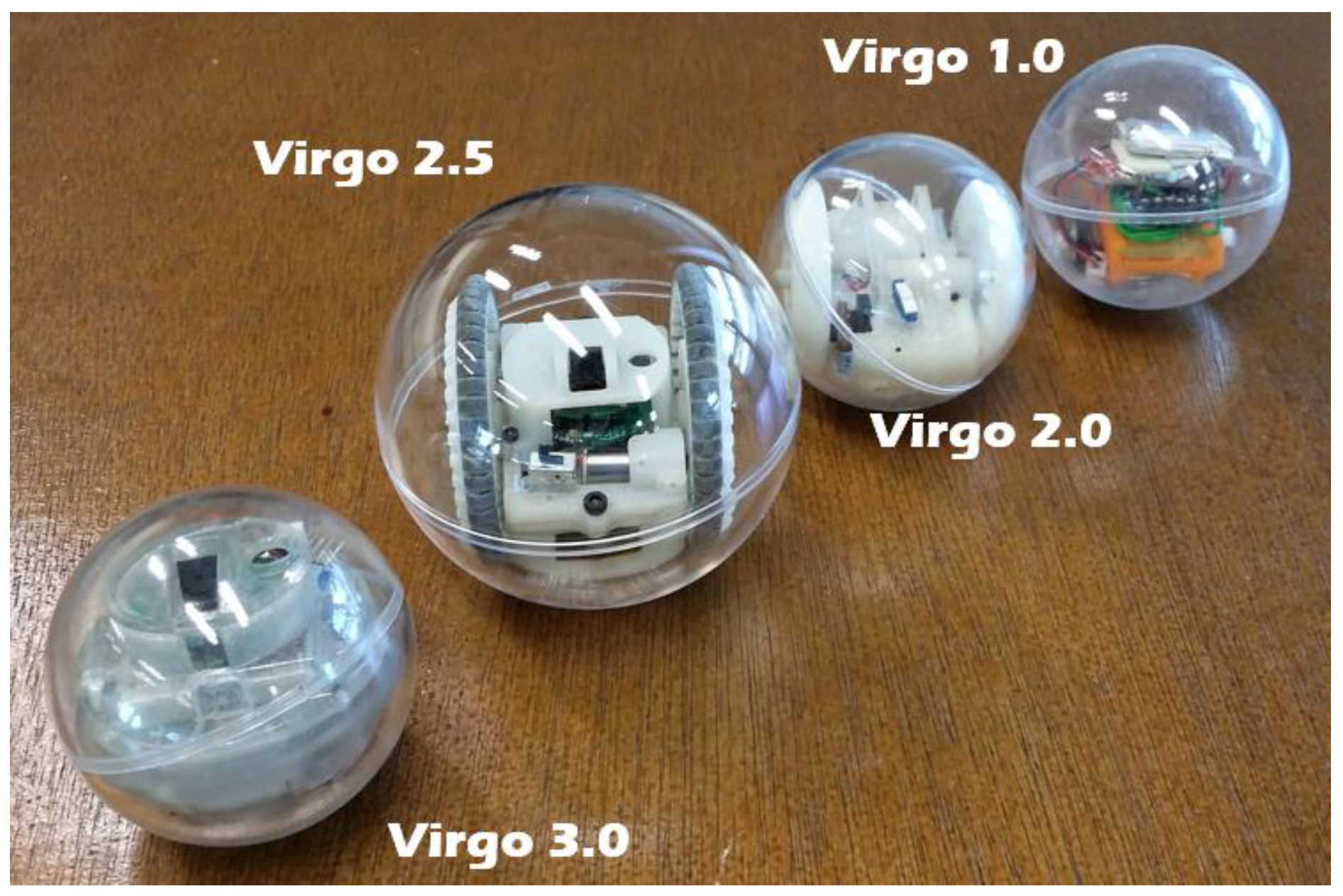

A Compact Magnetic Field-Based Obstacle Detection and Avoidance System for Miniature Spherical Robots

Abstract

:1. Introduction

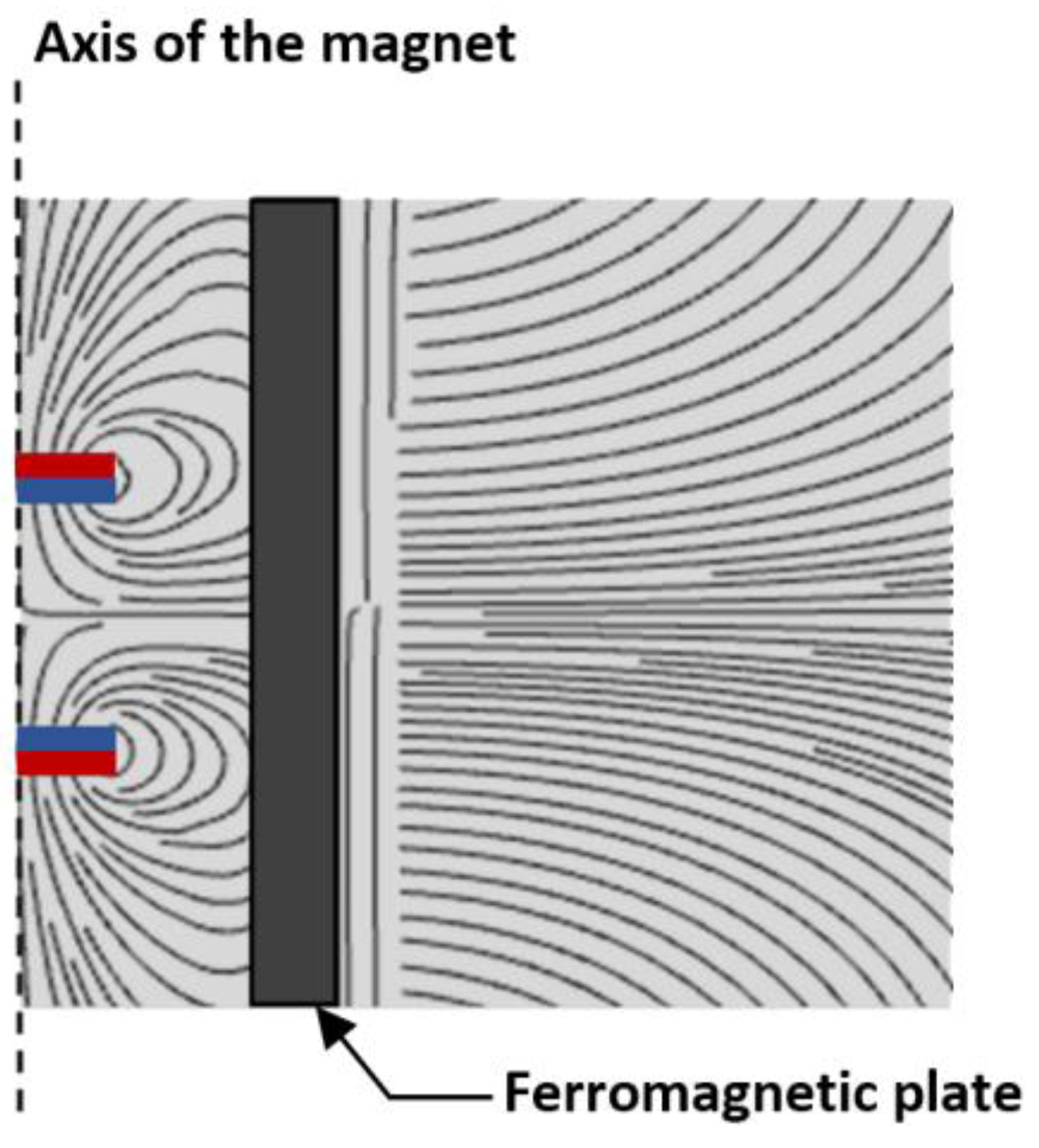

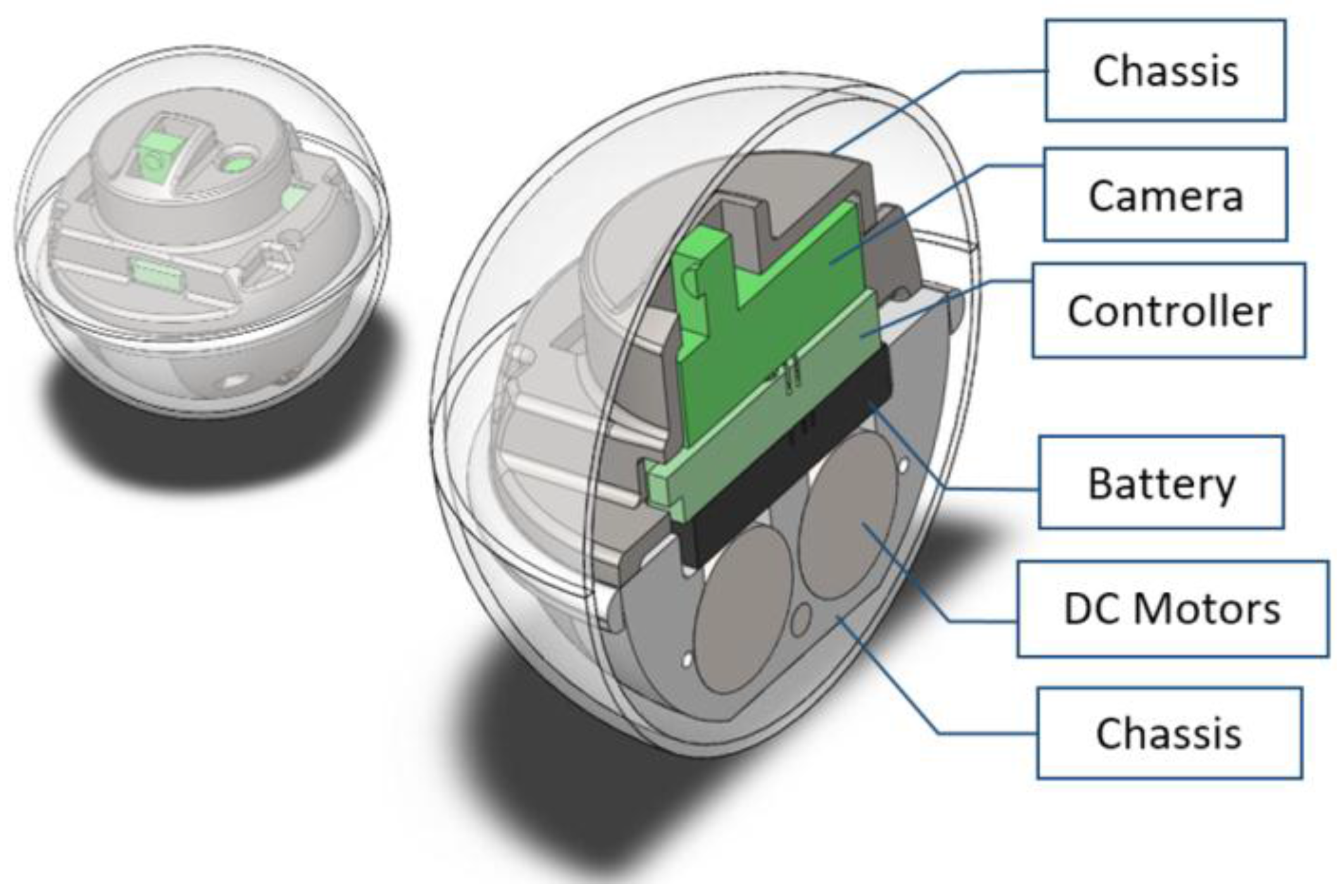

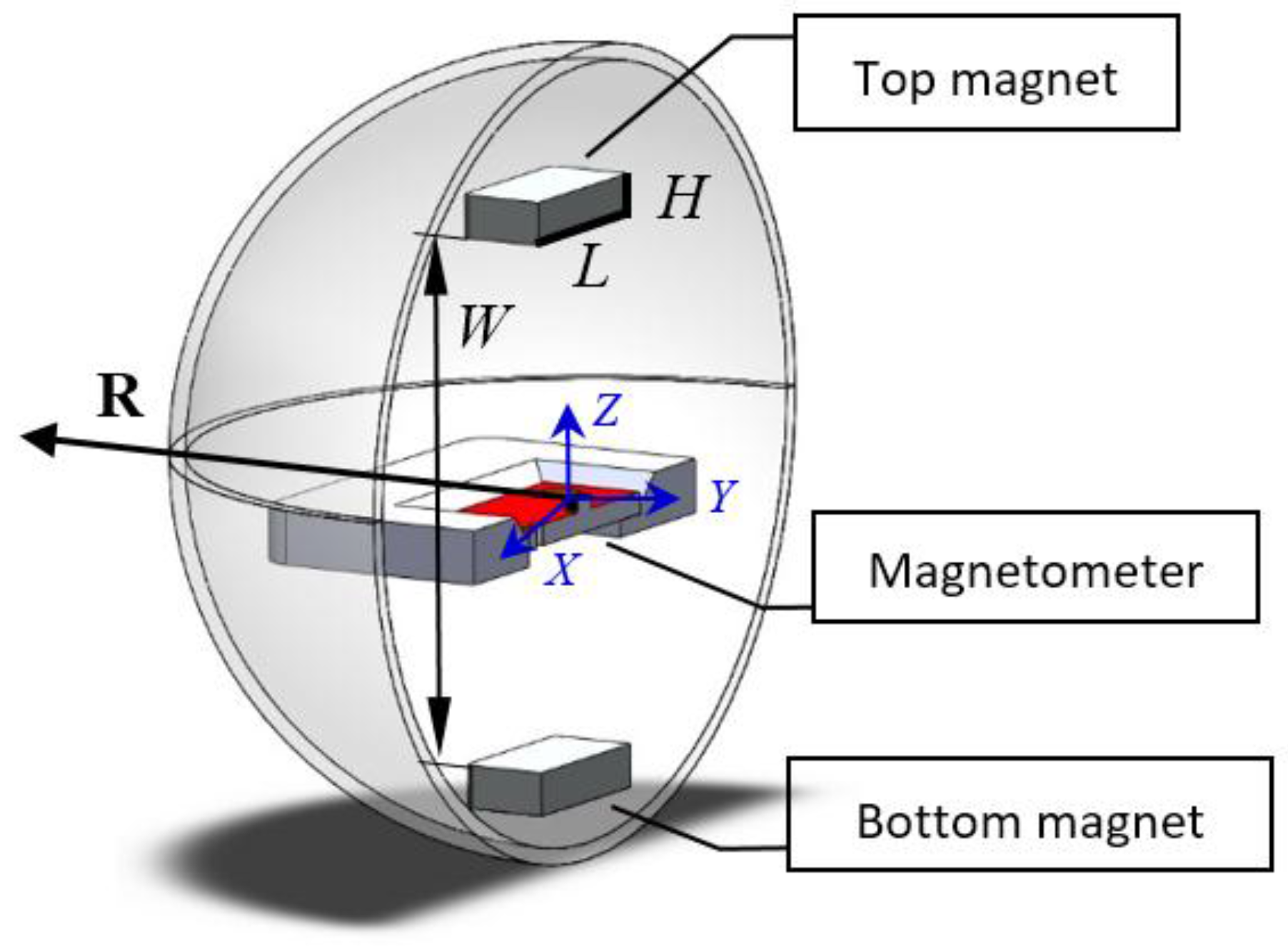

2. Passive Magnetic-Based Proximity Sensor

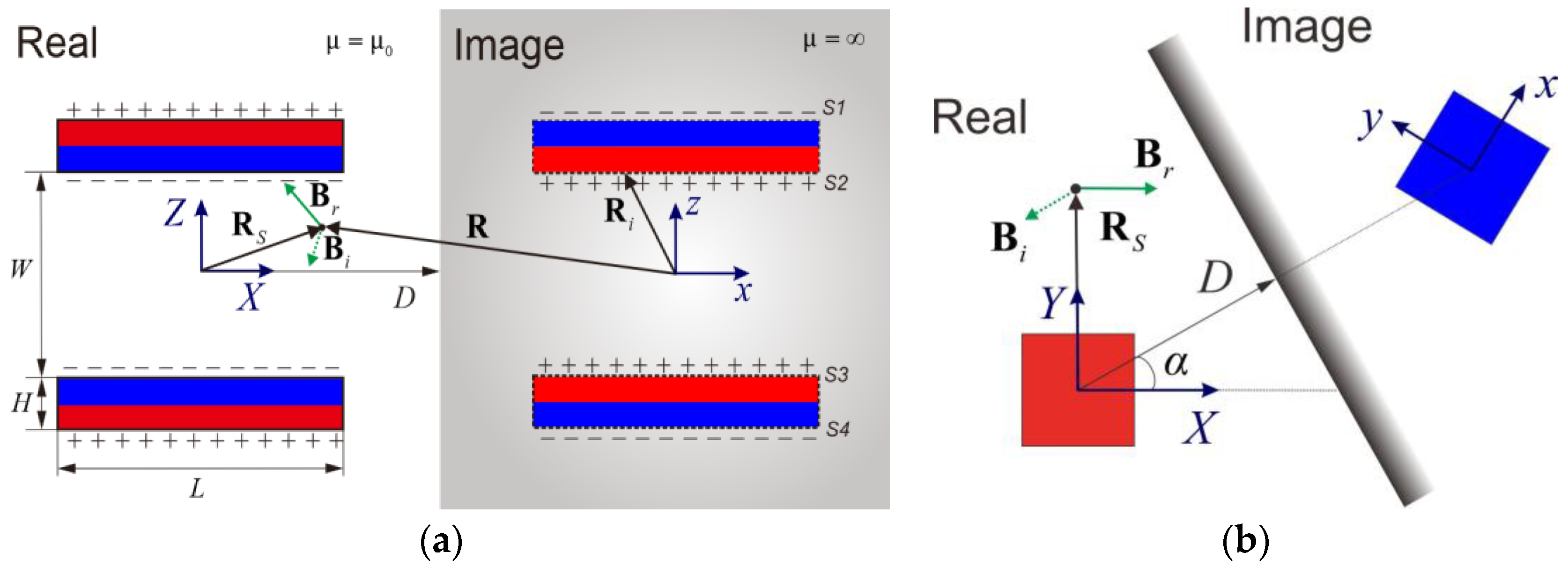

2.1. Design Concept and Modeling

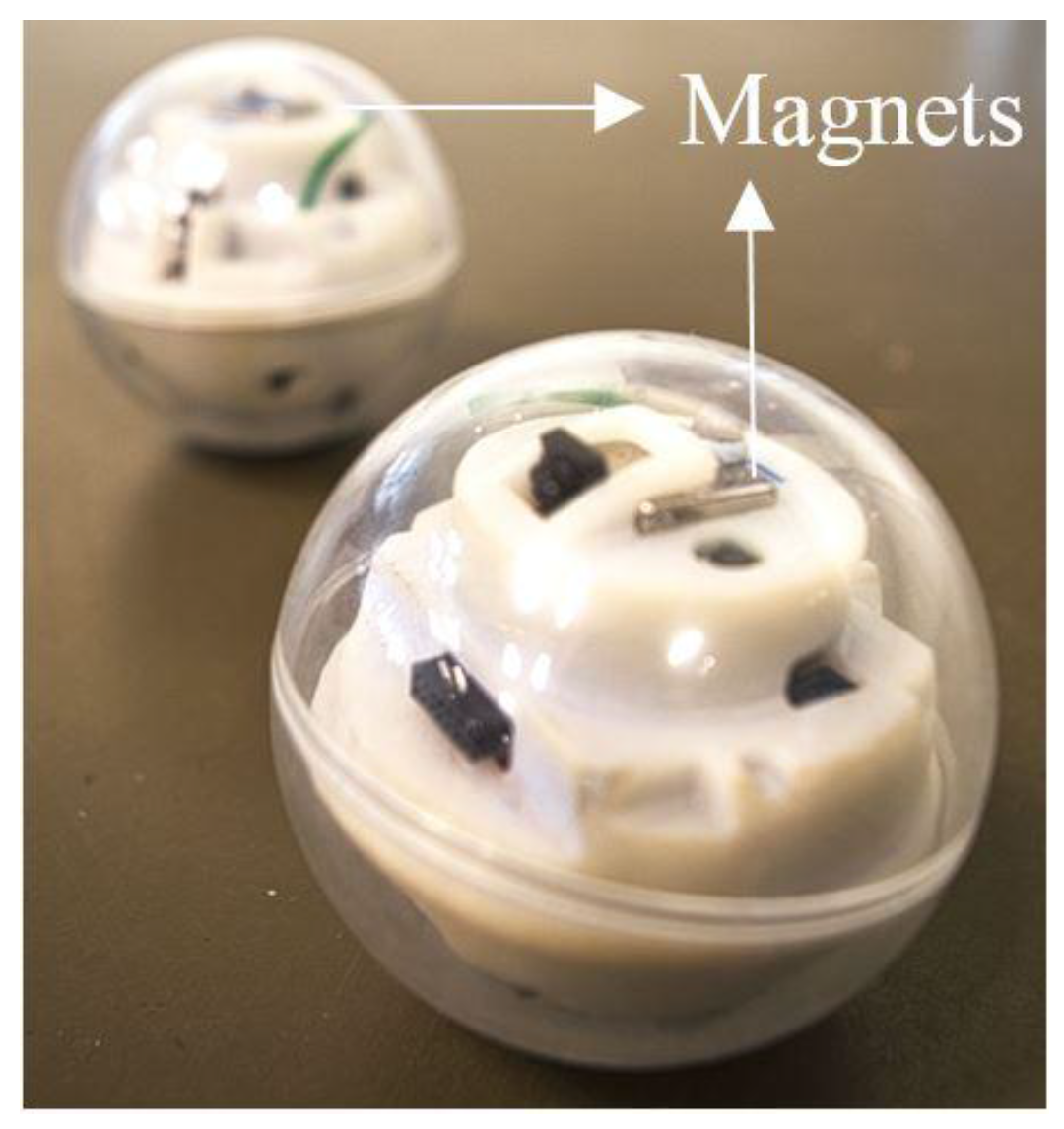

2.2. Design Integration and Optimization

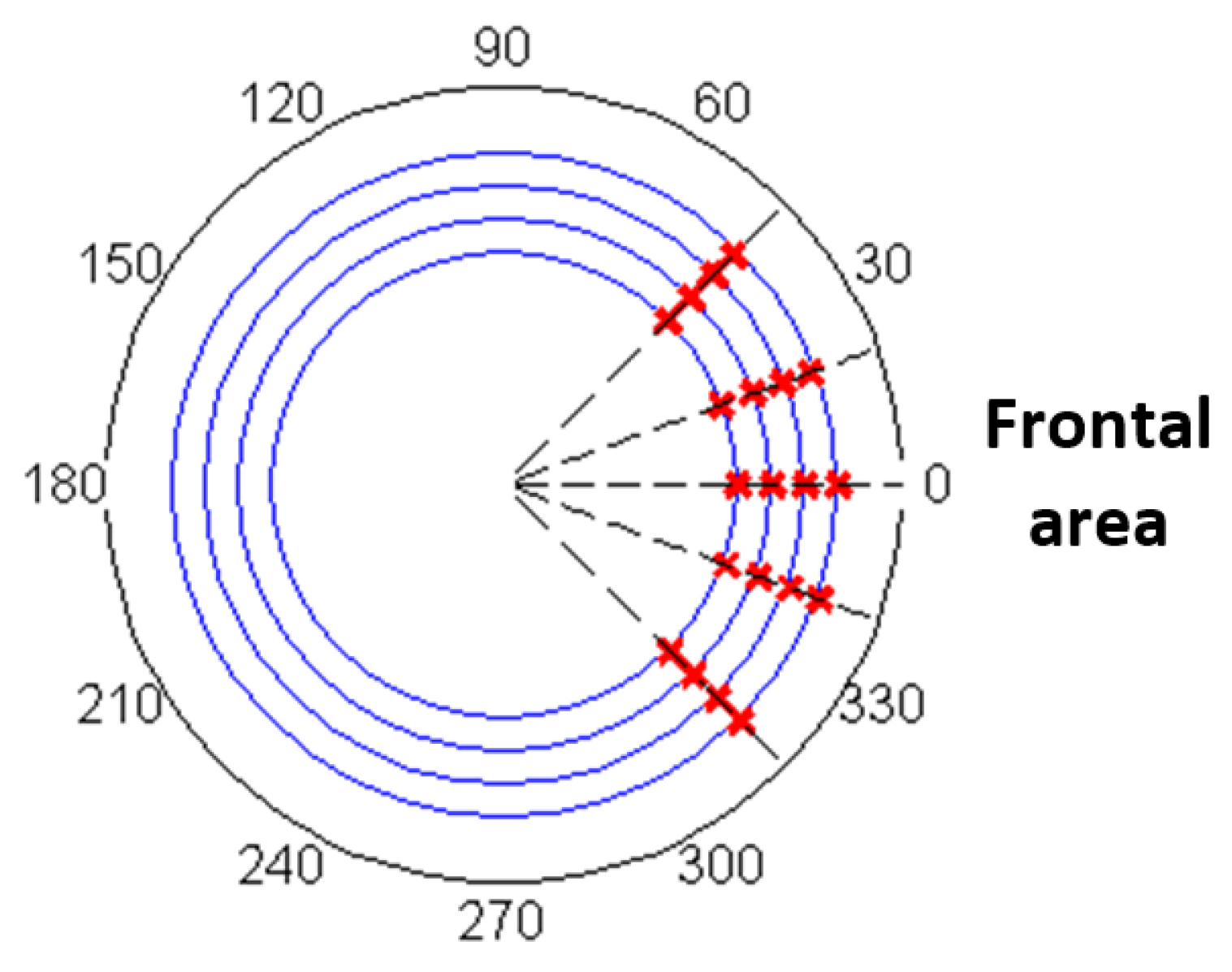

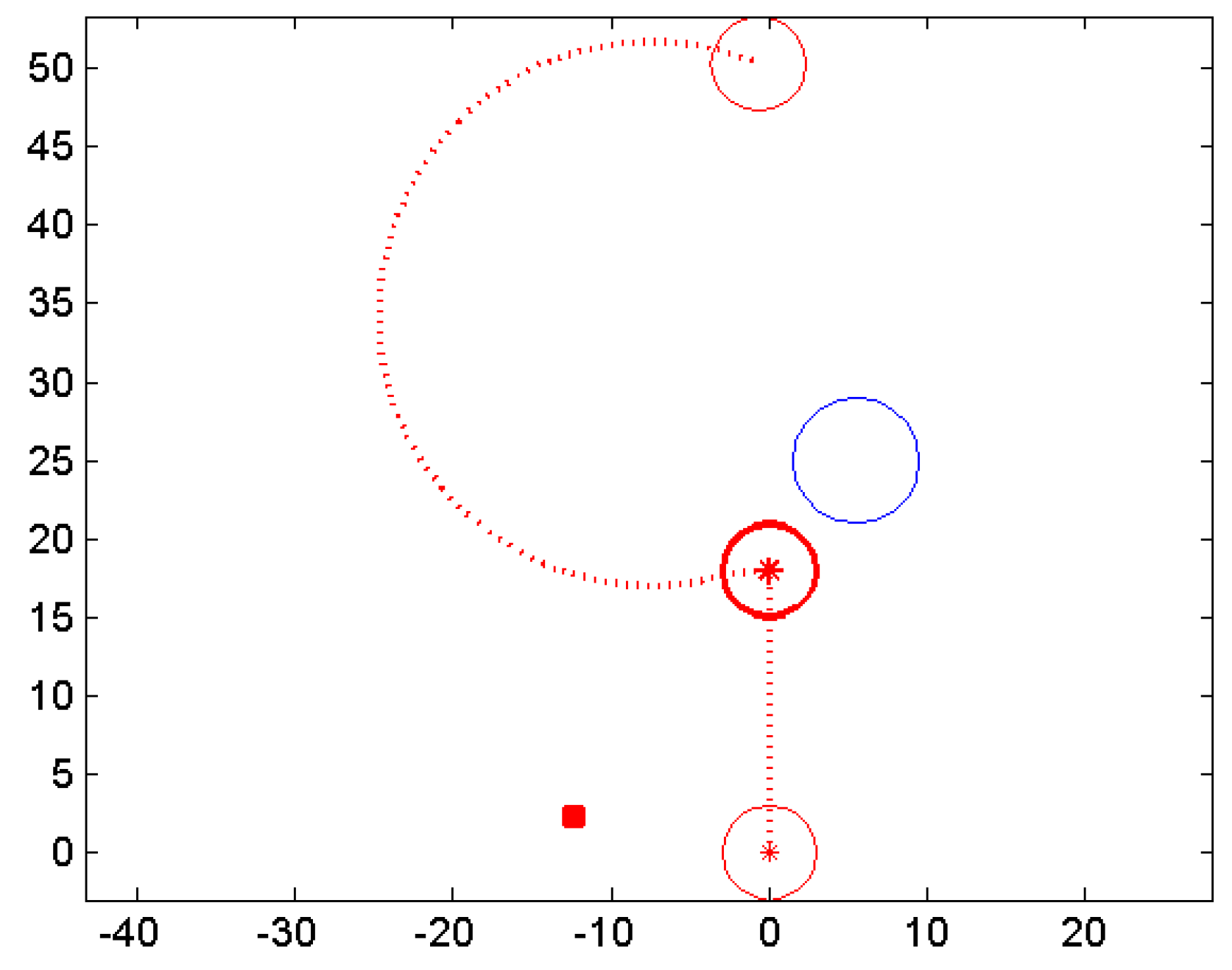

2.3. Detection and Avoidance Strategies

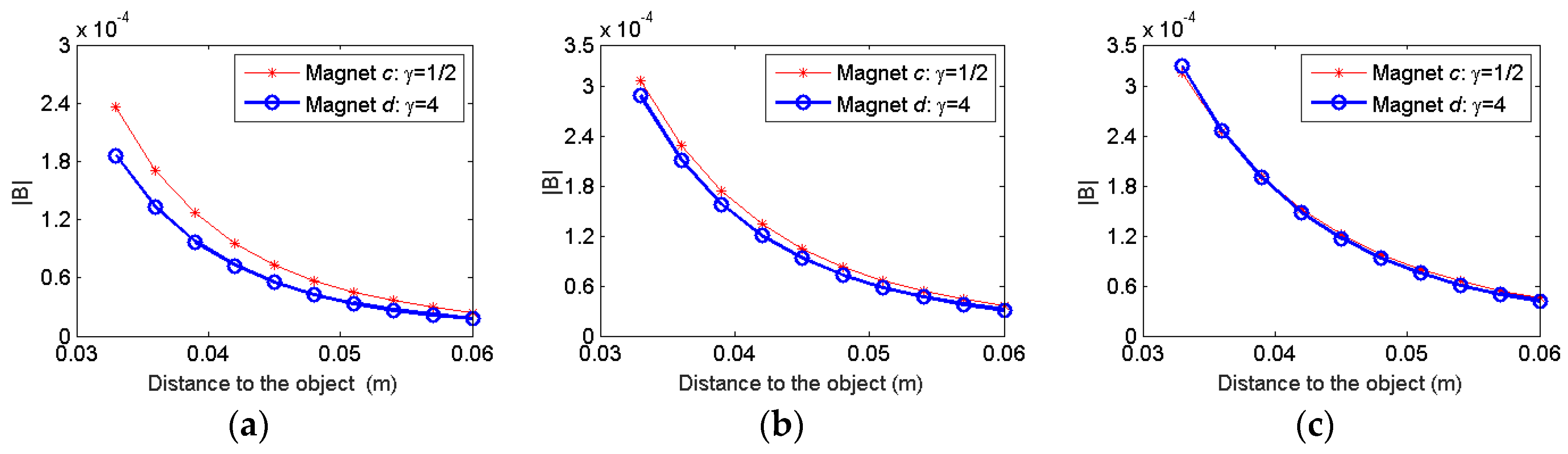

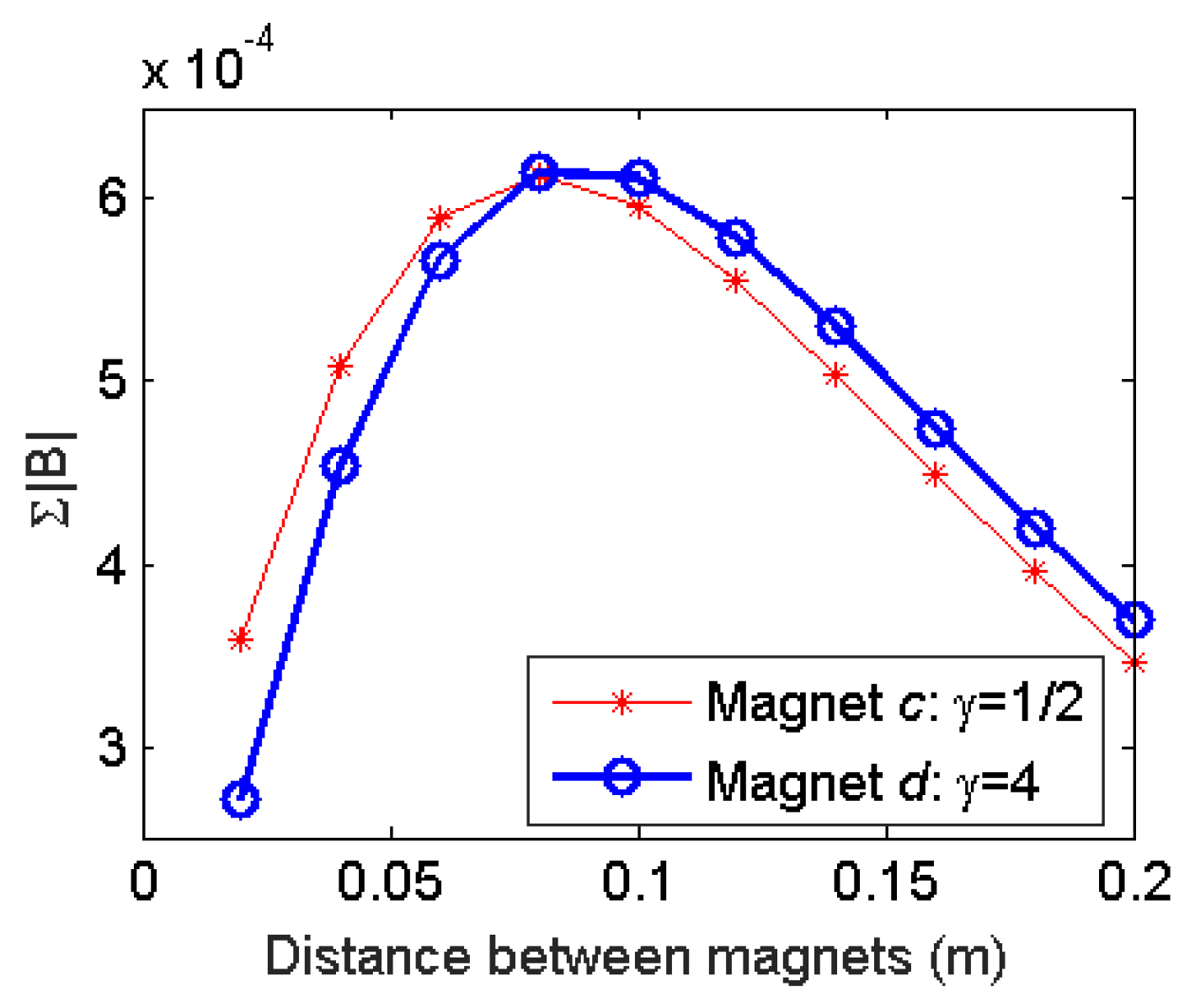

3. Simulation Studies of the Optimization Process

3.1. Analysis on the Effect of Magnet Geometry

3.2. Analysis on the Effect of Separation Distance

3.3. Optimization of Integration into Spherical Robot

4. Experimental Results

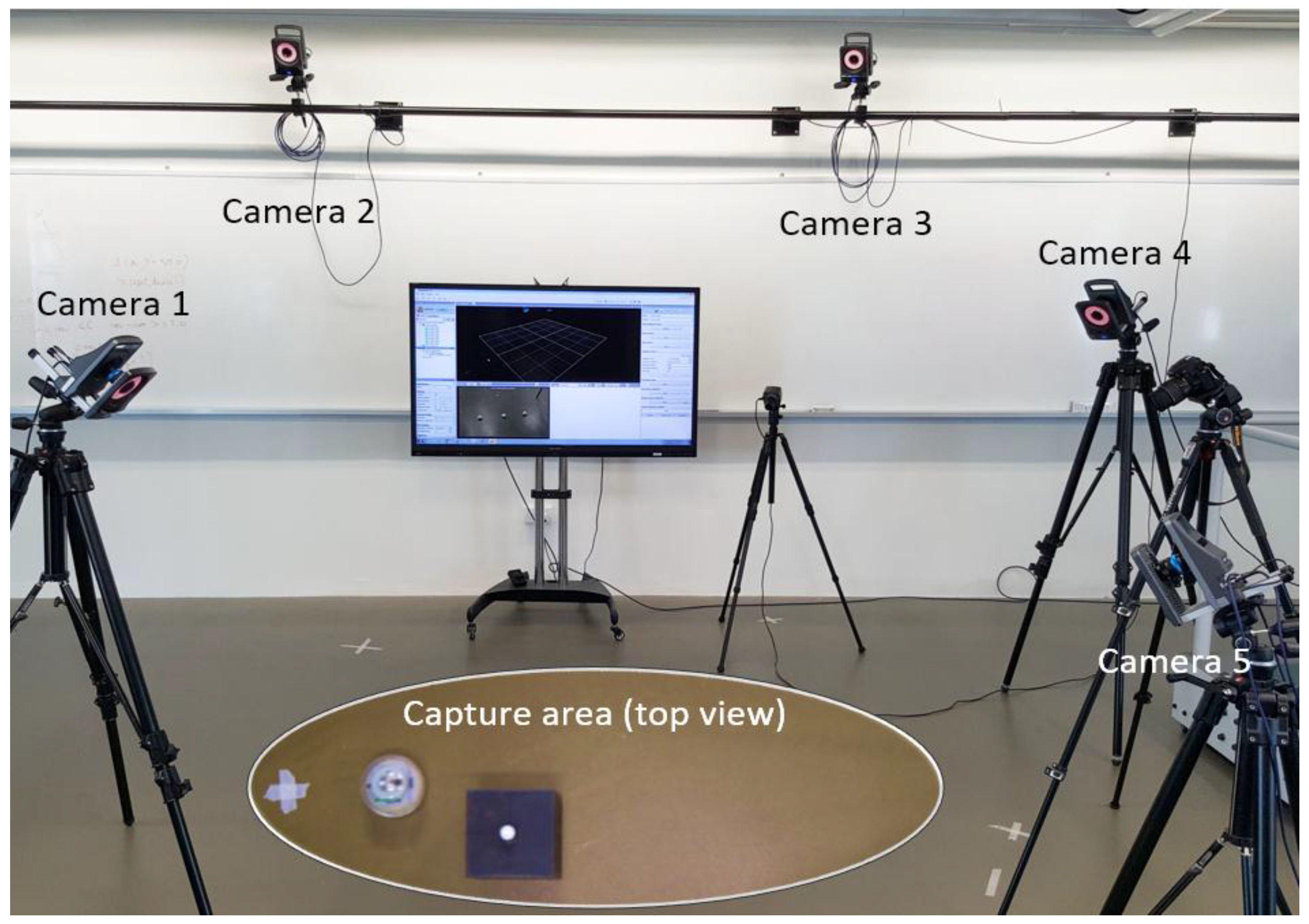

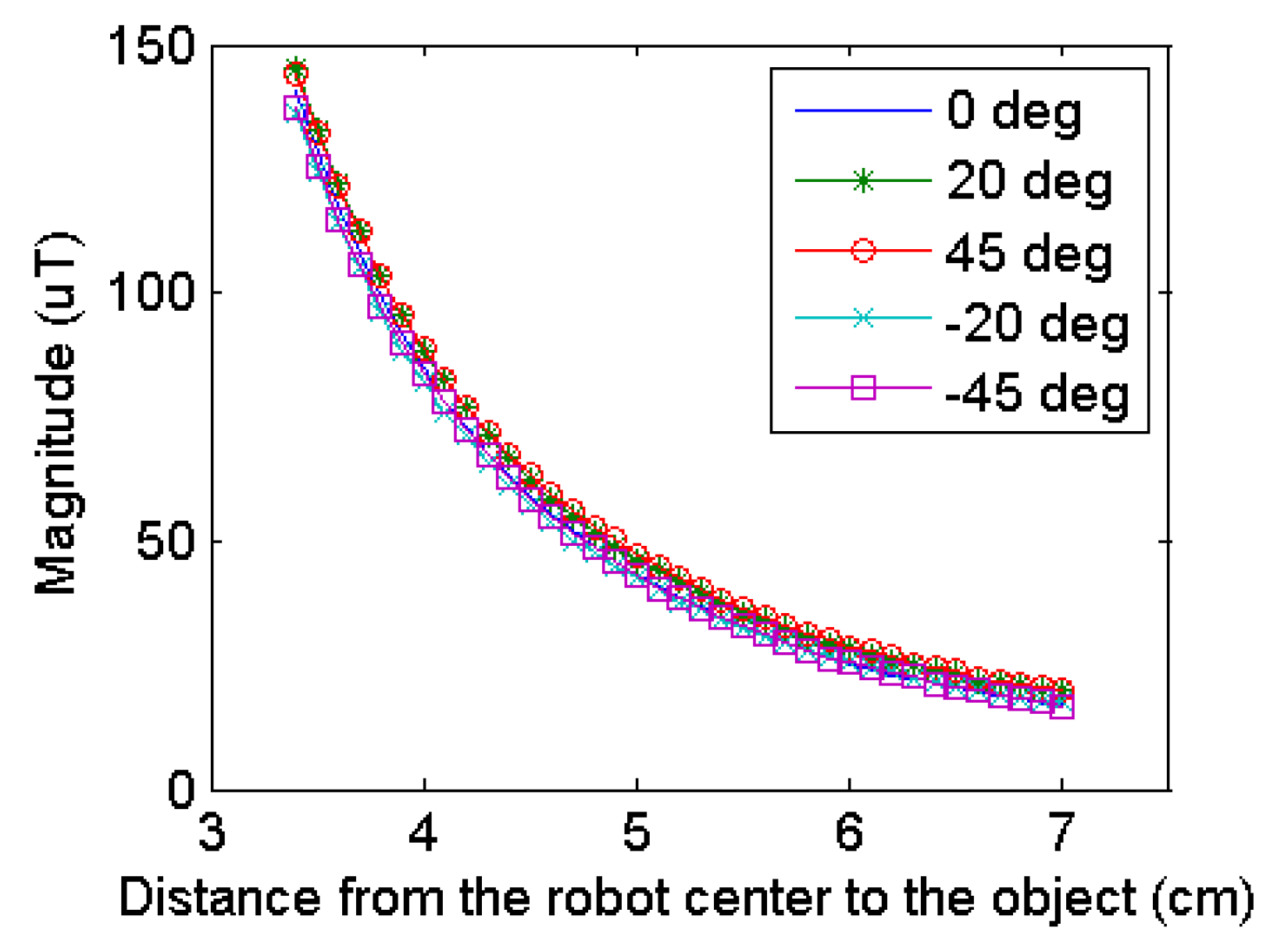

4.1. Calibration

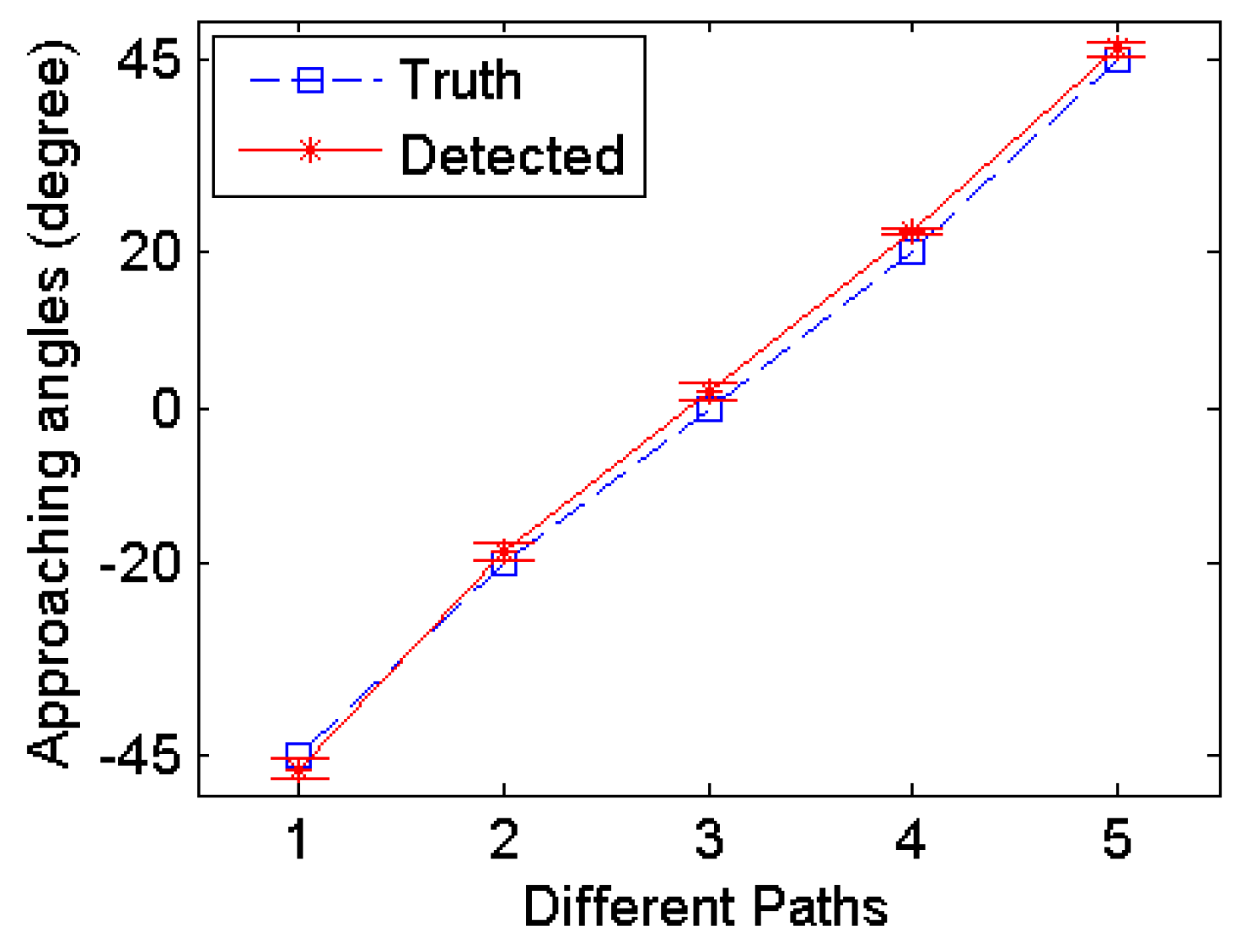

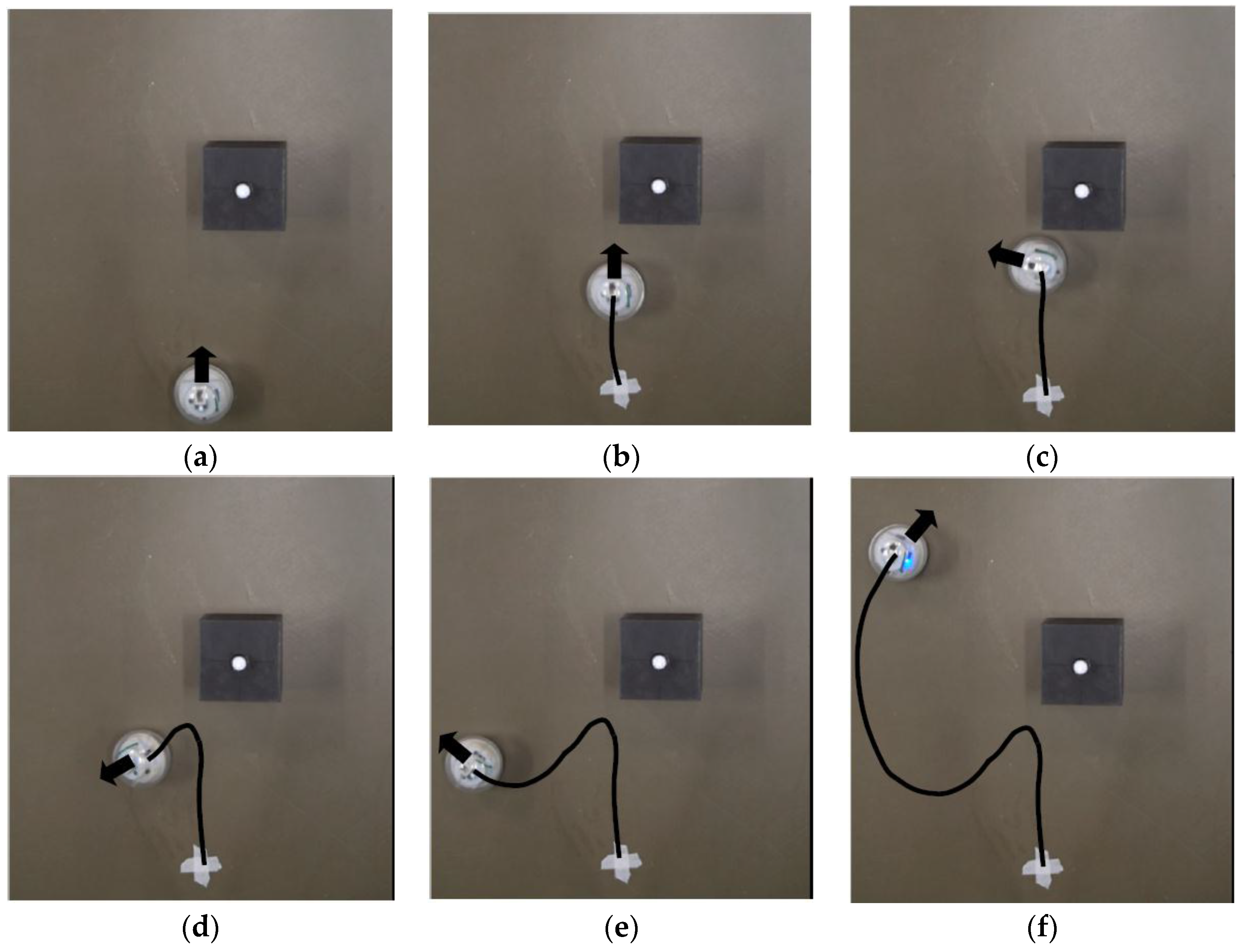

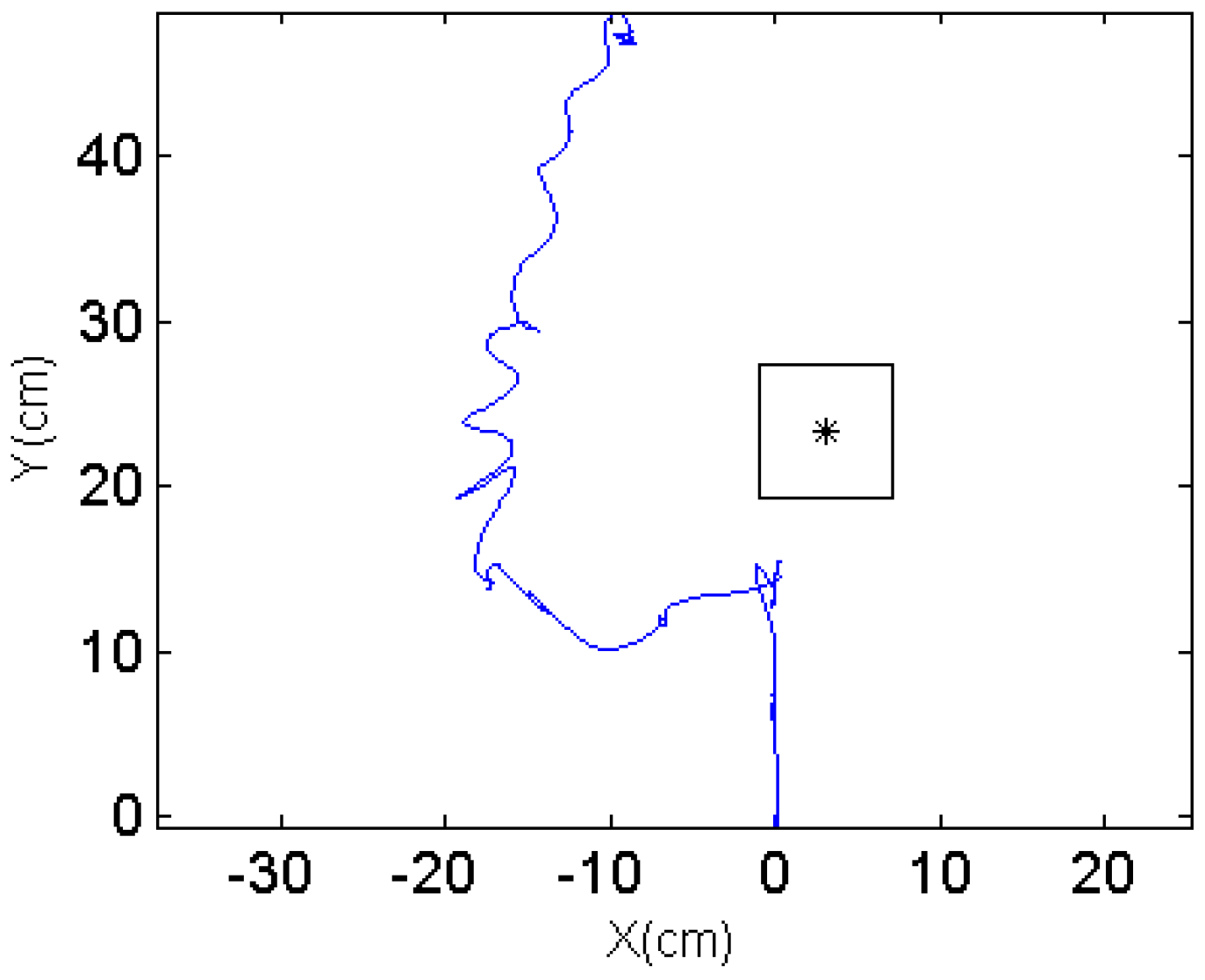

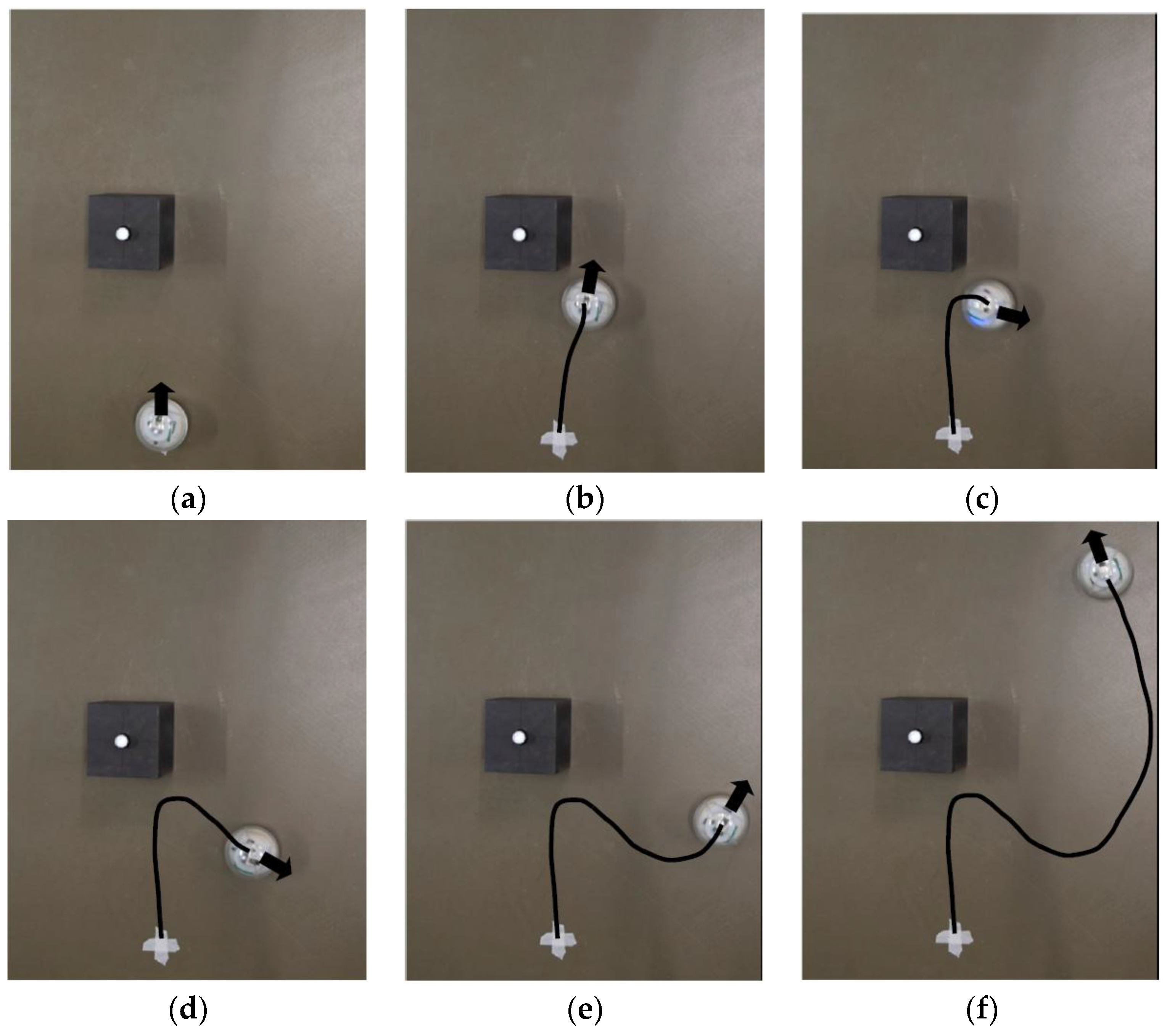

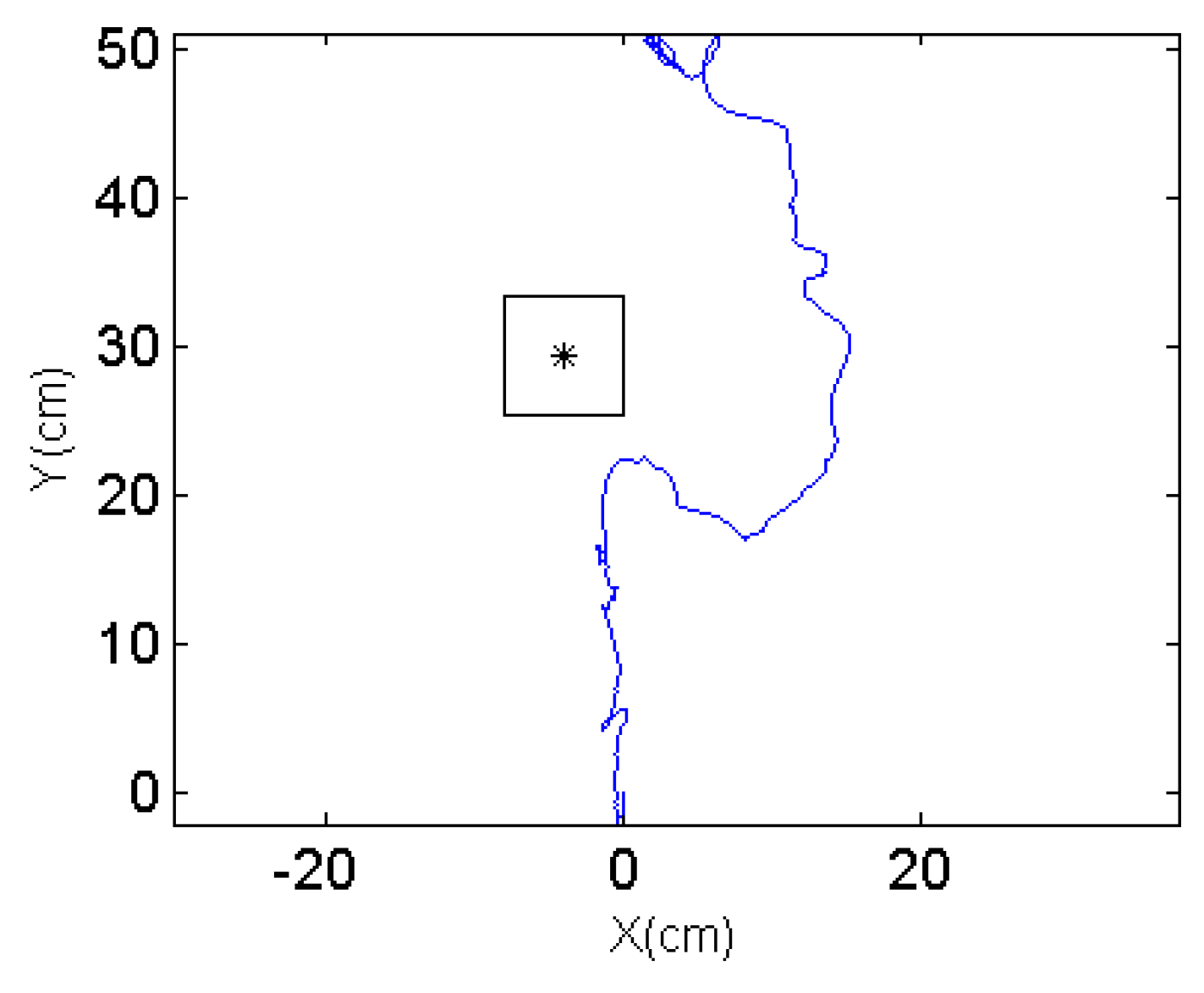

4.2. Obstacle Avoidance Performance

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

References

- Pol, R.S.; Murugan, M. A review on indoor human aware autonomous mobile robot navigation through a dynamic environment survey of different path planning algorithm and methods. In Proceedings of the International Conference on Industrial Instrumentation and Control (ICIC), Pune, India, 28–30 May 2015; pp. 1339–1344. [Google Scholar]

- Volos, C.K.; Kyprianidis, I.M.; Stouboulos, I.N. Experimental investigation on coverage performance of a chaotic autonomous mobile robot. Robot. Auton. Syst. 2013, 61, 1314–1322. [Google Scholar] [CrossRef]

- Martinez, D.; Teixidó, M.; Font, D.; Moreno, J.; Tresanchez, M.; Marco, S.; Palacín, J. Ambient intelligence application based on environmental measurements performed with an assistant mobile robot. Sensors 2014, 14, 6045–6055. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Hermosilla, J.; González, R.; Rodríguez, F.; Donaire, J. Mechatronic description of a laser autoguided vehicle for greenhouse operations. Sensors 2013, 13, 769–784. [Google Scholar] [CrossRef] [PubMed]

- Barai, S.; Dey, A.; Sau, B. Path following of autonomous mobile robot using passive rfid tags. In Proceedings of the 2016 International Conference on Microelectronics, Computing and Communications (MicroCom), Durgapur, India, 23–25 January 2016; pp. 1–6. [Google Scholar]

- Zhang, J.; Jiang, Y.; Wang, K. A modified fastslam for an autonomous mobile robot. In Proceedings of the 2016 IEEE International Conference on Mechatronics and Automation, Harbin, China, 7–10 August 2016; pp. 1755–1759. [Google Scholar]

- Zhao, R.; Lee, D.H.; Li, T.T.; Lee, H.K. Autonomous navigation of a mobile robot in unknown environment based on fuzzy inference. In Proceedings of the 2015 International Automatic Control Conference (CACS), Yilan, Taiwan, 18–20 November 2015; pp. 19–24. [Google Scholar]

- Boukattaya, M.; Jallouli, M.; Damak, T. On trajectory tracking control for nonholonomic mobile manipulators with dynamic uncertainties and external torque disturbances. Robot. Auton. Syst. 2012, 60, 1640–1647. [Google Scholar] [CrossRef]

- Roozegar, M.; Mahjoob, M.J.; Jahromi, M. Optimal motion planning and control of a nonholonomic spherical robot using dynamic programming approach: Simulation and experimental results. Mechatronics 2016, 39, 174–184. [Google Scholar] [CrossRef]

- Armour, R.H.; Vincent, J.F.V. Rolling in nature and robotics: A review. J. Bionic Eng. 2006, 3, 195–208. [Google Scholar] [CrossRef]

- Chase, R.; Pandya, A. A review of active mechanical driving principles of spherical robots. Robotics 2012, 1, 3–23. [Google Scholar] [CrossRef]

- Zhu, Y.; Jin, B.; Wu, Y.; Guo, T.; Zhao, X. Trajectory correction and locomotion analysis of a hexapod walking robot with semi-round rigid feet. Sensors 2016, 16, 1392. [Google Scholar] [CrossRef] [PubMed]

- Shi, L.; Guo, S.; Li, M.; Mao, S.; Xiao, N.; Gao, B.; Song, Z.; Asaka, K. A novel soft biomimetic microrobot with two motion attitudes. Sensors 2012, 12, 16732–16758. [Google Scholar] [CrossRef] [PubMed]

- Seeman, M.; Broxvall, M.; Saffiotti, A.; Wide, P. An autonomous spherical robot for security tasks. In Proceedings of the 2006 IEEE International Conference on Computational Intelligence for Homeland Security and Personal Safety, Alexandria, VA, USA, 16–17 October 2006; pp. 51–55. [Google Scholar]

- Lin, X.; Guo, S.; Tanaka, K.; Hata, S. Underwater experiments of a water-jet-based spherical underwater robot. In Proceedings of the 2011 IEEE International Conference on Mechatronics and Automation, Beijing, China, 7–10 August 2011; pp. 738–742. [Google Scholar]

- Pan, S.; Shi, L.; Guo, S. A kinect-based real-time compressive tracking prototype system for amphibious spherical robots. Sensors 2015, 15, 8232–8252. [Google Scholar] [CrossRef] [PubMed]

- Ajay, V.A.; Suherlan, A.P.; Soh, G.S.; Foong, S.; Wood, K.; Otto, K. Localization and trajectory tracking of an autonomous spherical rolling robot using imu and odometry. In Proceedings of the ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; American Society of Mechanical Engineers: Houston, TX, USA, 2015. [Google Scholar]

- Wu, F.; Maréchal, L.; Vibhute, A.; Foong, S.; Soh, G.S.; Wood, K.L. A compact magnetic directional proximity sensor for spherical robots. In Proceedings of the 2016 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Banff, AB, Canada, 12–15 July 2016; pp. 1258–1264. [Google Scholar]

- Lau, D.; Eden, J.; Oetomo, D. Fluid motion planner for nonholonomic 3-D mobile robots with kinematic constraints. IEEE Trans. Robot. 2015, 31, 1537–1547. [Google Scholar] [CrossRef]

- Palmieri, L.; Koenig, S.; Arras, K.O. Rrt-based nonholonomic motion planning using any-angle path biasing. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 2775–2781. [Google Scholar]

- Karaman, S.; Frazzoli, E. Sampling-based optimal motion planning for non-holonomic dynamical systems. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 5041–5047. [Google Scholar]

- Strakowski, M.R.; Kosmowski, B.B.; Kowalik, R.; Wierzba, P. An ultrasonic obstacle detector based on phase beamforming principles. IEEE Sens. J. 2006, 6, 179–186. [Google Scholar] [CrossRef]

- Mu, W.-Y.; Zhang, G.-P.; Huang, Y.-M.; Yang, X.-G.; Liu, H.-Y.; Yan, W. Omni-directional scanning localization method of a mobile robot based on ultrasonic sensors. Sensors 2016, 16, 2189. [Google Scholar] [CrossRef] [PubMed]

- Ko, N.; Kuc, T.-Y. Fusing range measurements from ultrasonic beacons and a laser range finder for localization of a mobile robot. Sensors 2015, 15, 11050–11075. [Google Scholar] [CrossRef] [PubMed]

- Mori, T.; Scherer, S. First results in detecting and avoiding frontal obstacles from a monocular camera for micro unmanned aerial vehicles. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 1750–1757. [Google Scholar]

- Bengochea-Guevara, J.; Conesa-Muñoz, J.; Andújar, D.; Ribeiro, A. Merge fuzzy visual servoing and GPS-based planning to obtain a proper navigation behavior for a small crop-inspection robot. Sensors 2016, 16, 276. [Google Scholar] [CrossRef] [PubMed]

- Hernández, A.; Gómez, C.; Crespo, J.; Barber, R. Object detection applied to indoor environments for mobile robot navigation. Sensors 2016, 16, 1180. [Google Scholar] [CrossRef] [PubMed]

- Herrero, D.; Martínez, H. Fuzzy mobile-robot positioning in intelligent spaces using wireless sensor networks. Sensors 2011, 11, 10820–10839. [Google Scholar] [CrossRef] [PubMed]

- Segura, M.; Auat Cheein, F.; Toibero, J.; Mut, V.; Carelli, R. Ultra wide-band localization and slam: A comparative study for mobile robot navigation. Sensors 2011, 11, 2035–2055. [Google Scholar] [CrossRef] [PubMed]

- Scalise, L.; Primiani, V.M.; Russo, P.; Shahu, D.; Mattia, V.D.; Leo, A.D.; Cerri, G. Experimental investigation of electromagnetic obstacle detection for visually impaired users: A comparison with ultrasonic sensing. IEEE Trans. Instrum. Meas. 2012, 61, 3047–3057. [Google Scholar] [CrossRef]

- Lee, K.-M.; Li, M. Magnetic field localization method for guiding visually impaired applications. In Proceedings of the 2013 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Wollongong, Australia, 9–12 July 2013; pp. 542–547. [Google Scholar]

- Nara, T.; Suzuki, S.; Ando, S. A closed-form formula for magnetic dipole localization by measurement of its magnetic field and spatial gradients. IEEE Trans Magn. 2006, 42, 3291–3293. [Google Scholar] [CrossRef]

- Lee, K.M.; Li, M.; Lin, C.Y. A novel way-finding method based on geomagnetic field effects and magnetic tensor measurements for visually impaired users. In Proceedings of the 2015 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Busan, Korea, 7–11 July 2015; pp. 232–237. [Google Scholar]

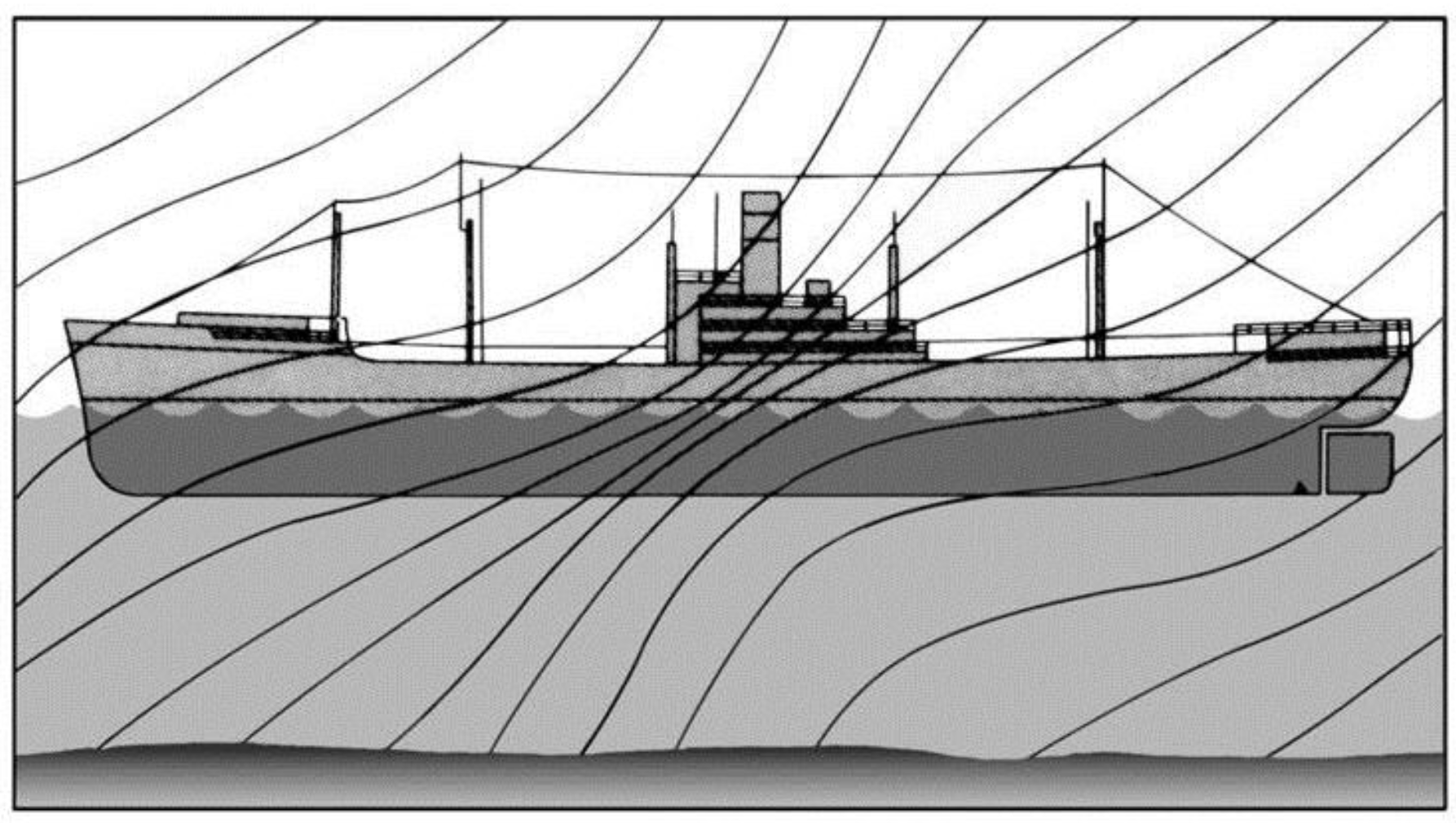

- The American Practical Navigator (Nima 2002 pdf Edition) 2013. Available online: https://en.wikisource.org/wiki/The_American_Practical_Navigator/Chapter_6 (accessed on 28 May 2017).

- Minguez, J.; Montano, L.; Santos-Victor, J. Reactive navigation for non-holonomic robots using the EGO-kinematic space. In Proceedings of the IEEE International Conference on Robotics and Automation 2002, Washington, DC, USA, 11–15 May 2002; pp. 3074–3080. [Google Scholar]

- Petti, S.; Fraichard, T. Safe motion planning in dynamic environments. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; pp. 2210–2215. [Google Scholar]

| V = 1.024 cm3 | V = 2.048 cm3 | |||

|---|---|---|---|---|

| Magnet a | Magnet b | Magnet c | Magnet d | |

| L (cm) | 0.635 | 1.27 | 0.635 | 1.27 |

| H (cm) | 0.635 | 0.1588 | 1.27 | 0.3175 |

| 1 | 8 | 1/2 | 4 | |

| Surface Field (T) | 0.5754 | 0.1448 | 0.6353 | 0.2704 |

| Motor | Faulhaber 1512U003SR 112:1, Max RPM: 119 |

| Wheel | Diameter: 10 mm, Width: 2 mm, Track width: 30 mm |

| Controller | STM32F411RE (ARM Cortex M4, 100 MHz, 128 Kb RAM, 512 Kb Flash) |

| IMU | Bosch BNO055 |

| Magnets | Length: 1/2 inch, Height: 1/8 inch, Grade: N52 |

| Magnetometer | MAG3110 |

| Frontal Area | |||||

|---|---|---|---|---|---|

| Designed angle (°) | −45 | −20 | 0 | 20 | 45 |

| Average detected angle (°) | −46.8 | −18.2 | 2.2 | 22.7 | 46.2 |

| Average error (%) | 1.9 | 1.5 | 2.4 | 2.9 | 1.4 |

| Maximum detection error (°) | 3.1 | 2.2 | 3.2 | 2.9 | 2.3 |

| Maximum error (%) | 3.4 | 2.4 | 3.5 | 3.3 | 2.5 |

| Robot Radius | 3 cm | Initial location of the robot | (0 cm, 0 cm) |

| Detection Range | 3 cm outside the shell | Location of the obstacle | (5 cm, 25 cm) |

| Waypoint Zone | Radius: 1 cm | Target waypoint | (0 cm, 50 cm) |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, F.; Vibhute, A.; Soh, G.S.; Wood, K.L.; Foong, S. A Compact Magnetic Field-Based Obstacle Detection and Avoidance System for Miniature Spherical Robots. Sensors 2017, 17, 1231. https://doi.org/10.3390/s17061231

Wu F, Vibhute A, Soh GS, Wood KL, Foong S. A Compact Magnetic Field-Based Obstacle Detection and Avoidance System for Miniature Spherical Robots. Sensors. 2017; 17(6):1231. https://doi.org/10.3390/s17061231

Chicago/Turabian StyleWu, Fang, Akash Vibhute, Gim Song Soh, Kristin L. Wood, and Shaohui Foong. 2017. "A Compact Magnetic Field-Based Obstacle Detection and Avoidance System for Miniature Spherical Robots" Sensors 17, no. 6: 1231. https://doi.org/10.3390/s17061231