Comparison of Measurement Models for 3D Magnetic Localization and Tracking

Abstract

:1. Introduction

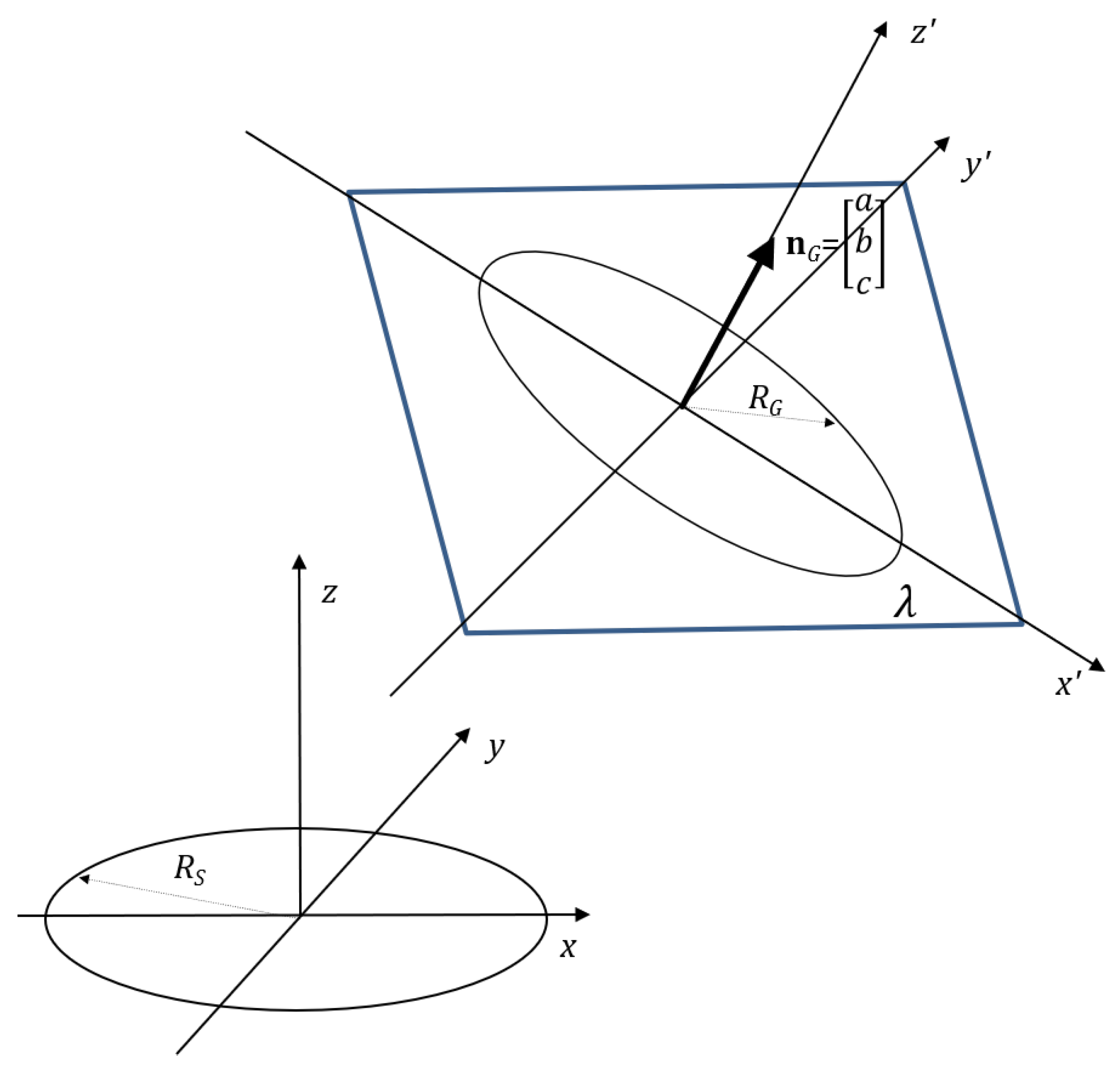

2. Measurement Models for Magnetic Positioning Systems

2.1. Magnetic Dipole Model

2.2. Mutual Inductance Model

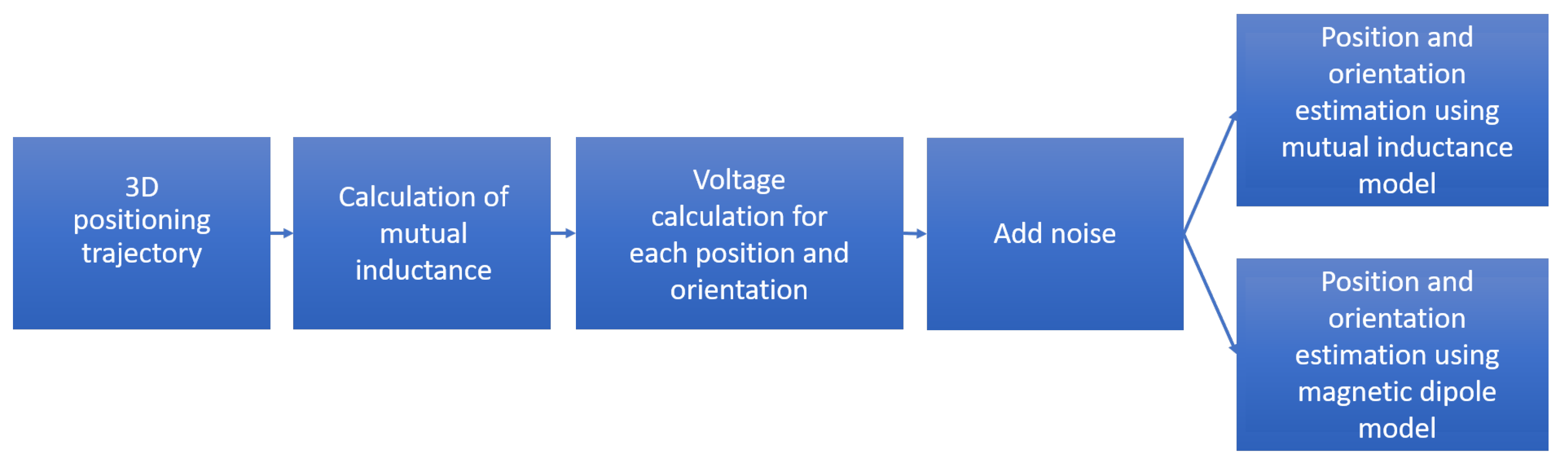

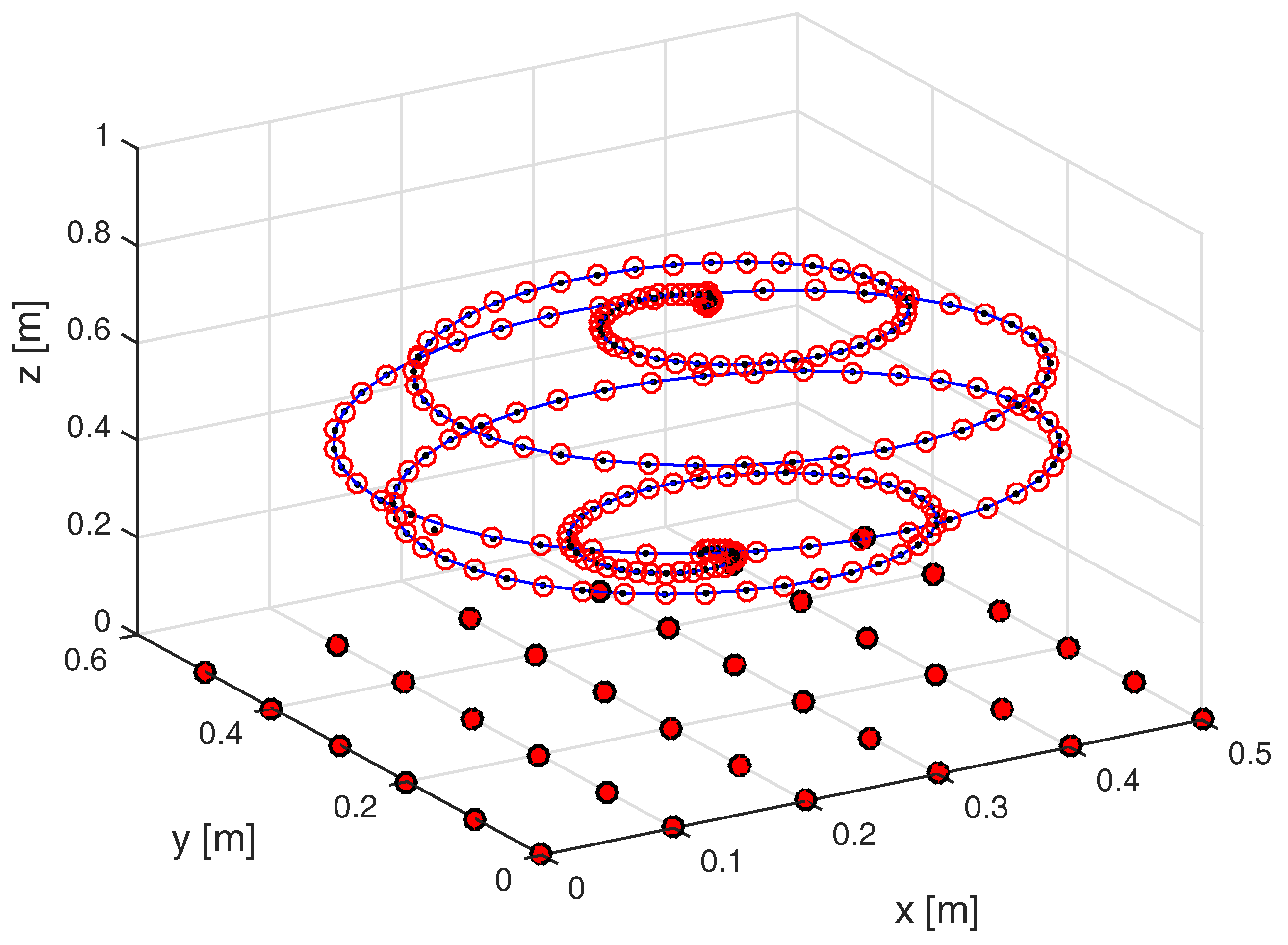

3. Numerical Simulation of a Magnetic Positioning System

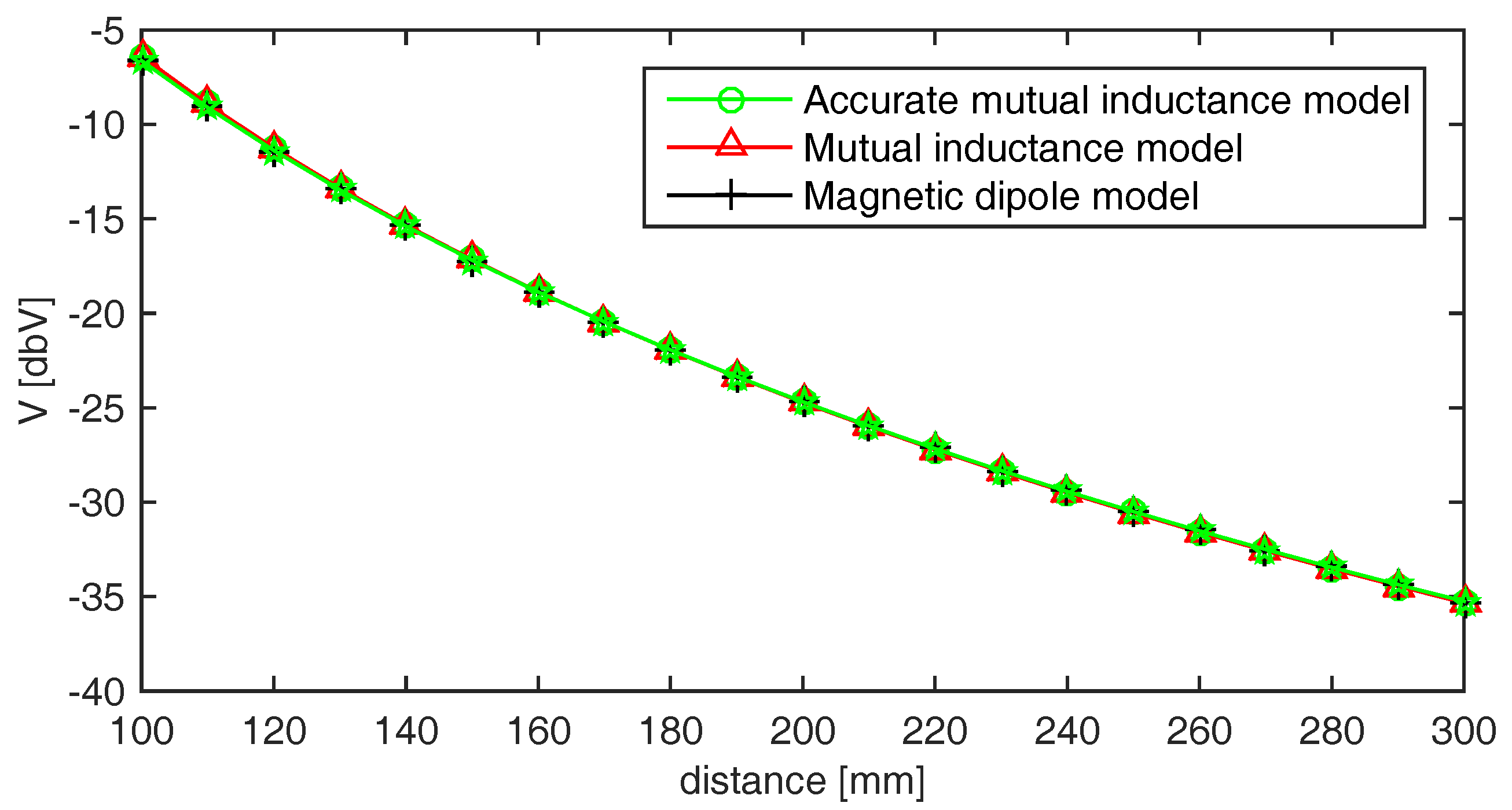

3.1. Simulation Data

3.2. Calibration

3.3. Simulation Setup and Performance Evaluation Metrics

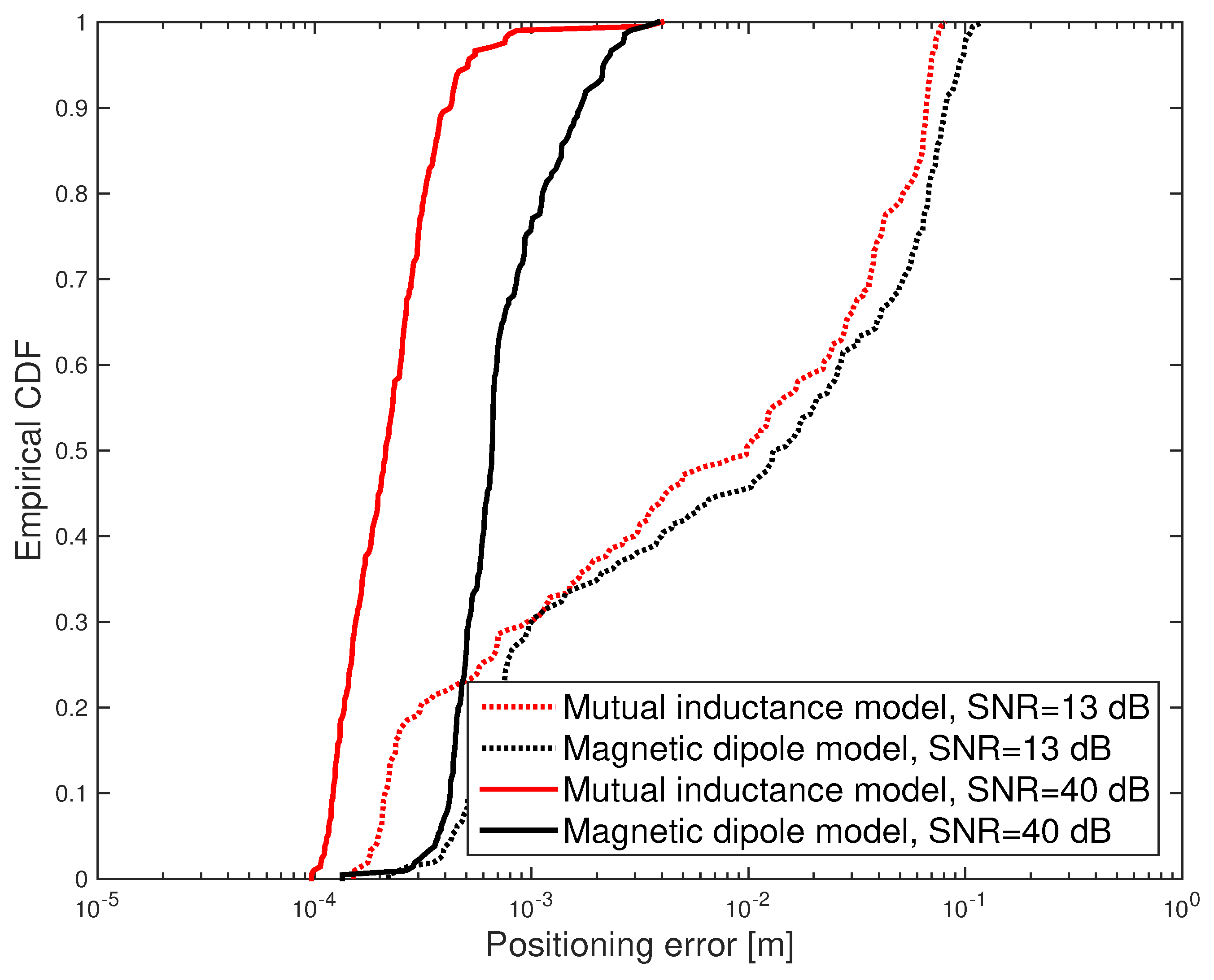

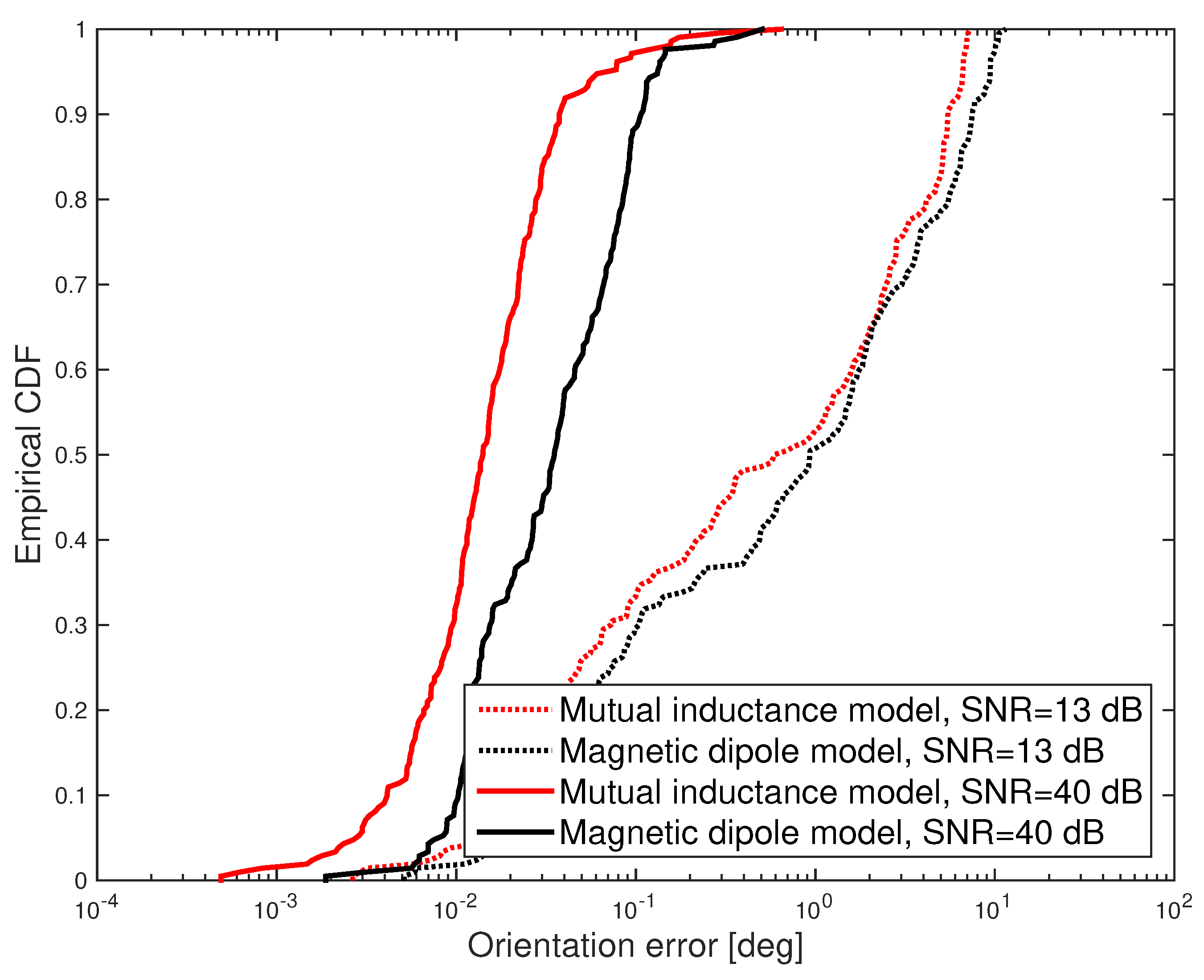

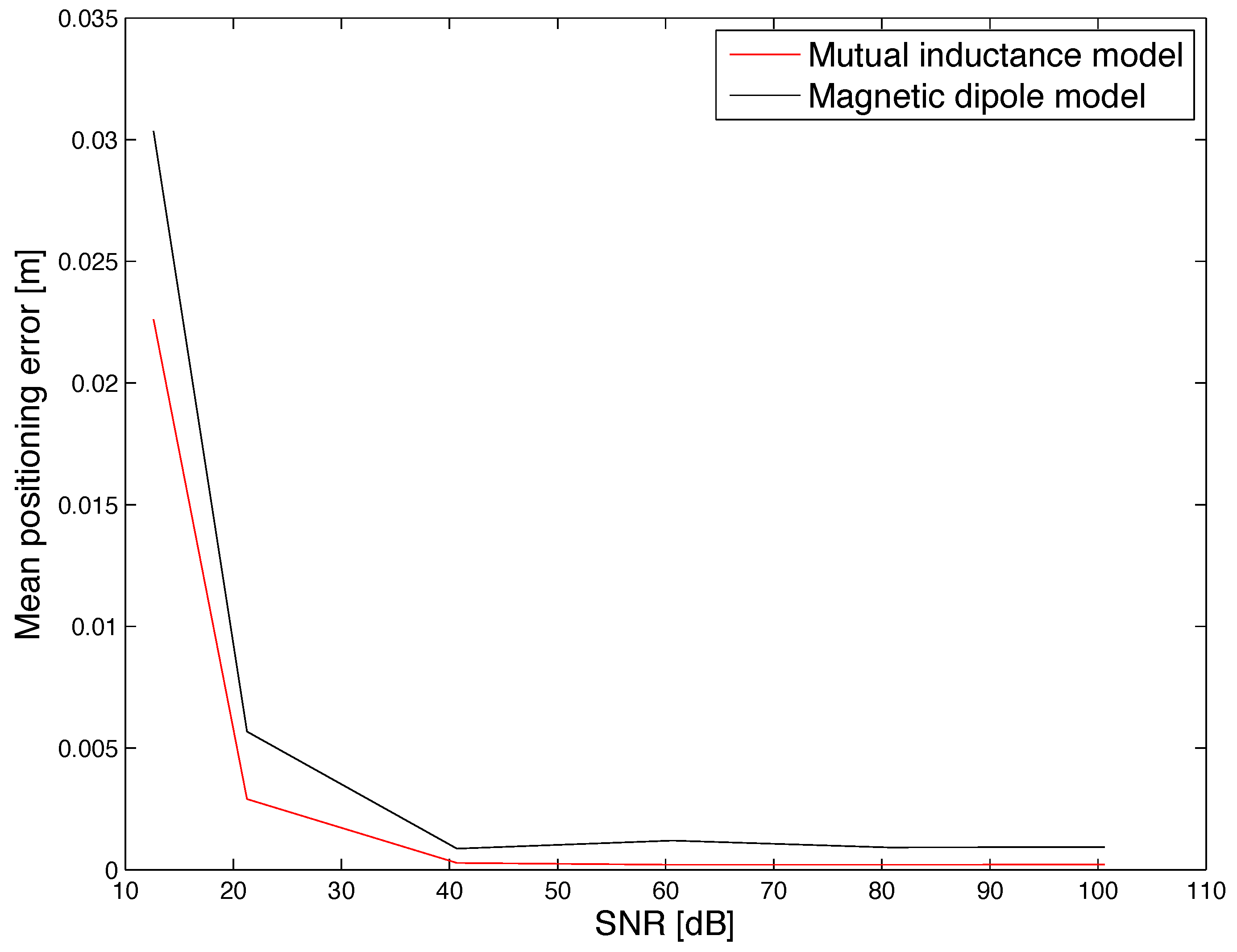

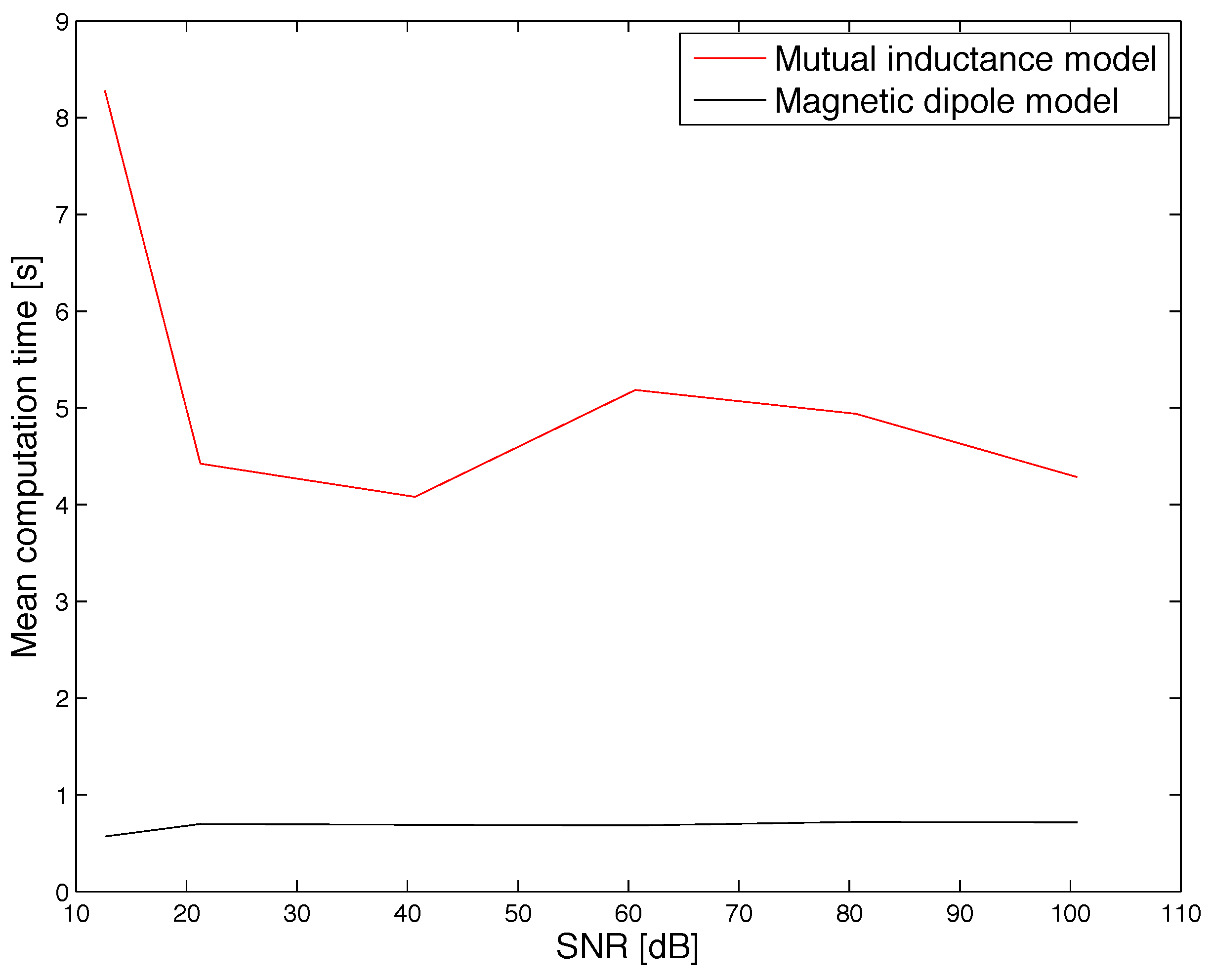

3.4. Numerical Simulation Results

4. Experimental Magnetic Tracking System (MTS)

4.1. Hardware Setup

4.2. Tracking Algorithm

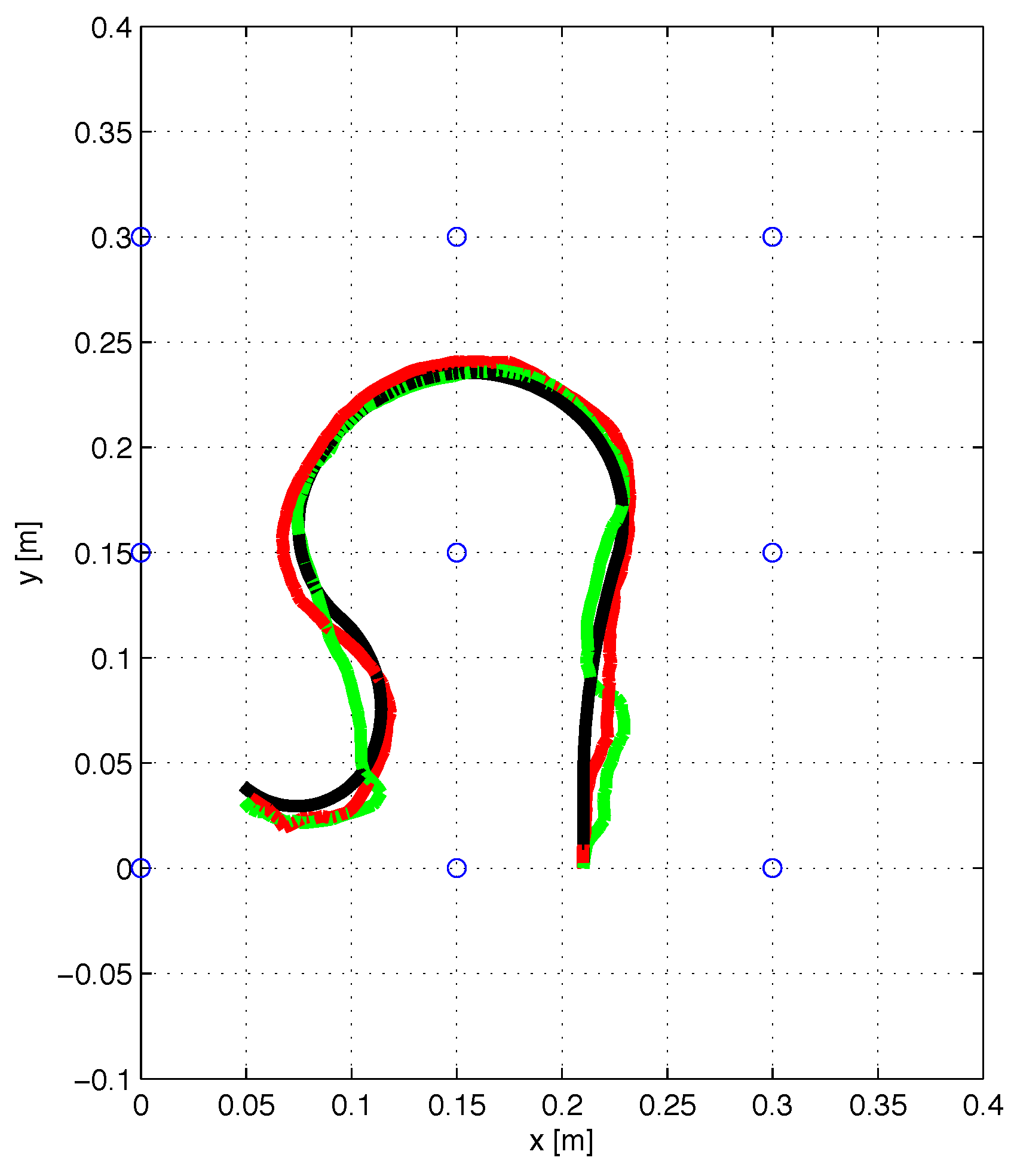

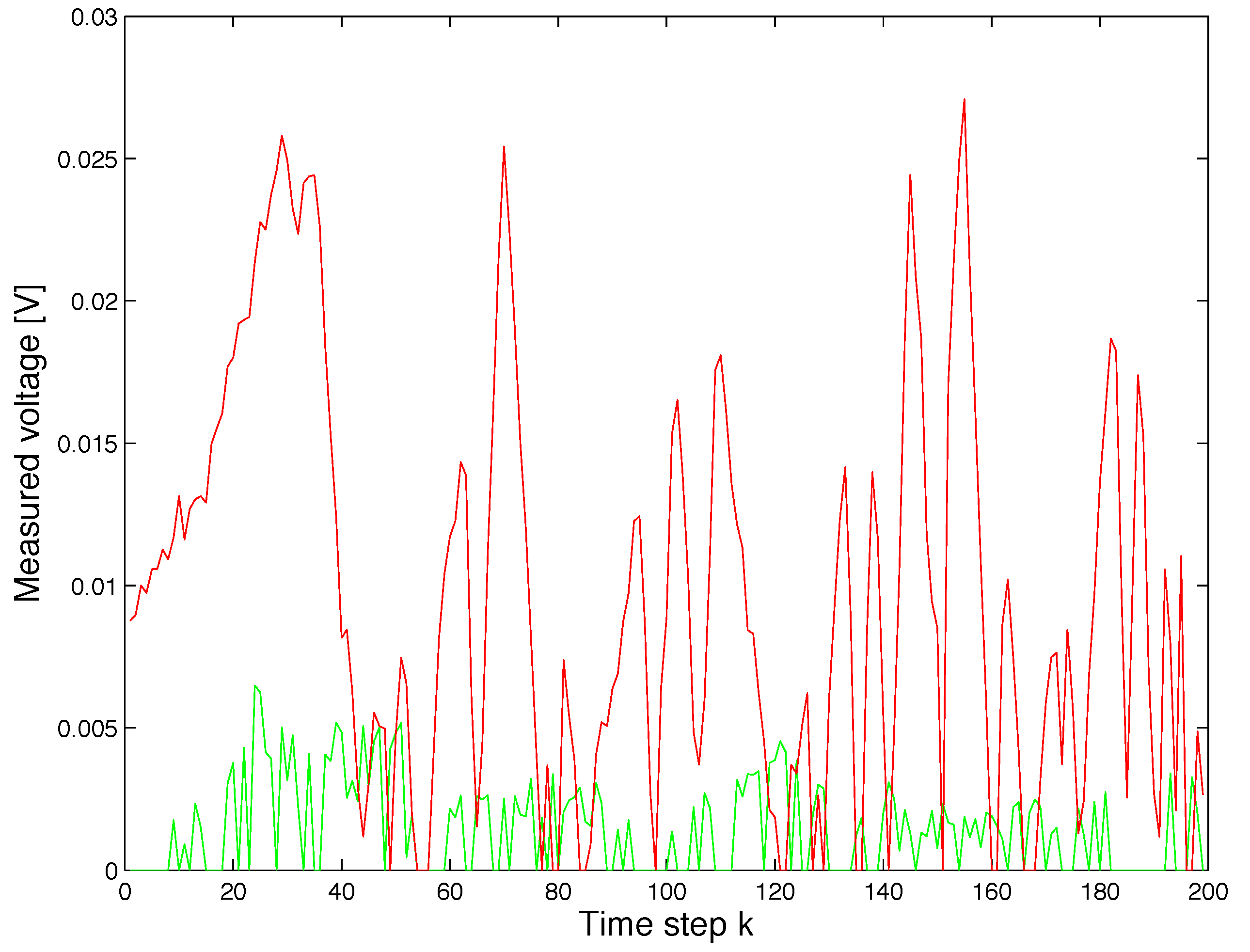

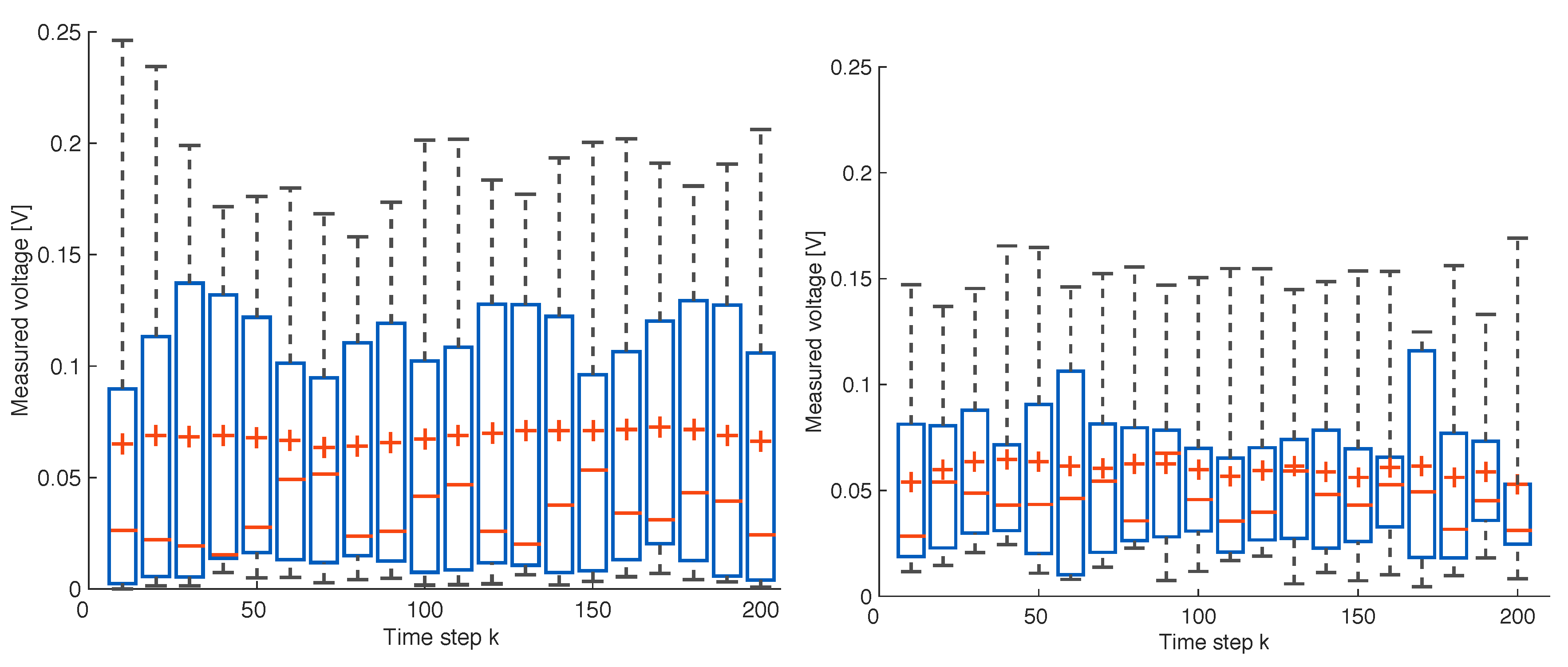

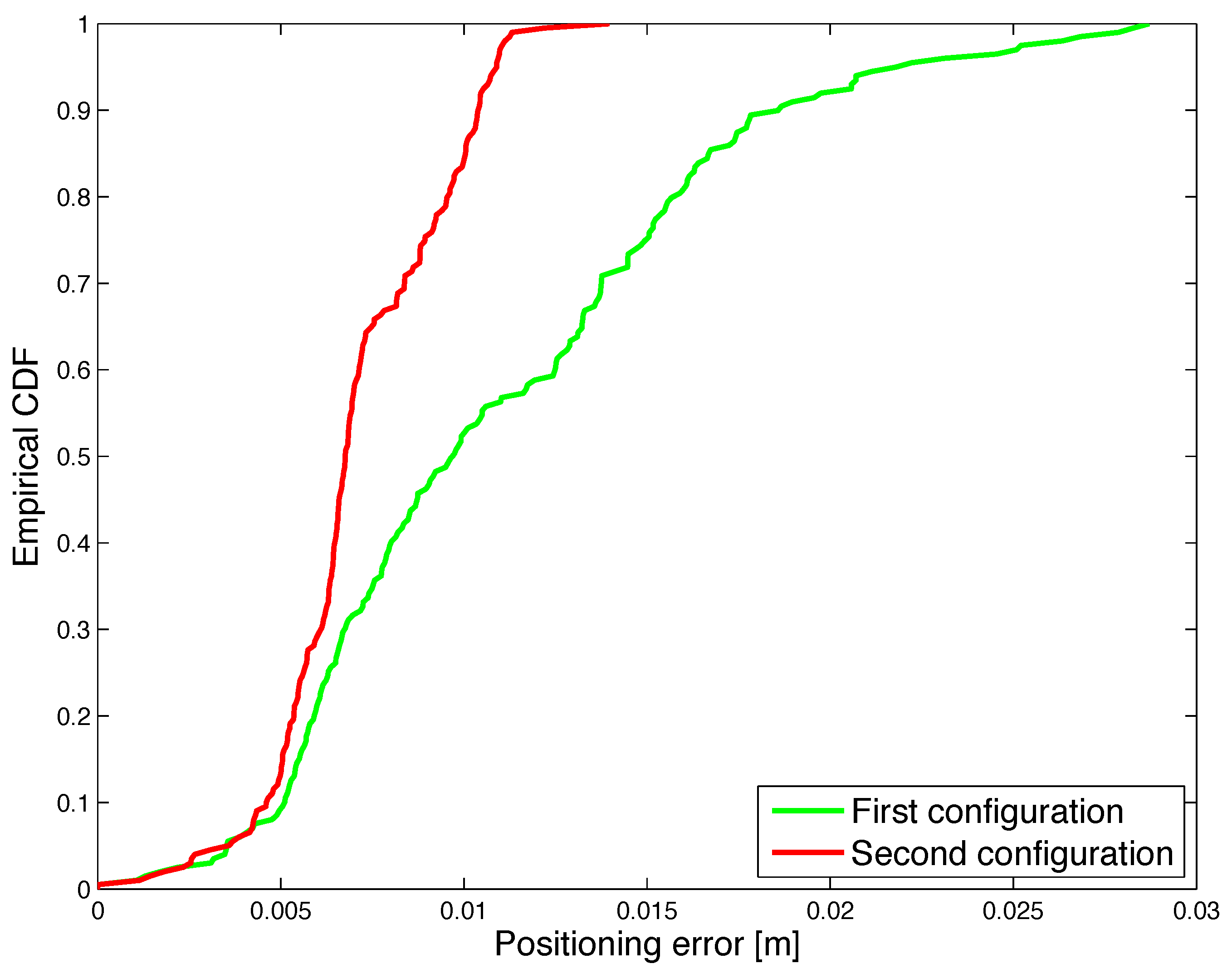

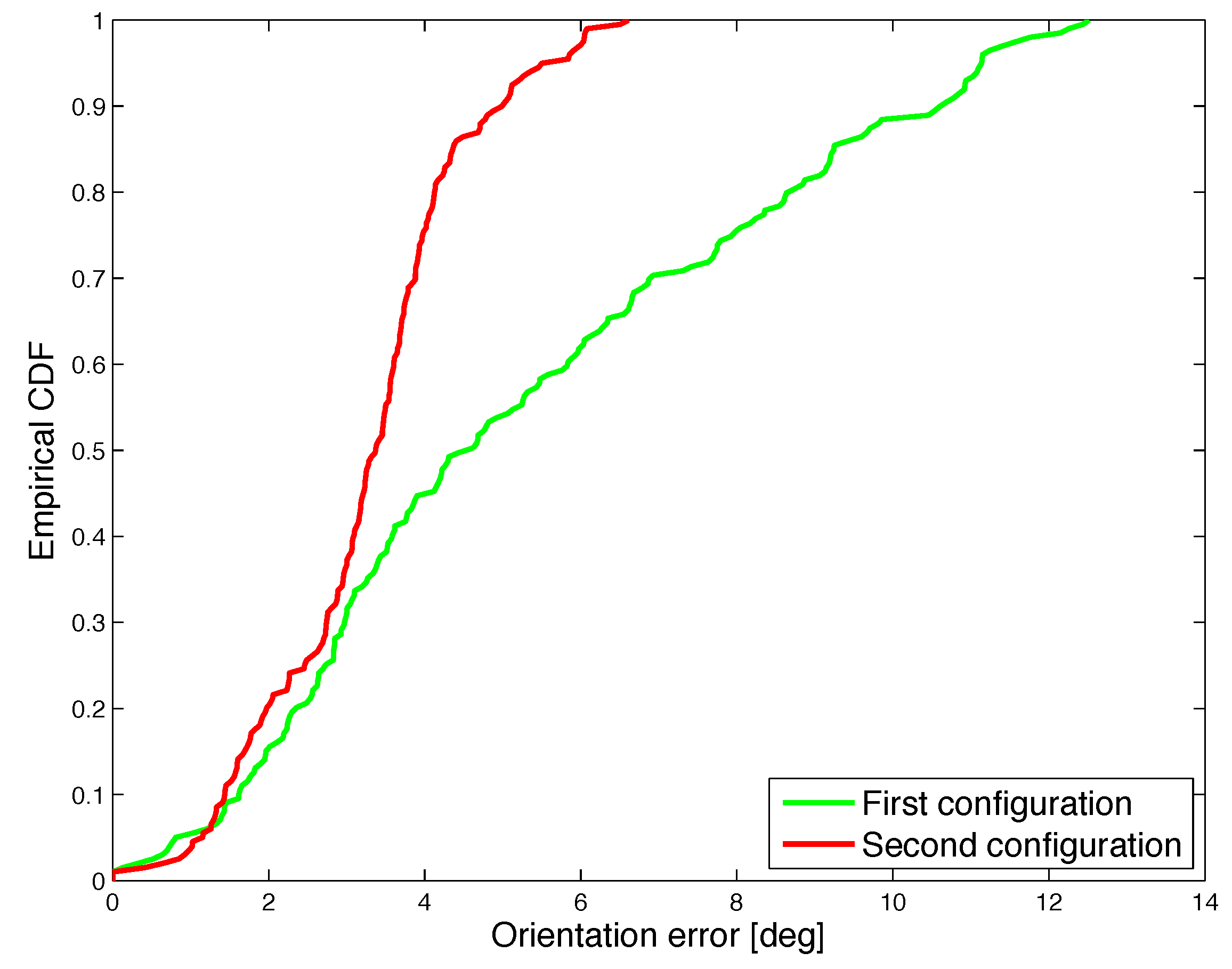

4.3. Experimental Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- De Angelis, G.; Moschitta, A.; Carbone, P. Positioning Techniques in Indoor Environments Based on Stochastic Modeling of UWB Round-Trip-Time Measurements. IEEE Trans. Intell. Transp. Syst. 2016, 17, 2272–2281. [Google Scholar] [CrossRef]

- Castillo-Cara, M.; Lovón-Melgarejo, J.; Bravo-Rocca, G.; Orozco-Barbosa, L.; García-Varea, I. An Empirical Study of the Transmission Power Setting for Bluetooth-Based Indoor Localization Mechanisms. Sensors 2017, 17, 1318. [Google Scholar] [CrossRef] [PubMed]

- Gharghan, S.K.; Nordin, R.; Ismail, M. A Wireless Sensor Network with Soft Computing Localization Techniques for Track Cycling Applications. Sensors 2016, 16, 1043. [Google Scholar] [CrossRef] [PubMed]

- Gualda, D.; Ureña, J.; García, J.C.; Lindo, A. Locally-Referenced Ultrasonic–LPS for Localization and Navigation. Sensors 2014, 14, 21750–21769. [Google Scholar] [CrossRef] [PubMed]

- De Angelis, A.; Moschitta, A.; Carbone, P.; Calderini, M.; Neri, S.; Borgna, R.; Peppucci, M. Design and Characterization of a Portable Ultrasonic Indoor 3D Positioning System. IEEE Trans. Instrum. Meas. 2015, 64, 2616–2625. [Google Scholar] [CrossRef]

- Pasku, V.; De Angelis, A.; De Angelis, G.; Arumugam, D.D.; Marco, D.; Paolo, C.; Antonio, M.; Ricketts, D.S. Magnetic Field Based Positioning Systems. IEEE Commun. Surv. Tutor. 2017, 19, 2003–2017. [Google Scholar] [CrossRef]

- Kasmi, Z.; Norrdine, A.; Blankenbach, J. Towards a Decentralized Magnetic Indoor Positioning System. Sensors 2015, 15, 30319–30339. [Google Scholar] [CrossRef] [PubMed]

- Pasku, V.; De Angelis, A.; De Angelis, G.; Moschitta, A.; Carbone, P. Magnetic Field Analysis for 3D Positioning Applications. IEEE Trans. Instrum. Meas. 2017, 66, 935–943. [Google Scholar] [CrossRef]

- Song, S.; Qiao, W.; Li, B.; Hu, C.; Ren, H.; Meng, M.Q.H. An Efficient Magnetic Tracking Method Using Uniaxial Sensing Coil. IEEE Trans. Magn. 2014, 50, 1–7. [Google Scholar] [CrossRef]

- Hu, C.; Song, S.; Wang, X.; Meng, M.Q.H.; Li, B. A Novel Positioning and Orientation System Based on Three-Axis Magnetic Coils. IEEE Trans. Magn. 2012, 48, 2211–2219. [Google Scholar] [CrossRef]

- Roetenberg, D.; Slycke, P.J.; Veltink, P.H. Ambulatory Position and Orientation Tracking Fusing Magnetic and Inertial Sensing. IEEE Trans. Biomed. Eng. 2007, 54, 883–890. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Foong, S.; Maréchal, L.; Teo, T.H.; Tan, U.X.; Shabbir, A. Using heterogeneous sensory measurements in a compliant magnetic localization system for medical intervention. In Proceedings of the 2015 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Busan, Korea, 7–11 July 2015; pp. 133–138. [Google Scholar]

- Plotkin, A.; Paperno, E. 3D magnetic tracking of a single subminiature coil with a large 2-D array of uniaxial transmitters. IEEE Trans. Magn. 2003, 39, 3295–3297. [Google Scholar] [CrossRef]

- Kofman, J.; Wu, X.; Luu, T.J.; Verma, S. Teleoperation of a robot manipulator using a vision-based human-robot interface. IEEE Trans. Ind. Electron. 2005, 52, 1206–1219. [Google Scholar] [CrossRef]

- Meli, L.; Salvietti, G.; Gioioso, G.; Malvezzi, M.; Prattichizzo, D. Multi-contact bilateral telemanipulation using wearable haptics. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 1431–1436. [Google Scholar]

- Babic, S.; Sirois, F.; Akyel, C.; Girardi, C. Mutual Inductance Calculation Between Circular Filaments Arbitrarily Positioned in Space: Alternative to Grover’s Formula. IEEE Trans. Magn. 2010, 46, 3591–3600. [Google Scholar] [CrossRef]

- Babic, S.I.; Akyel, C. Calculating Mutual Inductance Between Circular Coils With Inclined Axes in Air. IEEE Trans. Magn. 2008, 44, 1743–1750. [Google Scholar] [CrossRef]

- Babic, S.I.; Martinez, J.; Akyel, C.; Babic, B. Mutual inductance calculation between misalignment coils for wireless power transfer of energy. Prog. Electromagn. Res. M 2014, 38, 91–102. [Google Scholar] [CrossRef]

- Moschitta, A.; De Angelis, A.; Dionigi, M.; Carbone, P. Analysis of simultaneous 3D positioning and attitude estimation of a planar coil using inductive coupling. In Proceedings of the 2017 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Turin, Italy, 22–25 May 2017; pp. 1–6. [Google Scholar]

- Fukushima, T. Fast computation of complete elliptic integrals and Jacobian elliptic functions. Celest. Mech. Dyn. Astron. 2009, 105, 305. [Google Scholar] [CrossRef]

- Abramowitz, M.; Stegun, I.A. Section 17.3. Complete Elliptical Integrals of the First and Second Kinds. In Handbook of Mathematical Functions with Formulas, Graphs, and Mathematical Tables; Dover: New York, NY, USA, 1964. [Google Scholar]

- Dionigi, M.; De Angelis, G.; Moschitta, A.; Mongiardo, M.; Carbone, P. A Simple Ranging System Based on Mutually Coupled Resonating Circuits. IEEE Trans. Instrum. Meas. 2014, 63, 1215–1223. [Google Scholar] [CrossRef]

- Kim, K.-B.; Levi, E.; Zabar, Z.; Birenbaum, L. Mutual inductance of noncoaxial circular coils with constant current density. IEEE Trans. Magn. 1997, 33, 4303–4309. [Google Scholar]

- Nelder, J.A.; Mead, R. A Simplex Method fot Function Minimization. Comput. J. 1965, 7, 308–313. [Google Scholar] [CrossRef]

- Julier, S.; Uhlmann, J. A new extension of the Kalman filter to nonlinear systems. Int. Symp. Aerospace/Defense Sens. Simul. Controls 1997, 3, 182–193. [Google Scholar]

- Wan, E.A.; Van Der Merwe, R. The Unscented Kalman Filter for Nonlinear Estimation. In Proceedings of the IEEE 2000 Adaptive Systems for Signal Processing, Communications, and Control Symposium (Cat. No.00EX373), Lake Louise, AB, Canada, 4 October 2000; pp. 153–158. [Google Scholar]

- Bar-Shalom, Y.; Li, X.; Kirubarajan, T. Estimation with Applications to Tracking and Navigation: Theory Algorithms and Software; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- Thrun, S.; Burgard, W.; Fox, D. Probabilistic Robotics (Intelligent Robotics and Autonomous Agents); MIT Press: Cambridge, MA, USA, 2005. [Google Scholar]

| Model | Mean Computation Time [s] | Mean Positioning Error [mm] |

|---|---|---|

| Magnetic Dipole | 0.72 | 0.91 |

| Mutual Inductance | 4.94 | 0.21 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Angelis, G.; De Angelis, A.; Moschitta, A.; Carbone, P. Comparison of Measurement Models for 3D Magnetic Localization and Tracking. Sensors 2017, 17, 2527. https://doi.org/10.3390/s17112527

De Angelis G, De Angelis A, Moschitta A, Carbone P. Comparison of Measurement Models for 3D Magnetic Localization and Tracking. Sensors. 2017; 17(11):2527. https://doi.org/10.3390/s17112527

Chicago/Turabian StyleDe Angelis, Guido, Alessio De Angelis, Antonio Moschitta, and Paolo Carbone. 2017. "Comparison of Measurement Models for 3D Magnetic Localization and Tracking" Sensors 17, no. 11: 2527. https://doi.org/10.3390/s17112527