Design and Performance of a Metal-Shielded Piezoelectric Sensor

Abstract

:1. Introduction

2. Physical Model

3. Design and Methods

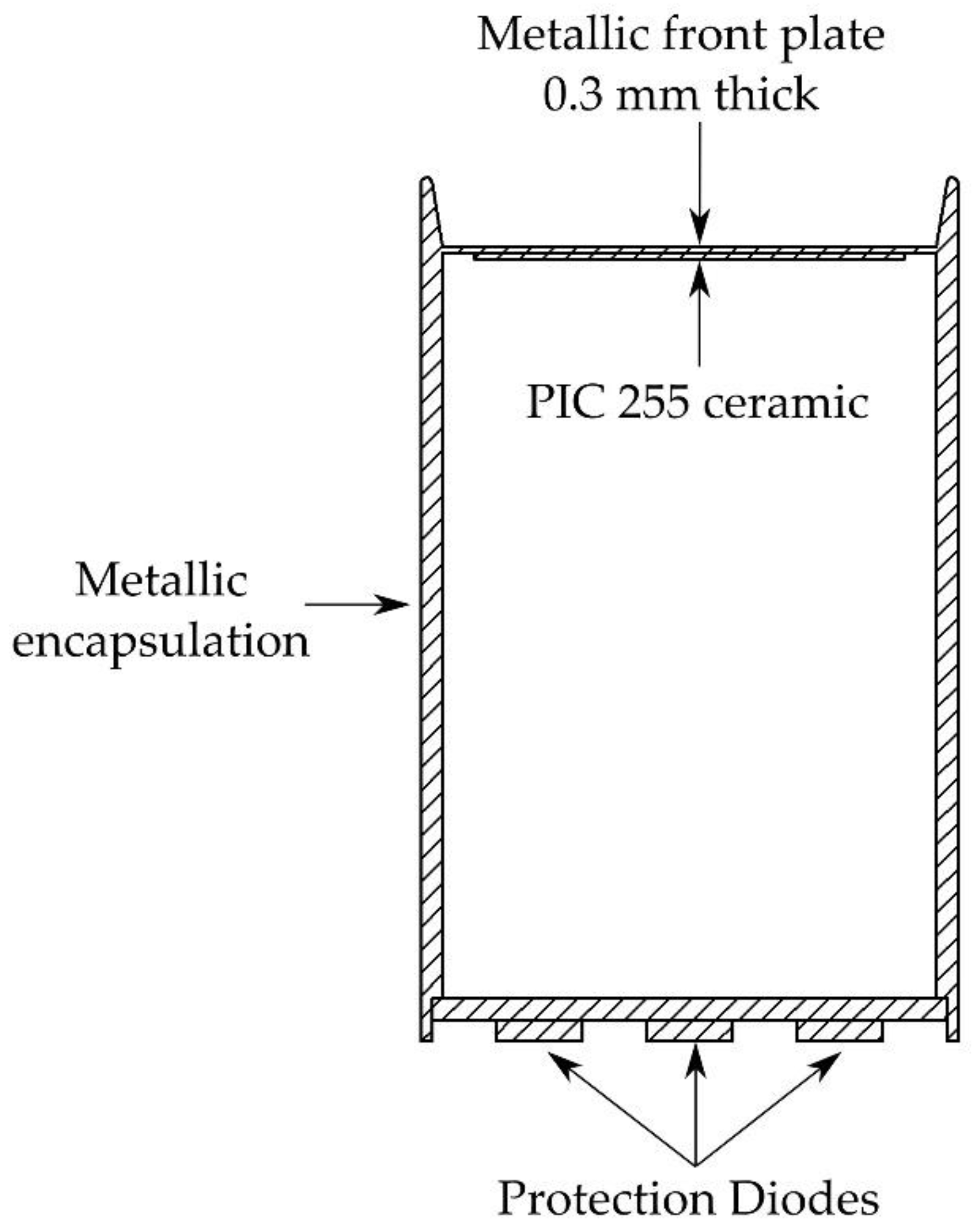

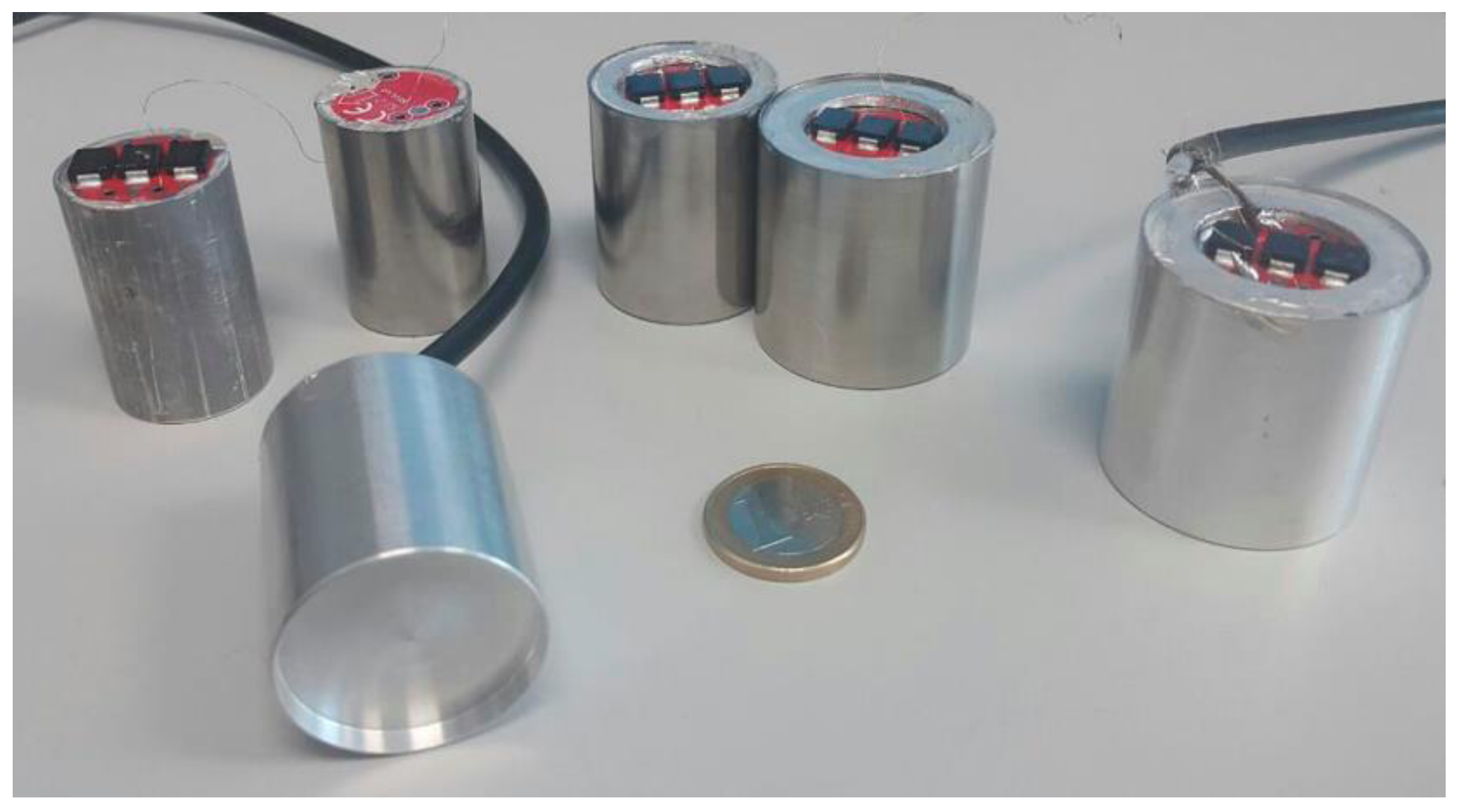

3.1. Design

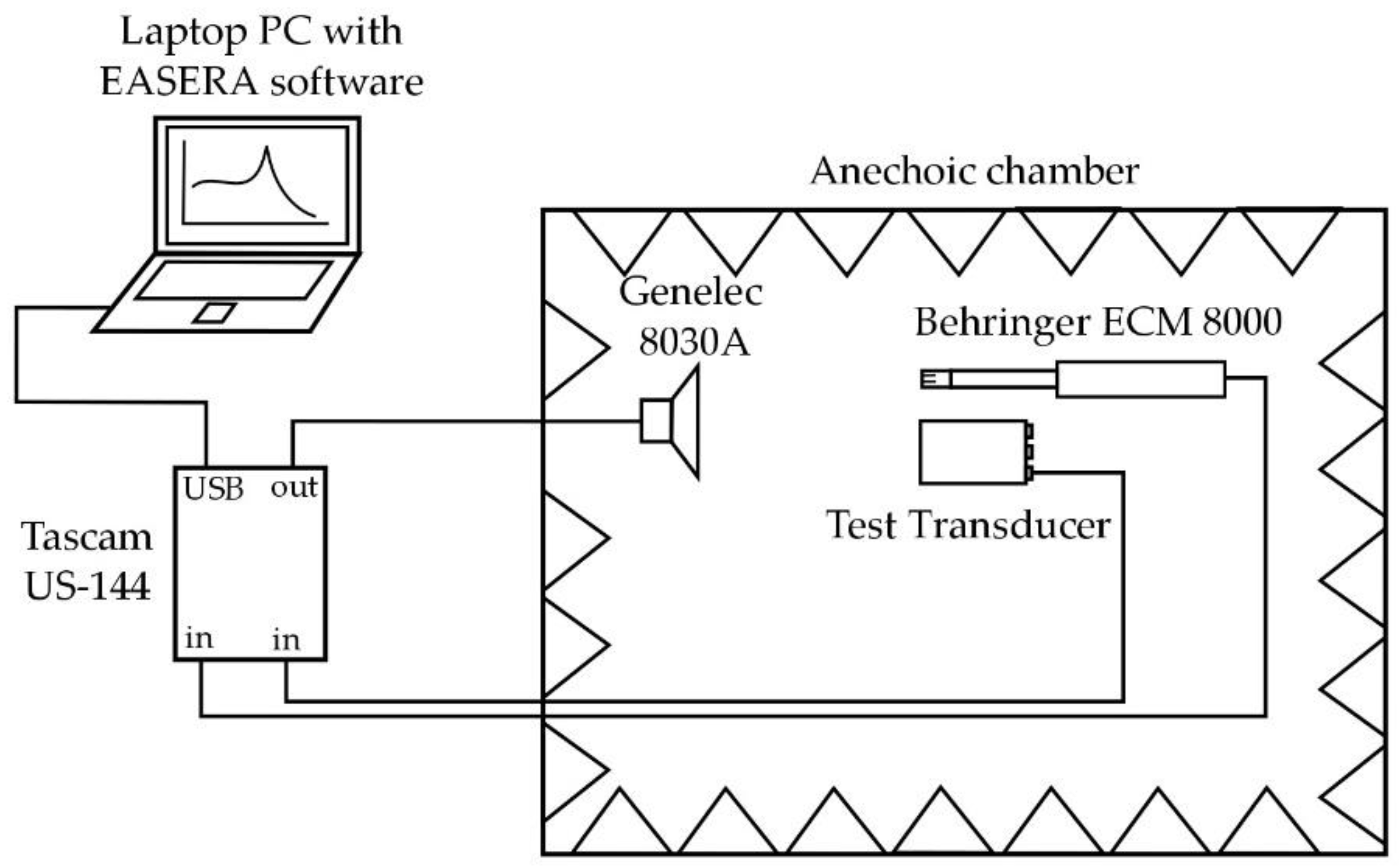

3.2. Experimental Set-Up

3.3. Finite Element Simulation

4. Results and Discussion

4.1. Mechanical Resonance Frequencies of the System

4.2. Electric Response of the Piezoelectric Ceramics

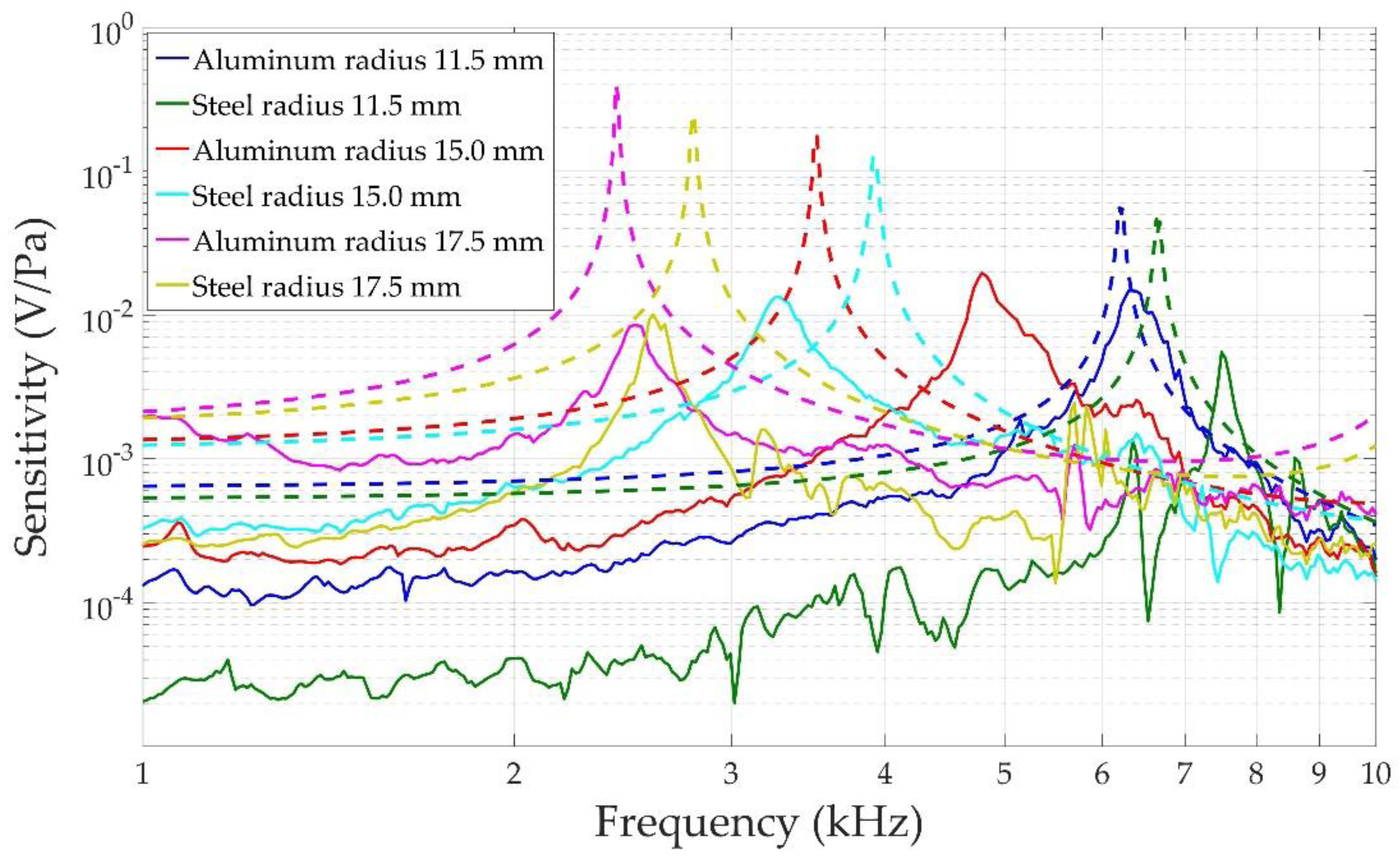

4.3. Sensitivity Response of the System

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bogle, T.G.; Tuma, J.E.; Williams, B.N. Method of Confirming the Presence of a Leak in a Liquid Storage Tank. U.S. Patent 5,319,956, 14 June 1994. [Google Scholar]

- Adams, T.E. Tank Leakage Detection Method. U.S. Patent 4,462,249, 31 July 1984. [Google Scholar]

- Horowitz, S.; Nishida, T.; Cattafesta, L.; Sheplak, M. Development of a micromachined piezoelectric microphone for aeroacoustics applications. J. Acoust. Soc. Am. 2007, 122, 3428–3436. [Google Scholar] [CrossRef] [PubMed]

- Castro, B.; Clerice, G.; Ramos, C.; Andreoli, A.; Baptista, F.; Campos, F.; Ulson, J. Partial discharge monitoring in power transformers using low-cost piezoelectric sensors. Sensors 2016, 16, 1266. [Google Scholar] [CrossRef] [PubMed]

- Lu, B.; Upadhyaya, B.R.; Perez, R.B. Structural integrity monitoring of steam generator tubing using transient acoustic signal analysis. IEEE Trans. Nucl. Sci. 2005, 52, 484–493. [Google Scholar] [CrossRef]

- Gayford, M. Microphone Engineering Handbook; Focal Press: Oxford, UK, 1994; Chapters 1–7. [Google Scholar]

- Eargle, J. The Microphone Book, 2nd ed.; Elsevier: Oxford, UK, 2005; Chapters 3–5. [Google Scholar]

- Blauert, J.; Xiang, N. Acoustics for Engineers, 2nd ed.; Springer: Berlin, Germany, 2009; Chapters 5. [Google Scholar]

- Williams, M.D. Development of a MEMS Piezoelectric Microphone for Aeroacoustic Applications. Ph.D. Thesis, University of Florida, Gainesville, FL, USA, 2011. [Google Scholar]

- Qiu, Y.; Gigliotti, J.V.; Wallace, M.; Griggio, F.; Demore, C.E.M.; Cochran, S.; Trolier-McKinstry, S. Piezoelectric Micromachined Ultrasound Transducer (PMUT) Arrays for Integrated Sensing, Actuation and Imaging. Sensors 2015, 15, 8020–8041. [Google Scholar] [CrossRef] [PubMed]

- Beranek, L.L.; Mellow, T.J. Acoustics: Sound Fields and Transducers; Academic Press: Kidlington, UK, 2012; Chapter 5. [Google Scholar]

- Vives, A.A. Piezoelectric Transducers and Applications, 2nd ed.; Springer-Verlag: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Dobrucki, A.B.; Pruchnicki, P. Theory of piezoelectric axisymmetric bimorph. Sens. Actuators A Phys. 1997, 58, 203–212. [Google Scholar] [CrossRef]

- Lee, W.S.; Lee, S.S. Piezoelectric microphone built on circular diaphragm. Sens. Actuators A Phys. 2008, 144, 367–373. [Google Scholar] [CrossRef]

- Galiano, G.; Lamberti, N.; Iula, A.; Pappalardo, M. A piezoelectric bimorph static pressure sensor. Sens. Actuators A Phys 1995, 46, 176–178. [Google Scholar]

- Kinsler, L.E.; Frey, A.R.; Coppens, A.B.; Sanders, J.V. Fundamentals of Acoustics, 4th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2000; Chapter 4. [Google Scholar]

- PI Ceramic. Available online: https://www.piceramic.com/en/ (accessed on 1 June 2017).

- Barnes, J.R. Robust Electronic Design Reference Book; Springer Science & Business Media: Berlin, Germany, 2004; Volume 1, Chapter 17. [Google Scholar]

- IEC 61094-8:2012. Measurement Microphones. Part 8: Methods for Determining the Free-Field Sensitivity of Working Standard Microphones by Comparison; International Electrotechnical Commission: Geneva, Switzerland, 2012.

- Behringer. Available online: https://www.music-group.com/brand/behringer/home (accessed on 1 June 2017).

- Genelec. Available online: http://www.genelec.com/ (accessed on 1 June 2017).

- Tascam Teac Professional. Available online: http://tascam.com/ (accessed on 1 June 2017).

- AFMG Easera—Electronic and Acoustic System Evaluation and Response Analysis. Available online: http://easera.afmg.eu/ (accessed on 1 June 2017).

- Comsol. Available online: https://www.comsol.com/ (accessed on 1 June 2017).

- Kuttruff, H. Ultrasonics Fundamentals and Applications; Elsevier Science Publishers Ltd.: Essex, UK, 1991; Chapter 5. [Google Scholar]

- Lerch, R. Simulation of Piezoelectric Devices by Two- and Three-Dimensional Finite Elements. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1990, 37, 233–247. [Google Scholar] [CrossRef] [PubMed]

- Ferri, M.; Camarena, F.; Redondo, J.; Pico, R.; Avis, M.R. Explicit finite-difference time-domain scheme for the simulation of 1-3 piezoelectric effect in axisymmetrical configurations. Wave Motion 2012, 49, 569–584. [Google Scholar] [CrossRef]

| Transducer | Measurement (mV/Pa) | Simulation (mV/Pa) |

|---|---|---|

| Aluminum (radius 17.5 mm) | 1.20 | 3.30 |

| Aluminum (radius 15 mm) | 0.23 | 1.60 |

| Aluminum (radius 11.5 mm) | 0.14 | 0.67 |

| Steel (radius 17.5 mm) | 0.33 | 2.50 |

| Steel (radius 15 mm) | 0.39 | 1.40 |

| Steel (radius 11.5 mm) | 0.03 | 0.55 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sáenz de Inestrillas, Á.; Camarena, F.; Bou Cabo, M.; Barreiro, J.M.; Reig, A. Design and Performance of a Metal-Shielded Piezoelectric Sensor. Sensors 2017, 17, 1284. https://doi.org/10.3390/s17061284

Sáenz de Inestrillas Á, Camarena F, Bou Cabo M, Barreiro JM, Reig A. Design and Performance of a Metal-Shielded Piezoelectric Sensor. Sensors. 2017; 17(6):1284. https://doi.org/10.3390/s17061284

Chicago/Turabian StyleSáenz de Inestrillas, Álvaro, Francisco Camarena, Manuel Bou Cabo, Julián M. Barreiro, and Antonio Reig. 2017. "Design and Performance of a Metal-Shielded Piezoelectric Sensor" Sensors 17, no. 6: 1284. https://doi.org/10.3390/s17061284