Development of a Distributed Crack Sensor Using Coaxial Cable

Abstract

:1. Introduction

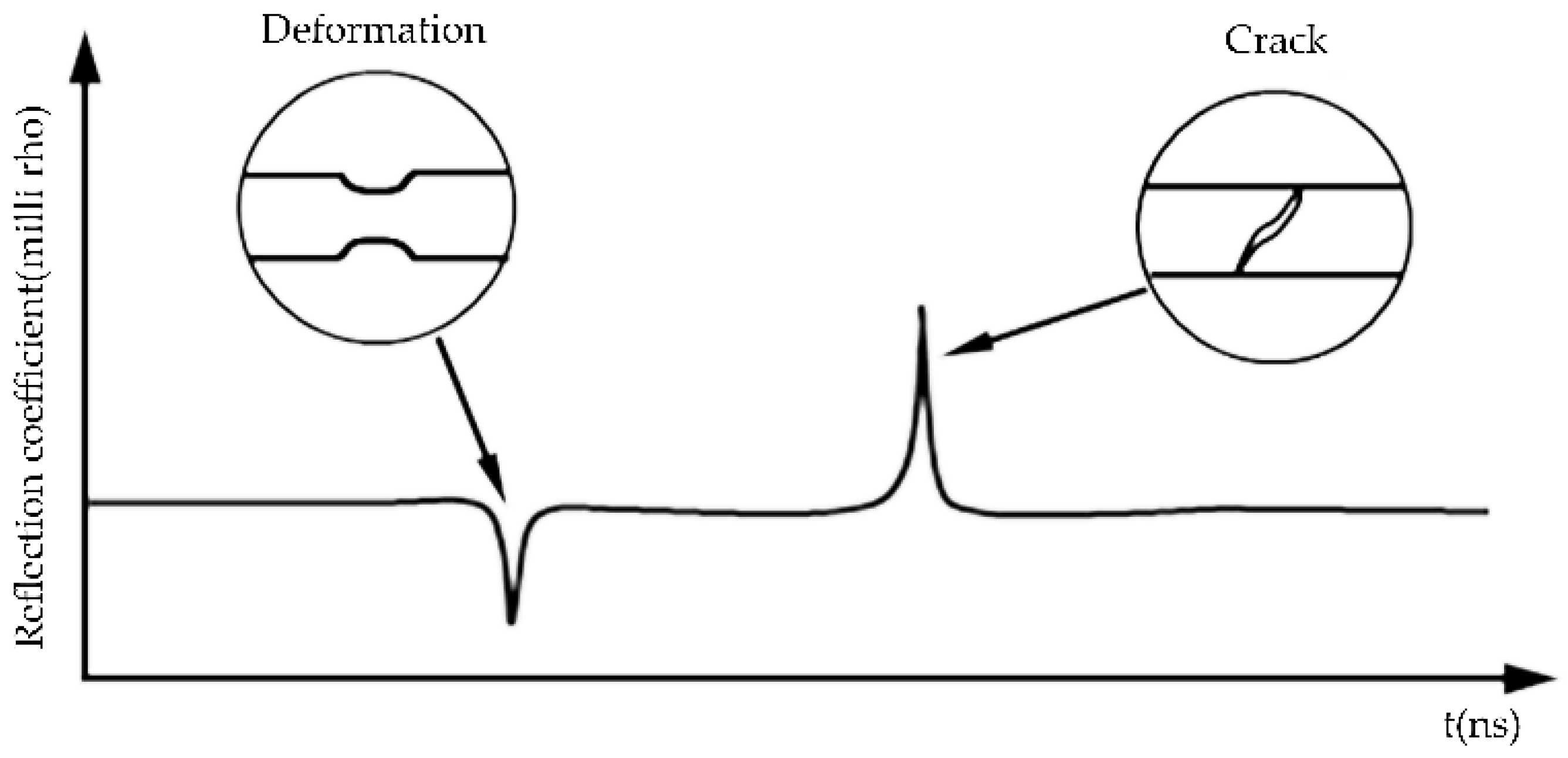

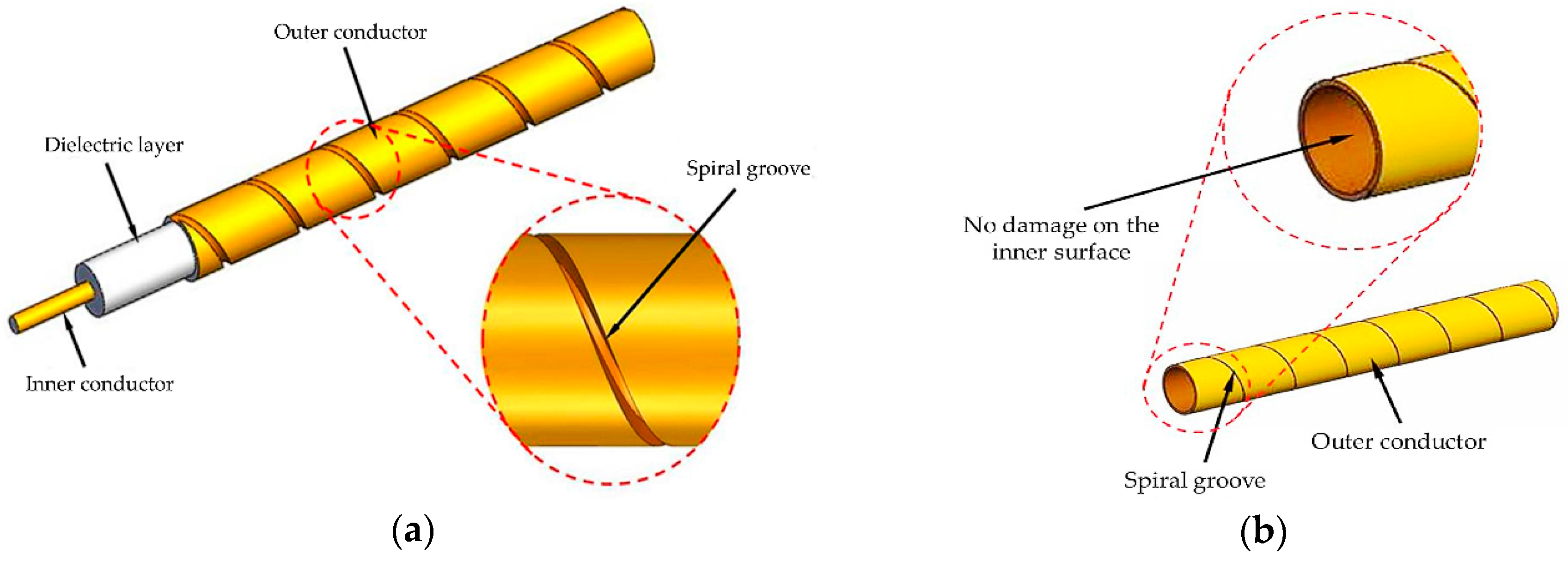

2. Sensing Mechanism of ETDR

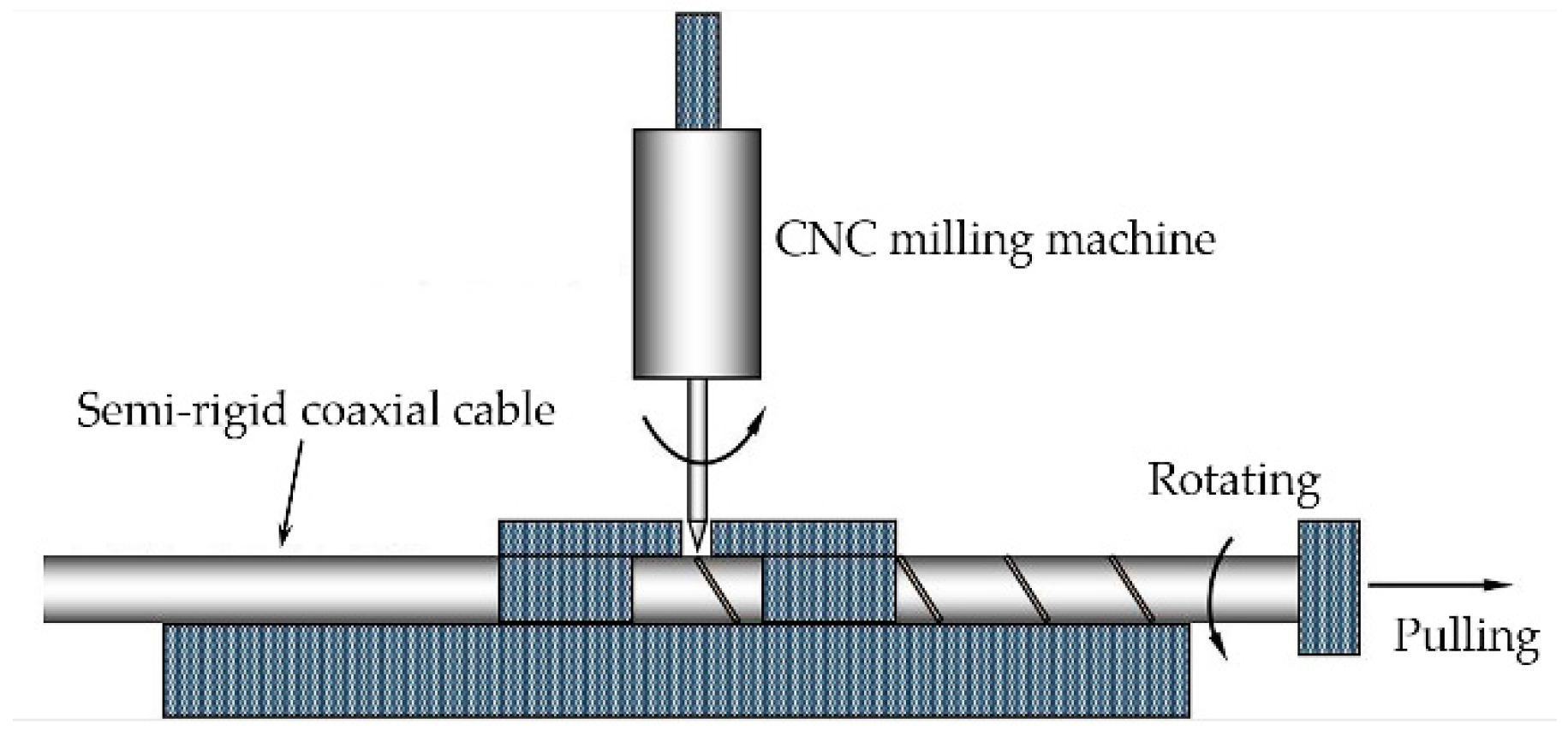

3. Design and Fabrication of the Prototype Sensor

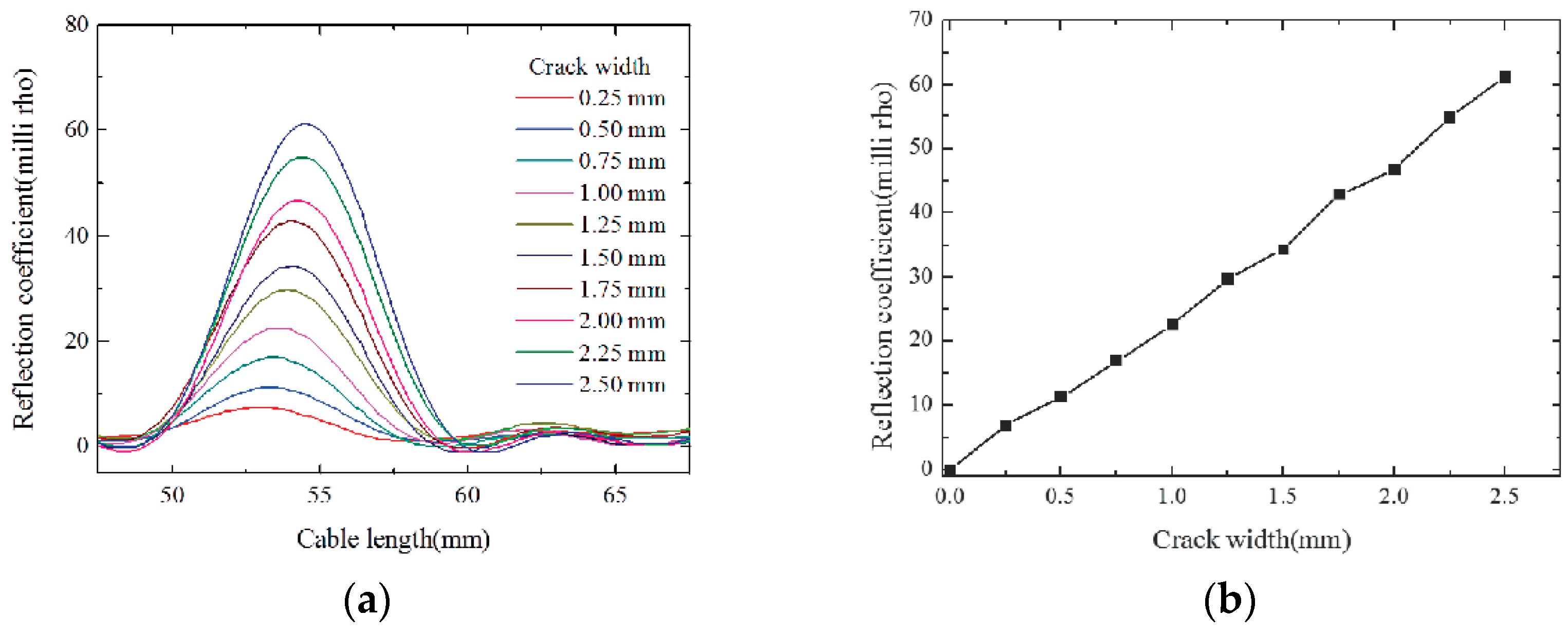

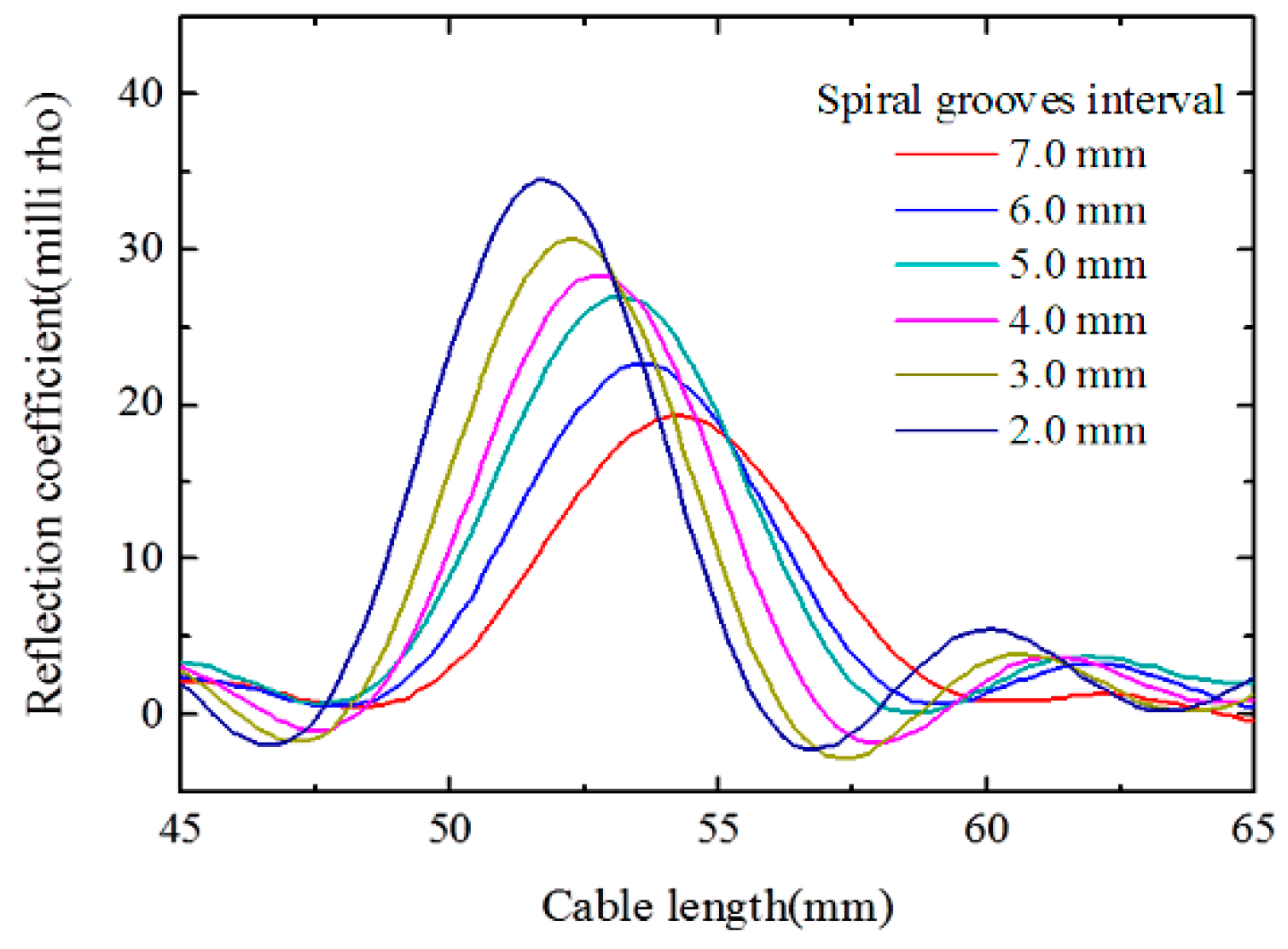

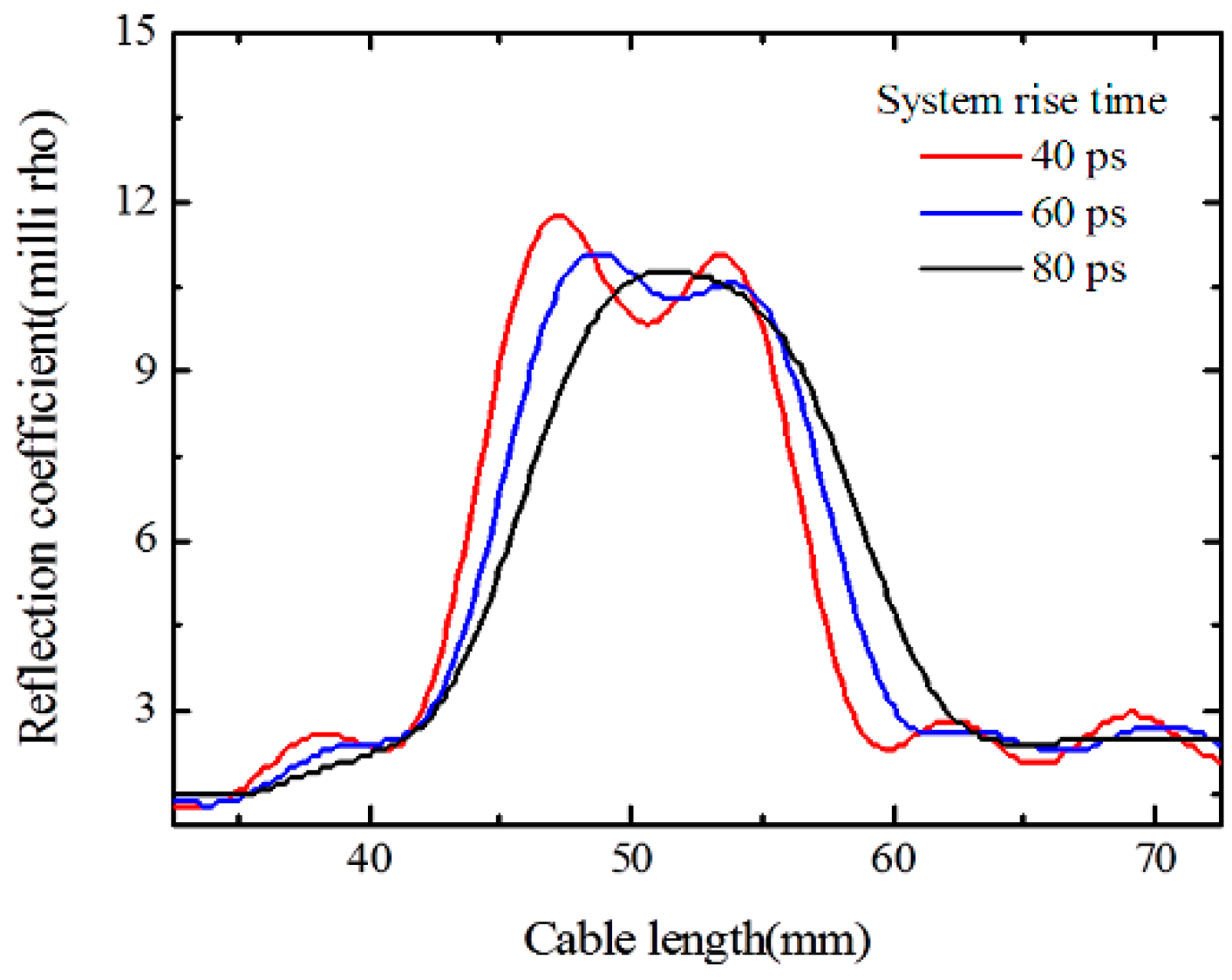

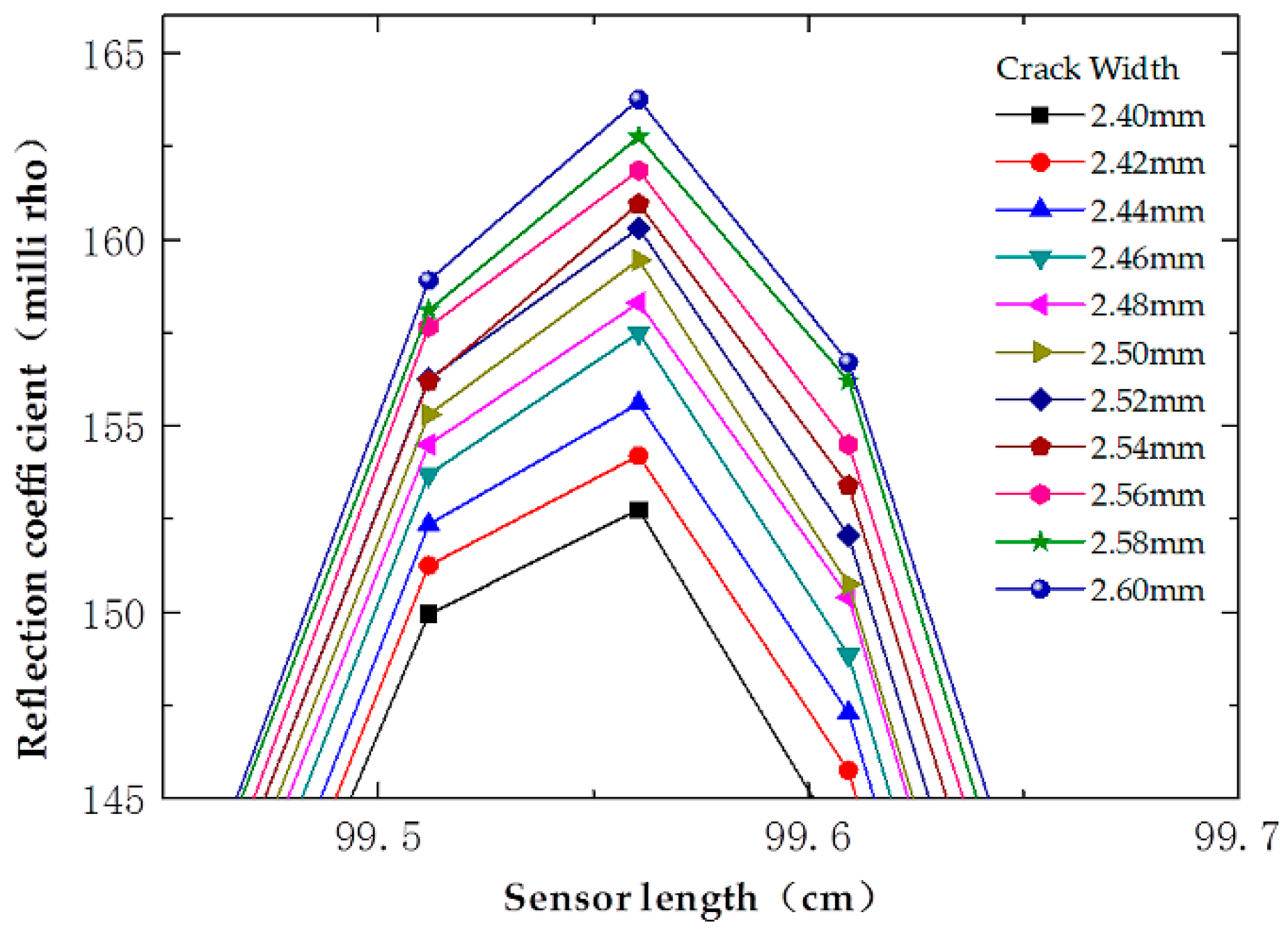

4. Numerical Simulations

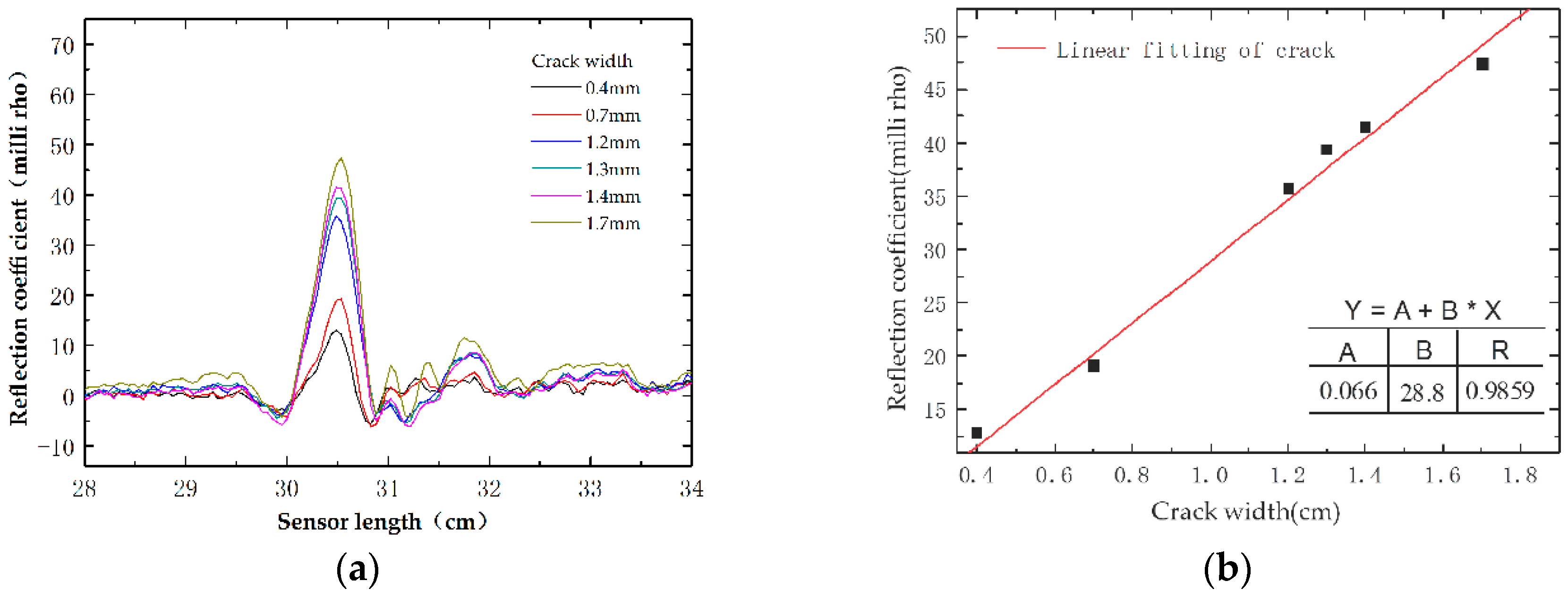

5. Sensor Calibration

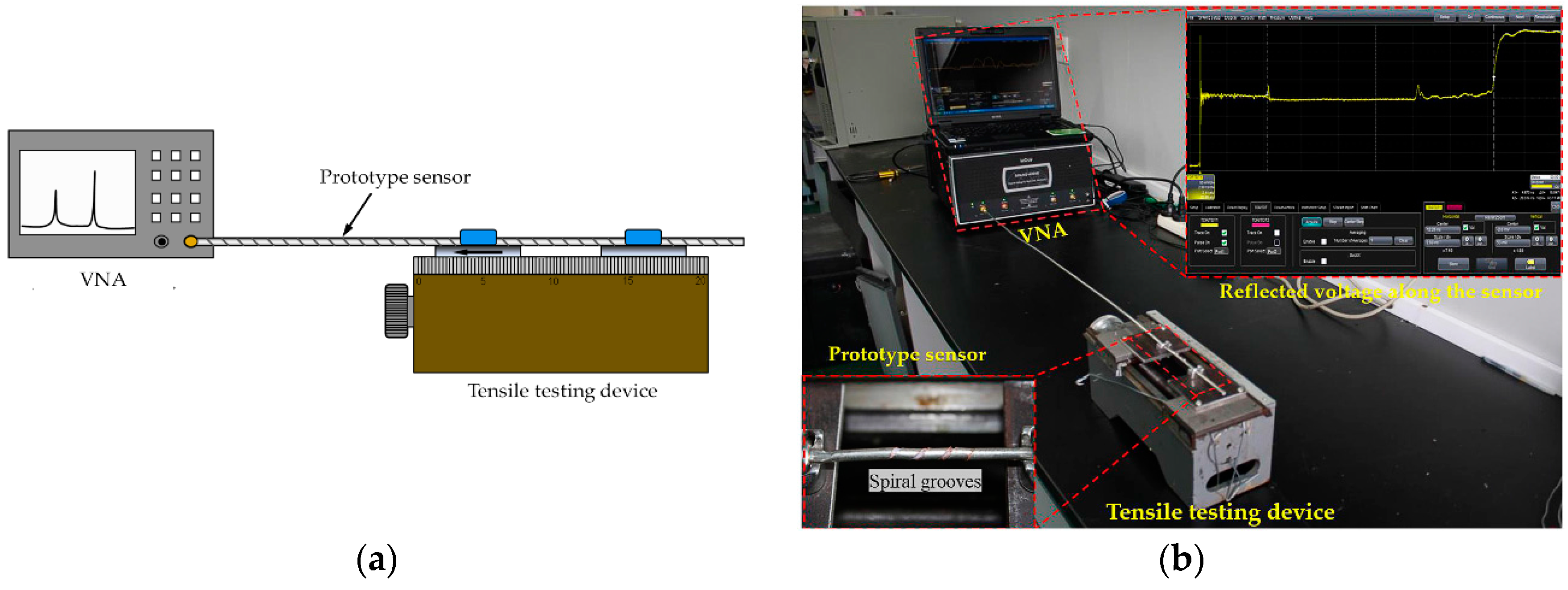

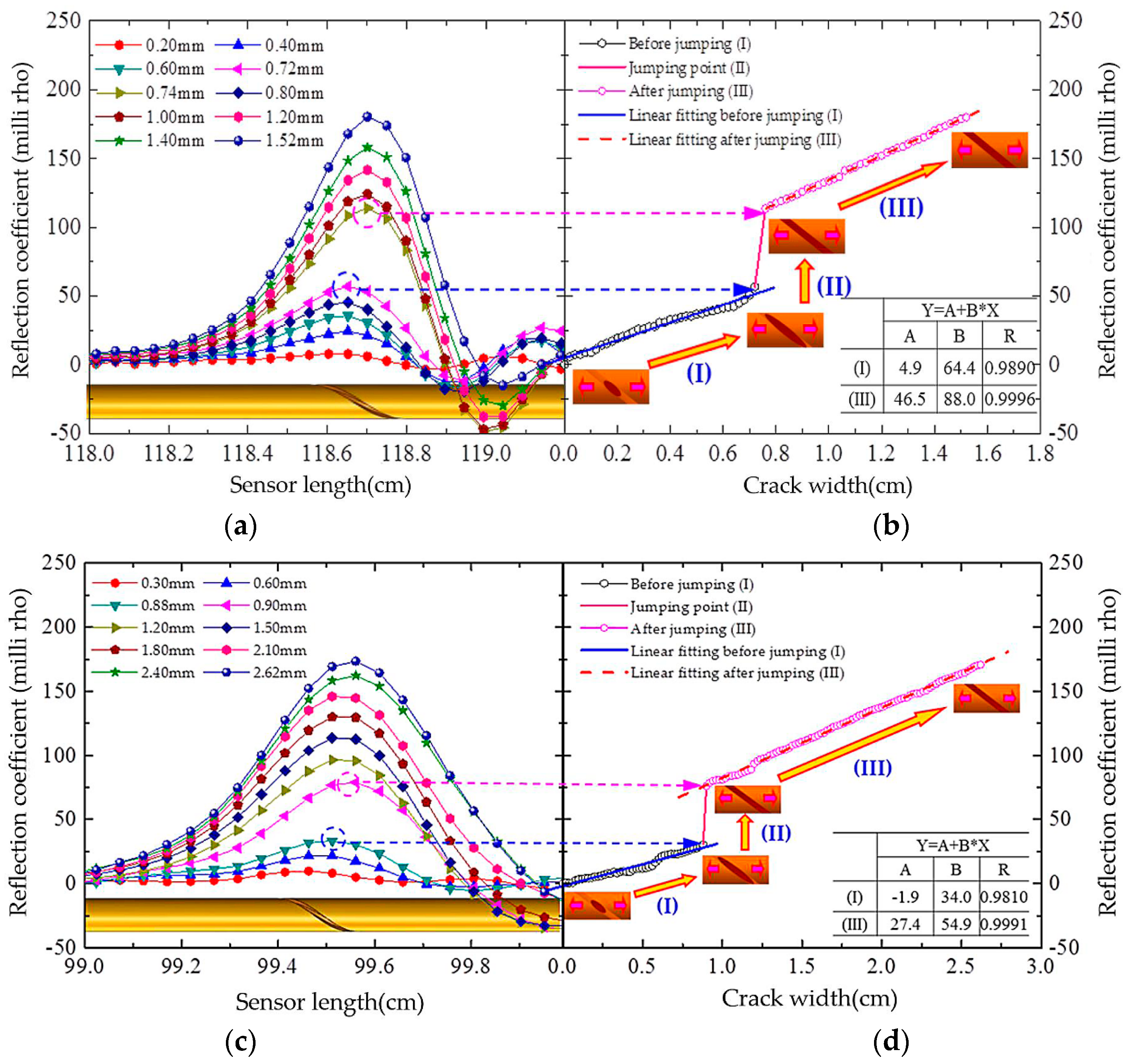

5.1. Sensitivity Test

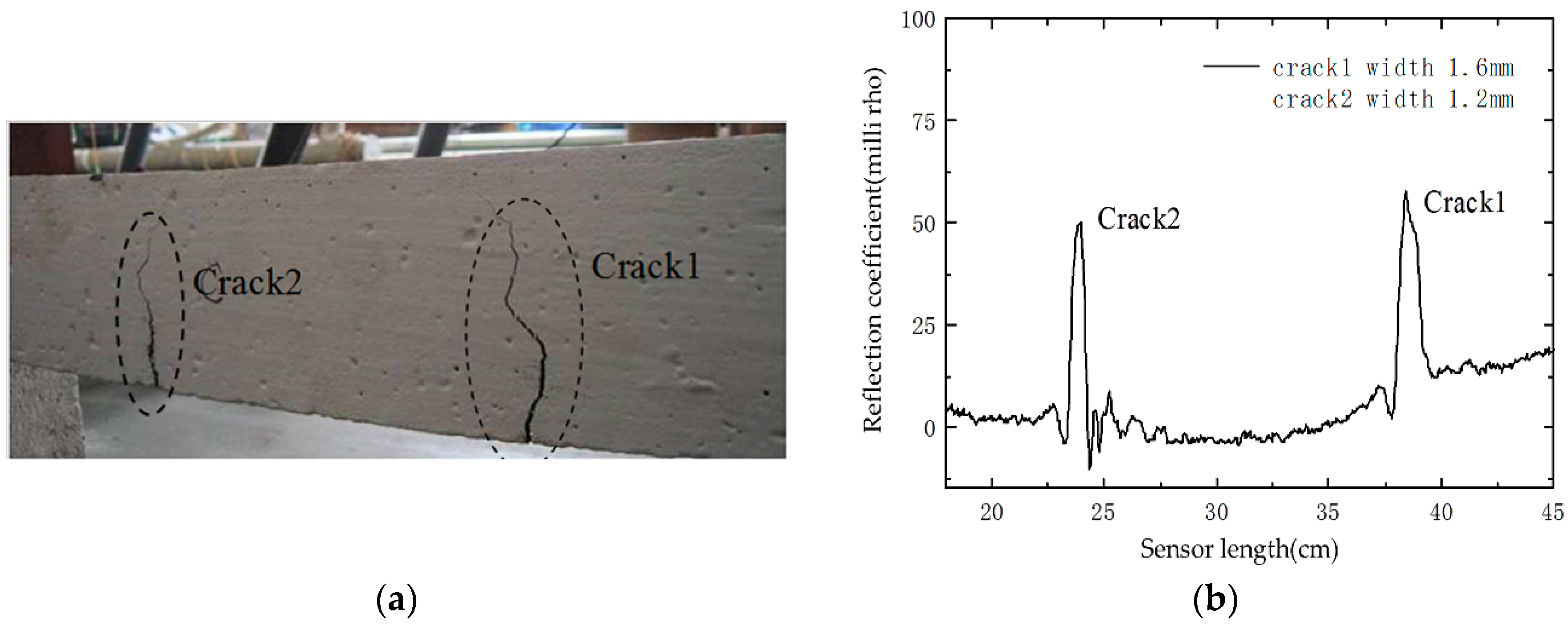

5.2. Multiple Crack Sensing Test

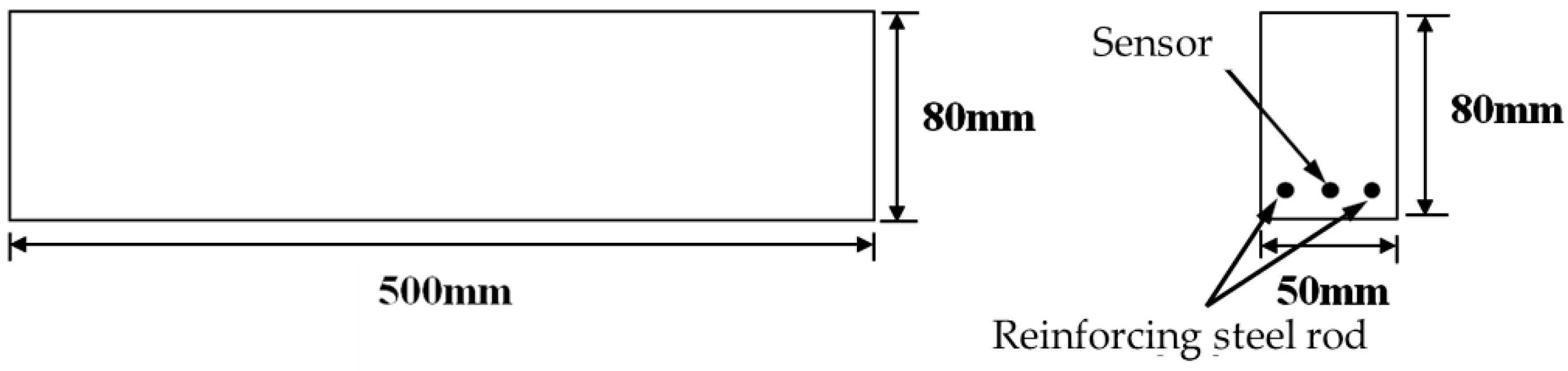

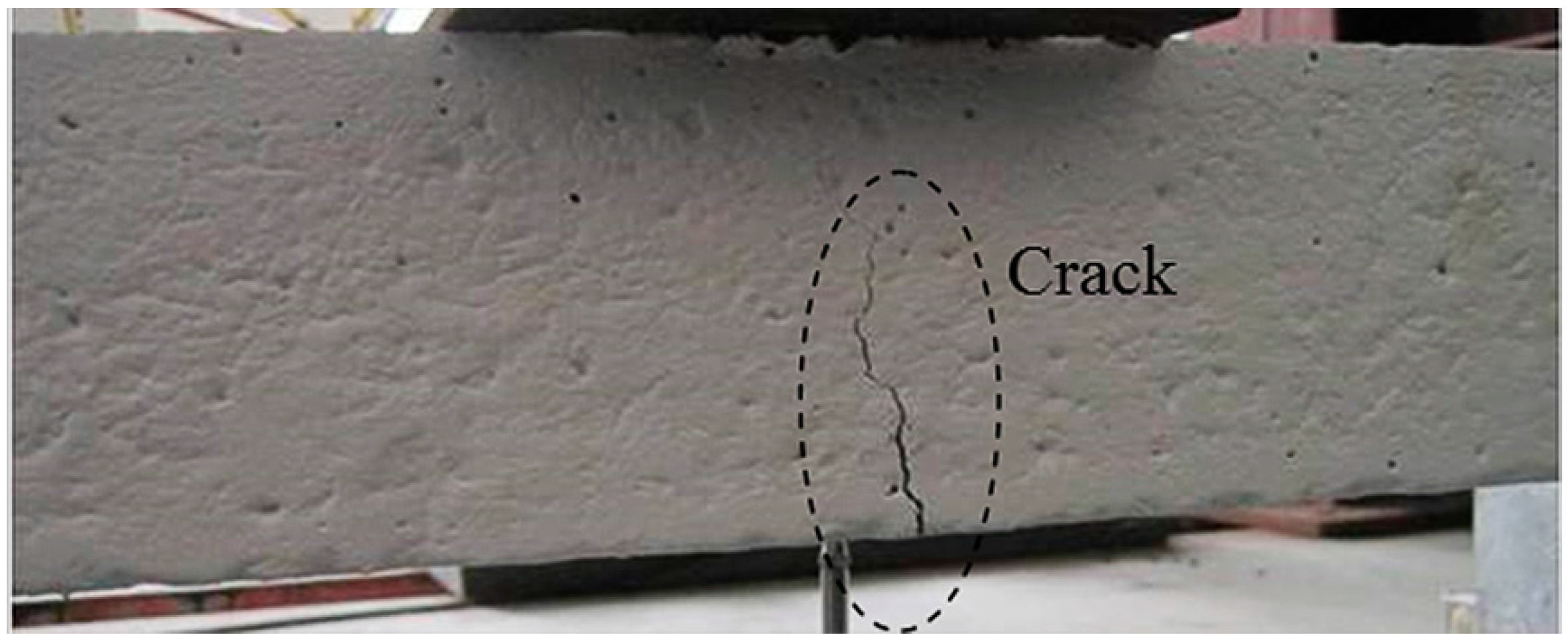

6. Experiment Validation on RC Members

6.1. Results Analysis of a Three-point Bending Test

6.2. Results Analysis of a Four-Point Bending Test

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Her, S.C.; Lin, S.T. Non-destructive evaluation of depth of surface cracks using ultrasonic frequency analysis. Sensors 2014, 14, 17146–17158. [Google Scholar] [CrossRef] [PubMed]

- Maria, S.; Dimitrios, G.A.; Dieter, B.; Patrick, G.; Danny, H. Evaluation of SHM System Produced by Additive Manufacturing via Acoustic Emission and Other NDT Methods. Sensors 2015, 15, 26709–26725. [Google Scholar]

- Cheng, C.C.; Cheng, T.M.; Chiang, C.H. Defect detection of concrete structures using both infrared thermography and elastic waves. Autom. Constr. 2008, 18, 87–92. [Google Scholar] [CrossRef]

- Mori, K.; Spagnoli, A.; Murakami, Y.; Kondo, G.; Torigoe, I. A new non-contacting non-destructive testing method for detection in concrete. NDT&E Int. 2002, 35, 399–406. [Google Scholar]

- Yao, Y.; Glisic, B. Detection of steel fatigue cracks with strain sensing sheets based on large area electronics. Sensors 2015, 15, 8088–8108. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.B.; Li, G.; Wang, G.L.; Yuan, L.B. CTOD measurement for cracks in concrete by fiber optic sensors. Opt. Lasers Eng. 2004, 42, 377–388. [Google Scholar] [CrossRef]

- Mao, J.H.; Chen, J.Y.; Cui, L.; Jin, W.L.; Xu, C.; He, Y. Monitoring the corrosion process of reinforced concrete using BOTDA and FBG sensors. Sensors 2015, 15, 8866–8883. [Google Scholar] [CrossRef] [PubMed]

- Sahay, P.; Kaya, M.; Wang, C.J. Fiber loop ringdown sensor for potential real-time monitoring of cracks in concrete structures: An exploratory study. Sensors 2013, 13, 39–57. [Google Scholar] [CrossRef] [PubMed]

- Ball, G.A.; Morey, W.W. Compression-tuned single-frequency Bragg grating fiber laser. Opt. Lett. 1994, 19, 1979–1981. [Google Scholar] [CrossRef] [PubMed]

- Lin, M.W.; Abatan, A.O.; Zhang, W.M. Crack damage detection of structures using distributed electrical time domain reflectometry (ETDR) sensors. In Proceedings of the SPIE Conference on Smart Structures and Materials 1998: Smart Systems for Bridges, Structures, and Highways, Newport Beach, CA, USA, 1 March 1998; Volume 3325, pp. 173–180.

- Lin, M.W.; Abatan, A.O.; Zhang, W.M. Crack damage detection of concrete structures using distributed electrical time domain reflectometry (ETDR) sensors. In Proceedings of the SPIE Conference on Smart Structures and Materials 1999: Smart Systems for Bridges, Structures, and Highways, Newport Beach, CA, USA, 18 May 1999; Volume 3671, pp. 297–304.

- Lin, M.W.; Abatan, A.O.; Zhou, Y.M. High sensitivity electric TDR distributed strain sensor. In Proceedings of the SPIE Conference on Smart Structures and Materials 2000: Sensory Phenomena and Measurement Instrumentation for Smart Structures and Materials, Newport Beach, CA, USA, 12 June 2000; Volume 3986, pp. 463–471.

- Lin, M.W.; Thaduri, J.; Abatan, A.O. Development of an electrical time domain reflectometry (ETDR) distributed strain sensor. Meas. Sci. Technol. 2005, 16, 1495–1505. [Google Scholar] [CrossRef]

- Chen, G.D.; Mu, H.M.; Pommerenke, D.J.; Drewniak, J.L. Damage detection of reinforced concrete beams with novel distributed crack/strain sensors. Struct. Health Monit. 2004, 3, 225–243. [Google Scholar] [CrossRef]

- Chen, G.D.; McDaniel, R.D.; Sun, S.S.; Mu, H.M.; Pommerenke, D.J.; Drewniak, J.L. Distributed crack sensors featuring unique memory capability for post-earthquake condition assessment of RC structures. Smart Struct. Syst. 2005, 1, 141–158. [Google Scholar] [CrossRef]

- Sun, S.S.; Pommerenke, D.J.; Drewniak, J.L.; Chen, G.D.; Xue, L.; Brower, M.A.; Koledintseva, M.Y. A novel TDR-based coaxial cable sensor for crack/strain sensing in reinforced concrete structures. IEEE Trans. Instrum. Meas. 2009, 58, 2714–2725. [Google Scholar]

- Chen, G.D.; Sun, S.S.; Pommerenke, D.J.; Drewniak, J.L.; Greene, G.; McDaniel, R.D. Crack detection of a full-scale reinforced concrete girder with a distributed cable sensor. Smart Mater. Struct. 2005, 14, S88–S97. [Google Scholar] [CrossRef]

- Chen, G.D.; McDaniel, R.D.; Brower, M.A.; Pommerenke, D.J. Crack detectability and durability of coaxial cable sensors in reinforced concrete bridge applications. Transp. Res. Rec. 2010, 2172, 151–156. [Google Scholar] [CrossRef]

| Diameter of Inner Conductor | Diameter of Outer Conductor | Thickness of Outer Conductor | Characteristic Impedance | Dielectric Constant |

|---|---|---|---|---|

| 0.92 mm | 3.60 mm | 0.30 mm | 50 Ω | 2.10 |

| Sensor | Length of Sensor | Turns of Spiral Separation | Initial Position of the Spiral Groove | Spiral Groove Interval |

|---|---|---|---|---|

| Sensor-I | 150 cm | 1.0 | 118.5 cm | 3.0 mm |

| Sensor-II | 150 cm | 1.0 | 99.5 cm | 5.0 mm |

| Sensor | Length of Sensor | Turns of Spiral Separation | Initial Position of the Spiral Groove | Spiral Groove Interval |

|---|---|---|---|---|

| Sensor-III | 150 cm | 4.0 | 134.0 cm | 5.0 mm |

| Sensor-IV | 150 cm | 2.0 | 79.5 cm | 3.0 mm |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Jiao, T.; Zhao, P.; Liu, J.; Xiao, H. Development of a Distributed Crack Sensor Using Coaxial Cable. Sensors 2016, 16, 1198. https://doi.org/10.3390/s16081198

Zhou Z, Jiao T, Zhao P, Liu J, Xiao H. Development of a Distributed Crack Sensor Using Coaxial Cable. Sensors. 2016; 16(8):1198. https://doi.org/10.3390/s16081198

Chicago/Turabian StyleZhou, Zhi, Tong Jiao, Peng Zhao, Jia Liu, and Hai Xiao. 2016. "Development of a Distributed Crack Sensor Using Coaxial Cable" Sensors 16, no. 8: 1198. https://doi.org/10.3390/s16081198