Fabrication of Ordered SnO2 Nanostructures with Enhanced Humidity Sensing Performance

Abstract

:1. Introduce

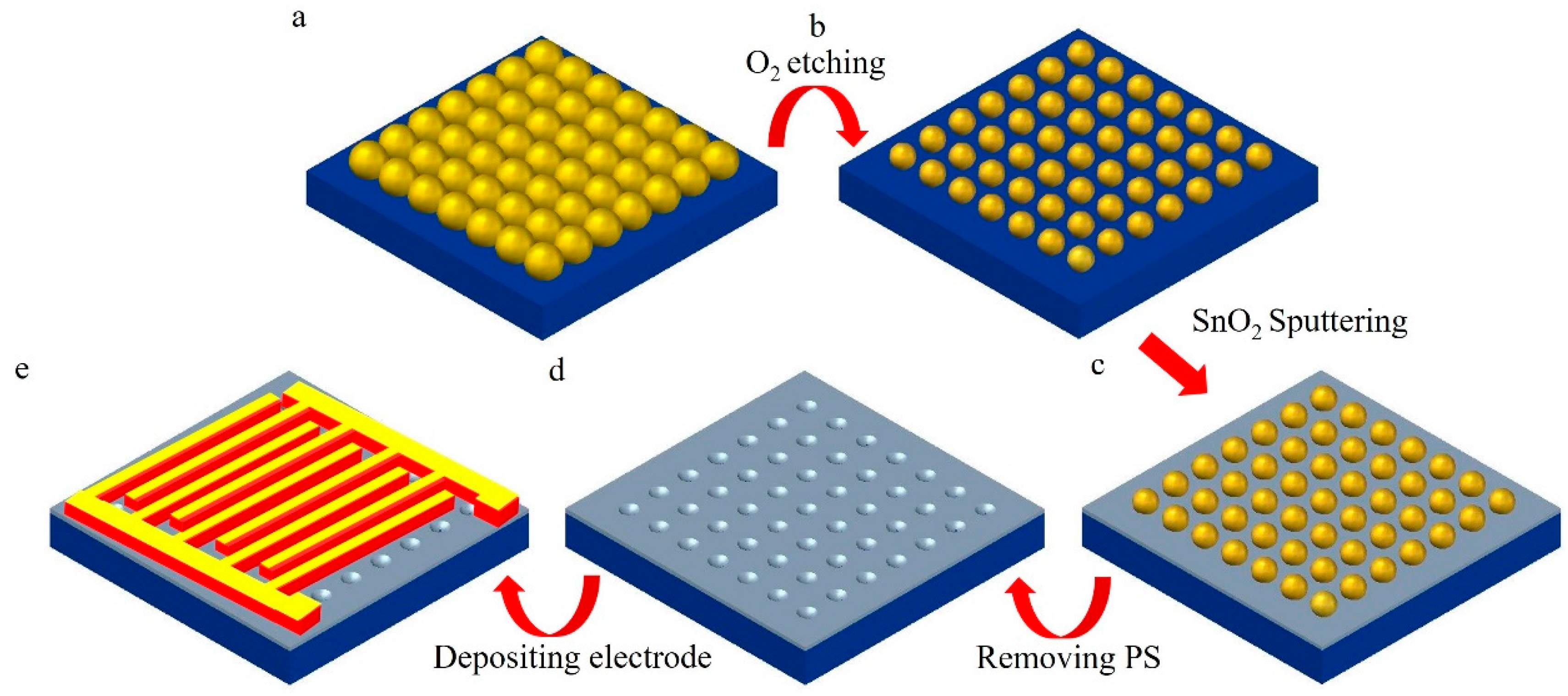

2. Experiment

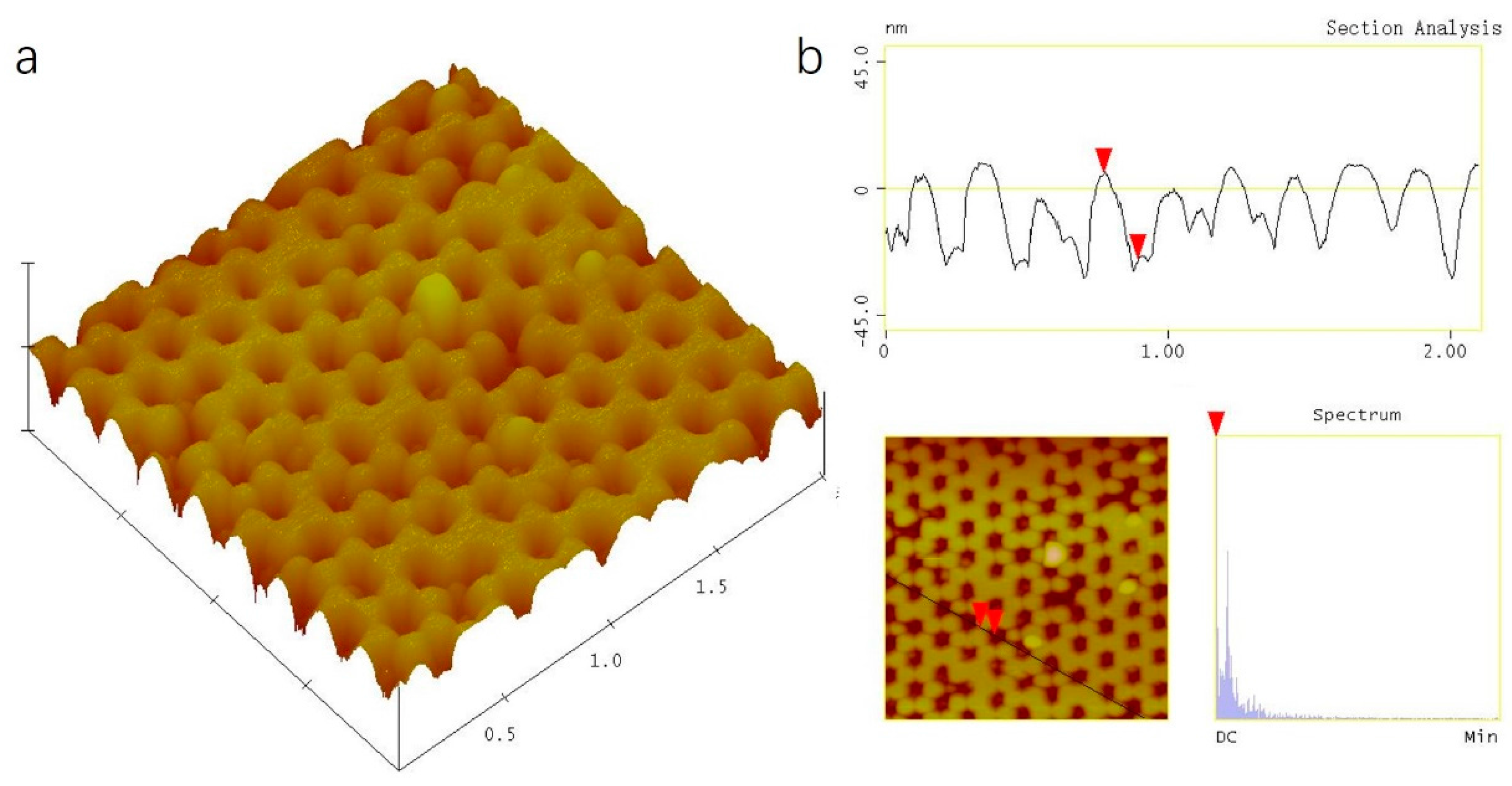

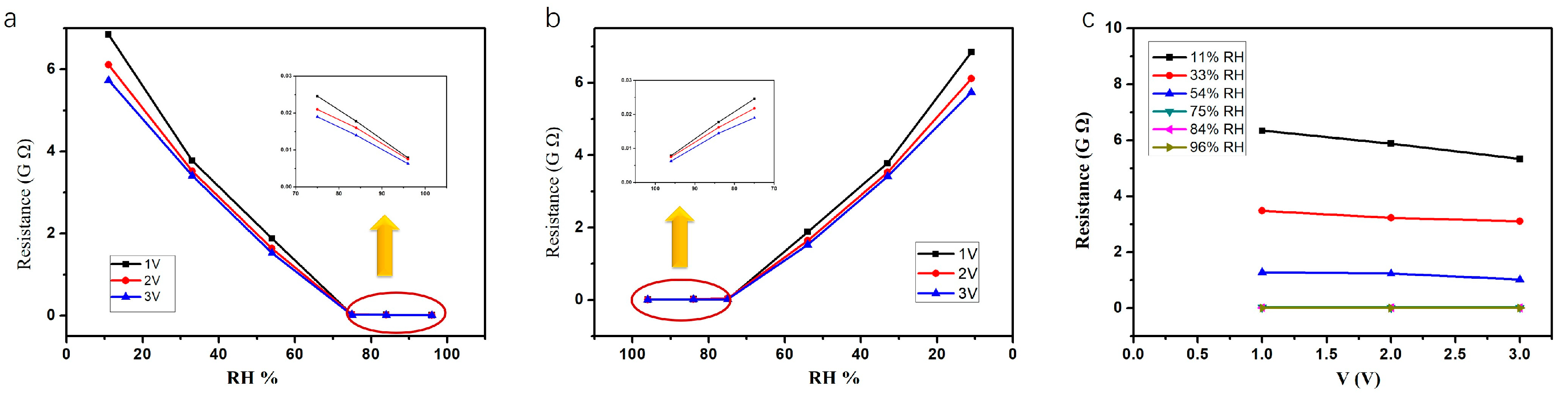

3. Results and Discussions

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kong, J.; Franklin, N.R.; Zhou, C.; Chapline, M.G.; Peng, S.; Cho, K.; Dai, H. Nanotube Molecular Wires as Chemical Sensors. Science 2000, 287, 622–625. [Google Scholar] [CrossRef] [PubMed]

- Borini, S.; White, R.; Wei, D.; Astley, M.; Haque, S.; Spigone, E.; Harris, N.; Kivioja, J.; Ryhanen, T. Ultrafast Graphene Oxide Humidity Sensors. ACS Nano 2013, 7, 11166–11173. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Park, S.; Yeow, J.T.W.; Langner, A.; Müller, F. A capacitive humidity sensor based on ordered macroporous silicon with thin film surface coating. Sens. Actuators B Chem. 2010, 149, 136–142. [Google Scholar] [CrossRef]

- Choi, K.; Hwang, S.J.; Dai, Z.; Kang, Y.C.; Lee, J.H. Rh-catalyzed WO3 with anomalous humidity dependence of gas sensing characteristics. RSC Adv. 2014, 4, 53130–53136. [Google Scholar] [CrossRef]

- Liu, X.; Wang, R.; Zhang, T.; He, Y.; Tu, J.; Li, X. Synthesis and characterization of mesoporous indium oxide for humidity sensing applications. Sens. Actuators B Chem. 2010, 150, 442–448. [Google Scholar] [CrossRef]

- Da Silva, L.F.; M’Pekob, J.C.; Ariadne, C.C.; Bernardini, S.; Mastelaro, V.R.; Aguir, K.; Ribeiro, C.; Longo, E. UV-enhanced ozone gas sensing response of ZnO-SnO2 heterojunctions at room temperature. Sens. Actuators B Chem. 2017, 240, 573–579. [Google Scholar] [CrossRef]

- Jha, R.K.; Guha, P.K. Liquid exfoliated pristine WS2 nanosheets for ultrasensitive and highly stable chemiresistive humidity sensors. Nanotechnology 2016, 27, 475503. [Google Scholar] [CrossRef] [PubMed]

- Duy, T.P.; Chung, G.S. Effects of rapid thermal annealing on humidity sensor based on graphene oxide thin films. Sens. Actuators B Chem. 2015, 220, 1050–1055. [Google Scholar]

- Rimeika, R.; Čiplys, D.; Poderys, V.; Rotomskis, R.; Shur, M.S. Fast-response and low-loss surface acoustic wave humidity sensor based on bovine serum albumin-gold nanoclusters film. Sens. Actuators B Chem. 2017, 239, 352–357. [Google Scholar] [CrossRef]

- Karthick, S.; Lee, H.S.; Kwon, S.J.; Natarajan, R.; Saraswathy, V. Standardization, Calibration, and Evaluation of Tantalum-Nano rGO-SnO2 Composite as a Possible Candidate Material in Humidity Sensors. Sensors 2016, 16, 2079. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Qi, Q.; Zhang, T.; Wang, C. A humidity sensor based on KCl-doped SnO2 nanofibers. Sens. Actuators B Chem. 2009, 138, 368–373. [Google Scholar] [CrossRef]

- Tomer, V.K.; Duhan, S. Highly sensitive and stable relative humidity sensors based on WO3 modified mesoporous silica. Appl. Phys. Lett. 2015, 106, 063105. [Google Scholar] [CrossRef]

- Staerz, A.; Berthold, C.; Russ, T. The oxidizing effect of humidity on WO3 based sensors. Sens. Actuators B Chem. 2016, 237, 54–58. [Google Scholar] [CrossRef]

- Hsu, C.L.; Su, I.L.; Hsueh, T.J. Tunable Schottky contact humidity sensor based on S-doped ZnO nanowires on flexible PET substrate with piezotronic effect. J. Alloy. Compd. 2017, 705, 722–733. [Google Scholar] [CrossRef]

- Mahjoub, M.A.; Monier, G.; Robert-Goumet, C. Synthesis and Study of Stable and Size-Controlled ZnO-SiO2 Quantum Dots: Application as a Humidity Sensor. J. Phys. Chem. C 2016, 120, 11652–11662. [Google Scholar] [CrossRef]

- Lopez-Torres, D.; Elosua, C.; Villatoro, J.; Zubia, J.; Rothhardt, M.; Schuster, K.; Arregui, F.J. Enhancing sensitivity of photonic crystal fiber interferometric humidity sensor by the thickness of SnO2 thin films. Sens. Actuators B Chem. 2017, 251, 1059–1067. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, Y.E.; Li, P.; Zhang, Y. Facile Fabrication of MoS2-Modified SnO2 Hybrid Nanocomposite for Ultrasensitive Humidity Sensing. ACS Appl. Mater. Interfaces 2016, 8, 14142–14149. [Google Scholar] [CrossRef] [PubMed]

- Tomer, V.K.; Duhan, S. In-situ synthesis of SnO2/SBA-15 hybrid nanocomposite as highly efficient humidity sensor. Sens. Actuators B Chem. 2015, 212, 517–525. [Google Scholar] [CrossRef]

- Georgieva, B.; Podolesheva, I.; Spasov, G.; Pirov, J. Nanosized Thin SnO2 Layers Doped with Te and TeO2 as Room Temperature Humidity Sensors. Sensors 2014, 14, 8950–8960. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.L.; Li, C.; Li, T.; Diao, F.; Xin, T.; Liu, B.; Wang, Y. Three-dimensional hierarchical SnO2 dodecahedral nanocrystals with enhanced humidity sensing properties. Sens. Actuators B Chem. 2017, 243, 704–714. [Google Scholar] [CrossRef]

- Li, W.; Wang, S.L.; He, S.F.; Wang, J.; Guo, Y.; Guo, Y. Enhanced photoluminescence from CdS with SiO2 nanopillar arrays. Sci. Rep. 2015, 5, 11375. [Google Scholar] [CrossRef] [PubMed]

- Rybczynski, J.; Ebels, U.; Giersig, M. Large-scale, 2D arrays of magnetic nanoparticles. Colloid Surf. A 2003, 219, 1–6. [Google Scholar] [CrossRef]

- Li, W.; Wang, S.L.; Hu, M.Y.; He, S.; Ge, P.; Wang, J.; Guo, Y.Y.; Zhaowei, L. Enhancement of electroluminescence from embedded Si quantum dots/SiO2 multilayers film by localized-surface-plasmon and surface roughening. Sci. Rep. 2015, 5, 11881. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Hu, M.Y.; Ge, P.P.; Wang, J.; Guo, Y. Humidity sensing properties of morphology-controlled ordered silicon nanopillar. Appl. Surf. Sci. 2014, 317, 970–973. [Google Scholar] [CrossRef]

- Li, W.; Dai, E.; Bang, G.; Xu, J. Depth-dependent humidity sensing properties of silicon nanopillar array. Sens. Actuators B Chem. 2016, 237, 526–533. [Google Scholar] [CrossRef]

- Li, W.; Feng, Z.; Dai, E.; Xu, J.; Bai, G. Organic vapour sensing properties of area-ordered and size-controlled silicon nanopillar. Sensors 2016, 16, 1880. [Google Scholar] [CrossRef] [PubMed]

- Morrison, S.R. The Chemical Physics of Surfaces; Plenum Press: New York, NY, USA, 1977. [Google Scholar]

- Li, L.; Wu, K.; Wang, Y.; Zhu, Z. Structure and humidity sensing properties of SnO2 zigzag belts. Cryst. Res. Technol. 2010, 45, 539–544. [Google Scholar] [CrossRef]

| RH | 11–33% | 11–54% | 11–75% | 11–84% | 11–96% |

|---|---|---|---|---|---|

| Response time (s) | 18 | 25 | 30 | 31 | 32 |

| Recovery time (s) | 25 | 33 | 39 | 40 | 42 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Liu, J.; Ding, C.; Bai, G.; Xu, J.; Ren, Q.; Li, J. Fabrication of Ordered SnO2 Nanostructures with Enhanced Humidity Sensing Performance. Sensors 2017, 17, 2392. https://doi.org/10.3390/s17102392

Li W, Liu J, Ding C, Bai G, Xu J, Ren Q, Li J. Fabrication of Ordered SnO2 Nanostructures with Enhanced Humidity Sensing Performance. Sensors. 2017; 17(10):2392. https://doi.org/10.3390/s17102392

Chicago/Turabian StyleLi, Wei, Juyan Liu, Chao Ding, Gang Bai, Jie Xu, Qingying Ren, and Jinze Li. 2017. "Fabrication of Ordered SnO2 Nanostructures with Enhanced Humidity Sensing Performance" Sensors 17, no. 10: 2392. https://doi.org/10.3390/s17102392