Plasma-Modified, Epitaxial Fabricated Graphene on SiC for the Electrochemical Detection of TNT

Abstract

:1. Introduction

2. Materials and Methods

2.1. Growth of Epitaxial Fabricated Graphene on SiC

2.2. Plasma Functionalization

2.3. Surface Characterization

2.4. Electrochemistry and Cell Design

3. Results

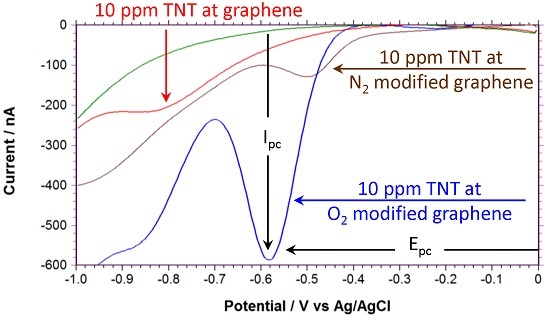

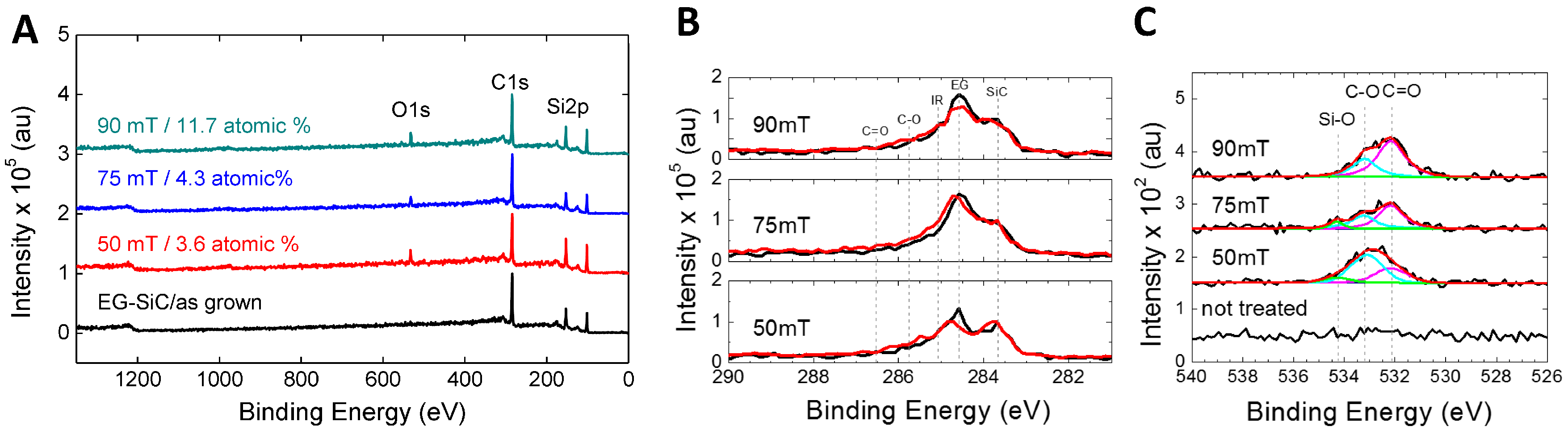

3.1. Plasma Functionalization and Surface Characterization

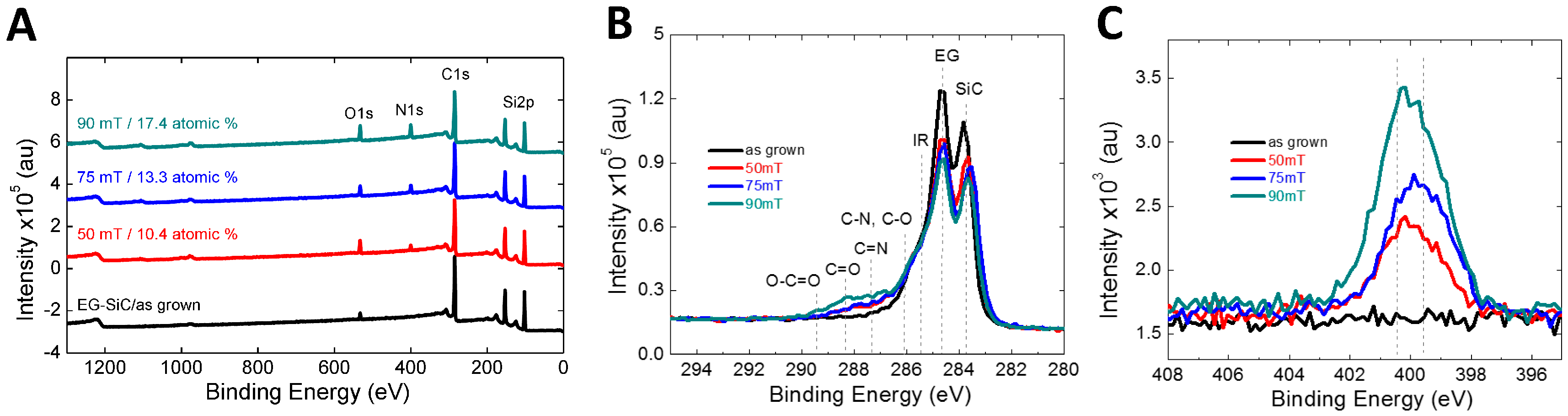

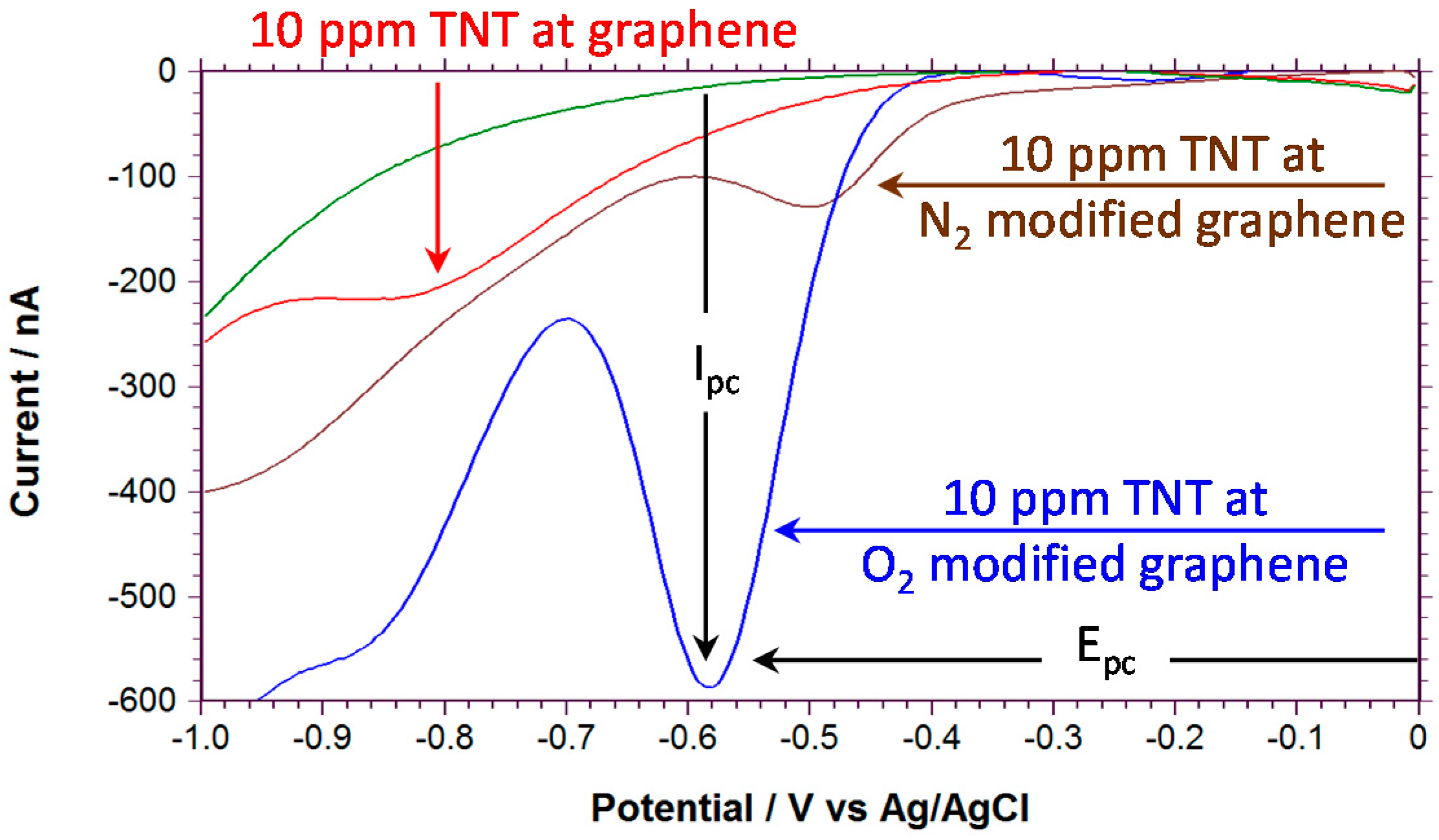

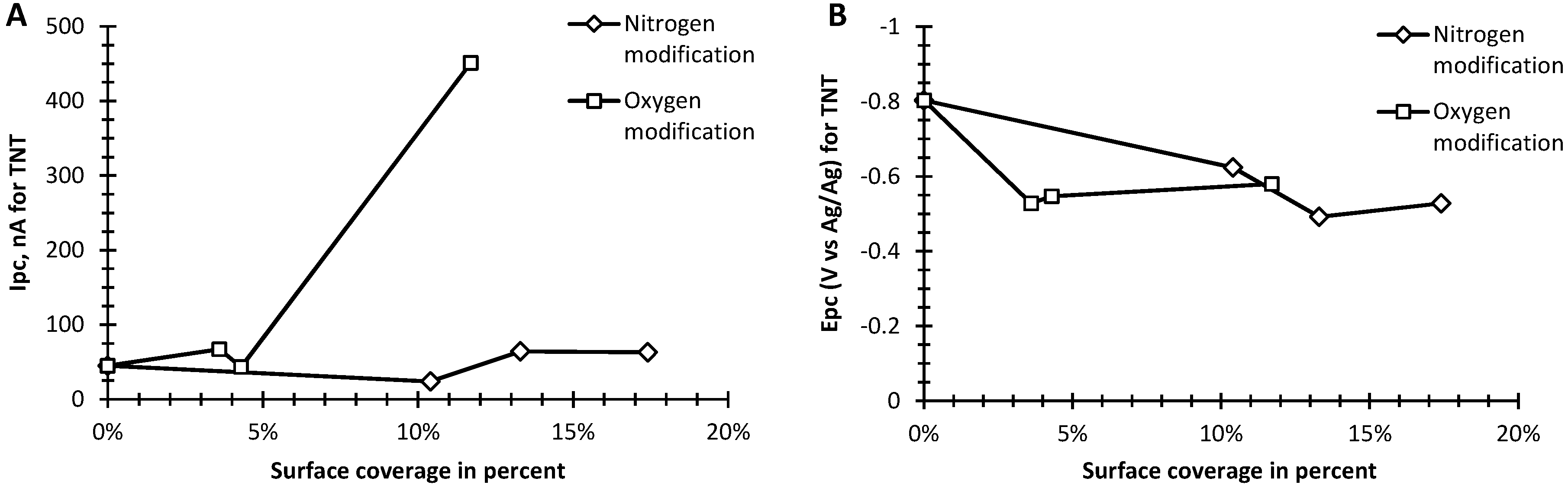

3.2. Electrochemistry of TNT at Modified Graphene

3.3. Trace Detection of TNT for Oxygen Modified EG

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| PBS | phosphate buffered saline |

| TNT | 2,4,6-trinitrotoluene |

| EG | epitaxial graphene |

References

- Schedin, F.; Geim, A.K.; Morozov, S.V.; Hill, E.W.; Blake, P.; Katsnelson, M.I.; Novoselov, K.S. Detection of individual gas molecules adsorbed on graphene. Nat. Mater. 2007, 6, 652–655. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nyakiti, L.O.; Wheeler, V.D.; Garces, N.Y.; Myers-Ward, R.L.; Eddy, C.R.; Gaskill, D.K. Enabling graphene-based technologies: Toward wafer-scale production of epitaxial graphene. MRS Bull. 2012, 37, 1149–1157. [Google Scholar] [CrossRef]

- Novikov, S.; Lebedeva, N.; Satrapinski, A. Ultrasensitive NO2 Gas Sensor Based on Epitaxial Graphene. J. Sens. 2015, 2015. [Google Scholar] [CrossRef]

- Iezhokin, I.; Offermans, P.; Brongersma, S.H.; Giesbers, A.J.M.; Flipse, C.F.J. High sensitive quasi freestanding epitaxial graphene gas sensor on 6H-SiC. Appl. Phys. Lett. 2013, 103. [Google Scholar] [CrossRef]

- Pearce, R.; Iakimov, T.; Andersson, M.; Hultman, L.; Spetz, A.L.; Yakimova, R. Epitaxially grown graphene based gas sensors for ultrasensitive NO2 detection. Sens. Actuators B Chem. 2011, 155, 451–455. [Google Scholar] [CrossRef]

- Kong, L.; Enders, A.; Rahman, T.S.; Dowben, P.A. Molecular adsorption on graphene. J. Phys. Condens. Matter 2014, 26. [Google Scholar] [CrossRef] [PubMed]

- Giusca, C.E.; Panchal, V.; Munz, M.; Wheeler, V.D.; Nyakiti, L.O.; Myers-Ward, R.L.; Gaskill, D.K.; Kazakova, O. Water affinity to epitaxial graphene: The impact of layer thickness. Adv. Mater. Interfaces 2015, 2. [Google Scholar] [CrossRef]

- Daniels, K.M.; Shetu, S.; Staser, J.; Weidner, J.; Williams, C.; Sudarshan, T.S.; Chandrashekhar, M.V.S. Mechanism of Electrochemical Hydrogenation of Epitaxial Graphene. J. Electrochem. Soc. 2015, 162, E37–E42. [Google Scholar] [CrossRef]

- Avouris, P.; Dimikratopoulos, C. Graphene: Synthesis and applications. Mater. Today 2012, 86, 86–97. [Google Scholar] [CrossRef]

- Fromm, F.; Oliveira, M.H.; Molina-Sanchez, A.; Hundhausen, M.; Lopes, J.M.J.; Riechert, H.; Wirtz, L.; Seyller, T. Contribution of the buffer layer to the Raman spectrum of epitaxial graphene on SiC(0001). New J. Phys. 2013, 15, 043031. [Google Scholar] [CrossRef]

- Hernandez, S.C.; Bezares, F.J.; Robinson, J.T.; Caldwell, J.D.; Walton, S.G. Controlling the local chemical reactivity of graphene through spatial functionalization. Carbon 2013, 60, 84–93. [Google Scholar] [CrossRef]

- Nagareddy, V.K.; Chan, H.K.; Hernandez, S.C.; Wheeler, V.D.; Nyakiti, L.O.; Myers-Ward, R.L.; Eddy, C.R.; Goss, J.P.; Wright, N.G.; Walton, S.G.; et al. Improved chemical detection and ultra-fast recovery using oxygen functionalized epitaxial graphene sensors. IEEE Sens. J. 2013, 13, 2810–2817. [Google Scholar] [CrossRef]

- Wujcik, E.K.; Monty, C.N. Nanotechnology for implantable sensors: Carbon nanotubes and graphene in medicine. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2013, 5, 233–249. [Google Scholar] [CrossRef] [PubMed]

- Wujcik, E.K.; Blasdel, N.J.; Trowbridge, D.; Monty, C.N. Ion sensor for the quantification of sodium in sweat samples. IEEE Sens. J. 2013, 13, 3430–3436. [Google Scholar] [CrossRef]

- Zhou, N.; Li, J.; Chen, H.; Liao, C.; Chen, L. A functional graphene oxide-ionic liquid composites-gold nanoparticle sensing platform for ultrasensitive electrochemical detection of Hg2+. Analyst 2013, 138, 1091–1097. [Google Scholar] [CrossRef] [PubMed]

- Charles, P.T.; Adams, A.A.; Howell, P.B.; Trammell, S.A.; Deschamps, J.R.; Kusterbeck, A.W. Fluorescence-based Sensing of 2,4,6-Trinitrotoluene (TNT) Using a Multi-channeled Poly(methyl methacrylate) (PMMA) Microimmunosensor. Sensors 2010, 10, 876–889. [Google Scholar] [CrossRef] [PubMed]

- Gao, D.; Wang, Z.; Liu, B.; Ni, L.; Wu, M.; Zhang, Z. Resonance energy transfer-amplifying fluorescence quenching at the surface of silica nanoparticles toward ultrasensitive detection of TNT. Anal. Chem. 2008, 80, 8545–8553. [Google Scholar] [CrossRef] [PubMed]

- Walsh, M.E. Determination of nitroaromatic, nitramine, and nitrate ester explosives in soil by gas chromatography and an electron capture detector. Talanta 2001, 54, 427–438. [Google Scholar] [CrossRef]

- Liu, M.; Chen, W. Graphene nanosheets-supported Ag nanoparticles for ultrasensitive detection of TNT by surface-enhanced Raman spectroscopy. Biosen. Bioelectron. 2013, 46, 68–73. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Thongngamdee, S. On-line electrochemical monitoring of (TNT) 2,4,6-trinitrotoluene in natural waters. Anal. Chim. Acta 2003, 485, 139–144. [Google Scholar] [CrossRef]

- Ryan, P.; Zabetakis, D.; Stenger, D.A.; Trammell, S.A. Integrating Paper Chromatography with Electrochemical Detection for the Trace Analysis of TNT in Soil. Sensors 2015, 15, 17048–17056. [Google Scholar] [CrossRef] [PubMed]

- Galik, M.; O’Mahony, A.M.; Wang, J. Cyclic and square-wave voltammetric signatures of nitro-containing explosives. Electroanalysis 2011, 23, 1193–1204. [Google Scholar] [CrossRef]

- Tang, L.; Feng, H.; Cheng, J.; Li, J. Uniform and rich-wrinkled electrophoretic deposited graphene film: A robust electrochemical platform for TNT sensing. Chem. Commun. 2010, 46, 5882–5884. [Google Scholar] [CrossRef] [PubMed]

- Tan, S.M.; Chua, C.K.; Pumera, M. Graphenes prepared from multi-walled carbon nanotubes and stacked graphene nanofibers for detection of 2,4,6-trinitrotoluene (TNT) in seawater. Analyst 2013, 138, 1700–1704. [Google Scholar] [CrossRef] [PubMed]

- Ong, B.K.; Poh, H.L.; Chua, C.K.; Pumera, M. Graphenes Prepared by hummers, staudenmaier and hofmann methods for analysis of TNT-based nitroaromatic explosives in seawater. Electroanalysis 2012, 24, 2085–2093. [Google Scholar] [CrossRef]

- Goh, M.S.; Pumera, M. Graphene-based electrochemical sensor for detection of 2,4,6-trinitrotoluene (TNT) in seawater: The comparison of single-, few-, and multilayer graphene nanoribbons and graphite microparticles. Anal. Bioanal. Chem. 2011, 399, 127–131. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.W.; Sheng, Z.H.; Wang, K.; Wang, F.B.; Xia, X.H. Determination of explosives using electrochemically reduced graphene. Chem. Asian J. 2011, 6, 1210–1216. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Sun, C.L.; Lu, Y.J.; Chen, W. Graphene nanoribbon-supported PtPd concave nanocubes for electrochemical detection of TNT with high sensitivity and selectivity. Anal. Chem. 2015, 87, 12262–12269. [Google Scholar] [CrossRef] [PubMed]

- O’Mahony, A.M.; Wang, J. Nanomaterial-based electrochemical detection of explosives: A review of recent developments. Anal. Methods 2013, 5, 4296–4309. [Google Scholar] [CrossRef]

- Trammell, S.A.; Zeinali, M.; Melde, B.J.; Charles, P.T.; Velez, F.L.; Dinderman, M.A.; Kusterbeck, A.; Markowitz, M.A. Nanoporous organosilicas as preconcentration materials for the electrochemical detection of trinitrotoluene. Anal. Chem. 2008, 80, 4627–4633. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Lu, F.; MacDonald, D.; Lu, J.M.; Ozsoz, M.E.S.; Rogers, K.R. Screen-printed voltammetric sensor for TNT. Talanta 1998, 46, 1405–1412. [Google Scholar] [CrossRef]

- Hernández, S.C.; Wheeler, V.D.; Osofsky, M.S.; Jernigan, G.G.; Nagareddy, V.K.; Nath, A.; Lock, E.H.; Nyakiti, L.O.; Myers-Ward, R.L.; Sridhara, K.; et al. Plasma-based chemical modification of epitaxial graphene with oxygen functionalities. Surf. Coat. Technol. 2014, 241, 8–12. [Google Scholar] [CrossRef]

- Jernigan, G.G.; VanMil, B.L.; Tedesco, J.L.; Tischler, J.G.; Glaser, E.R.; Davidson, A., 3rd; Campbell, P.M.; Gaskill, D.K. Comparison of epitaxial graphene on Si-face and C-face 4H SiC formed by ultrahigh vacuum and RF furnace production. Nano Lett. 2009, 9, 2605–2609. [Google Scholar] [CrossRef] [PubMed]

- Trammell, S.A.; Melde, B.J.; Zabetakis, D.; Deschamps, J.R.; Dinderman, M.A.; Johnson, B.J.; Kusterbeck, A.W. Electrochemical detection of TNT with in-line pre-concentration using imprinted diethylbenzene-bridged periodic mesoporous organosilicas. Sens. Actuators B Chem. 2011, 155, 737–744. [Google Scholar] [CrossRef]

- Trammell, S.A.; Velez, F.; Charles, P.T.; Kusterbeck, A. Electrochemical Detection of 2,4,6-Trinitrotoluene Using Interdigitated Array Electrodes. Anal. Lett. 2008, 41, 2634–2645. [Google Scholar] [CrossRef]

- Walton, S.G.; Boris, D.R.; Hernández, S.C.; Lock, E.H.; Petrova, T.B.; Petrov, G.M.; Fernsler, R.F. Electron Beam Generated Plasmas for Ultra Low Te Processing. ECS J. Solid State Sci. Technol. 2015, 4, N5033–N5040. [Google Scholar] [CrossRef]

- Baraket, M.; Stine, R.; Lee, W.K.; Robinson, J.T.; Tamanaha, C.R.; Sheehan, P.E.; Walton, S.G. Aminated graphene for DNA attachment produced via plasma functionalization. App. Phys. Lett. 2012, 100. [Google Scholar] [CrossRef]

- Walton, S.G.; Hernández, S.C.; Baraket, M.; Wheeler, V.D.; Nyakiti, L.O.; Myers-Ward, R.L.; Eddy, C.R.; Gaskill, D.K. Plasma-based chemical modification of graphene. Mater. Sci. Forum 2012, 657, 717–720. [Google Scholar] [CrossRef]

- Foley, B.M.; Hernández, S.C.; Duda, J.C.; Robinson, J.T.; Walton, S.G.; Hopkins, P.E. Modifying surface energy of graphene via plasma-based chemical functionalization to tune thermal and electrical transport at metal interfaces. Nano Lett. 2015, 15, 4876–4882. [Google Scholar] [CrossRef] [PubMed]

- Bard, A.J.; Faulkner, L.R. Electrochemical Methods: Fundamentals and Applications; Wiley: Hoboken, NJ, USA, 2001. [Google Scholar]

- Chen, T.-W.; Xu, J.-Y.; Sheng, Z.-H.; Wang, K.; Wang, F.-B.; Liang, T.-M.; Xia, X.-H. Enhanced electrocatalytic activity of nitrogen-doped graphene for the reduction of nitro explosives. Electrochem. Commun. 2012, 16, 30–33. [Google Scholar] [CrossRef]

- McCreery, R.L.; Cline, K.K. Carbon Electrodes. In Laboratory Techniques in Electroanalytical Chemistry, 2nd ed.; Kissinger, P.T., Heineman, W.R., Eds.; Marcel Dekker, Inc.: New York, NY, USA, 1996; pp. 293–330. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trammell, S.A.; Hernández, S.C.; Myers-Ward, R.L.; Zabetakis, D.; Stenger, D.A.; Gaskill, D.K.; Walton, S.G. Plasma-Modified, Epitaxial Fabricated Graphene on SiC for the Electrochemical Detection of TNT. Sensors 2016, 16, 1281. https://doi.org/10.3390/s16081281

Trammell SA, Hernández SC, Myers-Ward RL, Zabetakis D, Stenger DA, Gaskill DK, Walton SG. Plasma-Modified, Epitaxial Fabricated Graphene on SiC for the Electrochemical Detection of TNT. Sensors. 2016; 16(8):1281. https://doi.org/10.3390/s16081281

Chicago/Turabian StyleTrammell, Scott A., Sandra C. Hernández, Rachael L. Myers-Ward, Daniel Zabetakis, David A. Stenger, D. Kurt Gaskill, and Scott G. Walton. 2016. "Plasma-Modified, Epitaxial Fabricated Graphene on SiC for the Electrochemical Detection of TNT" Sensors 16, no. 8: 1281. https://doi.org/10.3390/s16081281