sensors encapsulated into 7-wire steel strand for tension monitoring of a prestressing tendon. Adv. Struct. Eng. 2012, 15, 907–917. [Google Scholar]

- Hill, K.O.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Lightwave Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Iten, M. Novel Applications of Distributed Fiber-Optic Sensing in Geotechnical Engineering; VDF Hochschulverlag AG: Zürich, Switzerland, 2012; Volume 19632. [Google Scholar]

- Di Sante, R.; Donati, L.; Troiani, E.; Proli, P. Reliability and accuracy of embedded fiber Bragg grating sensors for strain monitoring in advanced composite structures. Met. Mater. Int. 2014, 20, 537–543. [Google Scholar] [CrossRef]

- Gusarov, A.; Chojetzki, C.; Mckenzie, I.; Thienpont, H.; Berghmans, F. Effect of the fiber coating on the radiation sensitivity of type I FBGs. IEEE Photonics Technol. Lett. 2008, 20, 1802–1804. [Google Scholar] [CrossRef]

- Yamakawa, H.; Iwaki, H.; Mita, A.; Takeda, N. Health monitoring of steel structures using fiber bragg grating sensors. In Proceedings of the 2nd International Workshop on Structural Health Monitoring, Stanford, CA, USA, 8–10 September 1999; pp. 502–510. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-M.; Kim, C.-M.; Choi, S.-Y.; Lee, B.Y. Enhanced Strain Measurement Range of an FBG Sensor Embedded in Seven-Wire Steel Strands. Sensors 2017, 17, 1654. https://doi.org/10.3390/s17071654

Kim J-M, Kim C-M, Choi S-Y, Lee BY. Enhanced Strain Measurement Range of an FBG Sensor Embedded in Seven-Wire Steel Strands. Sensors. 2017; 17(7):1654. https://doi.org/10.3390/s17071654

Chicago/Turabian StyleKim, Jae-Min, Chul-Min Kim, Song-Yi Choi, and Bang Yeon Lee. 2017. "Enhanced Strain Measurement Range of an FBG Sensor Embedded in Seven-Wire Steel Strands" Sensors 17, no. 7: 1654. https://doi.org/10.3390/s17071654