2. Particle Path Algorithms Using Interpolation and Extrapolation

Using sensors that can collect the sensor’s position, wind velocity, chemical concentration, we can identify the particle paths that describe the pollutant’s propagation in the environment. This particle path map is the first step for detecting the chemical source [

13,

14,

15].

In this paper, we start with the interpolation of two nodes points

and

, where the points are the locations of two sensors with odor particle values of

and

, respectively. Since a direct interpolation of a path between the two points would be inconsistent with the odor propagation and the air flow, we generate two more localizations, denoted by

and

a propagation parameter “

t” where

, and consistent interpolation functions

and

, such that

where

In this approximation, we use Hermite polynomials. In Equation (1), we match the boundary values of the location; however we also need to match the velocities

From the sensor data, we can only collect the derivatives of

y with respect to

x, but we need the derivatives of

x and

y with respect to

t. However, these derivatives are easy to determine from using the relationship

Consequentially, we chose

and,

We, then, proceed to construct the two Hermite polynomials in the usual way, such that

where

denotes that the

jth Lagrange coefficient is the (2n + 1)st order polynomial.

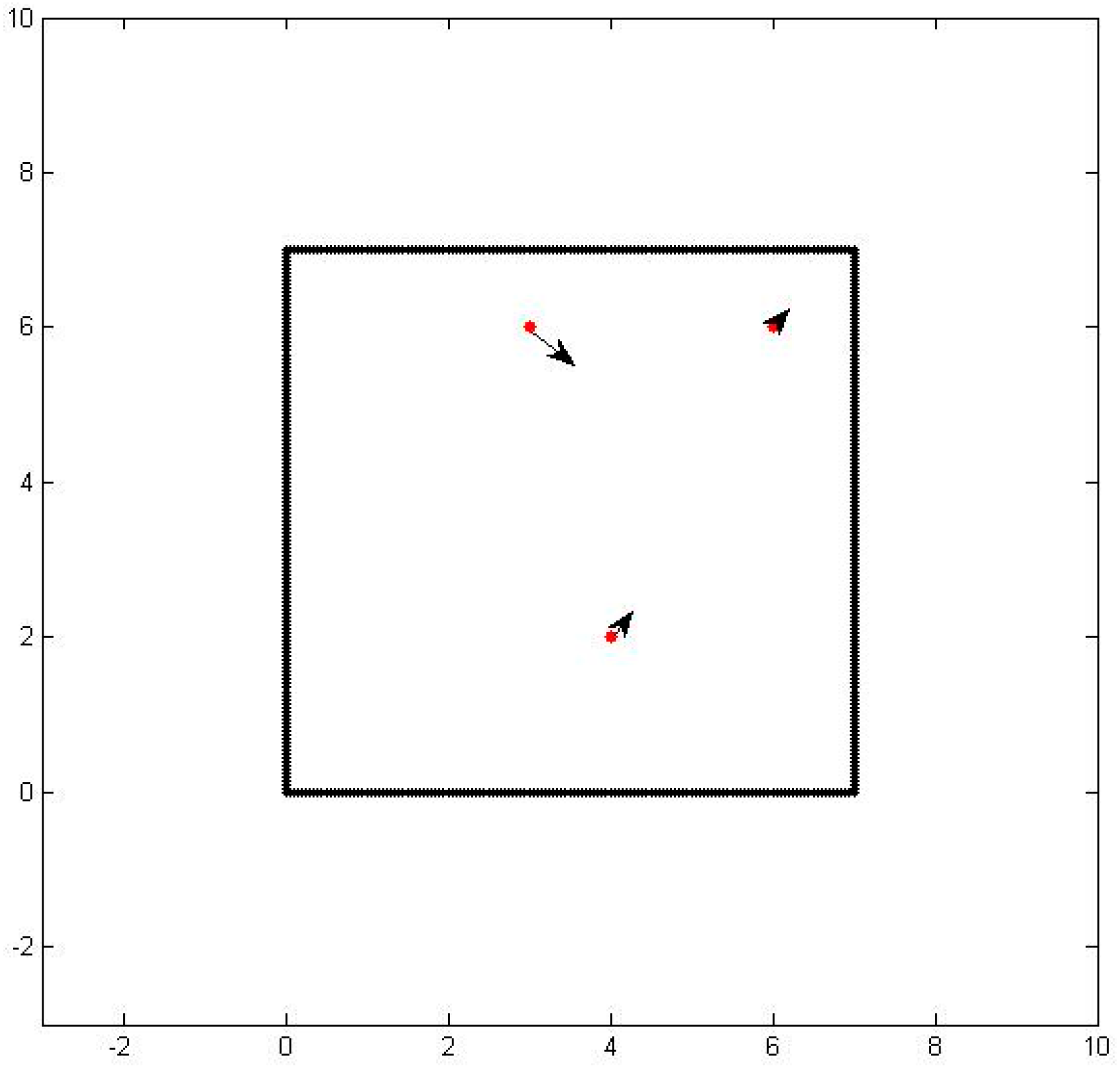

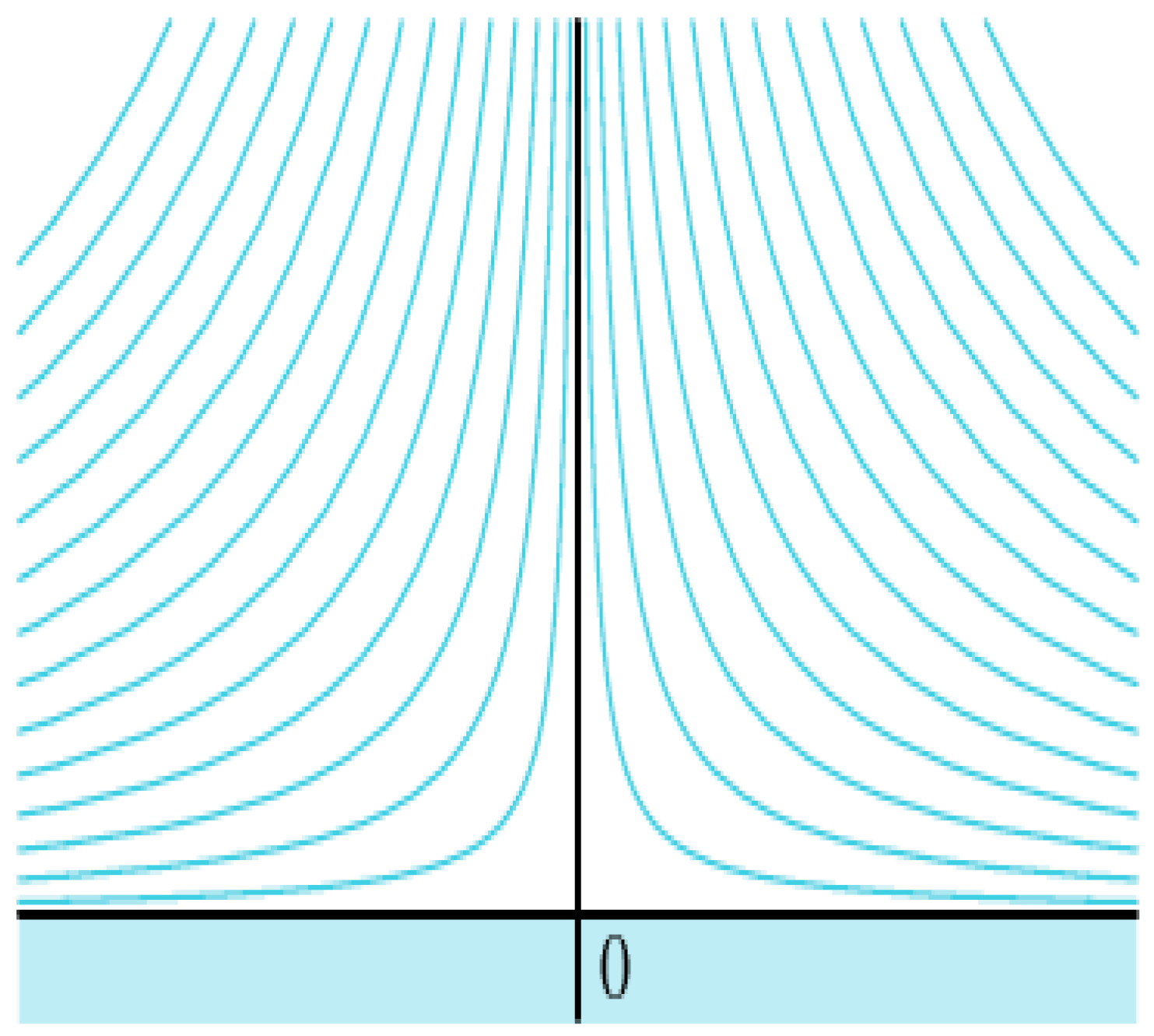

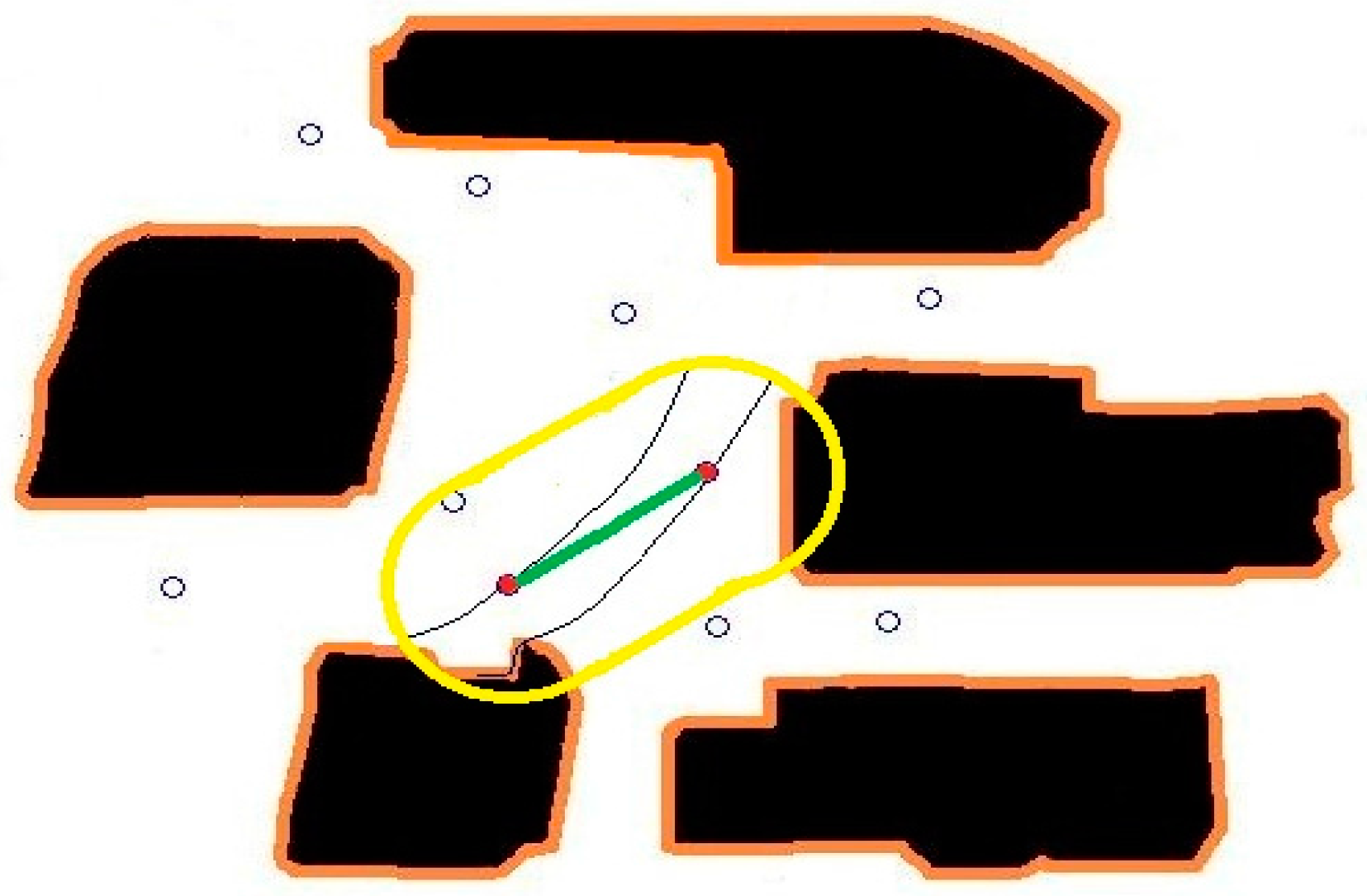

As a test case, we consider a three sensor configuration system as shown in

Figure 1. In the figure, the thick black lines are the boundaries of the area of interest, the red dots are the sensor locations, and the dotted lines designate the particle path lines.

Some chemical sensors are designed to simply detect the existence of a chemical particle and trigger a positive result when the concentration amounts are above a preset threshold level. In our design, instead of the threshold, we make use of the actual concentration levels that are detected. This approach along with some other data enables us to model the flow of the particles and the location of the source. Each sensor provides the co-located sensory information of the wind velocity, the concentration of the particles, and the concentration differential preferably perpendicular to the wind direction. The concentration differential information is obtained not by an additional sensory device but by an off-centered multi-orifice detection hardware configuration. In our derivations, we assume that the differential information is perpendicular to the wind direction, but we can accommodate any non-zero known angular orientation simply by a coordinate transformation. Designating the location of the sensors by (x, y), we represent the flow of air with (δx, δy). Similarly, we represent the sensed particle concentration with s and the concentration gradient with δs.

Once we obtain the sensory information, we start with an approximation of the particle path. In order to avoid multiple solutions, we make a number of assumptions. One assumption is that air-borne particles travel the most direct route. Thus, we configure paths that go through the sensor locations, such that the paths satisfy the locations as well as the differentials. This approach leads to a parametric cubic-polynomial representation of the path in terms of a variable

t. We use the cubic Hermite splines with the end point differentials weighted three times, such that

where the parametric curve starts at one sensor location at (

x(0),

y(0)) and ends at the other sensor location at (

x(1),

y(1)) as t goes from 0 to 1.

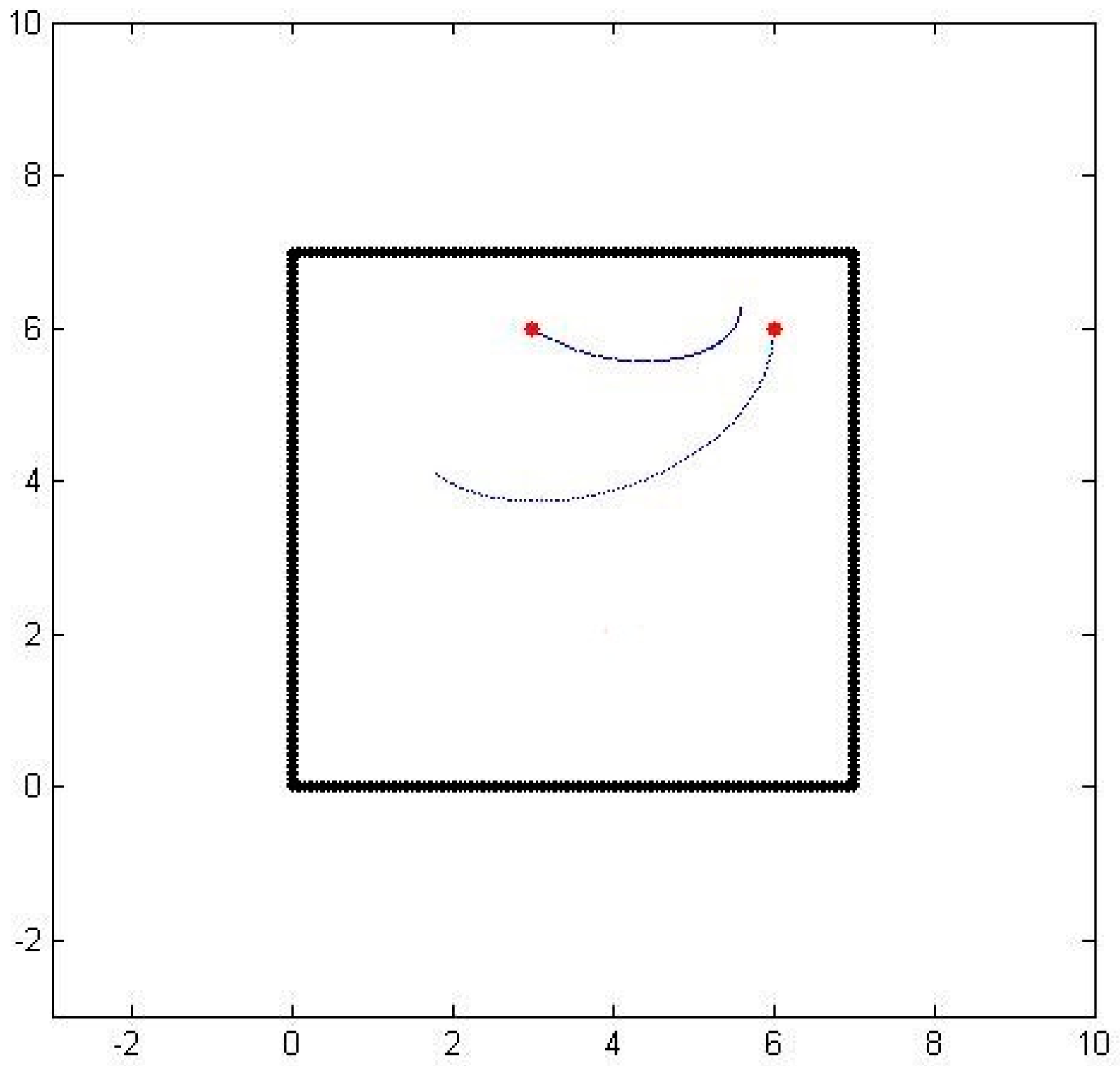

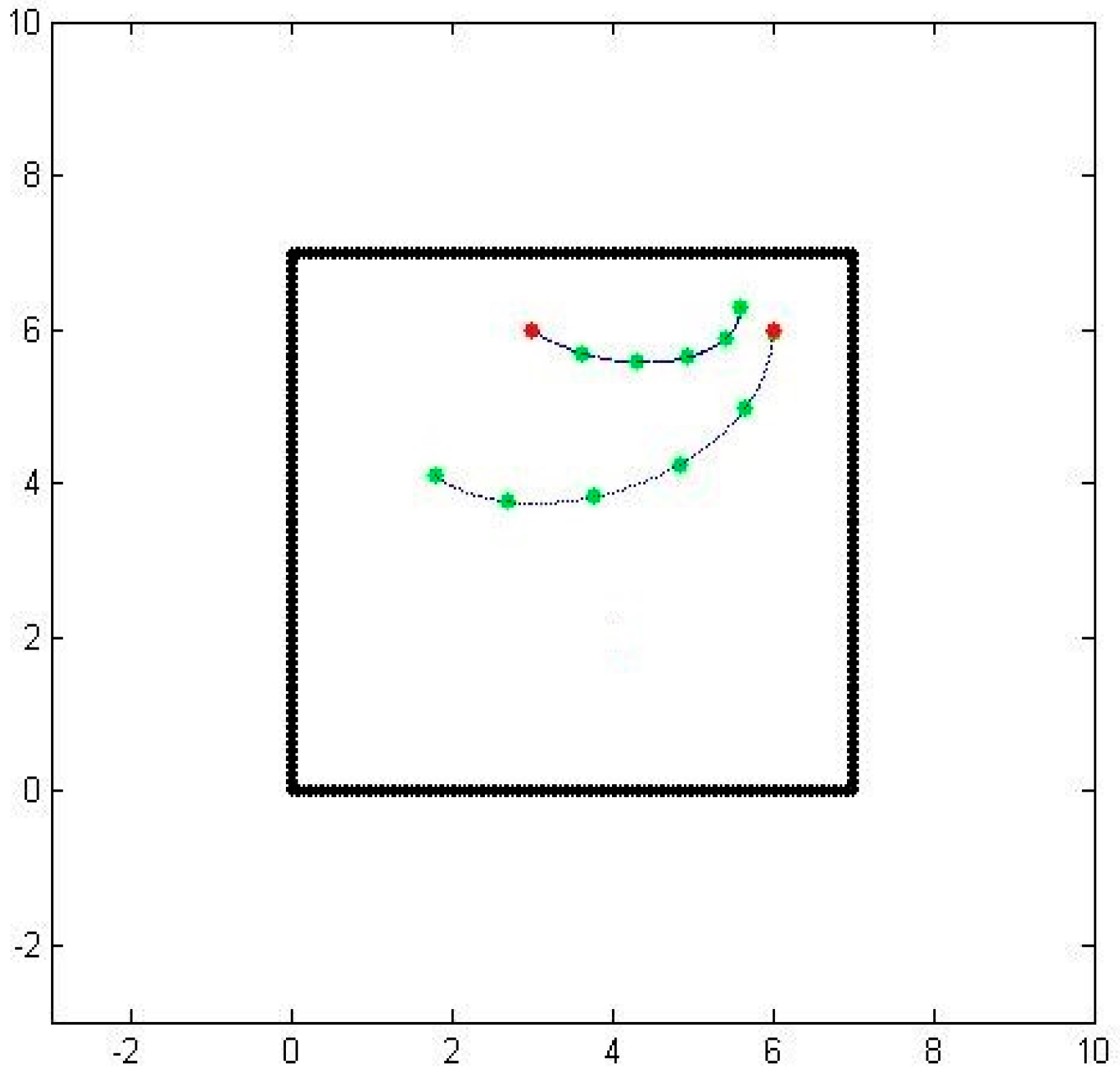

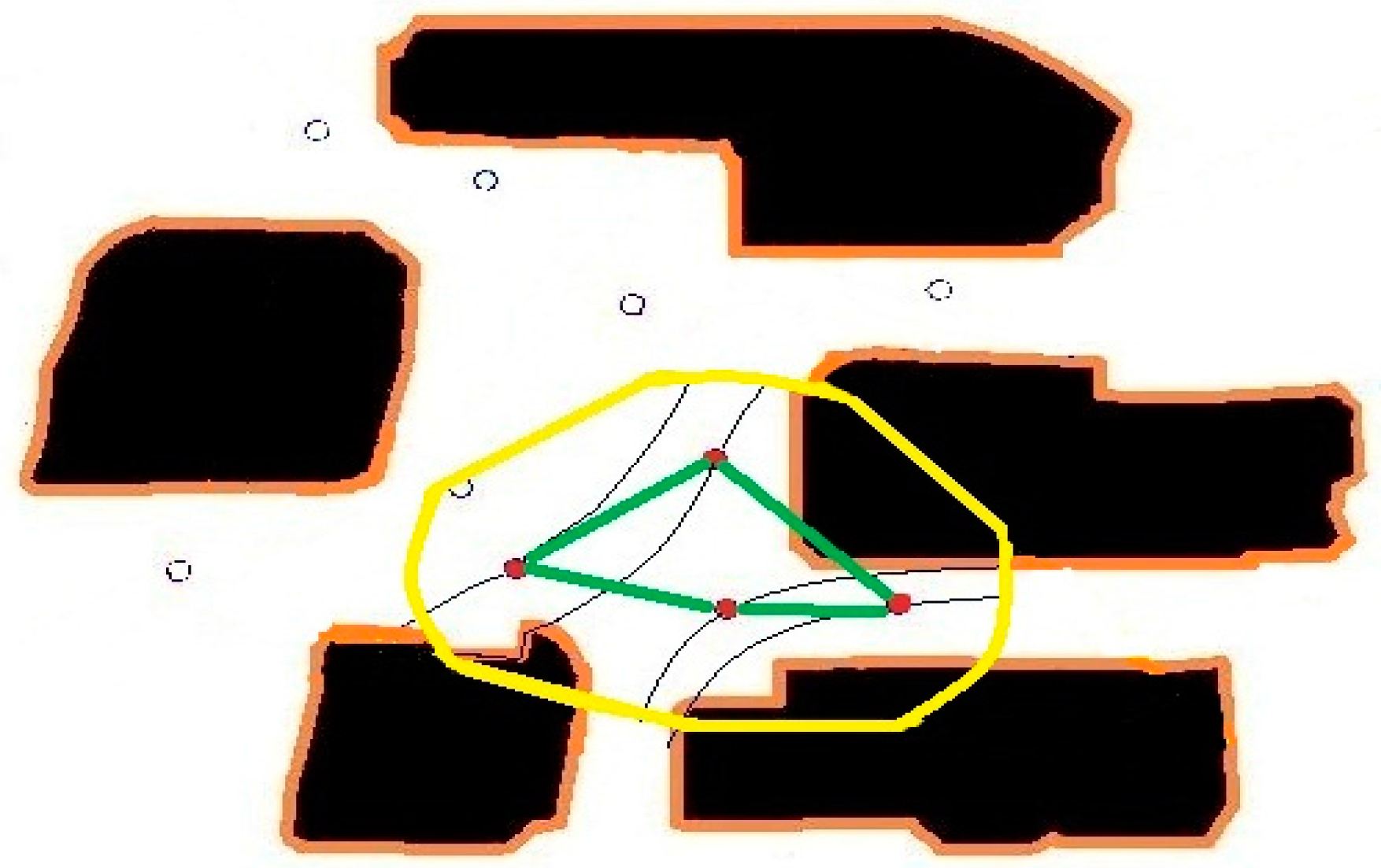

Figure 2 shows the spline approximation of a particle path from one sensor to another with matching initial and final velocities, but not necessarily matching the sensed values.

4. Compare and Validate Our Approach Using Computational Fluid Dynamics

To compare and validate our approach, we use exact analytical methods for simpler cases and use finite-element method based business software (such as COMSOL) for more complicated cases.

The analysis of airborne particle motion is identical to fluid motion analysis in physics. The fluid motion is governed by the Navier–Stokes nonlinear partial differential Equations (17) and (18), such that motion in the two dimensional space satisfies

where

u and

v are the components of the velocity in the

x and

y directions,

ρ is the fluid density, and

P is the pressure.The analytical solutions to the Navier-Stokes equations depend on the initial and the boundary conditions, and exact solutions exist only for simple cases.

In this paper, we assume that the particle flow dynamic is two dimensional, and is uncompressible, inviscid, and irrotational. If

D is a simply connected domain in 2 demensions and the flow is irrotational, the integral

is independent of the path in D. If we integrate from a fixed point (

a,

b) to a variable point (x, y), then the integral becomes a functions of the point (x, y).

We define the function

as velocity potential of the motion. Since the integral is independent of the path, and

is an exact differential, the differential of function

satisfies

From Equation (19), we get

By substituting u and v in Equation (20) into Equation (17), we observe that satisfies the Laplace’s equation

In other words, we can use the Laplace’s equation to model fluid motion.

Let

be a conjugate function of

. The function

is called the stream function of the flow. The curves where

is constant are called the streamlines of the fluid. We know that both

and

have continuous second derivatives as shown in [

13]. Consequentially the complex function

is analytic in the region of the flow. This function is called the complex potential of the flow.

We can determine the velocity of the flow by differentiating Equation (22) and using the Cauchy-Riemann Equation (19); such that

A general solution to Equation (23) can be complicated and unnecessary for the simple cases that we are considering. Indeed, we can assume the form of the function F from the initial flow and determine specifics by substituting the functions into the differential equations. Because of the uniqueness of the solution under initial and boundary conditions, if the function F satisfies Equation (21) and the boundary conditions, then it is the unique solution.

- Case 1.

Fluid flow with free boundary conditions

As the first case, we choose the no boundary case with a uniform infinite width flow of particles at a certain angle α, as shown in

Figure 7. By choosing

, where

are real numbers, we describe a uniform flow in the

plane.

If the flow is irrotational, then the equation is automatically satisfied by , where φ is the velocity potential, hence and . On the other hand, if the flow is incompressible then and , where ψ is the stream function.

Consequentially, by substituting into the differential equations, we can determine that the velocity potential is and the stream function is , such that the streamlines and the potential lines are orthogonal. The velocity of the flow can be obtained from where is the complex conjugate.

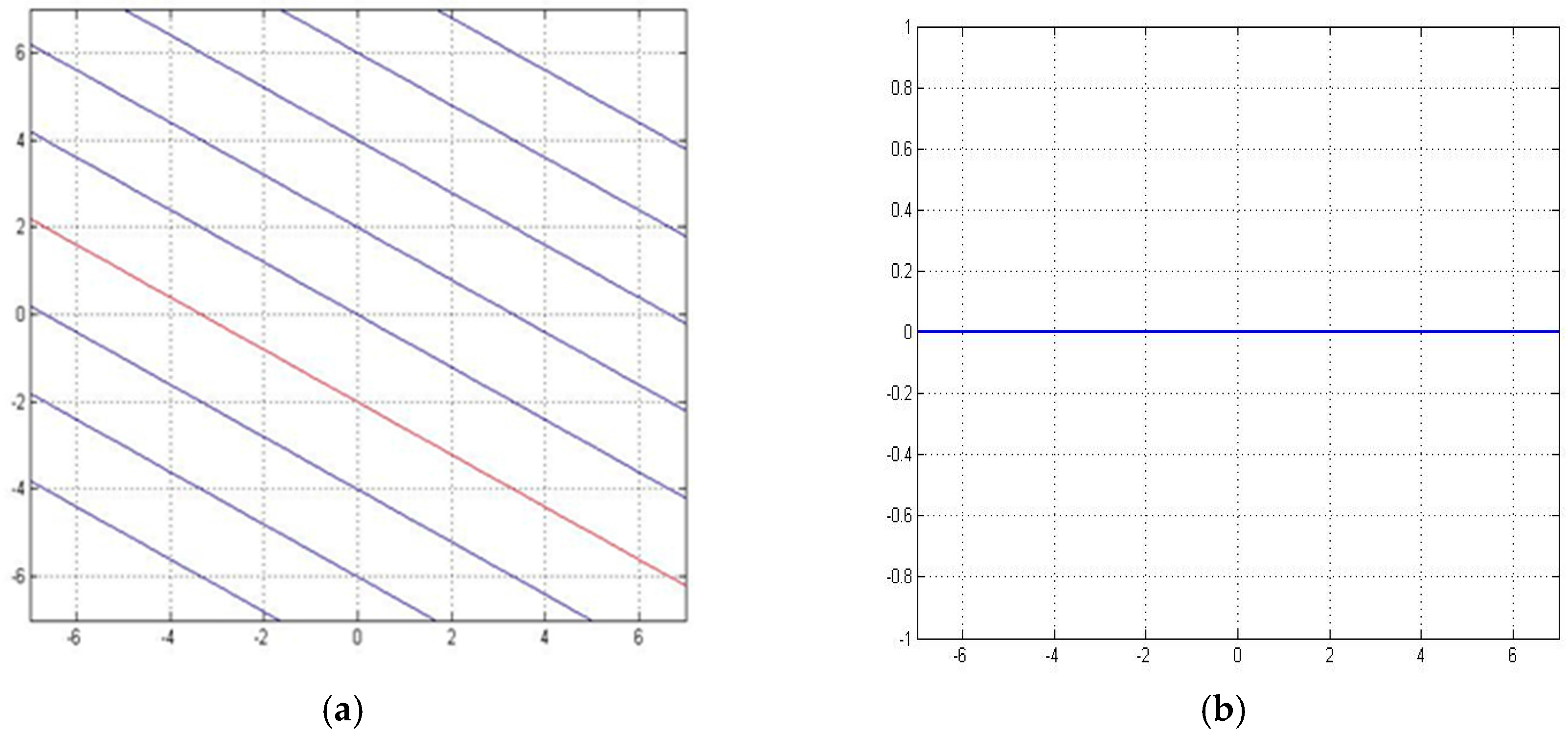

The streamlines are the parallel lines described by the equation and are inclined at an angle .

For two arbitrary locations of sensors in the plane and, we use our method to determine the fluid propagation path between the two points. However, to satisfy the sensed chemical concentration values, we need to modify the paths. In this case, when the two locations are on the same streamline, the streamlines become , where is a constant. In this case, we get zero error between the two methods, because the two methods give the same result.

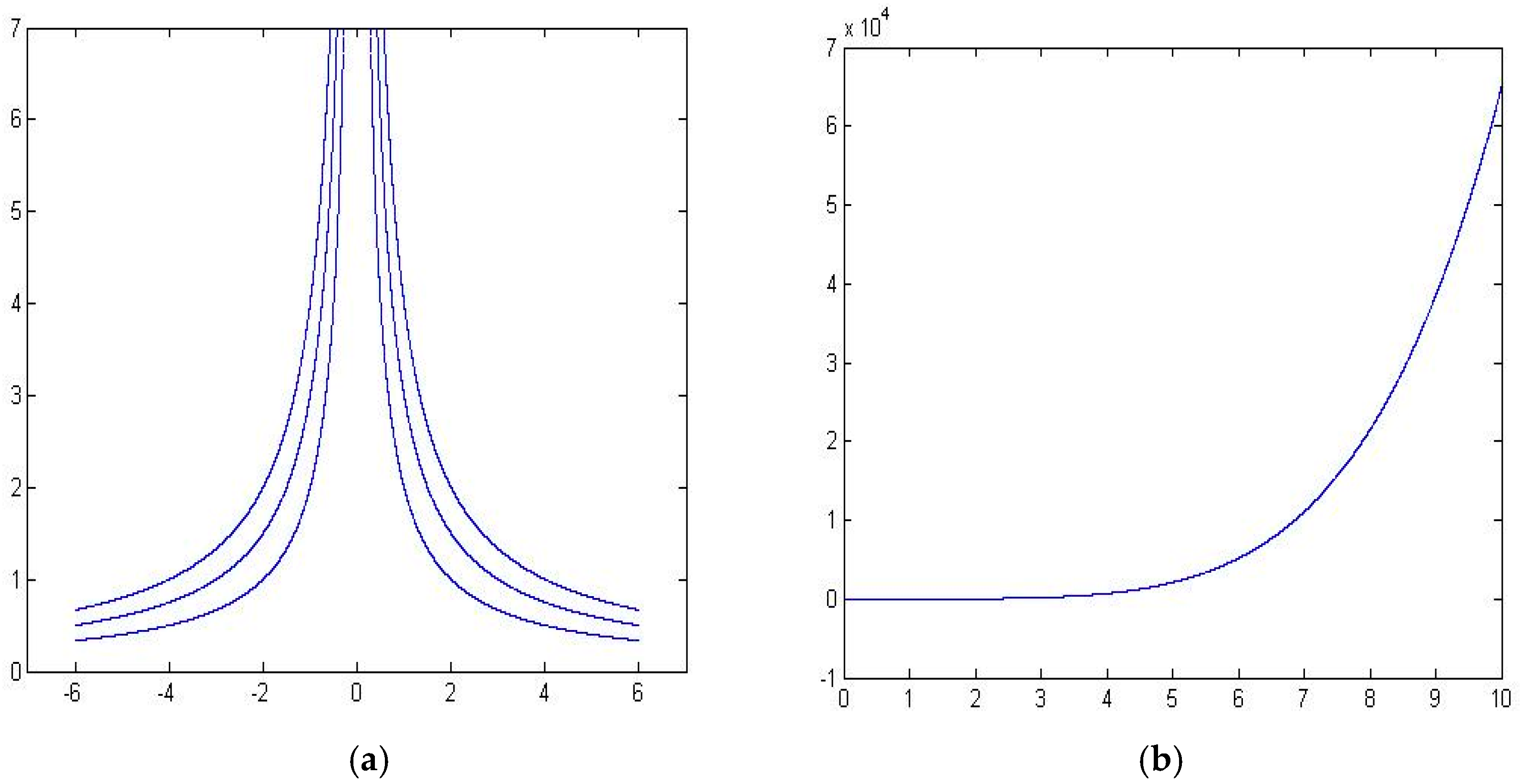

Figure 8a shows the map of particle paths obtained by our method,

Figure 8b shows the error between our method and the computational fluid dynamics.

- Case 2.

Fluid flow with infinite wall

In this case, the complex potential function is

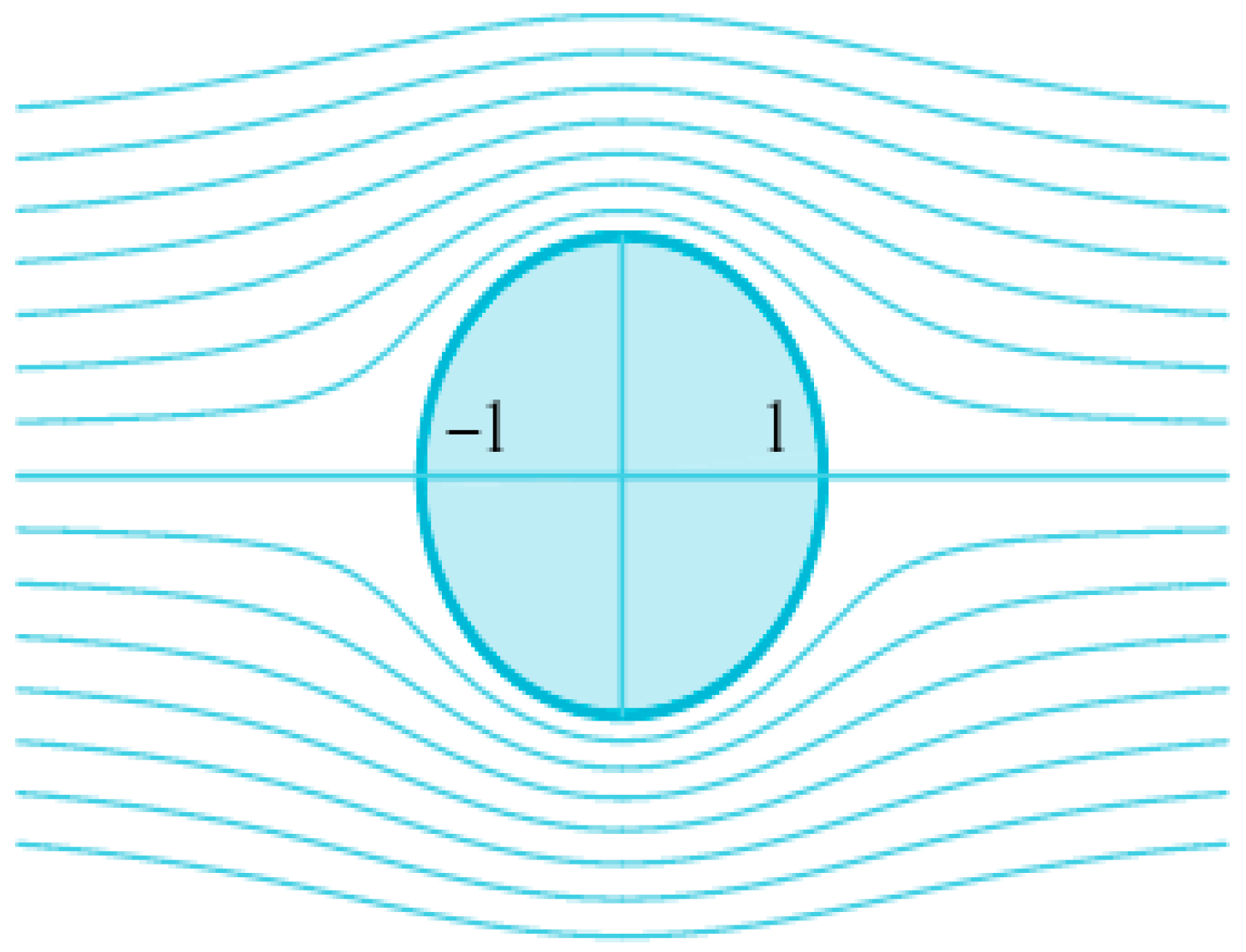

, as shown in

Figure 9, where

A is a positive real number. The velocity potential and the stream functions are given by

and

.

The streamlines, where is constant, are from a family of hyperbolic functions with asymptotes along the coordinate axes. The velocity vector indicates that in the upper half-plane, the fluid flows down along the streamlines and spreads out along the x axis, as against the wall.

Similarly, we choose two arbitrary points in the plane and as the two sensor’s locations, and use the interpolation method to get the propagation path between the two points. However, to be consistent with the chemical concentrations, we need to modify the endpoints of the path. When we choose the two points on a same streamline, the streamline can be described as a cubic function . The error term becomes , where the K is a real number and (a, b, c, d) are four parameters related with the coordinates of the two points and their derivatives. In this case, substituting the (a, b, c, d), we get the error term between our method and the computational fluid dynamics is

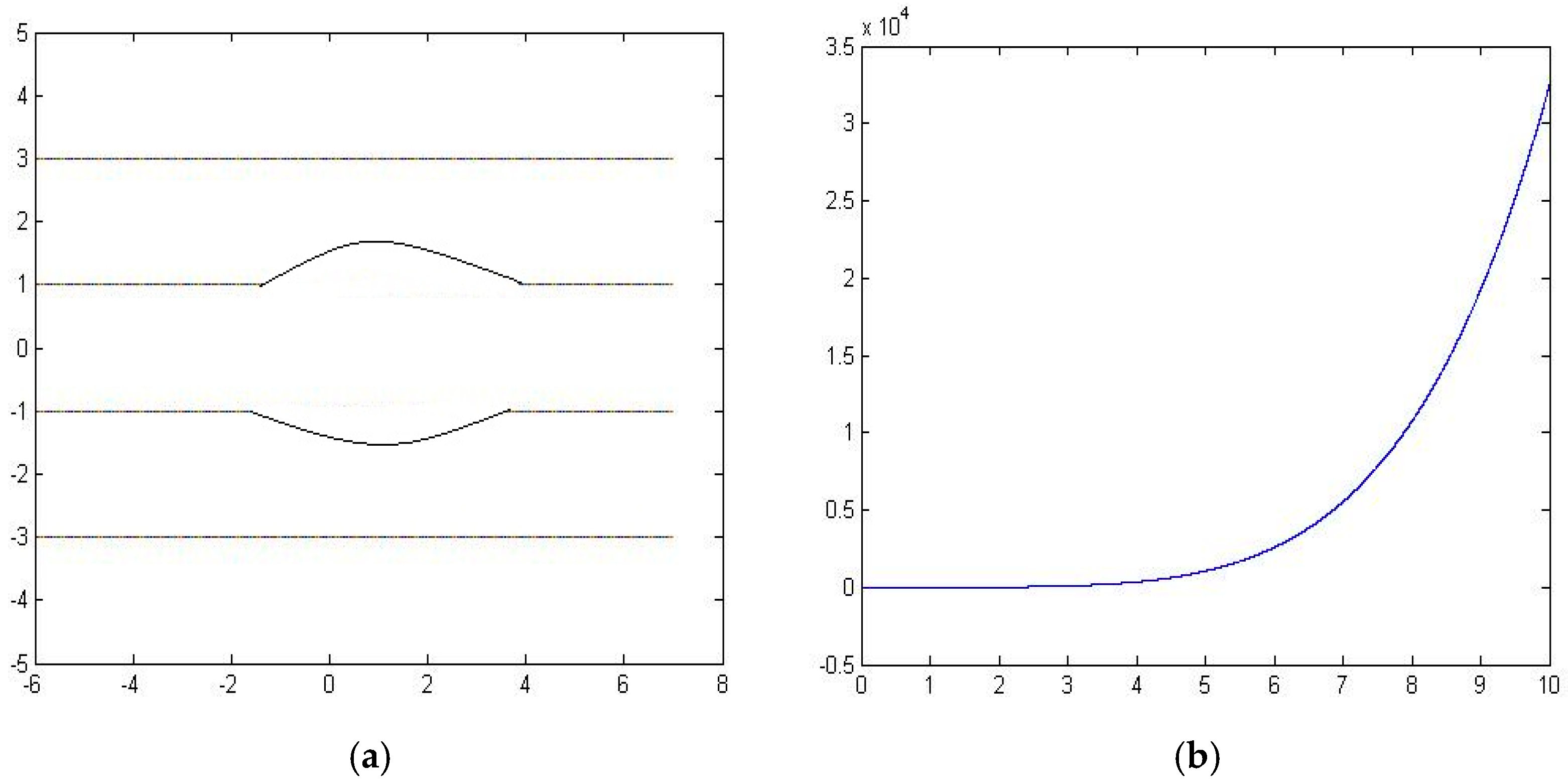

Figure 10 shows the error curve between the fluid dynamic method and our proposed method.

Figure 10a shows the particle path map by using our method, and

Figure 10b shows the error. From the figures, we can conclude that the error increases as the distance between two sensors increases.

- Case 3.

Inviscid flow past a cylindrical obstacle

In this case, we consider a circular obstacle in the direction of the flow, as shown in

Figure 11. We can use polar coordinates to express the complex potential function

F(

z) as

The streamline is , where A is a positive real number. When the constant is zero, it consists of the paths along the x axis and the curve , which is the unit circle . In the other words, the unit circle can be considered a boundary curve for the particle flow. The approximation is valid for large values of r, so we can approximate the flow with a uniform horizontal flow having speed at points that are distant from the origin.

Similarly, we chose two arbitrary points in the

plane (

and

) as the two sensor’s locations, and we use the interpolation method to get the particle propagation path between the two points.

Figure 10a shows the fluid path map by using our method. And

Figure 12b shows the error between the fluid dynamic method and our method.

From the error analysis, we observe that the error can be considerably large when the sensors are placed wide apart. In the other words, the more sensors we use, the better result are expected to obtain. Further analyzing the three examples, we conclude that when the Hermite polynomials can interpolate the stream function perfectly, we can get zero error as in the first example. On the other hand, when the streamline functions cannot be interpolated by using the 3rd order polynomials, we get the larger errors as in the third example.