Using the Kalman Algorithm to Correct Data Errors of a 24-Bit Visible Spectrometer

Abstract

:1. Introduction

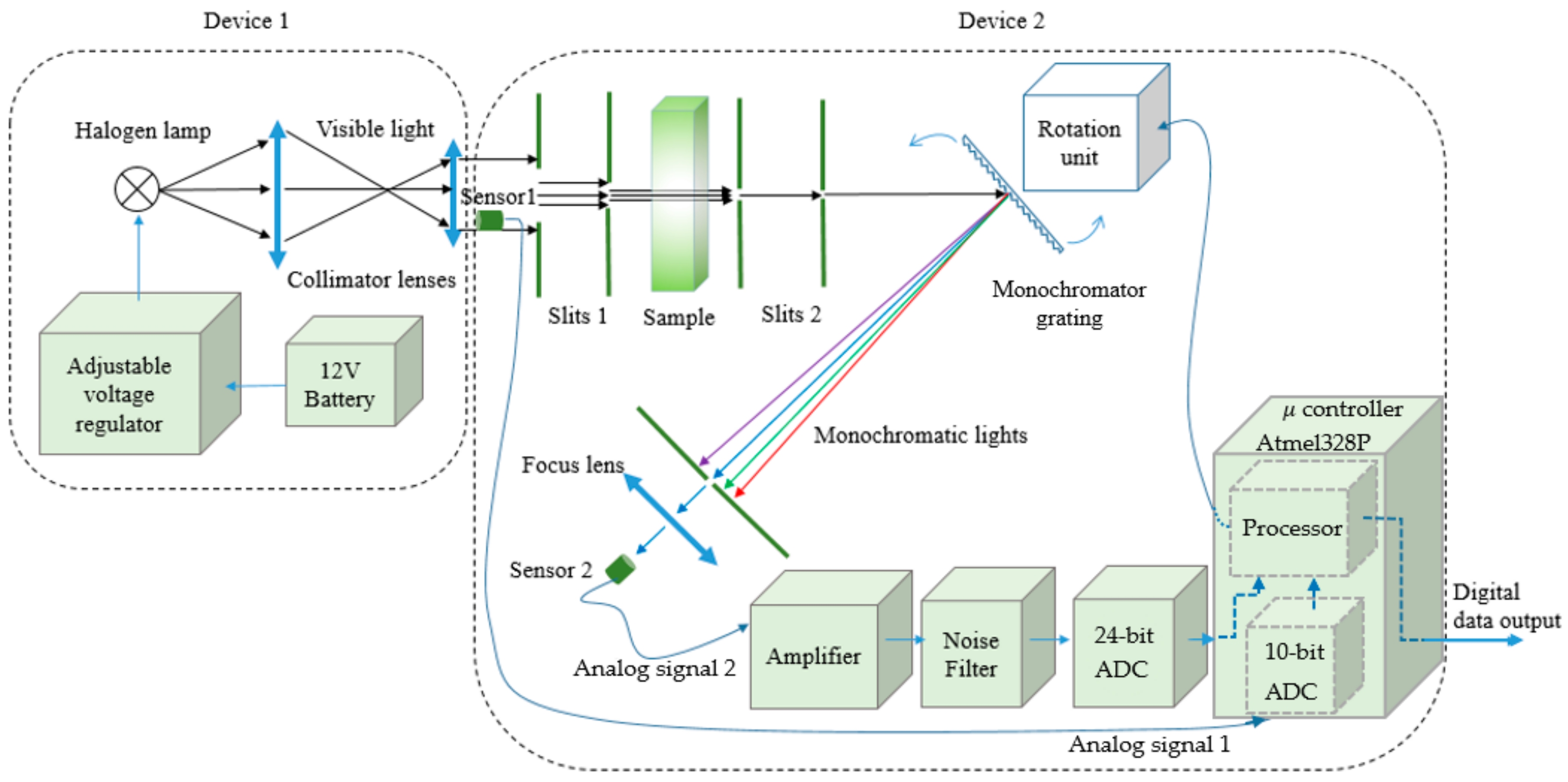

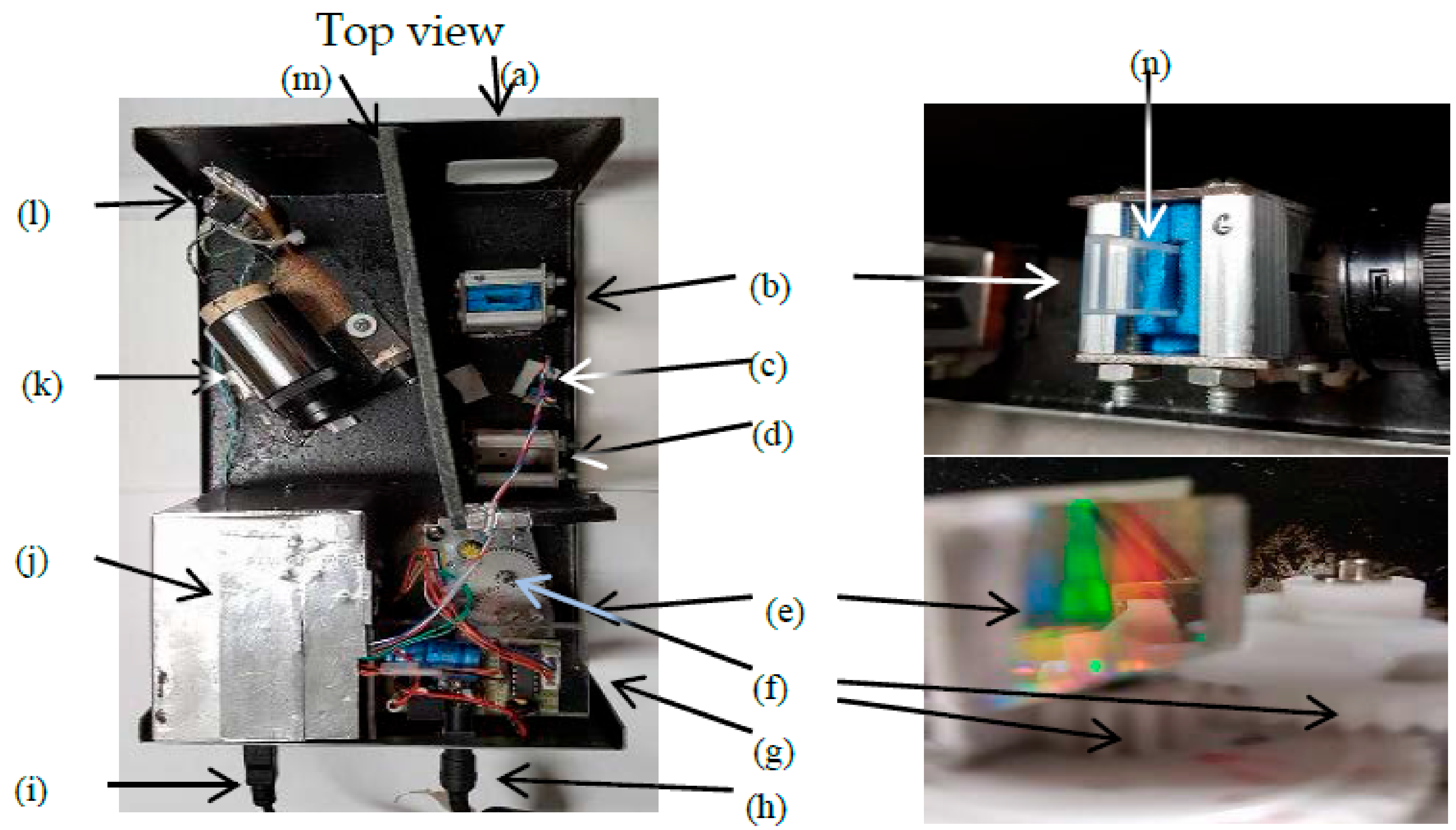

2. Methodology

2.1. Greedy Technique

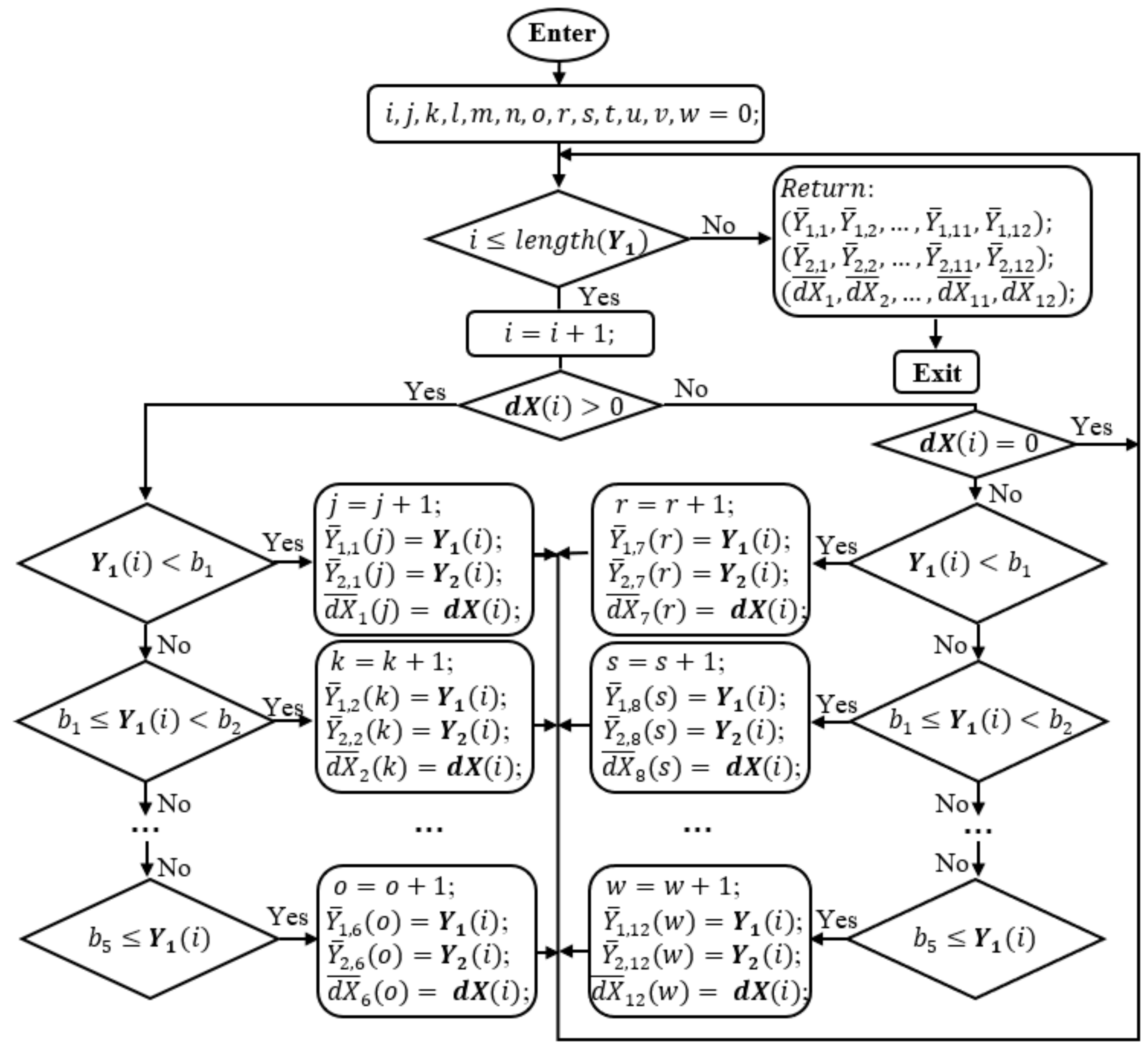

2.2. Divide and Conquer Algorithm

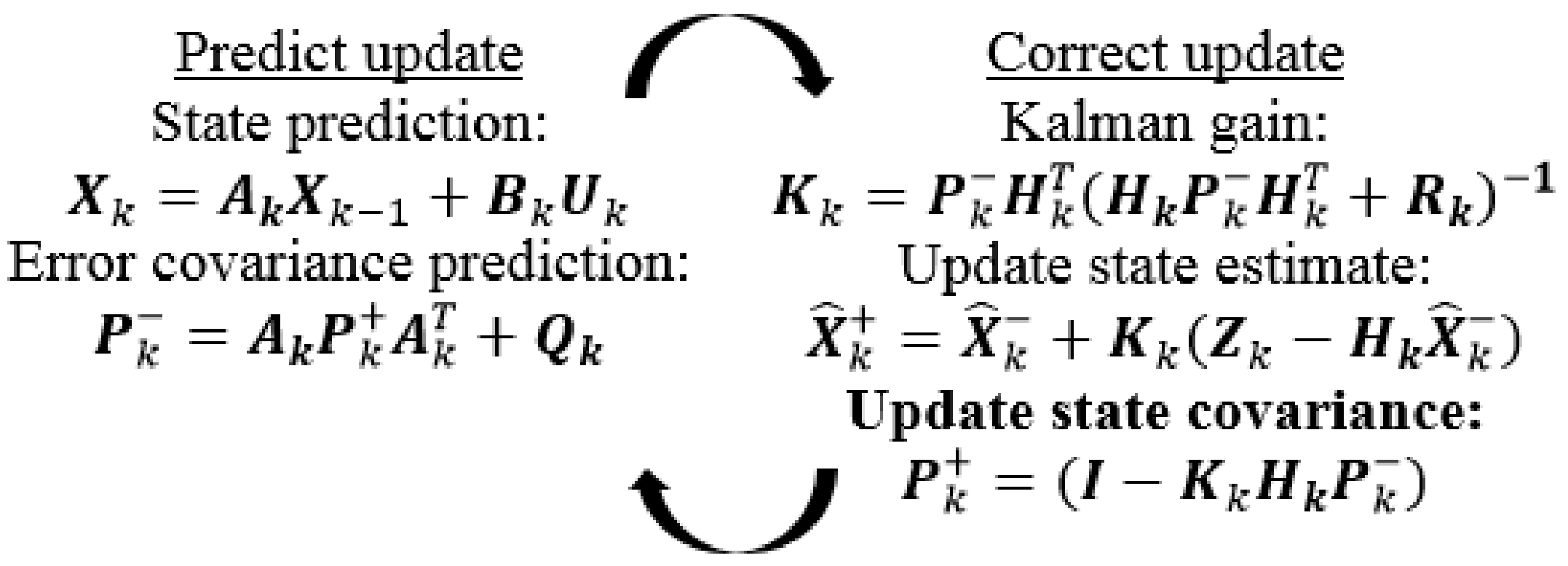

2.3. Kalman Algorithm

2.4. Performance Description

2.4.1. Correction Function Finding

2.4.2. Process Noise Covariance Finding

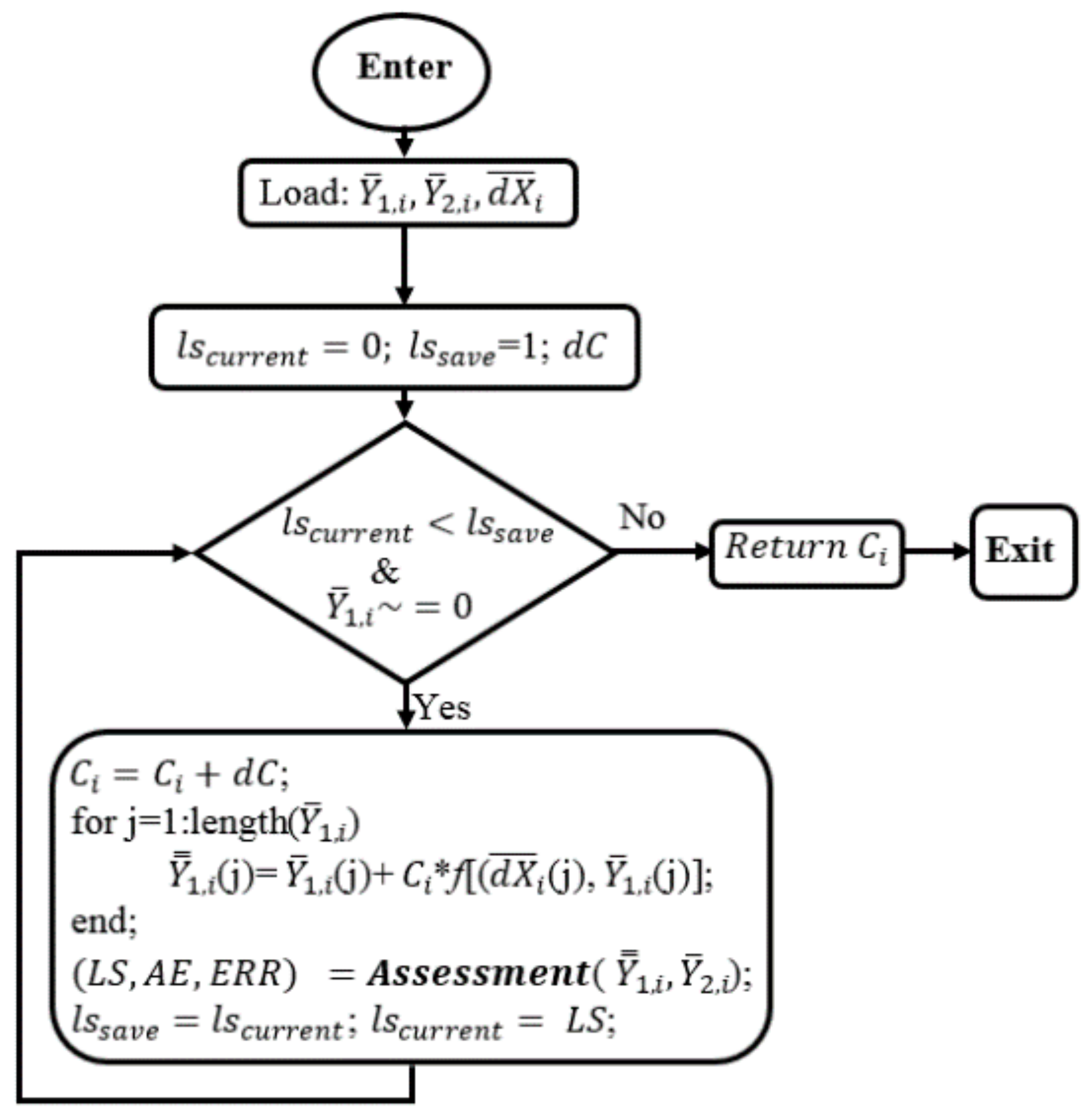

2.4.3. Correction Coefficients Finding

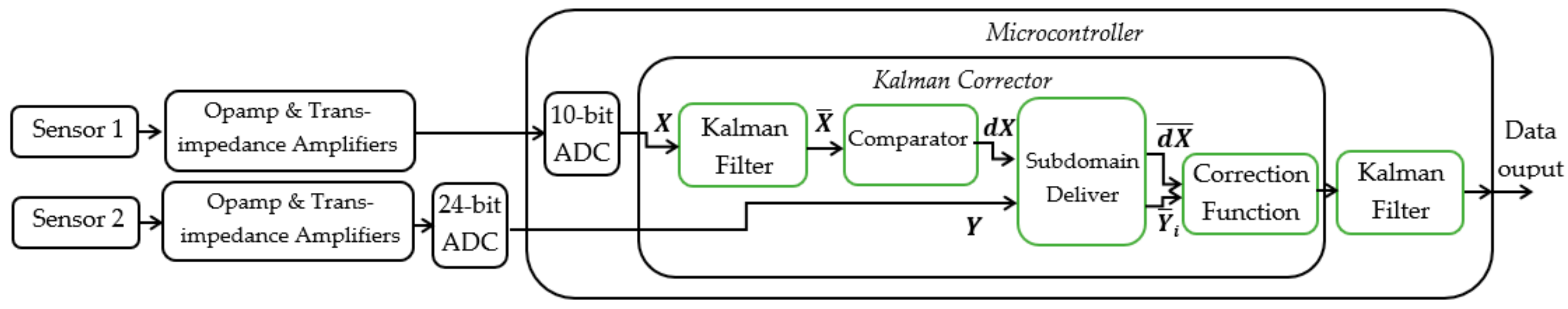

2.4.4. Application

3. Results

3.1. Initial Selection for Simulation

3.2. Correction Function Choice

3.3. Process Noise Covariance Search

3.4. Correction Parameters Finding

3.5. Practice

3.5.1. Dataset Correction Simulation

3.5.2. Measurements on Air, H2O, and KMnO4 Samples

4. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

References

- Parnis, J.M.; Oldham, K.B. Beyond the Beer-Lambert Law: The Dependence of Absorbance on Time in Photochemistry. J. Photochem. Photobio. A: Chem. 2103, 267, 6–10. [Google Scholar] [CrossRef]

- Microwaves and RF. Available online: http://www.webcitation.org/6vjkuW0CJ (accessed on 15 December 2017).

- Pham, S.; Dinh, A. Using Trans-impedance Amplifier and Smoothing Techniques to Improve Signal-to-Noise Ratio in a 24-bit Single Beam Visible Spectrometer. In Proceedings of the 105th IIER International Conference, Bangkok, Thailand, 5 June 2017; pp. 1–6, ISBN 978-93-86291-88-2. [Google Scholar]

- Mightex Co. Miniature CCD Spectrometers with High Resolution and High Stability. Available online: http://www.mightexsystems.com/images/File/Mightex_HRS_spectrometer_specifications_Sept2013.pdf (accessed on 15 December 2017).

- StellarNet Inc. Analytical Instrumentation—Surf the New Wave in Portable Fiber Optic Spectrometry. Available online: http://www.webcitation.org/6vjlqnZpm (accessed on 15 December 2017).

- Texas Instrument Inc. Manual: 24-bit, 40 khz Analog-to-Digital Converter. Available online: http://www.ti.com/lit/ds/symlink/ads1252.pdf (accessed on 15 December 2017).

- Osram. Silicon Pin Photodiode Version 1.4. BPW 34 S. Available online: http://www.osram-os.com/Graphics/XPic5/00215430_0.pdf/BPW%2034%20S.pdf (accessed on 15 December 2017).

- Jaffé, H.H.; Orchin, M. Theory and Applications of Ultraviolet Spectroscopy; Wiley: New York, NY, USA, 1962; Chapter 6; pp. 111–115. [Google Scholar]

- Tungsten Halogen Lamps. Available online: https://www.intl-lighttech.com/specialty-light-sources/tungsten-halogen-lamps-gas-filled-lamps (accessed on 15 December 2017).

- PS-1270 12 Volt 7.0 AH: Rechargeable Sealed Lead Acid Battery. Available online: http://www.powersonic.com/images/powersonic/sla_batteries/ps_psg_series/12volt/PS1270.pdf (accessed on 15 December 2017).

- Fullerton, S.; Bennett, K.; Toda, E.; Takahshi, T. Orca-Flash4.0 Changing the Game. Hama. Coper. Available online: http://www.webcitation.org/6v3pafaWg (accessed on 15 December 2017).

- Osi Optoelectronics Co. Manual: Photodiode Characteristics and Applications. Available online: http://www.osioptoelectronics.com/application-notes/an-photodiode-parameters-characteristics.pdf (accessed on 15 December 2017).

- What Is Dark Noise? Available online: http://camera.hamamatsu.com/jp/en/technical_guides/dark_noise/index.html (accessed on 15 December 2017).

- Smith, S.W. The Scientist and Engineer’s Guide to Digital Signal Processing; California Technical: Pasadena, CA, USA, 1999; ISBN 0-9660176-7-6. [Google Scholar]

- Texas Instrument Inc. Manual: LP2980,LP2982,LP2985-Engineers Note: Capacitors are Key to Voltage Regulator Design. Available online: http://www.ti.com/lit/wp/snoa842/snoa842.pdf (accessed on 15 December 2017).

- Vo-Dinh, T.; Gauglitz, G. Handbook of Spectroscopy; Wiley-VCH: Weinheim, Germany, 2003; Chapter 12; pp. 421–493. ISBN 3-527-29782-0. [Google Scholar]

- Belton, C. Lab Manual: UV-VIS. Available online: http://www.webcitation.org/6v70Gyhg7 (accessed on 15 December 2017).

- 2N1544 Germanium PNP Transistor. Available online: http://www.semicon-data.com/transistor/tc/2n/2N1544.html (accessed on 15 December 2017).

- LM317 3-Terminal Adjustable Regulator. Available online: http://www.ti.com/lit/ds/symlink/lm317.pdf (accessed on 15 December 2017).

- Halliday, D.; Resnick, R.; Walker, J. Fundamentals of Physics, 9th ed.; Wiley: New York, NY, USA, 1997; Chapter 35; pp. 958–983. ISBN 978-0-470-46908-8. [Google Scholar]

- 28BYJ-48 Stepper Motor 5VDC. Available online: http://www.webcitation.org/6ve05B41c (accessed on 15 December 2017).

- Atmel 8-Bit Microcontroller with 4/8/16/32kbytes In-System Programmable Flash. Available online: http://www.atmel.com/images/Atmel-8271-8-bit-AVR-Microcontroller-ATmega48A-48PA-88A-88PA-168A-168PA-328-328P_datasheet_Complete.pdf (accessed on 15 December 2017).

- Levitin, A. Introduction to the Design & Analysis of Algorithms, 3rd ed.; Pearson: Boston, MA, USA, 2012; Chapter 5, 9; pp. 169–174. ISBN 978-0-13-231681-1. [Google Scholar]

- Alur, R.; Radhakrishna, A. Scaling Enumerative Program Synthesis via Divide and Conquer. In Proceedings of the Tools and Algorithms for the Construction and Analysis of Systems: 23rd International Conference, TACAS, ETAPS, Uppsala, Sweden, 22–29 April 2017; ISBN 978-3-662-54580-5. [Google Scholar]

- Melsa, J.L.; Cohn, D.L. Decision and Estimation Theory; McGraw-Hill: New York, NY, USA, 1978; Chapter 11; pp. 244–251. ISBN 0-07-041468-8. [Google Scholar]

- Grewal, M.S.; Andrews, A.P. Kalman Filtering: Theory and Practice Using MATLAB, 3rd ed.; Wiley: Hoboken, NJ, USA, 2008; Chapter 3; pp. 100–167. ISBN 0-521-40573-4. [Google Scholar]

- Maybeck, P.S.; George, M.S. Stochastic Models, Estimation, and Control, 5th ed.; Academic Press: Cambridge, MA, USA, 1982; Volume 1, pp. 1–16. ISBN 0-12-480701-1. [Google Scholar]

- Pandit, S.M.; Wu, S.M. Time Series and System Analysis, with Applications; Wiley: New York, NY, USA, 1983; Chapter 2; pp. 13–74. ISBN 0-471-86886-8. [Google Scholar]

- Vincent, J.D. Fundamentals of Infrared Detector Operation and Testing; Wiley Series in Pure and Applied Optics; Wiley: New York, NY, USA, 1990; Chapter 6; pp. 275–303. ISBN 0-471-50272-3. [Google Scholar]

- Harvey, A. Forecasting, Structural Time Series Models and the Kalman Filter, 1st ed.; Cambridge University Press: New York, NY, USA, 1990; Chapter 3; pp. 100–163. ISBN 0-521-40573-4. [Google Scholar]

- Carlson, G.A. Experimental Errors and Uncertainty, 2002. Available online: http://www.webcitation.org/6u7N8FcKs (accessed on 15 December 2017).

- Welch, G.; Bishop, G. An Introduction to the Kalman Filter; UNC-Chapel Hill: Chapel Hill, NC, USA, 2006; Available online: http://www.webcitation.org/6u7M513uA (accessed on 15 December 2017).

| LS | AE | ERR | CP(, ) | CP(, ) | Feasibility | |

|---|---|---|---|---|---|---|

| 2.159 × 1011 | 1.483 × | 2.773 × 106 | 0.999608 | 0.999968 | Medium | |

| 1.846 × 1011 | 1.3747 × | 3.3367 × 106 | 0.999608 | 0.9999769 | Low | |

| 1.9372 × 1011 | 2.3045 × | 3.3367 × 106 | 0.999608 | 0.9999725 | Low | |

| 1.840 × 1011 | 1.3719 × | 2.8859 × 106 | 0.999608 | 0.9999756 | High |

| dataset 2 | dataset 3 | dataset 4 | dataset 5 | dataset 6 | dataset 7 | dataset 8 | dataset 9 | dataset 10 | |

| 0.0071 | 0.0321 | 0.0561 | 0.0147 | 0.0112 | 0.0076 | 0.0352 | 0.0119 | 0.0155 | |

| dataset 11 | dataset 12 | dataset 13 | dataset 14 | dataset 15 | dataset 16 | dataset 17 | dataset 18 | dataset 19 | |

| 0.0144 | 0.0349 | 0.0124 | 0.0203 | 0.0126 | 0.0249 | 0.0107 | 0.0165 | 0.0268 |

| of Subdomains | ||||||||

|---|---|---|---|---|---|---|---|---|

| Data Set | ||||||||

| 1 | 0.00386 | 0.00264 | 0.00245 | 0.00233 | 0.00208 | 0.00207 | 5.7078 | |

| 2 | 0.00345 | 0.00261 | 0.00202 | 0.00246 | 0.00231 | 0.00230 | 4.9686 | |

| 3 | 0.00392 | 0.00240 | 0.00231 | 0.00231 | 0.00206 | 0.00206 | 4.4369 | |

| 4 | 0.00377 | 0.00283 | 0.00204 | 0.00243 | 0.00240 | 0.00227 | 4.6495 | |

| 5 | 0.00356 | 0.00238 | 0.00201 | 0.00248 | 0.00229 | 0.00226 | 10.3858 | |

| 6 | 0.00359 | 0.00242 | 0.00196 | 0.00213 | 0.00206 | 0.00202 | 9.8095 | |

| 7 | 0.00364 | 0.0026 | 0.00227 | 0.00230 | 0.00222 | 0.00216 | 9.8672 | |

| 8 | 0.00328 | 0.00256 | 0.00247 | 0.00222 | 0.00212 | 0.00218 | 9.5766 | |

| 9 | 0.00345 | 0.00264 | 0.00236 | 0.00233 | 0.00220 | 0.00230 | 8.5105 | |

| 10 | 0.00391 | 0.00267 | 0.00238 | 0.00248 | 0.00229 | 0.00231 | 15.2758 | |

| 11 | 0.00393 | 0.00272 | 0.00234 | 0.00225 | 0.00216 | 0.00213 | 14.6995 | |

| 12 | 0.00380 | 0.00277 | 0.00238 | 0.00230 | 0.00224 | 0.00217 | 14.5844 | |

| 13 | 0.00398 | 0.00272 | 0.00247 | 0.00224 | 0.00215 | 0.00210 | 14.0529 | |

| 14 | 0.00391 | 0.00265 | 0.00215 | 0.00257 | 0.00238 | 0.00233 | 12.1743 | |

| 15 | 0.00340 | 0.00249 | 0.00246 | 0.00232 | 0.00215 | 0.00219 | 12.7739 | |

| 16 | 0.00341 | 0.00260 | 0.00236 | 0.00255 | 0.00236 | 0.00236 | 16.4325 | |

| 17 | 0.00341 | 0.00265 | 0.00233 | 0.00234 | 0.00224 | 0.00219 | 15.8561 | |

| 18 | 0.00357 | 0.00259 | 0.00242 | 0.00230 | 0.00215 | 0.00212 | 15.3245 | |

| 19 | 0.00371 | 0.00274 | 0.00252 | 0.00240 | 0.00227 | 0.00224 | 16.5607 | |

| 20 | 0.00342 | 0.00228 | 0.00210 | 0.00249 | 0.00234 | 0.00231 | 11.2676 | |

| 21 | 0.00349 | 0.00248 | 0.00235 | 0.00232 | 0.00228 | 0.00222 | 10.7491 | |

| 22 | 0.00384 | 0.00247 | 0.00234 | 0.00224 | 0.00221 | 0.00216 | 11.3957 | |

| 23 | 0.00368 | 0.00238 | 0.00216 | 0.00243 | 0.00236 | 0.00232 | 12.4826 | |

| 24 | 0.00391 | 0.00233 | 0.00223 | 0.00207 | 0.00208 | 0.00201 | 11.3750 | |

| 25 | 0.00370 | 0.00242 | 0.00212 | 0.00214 | 0.00217 | 0.00211 | 11.9064 | |

| 26 | 0.00386 | 0.00257 | 0.00218 | 0.00231 | 0.00221 | 0.00215 | 29.6674 | |

| 27 | 0.00396 | 0.00254 | 0.00222 | 0.00229 | 0.00216 | 0.00211 | 28.5594 | |

| 28 | 0.00385 | 0.00256 | 0.00221 | 0.00243 | 0.00228 | 0.00226 | 29.0910 | |

| 29 | 0.00366 | 0.00255 | 0.00232 | 0.00222 | 0.00214 | 0.00212 | 29.4339 | |

| 30 | 0.00388 | 0.00264 | 0.00229 | 0.00238 | 0.00224 | 0.00222 | 29.1488 | |

| Average | 0.00369 | 0.00256 | 0.00227 | 0.00233 | 0.00222 | 0.00219 | ||

| of Subdomains | ||||||||

|---|---|---|---|---|---|---|---|---|

| Data Set | ||||||||

| 1 | 0.00355 | 0.00231 | 0.00219 | 0.00187 | 0.0019 | 0.00188 | −20.2399 | |

| 2 | 0.00355 | 0.00226 | 0.00182 | 0.00225 | 0.00218 | 0.00209 | −13.4950 | |

| 3 | 0.00343 | 0.00253 | 0.00248 | 0.00189 | 0.00189 | 0.00187 | −6.5176 | |

| 4 | 0.00336 | 0.00232 | 0.00211 | 0.00209 | 0.00209 | 0.00196 | −18.0569 | |

| 5 | 0.00373 | 0.00242 | 0.00211 | 0.00206 | 0.002 | 0.00196 | −13.2514 | |

| 6 | 0.00381 | 0.00241 | 0.00203 | 0.00207 | 0.002 | 0.00197 | −13.7458 | |

| 7 | 0.00307 | 0.00226 | 0.00213 | 0.00194 | 0.00193 | 0.00188 | −13.3111 | |

| 8 | 0.00307 | 0.00236 | 0.00228 | 0.00203 | 0.00205 | 0.00202 | −12.9464 | |

| 9 | 0.00323 | 0.00199 | 0.00171 | 0.00186 | 0.00181 | 0.00172 | −10.6810 | |

| 10 | 0.00358 | 0.00251 | 0.00204 | 0.00234 | 0.00223 | 0.00213 | −13.0744 | |

| 11 | 0.00309 | 0.00239 | 0.00205 | 0.00197 | 0.00195 | 0.00201 | −17.5519 | |

| 12 | 0.00351 | 0.00229 | 0.00215 | 0.00183 | 0.00186 | 0.00183 | −13.5530 | |

| 13 | 0.00306 | 0.0021 | 0.00161 | 0.00195 | 0.00189 | 0.00185 | −11.2250 | |

| 14 | 0.00368 | 0.0023 | 0.00218 | 0.00185 | 0.00183 | 0.00187 | −14.6510 | |

| 15 | 0.00335 | 0.00238 | 0.00223 | 0.00187 | 0.00184 | 0.00188 | −13.2710 | |

| 16 | 0.00389 | 0.00253 | 0.00215 | 0.00205 | 0.00198 | 0.00196 | −17.3292 | |

| 17 | 0.00374 | 0.00249 | 0.00207 | 0.00227 | 0.00216 | 0.00209 | −23.2423 | |

| 18 | 0.00364 | 0.00248 | 0.00209 | 0.00219 | 0.0021 | 0.00201 | −24.7748 | |

| 19 | 0.00373 | 0.0026 | 0.00222 | 0.00214 | 0.00208 | 0.00205 | −26.7884 | |

| 20 | 0.00364 | 0.00255 | 0.00233 | 0.002 | 0.00199 | 0.00197 | −22.6055 | |

| 21 | 0.00347 | 0.00232 | 0.00204 | 0.00217 | 0.00212 | 0.00208 | −35.0176 | |

| 22 | 0.00341 | 0.00253 | 0.00227 | 0.00205 | 0.00202 | 0.00203 | −22.3267 | |

| 23 | 0.00382 | 0.00246 | 0.00207 | 0.00217 | 0.0021 | 0.00202 | −32.2190 | |

| 24 | 0.00373 | 0.00243 | 0.00202 | 0.00217 | 0.00209 | 0.00202 | −41.6049 | |

| 25 | 0.00347 | 0.00231 | 0.00191 | 0.00210 | 0.00201 | 0.00194 | −39.7620 | |

| 26 | 0.00379 | 0.00242 | 0.00198 | 0.00215 | 0.00206 | 0.00199 | −29.6439 | |

| 27 | 0.00309 | 0.00242 | 0.0022 | 0.00204 | 0.00197 | 0.00196 | −22.4463 | |

| 28 | 0.00361 | 0.00242 | 0.00214 | 0.00217 | 0.00213 | 0.00208 | −35.0595 | |

| 29 | 0.00383 | 0.00254 | 0.00227 | 0.00219 | 0.00208 | 0.00208 | −31.3988 | |

| 30 | 0.00347 | 0.00239 | 0.00215 | 0.0021 | 0.00197 | 0.00198 | −29.5559 | |

| Average | 0.00351 | 0.00239 | 0.00210 | 0.00206 | 0.00201 | 0.00197 | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pham, S.; Dinh, A. Using the Kalman Algorithm to Correct Data Errors of a 24-Bit Visible Spectrometer. Sensors 2017, 17, 2939. https://doi.org/10.3390/s17122939

Pham S, Dinh A. Using the Kalman Algorithm to Correct Data Errors of a 24-Bit Visible Spectrometer. Sensors. 2017; 17(12):2939. https://doi.org/10.3390/s17122939

Chicago/Turabian StylePham, Son, and Anh Dinh. 2017. "Using the Kalman Algorithm to Correct Data Errors of a 24-Bit Visible Spectrometer" Sensors 17, no. 12: 2939. https://doi.org/10.3390/s17122939