Design and Experimental Study of a Current Transformer with a Stacked PCB Based on B-Dot

Abstract

:1. Introduction

2. Principle of Current Measurement

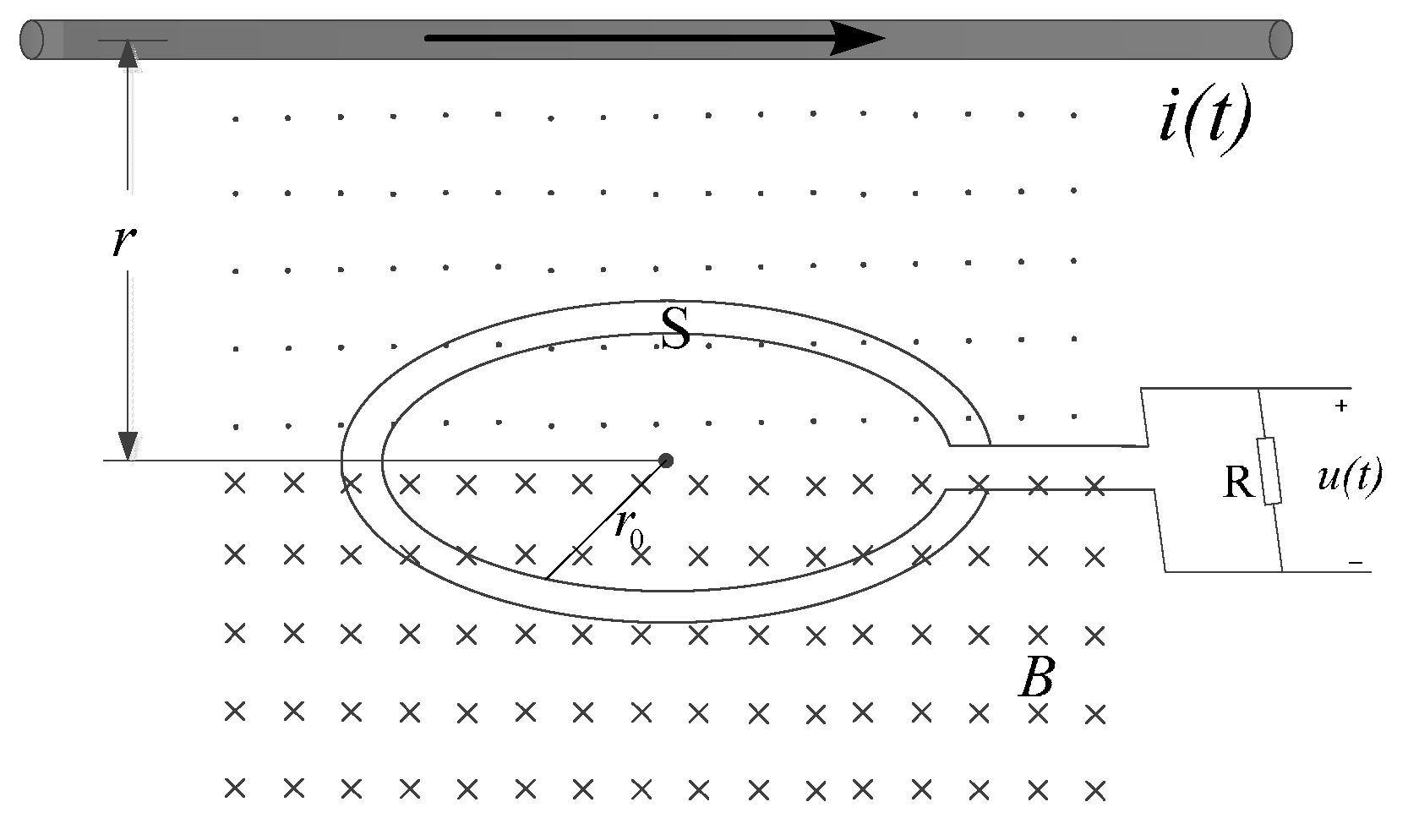

2.1. Principal for B-Dot

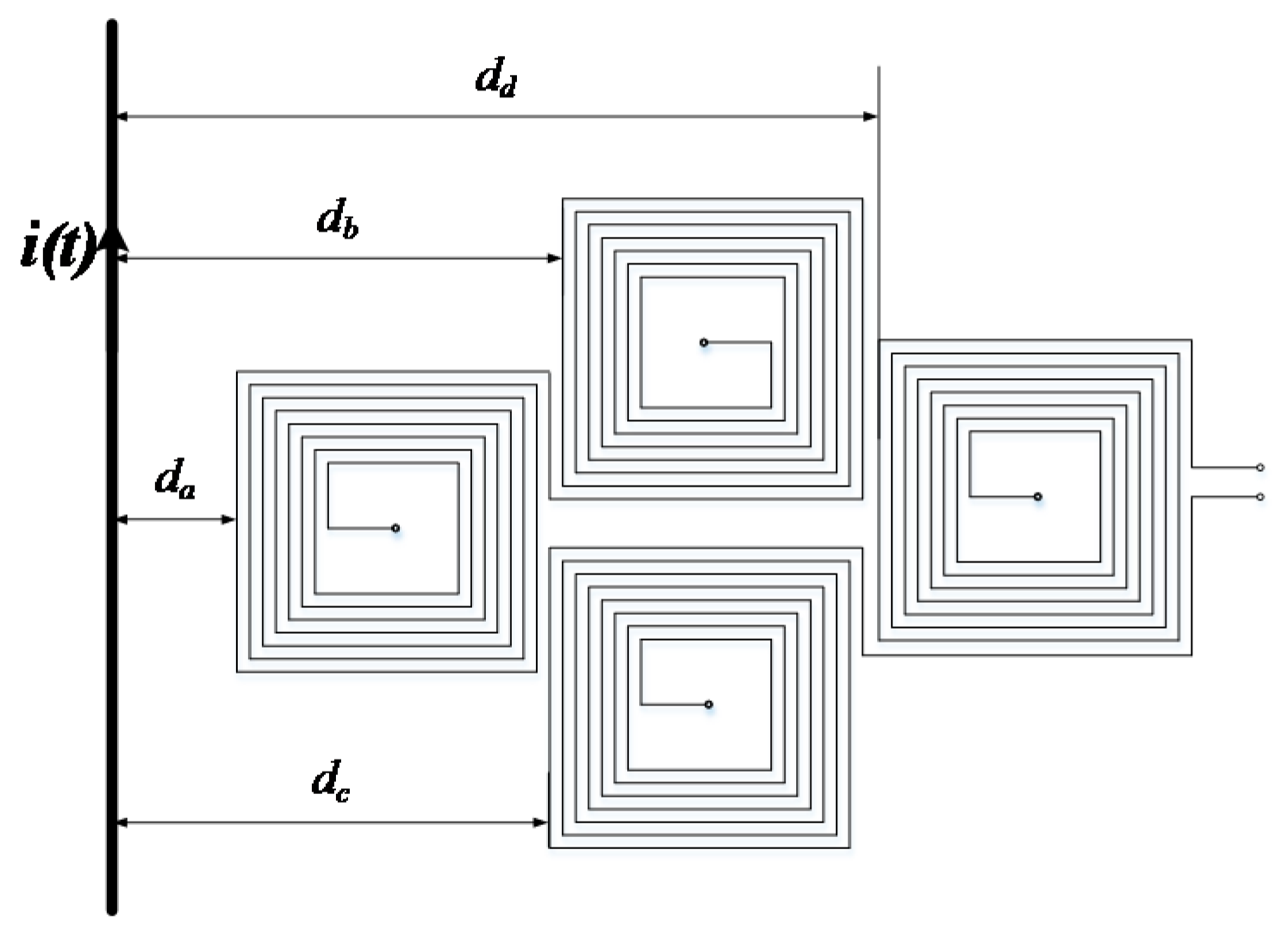

2.2. Sensor Design

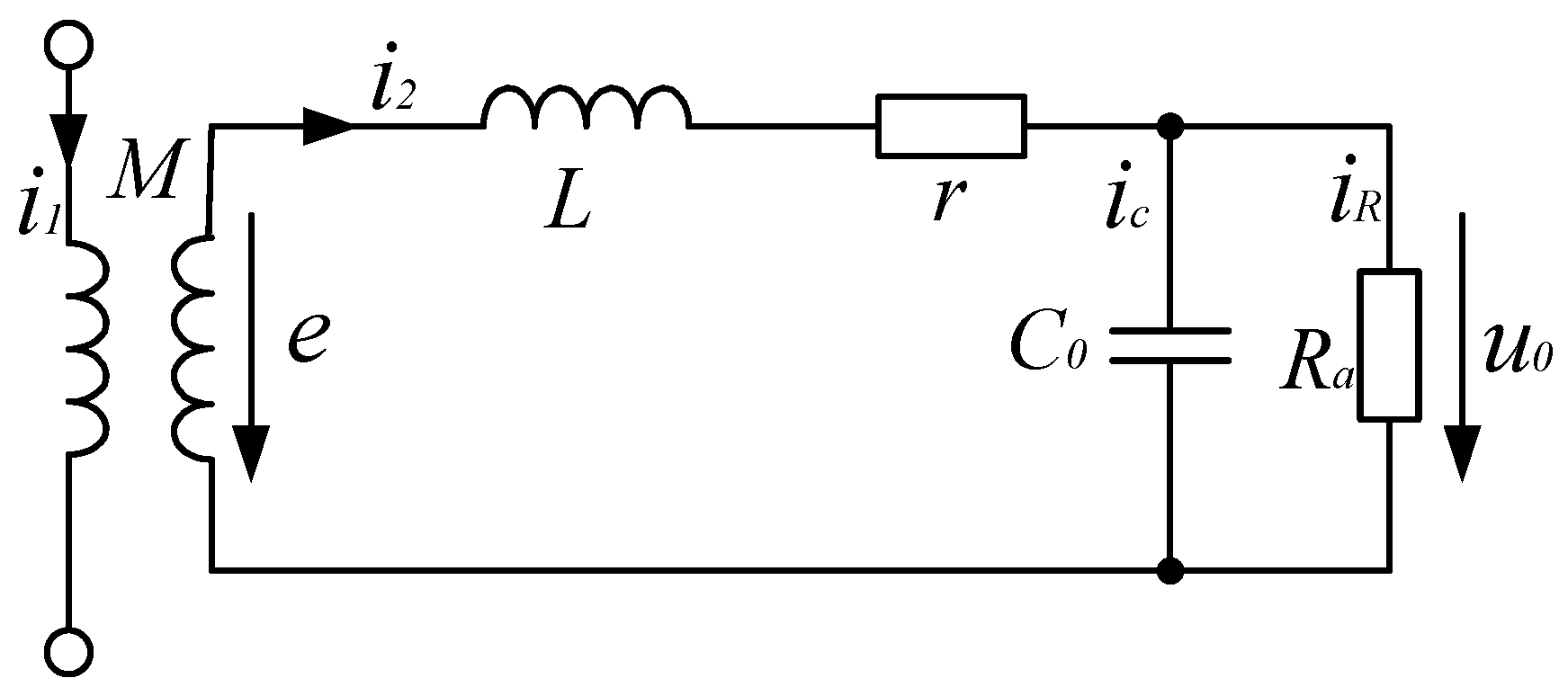

2.3. Sensor under Self-Integrating Mode

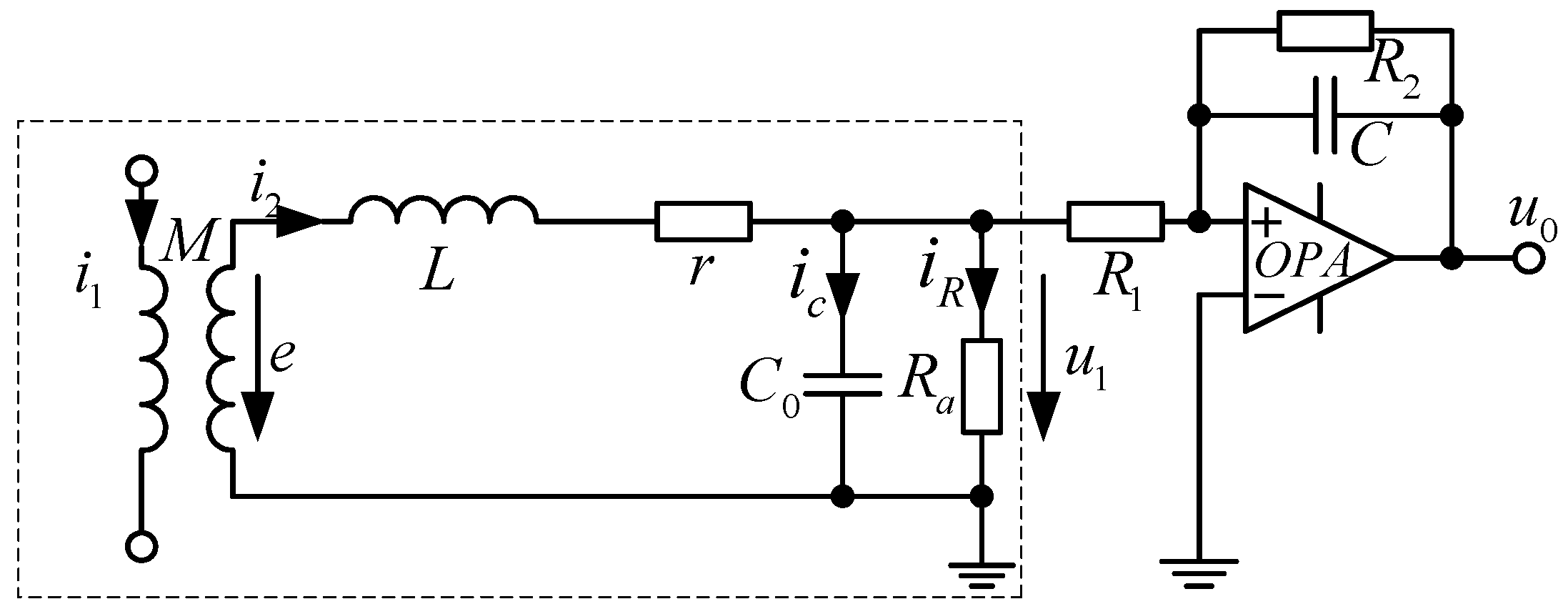

2.4. Sensor under Differential Mode

2.5. Anti-Interference Sensor Analysis

2.5.1. Magnetic Field Component Parallel to the PCB Board

2.5.2. Magnetic Field Component Vertical to the PCB Board

3. Design of the Current Transformer

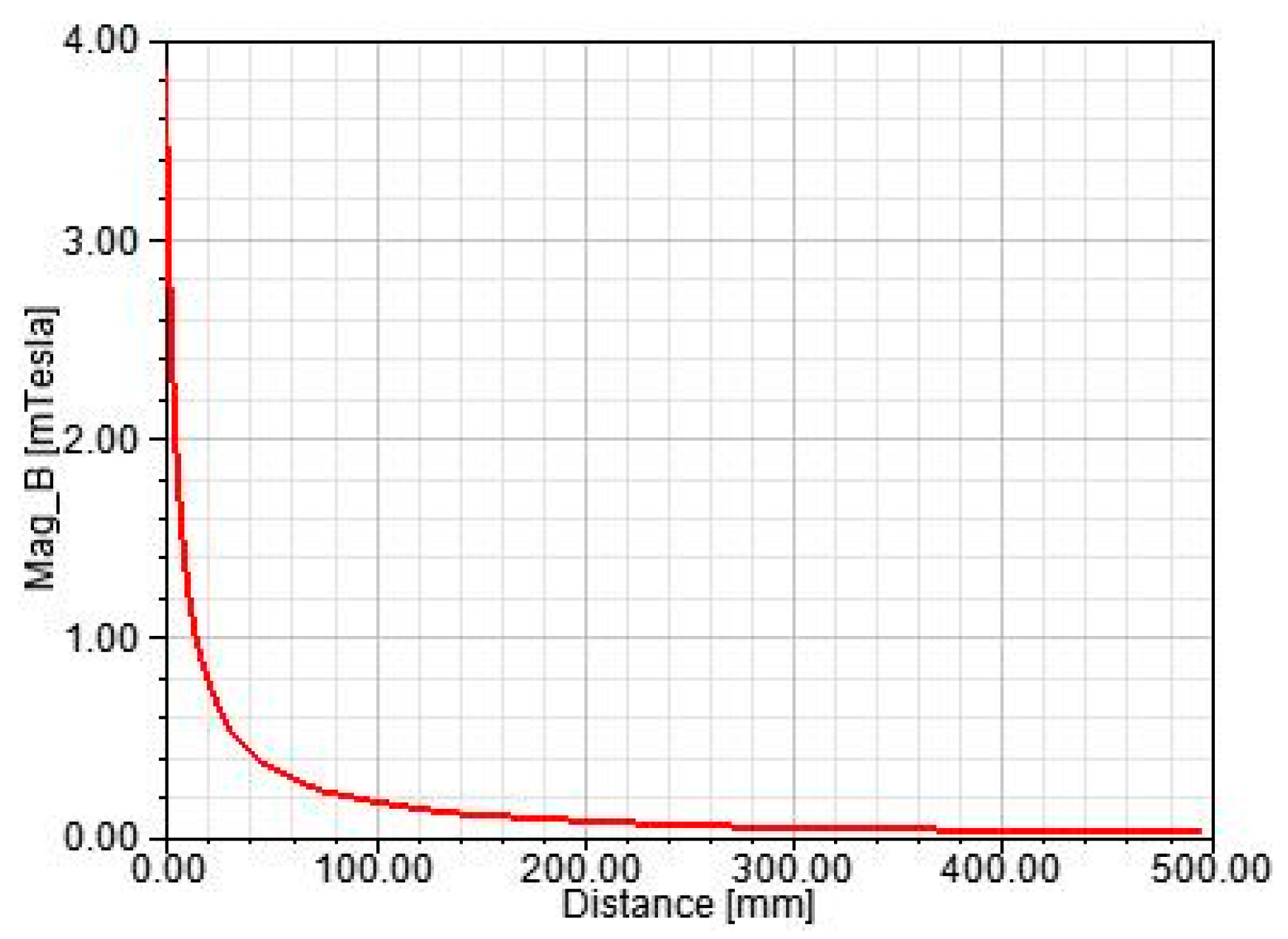

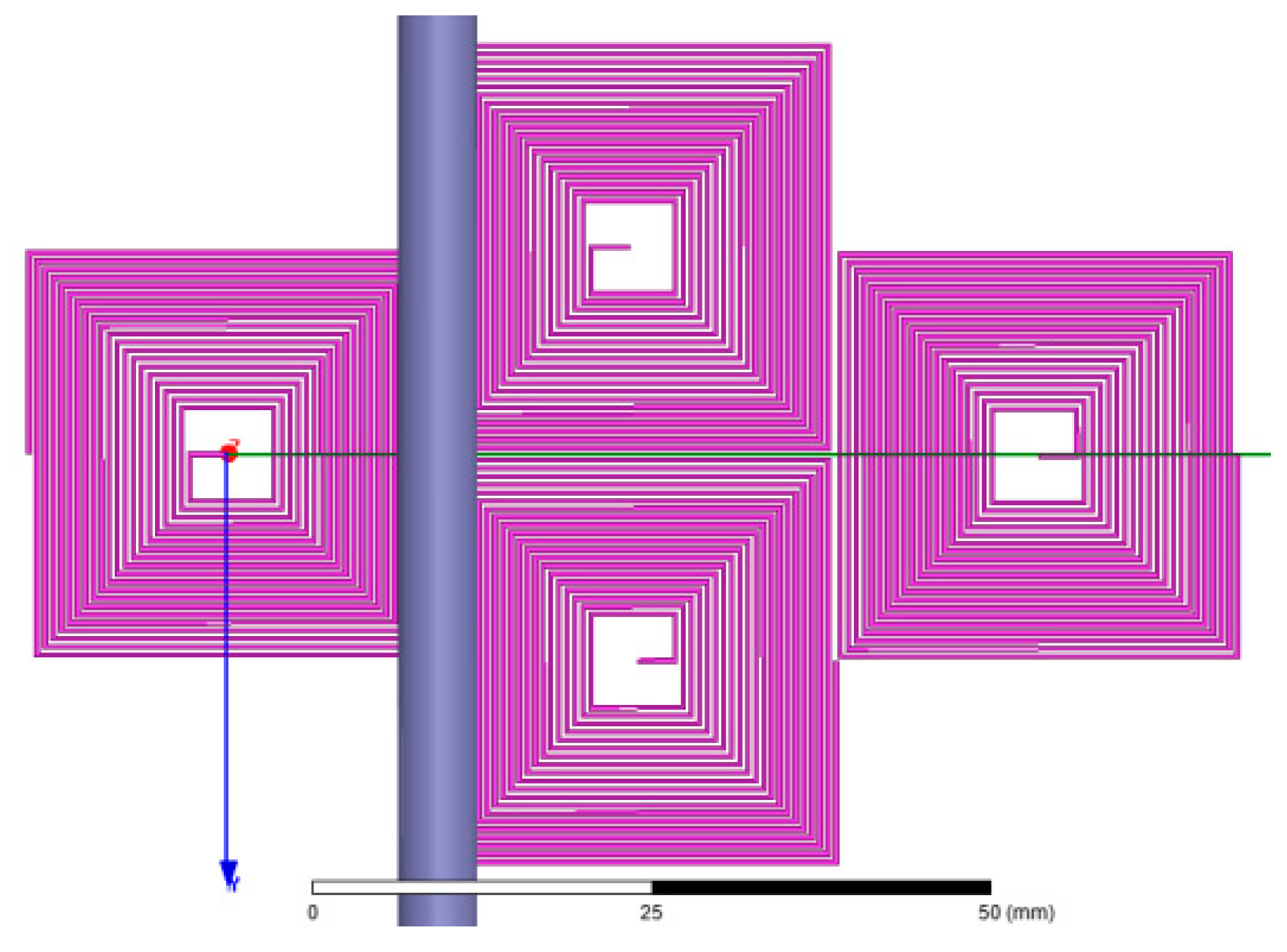

3.1. Sensor Optimization Based on Finite Element Simulation

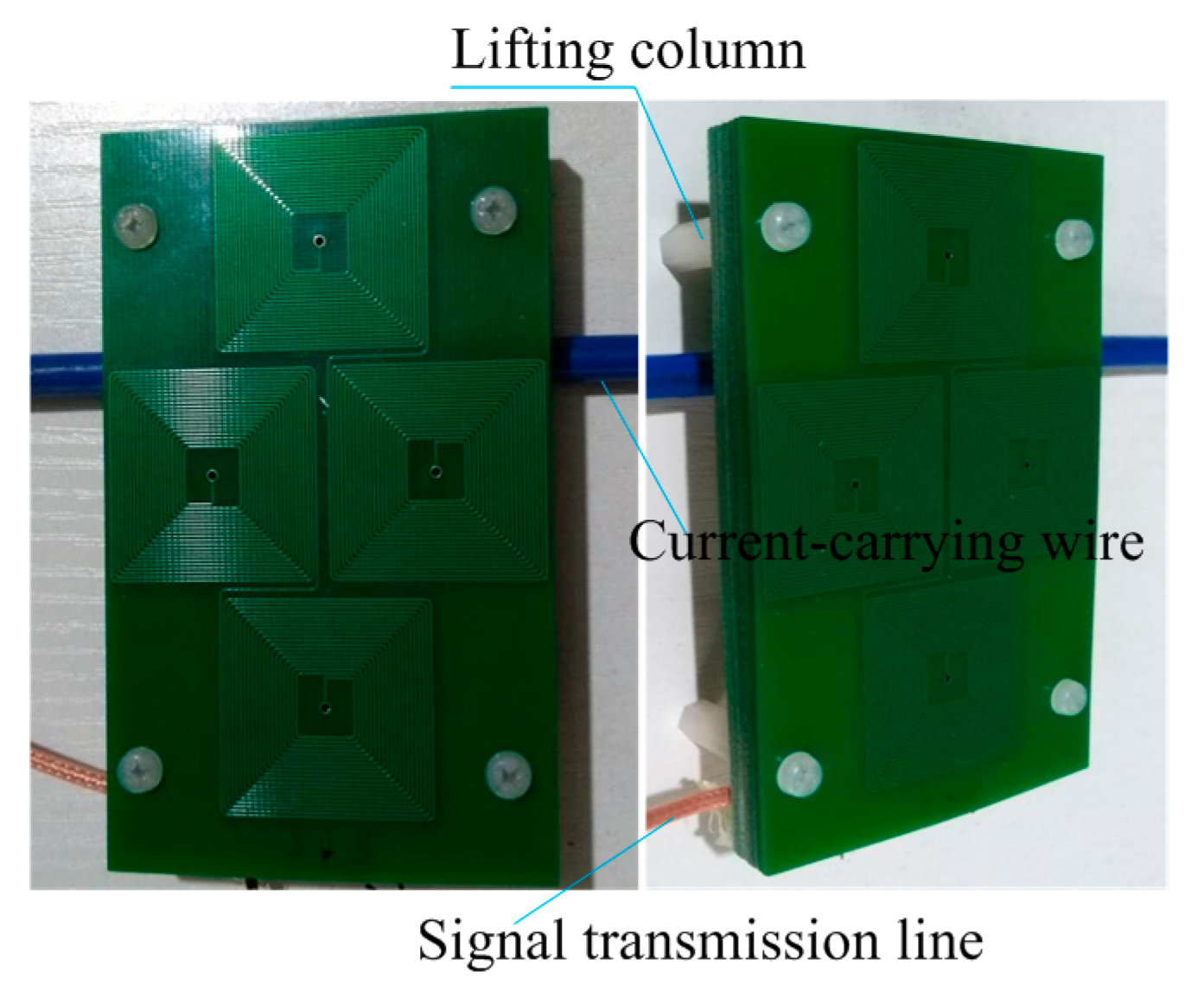

3.2. Device Design for the Electronic Transformer

4. Test Result Analysis

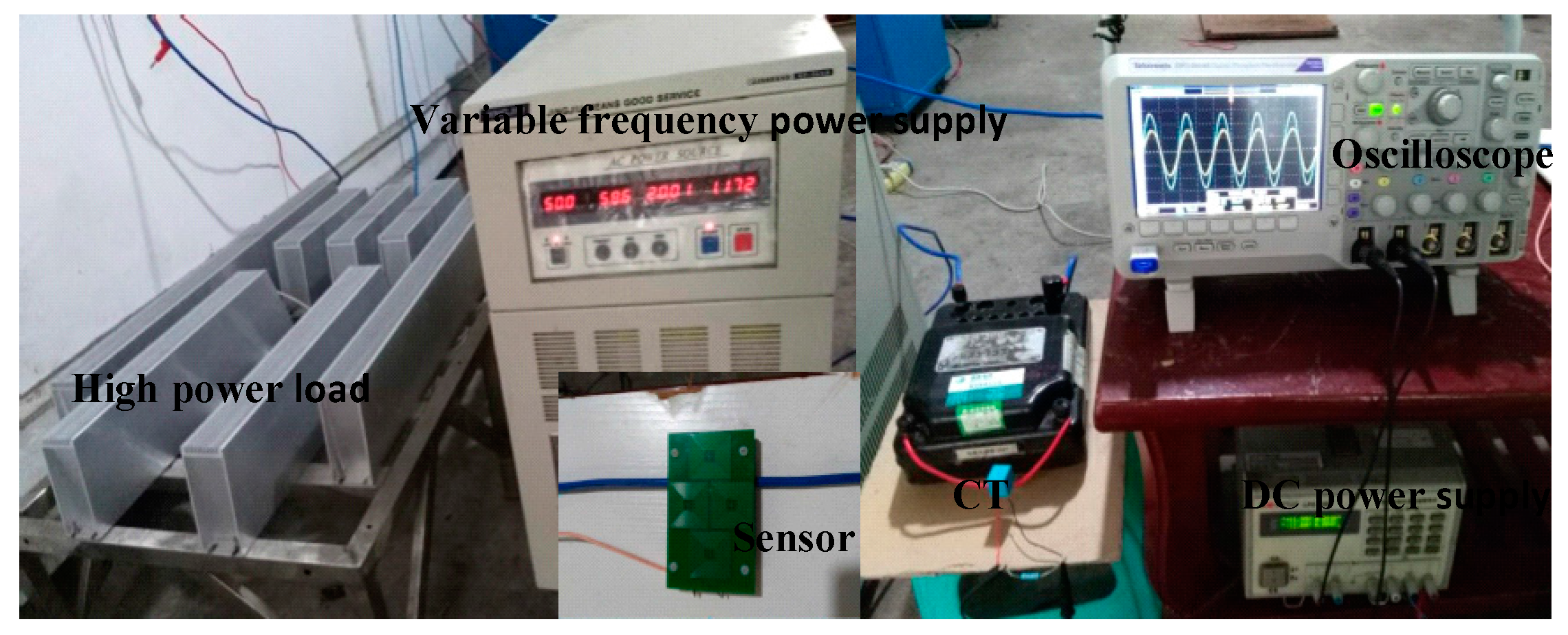

4.1. Test Platform

4.2. Steady-State Performance Test

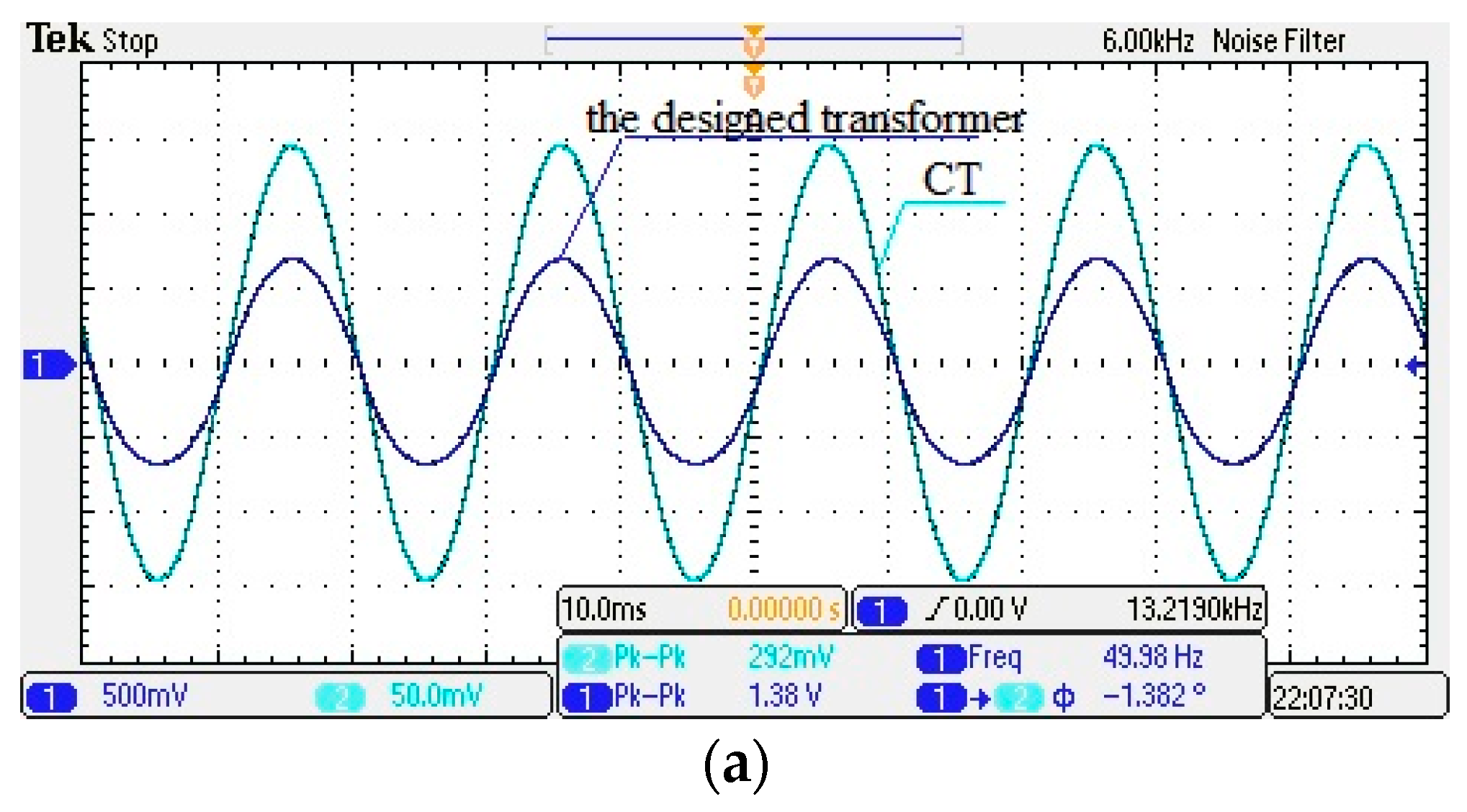

- (1)

- In Table 3, within the rated current range from 2% to 120%, the transformer ratio error ε% < 0.9%, and the phase difference φ < 3°. Thus, the designed transformer has high measurement accuracy.

- (2)

4.3. Linearity Test

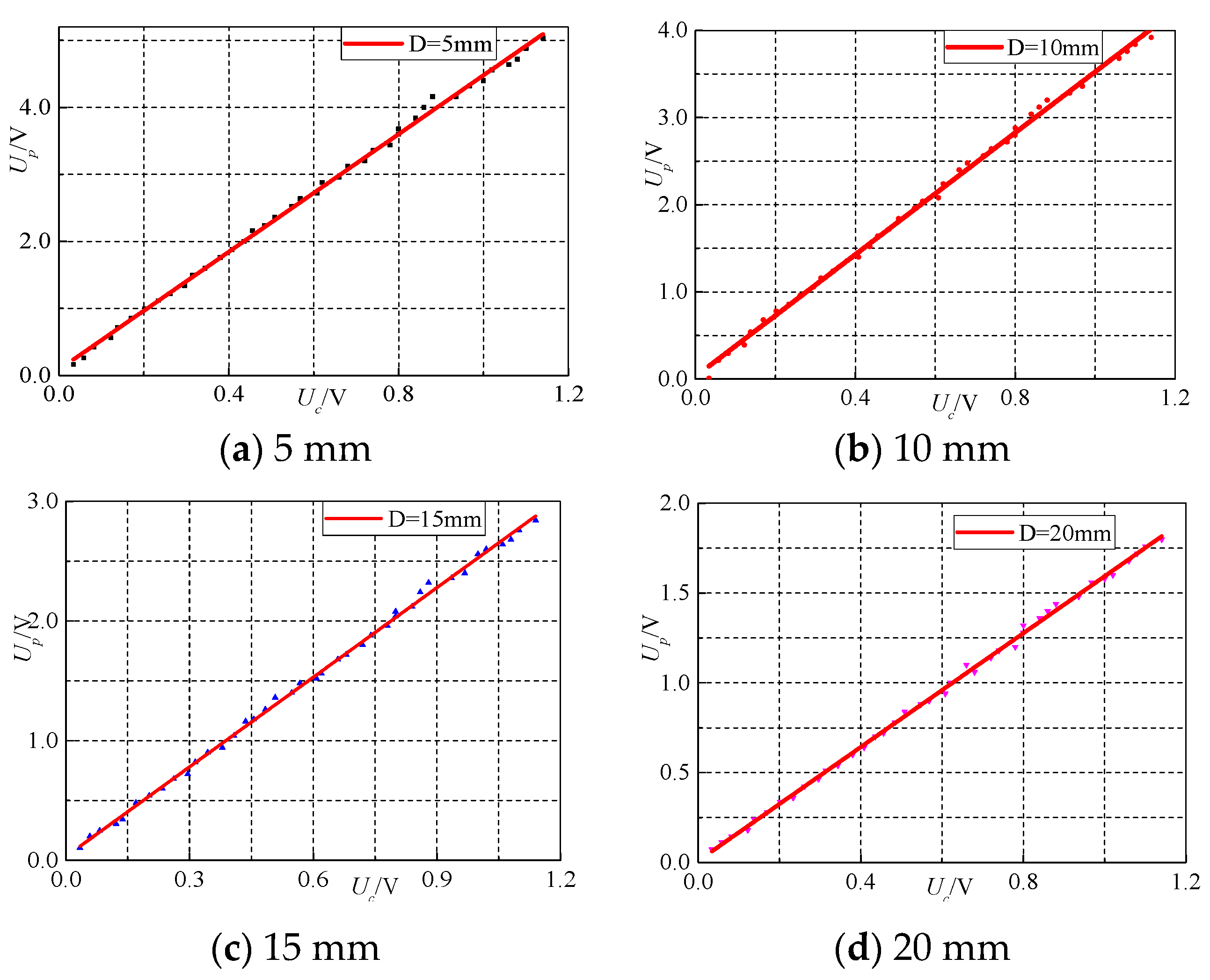

- (1)

- As shown in Figure 18, each point is extremely close to the fitting line, which indicates good linearity of the designed transformer.

- (2)

- In Table 5, the designed transformer maintains a small phase error at different distances. However, as can be seen in Table 5, the first-order fitting correction factor with the CT is gradually reduced. This finding means that when the distance from the designed transformer to the wire becomes closer, the transformer linearity also improves. However, as the distance increases, the phase error tends to enlarge. Chances are that when the distance is closer, the magnetic induction line through the sensor is denser, and then the impact of interference on the environment surrounding the sensor becomes relatively weak. When the distance is far, the sensor becomes more susceptible.

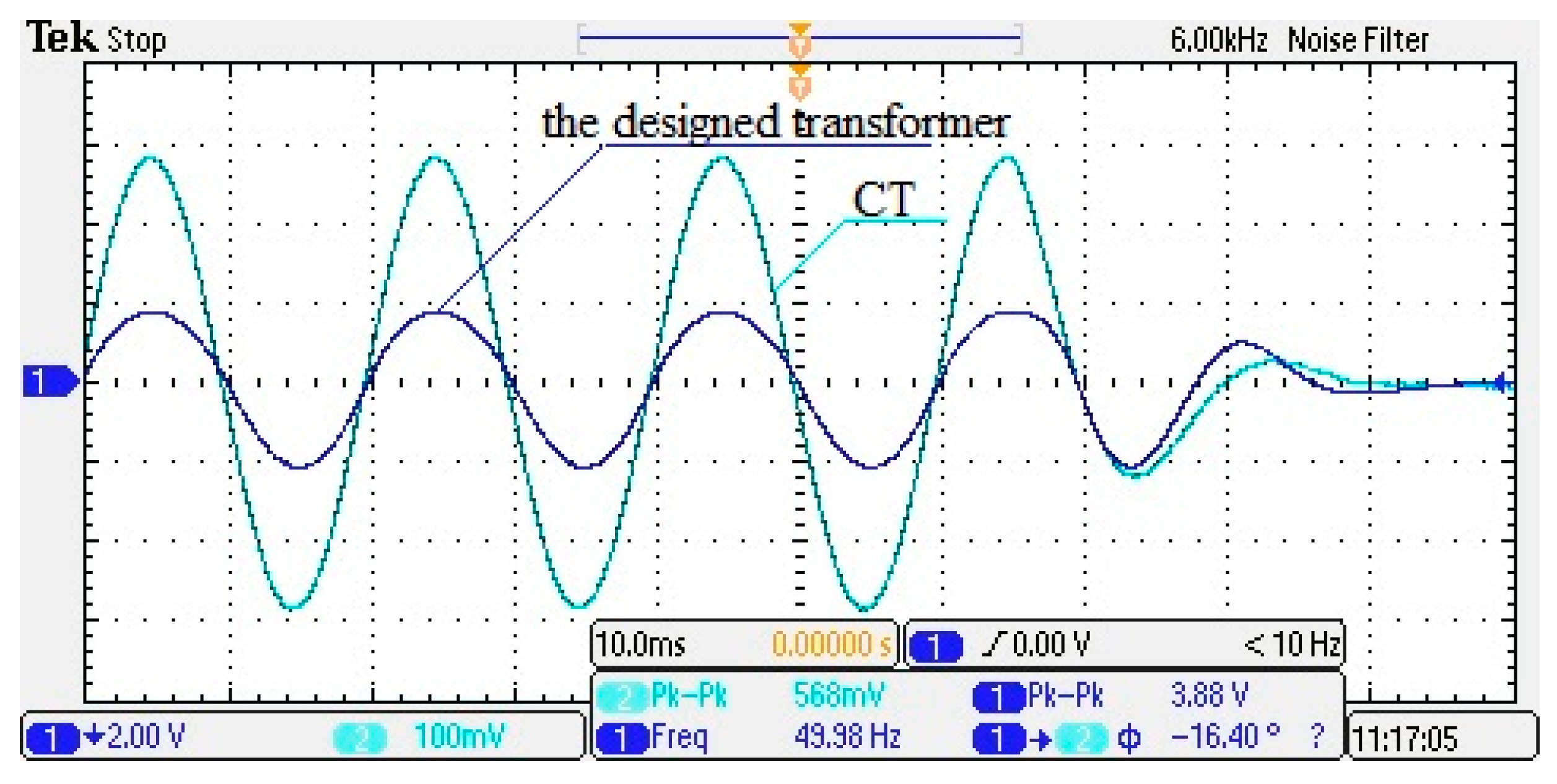

4.4. On-Off Operation Test

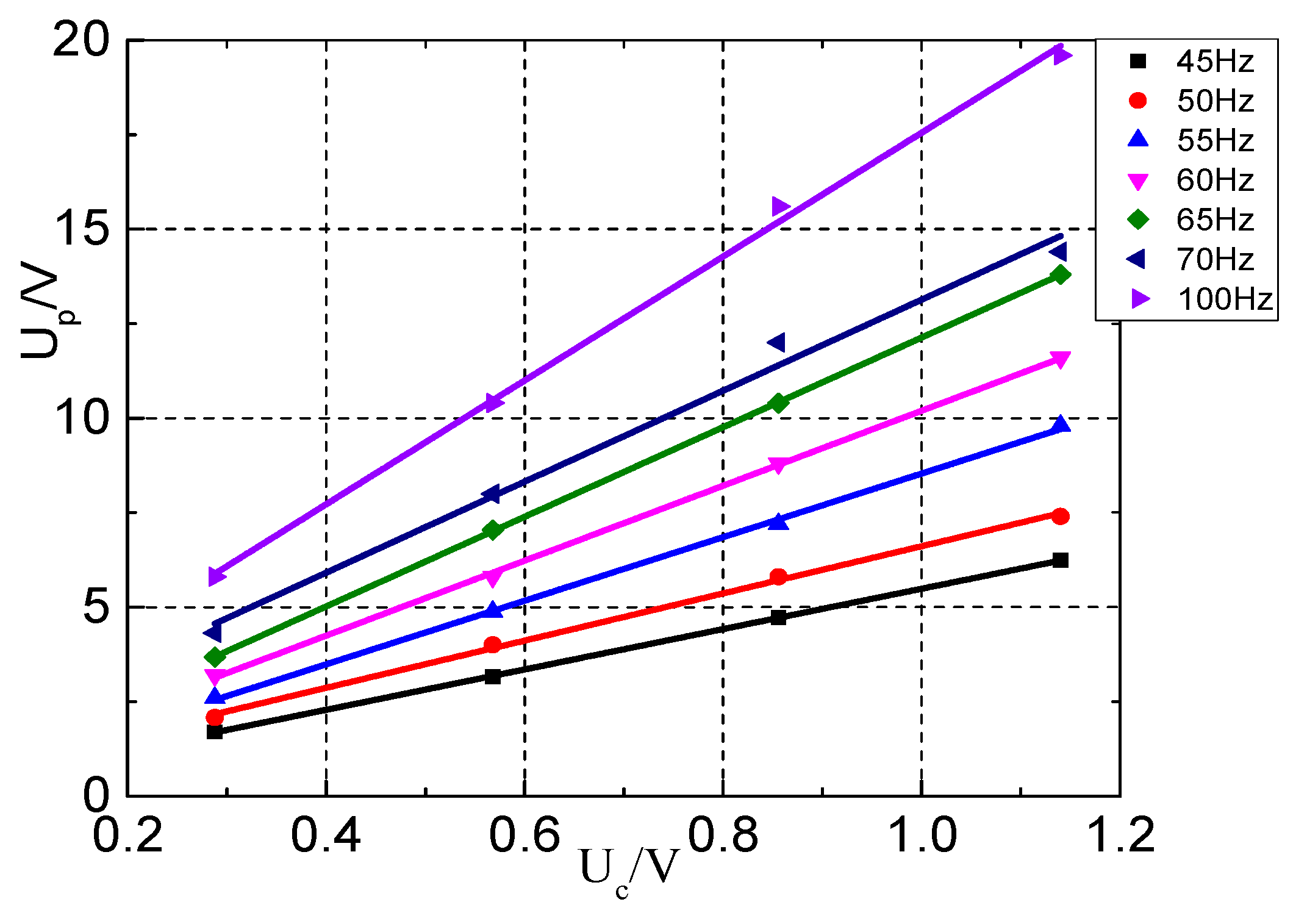

4.5. Frequency Test

5. Conclusions and Future Prospects

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, Z.; Zhang, X.; Wang, F.; Lan, X.; Zhou, Y. Effects of aging on the structural, mechanical, and thermal properties of the silicone rubber current transformer insulation bushing for a 500 kV substation. SpringerPlus 2016, 5, 790. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, K.; Ueda, N.; Ametani, A.; Natsuno, D. A Study of Lightning Current Distribution at a Wind Turbine Foot: Influence on Current Measurements Using a Rogowski Coil. Electr. Eng. Jpn. 2012, 180, 10–17. [Google Scholar] [CrossRef]

- Metwally, I.A. Tape-wound Rogowski coil for measuring large-magnitude pulsed currents. Instrum. Exp. Tech. 2016, 59, 250–257. [Google Scholar] [CrossRef]

- Ardila-Rey, J.A.; Albarracín, R.; Álvarez, F.; Barrueto, A. A validation of the spectral power clustering technique (SPCT) by using a Rogowski Coil in partial discharge measurements. Sensors 2015, 15, 25898–25918. [Google Scholar] [CrossRef] [PubMed]

- Metwally, I.A. Self-Integrating Rogowski Coil for High-Impulse Current Measurement. IEEE Trans. Instrum. Meas. 2010, 59, 353–360. [Google Scholar] [CrossRef]

- Yutthagowith, P.; Pattanadech, N.; Kunakorn, A.; Leelajindakrairerk, M. Design and construction of a Rogowski’s coil with compensated RC integrators for measuring impulse current. In Proceedings of the International Power Engineering Conference (IPEC 2007), Singapore, 3–6 December 2007; pp. 189–192. [Google Scholar]

- Liu, Y.; Lin, F.; Zhang, Q.; Zhong, H. Design and construction of a Rogowski coil for measuring wide pulse current. IEEE Sens. J. 2011, 11, 123–130. [Google Scholar] [CrossRef]

- Moonmirat, P.; Kunakorn, A.; Yutthagowith, P. A wide bandwidth Rogowski coil with an active integrator for measurement of impulse currents. In Proceedings of the Asia-Pacific International Conference on Lightning (APL 2013), Seoul, Korea, 26–28 June 2013; pp. 593–597. [Google Scholar]

- Liu, Y.; Xie, X.; Hu, Y.; Qian, Y.; Sheng, G.; Jiang, X. A novel transient fault current sensor based on the PCB Rogowski Coil for overhead transmission lines. Sensors 2016, 16, 742. [Google Scholar] [CrossRef] [PubMed]

- Shafiq, M.; Kutt, L.; Lehtonen, M.; Nieminen, T.; Hashmi, M. Parameters Identification and Modeling of High-Frequency Current Transducer for Partial Discharge Measurements. IEEE Sens. J. 2013, 13, 1081–1091. [Google Scholar] [CrossRef]

- Moreno, M.V.R.; Robles, G.; Albarracín, R.; Rey, J.A.; Tarifa, J.M.M. Study on the self-integration of a Rogowski coil used in the measurement of partial discharges pulses. Electr. Eng. 2016, 1–10. [Google Scholar] [CrossRef]

- Marracci, M.; Tellini, B. Analysis of precision Rogowski coil via analytical method and effective cross section parameter. In Proceedings of the 2016 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Taipei, Taiwan, 23–26 May 2016; pp. 1–5. [Google Scholar]

- Metwally, I.A. Multi-layer self-integrating Rogowski coils for high pulsed current measurement. Instrum. Exp. Tech. 2015, 58, 49–58. [Google Scholar] [CrossRef]

- Yao, C.; Xiao, Q.; Mi, Y.; Yuan, T.; Li, C.; Sima, W. Contactless Measurement of Lightning Current Using Self-integrating B-dot Probe. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1323–1327. [Google Scholar] [CrossRef]

- Zhang, H.; Xia, L.; Shen, Y.; Li, Q.; Wang, Y.; Zhang, L.; Liu, K. Analysis and Process of B-Dot Waveformsin a High-Current Injector. IEEE Trans. Plasma Sci. 2016, 44, 790–794. [Google Scholar] [CrossRef]

- Huiskamp, T.; Beckers, F.J.C.M.; van Heesch, E.J.M.; Pemen, A.J.M. B-Dot and D-Dot Sensors for (Sub)Nanosecond High-Voltage and High-Current Pulse Measurements. IEEE Sens. J. 2016, 16, 3792–3801. [Google Scholar] [CrossRef]

- Ahmad, A.A.; Robert, A.S. Calibration of Electromagnetic Dot Sensor—Part 2: B-dot Mode. IEEE Sens. J. 2014, 14, 3101–3110. [Google Scholar]

- Hardin, R. Magnetic Field Generation and B-dot Sensor Characterization in the High Frequency Band. Master’s Thesis, Air Force Institute of Technology, Wright-Patterson AFB, OH, USA, March 2012. [Google Scholar]

- Wagoner, T.C.; Stygar, W.A.; Ives, H.C.; Gilliland, T.L.; Spielman, R.B.; Johnson, M.F.; Reynolds, P.G.; Moore, J.K.; Mourning, R.L.; Fehl, D.L.; et al. Differential-output B-dot and D-dot monitors for current and voltage measurements on a 20-MA, 3-MV pulsed-power accelerator. Phys. Rev. Spec. Top. Accel. Beams 2008, 11, 100401. [Google Scholar] [CrossRef]

- Lane, B.; Campbell, C.; Sawada, I.; Ventzek, P.L.G. Measurement of spatial and temporal evolution of electromagnetic fields in a 100 MHz plasma source using B-dot and double dipole probes. J. Vac. Sci. Technol. A 2016, 34, 031302. [Google Scholar] [CrossRef]

- He, J.; Guo, R. Measurement of arc velocity in a rotating-arc pulsed-power switch based on B-dot probes. IEEE Trans. Plasma Sci. 2010, 38, 2669–2674. [Google Scholar] [CrossRef]

- Tao, T.; Zhao, Z.; Pan, Q.; Tang, J.; Zhang, Y. Design of PCB Rogowski coil and analysis of anti-interference. Trans. Chin. Electrotech. Soc. 2011, 26, 130–137. [Google Scholar] [CrossRef]

- Wang, R.; Prabhakaran, S.; Burdick, W.; Raymond, N. Rogowski current sensor design and analysis based on printed circuit boards (PCB). In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 3206–3211. [Google Scholar]

- Baschirotto, A.; Dallago, E.; Malcovati, P.; Marchesi, M.; Venchi, G.; Rossini, A. Multilayer PCB Planar Fluxgate Magnetic Sensor. In Proceedings of the 2006 Ph.D. Research in Microelectronics and Electronics (PRIME), Otranto, Italy, 12–15 June 2006; pp. 413–416. [Google Scholar]

- Kubo, T.; Furukawa, T.; Itoh, H.; Hisao, W.; Wakuya, H. Numerical electric field analysis of power status sensor observing power distribution system taking into account measurement circuit and apparatus. In Proceedings of the SICE Annual Conference, Tokyo, Japan, 13–18 September 2011; pp. 2741–2746. [Google Scholar]

- Koziy, K.; Bei, G.; Aslakson, J. A low-cost power quality meter with series arc-fault detection capability for smart grid. IEEE Trans. Power Deliv. 2013, 28, 1584–1591. [Google Scholar] [CrossRef]

- GB 1208-2006, Current Transformers; National Bureau of Quality Inspection: Beijing, China, 2006.

- IEC 60044-8-2002, Part 8: Electronic Current Transformers; International Electrotechnical Commission: Geneva, Switzerland, 2002.

| Coil | Number of Turns (n) | Length (cm) | Electrode Width (mil) | Distance Between Electrodes (mil) |

| 4 × 25 | 38 | 8 | 8 |

| PCB Air-core coil | Resistance | Induction | Fluctuating Deviation | Capacitance | Fluctuating Deviation |

| 25.75 Ω | 149.36 μH | 5 μH | 37.2 pF | 8 pF |

| Measuring Point | Im/A | Up/mv | ε%(±) | φ/(°) |

|---|---|---|---|---|

| 2% In | 0.602 | 60.62 | 0.70 | 2.0 |

| 5% In | 1.511 | 151.87 | 0.51 | 1.9 |

| 10% In | 3.024 | 303.62 | 0.40 | 1.6 |

| 20% In | 6.013 | 599.42 | 0.31 | 1.5 |

| 40% In | 12.161 | 1208.29 | 0.64 | 1.5 |

| 60% In | 18.06 | 1818.36 | 0.68 | 1.4 |

| 80% In | 24.120 | 2419.32 | 0.30 | 1.3 |

| 100% In | 30.060 | 3016.12 | 0.34 | 1.3 |

| 120% In | 36.042 | 3625.12 | 0.58 | 1.2 |

| Uc/mV | Up/mV | I/A | Uc/mV | Up/mV | I/A |

|---|---|---|---|---|---|

| 60 | 264 | 1.99 | 632 | 2880 | 22.01 |

| 121 | 568 | 4.01 | 680 | 3120 | 23.97 |

| 180 | 860 | 6.02 | 744 | 3360 | 26.01 |

| 226 | 1120 | 7.98 | 808 | 3600 | 27.99 |

| 292 | 1380 | 10.03 | 848 | 3840 | 30.02 |

| 352 | 1600 | 12.01 | 920 | 4160 | 32.02 |

| 396 | 1880 | 13.99 | 968 | 4320 | 34.02 |

| 464 | 2160 | 16.03 | 1020 | 4560 | 36.01 |

| 516 | 2360 | 17.97 | 1080 | 4720 | 37.99 |

| 580 | 2640 | 20.01 | 1140 | 5040 | 40.02 |

| Dstance/D | Fitting Correction Coefficient | Congruence Mean Error | Maximum Phase Difference φ (°) |

|---|---|---|---|

| 5 mm | 4.39 | 0.0041 | 1.5 |

| 10 mm | 3.49 | 0.0027 | 2.0 |

| 15 mm | 2.29 | 0.0017 | 2.1 |

| 20 mm | 1.59 | 0.0026 | 2.5 |

| 25 mm | 1.17 | 0.0032 | 2.8 |

| 30 mm | 0.86 | 0.0018 | 3.2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Si, D.; Tian, T.; Ren, R. Design and Experimental Study of a Current Transformer with a Stacked PCB Based on B-Dot. Sensors 2017, 17, 820. https://doi.org/10.3390/s17040820

Wang J, Si D, Tian T, Ren R. Design and Experimental Study of a Current Transformer with a Stacked PCB Based on B-Dot. Sensors. 2017; 17(4):820. https://doi.org/10.3390/s17040820

Chicago/Turabian StyleWang, Jingang, Diancheng Si, Tian Tian, and Ran Ren. 2017. "Design and Experimental Study of a Current Transformer with a Stacked PCB Based on B-Dot" Sensors 17, no. 4: 820. https://doi.org/10.3390/s17040820