Electrical and Self-Sensing Properties of Ultra-High-Performance Fiber-Reinforced Concrete with Carbon Nanotubes

Abstract

:1. Introduction

2. Experimental Program

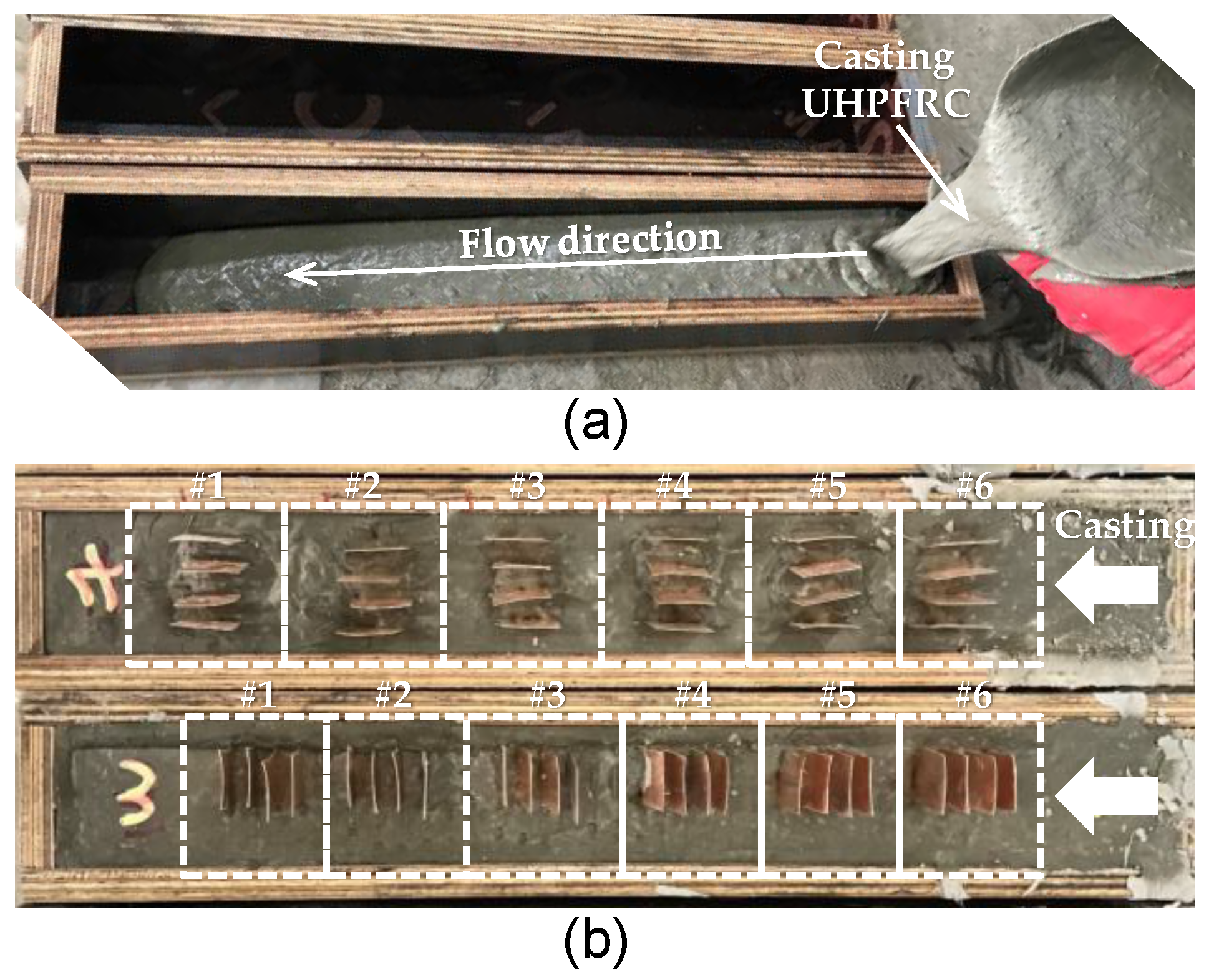

2.1. Constituents, Mix Proportions, and Specimen Preparation

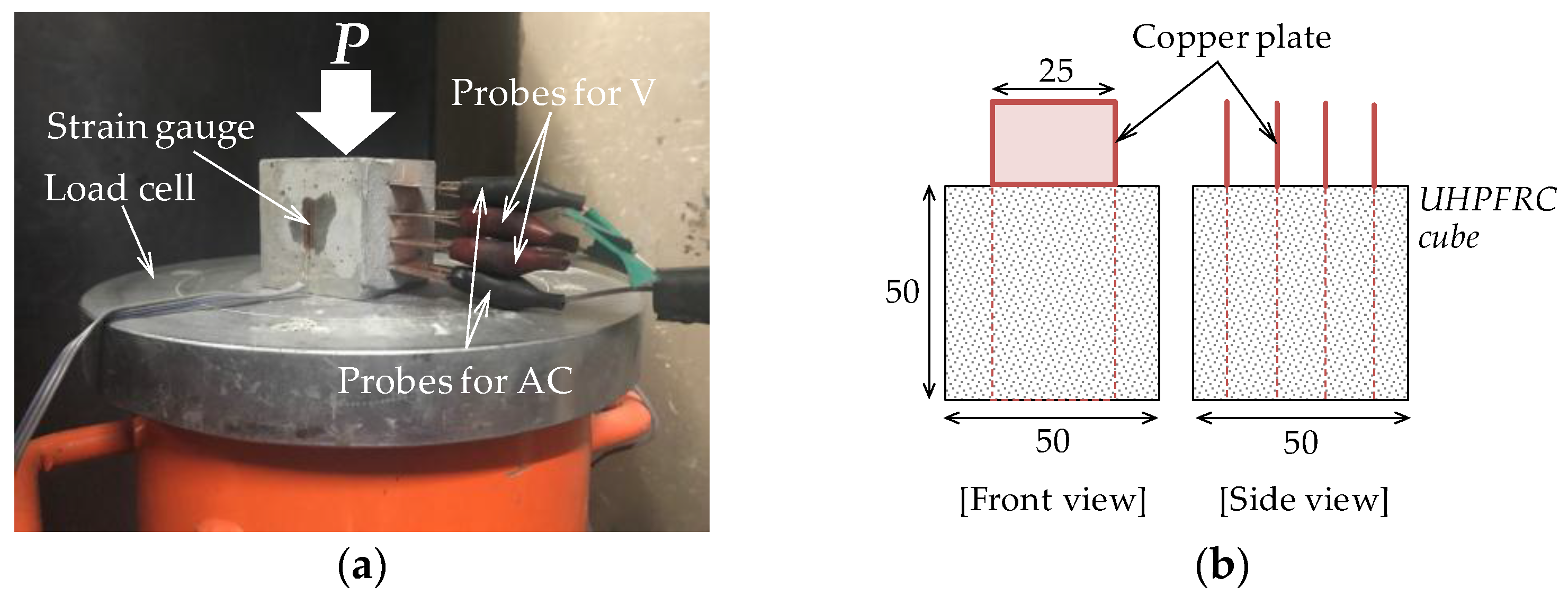

2.2. Test Setup for Electrical Resistance

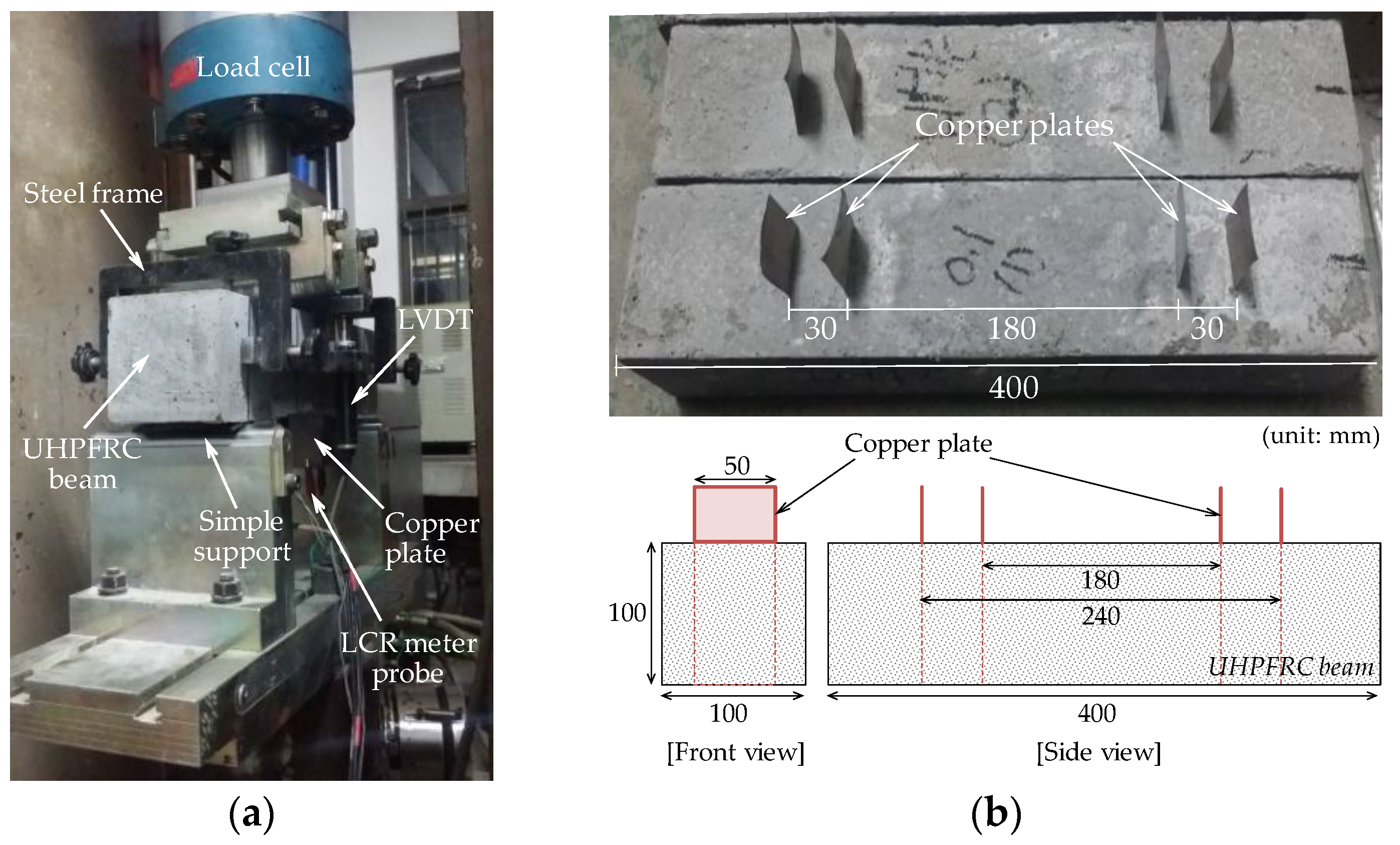

2.3. Test Setup for Evaluating Piezoresistive and Self-Sensing Capacities

3. Experimental Results and Discussion

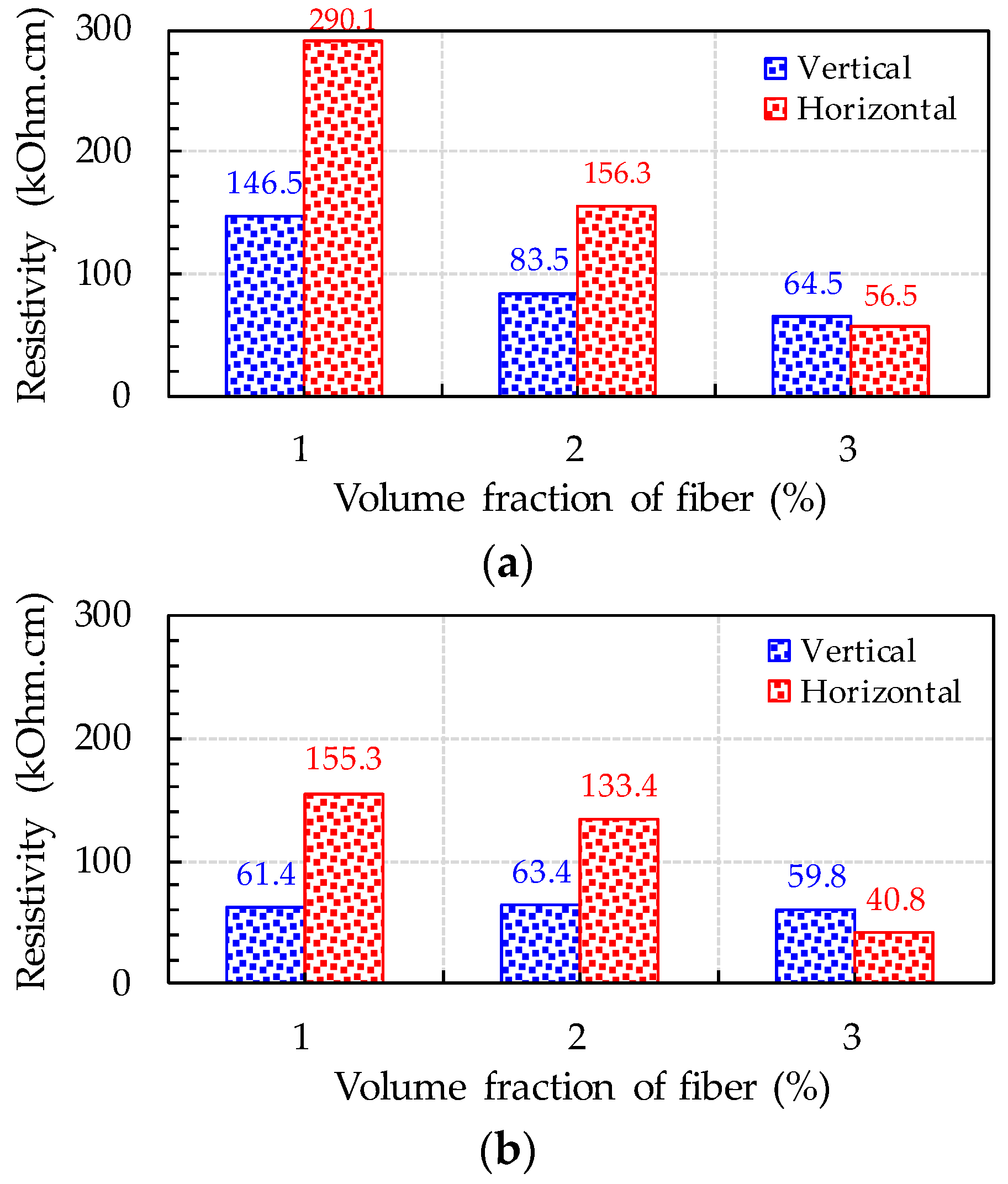

3.1. Part I: Effects of Steel Fiber Amount, Orientation, and Desiccation on Electrical Properties of UHPFRC

3.1.1. Effects of Fiber Content, Orientation, and Desiccation on Electrical Resistivity

3.1.2. Piezoresistive Properties of UHPFRC with 3 vol % Steel Fibers

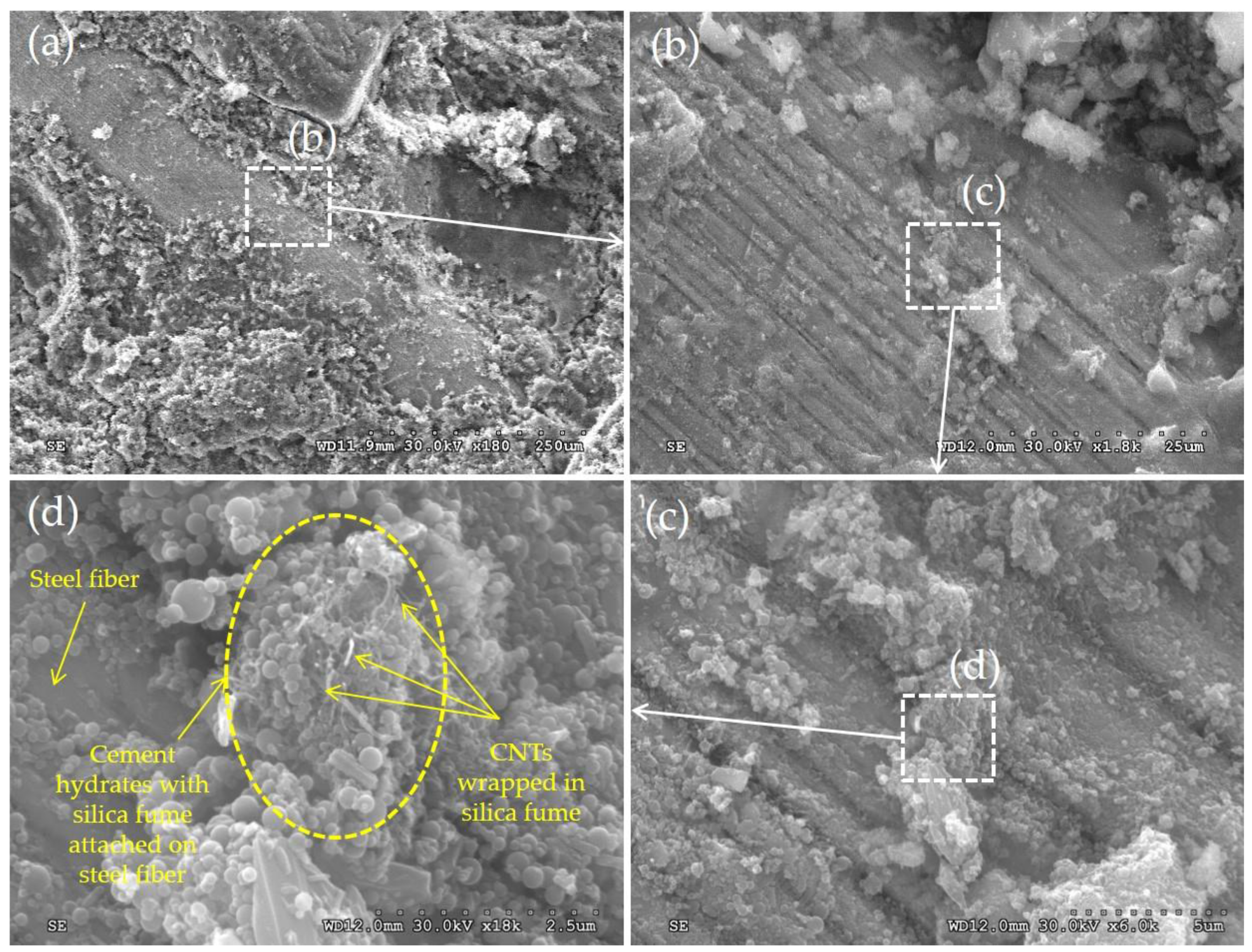

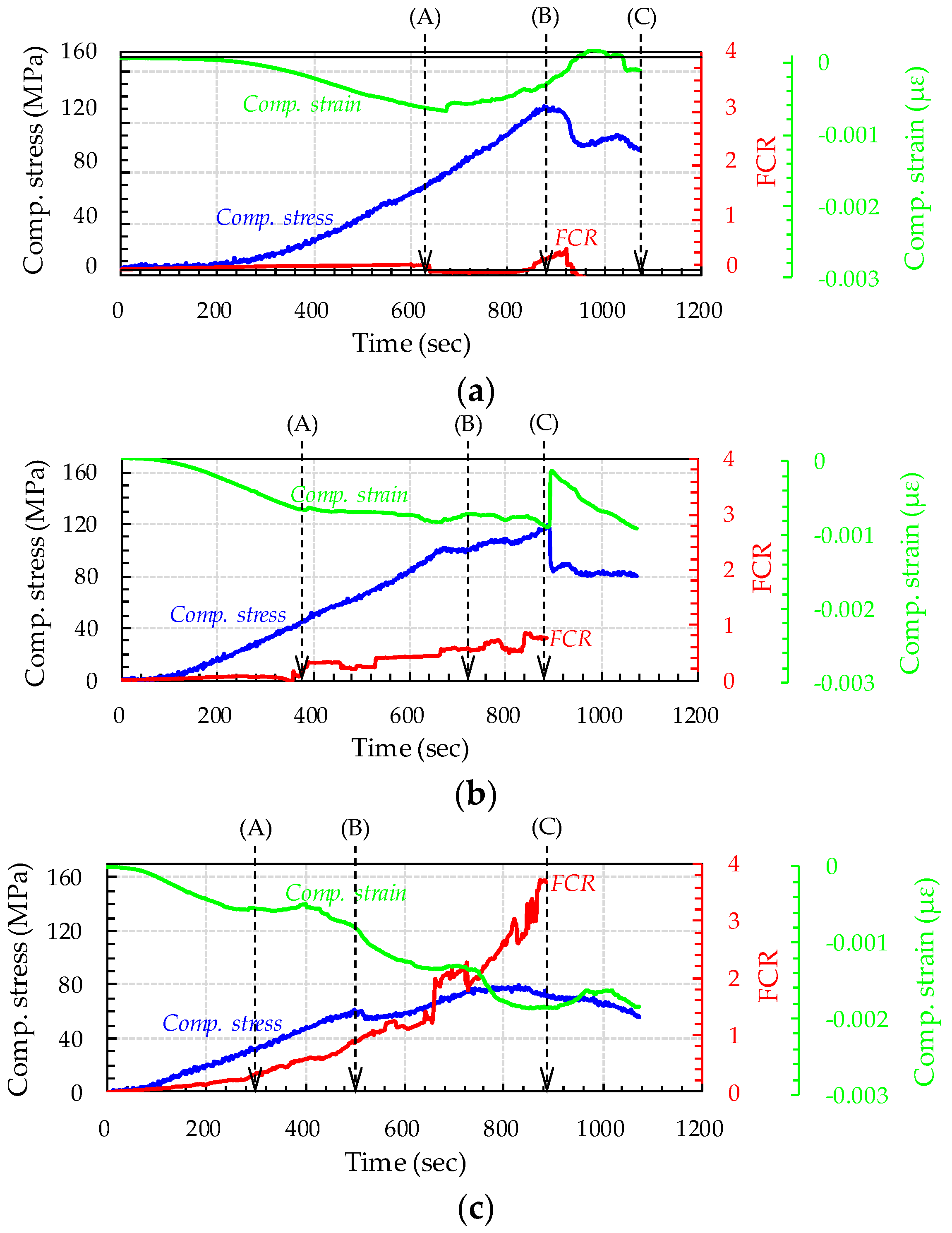

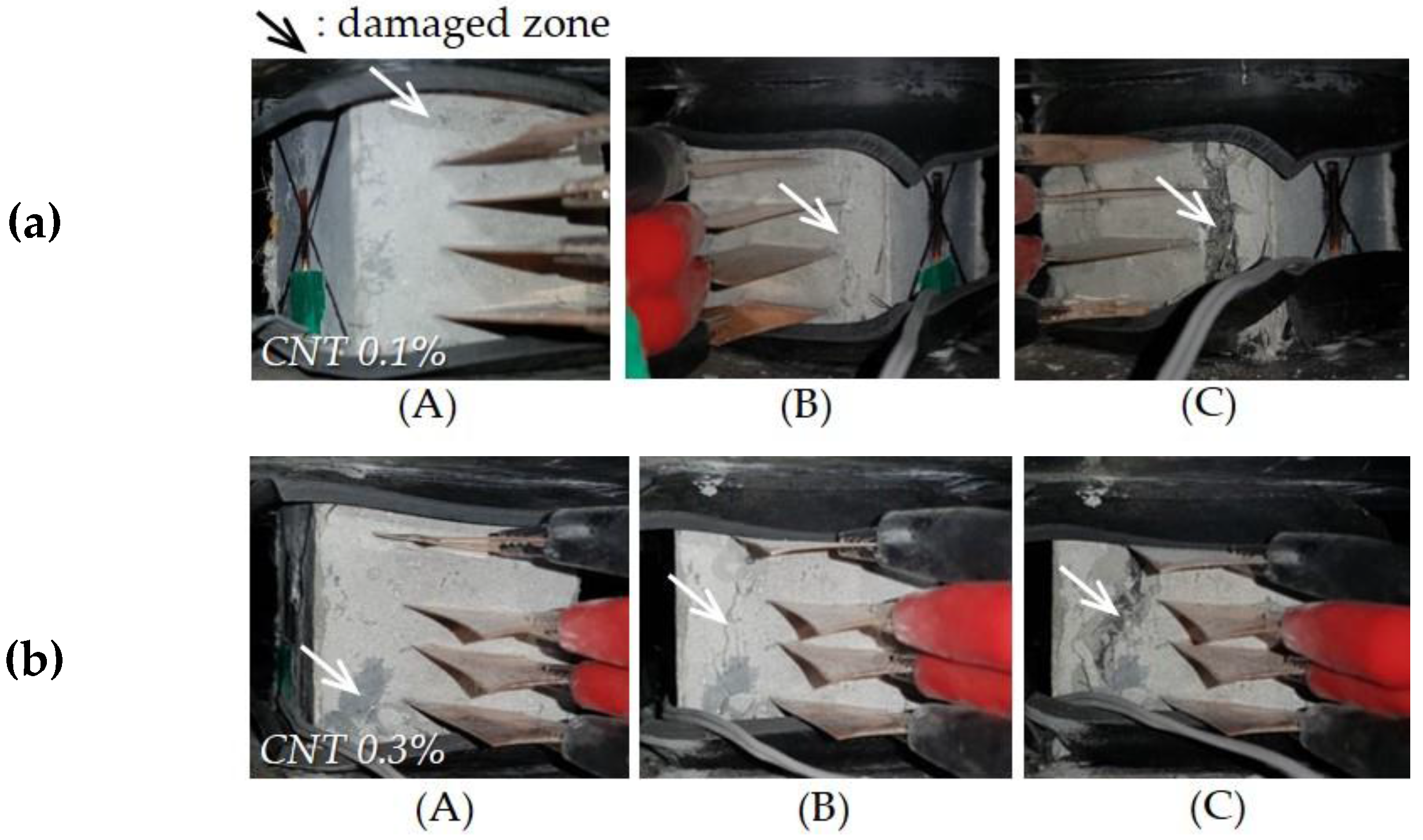

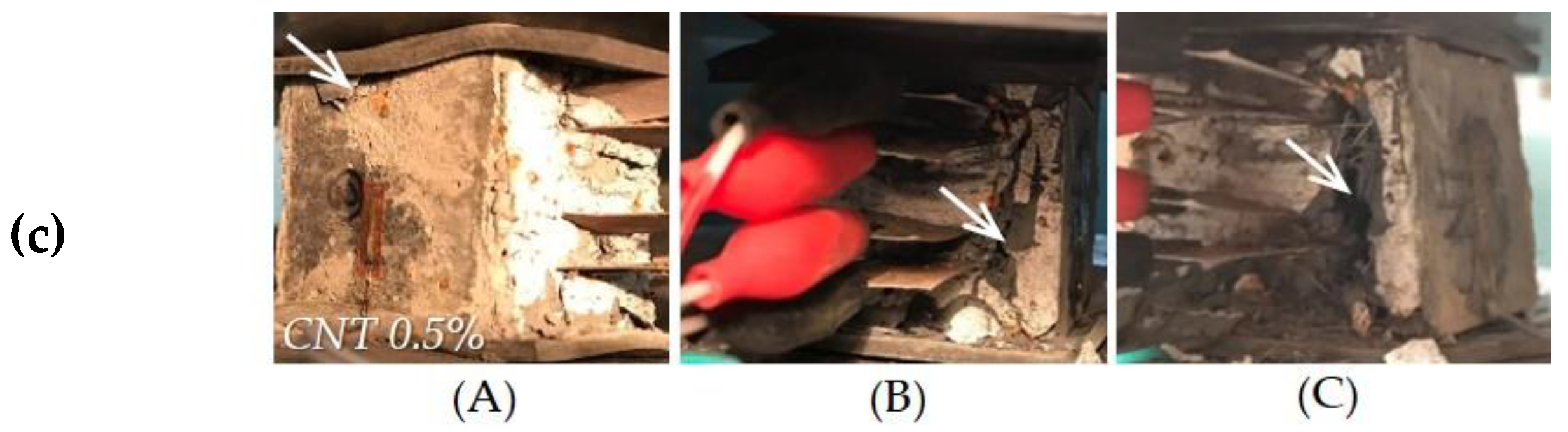

3.2. Part II: Electrical and Self-Sensing Capacities of UHPFRC with CNTs

3.2.1. Sonication Effect

3.2.2. Effects of CNT Content on Flowability and Compressive Behavior of UHPFRC

3.2.3. Effect of CNT Amount on Flexural Behavior

4. Conclusions

- (1)

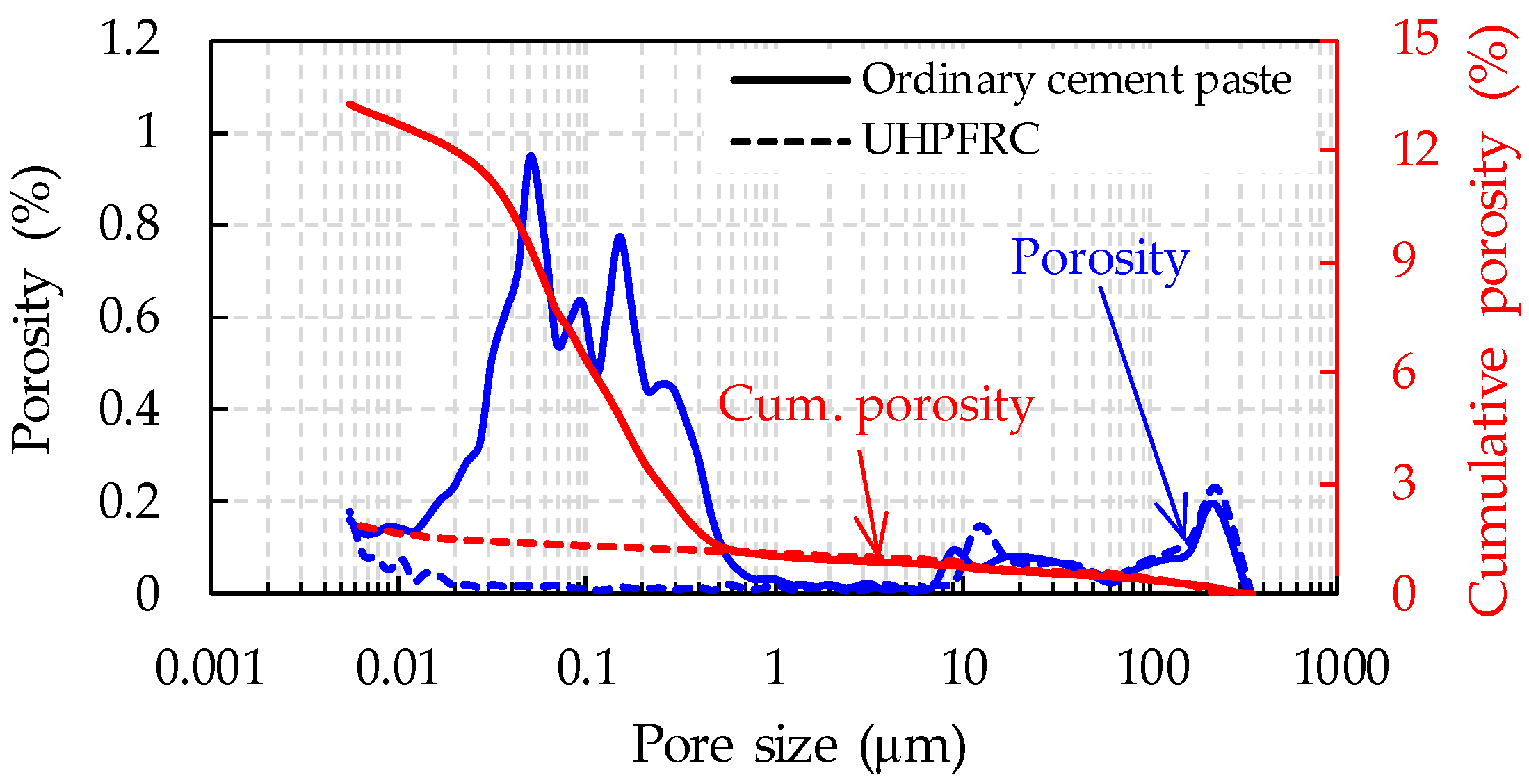

- Increasing the amounts of steel fibers and pore water in UHPFRC increases its conductivity. The electrical resistivity of UHPFRC was noticeably influenced by the fiber orientation and pore water content, but these effects became insignificant under conditions of higher steel fiber content. Thus, the resistivity of UHPFRC was not noticeably affected by the casting method and pore water content at a fiber volume fraction of 3%.

- (2)

- Including only steel fibers was insufficient to impart piezoresistivity to UHPFRC, although it allowed detection of ultimate failure.

- (3)

- The electrical resistivity of UHPFRC was substantially reduced by including CNTs. Although sonication improved the electrical conductivity of UHPFRC with 0.5 vol % CNTs, the improvement was not sufficient to justify its use.

- (4)

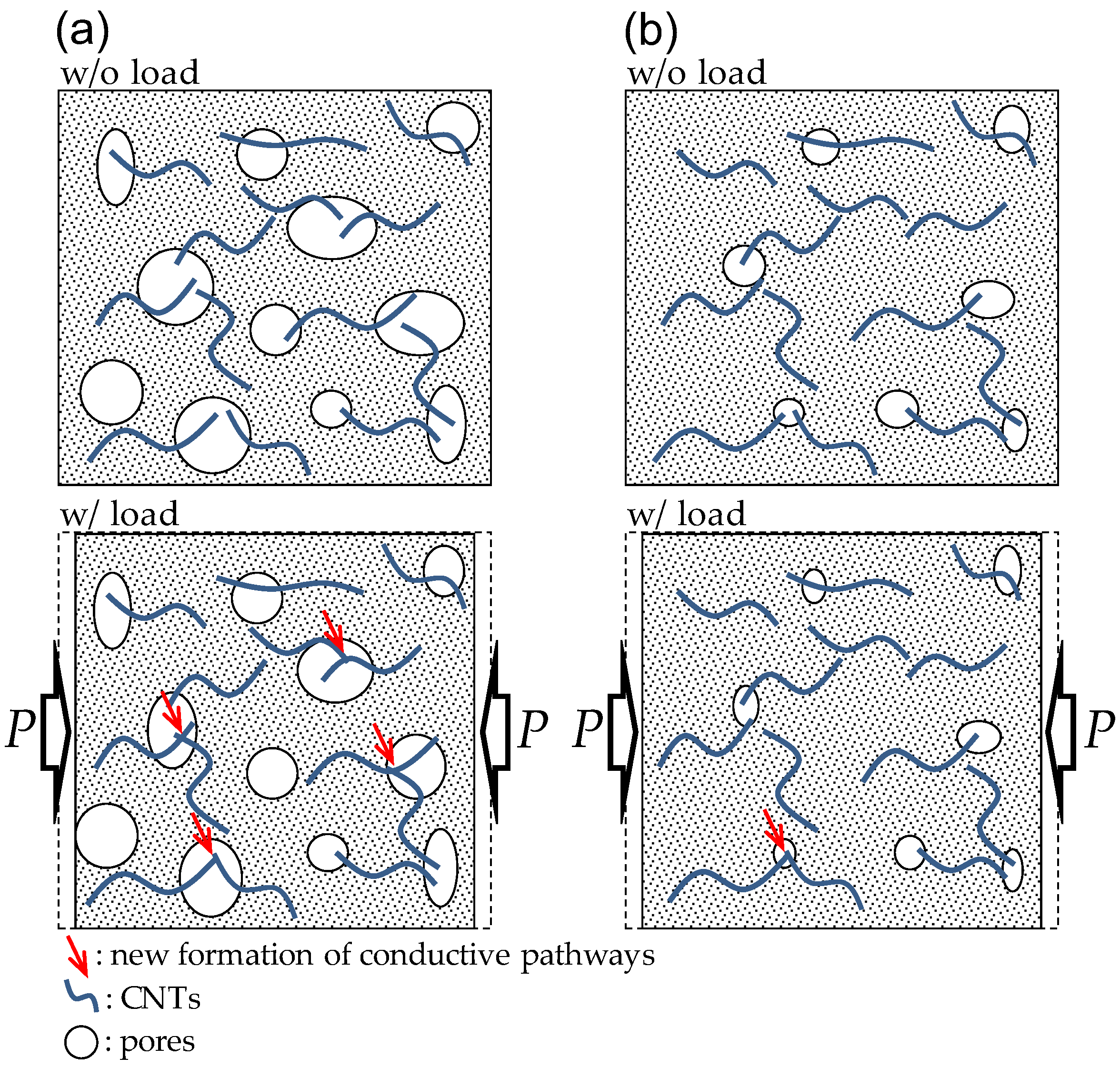

- The compressive strength of UHPFRC decreased by incorporating CNTs. Adding CNTs to UHPFRC imparted a self-sensing capacity that was activated by the formation of cracks, and higher self-sensing capacity was obtained by increasing the CNT content.

- (5)

- The pre-peak flexural behavior, including elastic and deflection–hardening regions, of UHPFRC beams was precisely simulated by measuring the FCR when 0.3% CNTs were incorporated. In addition, the pre-cracking self-sensing capacity of UHPFRC with CNTs was more efficient under tensile stress state than under compressive stress state.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, H.N.; Li, D.S.; Song, G.B. Recent applications of fiber optic sensors to health monitoring in civil engineering. Eng. Struct. 2004, 26, 1647–1657. [Google Scholar] [CrossRef]

- Gu, H.; Moslehy, Y.; Sanders, D.; Song, G.; Mo, Y.L. Multi-functional smart aggregate-based structural health monitoring of circular reinforced concrete columns subjected to seismic excitations. Smart Mater. Struct. 2010, 19, 065026. [Google Scholar] [CrossRef]

- Song, G.; Mo, Y.L.; Otero, K.; Gu, H. Health monitoring and rehabilitation of a concrete structure using intelligent materials. Smart Mater. Struct. 2006, 15, 309–314. [Google Scholar] [CrossRef]

- Yoo, D.Y.; You, I.; Lee, S.J. Electrical properties of cement-based composites with carbon nanotubes, graphene, and graphite nanofibers. Sensors 2017, 17, 1064–1076. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Liu, J.; Wu, K. Electrical responses of carbon fiber reinforced cementitious composites to monotonic and cyclic loading. Cem. Concr. Res. 2005, 35, 2183–2191. [Google Scholar] [CrossRef]

- Xu, J.; Zhong, W.; Yao, W. Modeling of conductivity in carbon fiber-reinforced cement-based composite. J. Mater. Sci. 2010, 45, 3538–3546. [Google Scholar] [CrossRef]

- Kim, G.M.; Naeem, F.; Kim, H.K.; Lee, H.K. Heating and heat-dependent mechanical characteristics of CNT-embedded cementitious composites. Compos. Struct. 2016, 136, 162–170. [Google Scholar] [CrossRef]

- Chung, D.D.L. Piezoresistive cement-based materials for strain sensing. J. Intell. Mater. Syst. Struct. 2002, 13, 599–609. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Rallini, M.; Ubertini, F.; Materazzi, A.L.; Kenny, J.M. Investigations on scalable fabrication procedures for self-sensing carbon nanotube cement-matrix composites for SHM applications. Cem. Concr. Compos. 2016, 65, 200–213. [Google Scholar] [CrossRef]

- Yu, X.; Kwon, E. A carbon nanotube/cement composite with piezoresistive properties. Smart. Mater. Struct. 2009, 18, 055010. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Kwon, E. A self-sensing carbon nanotube/cement composite for traffic monitoring. Nanotechnology 2009, 20, 445501. [Google Scholar] [CrossRef] [PubMed]

- Banthia, N.; Djeridane, S.; Pigeon, M. Electrical resistivity of carbon and steel micro-fiber reinforced cements. Cem. Concr. Res. 1992, 22, 804–814. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. A comparative study of steel-and carbon-fibre cement as piezoresistive strain sensors. Adv. Cem. Res. 2003, 15, 119–128. [Google Scholar] [CrossRef]

- Azhari, F.; Banthia, N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cem. Concr. Compos. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- Yoo, D.Y.; You, I.; Lee, S.J. Electrical and piezoresistive sensing capacities of cement paste with multi-walled carbon nanotubes. Arch. Civil Mech. Eng. 2017, in press. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Ou, J. Effect of water content on the piezoresistivity of MWNT/cement composites. J. Mater. Sci. 2010, 45, 3714–3719. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Kwon, E.; Ou, J. Effects of CNT concentration level and water/cement ratio on the piezoresistivity of CNT/cement composites. J. Compos. Mater. 2012, 46, 19–25. [Google Scholar] [CrossRef]

- Han, B.; Ding, S.; Yu, X. Intrinsic self-sensing concrete and structures: A review. Measurement 2015, 59, 110–128. [Google Scholar] [CrossRef]

- Dong, S.; Han, B.; Ou, J.; Li, Z.; Han, L.; Yu, X. Electrically conductive behaviors and mechanisms of short-cut super-fine stainless wire reinforced reactive powder concrete. Cem. Concr. Compos. 2016, 72, 48–65. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N.; Kang, S.T.; Yoon, Y.S. Size effect in ultra-high-performance concrete beams. Eng. Fract. Mech. 2016, 157, 86–106. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Collepardi, S.; Coppola, L.; Troli, R.; Collepardi, M. Mechanical properties of modified reactive powder concrete. ACI Spec. Publ. 1997, 173, 1–22. [Google Scholar]

- Park, J.J.; Kang, S.T.; Koh, K.T.; Kim, S.W. Influence of the ingredients on the compressive strength of UHPC as a fundamental study to optimize the mixing proportion. In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 105–112. [Google Scholar]

- ASTM C1437. Standard Test Method for Flow of Hydraulic Cement Mortar; ASTM International: West Conshohocken, PA, USA, 2007; pp. 1–2. [Google Scholar]

- Yoo, D.Y.; Yoon, Y.S. Structural performance of ultra-high-performance concrete beams with different steel fibers. Eng. Struct. 2015, 102, 409–423. [Google Scholar] [CrossRef]

- Graybeal, B.A. Flexural behavior of an ultrahigh-performance concrete I-girder. J. Bridge Eng. 2008, 13, 602–610. [Google Scholar] [CrossRef]

- Ruoff, R.S.; Qian, D.; Liu, W.K. Mechanical properties of carbon nanotubes: Theoretical predictions and experimental measurements. Comptes Rendus Phys. 2003, 9, 993–1008. [Google Scholar] [CrossRef]

- Chen, B.; Wu, K.; Yao, W. Conductivity of carbon fiber reinforced cement-based composites. Cem. Concr. Compos. 2004, 26, 291–297. [Google Scholar] [CrossRef]

- ASTM C 1609/C 1609M. Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2012; pp. 1–9. [Google Scholar]

- Martinie, L.; Roussel, N. Simple tools for fiber orientation prediction in industrial practice. Cem. Concr. Res. 2011, 41, 993–1000. [Google Scholar] [CrossRef]

- Mendoza, O.; Sierra, G.; Tobón, J.I. Influence of super plasticizer and Ca(OH)2 on the stability of functionalized multi-walled carbon nanotubes dispersions for cement composites applications. Constr. Build. Mater. 2013, 47, 771–778. [Google Scholar] [CrossRef]

- Kang, S.T.; Seo, J.Y.; Park, S.H. The characteristics of CNT/cement composites with acid-treated MWCNTs. Adv. Mater. Sci. Eng. 2015, 2015, 308725. [Google Scholar] [CrossRef]

- Han, B.; Guan, X.; Ou, J. Electrode design, measuring method and data acquisition system of carbon fiber cement paste piezoresistive sensors. Sens. Actuator A-Phys. 2007, 135, 360–369. [Google Scholar]

- Kim, H.K.; Nam, I.W.; Lee, H.K. Enhanced effect of carbon nanotube on mechanical and electrical properties of cement composites by incorporation of silica fume. Compos. Struct. 2014, 107, 60–69. [Google Scholar] [CrossRef]

- ACI Committee 239. Ultra-High Performance Concrete. ACI Fall Convention; American Concrete Institute: Toronto, ON, Canada, 2012. [Google Scholar]

- AFGC. Ultra High Performance Fibre-Reinforced Concretes; Interim Recommendations; AFGC Publication: Bagneux, France, 2013. [Google Scholar]

- Chu, T.J.; Robertson, R.E.; Najm, H.; Naaman, A.E. Effects of poly (vinyl alcohol) on fiber cement interfaces. Part II: Microstructures. Adv. Cem. Based Mater. 1994, 1, 122–130. [Google Scholar] [CrossRef]

- Chan, Y.W.; Chu, S.H. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Pressure-sensitive properties and microstructure of carbon nanotube reinforced cement composites. Cem. Concr. Compos. 2007, 29, 377–382. [Google Scholar] [CrossRef]

| W/B † | Unit Weight (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|

| Water | Cement | Zr SF | Silica Sand | Filler (S-SIL10) | SRA | SP * | |

| 0.2 | 175.0 | 799.5 | 199.9 | 879.5 | 239.9 | 8.0 | 18.4 |

| Composition % (Mass) | Cement * | Zr SF † |

|---|---|---|

| CaO | 61.33 | 0.38 |

| Al2O3 | 6.40 | 0.25 |

| SiO2 | 21.01 | 96.00 |

| Fe2O3 | 3.12 | 0.12 |

| MgO | 3.02 | 0.10 |

| SO3 | 2.30 | - |

| Specific surface area (cm2/g) | 3413 | 200,000 |

| Density (g/cm3) | 3.15 | 2.10 |

| Ig. loss (%) | 1.40 | 1.50 |

| Name | df (mm) | Lf (mm) | Aspect Ratio (Lf/df) | Density (g/cm3) | ft (MPa) | Ef (GPa) |

|---|---|---|---|---|---|---|

| SS fiber | 0.20 | 13.0 | 65.0 | 7.9 | 2788 | 200 |

| df (nm) | Lf (mm) | T (mm) | Layer | Carbon Content (%) | Lf/df | ft (GPa) | Ef (GPa) | Density (g/cm3) |

|---|---|---|---|---|---|---|---|---|

| 15 | 0.01 | 3.4–7 | - | >90 | 667 | 11–63 [27] | 270–950 [27] | 1.20 |

| Sonication Application | Resistivity (Ω·cm) | |

|---|---|---|

| UHPFRC w/o CNT | X | 260.4 × 103 |

| UHPFRC w/0.5% CNTs | X | 393 |

| UHPFRC w/0.5% CNTs | O | 323 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, I.; Yoo, D.-Y.; Kim, S.; Kim, M.-J.; Zi, G. Electrical and Self-Sensing Properties of Ultra-High-Performance Fiber-Reinforced Concrete with Carbon Nanotubes. Sensors 2017, 17, 2481. https://doi.org/10.3390/s17112481

You I, Yoo D-Y, Kim S, Kim M-J, Zi G. Electrical and Self-Sensing Properties of Ultra-High-Performance Fiber-Reinforced Concrete with Carbon Nanotubes. Sensors. 2017; 17(11):2481. https://doi.org/10.3390/s17112481

Chicago/Turabian StyleYou, Ilhwan, Doo-Yeol Yoo, Soonho Kim, Min-Jae Kim, and Goangseup Zi. 2017. "Electrical and Self-Sensing Properties of Ultra-High-Performance Fiber-Reinforced Concrete with Carbon Nanotubes" Sensors 17, no. 11: 2481. https://doi.org/10.3390/s17112481