Impact Damage Localisation with Piezoelectric Sensors under Operational and Environmental Conditions

Abstract

:1. Introduction

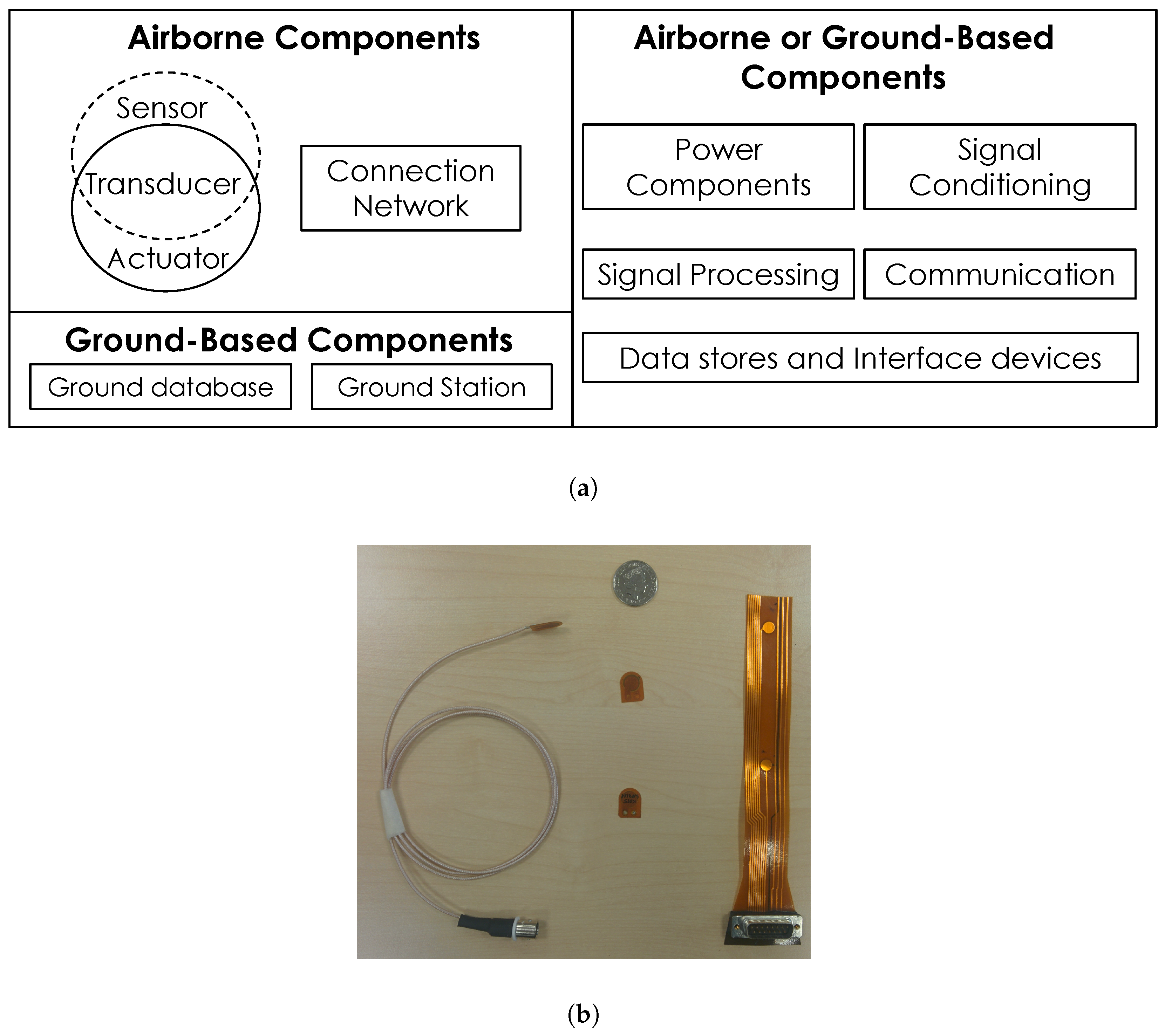

2. Environmental Test Conditions

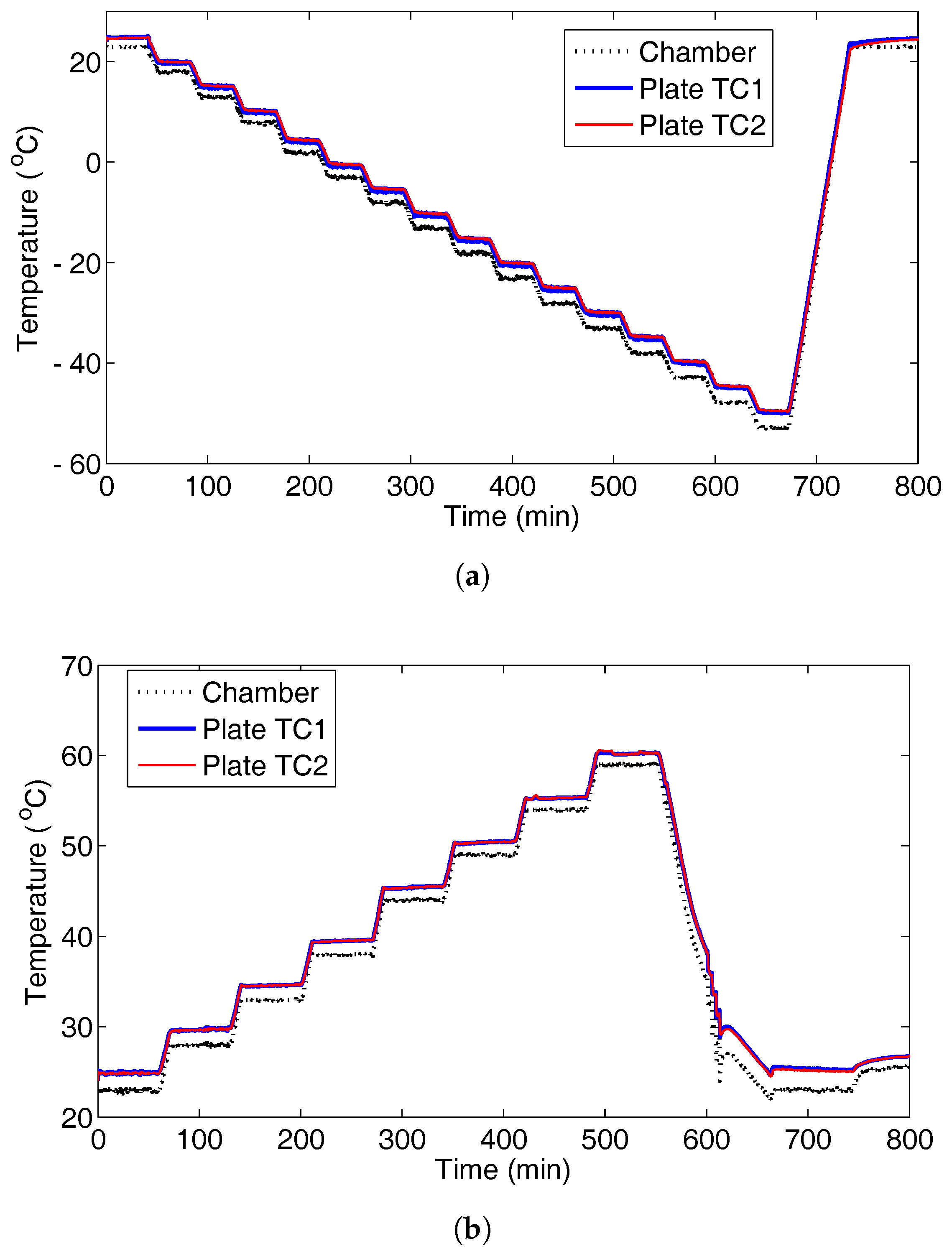

2.1. Temperature

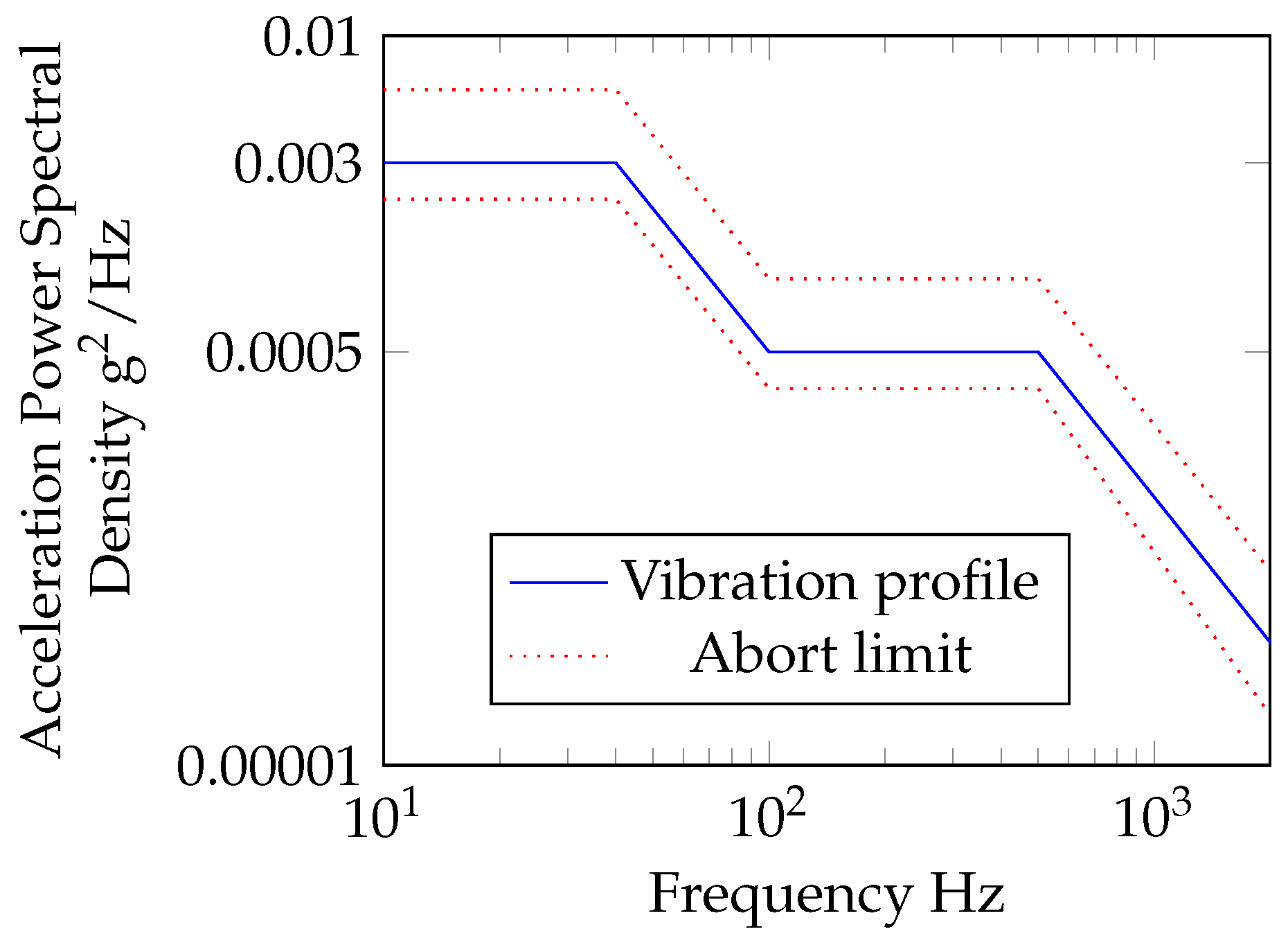

2.2. Vibration

3. Experimental Set-Up

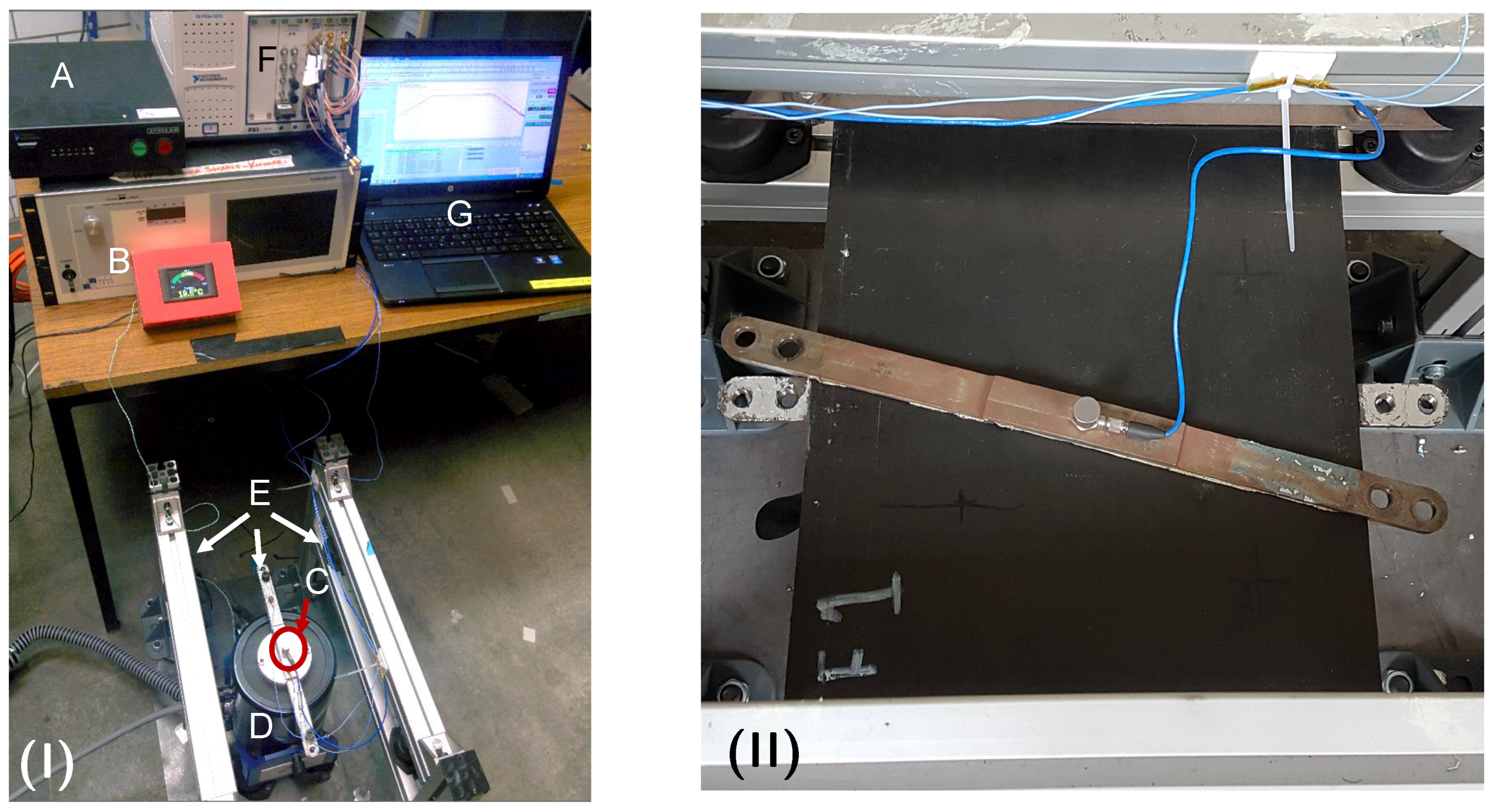

3.1. Vibration Set-Up

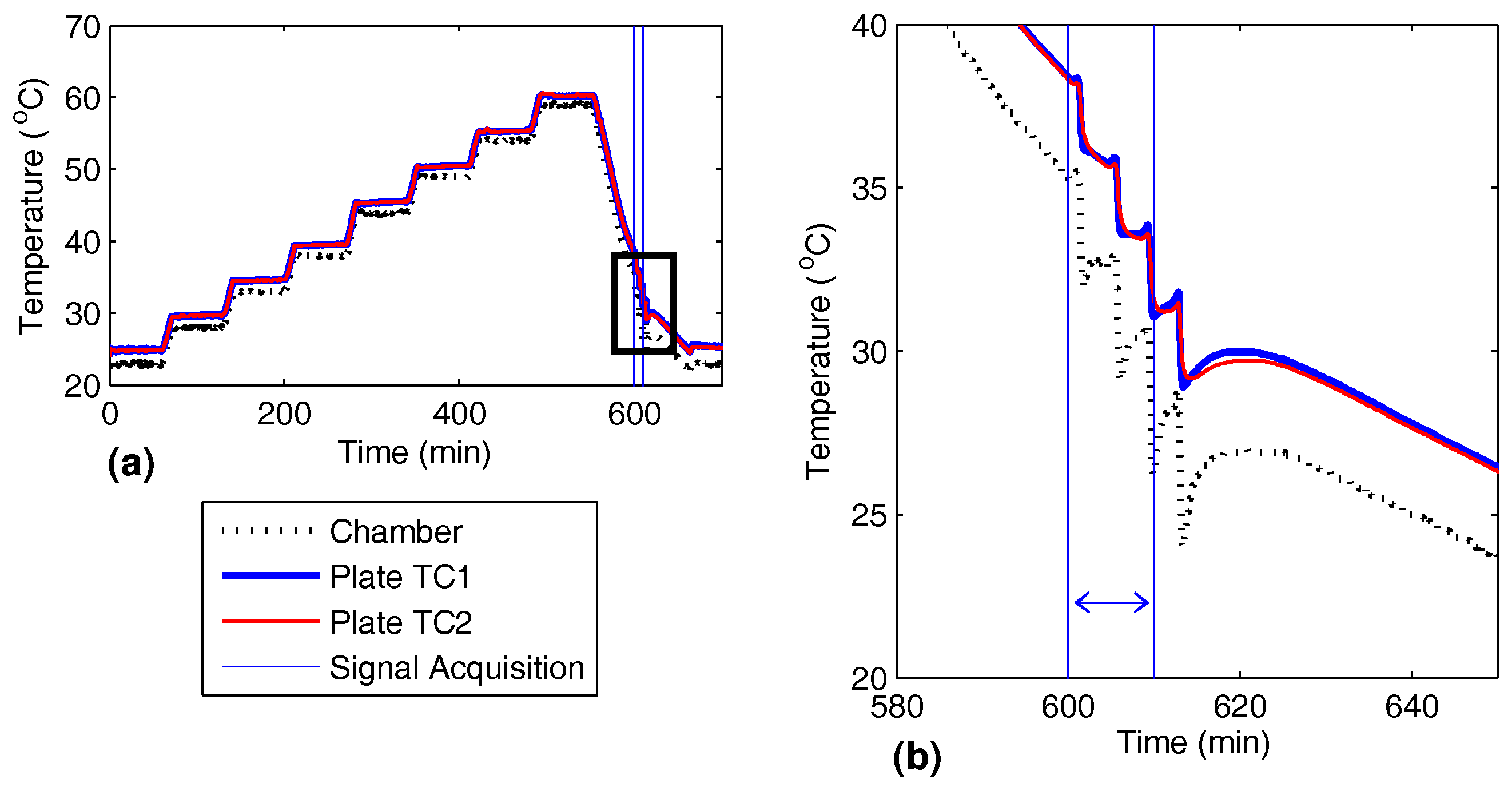

3.2. Temperature

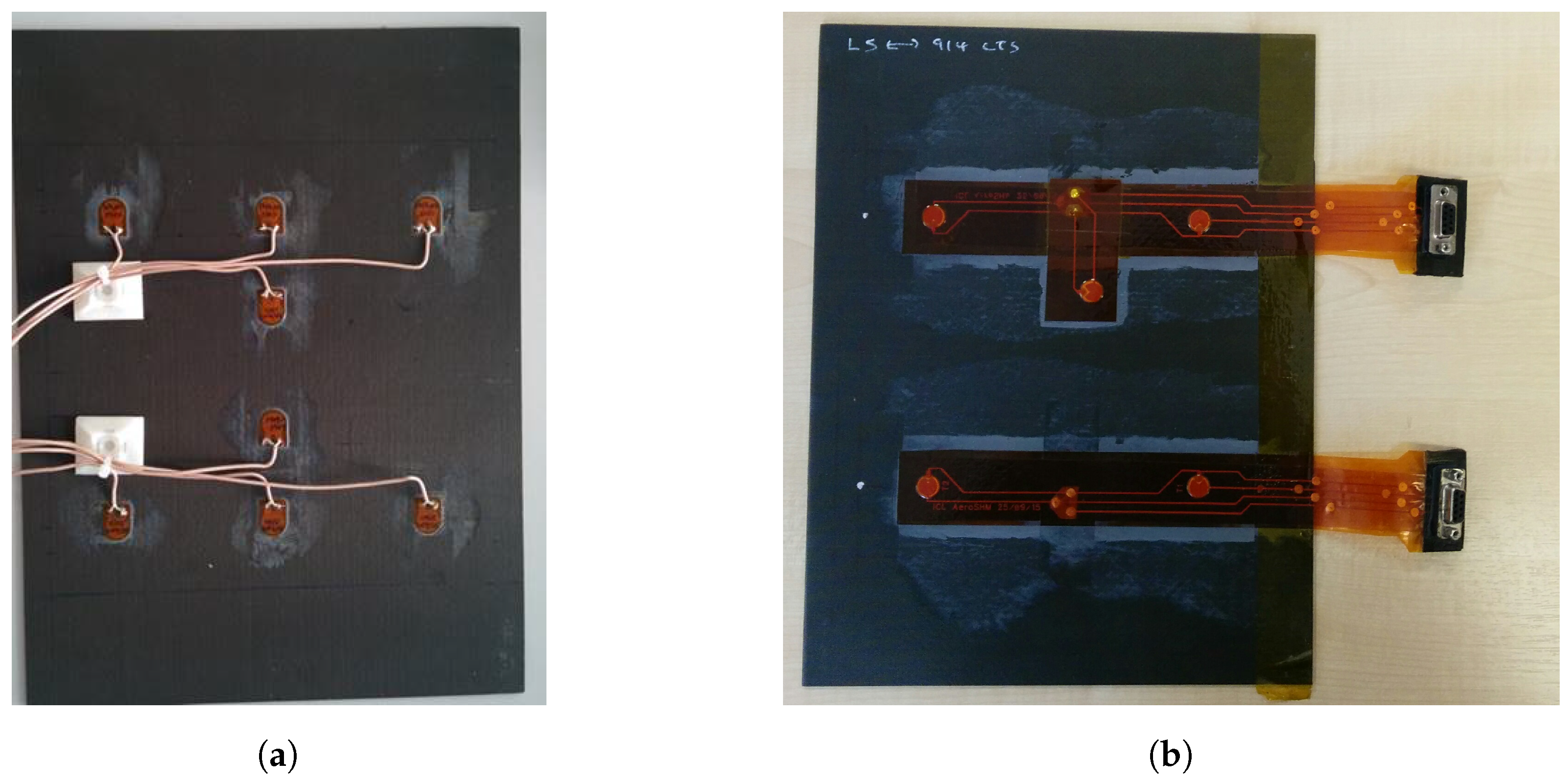

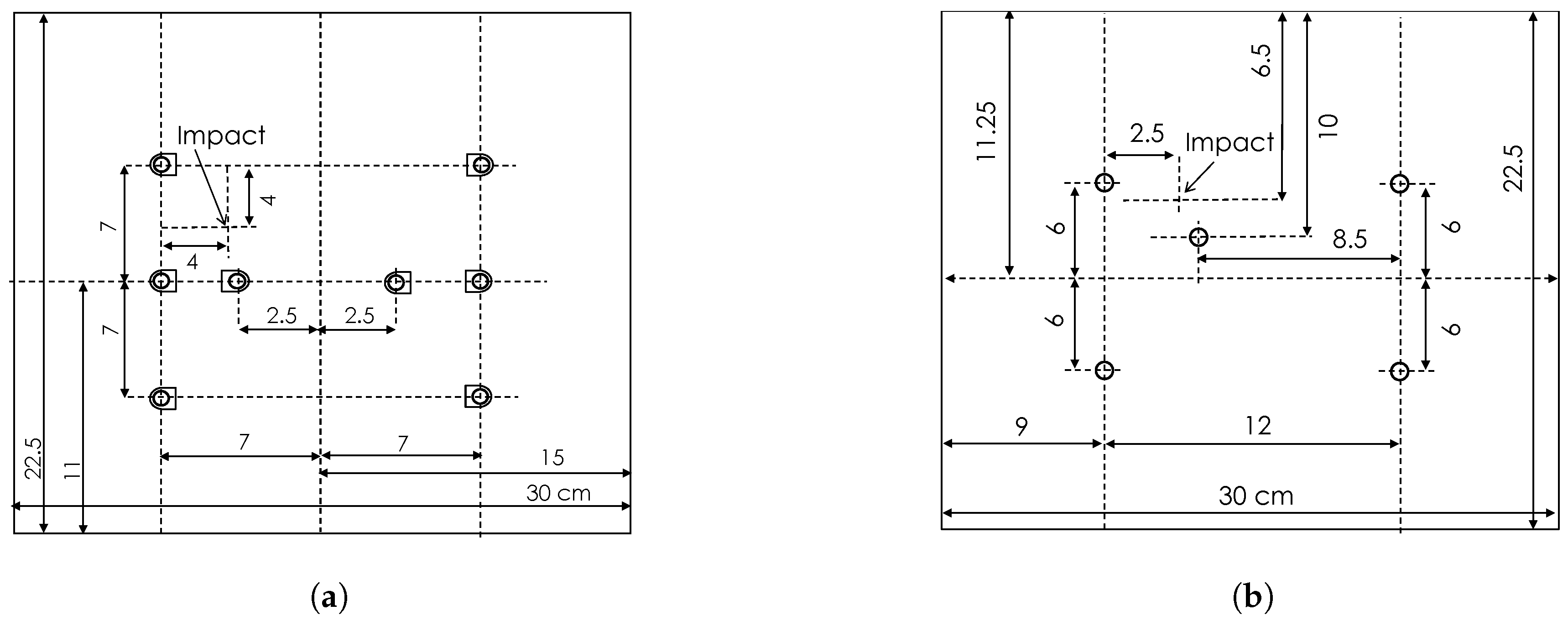

3.3. Plate Definitions

3.4. Impact Damage

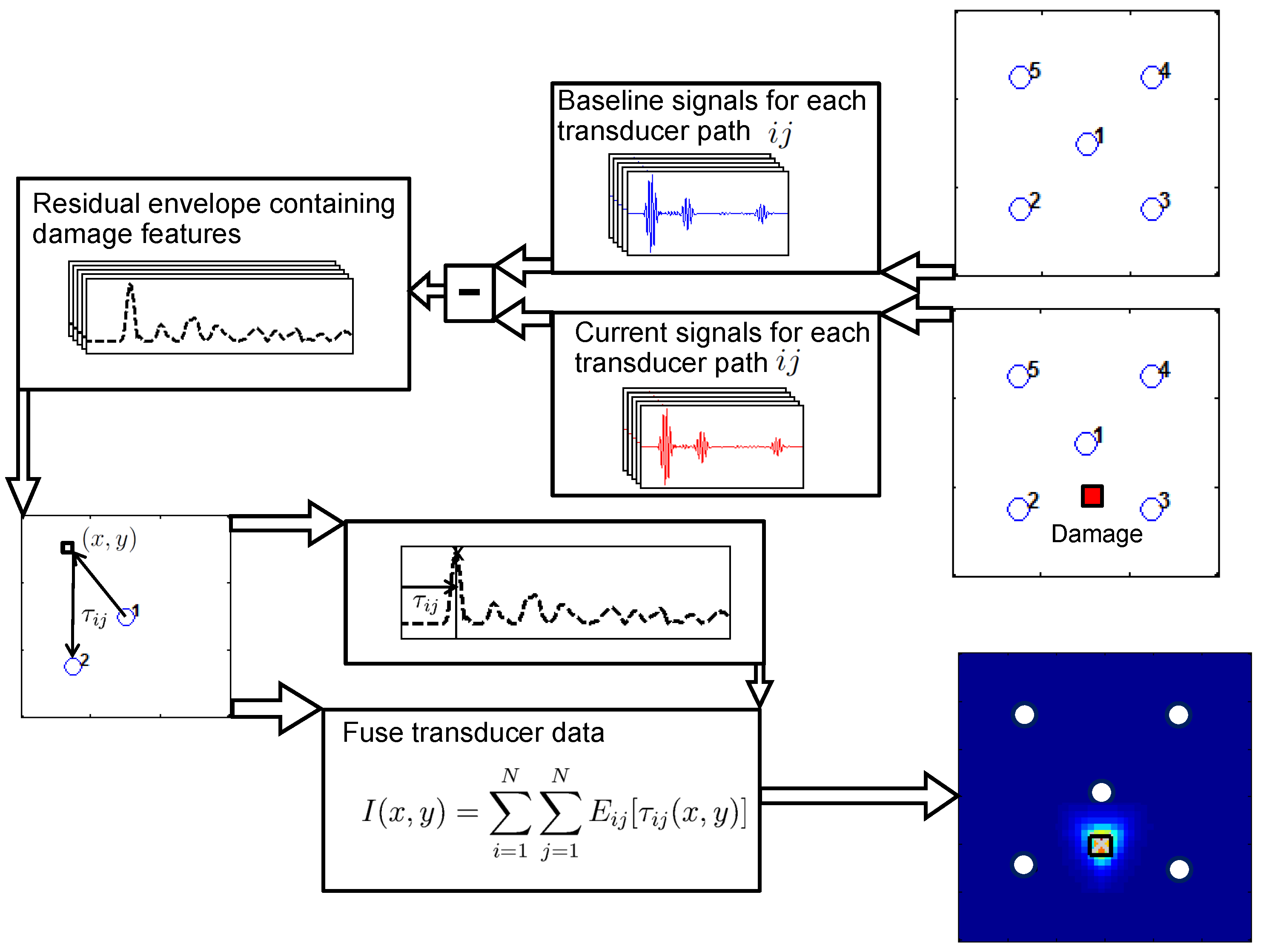

4. Damage Detection

4.1. Localisation Method

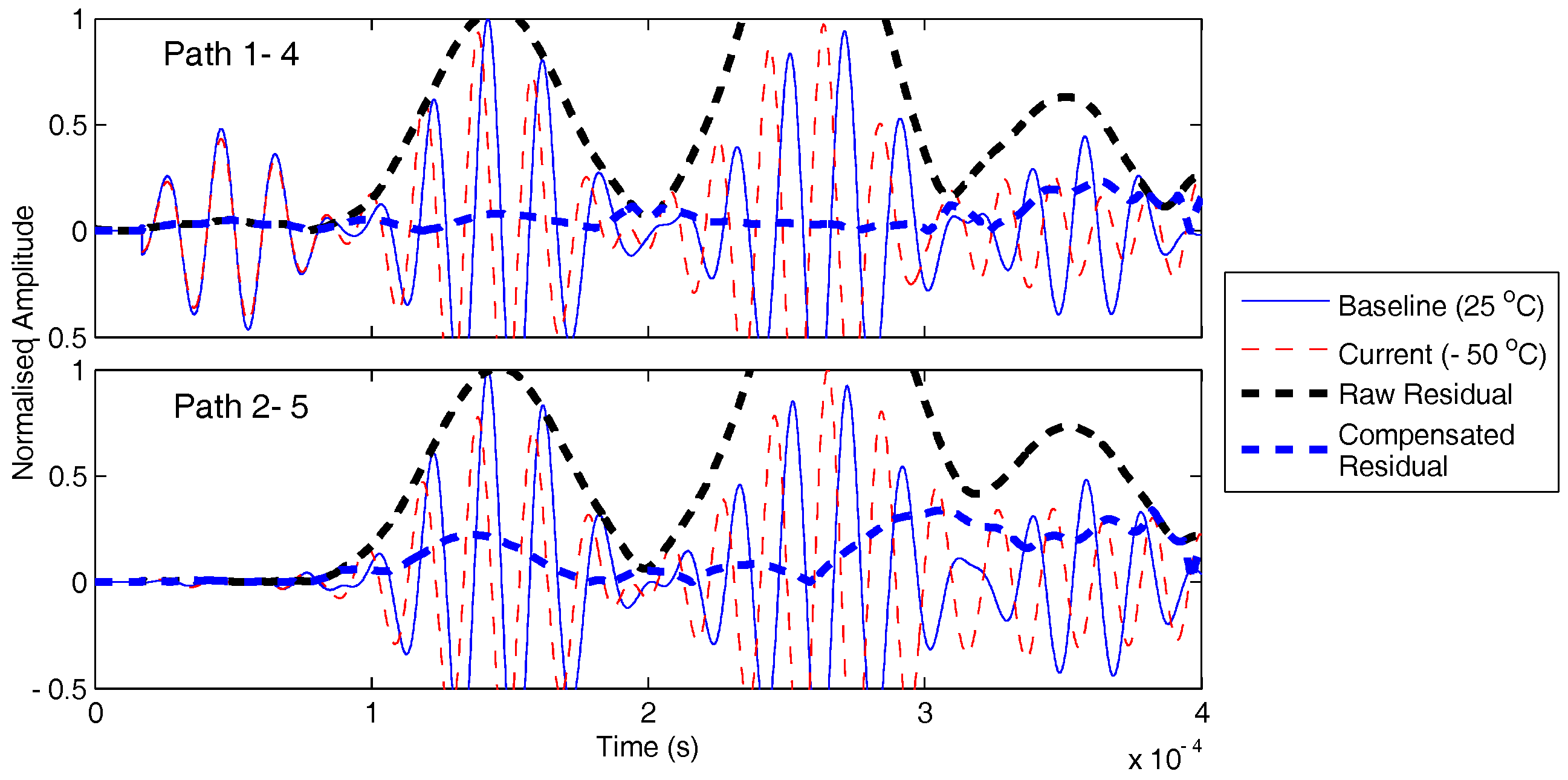

4.2. Temperature Correction

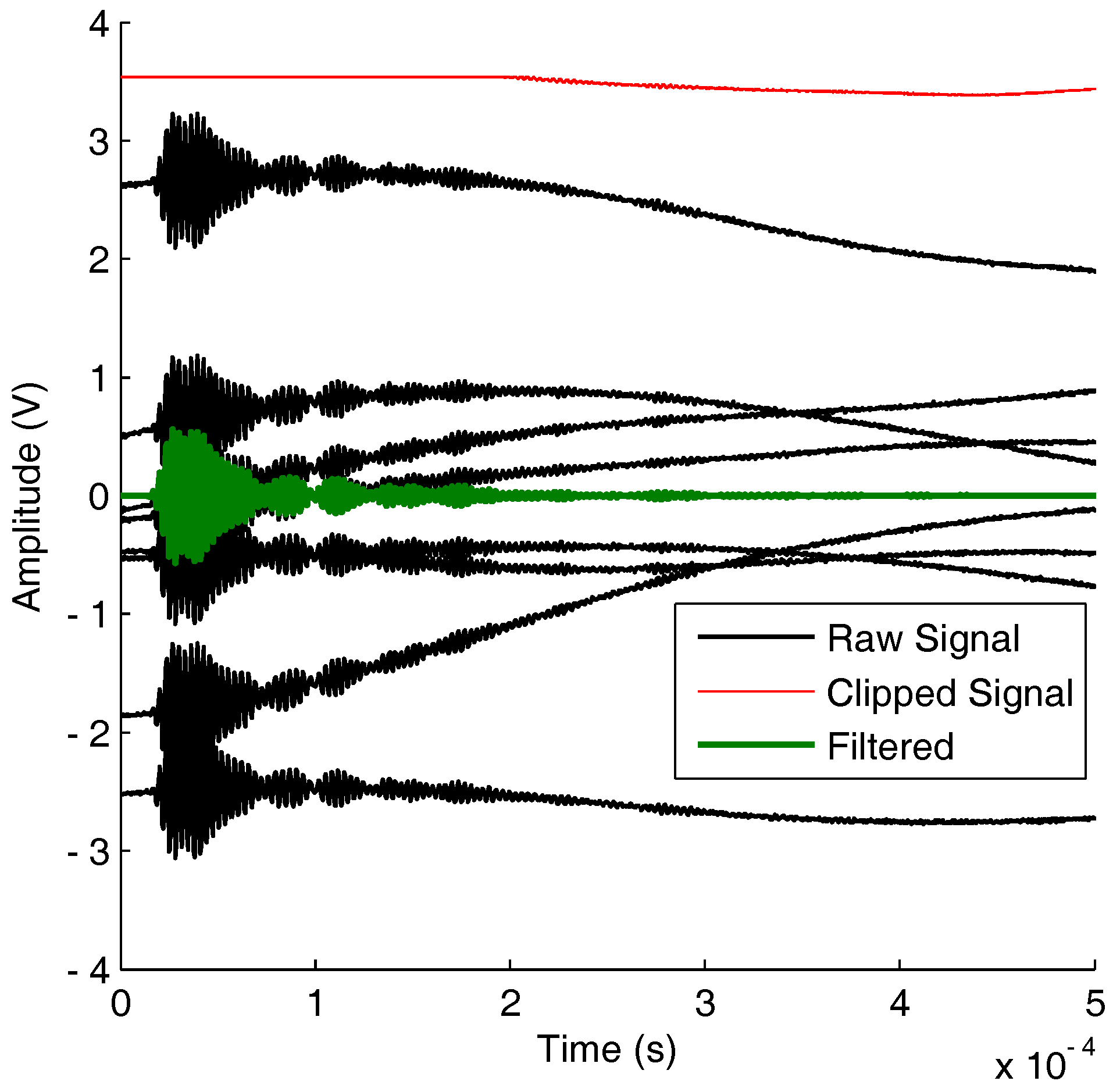

4.3. Vibration Filtering

5. Results and Discussion

5.1. BVID Localisation

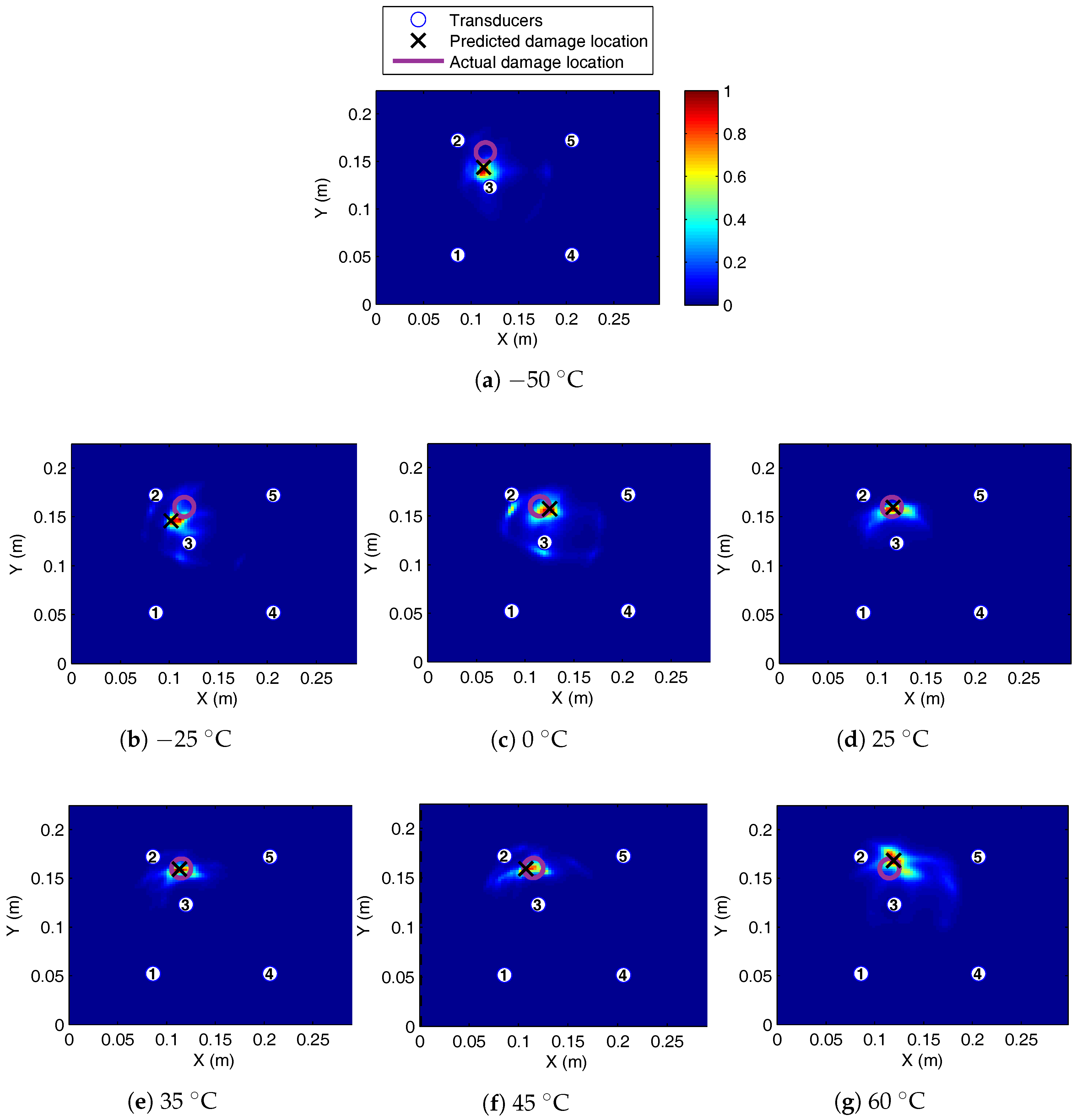

5.1.1. Steady State Thermal

5.1.2. Transient Thermal

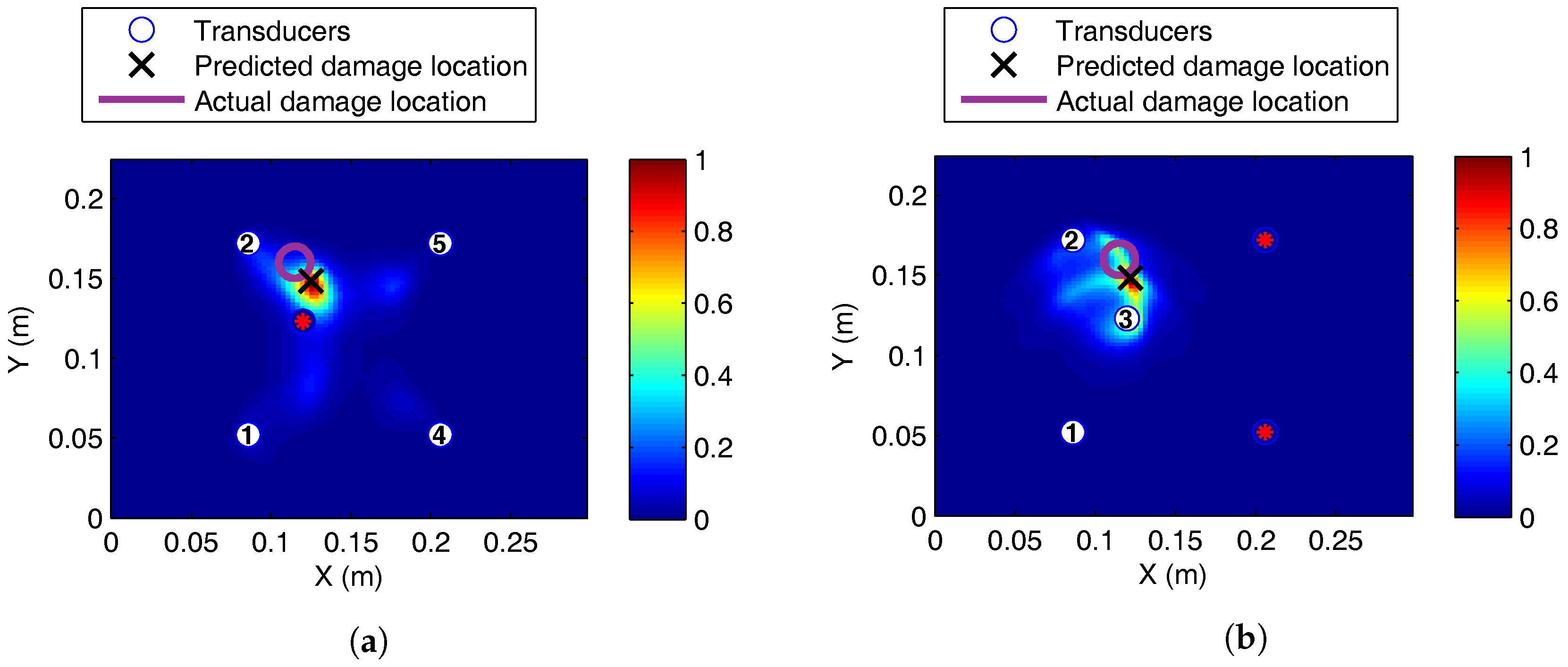

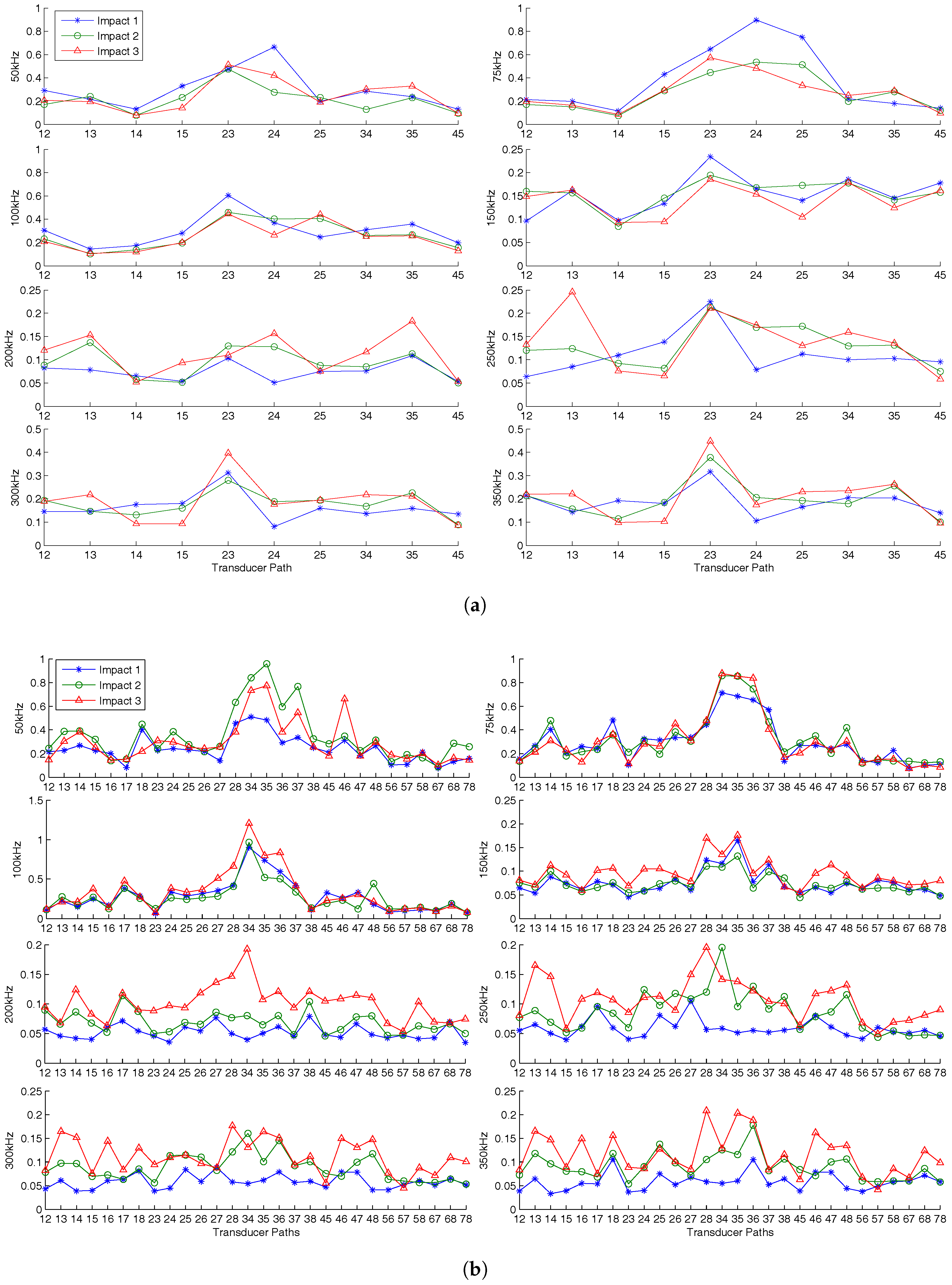

5.1.3. Vibration

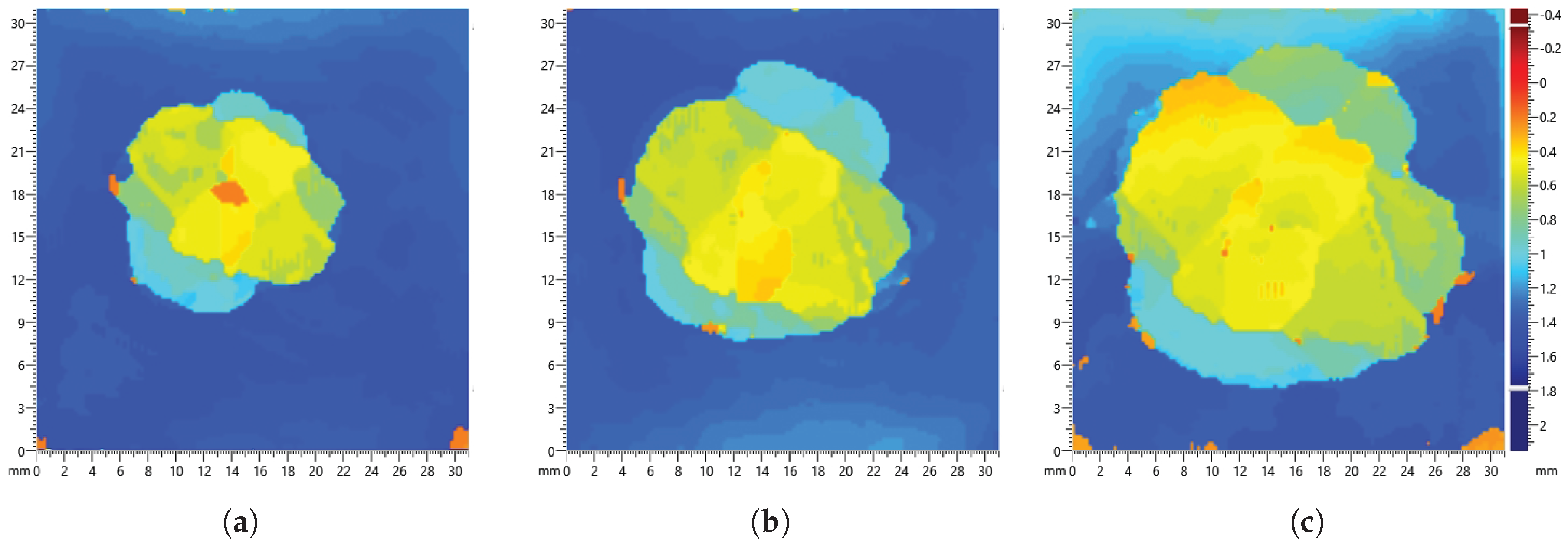

5.2. Damage Severity

6. Conclusions and Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Michaels, J.E. Detection, localization and characterization of damage in plates with an in situ array of spatially distributed ultrasonic sensors. Smart Mater. Struct. 2008, 17, 035035. [Google Scholar] [CrossRef]

- Sharif-Khodaei, Z.; Aliabadi, M.H. Assessment of delay-and-sum algorithms for damage detection in aluminium and composite plates. Smart Mater. Struct. 2014, 23, 075007. [Google Scholar] [CrossRef]

- RTCA/Special Committee 135 (SC-135). DO-160C Environmental Conditions and Test Procedures for Airborne Equipment; Radio Technical Commission for Aeronautics (RTCA): Washington, DC, USA, 1989. [Google Scholar]

- Salmanpour, M.S.; Sharif Khodaei, Z.; Aliabadi, M.H. Airborne Transducer Integrity under Operational Environment for Structural Health Monitoring. Sensors 2016, 16, 2110. [Google Scholar] [CrossRef] [PubMed]

- Thiene, M.; Ghajari, M.; Galvanetto, U.; Aliabadi, M.H. Effects of the transfer function evaluation on the impact force reconstruction with application to composite panels. Compos. Struct. 2014, 114, 1–9. [Google Scholar] [CrossRef]

- Qiu, L.; Yuan, S.; Zhang, X.; Wang, Y. A time reversal focusing based impact imaging method and its evaluation on complex composite structures. Smart Mater. Struct. 2011, 20, 105014. [Google Scholar] [CrossRef]

- Sharif-Khodaei, Z.; Ghajari, M.; Aliabadi, M.H. Determination of impact location on composite stiffened panels. Smart Mater. Struct. 2012, 21, 105026. [Google Scholar] [CrossRef]

- Ghajari, M.; Sharif-Khodaei, Z.; Aliabadi, M.H.; Apicella, A. Identification of impact force for smart composite stiffened panels. Smart Mater. Struct. 2013, 22, 085014. [Google Scholar] [CrossRef]

- Si, L.; Baier, H. Real-Time Impact Visualization Inspection of Aerospace Composite Structures with Distributed Sensors. Sensors 2015, 15, 16536–16556. [Google Scholar] [CrossRef] [PubMed]

- Gao, D.; Wang, Y.; Wu, Z.; Rahim, G.; Bai, S. Design of a sensor network for structural health monitoring of a full-scale composite horizontal tail. Smart Mater. Struct. 2014, 23, 055011. [Google Scholar] [CrossRef]

- Sharif Khodaei, Z.; Aliabadi, M.H. A Multi-Level Decision Fusion Strategy for Condition Based Maintenance of Composite Structures. Materials 2016, 9, 790. [Google Scholar] [CrossRef]

- Attarian, V.A.; Cegla, F.B.; Cawley, P. Long-term stability of guided wave structural health monitoring using distributed adhesively bonded piezoelectric transducers. Struct. Health Monit. 2014, 13, 265–280. [Google Scholar] [CrossRef]

- Salmanpour, M.S.; Sharif Khodaei, Z.; Aliabadi, M.H. Guided Wave Temperature Correction Methods in Structural Health Monitoring. J. Intell. Mater. Syst. Struct. 2016. [Google Scholar] [CrossRef]

- Putkis, O.; Dalton, R.P.; Croxford, A.J. The influence of temperature variations on ultrasonic guided waves in anisotropic CFRP plates. Ultrasonics 2015, 60, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Ha, S.; Lonkar, K.; Mittal, A.; Chang, F.K. Adhesive Layer Effects on PZT-induced Lamb Waves at Elevated Temperatures. Struct. Health Monit. 2010, 9, 247–256. [Google Scholar] [CrossRef]

- Lu, Y.; Michaels, J.E. Structural Health Monitoring Under Changing Environmental Conditions. IEEE Sens. J. 2009, 9, 1462–1471. [Google Scholar]

- Schubert, K.J.; Brauner, C.; Herrmann, A.S. Non-damage-related influences on Lamb wave-based structural health monitoring of carbon fiber-reinforced plastic structures. Struct. Health Monit. 2013, 13, 158–176. [Google Scholar] [CrossRef]

- Aranguren, G.; Monje, P.M.; Cokonaj, V.; Barrera, E.; Ruiz, M. Ultrasonic wave-based structural health monitoring embedded instrument. Rev. Sci. Instrum. 2013, 84, 125106. [Google Scholar] [CrossRef] [PubMed]

- Konstantinidis, G.; Drinkwater, B.W.; Wilcox, P.D. The temperature stability of guided wave structural health monitoring systems. Smart Mater. Struct. 2006, 15, 967–976. [Google Scholar] [CrossRef]

- Kundu, T.; Croxford, A.J.; Wilcox, P.D.; Konstantinidis, G.; Drinkwater, B.W. Strategies for overcoming the effect of temperature on guided wave structural health monitoring. In Proceedings of the SPIE 6532, Health Monitoring of Structural and Biological Systems, San Diego, CA, USA, 18 March 2007. [Google Scholar]

- Lu, Y.; Michaels, J.E. A methodology for structural health monitoring with diffuse ultrasonic waves in the presence of temperature variations. Ultrasonics 2005, 43, 717–731. [Google Scholar] [CrossRef] [PubMed]

- Wilcox, P.D.; Croxford, A.J.; Michaels, J.E.; Lu, Y.; Drinkwater, B.W.; Thompson, D.O.; Chimenti, D.E. A Comparison of Temperature Compensation Methods for Guided Wave Structural Health Monitoring. In AIP Conference Proceedings; AIP Publishing LLC.: College Park, MD, USA, 2008. [Google Scholar]

- Wang, Y.; Gao, L.; Yuan, S.; Qiu, L.; Qing, X. An adaptive filter-based temperature compensation technique for structural health monitoring. J. Intell. Mater. Syst. Struct. 2014, 25, 2187–2198. [Google Scholar] [CrossRef]

- Fendzi, C.; Rebillat, M.; Mechbal, N.; Guskov, M.; Coffignal, G. A data-driven temperature compensation approach for Structural Health Monitoring using Lamb waves. Struct. Health Monit. 2016, 15, 525–540. [Google Scholar] [CrossRef]

- APR6461. Guidelines for Implementation of Structural Health Monitoring on Fixed Wing Aircraft. In G-11SHM, Structural Health Monitoring and Mgmt (AISC); SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- USA Department of Defence Test Method Standard. MIL-STD-810G: Environmental Engineering Considerations and Laboratory Tests; US DoD: Arlington County, VA, USA, 2008.

- Salmanpour, M.S.; Sharif Khodaei, Z.; Aliabadi, M.H. Transducer Placement Optimisation Scheme for a Delay and Sum Damage Detection Algorithm. Struct. Control Health Monit. 2016, in press. [Google Scholar] [CrossRef]

- Croxford, A.J.; Moll, J.; Wilcox, P.D.; Michaels, J.E. Efficient temperature compensation strategies for guided wave structural health monitoring. Ultrasonics 2010, 50, 517–528. [Google Scholar] [CrossRef] [PubMed]

- Petculescu, G.; Krishnaswamy, S.; Achenbach, J.D. Group delay measurements using modally selective Lamb wave transducers for detection and sizing of delaminations in composites. Smart Mater. Struct. 2008, 17, 015007. [Google Scholar] [CrossRef]

- Glushkov, E.; Glushkova, N.; Golub, M.; Bostrom, A. Natural resonance frequencies, wave blocking, and energy localization in an elastic half-space and waveguide with a crack. J. Acoust. Soc. Am. 2006, 119, 3589. [Google Scholar] [CrossRef]

| Impact Event | Energy (J) |

|---|---|

| 1 | 5.68 |

| 2 | 6.41 |

| 3 | 7.84 |

| Impact Event | Energy (J) |

|---|---|

| 1 | 4.8 |

| 2 | 6.41 |

| 3 | 7.84 |

| Temperature (°C) | Localisation (mm) | Absolute Error (mm) | |

|---|---|---|---|

| x | y | ||

| −50 | 113.2 | 143.7 | 16.39 |

| −25 | 101.3 | 145.9 | 19.7 |

| 0 | 125.2 | 161.6 | 10.3 |

| 25 | 116.2 | 159.4 | 1.3 |

| 35 | 113.2 | 159.4 | 1.9 |

| 45 | 107.3 | 159.4 | 7.7 |

| 60 | 116.2 | 170.6 | 10.7 |

| −50 * | 113.2 | 139.2 | 20.9 |

| −25 * | 101.3 | 148.2 | 18.1 |

| 0 * | 125.2 | 157.2 | 10.6 |

| 25 * | 137.1 | 154.9 | 22.7 |

| 35 * | 122.2 | 163.9 | 8.2 |

| 45 * | 119.2 | 163.9 | 5.7 |

| 60 * | 119.2 | 168.4 | 9.4 |

| Temperature (°C) | Localisation (mm) | Absolute Error (mm) | |

|---|---|---|---|

| x | y | ||

| 20 | 137.1 | 123.5 | 42.7 |

| −15 | 131.1 | 123.5 | 39.9 |

| −10 | 131.1 | 125.7 | 37.9 |

| −5 | 116.2 | 141.4 | 18.6 |

| 0 | 116.2 | 141.4 | 18.6 |

| 5 | 110.3 | 143.7 | 17.0 |

| 10 | 116.2 | 139.2 | 20.8 |

| 15 | 160.9 | 143.7 | 48.7 |

| 20 | 116.2 | 145.9 | 14.2 |

| 25 | 101.3 | 159.4 | 13.7 |

| 30 | 95.4 | 163.9 | 20.0 |

| 35 | 95.4 | 166.1 | 20.6 |

| 40 | 86.5 | 51.6 | 112.1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salmanpour, M.S.; Sharif Khodaei, Z.; Aliabadi, M.H.F. Impact Damage Localisation with Piezoelectric Sensors under Operational and Environmental Conditions. Sensors 2017, 17, 1178. https://doi.org/10.3390/s17051178

Salmanpour MS, Sharif Khodaei Z, Aliabadi MHF. Impact Damage Localisation with Piezoelectric Sensors under Operational and Environmental Conditions. Sensors. 2017; 17(5):1178. https://doi.org/10.3390/s17051178

Chicago/Turabian StyleSalmanpour, Mohammad Saleh, Zahra Sharif Khodaei, and M. H. Ferri Aliabadi. 2017. "Impact Damage Localisation with Piezoelectric Sensors under Operational and Environmental Conditions" Sensors 17, no. 5: 1178. https://doi.org/10.3390/s17051178