Autonomous Microsystems for Downhole Applications: Design Challenges, Current State, and Initial Test Results

Abstract

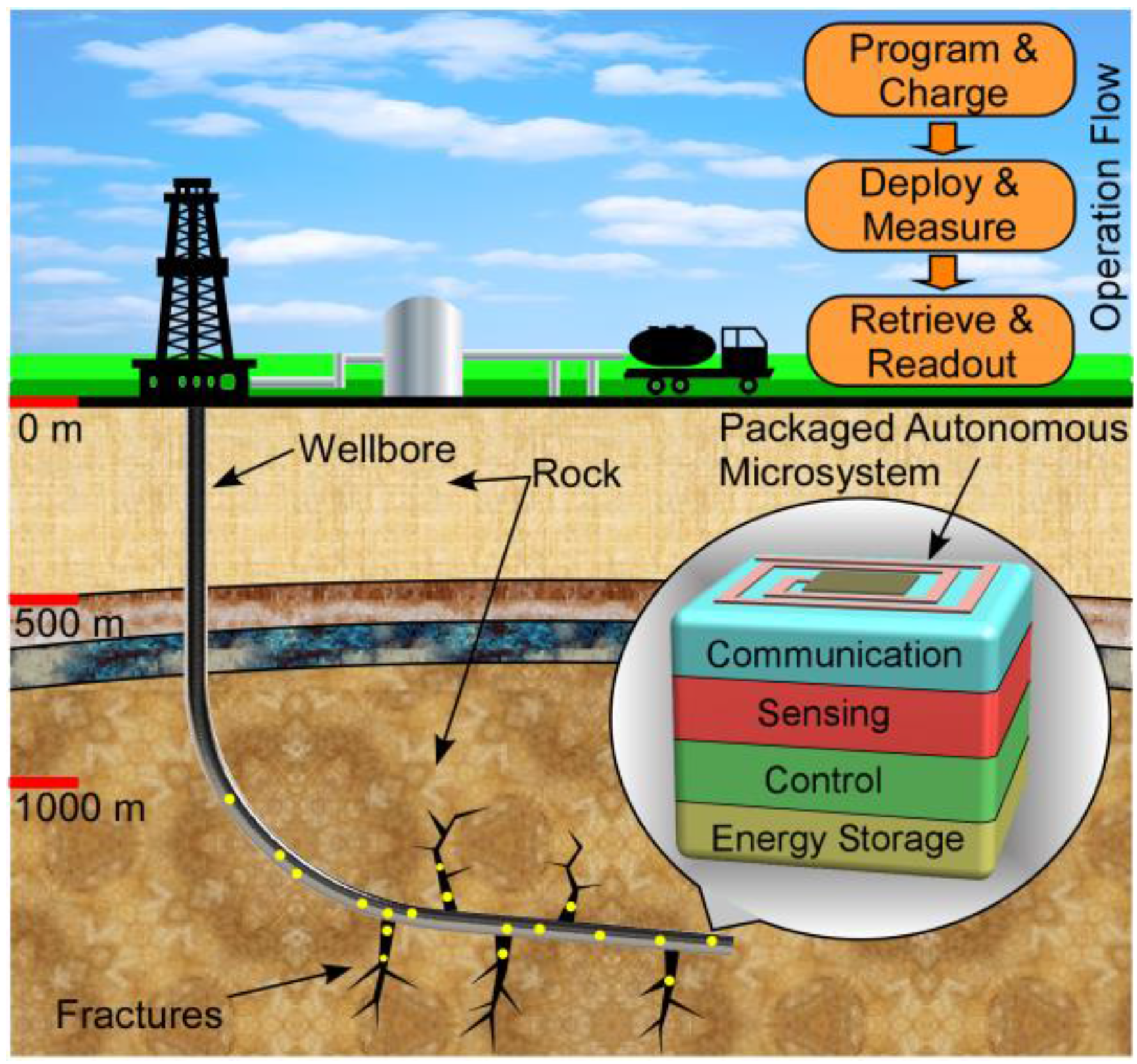

:1. Introduction

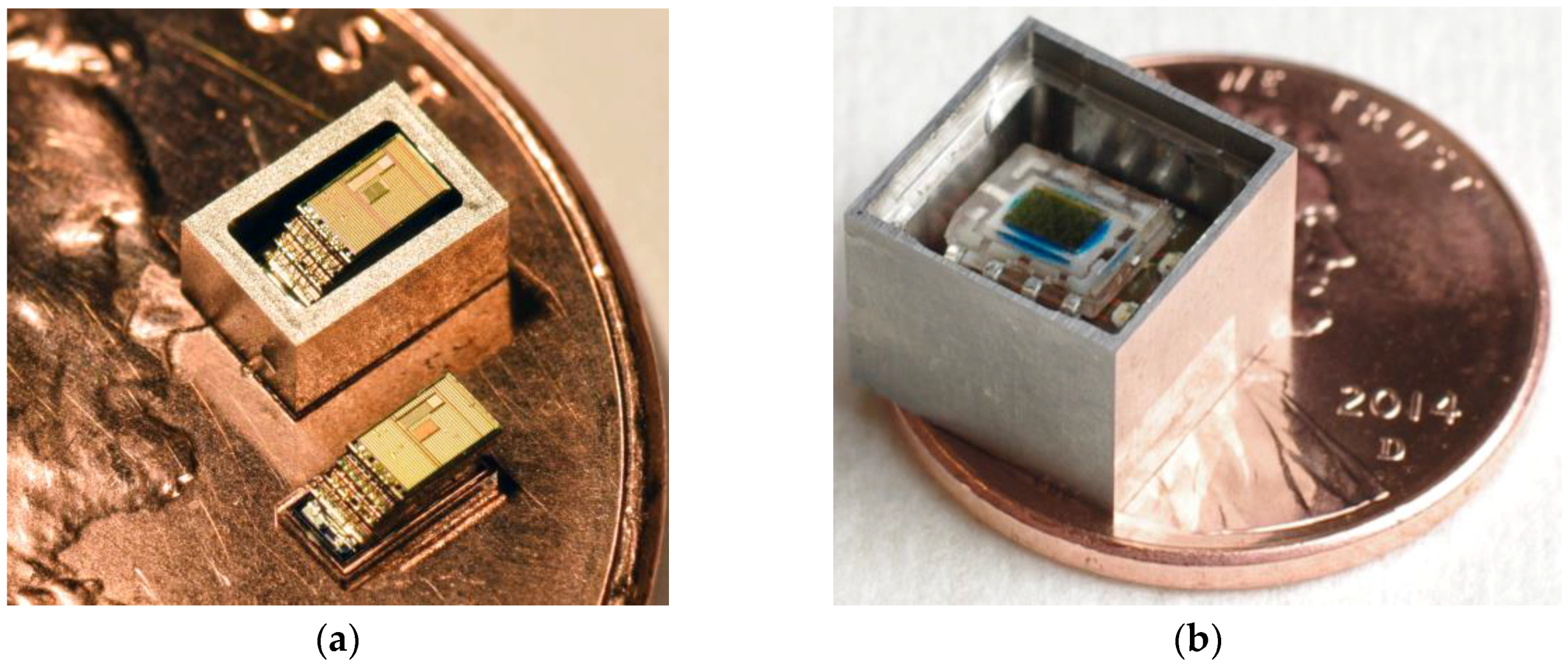

2. System Configuration

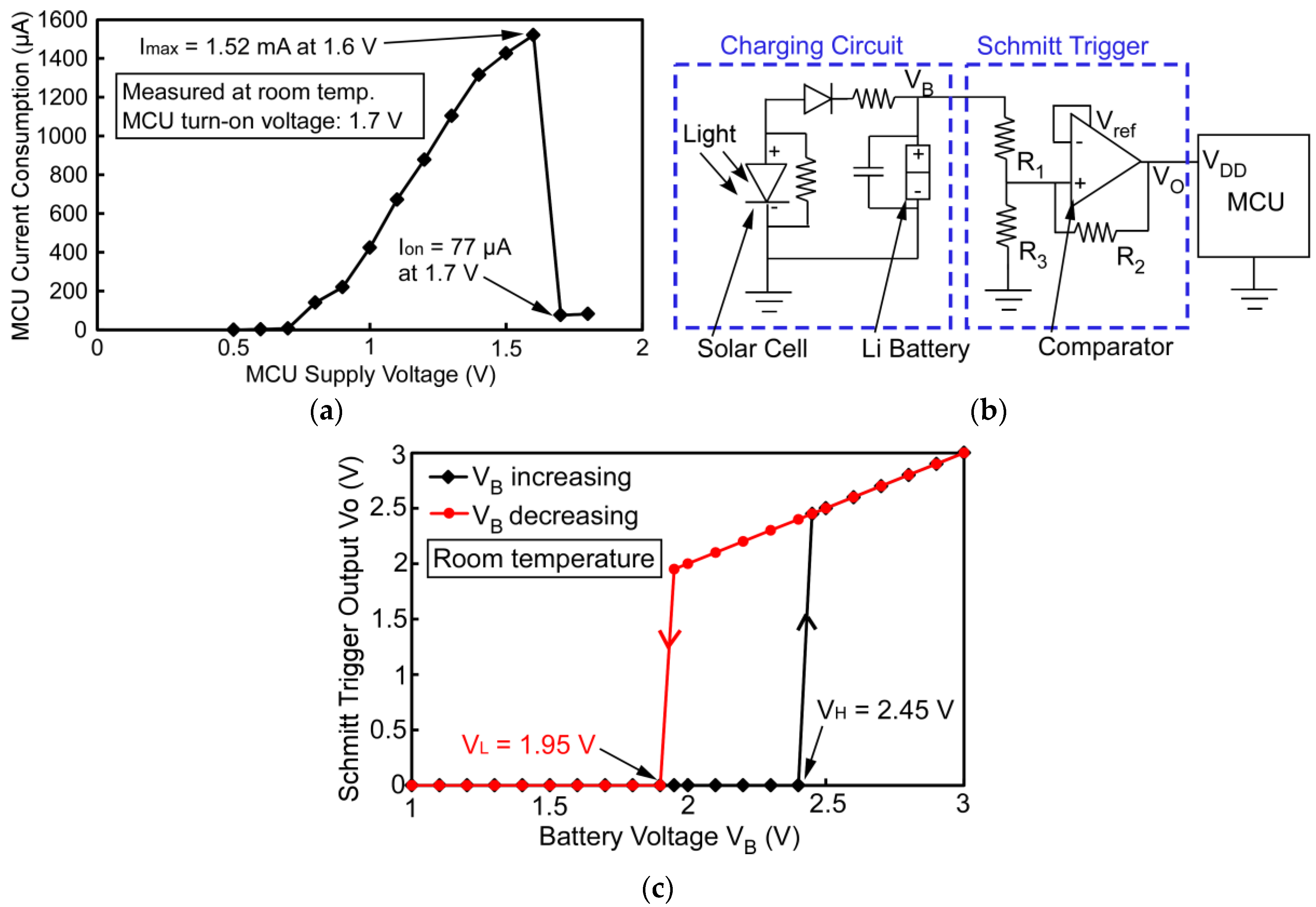

2.1. M3HT

2.2. ELM

3. System Encapsulation

4. Test Results

5. Discussion and Conclusions

Acknowledgments

Conflicts of Interest

References

- Timur, A. Downhole Geophysical Logging. Annu. Rev. Earth Planet. Sci. 1985, 13, 315–344. [Google Scholar] [CrossRef]

- Chapman, D.; Trybula, W. Meeting the Challenges of Oilfield Exploration using Intelligent Micro and Nano-Scale Sensors. In Proceedings of the 2012 12th IEEE Conference on Nanotechnology (IEEE-NANO), Birmingham, UK, 20–23 August 2012. [Google Scholar]

- Ellis, D.V.; Singer, J.M. Well Logging for Earth Scientists; Springer: Dordrecht, The Netherlands, 2007; pp. 1–39. [Google Scholar]

- Etnyre, L.M. Finding Oil and Gas from Well Logs; Springer: New York, NY, USA, 1989; pp. 1–20. [Google Scholar]

- Schlumberger, Crosswell Electromagnetic Resistivity Imaging: Illuminating the Reservoir. Middle East Asia Reserv. Rev. 2006, 7, 24–33.

- Ma, Y.; Sui, Y.; Li, T.; Gianchandani, Y.B. A Submillimeter Package for Microsystems in High-pressure and High-salinity Downhole Environment. J. Microelectromech. Syst. 2015, 24, 861–869. [Google Scholar] [CrossRef]

- Cressler, J.D.; Mantooth, H.A. Extreme Environmental Electronics; CRC Press: Boca Raton, FL, USA, 2012; pp. 319–329. [Google Scholar]

- McCluskey, F.P.; Podlesak, T.; Grzybowski, R. High Temperature Electronics; CRC Press: Boca Raton, FL, USA, 1996; pp. 1–52. [Google Scholar]

- Wolpert, D.; Ampadu, P. Managing Temperature Effects in Nanoscale Adaptive Systems; Springer: New York, NY, USA, 2012; pp. 15–34. [Google Scholar]

- Shoucair, F.S. Scaling, Subthreshold, and Leakage Current Matching Characteristics in High-Temperature (25 °C–250 °C) VLSI CMOS Devices. IEEE Trans. Compon. Hybrids Manuf. Technol. 1989, 12, 780–788. [Google Scholar] [CrossRef]

- Sze, S.M. VLSI Technology; McGraw Hill Science/Engineering/Math: New York, NY, USA, 1988; pp. 612–655. [Google Scholar]

- Hensley, D.; Milewits, M.; Zhang, W. The Evolution of Oil Field Batteries. Oil Field Rev. 1998, 10, 42–57. [Google Scholar]

- Caja, J.; Dunstan, T.; Caja, M. Rechargeable, Lithium-Ion Molten Salt Battery for High Temperature Applications. ECS Trans. 2012, 50, 3–11. [Google Scholar] [CrossRef]

- Muñoz-Rojas, D.; Leriche, J.; Delacourt, C.; Poizot, P.; Palacín, M.; Tarascon, J. Development and Implementation of a High Temperature Electrochemical Cell for Lithium Batteries. Electrochem. Commun. 2007, 9, 708–712. [Google Scholar] [CrossRef]

- Seiko Instrument Inc. Micro Battery Product Catalogue, 2014–2015. Available online: http://www.sii.co.jp/en/me/files/2014/11/BAC3011EJ-01C1409_web__.pdf (accessed on 12 August 2017).

- Cymbet Corporation. Rechargeable Solid State Bare Die Batteries Datasheet, 2014. Available online: http://www.cymbet.com/pdfs/DS-72-41.pdf (accessed on 12 August 2017).

- Openfield Technology. Micro Pressure and Temperature Digital Sensor for OEM Integration Product Specification, 2011–2013. Available online: http://openfield-technology.com/wp-content/uploads/2012/04/OpenFieldBrochure_OEM_recorderLight.pdf (accessed on 12 August 2017).

- Yu, M.; He, S.; Chen, Y.; Takach, N.; LoPresti, P.; Zhou, S.; Al-Khanferi, N. A Distributed Microchip System for Subsurface Measurement. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar]

- Shi, Z.; Chen, Y.; Yu, M.; Zhou, S.; Al-Khanferi, N.M. Development and Field Evaluation of a Distributed Microchip Downhole Measurement System. In Proceedings of the SPE Digital Energy Conference and Exhibition, Woodlands, TX, USA, 3–5 March 2015. [Google Scholar]

- Chen, G.; Ghaed, H.; Haque, R.; Wieckowski, M.; Kim, Y.; Kim, G.; Fick, D.; Kim, D.; Seok, M.; Wise, K.; et al. A Cubic-millimeter Energy-autonomous Wireless Intraocular Pressure Monitor. In Proceedings of the IEEE International Solid-State Circuits Conference (ISSCC ’11), San Francisco, CA, USA, 20–24 February 2011. [Google Scholar]

- Pierret, R.F. Semiconductor Device Fundamentals; Pearson Education: Boston, MA, USA, 1996; pp. 270–282. [Google Scholar]

- Clarke, E.E.; Trofimenkoff, F.N.; Haslett, J.W. High-Temperature Silicon Diode Models. Solid-State Electron. 1992, 35, 103–111. [Google Scholar] [CrossRef]

- Roy, K.; Mukhopadhyay, S.; Mahmoodi-Meimand, H. Leakage Current Mechanisms and Leakage Reduction Techniques in Deep-Submicrometer CMOS Circuits. Proc. IEEE 2003, 91, 305–327. [Google Scholar] [CrossRef]

- Choi, M.; Lee, I.; Jang, T.K.; Blaauw, D.; Sylvester, D. A 23 pW, 780 ppm/°C Resistor-less Current Reference Using Subthreshold MOSFETs. In Proceedings of the 40th European Solid State Circuits Conference (ESSCIRC 2014), Venice Lido, Italy, 22–26 September 2014. [Google Scholar]

- Yang, K.; Dong, Q.; Jung, W.; Zhang, Y.; Choi, M.; Blaauw, D.; Sylvester, D. 9.2 A 0.6 nJ −0.22/+0.19 °C inaccuracy temperature sensor using exponential subthreshold oscillation dependence. In Proceedings of the 2017 IEEE International Solid-State Circuits Conference (ISSCC 2017), San Francisco, CA, USA, 5–9 February 2017; pp. 160–162. [Google Scholar]

- Silicon Laboratories. C8051F99x-C8051F98x Datasheet, 2011. Available online: https://www.silabs.com/documents/public/data-sheets/C8051F99x.pdf (accessed on 12 August 2017).

- IXYS Corporation. CPC1822 4V Output Solar Cell Datasheet, 2012. Available online: https://www.sparkfun.com/datasheets/Prototyping/Solar/CPC1822-1.pdf (accessed on 12 August 2017).

- Smith, M.J.S. On the Circuit Analysis of Schmitt Trigger. IEEE J. Solid-State Circuits 1988, 23, 292–294. [Google Scholar] [CrossRef]

- Yang, L.; Bernstein, J.B. Encapsulation Process Development for Flexible-circuit Based Chip Scale Packages. IEEE Trans. Electron. Packag. Manuf. 2002, 25, 344–354. [Google Scholar] [CrossRef]

- Yang, J. A Harsh Environment Wireless Pressure Sensing Solution Utilizing High Temperature Electronics. Sensors 2013, 13, 2719–2734. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Bates, J.B.; Jellison, G.E., Jr.; Hart, F.X. A Stable Thin-Film Lithium Electrolyte: Lithium Phosphorus Oxynitride. J. Electrochem. Soc. 1997, 144, 524–532. [Google Scholar] [CrossRef]

- Tadiran Batteries. Model TLH2450 Datasheet, 2011. Available online: http://www.tadiranbat.com/assets/tlh-2450.pdf (accessed on 12 August 2017).

| Parameter | M3HT System | ELM System |

|---|---|---|

| Stack size (L × W × H) | 2.9 × 1.1 × 1.5 mm3 | 6.5 × 6.3 × 4.5 mm3 |

| Package size (L × W × H) | 4.2 × 2.2 × 2.8 mm3 | 8.9 × 8.9 × 6.85 mm3 |

| Integration method | Wire bonded stack | Flexible PCB |

| Packaging materials | SS shell filled with epoxy | SS shell with sapphire lid |

| Nominal operating voltage | 4.1 V (converted to 1.2 V/0.6 V) | 3.0 V |

| Power consumpt. (sleep, 125 °C) | 2.7 µW | 30 µW |

| Operating frequency | 0.2 Hz sleep/740 kHz active | 32.768 kHz sleep/active |

| Wireless comm. method | RF 900 MHz/Optical | Optical |

| Battery type: rechargeable Li | Thin film, custom | Coin cell, commercial |

| Battery size | 1.7 × 1.1 × 0.15 mm3 each, ×2 | Φ4.8 mm × 1.2 mm |

| Battery capacity | 2 µAh each, ×2 | 1 mAh |

| Optical recharging | Yes | Yes |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, M.; Sui, Y.; Lee, I.H.; Meredith, R.; Ma, Y.; Kim, G.; Blaauw, D.; Gianchandani, Y.B.; Li, T. Autonomous Microsystems for Downhole Applications: Design Challenges, Current State, and Initial Test Results. Sensors 2017, 17, 2190. https://doi.org/10.3390/s17102190

Choi M, Sui Y, Lee IH, Meredith R, Ma Y, Kim G, Blaauw D, Gianchandani YB, Li T. Autonomous Microsystems for Downhole Applications: Design Challenges, Current State, and Initial Test Results. Sensors. 2017; 17(10):2190. https://doi.org/10.3390/s17102190

Chicago/Turabian StyleChoi, Myungjoon, Yu Sui, In Hee Lee, Ryan Meredith, Yushu Ma, Gyouho Kim, David Blaauw, Yogesh B. Gianchandani, and Tao Li. 2017. "Autonomous Microsystems for Downhole Applications: Design Challenges, Current State, and Initial Test Results" Sensors 17, no. 10: 2190. https://doi.org/10.3390/s17102190