Research Progress on F-P Interference—Based Fiber-Optic Sensors

Abstract

:1. Introduction

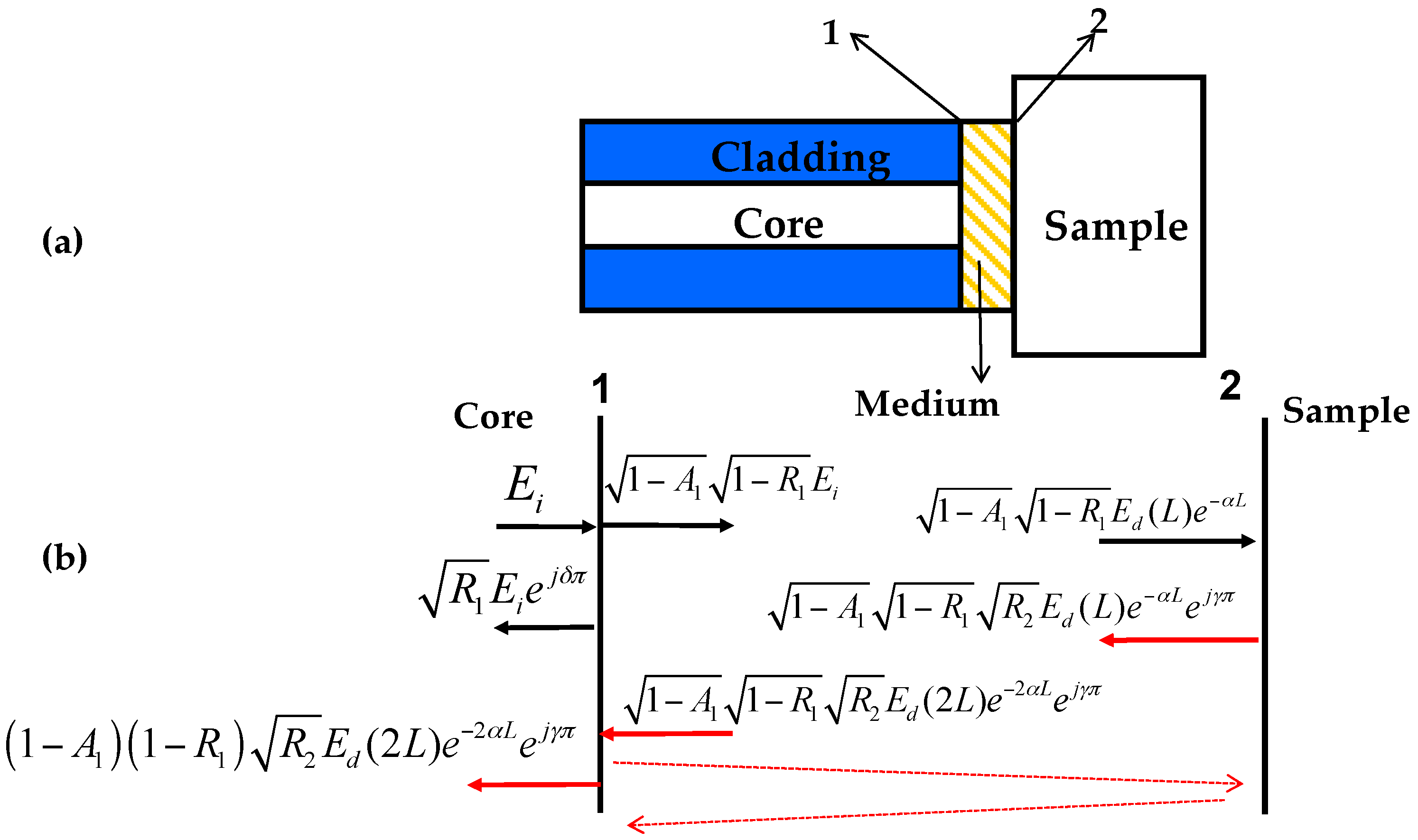

2. The Basic Principle of Operation

2.1. The Principle

2.2. Experimental Setup

3. Experiment Results and Discussions of Various Sensing Applications

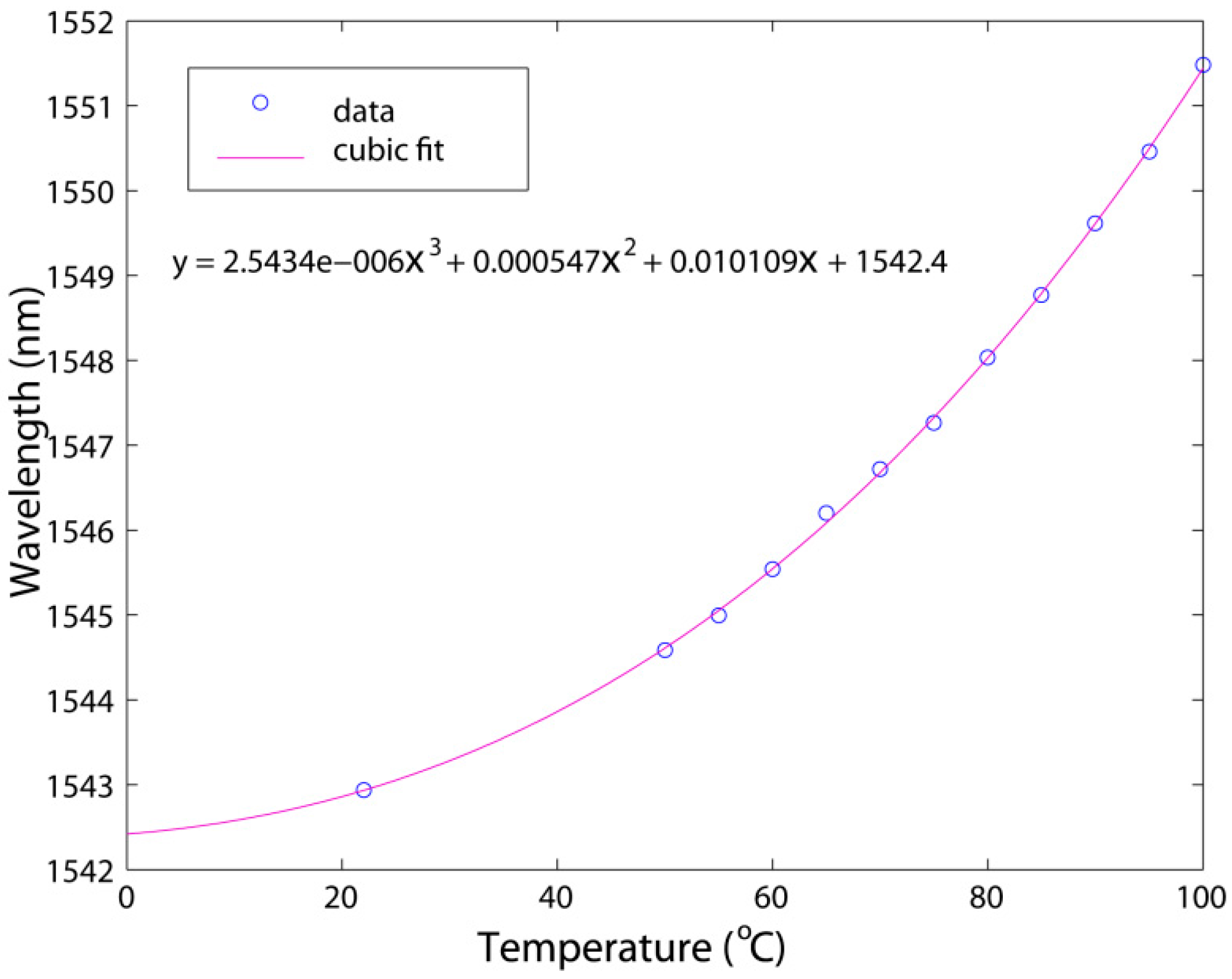

3.1. Simple Fiber-Optic Temperature Sensor Based on Wavelength Interrogation [48]

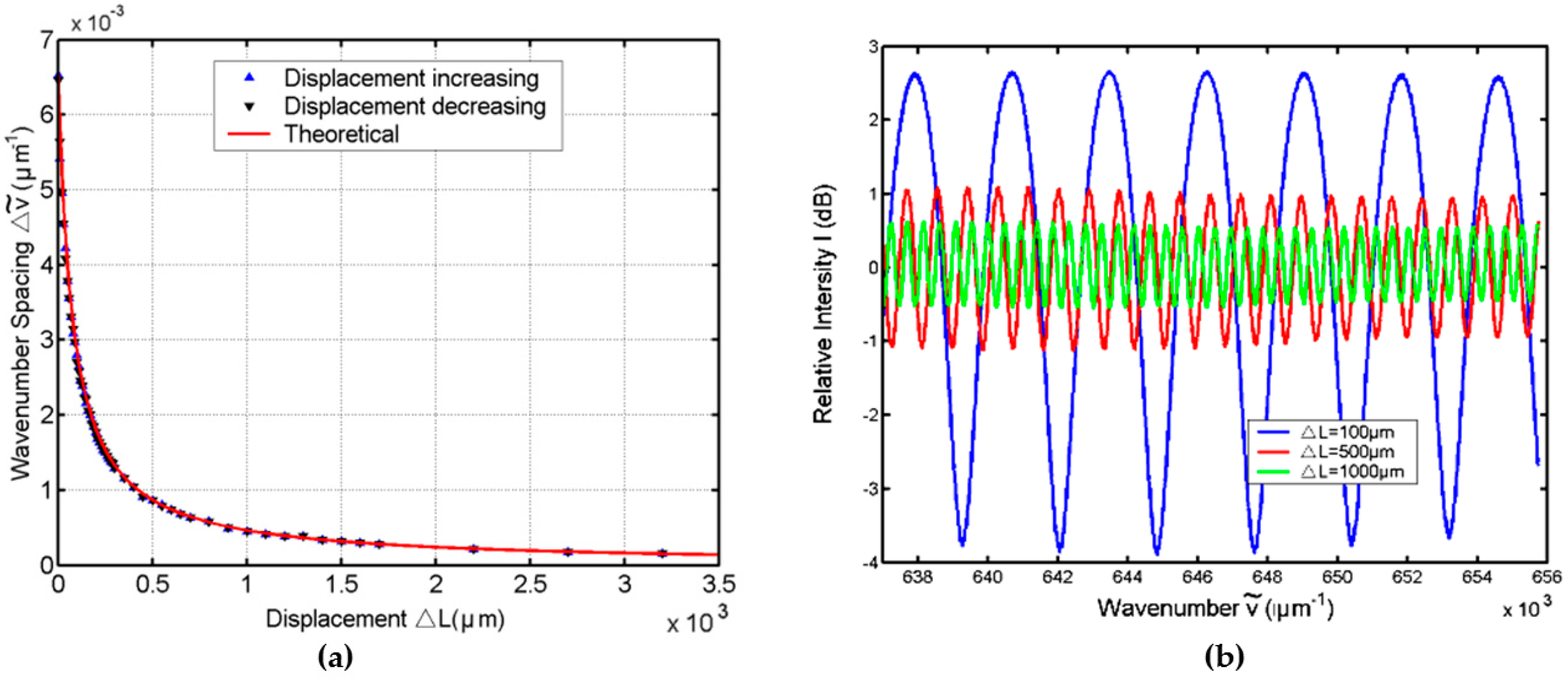

3.2. Fiber-Optic Sensors for Small Displacement Measurement [50]

3.3. Temperature-Insensitive Sensor for RI Measurement of Liquid [51]

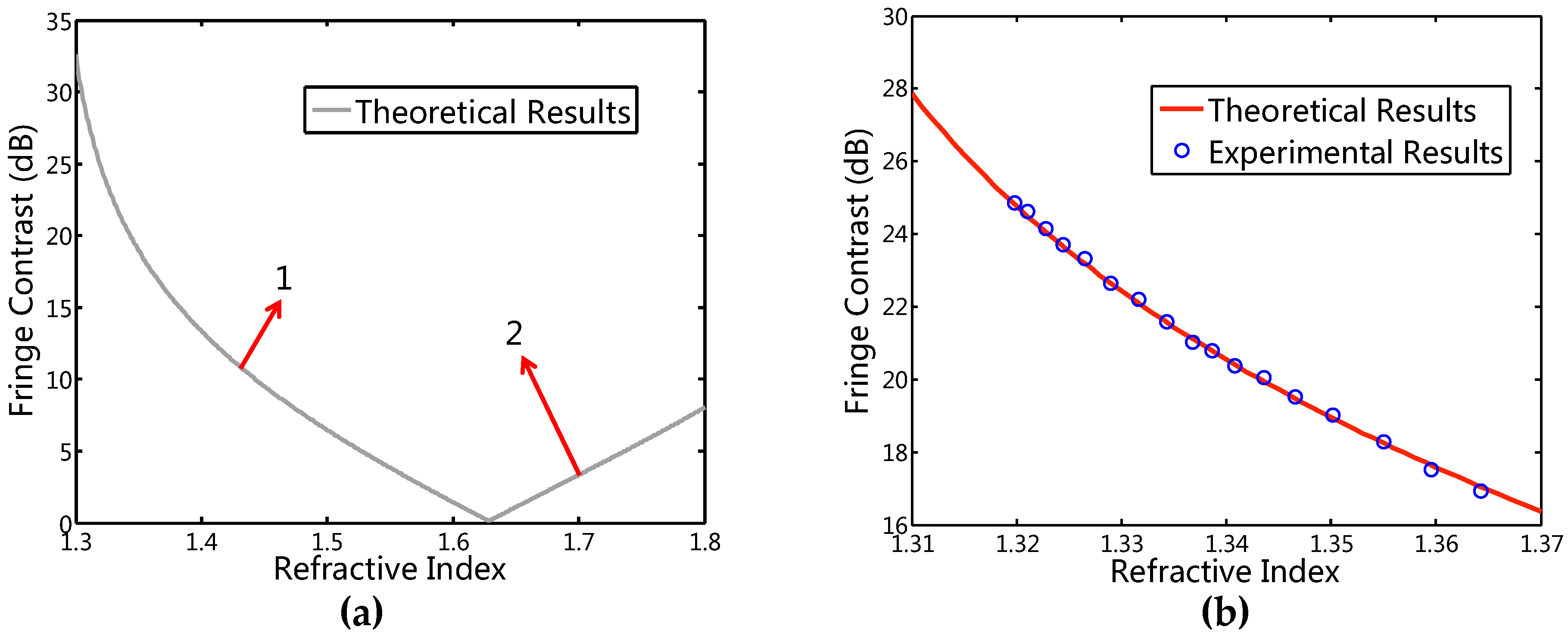

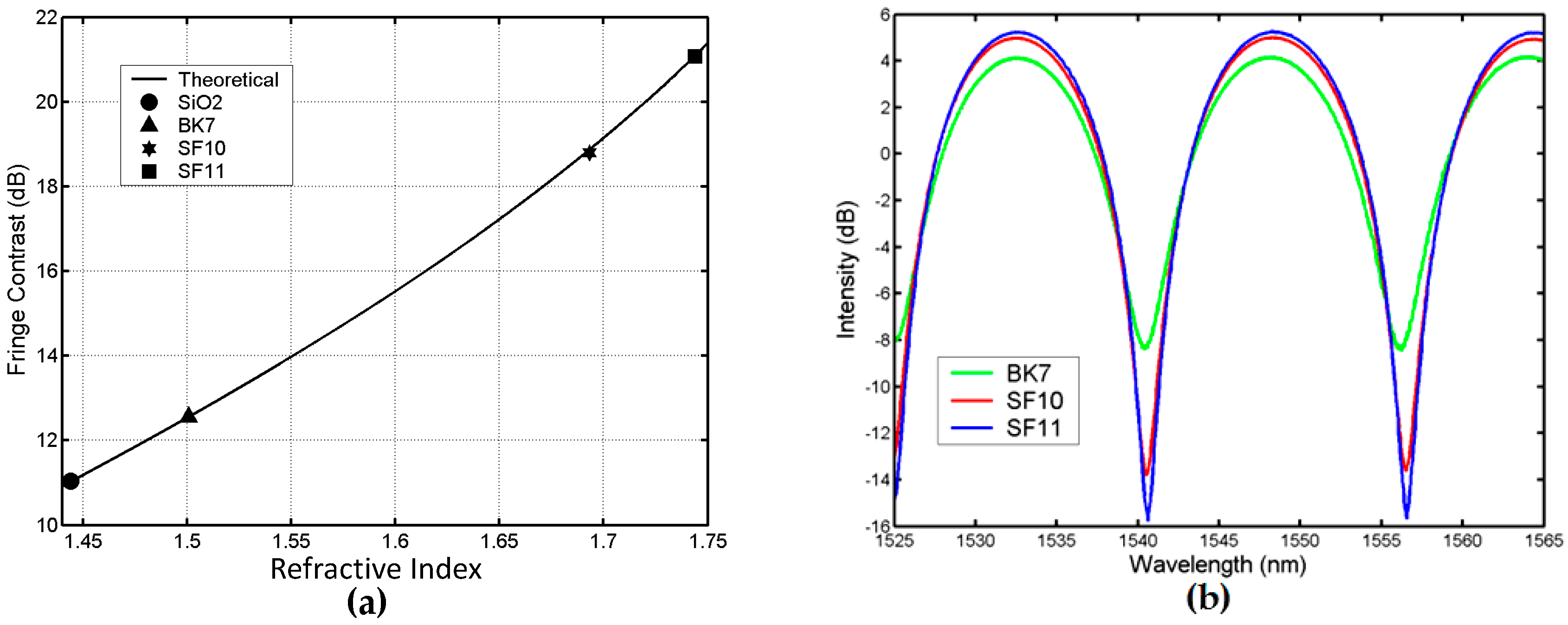

3.4. Fiber Optic F-P Interferometric Sensor for RI Measurement of Solid [52]

4. Conclusions and Outlook

Acknowledgments

Conflicts of Interest

References

- Islam, M.R.; Ali, M.M.; Lai, M.H.; Lim, K.S.; Ahmad, H. Chronology of fabry-perot interferometer fiber-optic sensors and their applications: A review. Sensors 2014, 14, 7451–7488. [Google Scholar] [CrossRef] [PubMed]

- Majchrowicz, D.; Hirsch, M.; Wierzba, P.; Bechelany, M.; Viter, R.; Jedrzejewska-Szczerska, M. Application of Thin ZnO ALD Layers in Fiber-Optic Fabry-Pérot Sensing Interferometers. Sensors 2016, 16, 416. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, V.; Murphy, K.A.; Claus, R.O.; Jones, M.E.; Grace, J.L.; Tran, T.L.; Greene, J.A. Optical fibre based absolute extrinsic Fabry-Perot interferometric sensing system. Meas. Sci. Technol. 1996, 7, 58–61. [Google Scholar] [CrossRef]

- Chen, P.; Chen, C.C.; Tsai, C.C.; Lu, W.F. A time-to-digital-converter-based CMOS smart temperature sensor. IEEE J. Solid-St. Circ. 2005, 40, 1642–1648. [Google Scholar] [CrossRef]

- Yang, J. A silicon carbide wireless temperature sensing system for high temperature applications. Sensors 2013, 13, 1884–1901. [Google Scholar] [CrossRef] [PubMed]

- Guzmán-Sepúlveda, J.R.; Guzmán-Cabrera, R.; Torres-Cisneros, M.; Sánchez-Mondragón, J.J.; May-Arrioja, D.A. A Highly Sensitive Fiber Optic Sensor Based on Two-Core Fiber for Refractive Index Measurement. Sensors 2013, 13, 14200–14213. [Google Scholar] [CrossRef] [PubMed]

- Monzón-Hernández, D.; Villatoro, J. High-resolution refractive index sensing by means of a multiple-peak surface plasmon resonance optical fiber sensor. Sens. Actuators B Chem. 2006, 115, 227–231. [Google Scholar] [CrossRef]

- Koronkevitch, V.P.; Lenkova, G.A.; Tsherbatchenko, A.M.; Lokhmatov, A.L.; Kiryanov, V.P.; Matienko, B.G.; Golubkova, V.P. Laser interferometers for measuring displacements and determining object positions. Appl. Opt. 1972, 11, 359–361. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.F.; Chiu, M.H.; Chen, W.W.; Kao, F.H.; Chang, R.S. Small-displacement sensing system based on multiple total internal reflections in heterodyne interferometry. Appl. Opt. 2009, 48, 2566–2573. [Google Scholar] [CrossRef] [PubMed]

- Su, S.F. Moire fringe multiplication technique for measuring small displacements. Appl. Opt. 1983, 22, 2949–2950. [Google Scholar] [CrossRef] [PubMed]

- Balling, P.; Křen, P.; Mašika, P.; van den Berg, S.A. Femtosecond frequency comb based distance measurement in air. Opt. Express 2009, 17, 9300–9313. [Google Scholar] [CrossRef] [PubMed]

- Carlsson, T.E.; Gustafsson, J.; Abramson, N.H. Method for fringe enhancement in holographic interferometry for measurement of in-plane displacements. Appl. Opt. 1998, 37, 1845–1848. [Google Scholar] [CrossRef] [PubMed]

- Mehta, A.; Mohammed, W.; Johnson, E.G. Multimode interference-based fiber-optic displacement sensor. IEEE Photonics Technol. Lett. 2003, 15, 1129–1131. [Google Scholar] [CrossRef]

- Choi, H.Y.; Park, K.S.; Park, S.J.; Paek, U.C.; Lee, B.H.; Choi, E.S. Miniature fiber-optic high temperature sensor based on a hybrid structured Fabry-Perot interferometer. Opt. Lett. 2008, 33, 2455–2457. [Google Scholar] [CrossRef] [PubMed]

- Scarcia, W.; Palma, G.; Falconi, M.C.; Leonardis, F.D.; Passaro, V.M.N.; Prudenzano, F. Electromagnetic Modelling of Fiber Sensors for Low-Cost and High Sensitivity Temperature Monitoring. Sensors 2015, 15, 29855–29870. [Google Scholar] [CrossRef] [PubMed]

- Mathew, J.; Schneller, O.; Polyzos, D.; Havermann, D.; Caryer, R.M.; MacPherson, W.N.; Hand, D.P.; Maier, R.R.J. In-Fiber Fabry-Perot Cavity Sensor for High-Temperature Applications. J. Light. Technol. 2015, 33, 2419–2425. [Google Scholar] [CrossRef]

- Ran, Z.L.; Rao, Y.J.; Liu, W.J.; Liao, X.; Chiang, K.S. Laser-micromachined Fabry-Perot optical fiber tip sensor for high-resolution temperature-independent measurement of refractive index. Opt. Express 2008, 16, 2252–2263. [Google Scholar] [CrossRef]

- Jáuregui-Vázquez, D.; Estudillo-Ayala, J.M.; Rojas-Laguna, R.; Vargas-Rodriguez, E.; Sierra-Hernández, J.M.; Hernández-García, J.C.; Mata-Chávez, R.I. An all fiber intrinsic Fabry-Perot interferometer based on an air-microcavity. Sensors 2013, 13, 6355–6364. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Qiao, X.; Guo, T.; Wang, R.H.; Zhang, J.; Weng, Y.Y.; Rong, Q.Z.; Hu, M.L.; Feng, Z.Y. Temperature-independent refractive index measurement based on Fabry-Perot fiber tip sensor modulated by Fresnel reflection. Chin. Opt. Lett. 2012, 10, 050603. [Google Scholar] [CrossRef]

- Hirai, A.; Matsumoto, H. Low-coherence tandem interferometer for measurement of group refractive index without knowledge of the thickness of the test sample. Opt. Lett. 2003, 28, 2112–2114. [Google Scholar] [CrossRef]

- Yeh, Y.L. Simultaneous measurement of refractive index and thickness of birefringent wave plates. Appl. Opt. 2008, 47, 1457–1464. [Google Scholar] [CrossRef] [PubMed]

- Santić, B.; Gracin, D.; Juraić, K. Measurement method for the refractive index of thick solid and liquid layers. Appl. Opt. 2009, 48, 4430–4436. [Google Scholar]

- Santić, B. Measurement of the refractive index and thickness of a transparent film from the shift of the interference pattern due to the sample rotation. Thin Sol. Films 2010, 518, 3619–3624. [Google Scholar] [CrossRef]

- Hori, Y.; Hirai, A.; Minoshima, K.; Matsumoto, H. High-accuracy interferometer with a prism pair for measurement of the absolute refractive index of glass. Appl. Opt. 2009, 48, 2045–2050. [Google Scholar] [CrossRef]

- Liu, T.; Fernando, G.F. A frequency division multiplexed low-finesse fiber optic Fabry–Perot sensor system for strain and displacement measurements. Rev. Sci. Instrum. 2000, 71, 1275–1278. [Google Scholar] [CrossRef]

- Lawall, J.R. Fabry-Perot metrology for displacements up to 50 mm. JOSA A 2005, 12, 2786–2798. [Google Scholar] [CrossRef]

- Bitou, Y. High-accuracy displacement metrology and control using a dual Fabry-Perot cavity with an optical frequency comb generator. Precis. Eng. 2009, 33, 187–193. [Google Scholar] [CrossRef]

- Oh, K.D.; Ranade, J.; Arya, V.; Wang, A.; Claus, R.O. Optical Fiber Fabry-Perot Interferometric Sensor for Magnetic Field Measurement. IEEE Photon. Technol. Lett. 1997, 9, 797–799. [Google Scholar]

- Oh, K.D.; Wang, A.; Claus, R.O. Fiber-optic extrinsic Fabry-Perot dc magnetic field sensor. Opt. Lett. 2004, 29, 2115–2117. [Google Scholar] [CrossRef] [PubMed]

- Lv, R.; Zhao, Y.; Wang, D.; Wang, Q. Magnetic fluid-filled optical fiber Fabry-Perot sensor for magnetic field measurement. IEEE Photon. Technol. Lett. 2014, 26, 217–219. [Google Scholar] [CrossRef]

- Zhao, Y.; Lv, R.-Q.; Ying, Y.; Wang, Q. Hollow-core photonic crystal fiber Fabry-Perot sensor for magnetic field measurement based on magnetic fluid. Opt. Laser Technol. 2012, 44, 899–902. [Google Scholar] [CrossRef]

- Jin, X.; Huang, X.; Chen, L. An extrinsic fabry-perot optical fiber sensor based on nano-magnetic fluid. Fiber Integr. Opt. 2013, 32, 233–241. [Google Scholar] [CrossRef]

- Jiang, M.; Gerhard, E. A simple strain sensor using a thin film as a low-finesse fiber-optic Fabry-Perot interferometer. Sens. Actuators A Phys. 2001, 88, 41–46. [Google Scholar] [CrossRef]

- Murphy, K.A.; Gunther, M.F.; Vengsarkar, A.M.; Claus, R.O. Quadrature phase-shifted, extrinsic Fabry-Perot optical fiber sensors. Opt. Lett. 1991, 16, 273–275. [Google Scholar] [CrossRef] [PubMed]

- Quirion, M.; Ballivy, G. Concrete strain monitoring with Fabry-Perot fibre-optic sensor. J. Mater. Civil. Eng. 2000, 12, 254–261. [Google Scholar] [CrossRef]

- Reich, S.M. Fiber Optic Fabry-Perot Sensor for Measuring Absolute Strain. U.S. Patent 6173091, 9 January 2001. [Google Scholar]

- Zhang, Q.; Zhu, T.; Hou, Y.; Chiang, K.S. All-fiber vibration sensor based on a Fabry-Perot interferometer and a microstructure beam. JOSA B 2013, 30, 1211–1215. [Google Scholar] [CrossRef]

- Gangopadhyay, T.K.; Chakravorti, S.; Chatterjee, S.; Bhattacharya, K. Time-frequency analysis of multiple fringe and nonsinusoidal signals obtained from a fiber-optic vibration sensor using an extrinsic Fabry-Perot interferometer. J. Light. Technol. 2006, 24, 2122. [Google Scholar] [CrossRef]

- Arregui, F.J.; Liu, Y.; Matias, I.R.; Claus, R.O. Optical fiber humidity sensor using a nano Fabry-Perot cavity formed by the ionic self-assembly method. Sens. Actuator B Chem. 1999, 59, 54–59. [Google Scholar] [CrossRef]

- Chen, L.H.; Li, T.; Chan, C.C.; Menon, R.; Balamurali, P.; Shaillender, M.; Neu, B.; Ang, X.M.; Zu, P.; Wong, W.C.; et al. Chitosan based fiber-optic Fabry-Perot humidity sensor. Sens. Actuators B Chem. 2012, 169, 167–172. [Google Scholar] [CrossRef]

- Xu, W.; Huang, W.B.; Huang, X.G.; Yu, C.Y. A simple fiber-optic humidity sensor based on extrinsic Fabry-Perot cavity constructed by cellulose acetate butyrate film. Opt. Fiber Technol. 2013, 19, 583–586. [Google Scholar] [CrossRef]

- Xia, J.; Wang, Q.; Liu, X.; Luo, H. Fiber Optic Fabry-Perot Current Sensor Integrated with Magnetic Fluid Using a Fiber Bragg Grating Demodulation. Sensors 2015, 15, 16632–16641. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Sun, Y.; Fan, X. Highly versatile fiber-based optical Fabry-Pé rot gas sensor. Opt. Express 2009, 17, 2731–2738. [Google Scholar] [CrossRef] [PubMed]

- Lai, C.W.; Lo, Y.L.; Yur, J.P.; Chuang, C.H. Application of fiber Bragg grating level sensor and Fabry-Perot pressure sensor to simultaneous measurement of liquid level and specific gravity. IEEE Sens. J. 2012, 12, 827–831. [Google Scholar] [CrossRef]

- Silva, S.; Coelho, L.; Frazão, O. An all-fiberFabry-Pé rot interferometer for pressure sensing in different gaseous environments. Measurement 2014, 47, 418–421. [Google Scholar] [CrossRef]

- Gander, M.J.; MacPherson, W.N.; Barton, J.S.; Reuben, R.L.; Jones, J.D.C.; Stevens, R.; Chana, K.S.; Anderson, S.J.; Jones, T.V. Embedded micromachined fiber-optic Fabry-Perot pressure sensors in aerodynamics applications. IEEE Sens. J. 2003, 3, 102–107. [Google Scholar] [CrossRef]

- Yu, Q.; Zhou, X. Pressure sensor based on the fiber optic extrinsic Fabry-Perot interferometer. Photon. Sens. 2011, 1, 72–83. [Google Scholar] [CrossRef]

- Chen, J.H.; Huang, X.G.; Huang, Z.J. Simple thin-film fiber optic temperature sensor based on Fabry-Perot interference. Opt. Eng. 2010, 49, 044402. [Google Scholar] [CrossRef]

- Erden, M.F.; Ozaktas, H.M. Accumulated Gouy phase shift in Gaussian beam propagation through first-order optical systems. JOSA A 1997, 14, 2190–2194. [Google Scholar] [CrossRef]

- Chen, J.H.; Huang, X.G.; Zhao, J.R.; Tao, J.; He, W.X.; Liu, S.H. Fabry-Perot interference-based fiber-optic sensor for small displacement measurement. Opt. Commun. 2010, 283, 3315–3319. [Google Scholar] [CrossRef]

- Zhao, J.R.; Huang, X.G.; He, W.X.; Chen, J.H. High-resolution and temperature-insensitive fiber optic refractive index sensor based on fresnel reflection modulated by Fabry-Perot interference. J. Lightwave Technol. 2010, 28, 2799–2803. [Google Scholar] [CrossRef]

- Chen, J.H.; Zhao, J.R.; Huang, X.G.; Huang, Z.J. Extrinsic fiber-optic Fabry-Perot interferometer sensor for refractive index measurement of optical glass. Appl. Opt. 2010, 49, 5592–5596. [Google Scholar] [CrossRef] [PubMed]

- Optical Glass-SCHOTT AG. Available online: http://www.schott.com/advanced_optics/english/abbe_datasheets/schott-datasheet-all-english.pdf (accessed on 7 August 2016).

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.W.; Tao, J.; Huang, X.G. Research Progress on F-P Interference—Based Fiber-Optic Sensors. Sensors 2016, 16, 1424. https://doi.org/10.3390/s16091424

Huang YW, Tao J, Huang XG. Research Progress on F-P Interference—Based Fiber-Optic Sensors. Sensors. 2016; 16(9):1424. https://doi.org/10.3390/s16091424

Chicago/Turabian StyleHuang, Yi Wen, Jin Tao, and Xu Guang Huang. 2016. "Research Progress on F-P Interference—Based Fiber-Optic Sensors" Sensors 16, no. 9: 1424. https://doi.org/10.3390/s16091424