Modeling and Compensation of Random Drift of MEMS Gyroscopes Based on Least Squares Support Vector Machine Optimized by Chaotic Particle Swarm Optimization

Abstract

:1. Introduction

2. The Principles of Algorithms

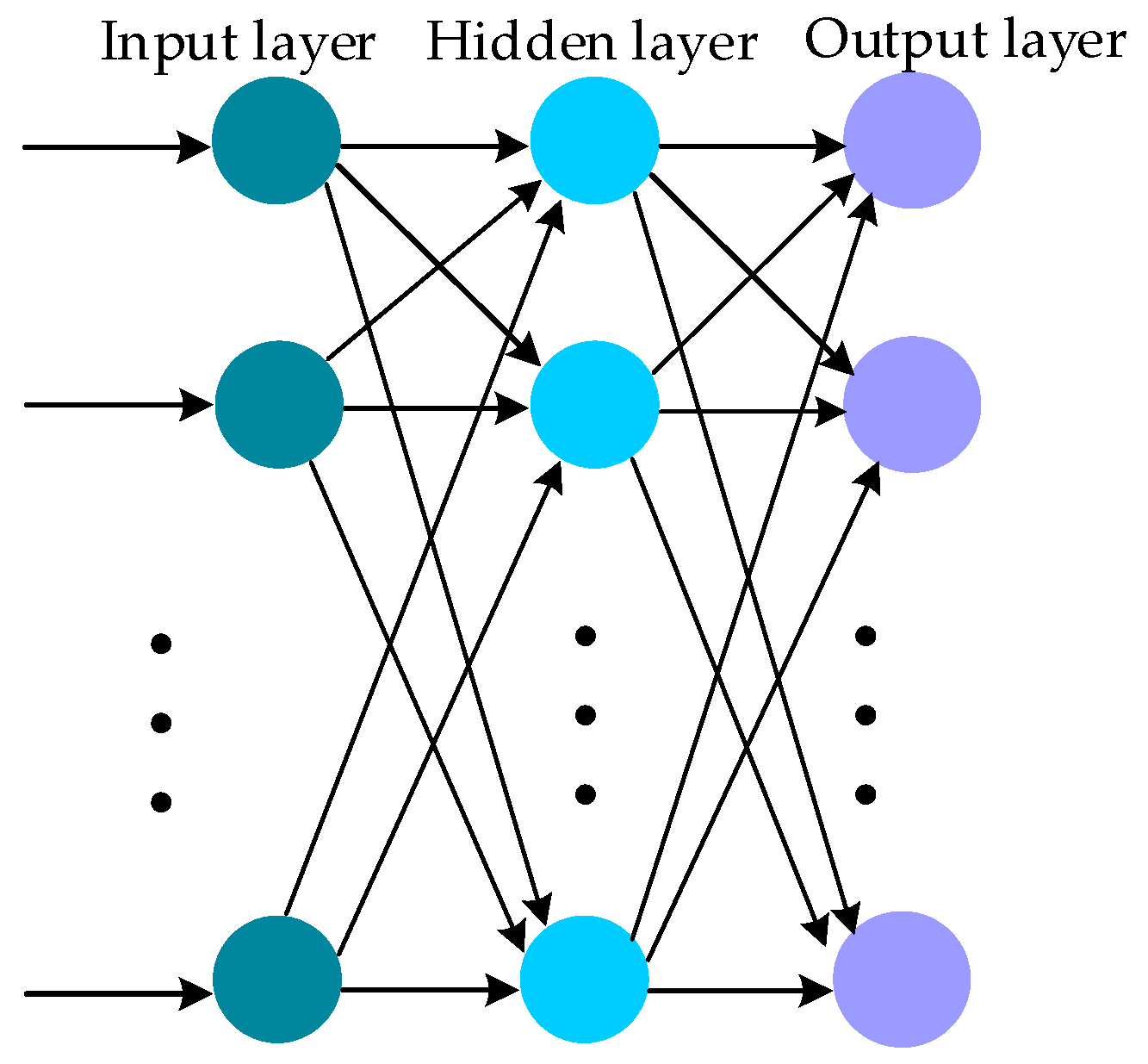

2.1. Back Propagation Artificial Neural Networks

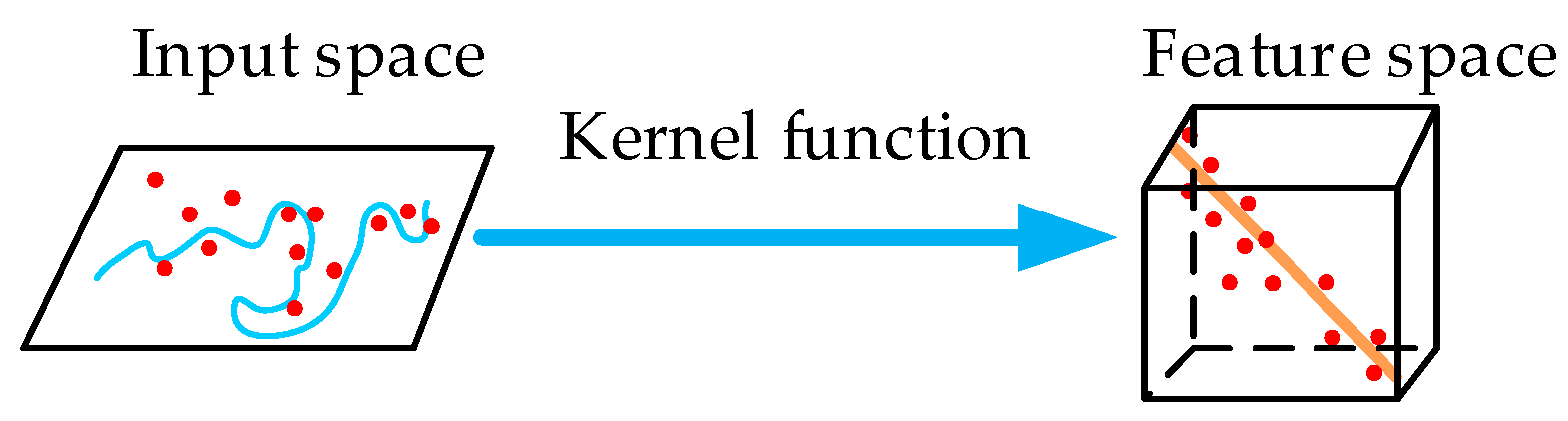

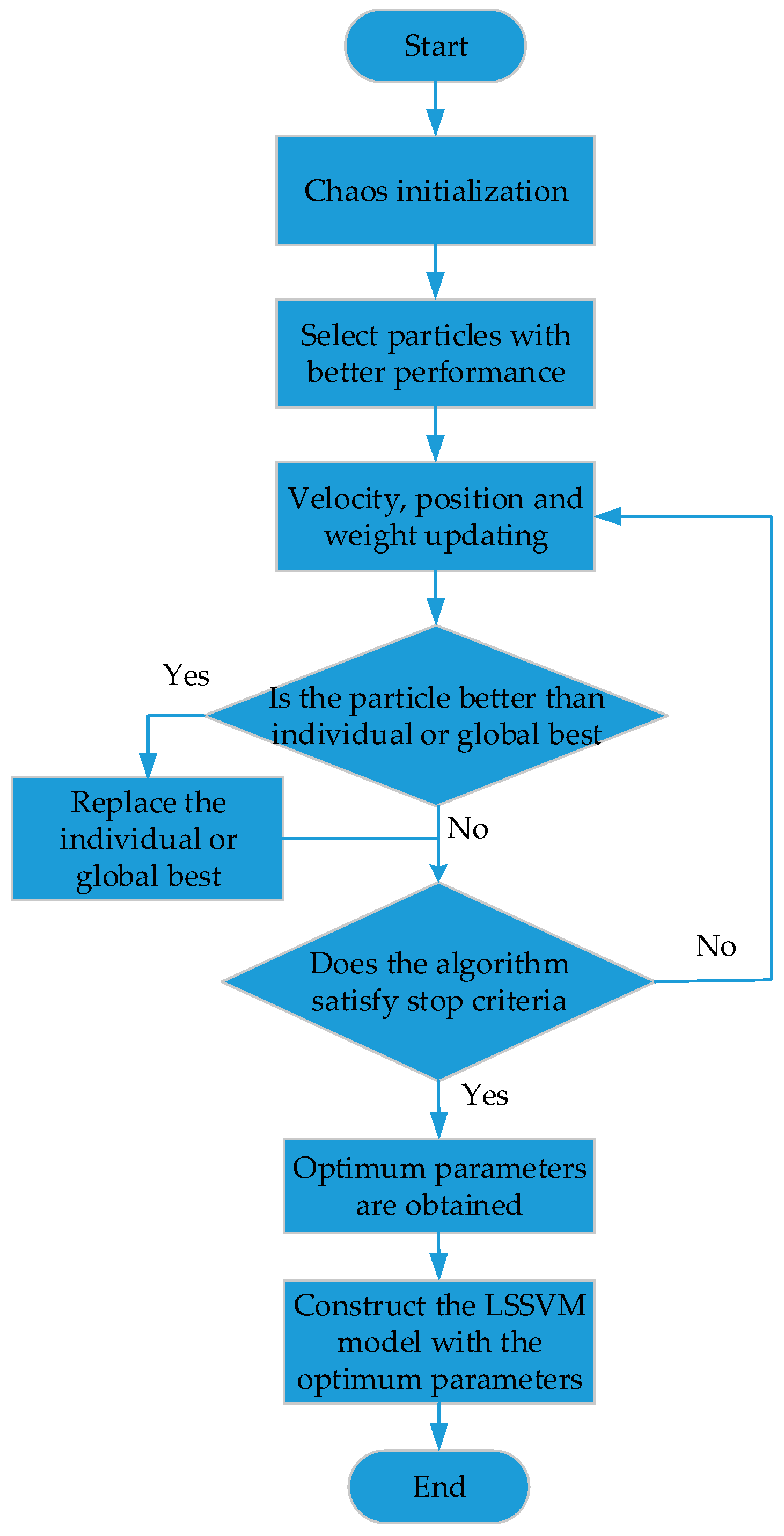

2.2. LSSVM Model with CPSO

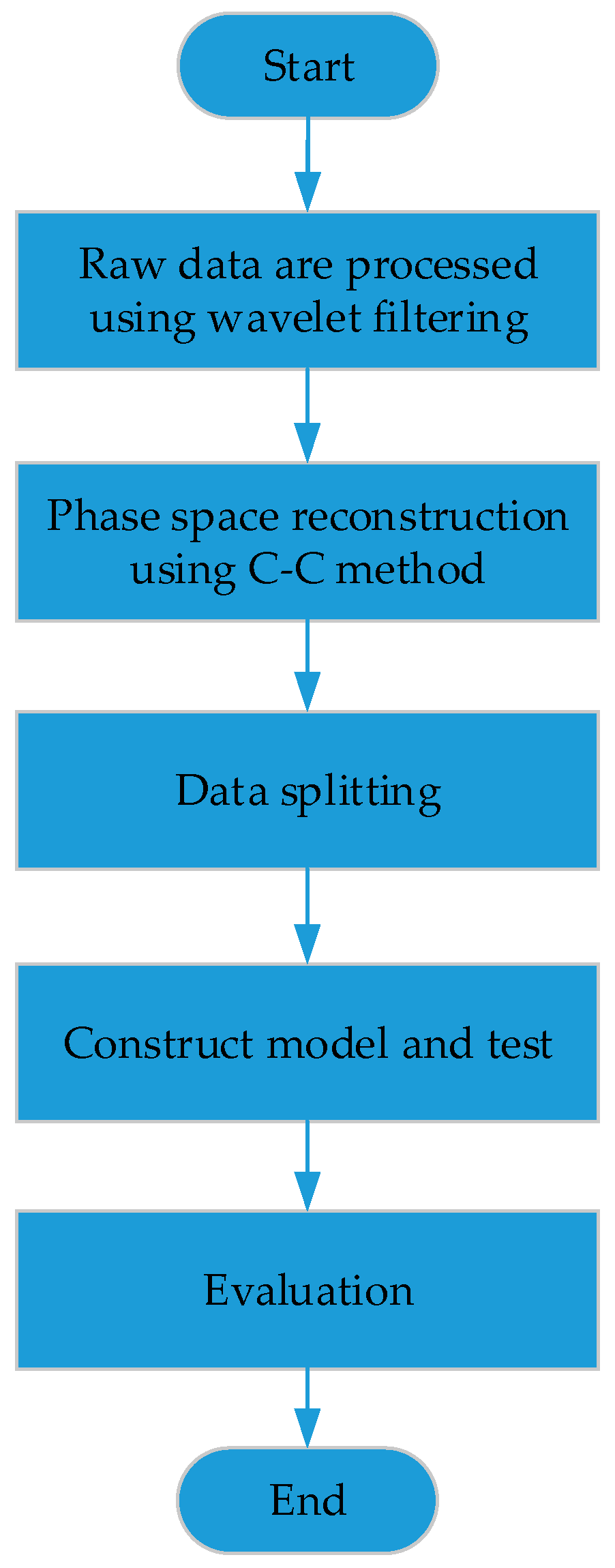

3. Construction of MEMS Gyroscope Drift Model

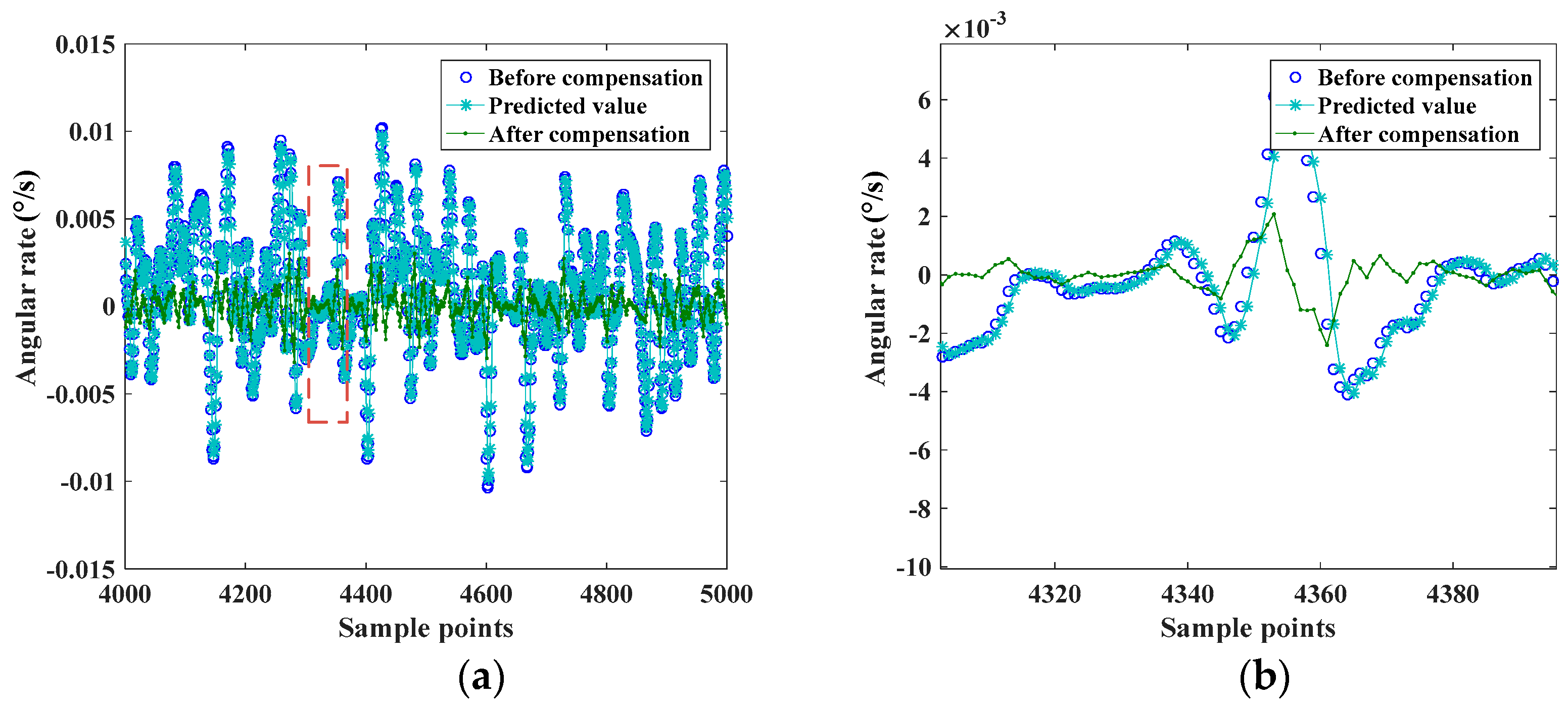

4. Results and Discussion

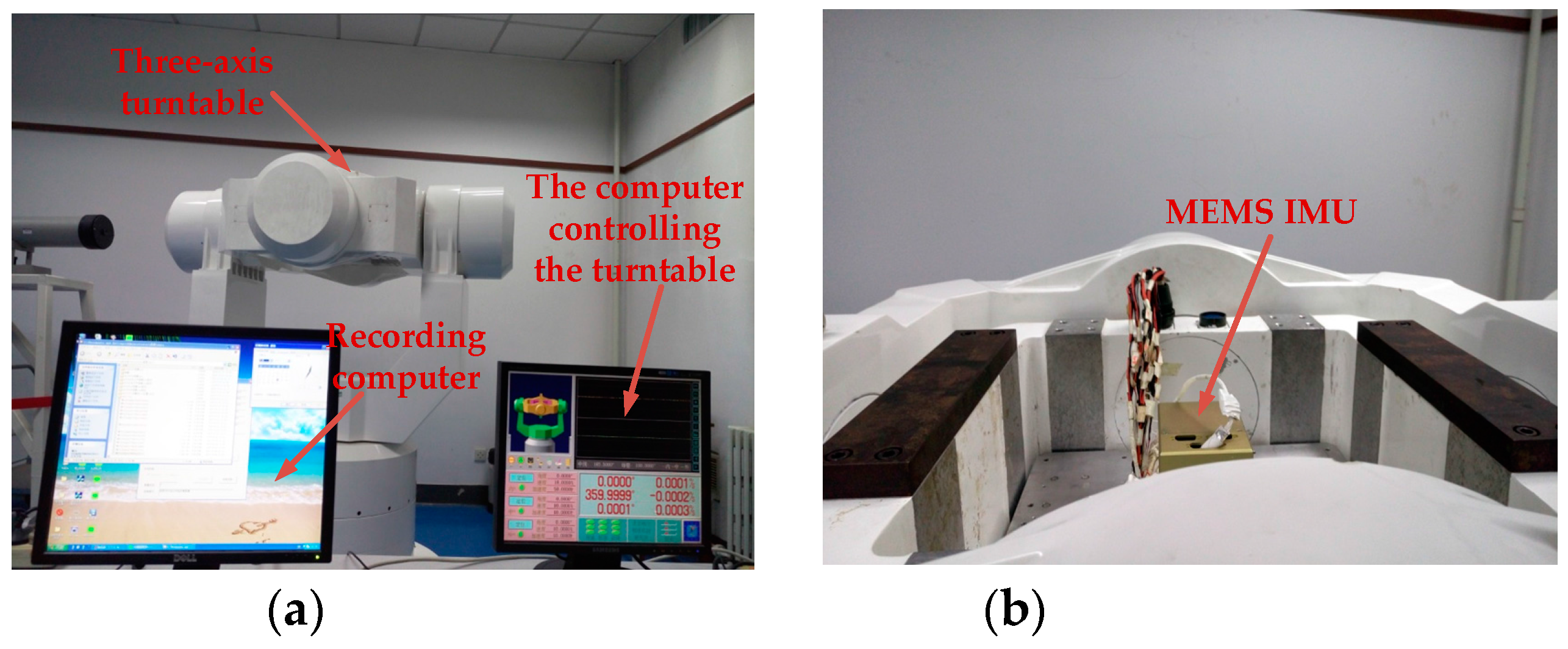

4.1. Experiment Setup

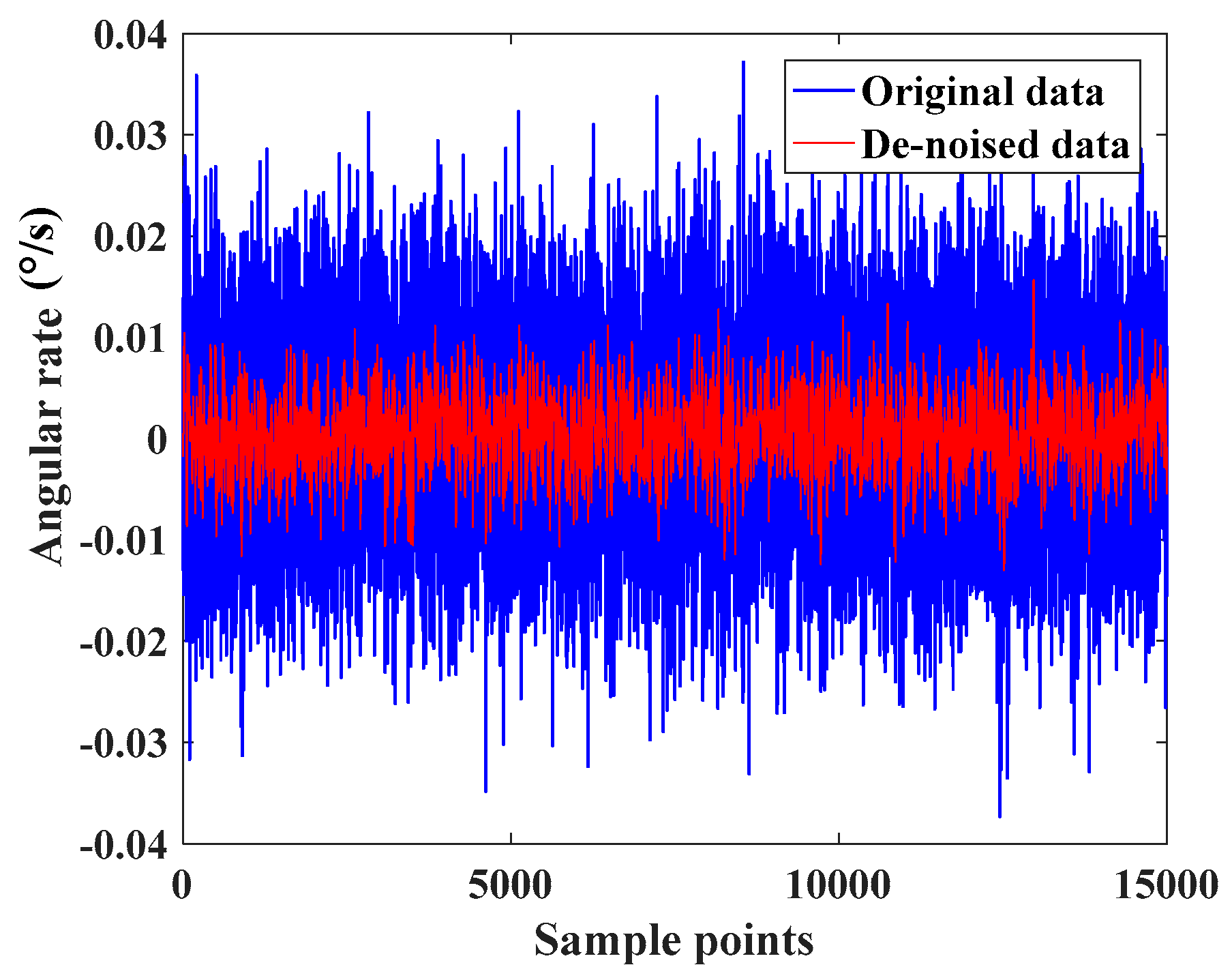

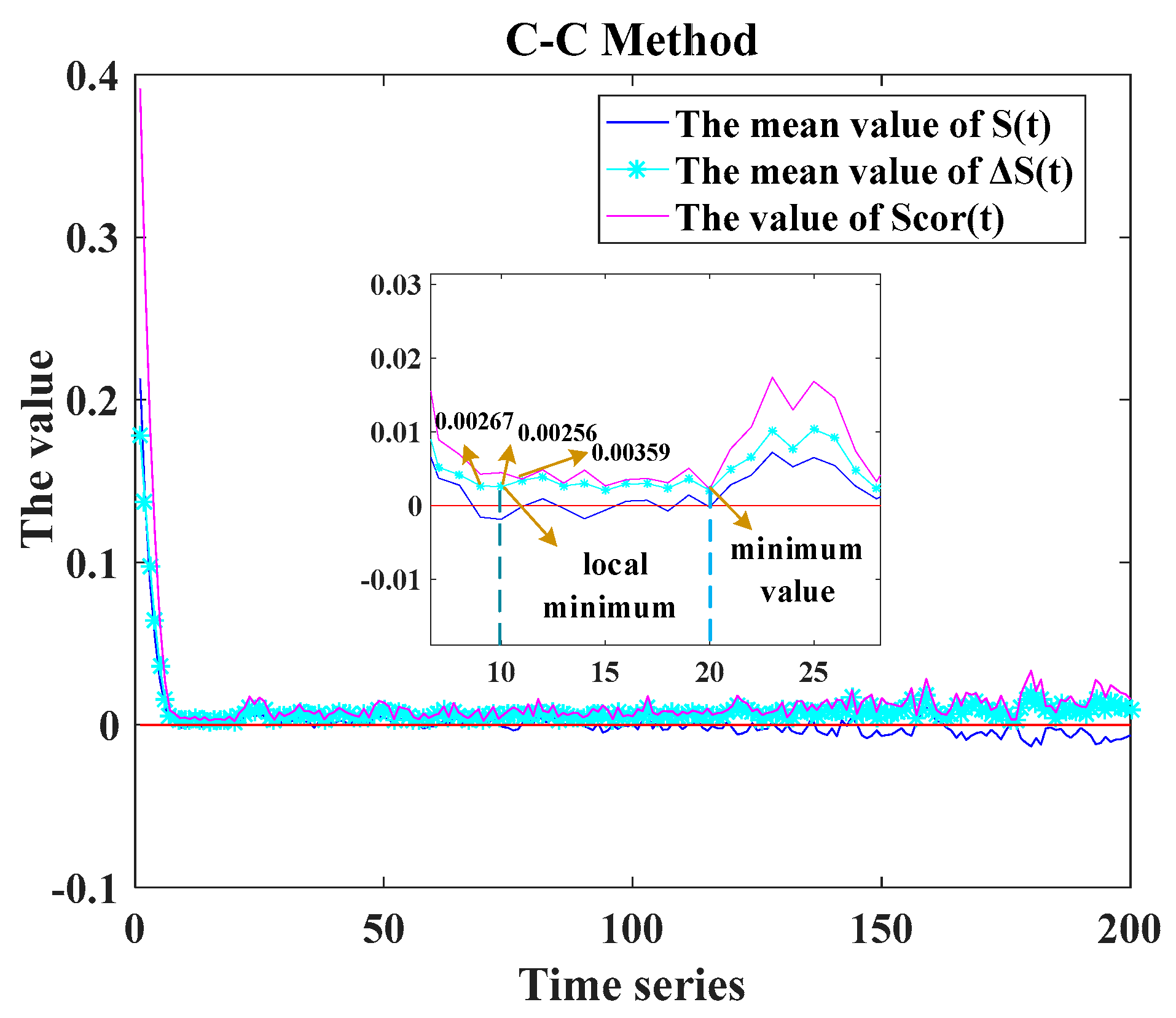

4.2. Data Preprocessing

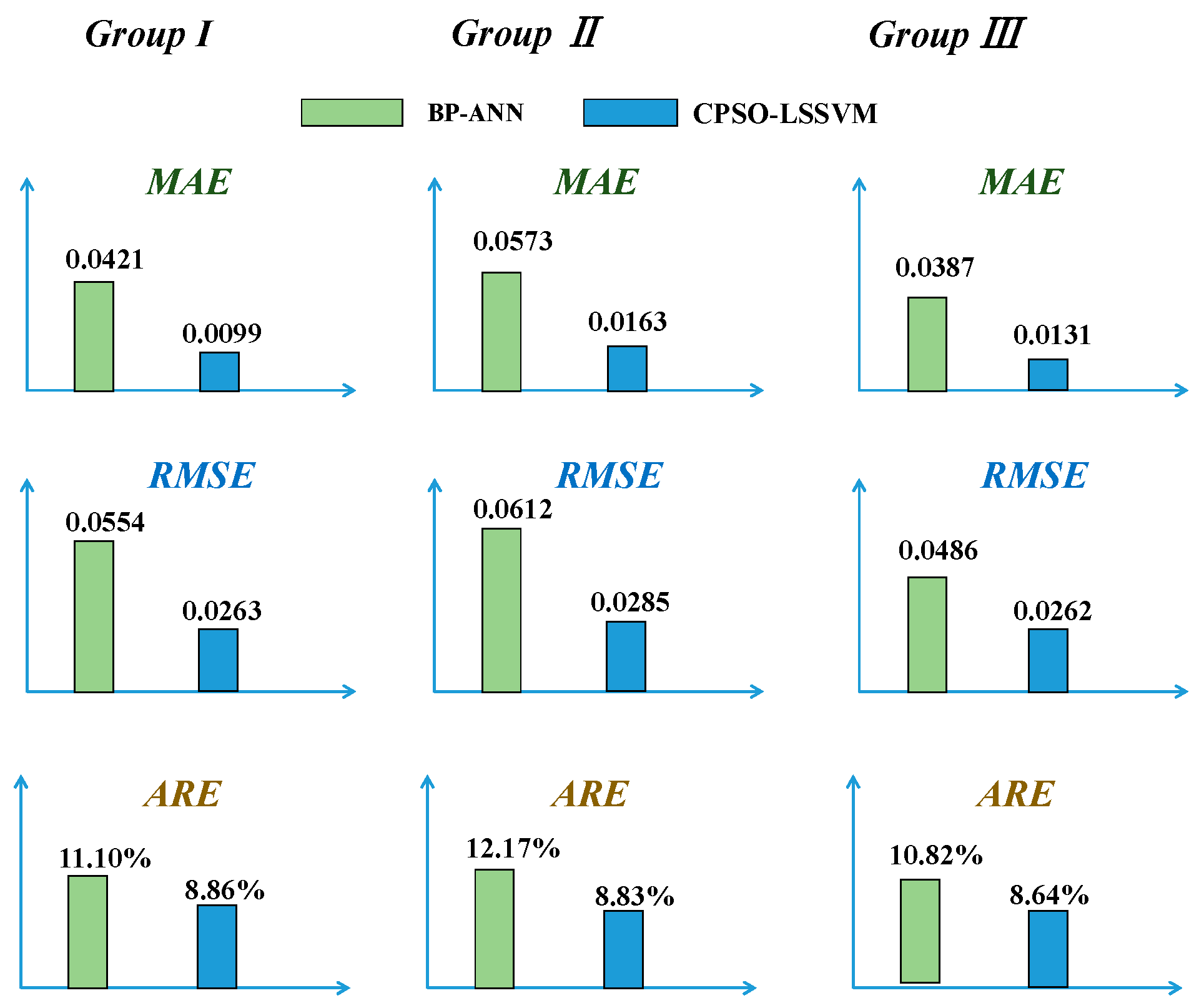

4.3. Comparing the Effects of Modeling

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Wang, X.Y.; Meng, X.Y. Research on Time-series Modeling and Filtering Methods for MEMS Gyroscope Random Drift Error. In Proceedings of the Materials Science and Engineering Conference Series, Harbin, China, 5 September 2017; p. 012005. [Google Scholar]

- Li, B.-W.; Yao, D.-Y. Low-cost MEMS IMU navigation positioning method for land vehicle. J. Chin. Inert. Technol. 2014, 22, 719–723. [Google Scholar]

- Wang, S.; Deng, Z.; Yin, G. An Accurate GPS-IMU/DR Data Fusion Method for Driverless Car Based on a Set of Predictive Models and Grid Constraints. Sensors 2016, 16, 280. [Google Scholar] [CrossRef] [PubMed]

- Chia, J.; Low, K.; Goh, S.; Xing, Y. A low complexity Kalman filter for improving MEMS based gyroscope performance. In Proceedings of the Aerospace Conference, Big Sky, MT, USA, 5–12 March 2016; pp. 1–7. [Google Scholar]

- Cao, H.; Li, H.; Kou, Z.; Shi, Y.; Tang, J.; Ma, Z.; Shen, C.; Liu, J. Optimization and experimentation of dual-mass MEMS gyroscope quadrature error correction methods. Sensors 2016, 16, 71. [Google Scholar] [CrossRef] [PubMed]

- Hsu, Y.L.; Chou, P.H.; Kuo, Y.C. Drift modeling and compensation for MEMS-based gyroscope using a Wiener-type recurrent neural network. In Proceedings of the IEEE International Symposium on Inertial Sensors and Systems, Kauai, HI, USA, 28–30 March 2017; pp. 39–42. [Google Scholar]

- Liu, Y.; Niu, R.; Wang, C.; Wang, L. Random Error Model and Compensation of MEMS Gyroscope Based on BP Neural Network. Int. J. Digit. Content Technol. Its Appl. 2013, 7, 284–290. [Google Scholar]

- Ansari, A.; Bakar, A.A. A Comparative Study of Three Artificial Intelligence Techniques: Genetic Algorithm, Neural Network, and Fuzzy Logic, on Scheduling Problem. In Proceedings of the Artificial Intelligence with Applications in Engineering and Technology (ICAIET), Kota Kinabalu, Malaysia, 3–5 December 2014; pp. 31–36. [Google Scholar]

- Chen, M.M.; Gao, G.W. Research on MEMS gyroscope random error compensation algorithm based on ARMA model. Appl. Mech. Mater. 2014, 602–605, 891–894. [Google Scholar] [CrossRef]

- Yuan, J.; Yuan, Y.; Liu, F.; Pang, Y.; Lin, J. An improved noise reduction algorithm based on wavelet transformation for MEMS gyroscope. Front. Optoelectron. 2015, 8, 413–418. [Google Scholar] [CrossRef]

- Shi, Y.S.; Gao, Z.F. Study on MEMS gyro signal de-noising based on improved wavelet threshold method. Appl. Mech. Mater. 2013, 433–435, 1558–1562. [Google Scholar]

- Zha, F.; Xu, J.; Li, J.; He, H. IUKF neural network modeling for FOG temperature drift. J. Syst. Eng. Electron. 2013, 24, 838–844. [Google Scholar] [CrossRef]

- Chong, S.; Rui, S.; Jie, L.; Xiaoming, Z.; Jun, T.; Yunbo, S.; Jun, L.; Huiliang, C. Temperature drift modeling of MEMS gyroscope based on genetic-Elman neural network. Mech. Syst. Signal Process. 2016, 72, 897–905. [Google Scholar] [CrossRef]

- Xu, D.; Yang, Z.; Zhao, H.; Zhou, X. A temperature compensation method for MEMS accelerometer based on LM_BP neural network. In Proceedings of the 2016 IEEE Sensors, Orlando, FL, USA, 30 October–3 November 2016; pp. 1–3. [Google Scholar]

- Fei, J.; Wu, D. Adaptive control of MEMS gyroscope using fully tuned RBF neural network. Neural Comput. Appl. 2017, 28, 695–702. [Google Scholar] [CrossRef]

- Deng, F.; Guo, S.; Zhou, R.; Chen, J. Sensor multifault diagnosis with improved support vector machines. Trans. Autom. Sci. Eng. 2017, 14, 1053–1063. [Google Scholar] [CrossRef]

- Suykens, J.A.; Vandewalle, J. Least squares support vector machine classifiers. Neural Process. Lett. 1999, 9, 293–300. [Google Scholar] [CrossRef]

- You, H.; Ma, Z.; Tang, Y.; Wang, Y.; Yan, J.; Ni, M.; Cen, K.; Huang, Q. Comparison of ANN (MLP), ANFIS, SVM, and RF models for the online classification of heating value of burning municipal solid waste in circulating fluidized bed incinerators. Waste Manag. 2017, 68, 186–197. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Liu, J. Predicting MEMS gyroscope’s random drifts using LSSVM optimized by modified PSO. In Proceedings of the Guidance, Navigation and Control Conference (CGNCC), Nanjing, China, 12–14 August 2016; pp. 146–149. [Google Scholar]

- Bo, R.; Huan, L. On forecast modeling of MEMS gyroscope random drift error. In Proceedings of the 2015 34th Chinese Control Conference (CCC), Hangzhou, China, 28–30 July 2015; pp. 4563–4567. [Google Scholar]

- Qin, W.-W.; Zheng, Z.-Q.; Liu, G.; Wang, L.-X. Modeling method of gyroscope's random drift based on wavelet analysis and LSSVM. J. Chin. Inertial Technol. 2008, 16, 721–724. [Google Scholar]

- Torrecilla, J.S.; Deetlefs, M.; Seddon, K.R.; Rodríguez, F. Estimation of ternary liquid–liquid equilibria for arene/alkane/ionic liquid mixtures using neural networks. Phys. Chem. Chem. Phys. 2008, 10, 5114–5120. [Google Scholar] [CrossRef] [PubMed]

- Bhatti, M.S.; Kapoor, D.; Kalia, R.K.; Reddy, A.S.; Thukral, A.K. RSM and ANN modeling for electrocoagulation of copper from simulated wastewater: Multi objective optimization using genetic algorithm approach. Desalination 2011, 274, 74–80. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, H.; Liu, G.; Wang, Z. Optimization of Stripping Voltammetric Sensor by a Back Propagation Artificial Neural Network for the Accurate Determination of Pb(II) in the Presence of Cd(II). Sensors 2016, 16, 1540. [Google Scholar] [CrossRef] [PubMed]

- Suah, F.B.M.; Ahmad, M.; Taib, M.N. Optimisation of the range of an optical fibre pH sensor using feed-forward artificial neural network. Sens. Actuators B Chem. 2003, 90, 175–181. [Google Scholar] [CrossRef]

- Bade, R.; Bijlsma, L.; Miller, T.H.; Barron, L.P.; Sancho, J.V.; Hernández, F. Suspect screening of large numbers of emerging contaminants in environmental waters using artificial neural networks for chromatographic retention time prediction and high resolution mass spectrometry data analysis. Sci. Total Environ. 2015, 538, 934–941. [Google Scholar] [CrossRef] [PubMed]

- Torrecilla, J.S.; García, J.; Rojo, E.; Rodríguez, F. Estimation of toxicity of ionic liquids in Leukemia Rat Cell Line and Acetylcholinesterase enzyme by principal component analysis, neural networks and multiple lineal regressions. J. Hazard. Mater. 2009, 164, 182–194. [Google Scholar] [CrossRef] [PubMed]

- Alharbi, N.; Hassani, H. A new approach for selecting the number of the eigenvalues in singular spectrum analysis. J. Frankl. Inst. 2016, 353, 1–16. [Google Scholar] [CrossRef]

- Suykens, J.; Lukas, L.; Van Dooren, P.; De Moor, B.; Vandewalle, J. Least squares support vector machine classifiers: A large scale algorithm. In Proceedings of the European Conference on Circuit Theory and Design, ECCTD, Stresa, Italy, 4–6 September 1999; pp. 839–842. [Google Scholar]

- Long, B.; Huang, J.; Tian, S. Least squares support vector machine based analog-circuit fault diagnosis using wavelet transform as preprocessor. In Proceedings of the International Conference on Communications, Circuits and Systems, Fujian, China, 25–27 May 2008; pp. 1026–1029. [Google Scholar]

- Lin, W.-M.; Tu, C.-S.; Yang, R.-F.; Tsai, M.-T. Particle Swarm Optimisation Aided Least-Square Support Vector Machine for Load Forecast with Spikes. IET Gener. Transm. Distrib. 2016, 10, 1145–1153. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Zhang, K. Short-term electric load forecasting based on singular spectrum analysis and support vector machine optimized by Cuckoo search algorithm. Electr. Power Syst. Res. 2017, 146, 270–285. [Google Scholar] [CrossRef]

- Pan, A.; Zhou, J.; Zhang, P.; Lin, S.; Tang, J. Predicting of Power Quality Steady State Index Based on Chaotic Theory Using Least Squares Support Vector Machine. Power 2017, 3, 5. [Google Scholar] [CrossRef]

- Bian, Q.; Wang, X.; Xie, R.; Li, T.; Ma, T. Small scale helicopter system identification based on Modified Particle Swarm Optimization, Guidance. In Proceedings of the 2016 IEEE Chinese Navigation and Control Conference (CGNCC), Nanjing, China, 10 March 2016; pp. 182–186. [Google Scholar]

- Lagos-Eulogio, P.; Seck-Tuoh-Mora, J.C.; Hernandez-Romero, N.; Medina-Marin, J. A new design method for adaptive IIR system identification using hybrid CPSO and DE. Nonlinear Dyn. 2017, 88, 2371–2389. [Google Scholar] [CrossRef]

- Chuanwen, J.; Bompard, E. A hybrid method of chaotic particle swarm optimization and linear interior for reactive power optimisation. Math. Comput. Simul. 2005, 68, 57–65. [Google Scholar] [CrossRef]

- Tao, H.Y.C. Phase-space reconstruction technology of chaotic attractor based on CC method. J. Electron. Meas. Instrum. 2012, 5, 010. [Google Scholar]

- Liu, F.; Liu, F.; Wang, W.; Xu, B. MEMS gyro’s output signal de-noising based on wavelet analysis. In Proceedings of the International Conference on Mechatronics and Automation, Harbin, China, 5–9 August 2007; pp. 1288–1293. [Google Scholar]

- Kim, H.S.; Eykholt, R.; Salas, J. Nonlinear dynamics, delay times, and embedding windows. Phys. D Nonlinear Phenom. 1999, 127, 48–60. [Google Scholar] [CrossRef]

| Model | MAE () | RMSE () | ARE |

|---|---|---|---|

| BP-ANN | 0.0421 | 0.0554 | 11.10% |

| CPSO-LSSVM | 0.0099 | 0.0263 | 8.86% |

| Group | I | II | III |

|---|---|---|---|

| Before compensation ( | 0.00354 | 0.00412 | 0.00328 |

| After compensation ( | 0.00065 | 0.00072 | 0.00053 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, H.; Hou, B.; Lin, Z.; Guo, M. Modeling and Compensation of Random Drift of MEMS Gyroscopes Based on Least Squares Support Vector Machine Optimized by Chaotic Particle Swarm Optimization. Sensors 2017, 17, 2335. https://doi.org/10.3390/s17102335

Xing H, Hou B, Lin Z, Guo M. Modeling and Compensation of Random Drift of MEMS Gyroscopes Based on Least Squares Support Vector Machine Optimized by Chaotic Particle Swarm Optimization. Sensors. 2017; 17(10):2335. https://doi.org/10.3390/s17102335

Chicago/Turabian StyleXing, Haifeng, Bo Hou, Zhihui Lin, and Meifeng Guo. 2017. "Modeling and Compensation of Random Drift of MEMS Gyroscopes Based on Least Squares Support Vector Machine Optimized by Chaotic Particle Swarm Optimization" Sensors 17, no. 10: 2335. https://doi.org/10.3390/s17102335