1. Introduction

Horizontal two-phase flow occurs widely in the petroleum, nuclear, and chemical industries. Pipeline transportation of natural gas in the presence of a liquid phase or mixture of crude oil and water are examples of two-phase flow [

1]. One of the most common observations in two-phase flow is the complete separation between the two phases at moderately low velocities, where such a phenomenon is known as stratified flow. On the other hands, bubbly, intermittent, and annular flows can be observed at higher velocities [

2].

A number of techniques have been applied to measure the holdup in two-phase flow, e.g., X-ray, gamma ray, optical, ultrasonic, and capacitive method [

3,

4]. The definition of holdup can be found in [

5]. Amongst all these, the capacitive method was often employed due to its relatively cheap cost, simple design, and non-invasive approach—one just needs to attach the electrodes on the outer surface of the nonconductive section of the pipe. Relatively high sensitivity to water content could be achieved in two-phase flow, owing to the disparity in their permittivity values [

5,

6,

7,

8,

9]. The signals from the capacitance sensors had been studied to characterize and identify the flow patterns in horizontal two-phase flow [

10,

11,

12]. In addition to two-phase flow measurements, the capacitive sensing technique has also been adopted in numerous applications, e.g., occupancy, motion, position, displacement, level, touch, pressure, humidity, and moisture detectors [

13,

14].

Finite element method (FEM) is one of the most widely used design and analysis tools for capacitance sensor. Several configurations of two-electrode capacitance sensors have been proposed and analysed, i.e., concave, helical, and ring structures. Although increasing the number of electrodes (typically eight or more) to create an electrical capacitance tomography (ECT) has been explored [

15], such a technique involves solving an inverse problem that is rather challenging in nature. A brief review of holdup measurement in horizontal two-phase flow using two-electrode capacitance system is presented in

Table 1. Note that there were also other groups who conducted similar experiments on vertical two-phase flow [

7,

8,

16,

17,

18,

19]. Xie et al. [

20] and An et al. [

21] used two-dimensional (2D) finite element models to investigate and optimize the sensitivity distribution of concave electrode for holdup measurement in different flow patterns. In order to reduce the dependency of angle orientation in concave design, Hammer et al. [

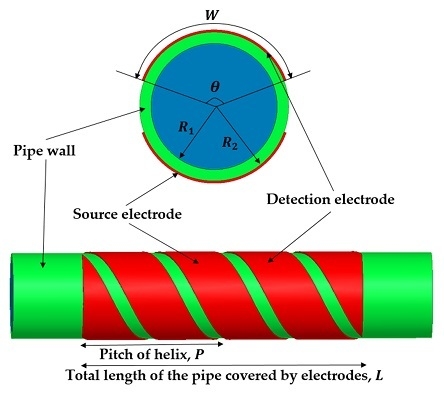

22] proposed a helical shape electrode of 180° and 360°. This was further validated by Tollefsen and Hammer [

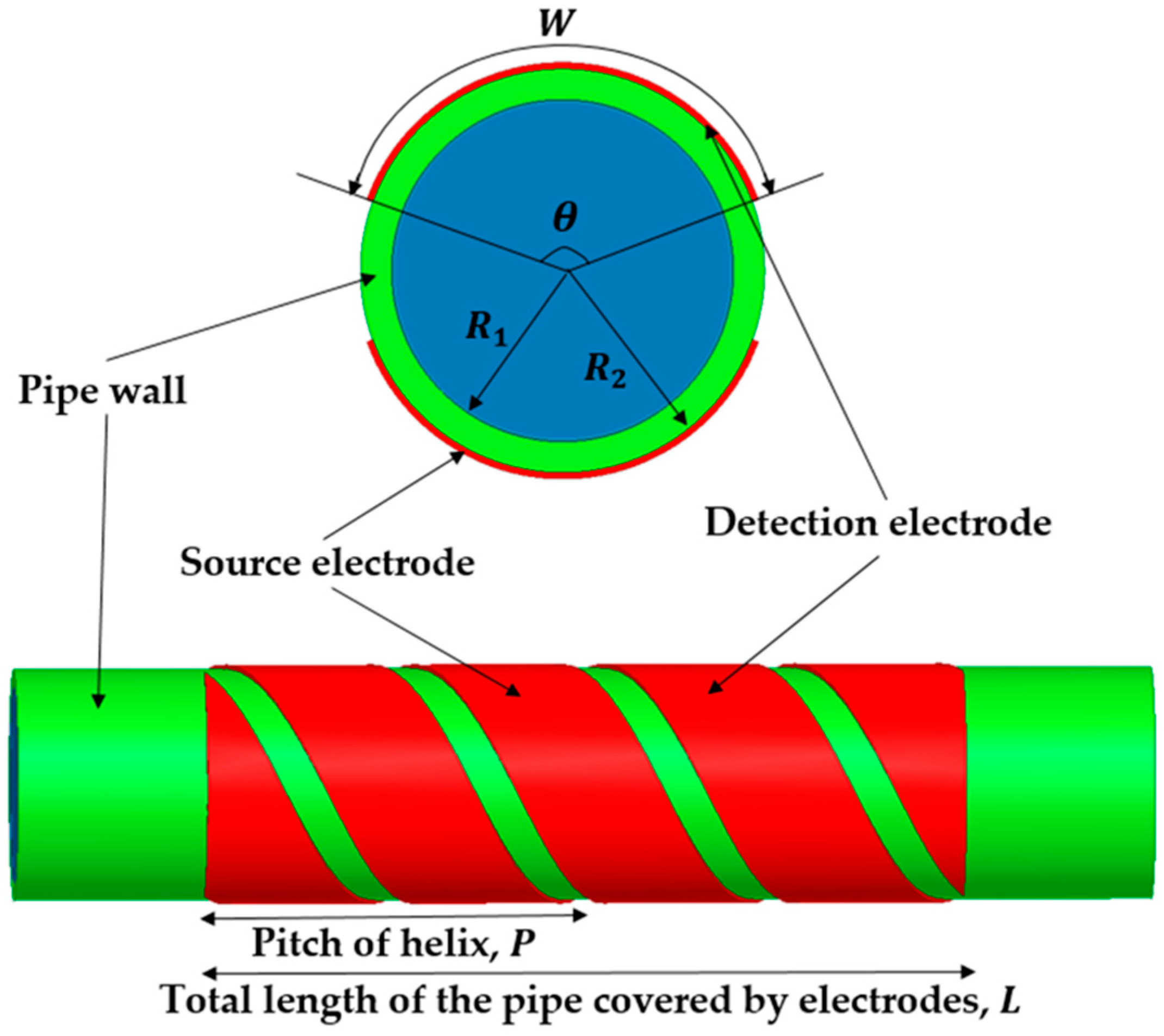

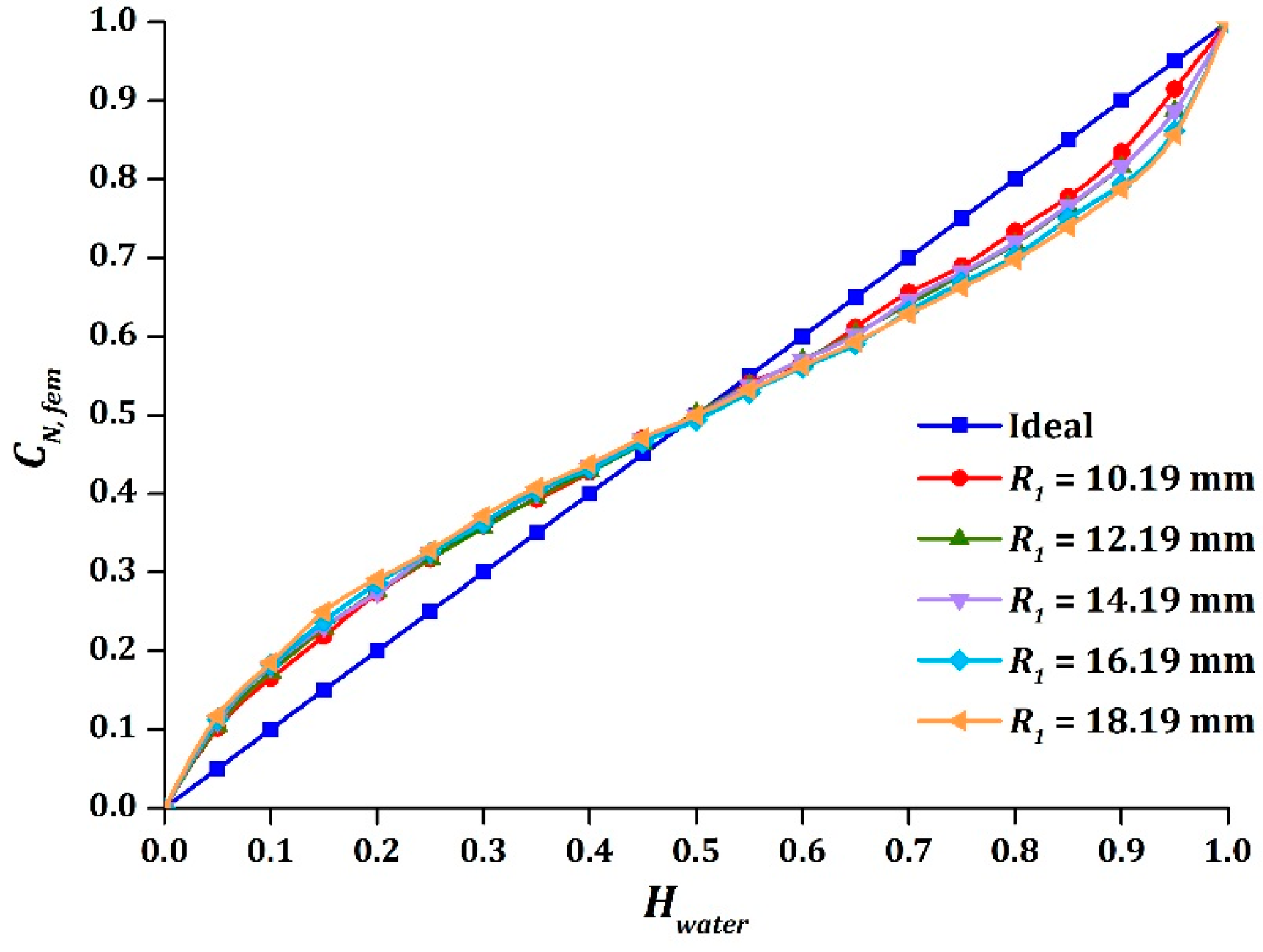

23] using a three-dimensional (3D) finite element model, where helical design was found to be more robust against the variation of flow patterns, specifically in stratified flow.

As compared to a concave design of the same spatial resolution, Ahmed [

25] suggested that ring design was more sensitive to void fraction measurement. Similarly, Reis and Cunha [

29] conducted an experimental study on several configurations of capacitance sensors for holdup measurement in air-water smooth stratified flow. They reported that ring design was the best configuration due to the least dependency of air-water distribution, but also found that all designs showed some levels of nonlinear response. Jaworek and Krupa [

31] further pointed out that the electric field was strongly localized in the gap separating the rings, which in turn causes the ring design to be less sensitive to the changes of holdup.

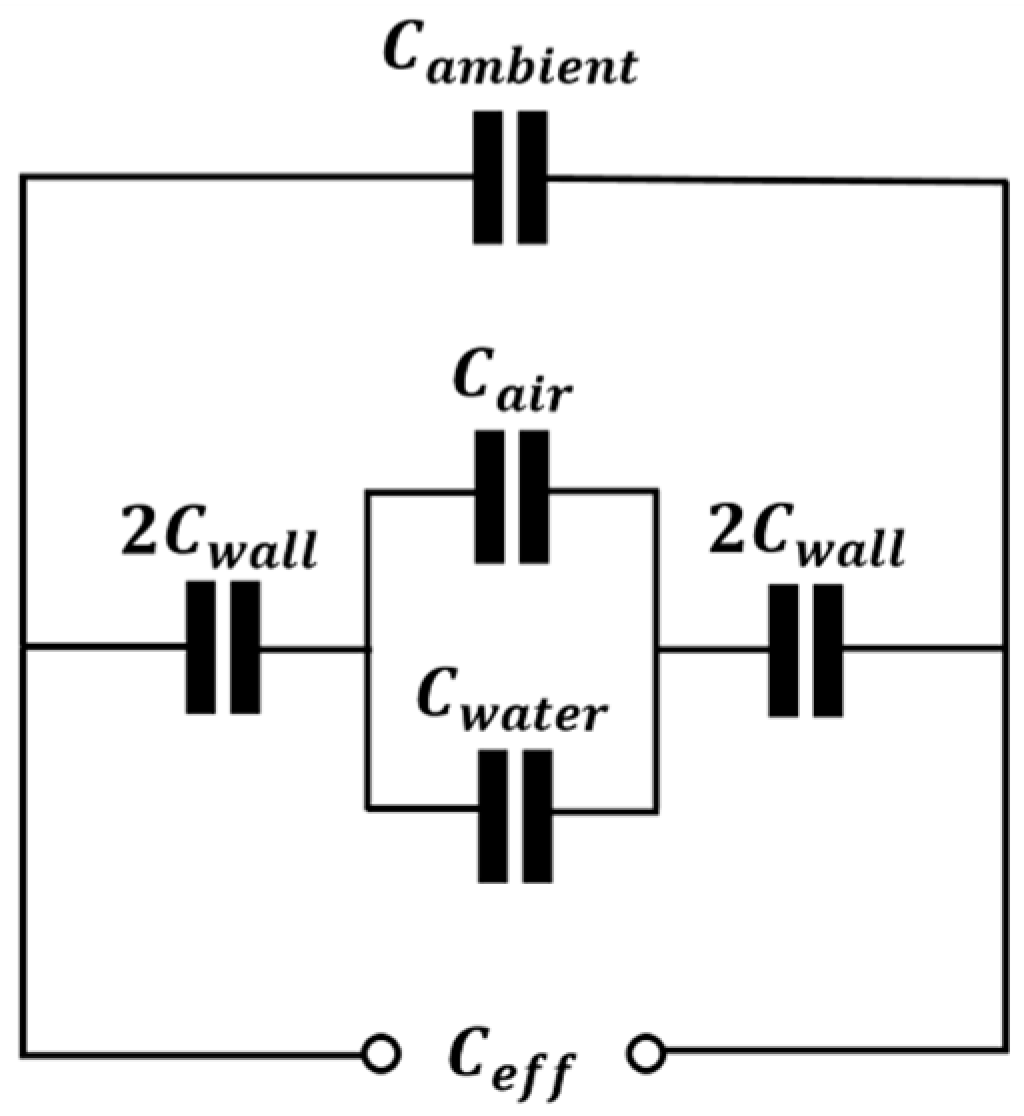

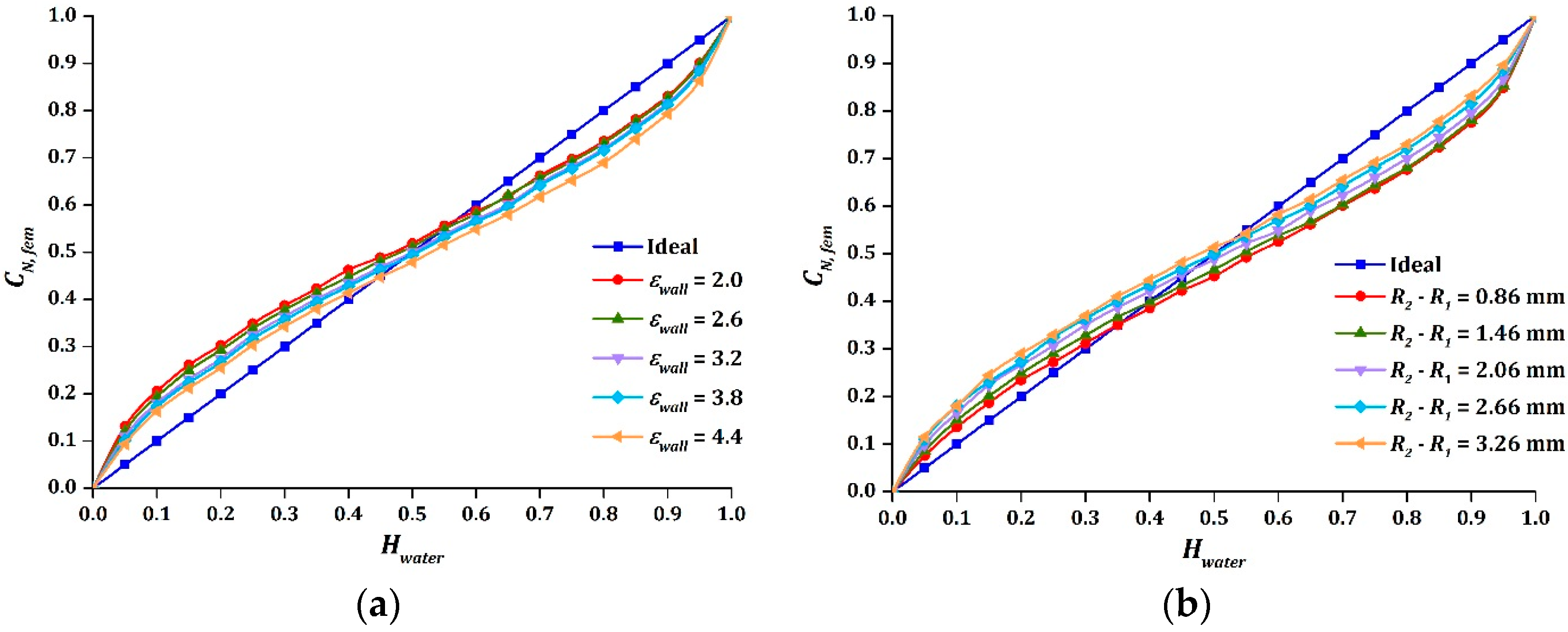

On the other hand, the design of the helical sensor could be optimized by adding guard electrodes to improve the homogeneity in the sensitivity distribution field of capacitance sensor [

7,

8,

16]. Despite that, the nonlinearity in response still could not be eliminated completely due to the nonlinear behaviour of the electrostatic field [

20,

23]. Thus, De Kerpel et al. [

28] proposed a flow pattern based calibration for capacitive void fraction sensor to counter the nonlinear response, albeit at the expense of computational cost. One of the major patterns observed for the holdup measurement in stratified flow was the nonlinear response assimilated to a sinusoidal function alongside the ideal response, and it was found in various sensor designs [

23,

27,

28,

29].

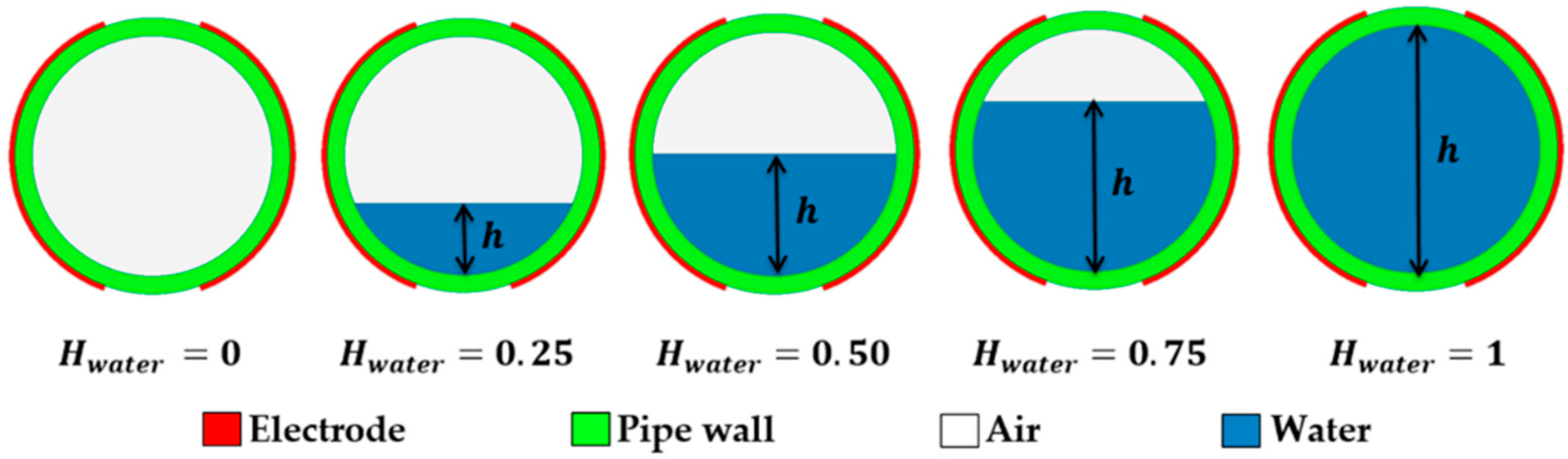

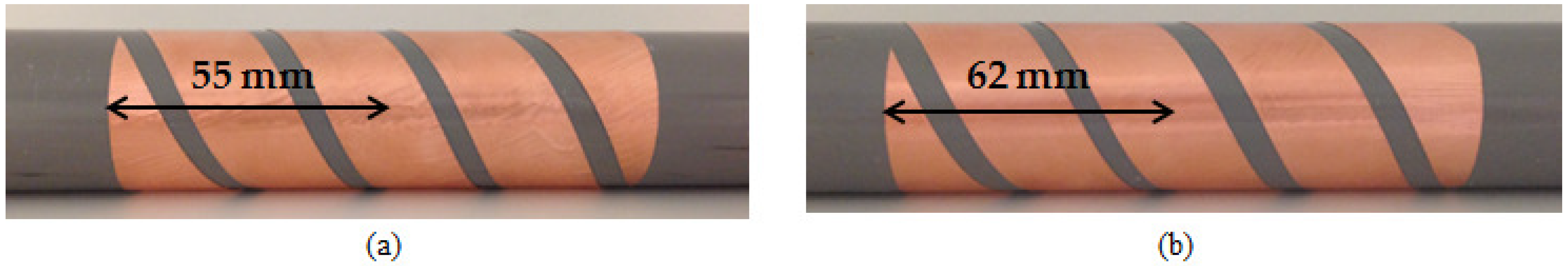

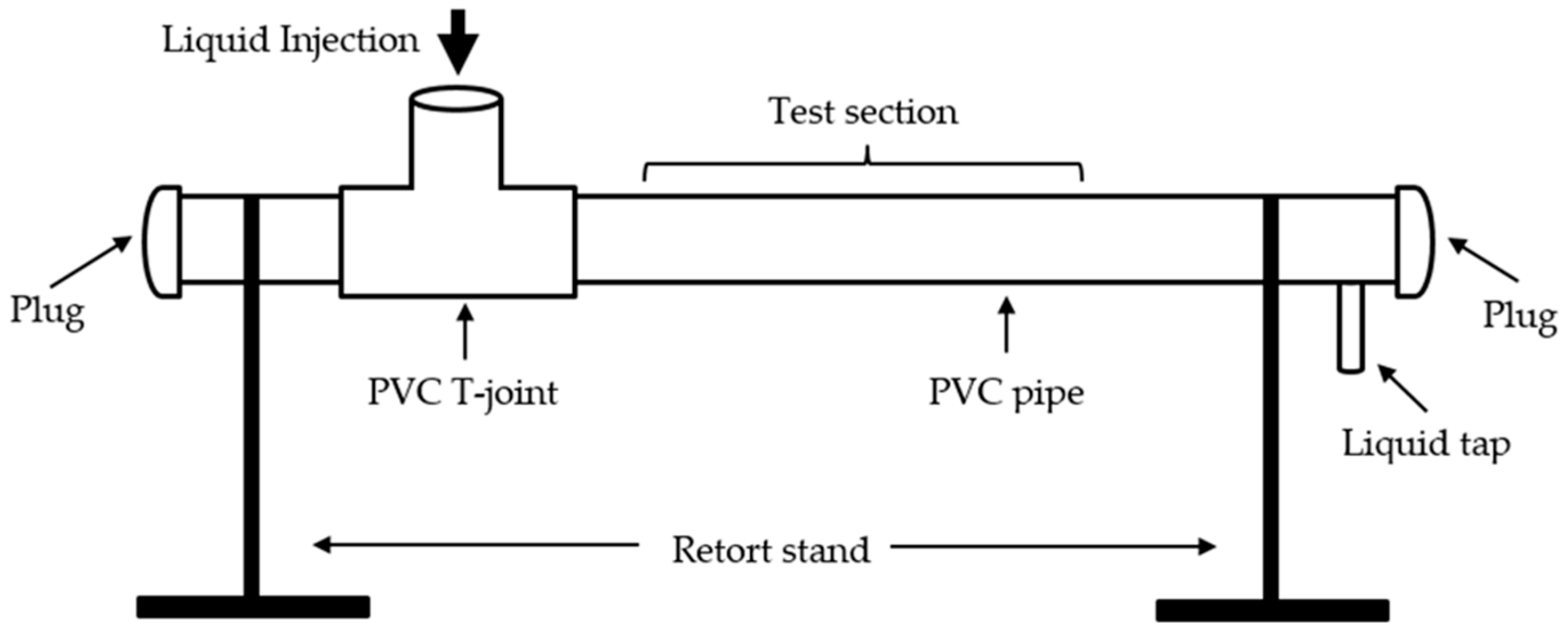

Instead of suppressing, we propose to exploit the sinusoidal response characteristics as a novel design concept of helical capacitance sensor for holdup measurement in two-phase stratified flow. Helical design is chosen because of its minimal dependency on angle orientation as compared to a concave design. At the same time, this is also due to its higher sensitivity as compared to a ring design [

29]. The proposed design is simpler as guard electrodes are not required. We derive an approximation model of the sinusoidal relationship observed between the capacitance readings and the holdup values. Experimental studies based on air-water and oil-water two-phase stratified flows are carried out to validate the sinusoidal model. If modelled accurately, the approximation model can be used to calibrate the capacitance sensor to acquire the actual holdup for two-phase stratified flow.

5. Results and Discussion

5.1. Air-Water Stratified Flow

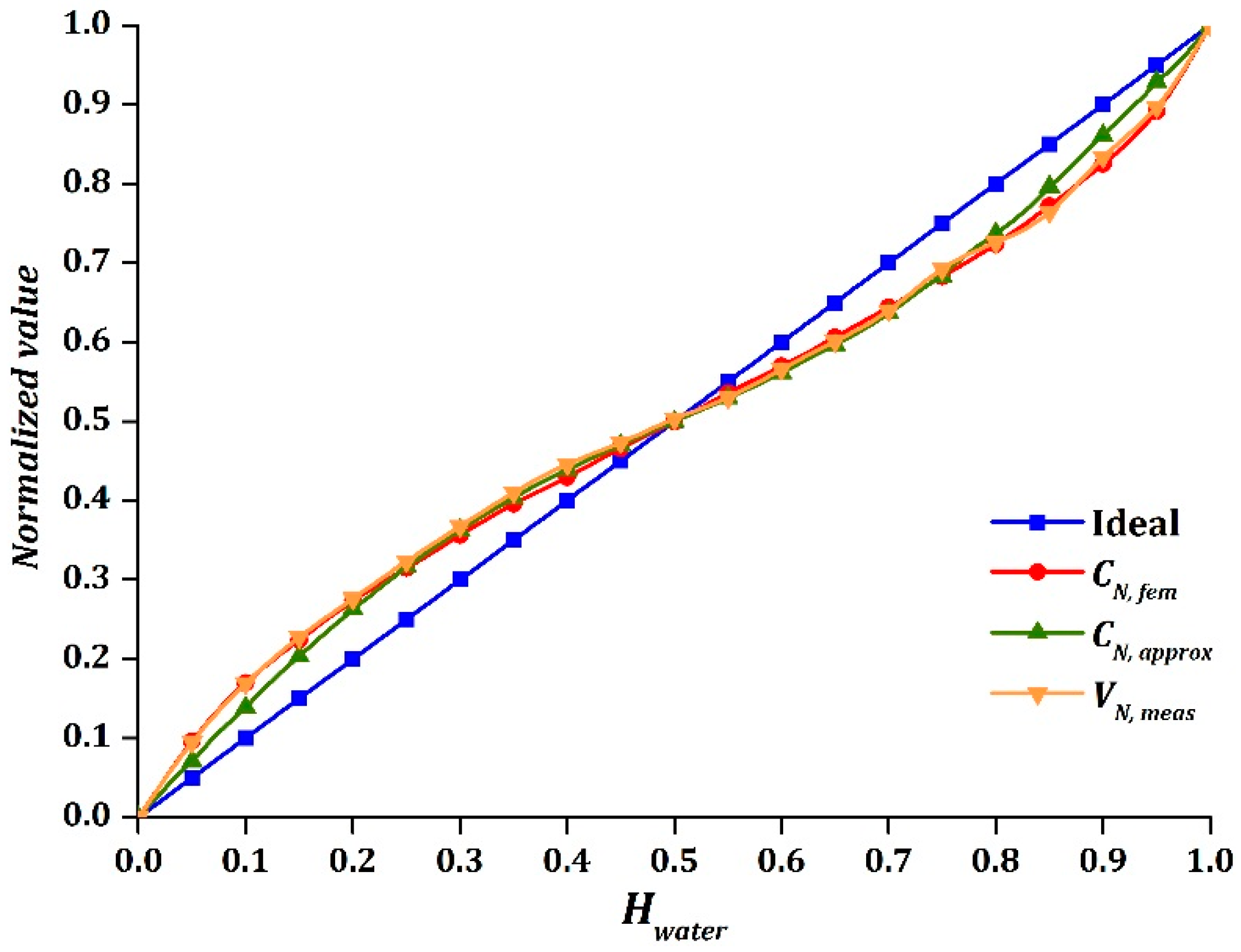

Figure 12 shows the experimental results of air-water stratified flow. It was shown clearly that the output

behaved similar to a sinusoidal function, as observed in FEM simulation. The amplitude of the sinusoidal function was equal to 0.071, based on FEM calculation. The intersection point of

was closely located at

, indicates that the sinusoidal function was symmetrical.

Table 9 tabulates the maximum absolute difference of

and

for air-water test. It was found that the experimental results had a higher accuracy as compared to the FEM simulation, particularly when water holdup was less than 0.15 and greater than 0.85. Note that smooth stratified flow was simulated using FEM. However, in reality, smooth stratified flow was hardly observed when the amount of water was either too little or almost full in the pipe due to the natural properties of water, which cause the distribution of the water in the pipe to be uneven. This could also be part of the reason why the range of water holdup

was limited in the experimental study of [

29].

Two important properties that influence the experimental results are cohesion and adhesion of water. According to Marshall et al. [

36], cohesion refers to the attraction of the same kind of molecules, where it holds hydrogen bonds together to create surface tension on water. On the other hand, adhesion refers to the molecular attractions at the interface of different kind of molecules. In this case, it has been observed that water molecules are inclined to stick to each other rather than to the inner surface of the pipe for water holdup of less than 0.15, which indicates that the cohesive force was stronger than the adhesive force. Since a trace amount of water was attached to the inner surface of the pipe, the capacitance readings would be expected to be lower than the simulated results in smooth stratified flow. As observed in

Figure 12,

was smaller than

for water holdup of less than 0.15.

Meanwhile, the adhesive and cohesive forces of water were almost equal for values of water holdup from 0.15 to 0.85 as smooth stratified flow was easily formed inside the pipe. This showed that the simulation results and experimental results were close to each other. However, smooth stratified flow could not be generated as water holdup increased above 0.85. It was observed that the tendency of water to stick to the inner surface of the pipe was higher as adhesive force overwhelmed cohesive force. Due to this phenomenon, the capacitance readings would be expected to be higher than the simulated results in smooth stratified flow as more water attached to the inner surface of the pipe. Thus, the results showed that the values of were larger than for water holdup of greater than 0.85, where this brought the values closer to the approximation model. In addition, the air-water distribution had been re-simulated in FEM to validate the experimental result for water holdup of less than 0.15 and greater than 0.85. Overall, the output obtained a good agreement with the approximation model, , where it was found to be even better than .

5.2. Oil-Water Stratified Flow

A clear and even separated interface between oil and water was observed after a few minutes for each change of holdup value. In addition, there were no cross-linking between oil and water when interfacial waves were absent, as reported by Al-Wahaibi and Angeli [

37]. Thus, the flow pattern can be assumed to be smooth stratified.

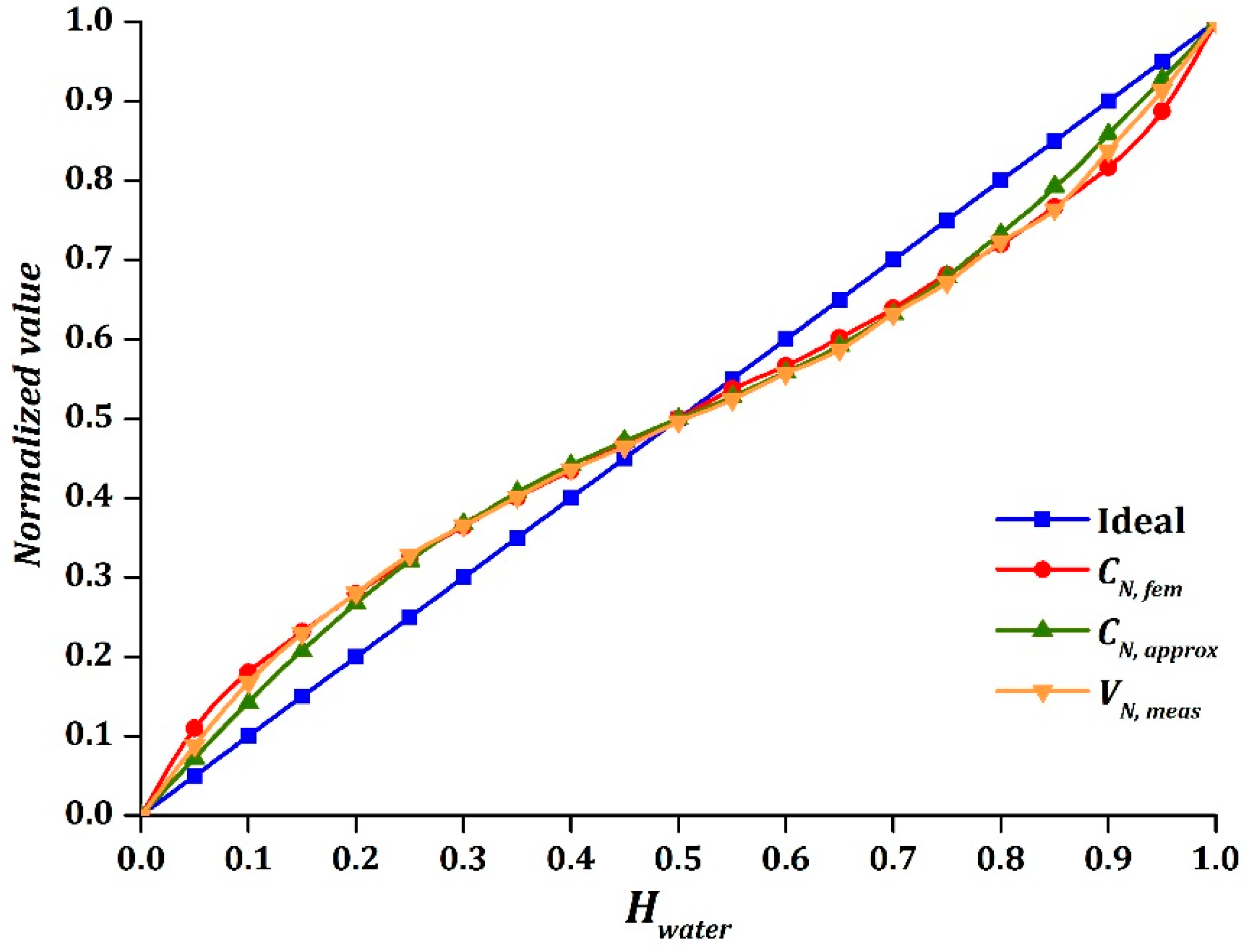

Figure 13 displays the experimental results of oil-water stratified flow. It was clearly shown that the output,

, acted identically to a sinusoidal function, where the amplitude of the sinusoidal function was equal to 0.066. The sinusoidal function was proved to be symmetrical as the intersection point of

with the ideal line was nearly obtained at

.

Table 10 presents the absolute difference of

and

of the oil-water test, where the experimental result was found to be very close to the simulation result.

It was also noted that the nonlinear response was greater when the permittivity difference between the two-phase components increased. As the value of amplitude implies the degree of nonlinear response of sinusoidal output, the air-water stratified flow was found to be shifted more significantly from the ideal response, as compared to the oil-water flow. This is manifested by the larger difference in permittivity values of air-water as compared to oil-water. Overall, the approximation model obtained a good agreement in air-water and oil-water stratified flow for water holdup values from 0.15 to 0.85.