Recent Enhancements to Interline and Electron Multiplying CCD Image Sensors †

Abstract

:1. Introduction

- Improving micro-lens focusing and fill factor

- Reducing reflection losses

- Reducing absorption losses

- Increasing the collection volume of the photodiodes

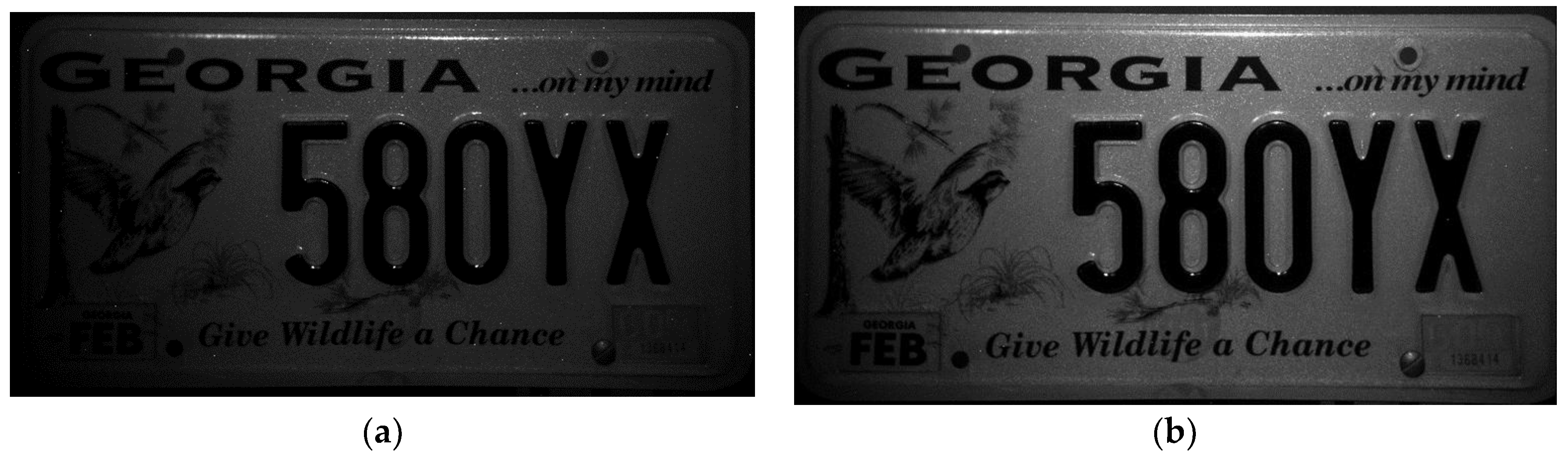

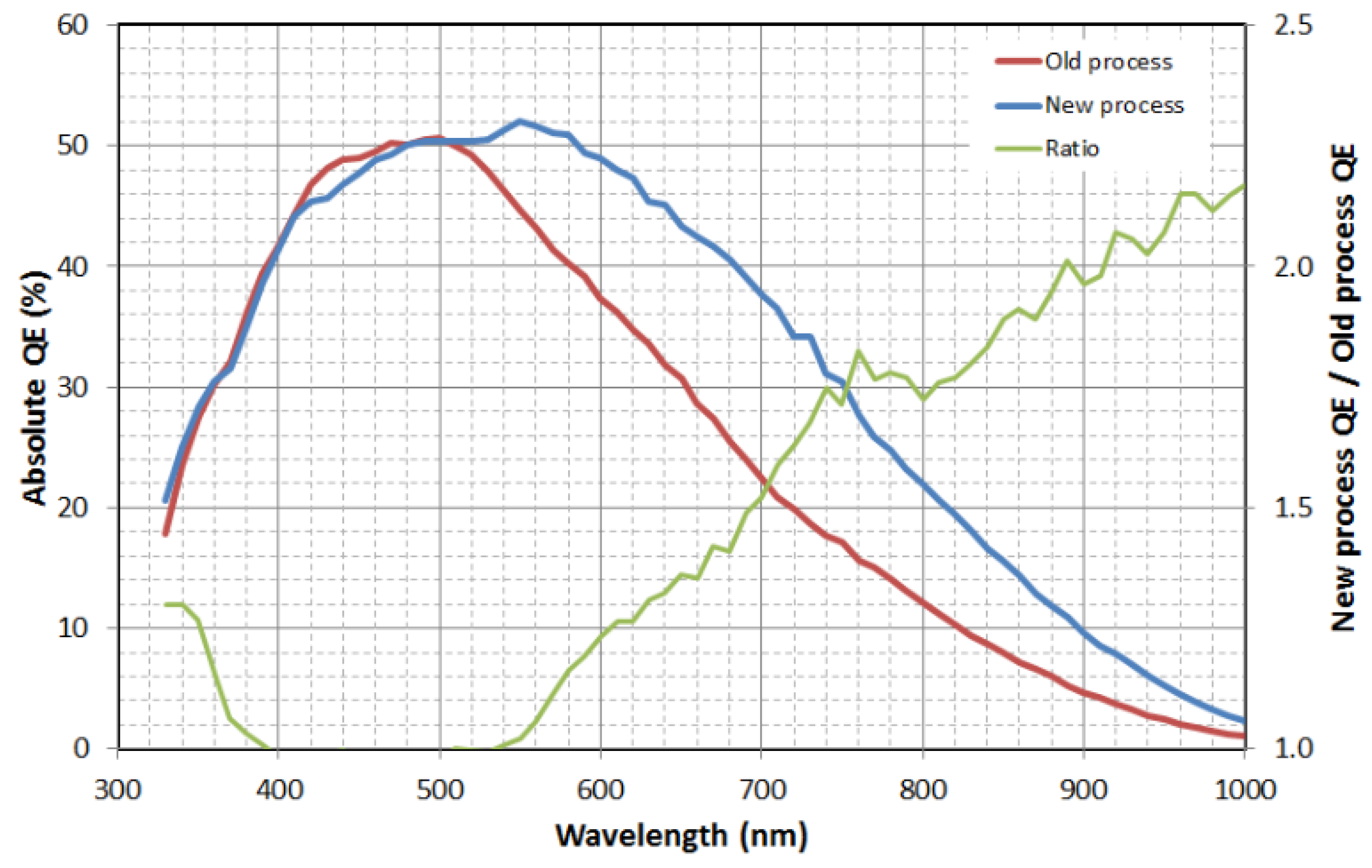

2. Improved Quantum Efficiency

3. Masking of High-Energy Implants

3.1. Patterning

3.2. Radiation

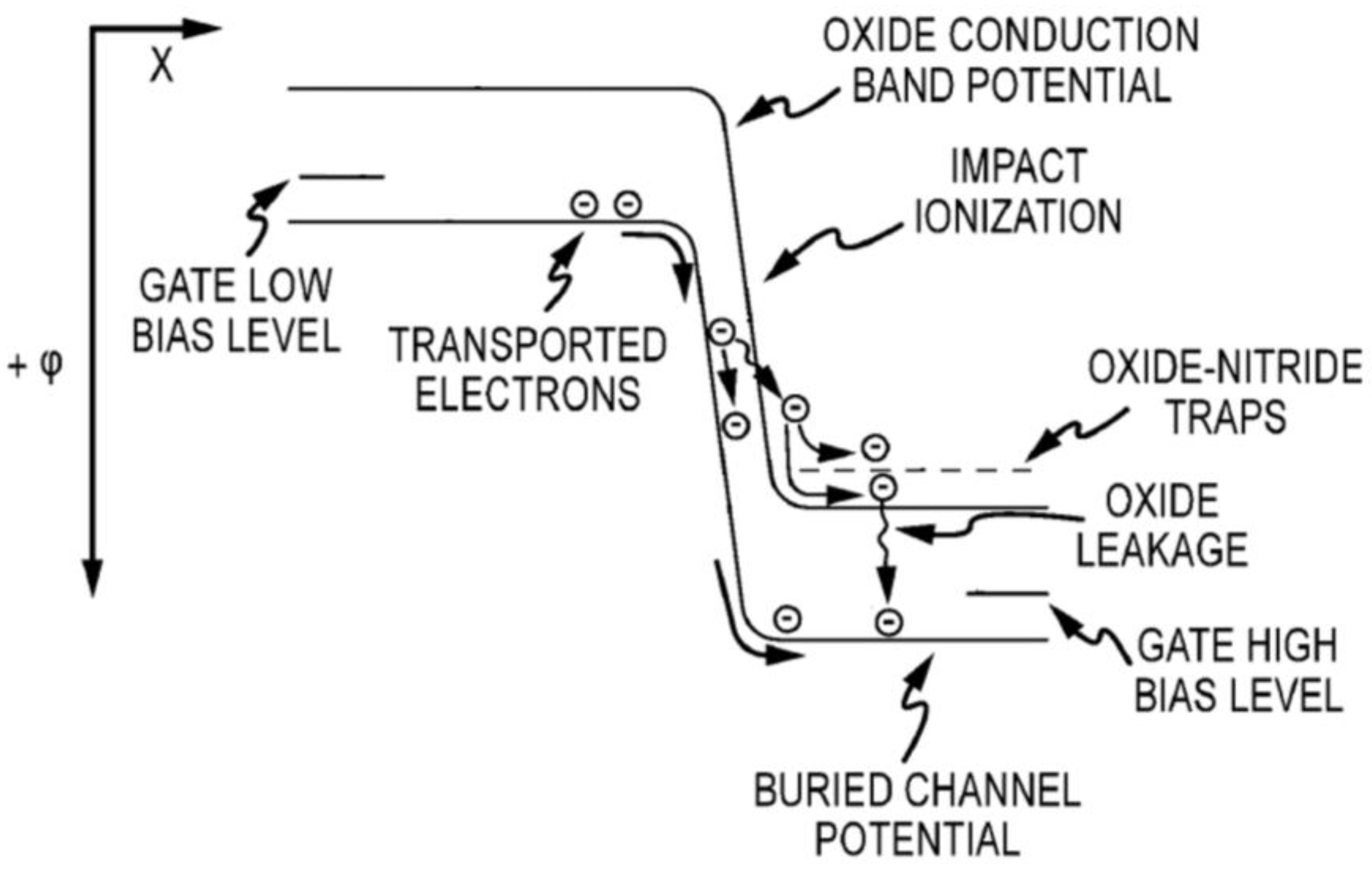

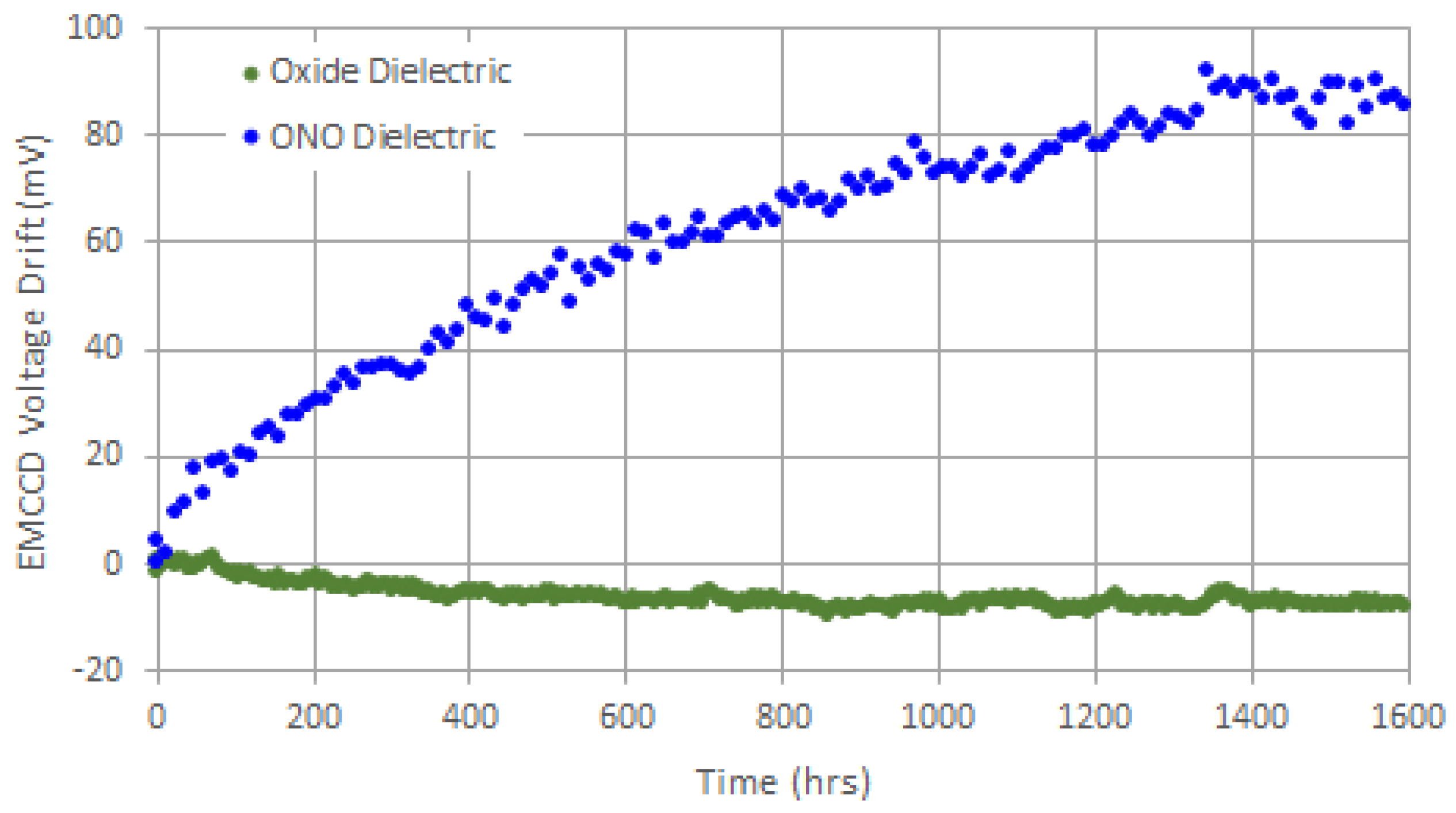

4. Improved Reliability

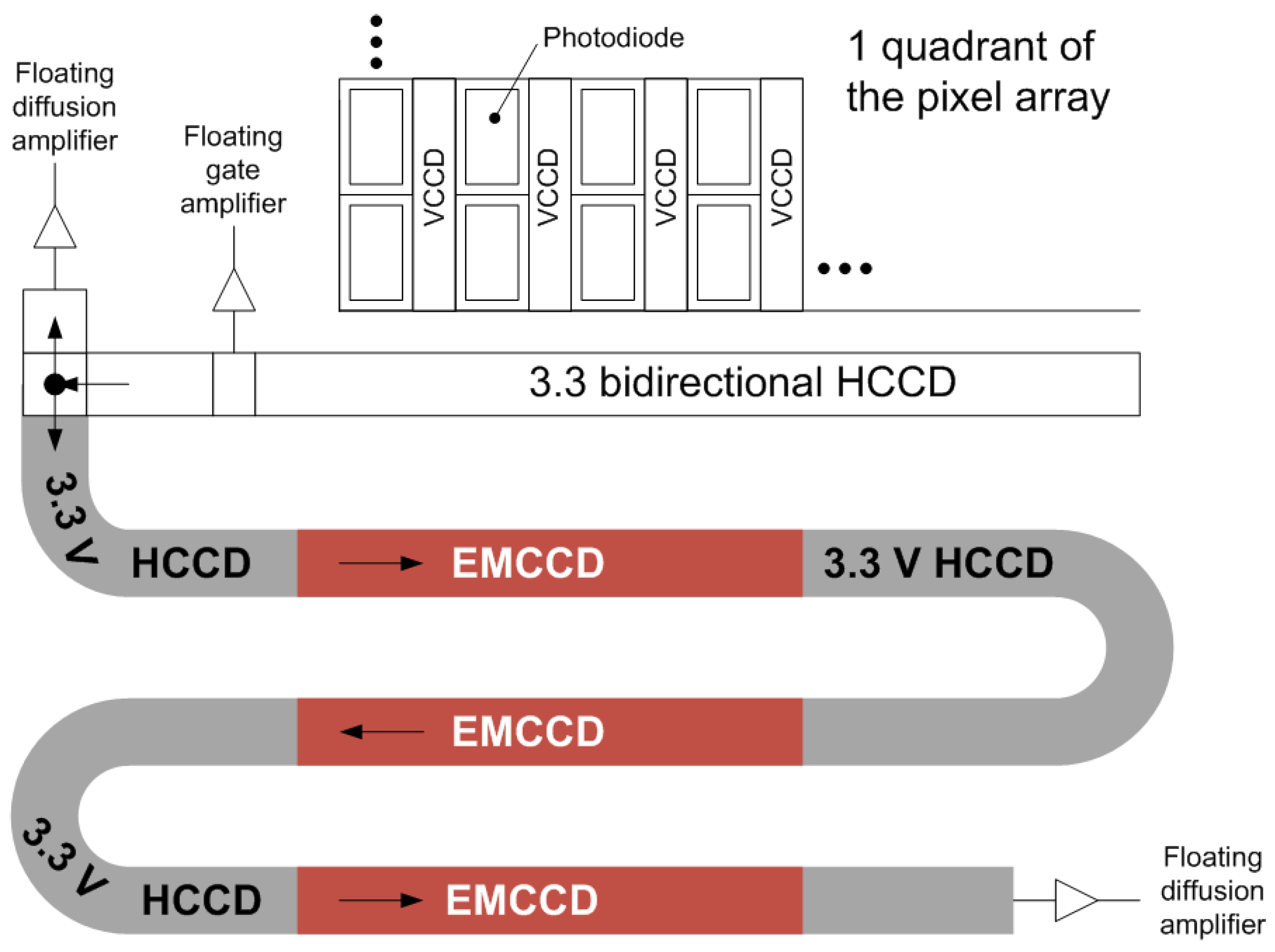

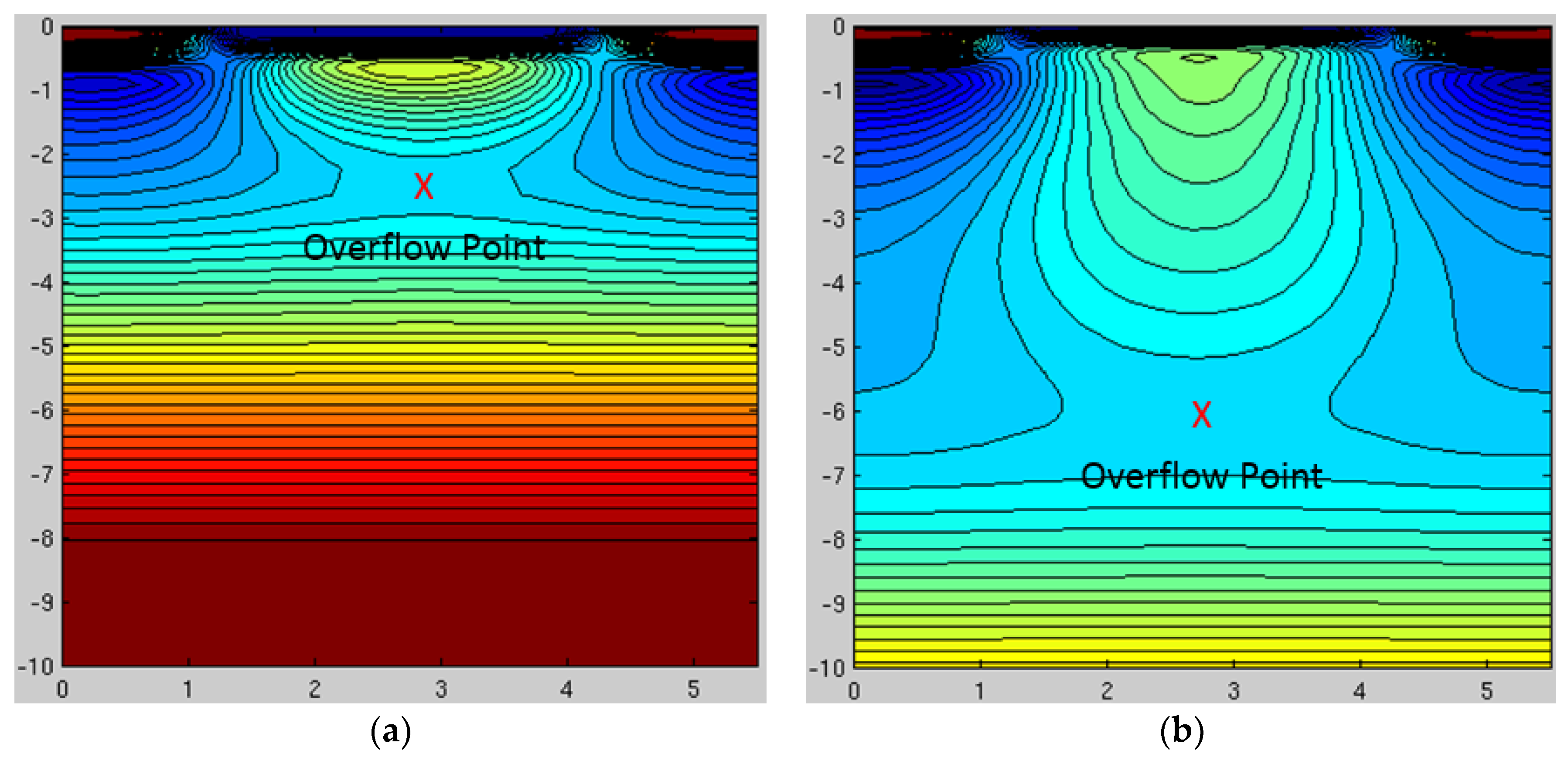

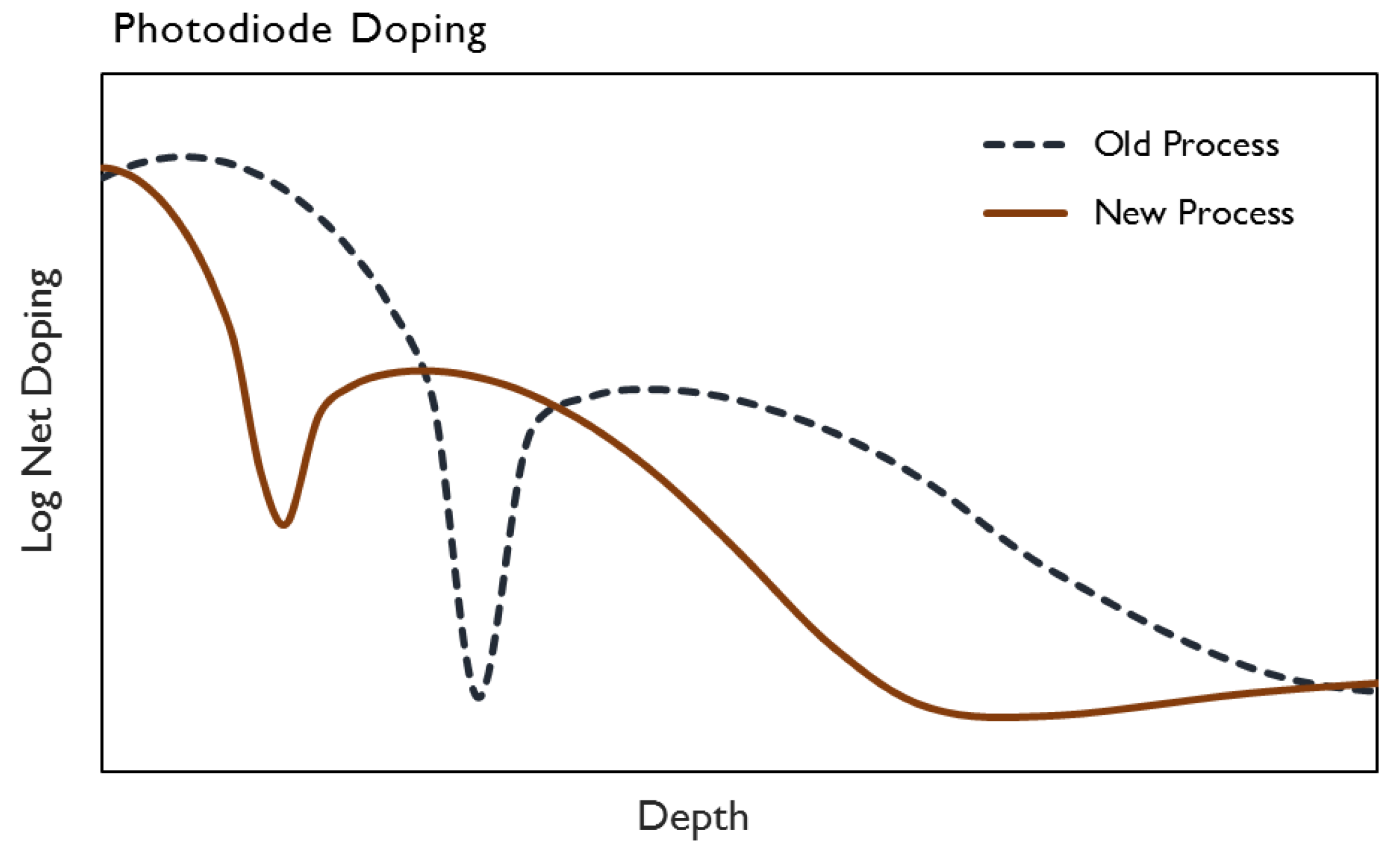

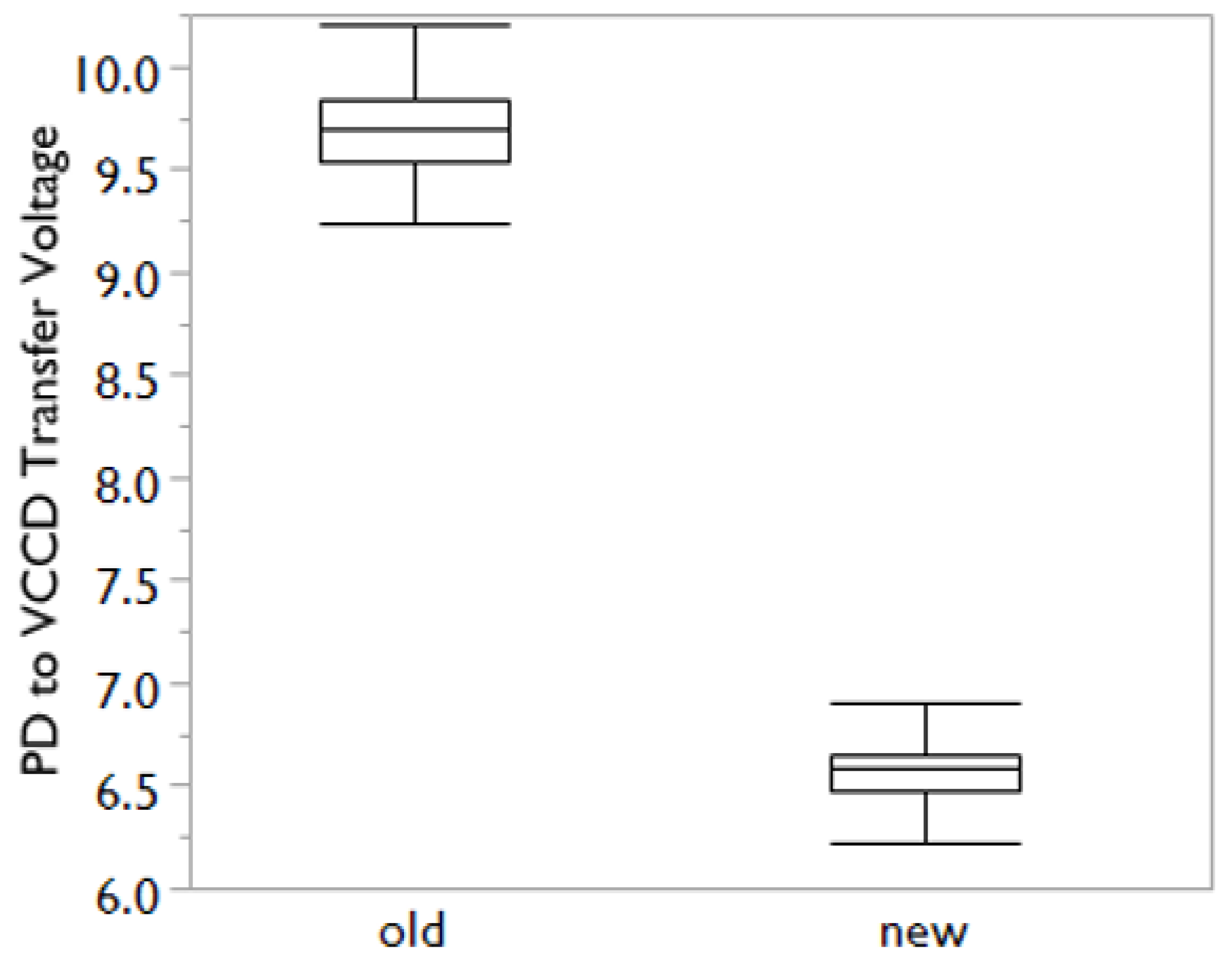

5. Improved Transfer Efficiency

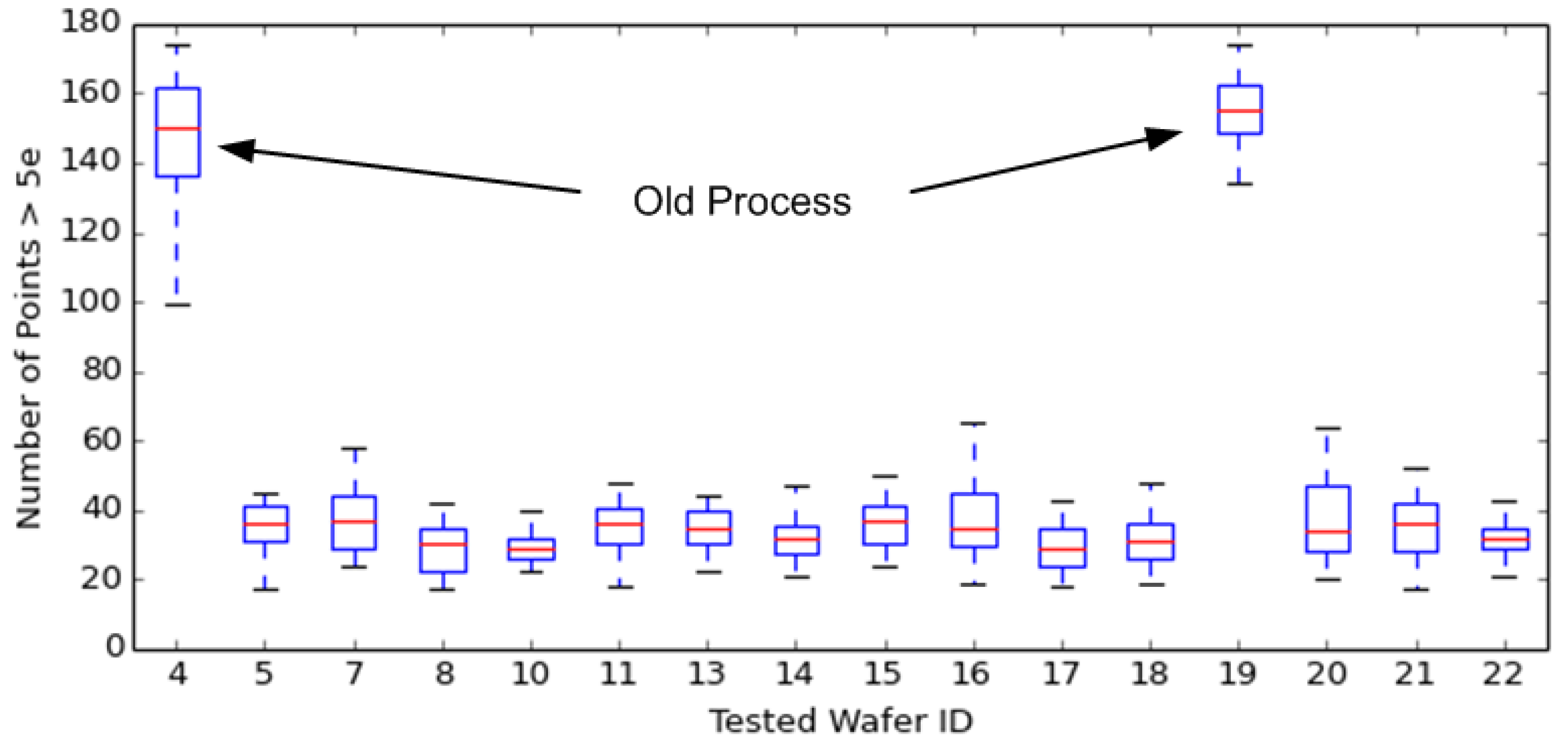

6. Reduced Point Defects

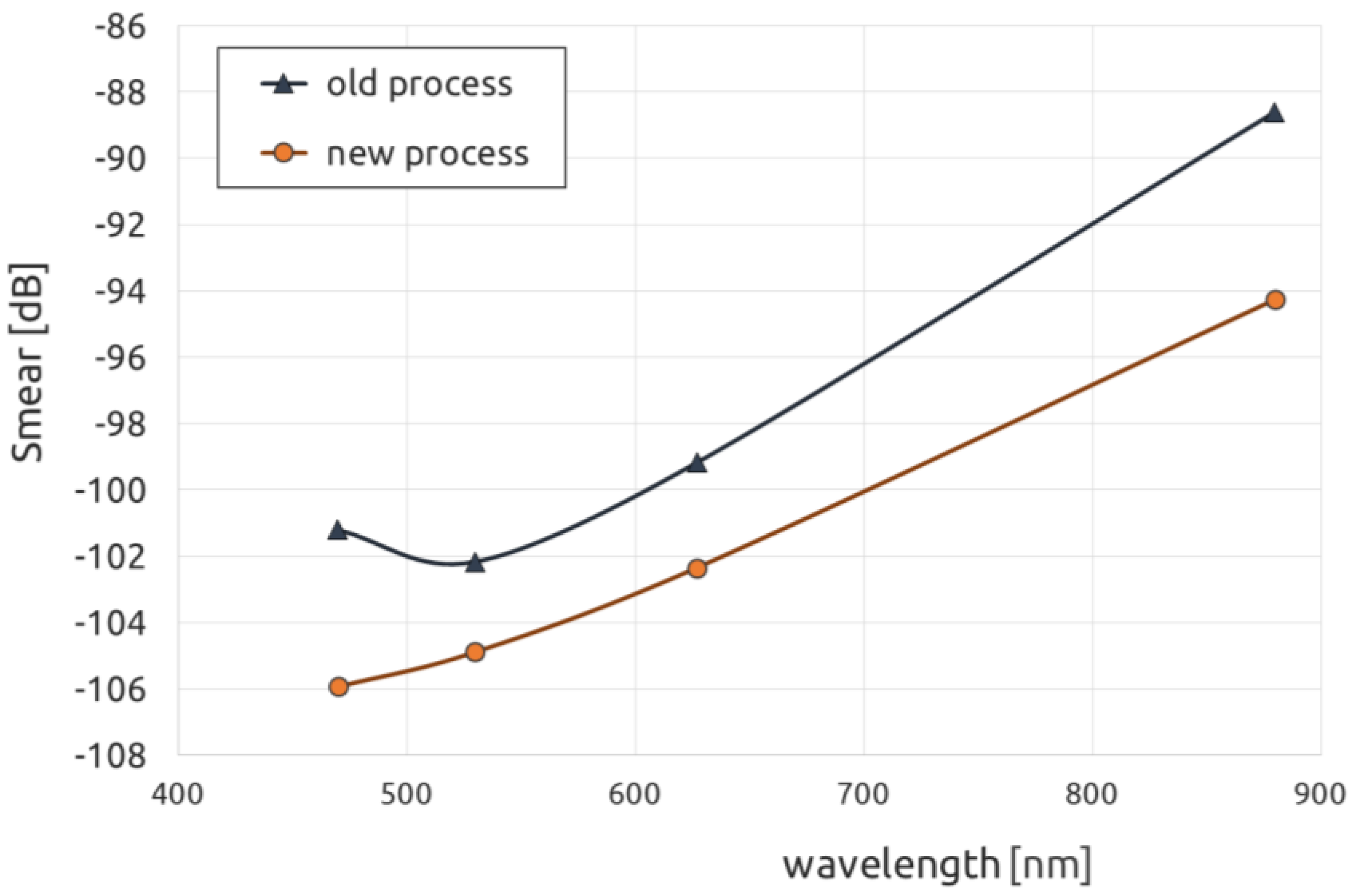

7. Reduced Image Smear

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

References

- Hynecek, J. CCM—A New Low-Noise Charge Carrier Multiplier Suitable for Detection of Charge in Small Pixel CCD Image Sensors. IEEE Trans. Electron Devices 1992, 39, 1972–1975. [Google Scholar] [CrossRef]

- Parks, C.; Kosman, S.; Nelson, E.; Roberts, N.; Yaniga, S. A 30 fps 1920 × 1080 Pixel Electron Multiplying CCD Image Sensor with Per-Pixel Switchable Gain. In Proceedings of the 2015 International Image Sensor Workshop (IISW), Vaals, The Netherlands, 8–11 June 2015. [Google Scholar]

- Stevens, E.G.; Clayhold, J.A.; Doan, H.; Fabinski, R.P.; Hynecek, J.; Kosman, S.L.; Parks, C. Recent Enhancements to Electron Multiplying CCD Image Sensors. In Proceedings of the 2017 International Image Sensor Workshop (IISW), Hiroshima, Japan, 30 May–2 June 2017; pp. 93–95. [Google Scholar]

- De Monte, B.; Bell, R.T. Development of an EMCCD for LIDAR applications. In Proceedings of the International Conference on Space Optics, Session 28, Toulouse, France, 14–17 October 2008. [Google Scholar]

- Ingley, R.; Smith, D.R.; Holland, A.D. Life Testing of EMCCD Gain Characteristics. Nucl. Instrum. Methods Phys. Res. Sect. A 2009, 600, 460–465. [Google Scholar] [CrossRef]

- Jenkins, F.; White, H.E. Fundamentals of Optics, 4th ed.; McGraw-Hill Education: Columbus, OH, USA, 2001. [Google Scholar]

- White, N.R.; Tokoro, N.; Bell, E. Radiation Issues Surrounding Very High Energy Ion Implantation. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2008; Volume 1066, pp. 277–280. [Google Scholar]

- Burkey, B.C.; Chang, W.C.; Littlehale, J.; Lee, T.H.; Tredwell, T.J.; Lavine, J.P.; Trabka, E.A. The Pinned Photodiode for an Interline-Transfer CCD Image Sensor. In Proceedings of the 1984 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 9–12 December 1984. [Google Scholar]

- Kuroda, T.; Kuriyama, T.; Matsuda, Y.; Kozono, T.; Matsumoto, S.; Hiroshima, Y.; Horii, K. A Smear-Suppressing CCD Imager. In Proceedings of the 1986 IEEE International Solid-State Circuits Conference, Digest of Technical Papers, Anaheim, CA, USA, 19–21 February 1986; Volume 29. [Google Scholar]

- Tanabe, A.; Kudoh, Y.; Kawakami, Y.; Masubuchi, K.; Kawai, S.; Yamada, T.; Morimoto, M.; Arai, K.; Hatano, K.; Furumiya, M.; et al. Dynamic Range Improvement by Narrow-Channel Effect Suppression and Smear Reduction Technologies in Small Pixel IT-CCD Image Sensors. IEEE Trans. Electron Devices 2000, 47, 1700–1706. [Google Scholar] [CrossRef]

| Boron Dose/cm−2 | Bq/cm2 | Bq for 150 mm Wafer |

|---|---|---|

| 1.0 × 1011 | 1.0 × 10−7 | 1.0 × 10−5 |

| 1.0 × 1012 | 1.0 × 10−6 | 1.0 × 10−4 |

| 1.0 × 1013 | 1.0 × 10−5 | 1.0 × 10−3 |

| Parameter | Old Process | New Process |

|---|---|---|

| pixel size (µm) | 5.5 | 5.5 |

| charge-to-voltage (µV/e−) | 44 | 44 |

| charge capacity, nominal (ke−) | 20 | 20 |

| quantum efficiency at 450, 550, 650, 900 nm (%) | 49, 45, 31, 5 | 48, 52, 43, 10 |

| absolute electronic shutter voltage (V) | 27 | 18 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stevens, E.G.; Clayhold, J.A.; Doan, H.; Fabinski, R.P.; Hynecek, J.; Kosman, S.L.; Parks, C. Recent Enhancements to Interline and Electron Multiplying CCD Image Sensors. Sensors 2017, 17, 2841. https://doi.org/10.3390/s17122841

Stevens EG, Clayhold JA, Doan H, Fabinski RP, Hynecek J, Kosman SL, Parks C. Recent Enhancements to Interline and Electron Multiplying CCD Image Sensors. Sensors. 2017; 17(12):2841. https://doi.org/10.3390/s17122841

Chicago/Turabian StyleStevens, Eric G., Jeffrey A. Clayhold, Hung Doan, Robert P. Fabinski, Jaroslav Hynecek, Stephen L. Kosman, and Christopher Parks. 2017. "Recent Enhancements to Interline and Electron Multiplying CCD Image Sensors" Sensors 17, no. 12: 2841. https://doi.org/10.3390/s17122841