A New Approach of Oil Spill Detection Using Time-Resolved LIF Combined with Parallel Factors Analysis for Laser Remote Sensing

Abstract

:1. Introduction

2. Apparatus and Methods

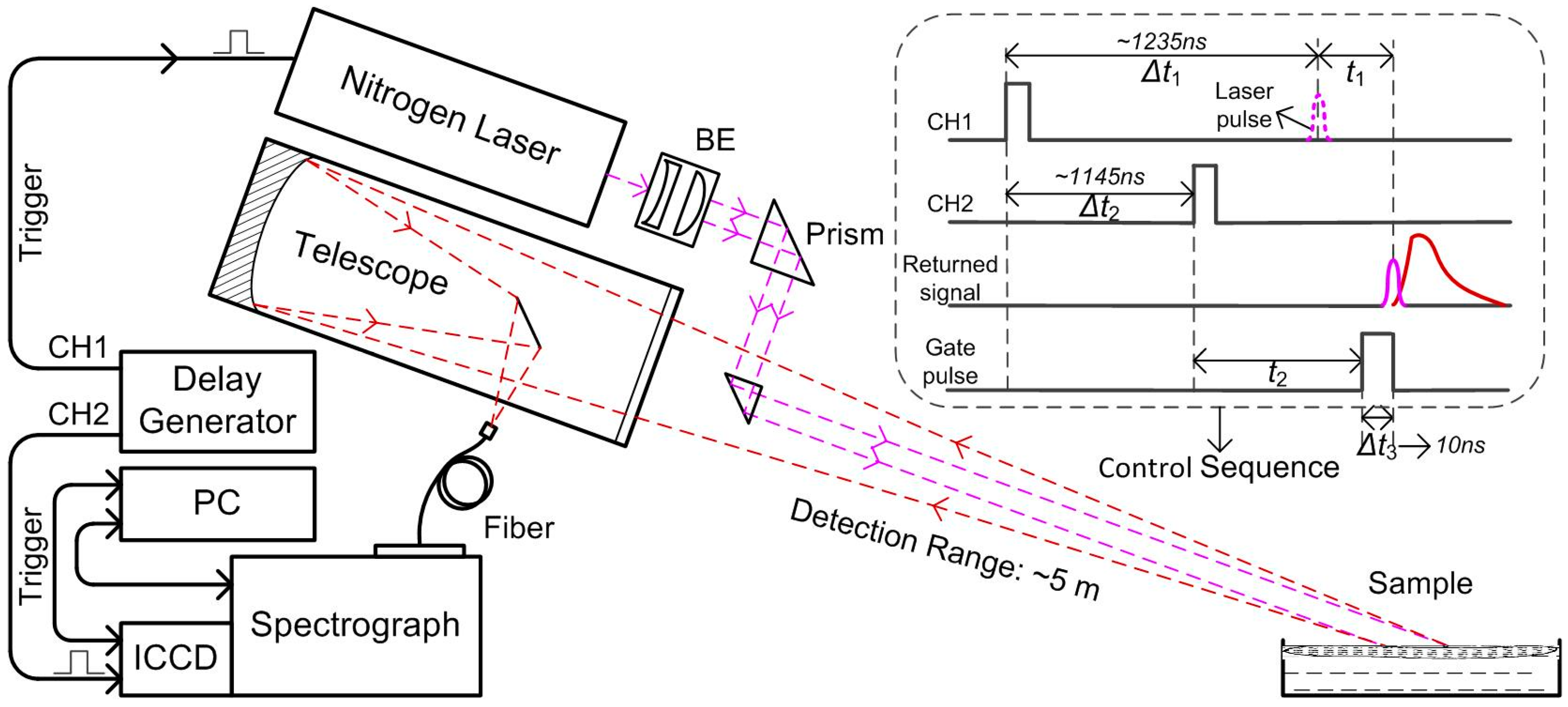

2.1. Time-Resolved Fluorescence Apparatus

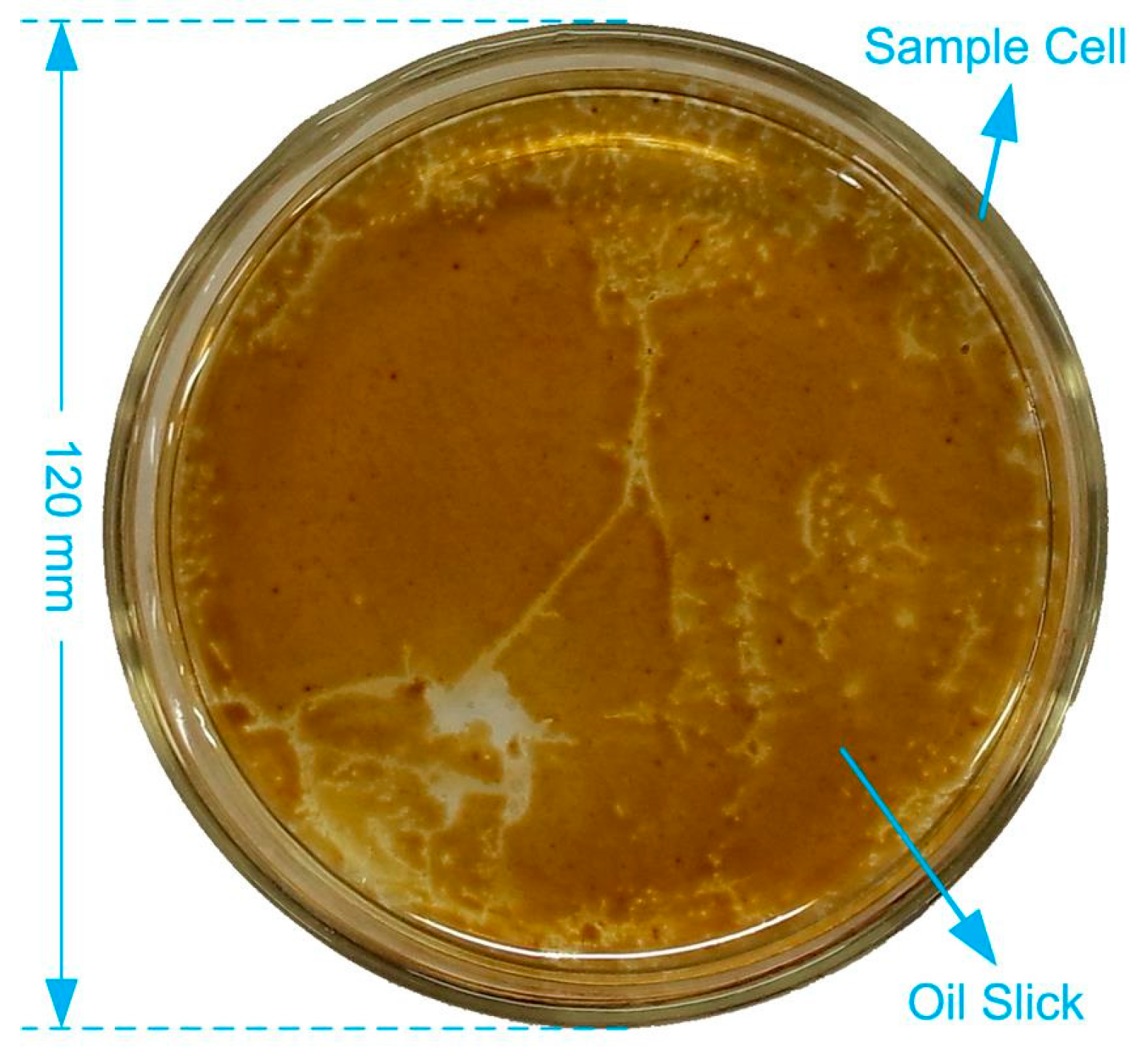

2.2. Sample Preparation

2.3. Multi-Way Model: PARAFAC

3. Results and Discussion

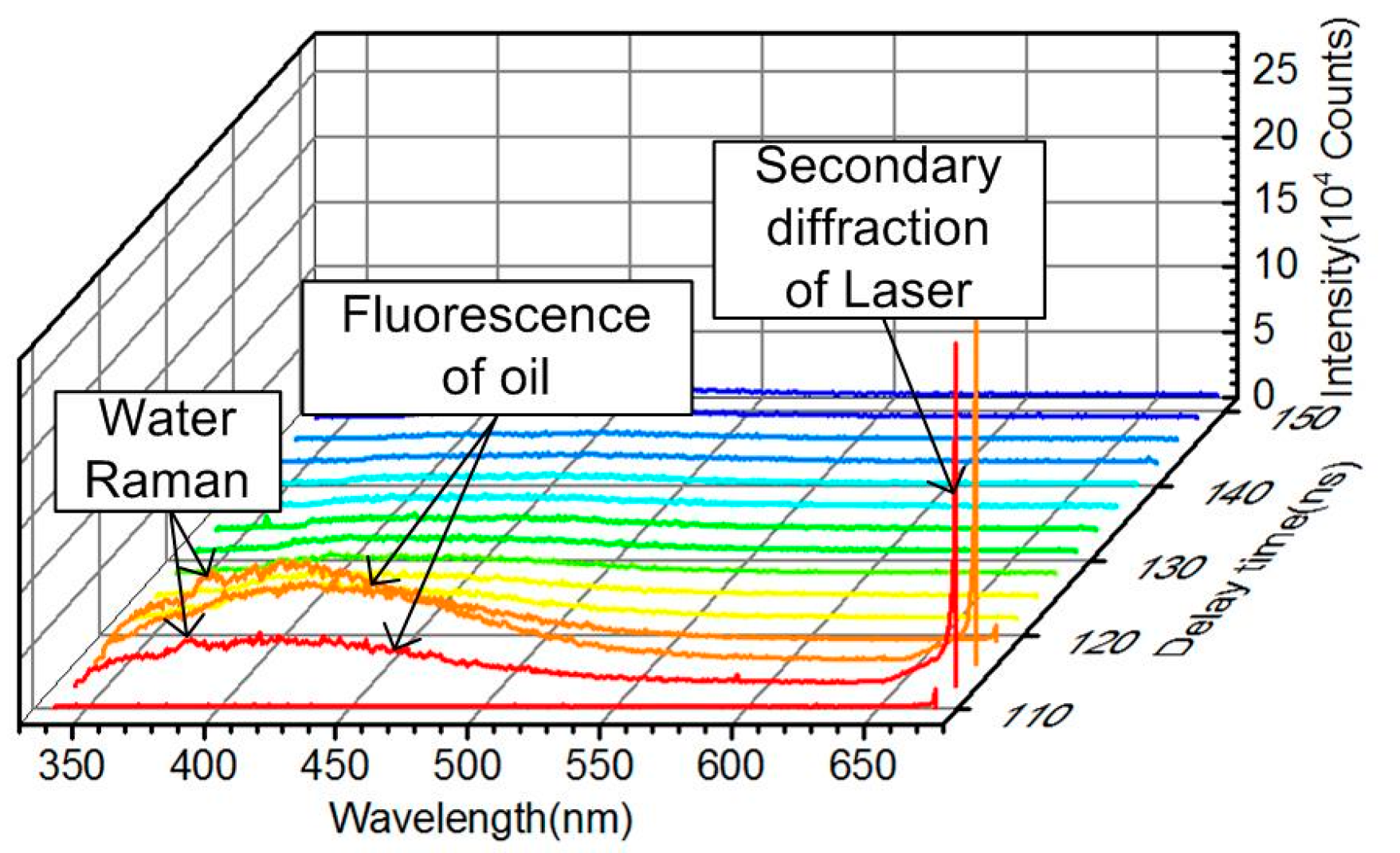

3.1. Time-Resolved Fluorescence Spectra of Oils

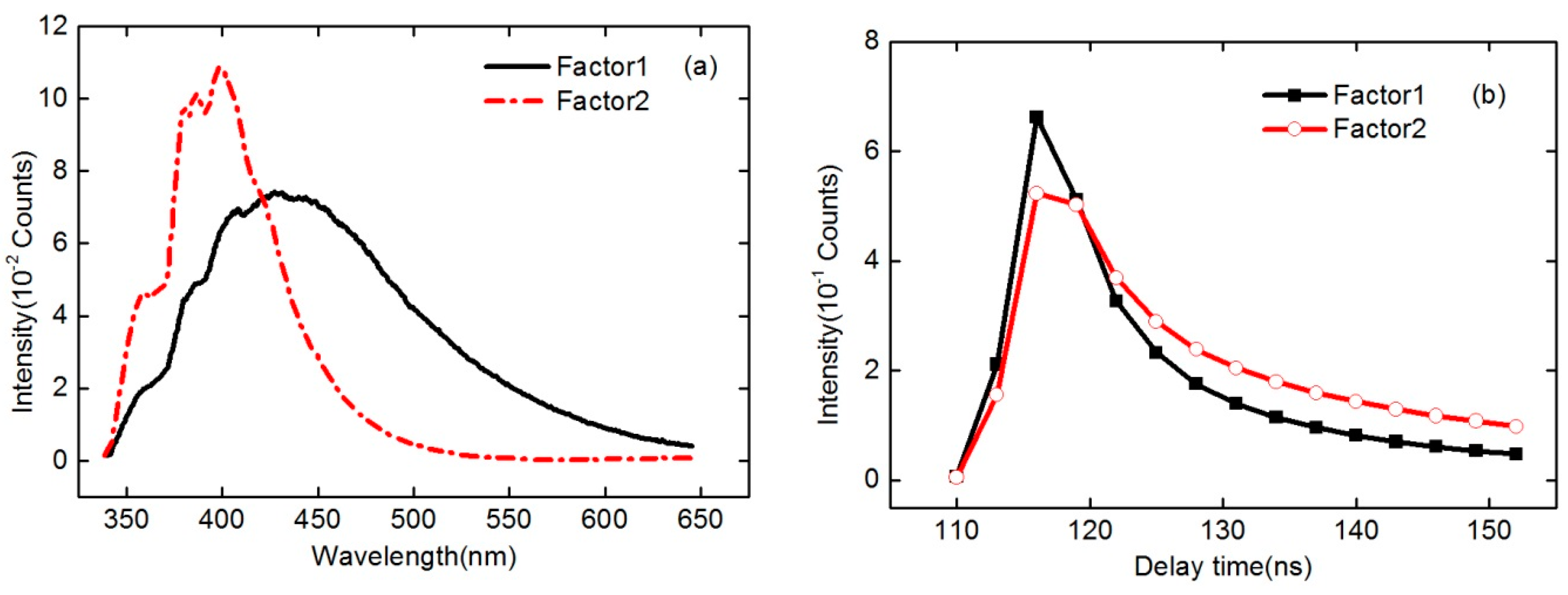

3.2. Oil Identification Using PARAFAC

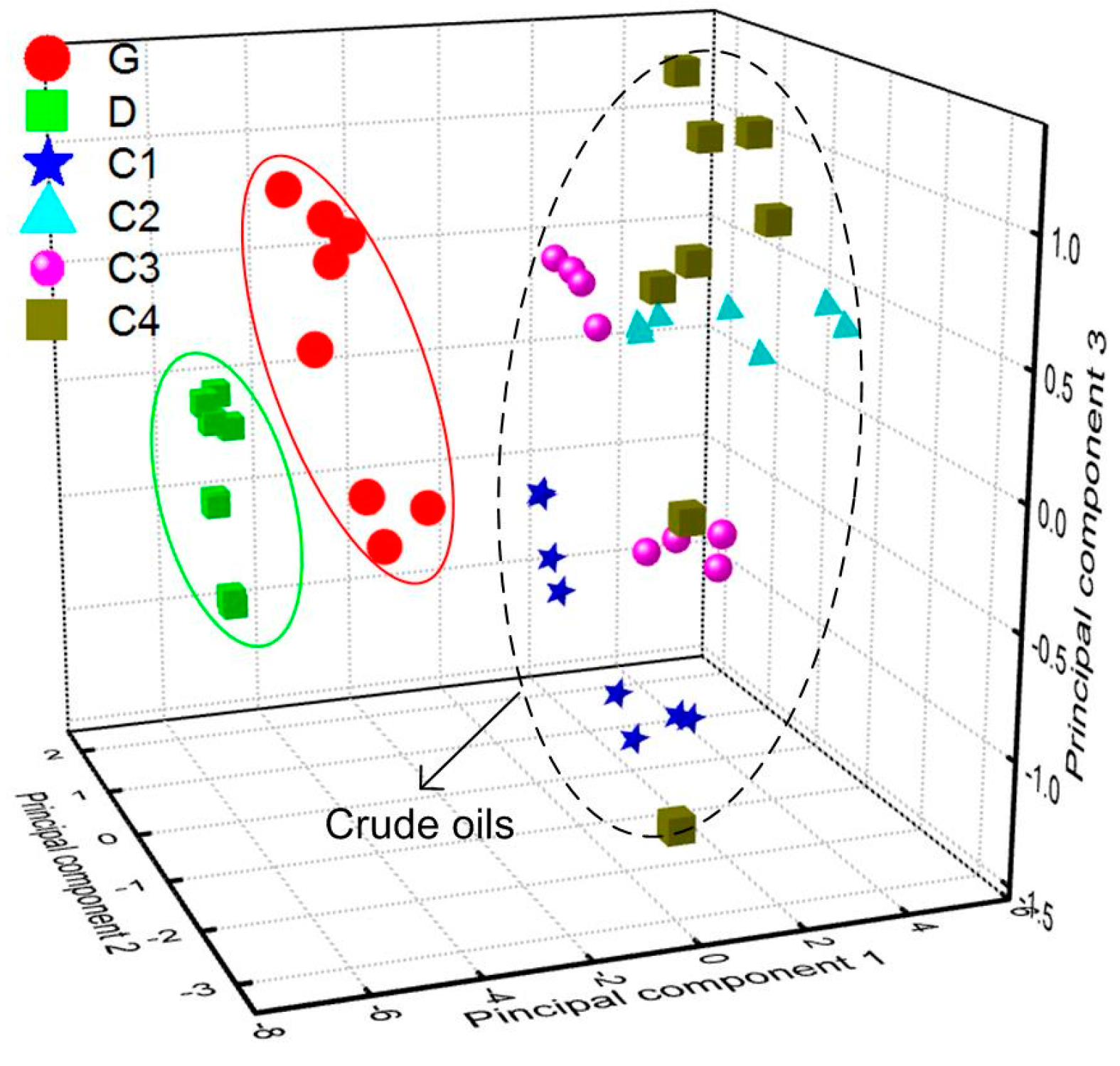

3.3. Comparative Analysis of PARAFAC and PCA

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Frank, U. A review of fluorescence spectroscopic methods for oil spill source identification. Toxicol. Environ. Chem. 1978, 2, 163–185. [Google Scholar] [CrossRef]

- Li, J.; Fuller, S.; Cattle, J.; Way, C.P.; Hibbert, D.B. Matching fluorescence spectra of oil spills with spectra from suspect sources. Anal. Chim. Acta 2004, 514, 51–56. [Google Scholar] [CrossRef]

- Wang, Z.; Fingas, M.; Page, D.S. Oil spill identification. J. Chromatogr. A 1999, 843, 369–411. [Google Scholar] [CrossRef]

- Fingas, M.; Brown, C. Review of oil spill remote sensing. Mar. Pollut. Bull. 2014, 83, 9–23. [Google Scholar] [CrossRef] [PubMed]

- Jha, M.N.; Levy, J.; Gao, Y. Advances in remote sensing for oil spill disaster management: State-of-the-art sensors technology for oil spill surveillance. Sensors 2008, 8, 236–255. [Google Scholar] [CrossRef]

- Leifer, I.; Lehr, W.J.; Simecek-Beatty, D.; Bradley, E.; Clark, R.; Dennison, P.; Hu, Y.; Matheson, S.; Jones, C.E.; Holt, B.; et al. State of the art satellite and airborne marine oil spill remote sensing: Application to the BP Deepwater Horizon oil spill. Remote Sens. Environ. 2012, 124, 185–209. [Google Scholar] [CrossRef]

- Almhdi, K.M.; Valigi, P.; Gulbinas, V.; Westphal, R.; Reuter, R. Classification with artificial neural networks and support vector machines: Application to oil fluorescence spectra. EARSeL eProc. 2007, 6, 115–129. [Google Scholar]

- Alostaz, M.D.; Biggar, K.; Donahue, R.; Hall, G. Petroleum contamination characterization and quantification using fluorescence emission-excitation matrices (EEMs) and parallel factor analysis (PARAFAC). J. Environ. Eng. Sci. 2008, 7, 183–197. [Google Scholar] [CrossRef]

- Reuter, R.; Wang, H.; Willkomm, R.; Loquay, K.; Hengstermann, T.; Braun, A. A Laser Fluoresensor for Maritime Surveillance: Measurement of Oil Spills. EARSeL Adv. Remote Sens. 1995, 3, 152–169. [Google Scholar]

- James, R.T.B.; Dick, R. Design of algorithms for the real-time airborne detection of littoral oil-spills by laser-induced fluorescence. In Proceedings of the 19th Arctic and Marine Oilspill (AMOP) Technical Seminar, Calgary, AL, Canada, 12–14 June 1996; pp. 1599–1608.

- Brown, C.E.; Marois, R.; Fingas, M.F.; Choquet, M.; Monchalin, J.P.; Mullin, J.V.; Goodman, R.H. Airborne oil spill sensor testing: Progress and recent developments. In Proceedings of the International Oil Spill Conference, Portland, OR, USA, 23–26 May 2001; pp. 917–921.

- Quinn, M.F.; Al-Otaibi, A.S.; Sethi, P.S.; Al-Bahrani, F.; Alameddine, O. Measurement and analysis procedures for remote identification of oil spills using a laser fluorosensor. Int. J. Remote Sens. 1994, 15, 2637–2658. [Google Scholar] [CrossRef]

- Brown, C.E.; Fingas, M.F. Review of the development of laser fluorosensors for oil spill application. Mar. Pollut. Bull. 2003, 47, 477–484. [Google Scholar] [CrossRef]

- Christensen, J.H.; Hansen, A.B.; Mortensen, J.; Andersen, O. Characterization and matching of oil samples using fluorescence spectroscopy and parallel factor analysis. Anal. Chem. 2005, 77, 2210–2217. [Google Scholar] [CrossRef] [PubMed]

- Mendoza, W.G.; Riemer, D.D.; Zika, R.G. Application of fluorescence and PARAFAC to assess vertical distribution of subsurface hydrocarbons and dispersant during the Deepwater Horizon oil spill. Environ. Sci. 2013, 15, 1017–1030. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Guo, L.; Shiller, A.M.; Lohrenz, S.E.; Asper, V.L.; Osburn, C.L. Characterization of oil components from the Deepwater Horizon oil spill in the Gulf of Mexico using fluorescence EEM and PARAFAC techniques. Mar. Chem. 2013, 148, 10–21. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, Z.; Guo, L. Chemical evolution of Macondo crude oil during laboratory degradation as characterized by fluorescence EEMs and hydrocarbon composition. Mar. Pollut. Bull. 2013, 66, 164–175. [Google Scholar] [CrossRef] [PubMed]

- Abu-Zeid, M.E.; Bhatia, K.S.; Marafi, M.A.; Makdisi, Y.Y.; Amer, M.F. Measurement of fluorescence decay of crude oil: A potential technique to identify oil slicks. Environ. Pollut. 1987, 46, 197–207. [Google Scholar] [CrossRef]

- Hegazi, E.; Hamdan, A.; Mastromarino, J. New approach for spectral characterization of crude oil using time-resolved fluorescence spectra. Appl. Spectrosc. 2001, 55, 202–207. [Google Scholar] [CrossRef]

- Ryder, A.G.; Glynn, T.J.; Feely, M.; Barwise, A.J.G. Characterization of crude oils using fluorescence lifetime data. Spectrochim. Acta Part A 2002, 58, 1025–1037. [Google Scholar] [CrossRef]

- Ryder, A.G. Time-resolved fluorescence spectroscopic study of crude petroleum oils: Influence of chemical composition. Appl. Spectrosc. 2004, 58, 613–623. [Google Scholar] [CrossRef] [PubMed]

- Baszanowska, E.; Otremba, Z.; Rohde, P.; Zieliński, O. Adoption of the time resolved fluorescence to oil type identification. J. KONES 2011, 18, 25–29. [Google Scholar]

- Liu, D.Q.; Luan, X.N.; Han, X.S.; Guo, J.J.; An, J.B.; Zheng, R.E. Characterization of time-resolved laser-induced fluorescence from crude oil samples. Spectrosc. Spectr. Anal. 2015, 35, 1582–1586. [Google Scholar]

- Rayner, D.M.; Szabo, A.G. Time-resolved laser fluorosensors: A laboratory study of their potential in the remote characterization of oil. Appl. Opt. 1978, 17, 1624–1630. [Google Scholar] [CrossRef] [PubMed]

- Hegazi, E.; Hamdan, A.; Mastromarino, J. Remote fingerprinting of crude oil using time-resolved fluorescence spectra. Arabian J. Sci. Eng. 2005, 30, 3–12. [Google Scholar]

- Harshman, R.A.; Lundy, M.E. PARAFAC: Parallel factor analysis. Comput. Stat. Data Anal. 1994, 18, 39–72. [Google Scholar] [CrossRef]

- Bro, R. PARAFAC. Tutorial and applications. Chemom. Intell. Lab. Syst. 1997, 38, 149–171. [Google Scholar] [CrossRef]

- Selli, E.; Zaccaria, C.; Sena, F.; Tomasi, G.; Bidoglio, G. Application of multi-way models to the time-resolved fluorescence of polycyclic aromatic hydrocarbons mixtures in water. Water Res. 2004, 38, 2269–2276. [Google Scholar] [CrossRef] [PubMed]

- Saito, T.; Sao, H.; Ishida, K.; Aoyagi, N.; Kimura, T.; Nagasaki, S.; Tanaka, S. Application of parallel factor analysis for time-resolved laser fluorescence spectroscopy: Implication for metal speciation study. Environ. Sci. Technol. 2010, 44, 5055–5060. [Google Scholar] [CrossRef] [PubMed]

- Fingas, M. Oil Spill Science and Technology; Gulf Professional Publishing, Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Pantoja, P.A.; Lopez-Gejo, J.; Le Roux, G.A.; Quina, F.H.; Nascimento, C.A. Prediction of crude oil properties and chemical composition by means of steady-state and time-resolved fluorescence. Energy Fuels 2011, 25, 3598–3604. [Google Scholar] [CrossRef]

| Oil Samples | Density (kg·L−1) | API Gravity | Emission Peak Location (nm) | |

|---|---|---|---|---|

| Refined oil | Gasoline(G) | 0.725 | 63.4 | 409.3 |

| Diesel(D) | 0.835 | 38.0 | 401.0 | |

| Crude oil | Bo601(C1) | 0.807 | 43.9 | 440.5 |

| Chengbei305(C2) | 0.823 | 40.3 | 444.4 | |

| Shi138(C3) | 0.905 | 24.9 | 445.5 | |

| Zhengqi3(C4) | 0.979 | 13.1 | 449.4 | |

| Detection Positions | Peak Fluorescent Intensity (104 Counts) | |||||

|---|---|---|---|---|---|---|

| Gasoline(G) | Diesel(D) | Bo601(C1) | Chengbei305(C2) | Shi138(C3) | Zhengqi3(C4) | |

| Position1 | 8.4 | 50.8 | 53.1 | 23.1 | 3.9 | 3.9 |

| Position2 | 8.0 | 48.7 | 53.8 | 18.8 | 4.1 | 3.8 |

| Position3 | 4.6 | 46.3 | 56.1 | 17.6 | 4.3 | 3.9 |

| Position4 | 5.7 | 49.6 | 48.3 | 17.3 | 4.5 | 4.0 |

| Position5 | 7.6 | 48.7 | 55.6 | 15.7 | 4.5 | 3.7 |

| Average | 6.9 | 48.8 | 53.4 | 18.5 | 4.3 | 3.8 |

| Relative standard deviation (RSD) | 23.9% | 3.4% | 5.8% | 15.2% | 5.6% | 3.3% |

| Oil Samples | PARAFAC | PCA | |||||

|---|---|---|---|---|---|---|---|

| Spectra Number | Number of Overlapping | Runtime | Spectra Number | Number of Overlapping | Runtime | ||

| Refined oil | G | 5 | 0 | ~4 s 1 | 8 | 0 | ~6 s |

| D | 5 | 0 | 8 | 0 | |||

| Crude oil | C1 | 5 | 1 | 8 | 6 | ||

| C2 | 5 | 0 | 8 | 10 | |||

| C3 | 5 | 0 | 8 | 15 | |||

| C4 | 5 | 0 | 8 | 21 | |||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Luan, X.; Guo, J.; Cui, T.; An, J.; Zheng, R. A New Approach of Oil Spill Detection Using Time-Resolved LIF Combined with Parallel Factors Analysis for Laser Remote Sensing. Sensors 2016, 16, 1347. https://doi.org/10.3390/s16091347

Liu D, Luan X, Guo J, Cui T, An J, Zheng R. A New Approach of Oil Spill Detection Using Time-Resolved LIF Combined with Parallel Factors Analysis for Laser Remote Sensing. Sensors. 2016; 16(9):1347. https://doi.org/10.3390/s16091347

Chicago/Turabian StyleLiu, Deqing, Xiaoning Luan, Jinjia Guo, Tingwei Cui, Jubai An, and Ronger Zheng. 2016. "A New Approach of Oil Spill Detection Using Time-Resolved LIF Combined with Parallel Factors Analysis for Laser Remote Sensing" Sensors 16, no. 9: 1347. https://doi.org/10.3390/s16091347