A 4 mm2 Double Differential Torsional MEMS Accelerometer Based on a Double-Beam Configuration

Abstract

:1. Introduction

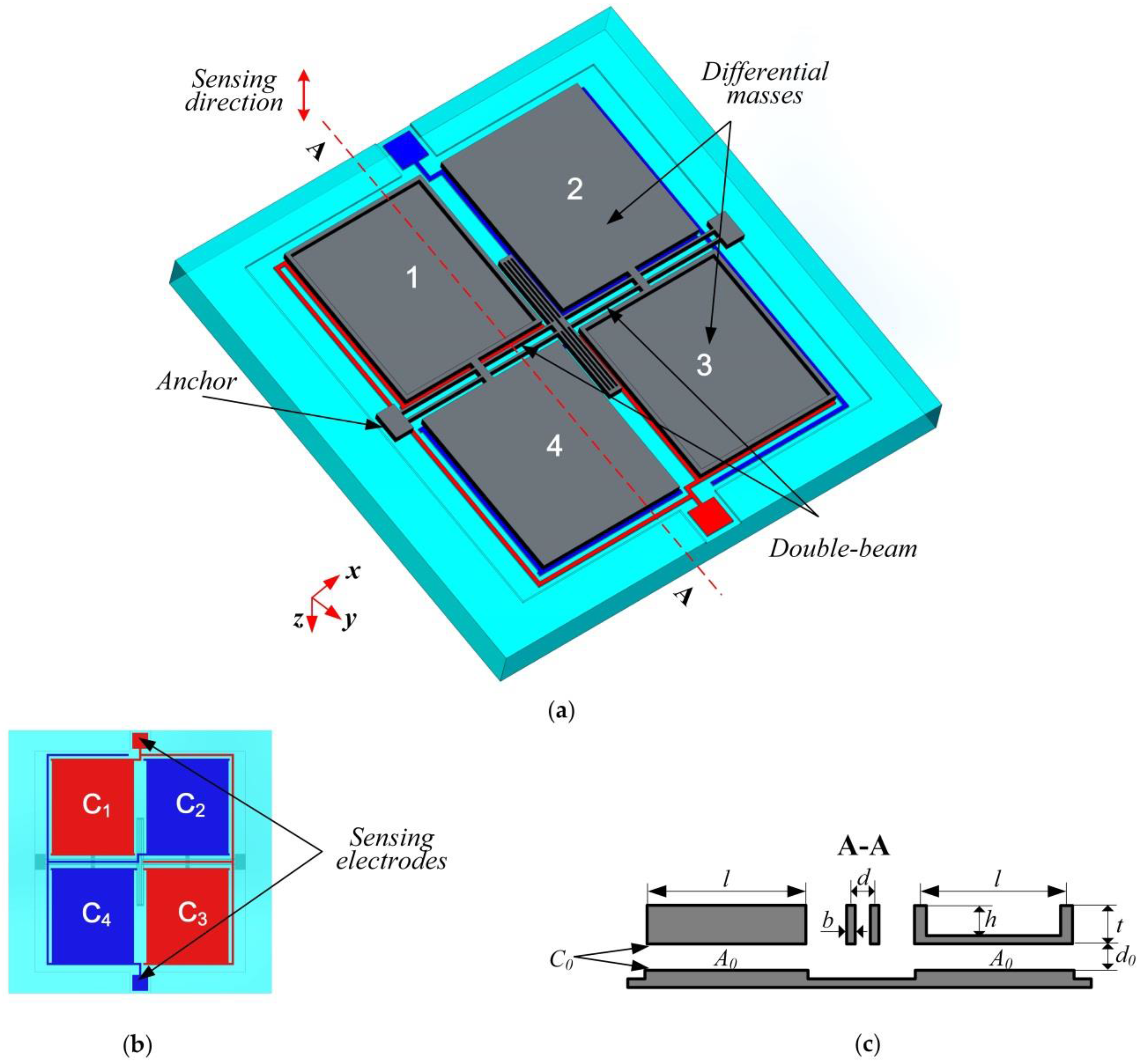

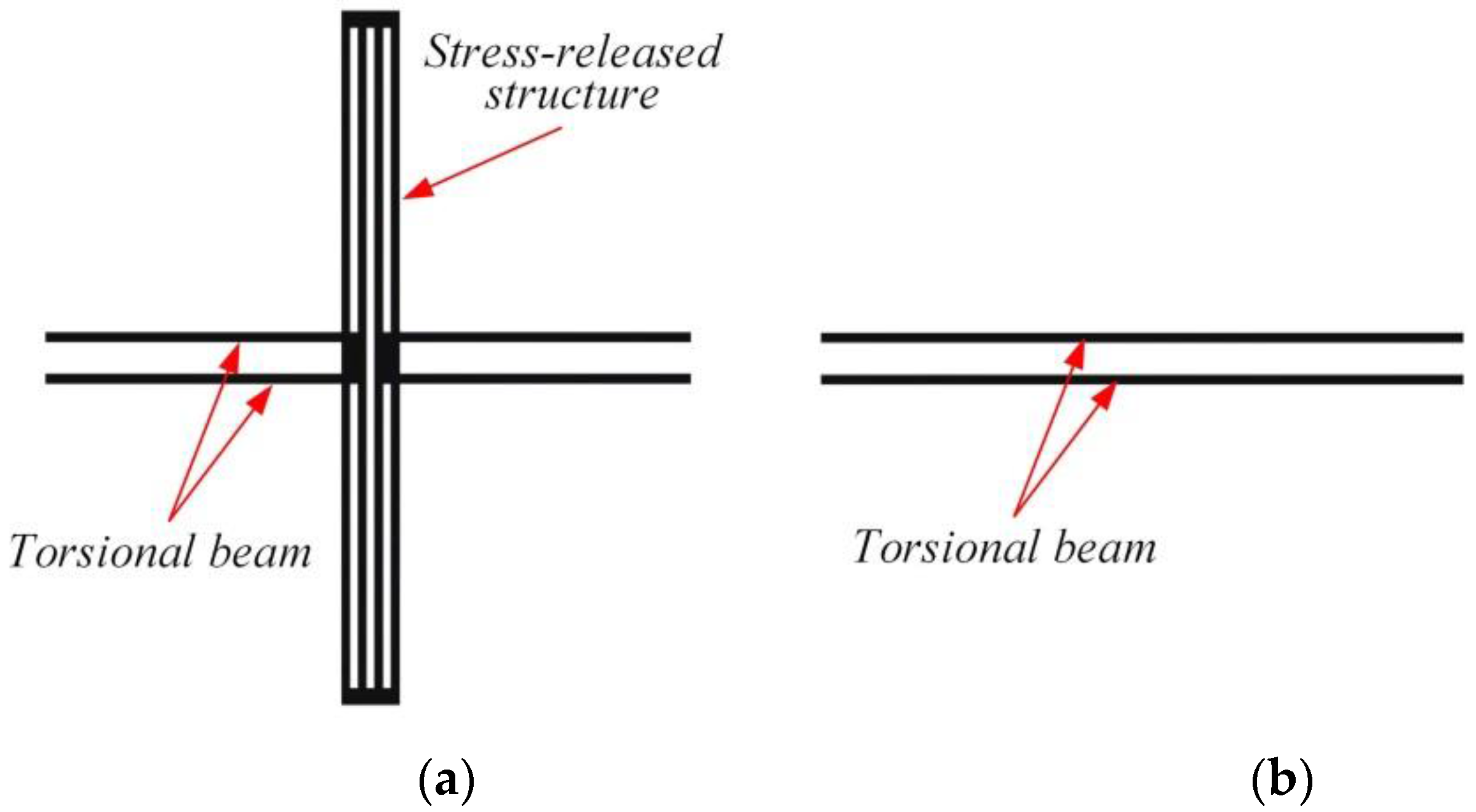

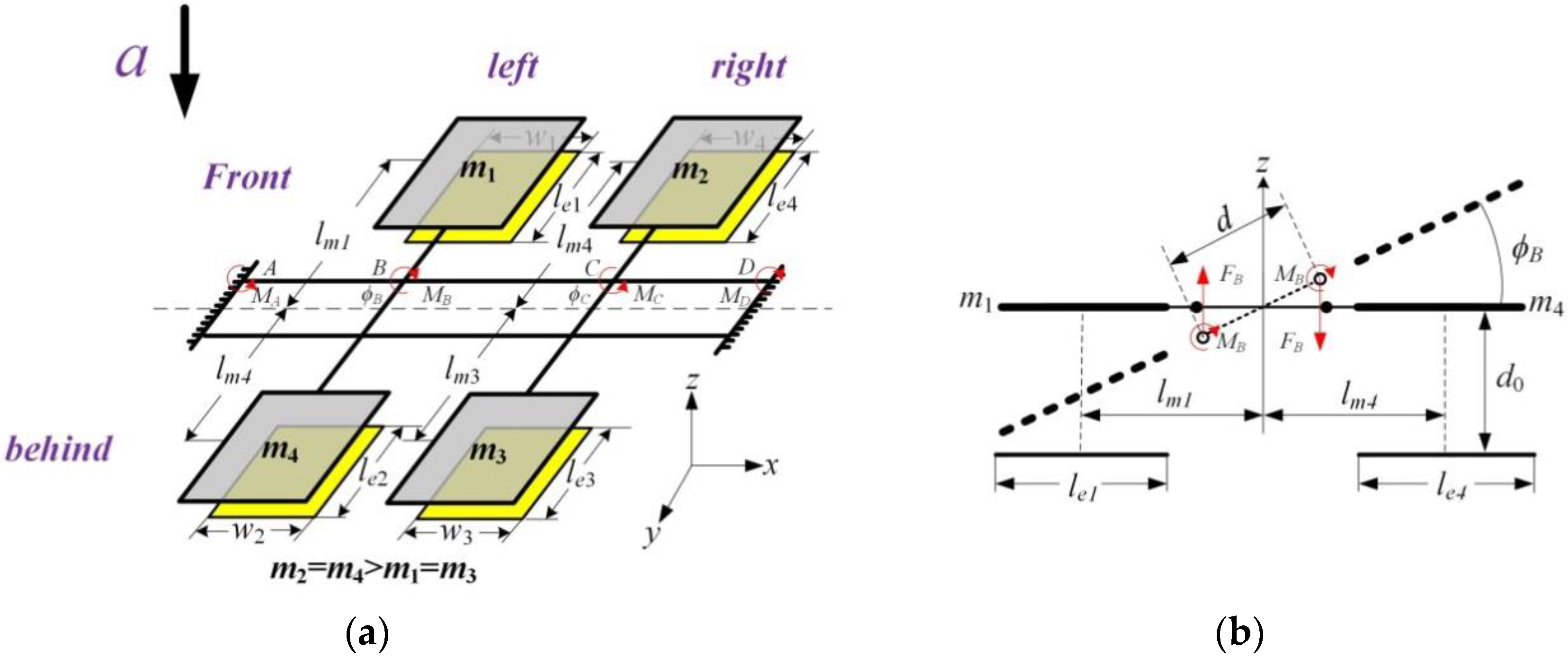

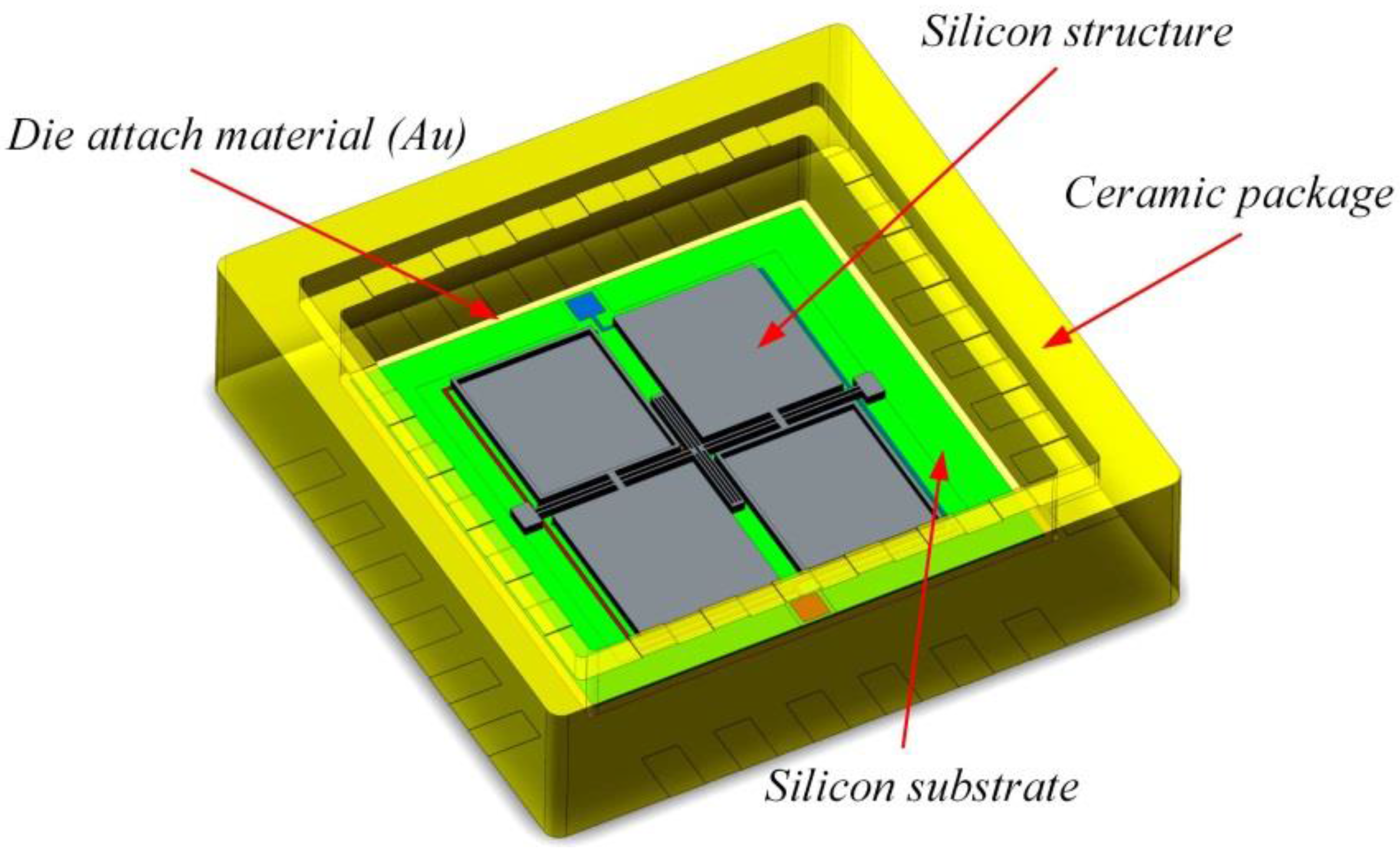

2. Structure Design and Theoretical Considerations

2.1. Description and Working Principle

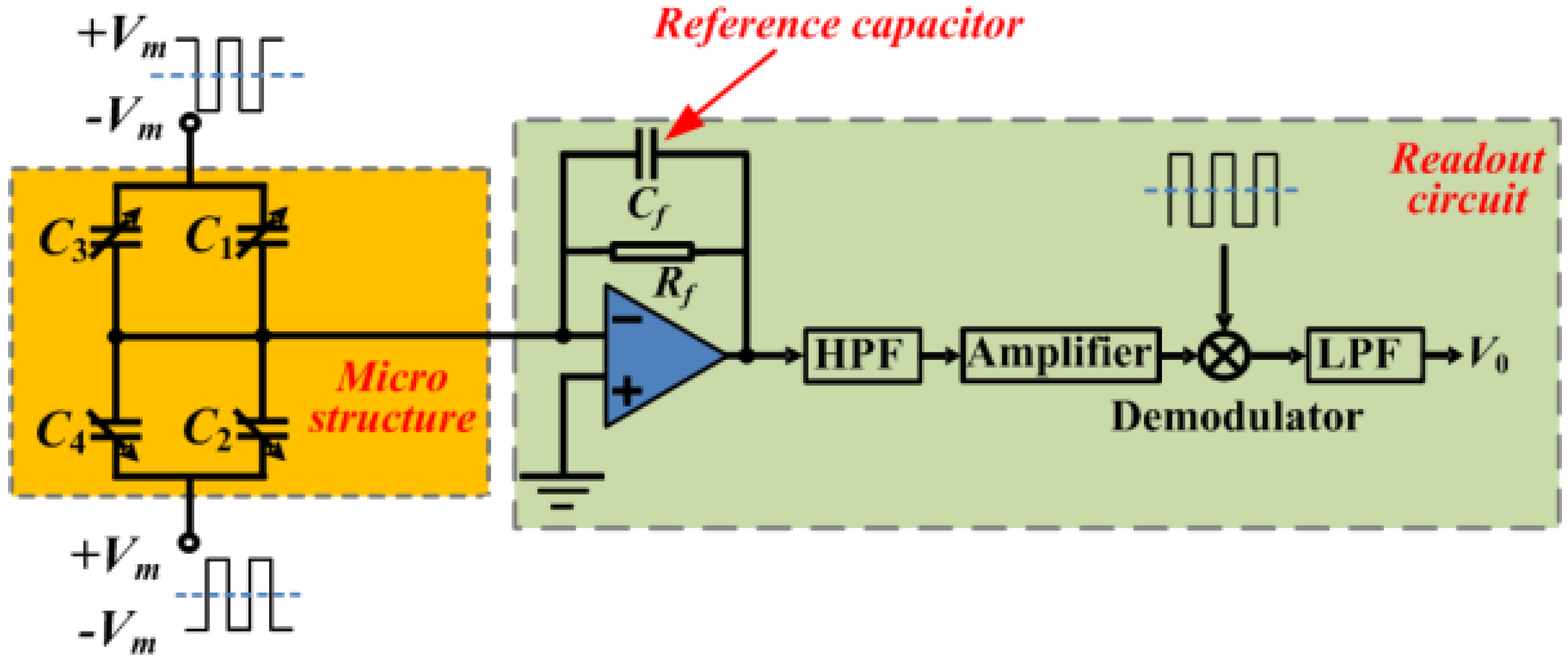

2.2. Theoretical Consideration

3. Simulation Analysis

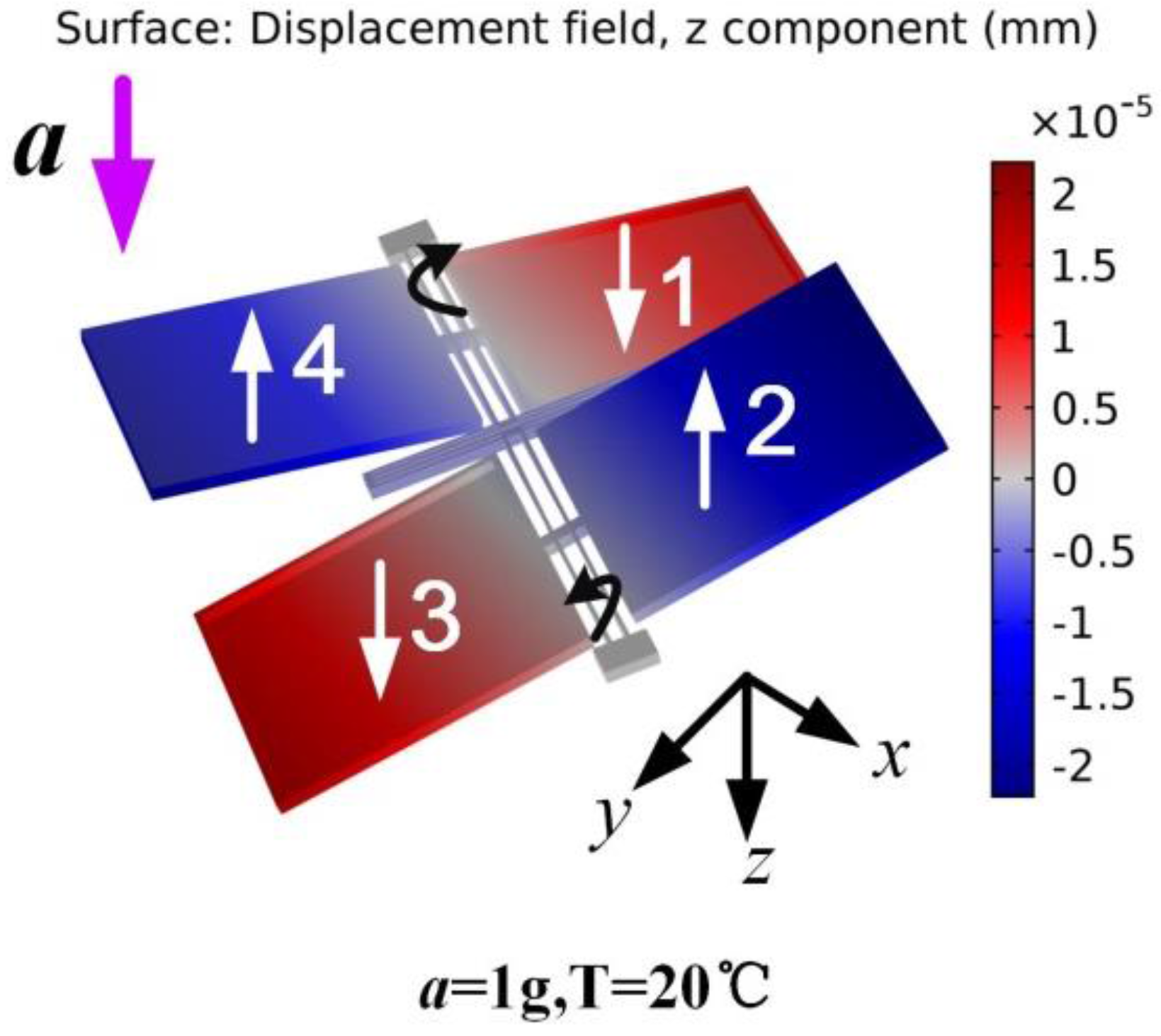

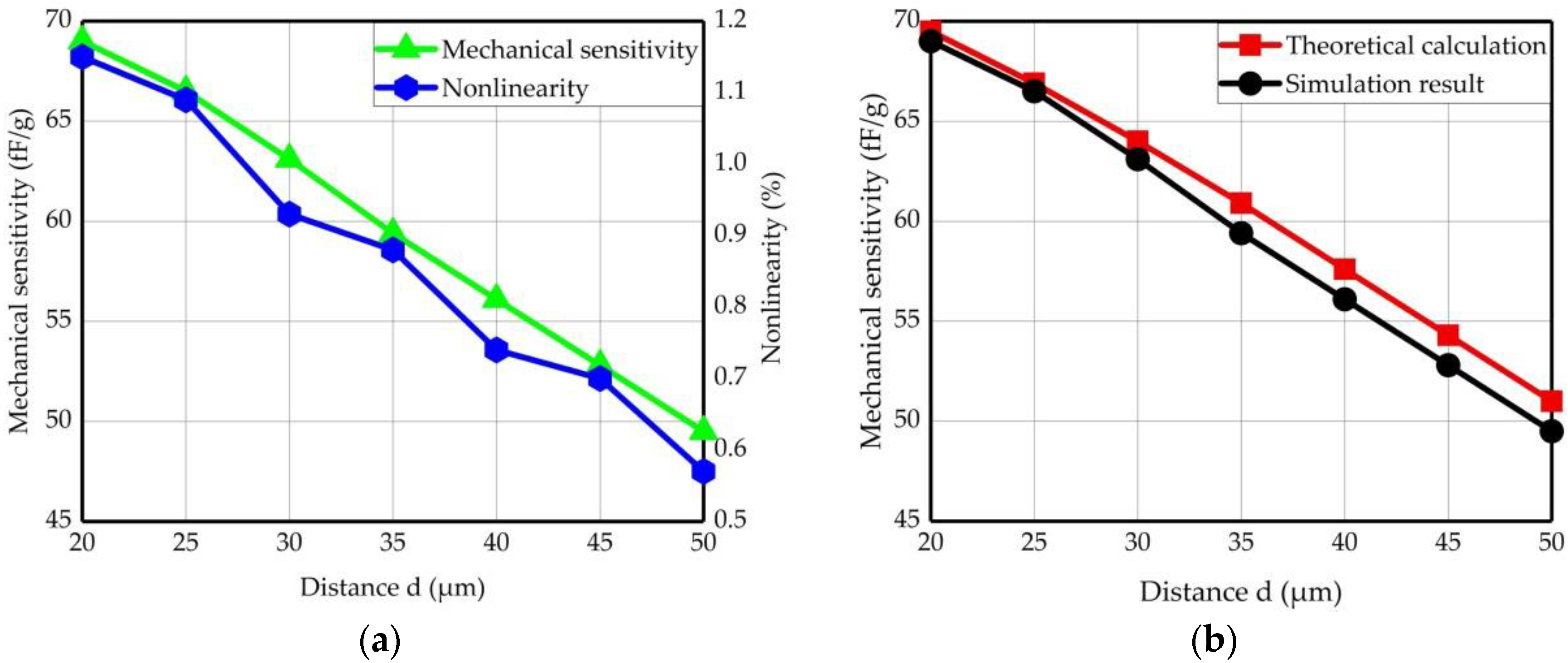

3.1. Simulation Analysis of Mechanical Sensitivity and Nonlinearity

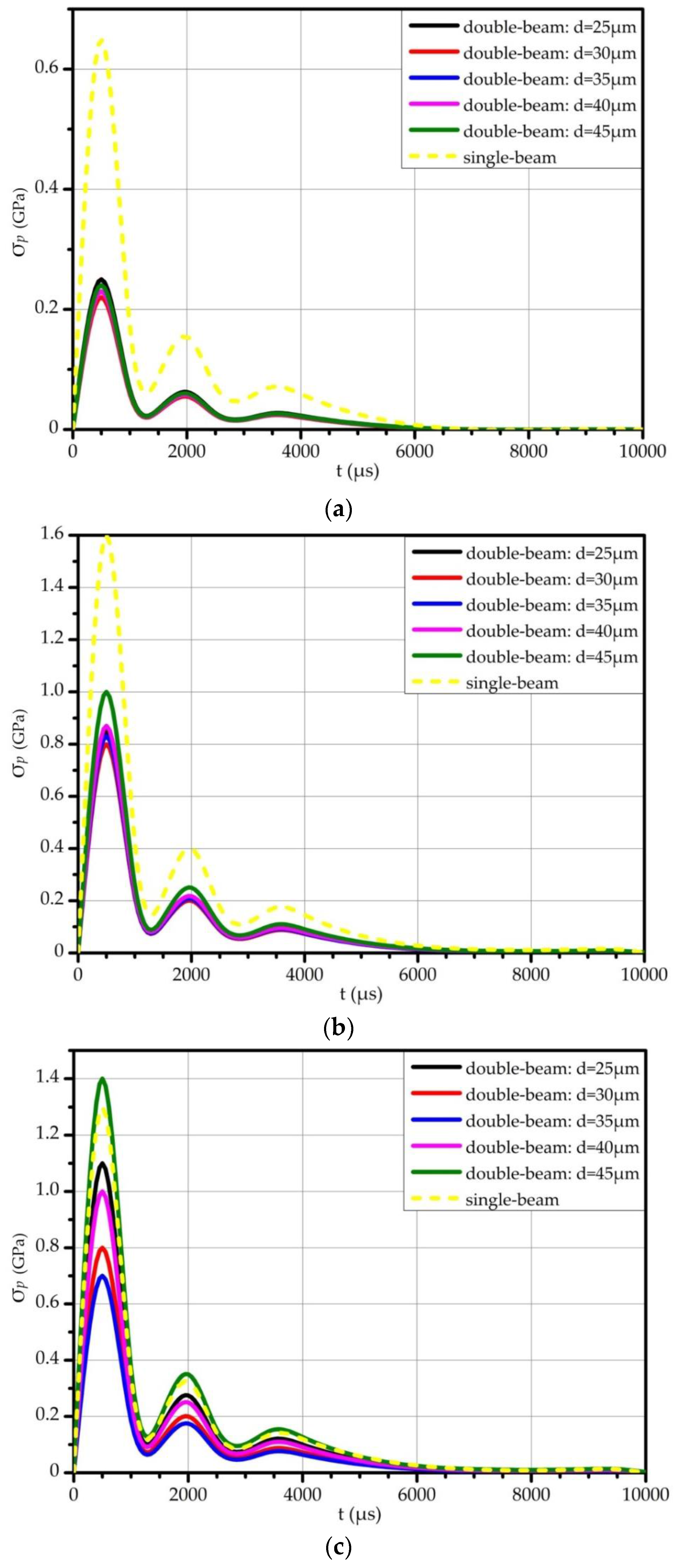

3.2. Simulation Analysis of Shock Resistance

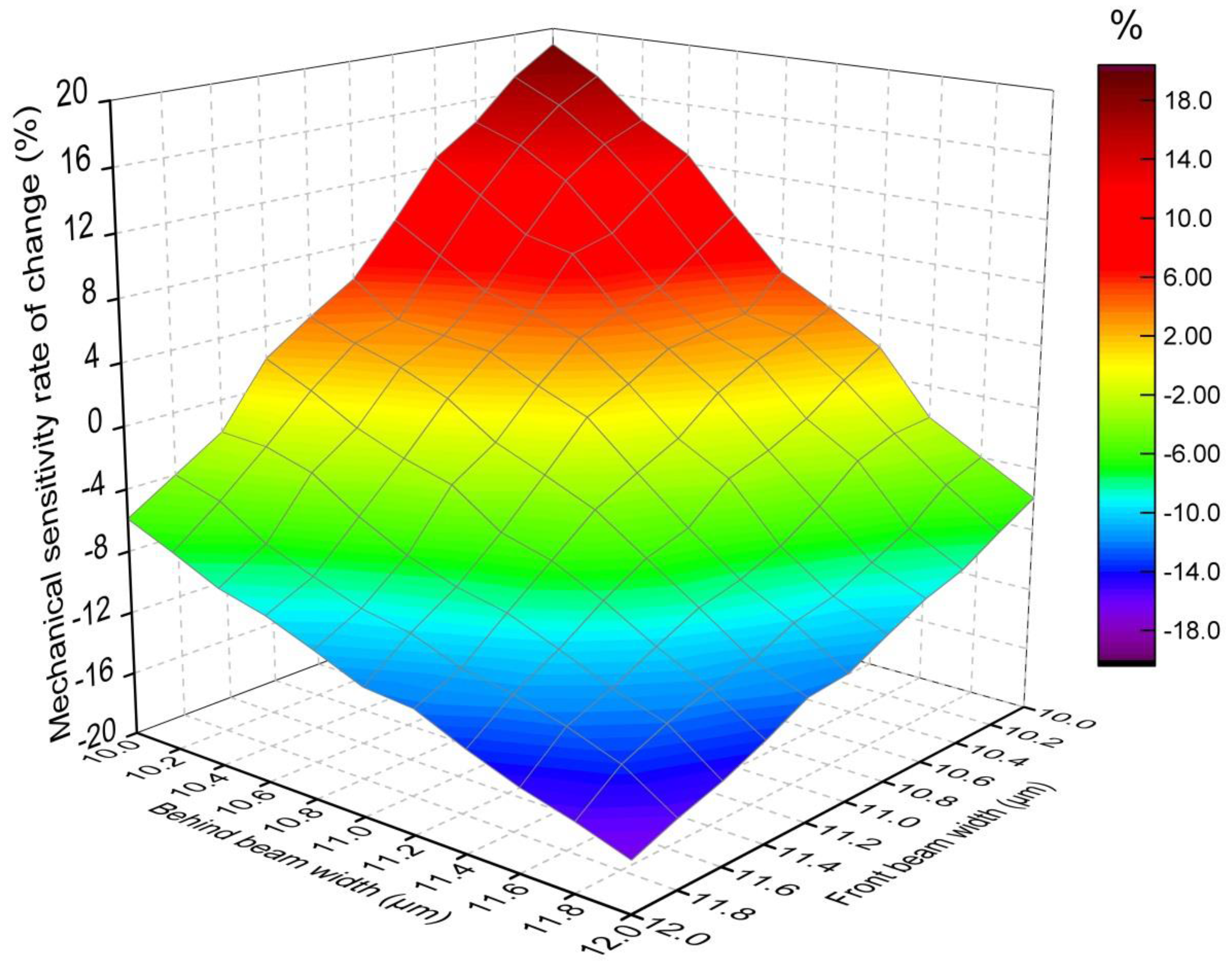

3.3. Simulation Analysis of Tolerance in Fabrication

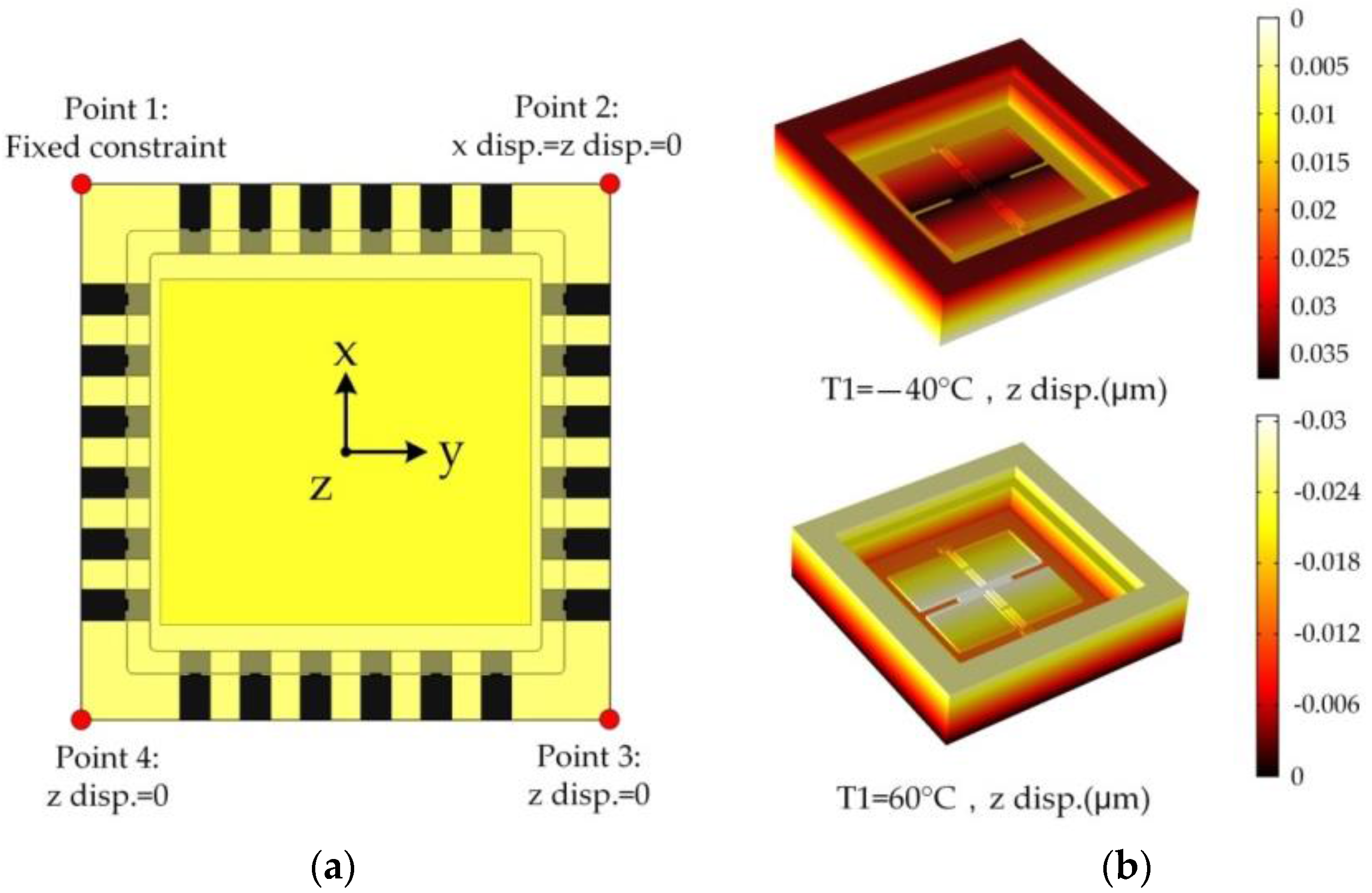

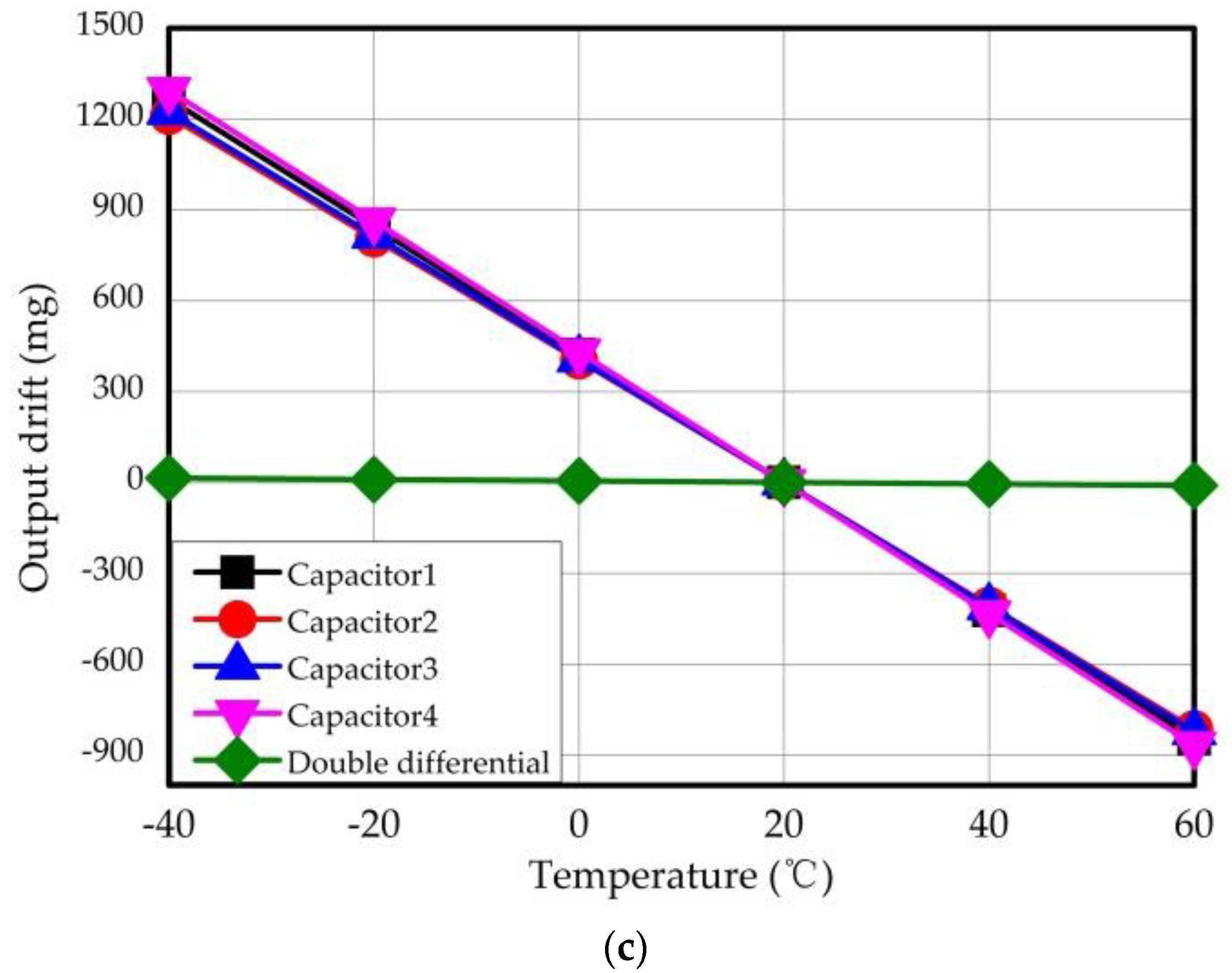

3.4. Simulation Analysis of Temperature Robustness

4. Fabrication Process

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lammel, G. The future of MEMS sensors in our connected world. In Proceedings of the 2015 28th International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; pp. 61–64. [Google Scholar]

- Terzioglu, Y.; Kose, T.; Azgin, K.; Akin, T. A simple out-of-plane capacitive MEMS accelerometer utilizing lateral and vertical electrodes for differential sensing. In Proceedings of the 2015 SENSORS, Busan, Korea, 1–4 November 2015; pp. 1–3. [Google Scholar]

- Li, W.; Song, Z.; Li, X.; Che, L. A novel sandwich capacitive accelerometer with a double-sided 16-beam-mass structure. Microelectron. Eng. 2014, 115, 32–38. [Google Scholar] [CrossRef]

- Xiao, D.B.; Li, Q.S.; Hou, Z.Q.; Wang, X.H.; Chen, Z.H.; Xia, D.W.; Wu, X.Z. A novel sandwich differential capacitive accelerometer with symmetrical double-sided serpentine beam-mass structure. J. Micromech. Microeng. 2015, 26, 2. [Google Scholar] [CrossRef]

- Tseng, S.-H.; Lu, M.S.; Wu, P.-C. Implementation of a monolithic capacitive accelerometer in a wafer-level 0.18 µm CMOS MEMS process. J. Micromech. Microeng. 2012, 22, 10–23. [Google Scholar] [CrossRef]

- Zotov, S.A.; Simon, B.R.; Trusov, A.A.; Shkel, A.M. High quality factor resonant mems accelerometer with continuous thermal compensation. Sensors 2015, 15, 5045–5052. [Google Scholar] [CrossRef]

- Caspani, A.; Comi, C.; Corigliano, A.; Langfelder, G.; Tocchio, A. Compact biaxial micromachined resonant accelerometer. J. Micromech. Microeng. 2013, 23, 10. [Google Scholar] [CrossRef]

- Zou, X.; Thiruvenkatanathan, P.; Seshia, A.A. A seismic-grade resonant mems accelerometer. J. Microelectromech. Syst. 2014, 23, 768–770. [Google Scholar]

- Lu, Q.; Bai, J.; Lian, W.; Lou, S. A novel scheme design of a high-g optical NEMS accelerometer based on a single chip grating with proper sensitivity and large bandwidth. In Proceedings of the 2015 IEEE 10th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xi’an, China, 7–11 April 2015; pp. 248–253. [Google Scholar]

- Partridge, A.; Reynolds, J.K.; Chui, B.W.; Chow, E.M. A high-performance planar piezoresistive accelerometer. J. Microelectromech. Syst. 2000, 9, 58–66. [Google Scholar] [CrossRef]

- Barbour, N.; Connelly, J.; Gilmore, J. Micromechanical silicon instrument and systems development at draper laboratory. In Proceedings of the 1996 AIAA Guidance, Navigation and Control Conference, San Diego, CA, USA, 29–31 July 1996; pp. 1–7. [Google Scholar]

- Dong, Y.; Zwahlen, P.; Nguyen, A.M. Ultra-high precision MEMS accelerometer. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; pp. 695–698. [Google Scholar]

- Ko, H. Highly programmable temperature compensated readout circuit for capacitive microaccelerometer. Sens. Actuators A Phys. 2010, 158, 72–83. [Google Scholar] [CrossRef]

- Falconi, C.; Fratini, M. Cmos microsystems temperature control. Sens. Actuators B Chem. 2008, 129, 59–66. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, C.; Meng, F.; Hao, Y. A SOI sandwich differential capacitance accelerometer with low-stress package. In Proceedings of the 2014 9th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Waikiki Beach, HI, USA, 13–16 April 2014; pp. 341–345. [Google Scholar]

- Tang, B.; Sato, K.; Xi, S. Process development of an all-silicon capacitive accelerometer with a highly symmetrical spring-mass structure etched in TMAH+ Triton-X-100. Sens. Actuators A Phys. 2014, 217, 105–110. [Google Scholar] [CrossRef]

- Zwahlen, P.; Nguyen, A.-M.; Dong, Y. Navigation grade MEMS accelerometer. In Proceedings of the 23rd IEEE International Conference on Micro Electro Mechanical Systems (MEMS ’10), Hong Kong, China, 24–28 January 2010; pp. 631–634. [Google Scholar]

- Tan, S.S.; Liu, C.Y.; Yeh, L.K.; Chiu, Y.H. A new process for CMOS MEMS capacitive sensors with high sensitivity and thermal stability. J. Micromech. Microeng. 2011, 21, 3. [Google Scholar] [CrossRef]

- Andersson, G.; Hedenstierna, N.; Svensson, P. A novel silicon bulk gyroscope. In Proceedings of the 1999 International Conference on Solid-State sensors and Actuators, Sendai, Japan, 7–10 June 1999; pp. 902–905. [Google Scholar]

- Su, J.; Xiao, D.; Wang, X.; Chen, Z.; Wu, X. Vibration sensitivity analysis of the ‘butterfly-gyro’ structure. Microsyst. Technol. 2014, 20, 1281–1290. [Google Scholar] [CrossRef]

- Trusov, A.A.; Zotov, S.A.; Simon, B.R.; Shkel, A.M. Silicon accelerometer with differential frequency modulation and continuous self-calibration. In Proceedings of the 2013 IEEE 26th International Conference on Micro Electro Mechanical Systems (MEMS), Taipei, Taiwan, 20–24 January 2013; pp. 29–32. [Google Scholar]

- Xiao, D.; Xia, D.; Li, Q.; Hou, Z. A double differential torsional accelerometer with improved temperature robustness. Sens. Actuators A Phys. 2016, 243, 43–51. [Google Scholar] [CrossRef]

- Xiao, D.; Li, Q.; Hou, Z.; Xia, D. A double differential torsional micro-accelerometer based on V-shape beam. Sens. Actuators A Phys. 2017, 258, 182–192. [Google Scholar] [CrossRef]

- Wagner, U.; Franz, J.; Schweiker, M.; Bernhard, W.; Müller-Friedler, R.; Michel, B.; Paul, O. Mechanical reliability of MEMS-structures under shock load. Microelectron. Reliab. 2001, 41, 1657–1662. [Google Scholar] [CrossRef]

- Suhir, E. Is the maximum acceleration an adequate criterion of the dynamic strength of a structural element in an electronic product? IEEE Trans. Compon. Packag. Manuf. Technol. 1997, 20, 513–517. [Google Scholar] [CrossRef]

- Hauck, T.; Li, G.; McNeill, A.; Knoll, H.; Ebert, M.; Bagdahn, J. Drop simulation and stress analysis of MEMS devices. In Proceedings of the International Conference on Thermal, Mechanical and Multiphysics Simulation and Experiments in Micro-Electronics and Micro-Systems (EuroSimE 2006), Como, Italy, 23–25 April 2006; pp. 203–207. [Google Scholar]

- Ghisi, A.; Mariani, S.; Corigliano, A.; Zerbini, S. Physically–-Based Reduced Order Modelling of a Uni–Axial Polysilicon MEMS Accelerometer. Sensors 2012, 12, 13985–14003. [Google Scholar] [CrossRef] [PubMed]

- Mariani, S.; Martini, R.; Corigliano, A.; Beghi, M. Overall elastic domain of thin polysilicon films. Comput. Mater. Sci. 2011, 50, 2993–3004. [Google Scholar] [CrossRef]

- Mariani, S.; Ghisi, A.; Martini, R.; Corigliano, A.; Simoni, B. Advances in Electrical Engineering; NOVA Science Publisher Inc.: Huntington, NY, USA, 2011; Chapter 8; pp. 267–292. [Google Scholar]

- Ghisi, A.; Kalicinski, S.; Mariani, S.; Wolf, I.D.; Corigliano, A. PolysiliconMEMS accelerometers exposed to shocks: Numerical-experimental investigation. J. Micromech. Microeng. 2009, 19, 035023. [Google Scholar] [CrossRef]

- Jang, Y.H.; Kim, J.W.; Kim, J.M.; Kim, Y.K. Engineering design guide for etch holes to compensate spring width loss for reliable resonant frequencies. In Proceedings of the 2012 IEEE 25th International Conference on Micro Electro Mechanical Systems (MEMS), Paris, France, 29 January–2 February 2012; pp. 424–427. [Google Scholar]

- Xiong, X.; Wu, Y.L.; Jone, W.B. A dual-mode built-in self-test technique for capacitive MEMS devices. IEEE Trans. Instrum. Meas. 2005, 54, 1739–1750. [Google Scholar] [CrossRef]

- Mirzazadeh, R.; Eftekhar Azam, S.; Mariani, S. Micromechanical characterization of polysilicon films through on-chip tests. Sensors 2016, 16, E1191. [Google Scholar] [CrossRef] [PubMed]

- Hong, Y.; Lee, J.; Kim, S. Laterally driven symmetric micro-resonator for gyroscopic applications. J. Micromech. Microeng. 2000, 10, 452–458. [Google Scholar] [CrossRef]

- Alper, S.; Temiz, Y.; Akin, T. A compact angular rate sensor system using a fully decoupled silicon-on-glass MEMS gyroscope. J. Microelectromech. Syst. 2008, 17, 1418–1429. [Google Scholar] [CrossRef]

- Gad-el Hak, M. The MEMS Handbook; CRC Press: Boca Raton, FL, USA, 2001; Volume 20. [Google Scholar]

| Description | Symbol | Value |

|---|---|---|

| Wafer thickness | t | 50 μm |

| Curved depth | h | 40 μm |

| Width of single beam | b | 11 μm |

| Distance between two torsional beams | d | 35 μm |

| Effective area of each sensing capacitor | 0.72 | |

| Original gap of the capacitor | 2.0 μm | |

| Original capacitance of each sensing capacitor | 3.18 pF | |

| Capacitance of reference capacitor | 6.36 pF | |

| Mechanical sensitivity | 59.4 fF/g | |

| Fundamental resonance frequency | 3269 Hz | |

| Measuring range | ±15 g |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, T.; Xiao, D.; Li, Q.; Hou, Z.; Wu, X. A 4 mm2 Double Differential Torsional MEMS Accelerometer Based on a Double-Beam Configuration. Sensors 2017, 17, 2264. https://doi.org/10.3390/s17102264

Miao T, Xiao D, Li Q, Hou Z, Wu X. A 4 mm2 Double Differential Torsional MEMS Accelerometer Based on a Double-Beam Configuration. Sensors. 2017; 17(10):2264. https://doi.org/10.3390/s17102264

Chicago/Turabian StyleMiao, Tongqiao, Dingbang Xiao, Qingsong Li, Zhanqiang Hou, and Xuezhong Wu. 2017. "A 4 mm2 Double Differential Torsional MEMS Accelerometer Based on a Double-Beam Configuration" Sensors 17, no. 10: 2264. https://doi.org/10.3390/s17102264